Page 1

Industrial Solutions

Manual Powder Finishing

SIMPLY SMOOTH COATINGS - THE NEW X-FAMILY

■

Efficient and economical

■

Flexible and user friendly

■

Ergonomic design

Page 2

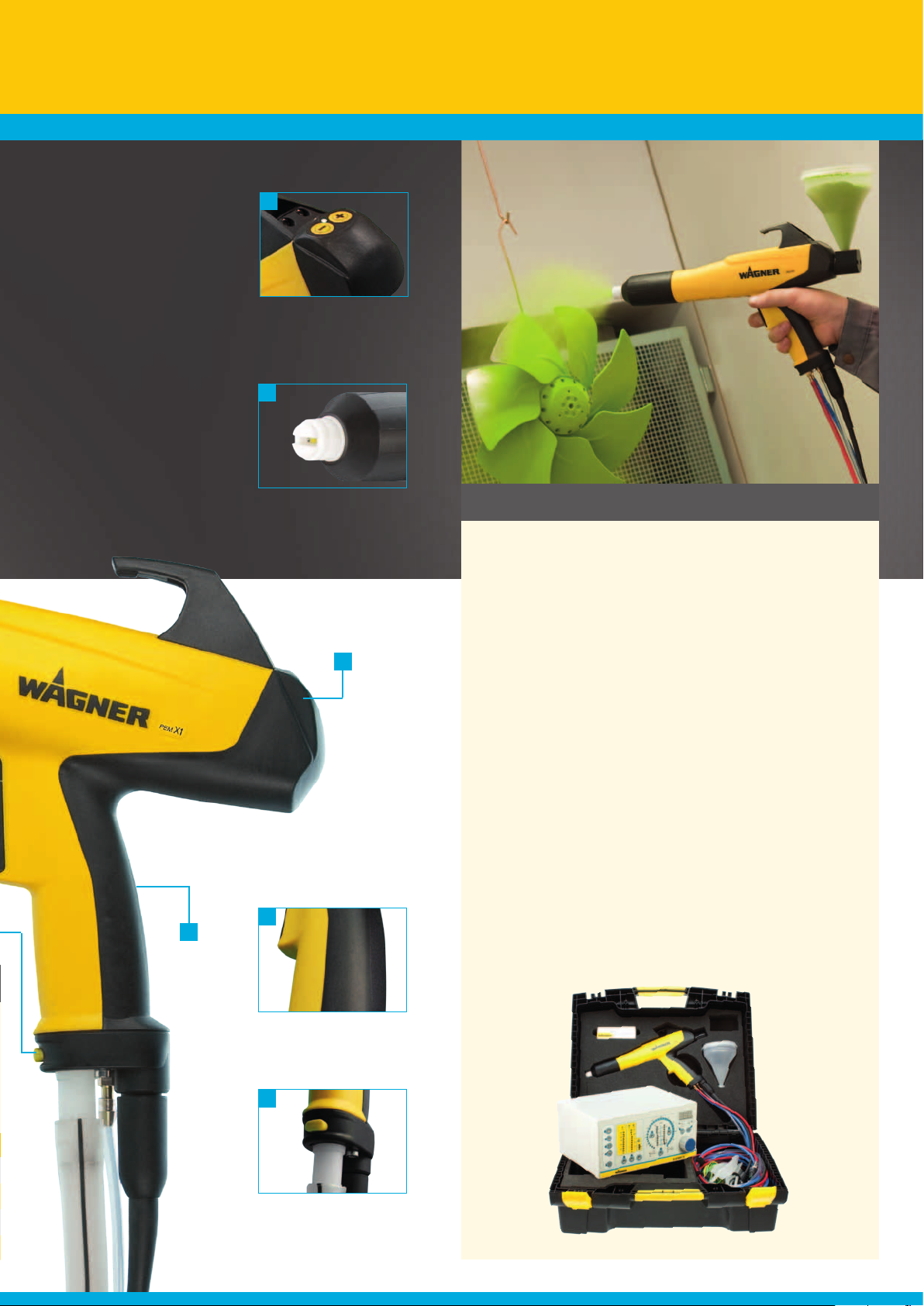

WAGNER manual gun 1

The next generation of WAGNER manual guns:

EXCELLENT FINISHING · PERFECT BALANCE · OPTIMAL HANDLING · LIGHTWEIGHT (490G)

The new WAGNER manual gun PEM-X1 sets the standard and trend for all kinds of surfaces used today in powder

coating. The new gun generation improves perfection and precision even further – the product philosophy

combines a balanced nesse on all levels with long life expectancy and optimal handling.

Well-balanced ergonomics are based on experience! WAGNER has incorporated this experience in the design of

the new gun generation. – Yet again, WAGNER combines rst-class design and functionality for perfect nishing

solutions.

2

Unique Design

■

Weight

Weighing only 490g, the PEM-X1 is a

lightweight among powder guns.

Despite being light, it maintains its

robust design.

■

Balance

Perfectly balanced to the minutest

gram, the PEM-X1 gun is exible and

reduces fatigue.

■

Ergonomics

The integrated remote control allows for a quick adjustment of

the powder amount. Via a double-click on the trigger, switching to another mix recipe is simple and fast.

■

Nozzles

The new nozzle-concept not only provides a perfect powder

cloud, but also an improved nishing quality. The at spray can

easily be adjusted for particular coating requirements, using a

sliding ring.

4

Manual guns

PEM- 1 and PEM- 1 CG

High transfer eciency

Easy and fast to service

Enormous exibility for perfect coating results

Technical data: PEM-X1 PEM-X1 CG

Length 335 mm/ 13 inch 365 mm / 14 inch

Weight 490 g/ 17 oz 530 g/ 18.6 oz w/o cup

ATEX-Certication PTB 12 ATEX 5002 EN50050-2

Powder output 450 g (16 oz) /min. 200 g (7 oz) /min.

Page 3

1

Remote Control - more

exibility during application

2

New nozzles - for perfect

Powder cup laboratory set PEM-X1 CG

coating

The powder cup laboratory set is a useful, handy, exible

but yet high-performing equipment for powder coating

component parts and small amounts as i.e. needed for

laboratory- and development purposes.

SPECIAL ADVANTAGES

1

3

3

■

Compact and always ready-to-use: The set is perfectly suitable

for small quantity production as well as laboratory

applications. Independent of ever-changing conditions,

the same coating result is obtained.

■

System for perfect results: Due to the precise WAGNER regulati-

on-technology and the gun-integrated dosing system,

small amounts of powder can be applied, while still

obtaining incredible results.

■

Clear and user friendly: Taking advantage of the simple

plugging-system, the powder container is easily attached

and handy at the same time.

■

Mobile system with convenient case Everything needed for

powder-application is provided. Even the smallest piece

has its own spot, creating a clear overview.

Ergonomic handle -

good grip for perfect

handling

4

Quick release coupling -

for fast and ecient color

changes

Page 4

Precise and Intuitive

The new control-unit EPG-Sprint

Precise and extremely reliable for optimal coating results – that is the spirit of the new WAGNER control

unit EPG-Sprint X. All parameters are arranged logically and can be easily adjusted. Hence guaranteed

reproducible results for ecient and high-quality manual coating can be obtained.

Control-units

Highest Eciency

■

Precision

WAGNER Air Flow Control (AFC) guarantees

exact powder control and optimal coating

results. A high precision, closed loop regulation cycle measures and regulates the air

pressure constantly to obtain continuous

values.

■

Handling

Easy to locate control elements provides

intuitive operation during daily work. The

intelligent control unit EPG-Sprint X can easily

be adjusted to any requirements due to numerous adjustment-possibilities.

■

Reproducibility

EPG-Sprint X oers direct access to the most used settings and can

save up to 50 coating programs. This is how you achieve highest

quality and reproducibility.

■

Design

The logical arrangement of the dierent control parts supports the

daily operation. All parameters are always identiable and guarantee

a controlled coating process.

Control-unit EPG-Sprint

Intuitive, easy handling

Modular and expandable

Maximum precision through closed loop regulation

Technical data EPG-Sprint X

Length 270 x 260 x 136 mm (10.6 x 10.2 x 5.3 in.)

Weight 4,6 kg

Type 0102 II 3(2) D IP 64 80°

ATEX-Certication PTB 102 II D T (Zone 4)

Page 5

Wide range of accessories for perfect results

The perfect accessories for

individual requirements!

For every task, the right tool – the system can be easily adjusted

according to your requirements for professional coating results.

One for all - the Flexibility

Quick release coupling

A variety of quick release couplings guarantee the

optimal solution for your application. Depending

on the hose diameter, the matching adapter is

available.

Nozzle-extension

Perfectly suitable for extra deep and hard-to-reach

work pieces such as radiators, cupboards etc.

Available in dierent lengths to suit your

application.

Nozzles

Whether at jet or round jet, with the WAGNER nozzle selection you will nd

the best nozzle to obtain the best results.

Powder hose

Powder hoses with dierent diameters and integrated grounding lead

optimize powder consumption and the coating quality.

CoronaStar

The CoronaStar is a helpful tool to reduce the “orange peel eect”. Following

a simple plugin-principle, such accessories can be installed quickly and easily.

Page 6

Simply smooth coatings

WAGNER manual units Eciency and exibility in perfect design

The new manual unit combines functionality and extraordinary design. All parameters can easily and

quickly be entered in the EPG-Sprint X. By means of a central and dynamic knob, all parameters –grouped

into four functional sections- can be set easily. The unique Cascade characteristic line setting and the

TRIBO-compatibility oer a high level of exibility for any powder. In combination with the new manual

gun PEM-X1, the manual unit gives perfect coating results. The powder feeding is carried out directly from

the original container – optionally out of the 60l stainless steel container.

Fast color change

The xation of the suction tube

allows for a quick and easy

color change.

Wheels for optimal agility

By mounting the small wheels,

the manual system can be used

and positioned in small places.

60 l Model

Airuid Model

Page 7

Your advantages

■

Robust trolley with pneumatic vibrating table.

■

Powder manual gun PEM-X1 or PEM-T3 Tribo.

■

A uid bed plate in the stainless steel container

guarantees an ideal powder preparation.

■

The injector Pl-F1 allows for a continuous and

calm powder-cloud.

Handling

■

Intuitive user guidance

The logical layout of the control elements

make adjusting recipes fast and clear. Up to

50 coating recipes can be saved creating

endless possibilities to set parameters to t

your individual needs.

■

Quick color changes

Quick color changes can be achieved by

using a pre-programmed button to initiate

the process. The position of the suction tube

and the coupling for the powder hose aid a fast and secure color

change.

■

Flexibility

The unit can be changed from box feeding to container feeding

with ease. Using dierent powder hoses and injectors, the

WAGNER SPRINT can easily be adjusted for any application.

■

Design

The new SPRINT manual unit design is light and modern. Its robust

construction and reliable quality output, is the perfect solution for

optimal manual coating.

Convertable for exibility

The manual system can be transformed

into a 3l-model or a 60l-model with

vibration table.

Page 8

Manual booth technology from WAGNER

Booth technology

Ecient booth systems

Whether you are just starting powder coating or

transitioning from wet paint to powder coating,

WAGNER has a cost eective and reliable solution

for your needs.

This is exactly what the BASIC WAGNER 4000 and

8000 Booth Systems are: Aordable, reliable and

durable powder coating technology. Fast color

change, ecient use of coating material as well as

compliance with important industry standards.

J. Wagner GmbH

Industrial Solutions

D-88677 Markdorf

Tel. +49 (0) 75 44/5 05-0

Fax +49 (0) 75 44/505-200

Xtremely strong features

WAGNER oers all components for perfect manual coating. It starts with the gun and includes the

control unit and accessories as well as the manual unit and booth system. All components can be

described by the following simple scheme:

■

Eciency

■

Handling

■

Flexibility

■

Design

www.wagner-group.com

J. Wagner AG

Industrial Solutions

CH-9450 Altstätten/SG

Tel. +41 (0) 71/7 57 22 11

Fax +41 (0) 71/7 57 23 23

Printed in Germany · AME · 2332288 · 04/2012 · All information, illustrations, and specifications in this document are based on the

latest product information available at the time of publication. The right is reserved to make changes at any time without notice.

Page 9

X-Family Ordering Information

Description Item number

Basic units

Manaul Spray Gun PEM-X1 2322587

Manaul Spray Set X1 2331090

Manual Unit SPRINT AF 2329483

Manual Unit SPRINT 60L 2329489

Manual Unit SPRINT AF USA 2329487

Manual Unit SPRINT 60L USA 2329491

Dual Manual Set SPRINT 2331417

Conversion Set SPRINT 60L V 2309276

Conversion Set SPRINT 3L V 2309277

Manual CupGun PEM-X1 CG 2322588

CupGun Set PEM-X1 CG 2328172

Controler EPG-Sprint X 2324731

Accessories

Trolley Front Caster Set 2324869

Recipe Sticker 2331223

CoronaStar PEM-X1 assy 2322868

Wedge tool X1 2324205

Wedge tool X1 + 20 wedge‘s 2324124

Spare parts starter kit X1 2331976

Nozzle Extension X1 EXT150 2323366

Nozzle Extension X1 EXT300 2323356

Nozzle Extension X1 EXT500 2323338

Hose Connector D10-D12 assy 2322761

Hose Connector D8-D10 assy 2322768

Gun Holder 2330599

Gun Holder f. Cabine 2332139

Console 2331558

Wallmount w. Console 2330223

Powder Measuring Adapter X1 assy 2325320

Spare parts

Gun Hook X1 SP 2320330

PT-Pan head screw, self-tapping, Torx 2316896

Outer Nut X1 2320464

Cascade neg. X1 SP 2324136

1x Cup with Cover SP 2324139

5x Cup with Cover SP 2324140

Injector holder Sprint complete 2307117

Electrode Holder X1 R SP 2322490

Electrode Holder X1 R + Spray Nozzle 2322493

Electrode Holder X1 F SP 2322529

Description Item number

Wear parts

Wedge X1 2320488

Flat Spray Nozzle X1 assy 2321976

Deector Cone D18 asse. 2321981

Deector Cone D25 asse. 2321980

Deector Cone D34 asse. 2321171

Deector cone sleeve X1 2320503

Round Spray Nozzle X1 VL SP 2324148

Flat Spray Nozzle X1 VL SP 2324147

Electrode X1 VL150 SP 2324144

Electrode X1 VL300 SP 2324145

Electrode X1 VL500 SP 2324146

Nozzle Insert X1 EXT F 2323401

Nozzle Insert X1 EXT R 2323461

Contact X1 EXT assy 2323361

Electrode CoronaStar X1 SP 2322835

Others

Tribo Manual Gun PEM-T3 351019

Tribo Cup Gun PEM-TG3 351036

Loading...

Loading...