Wagner SprayTech 9175, 9155, 9195, 9145 User Manual

Twin Stroke

Piston Pump

Models: 9145

9155

Owner’s Manual 9175

9195

Read this manual for complete instructions

|

Table of Contents |

|

|

Safety................................................................................ |

2-3 |

|

Components and Description......................................... |

4-5 |

|

Assembly............................................................................. |

6 |

|

Before You Begin................................................................ |

7 |

|

Locking the Spray Gun................................................. |

7 |

|

Pressure Relief Procedure............................................ |

7 |

|

Grounding the Spray Gun............................................. |

7 |

|

Preparing the Sprayer......................................................... |

8 |

|

Preparing the Spray Hose.................................................. |

9 |

|

Practice / Spraying Technique......................................... |

10 |

|

Spraying Troubleshooting.......................................... |

11-12 |

|

Unclogging the Spray Tip............................................ |

11 |

|

Cleaning the Spray Gun Filter..................................... |

12 |

|

Cleaning the Inlet Filter............................................... |

12 |

|

Cleanup......................................................................... |

13-17 |

|

Cleanup for Latex materials................................... |

13-14 |

|

Cleanup for Oil-based materials................................. |

15 |

|

Cleaning the Suction Set............................................ |

16 |

|

Cleaning the Spray Gun Components........................ |

17 |

|

Short-Term Storage.......................................................... |

18 |

|

Long-Term Storage........................................................... |

19 |

|

Cleaning the Inlet Valve.................................................... |

20 |

|

Fluid Section...................................................................... |

21 |

|

Troubleshooting / Maintenance....................................... |

22 |

|

Français............................................................................. |

23 |

|

Español.............................................................................. |

45 |

This pump is available in a stand model (9145) and cart models (9155, |

Parts List....................................................................... |

67-70 |

9175 and 9195). All information given for the stand model applies to the |

Accessories....................................................................... |

71 |

cart models except where indicated. |

Warranty............................................................................. |

72 |

1-800-880-0993

1-800-880-0993

Wagner Technical Service

Register your product online at:

http://www.wagnerspraytech.com

1770 Fernbrook Lane, Plymouth, MN 55447

Need Help? Call us first for answers

fast. Call toll-free if you have any comments or problems with this product.

Technical service hours: Monday through Friday, 8:00 am to 4:30 pm Central Time

1208 • Form No. 0523860A

English

Important Safety Information · Read all safety information before operating the equipment. Save these instructions.

To reduce the risks of fire or explosion, electrical shock and the injury to persons, read and understand all instructions included in this manual. Be familiar with the controls and proper usage of the equipment.

This symbol indicates a hazardous situation, which, if not not avoided could result in death or serious injury.

HAZARD: Injection injury

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to serious injury and possible amputation. See a physician immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT! Injection can lead to amputation. See a physician immediately.

The maximum operating range of the gun is 3000 PSI/207 BAR fluid pressure.

PREVENTION:

•NEVER aim the gun at any part of the body.

•Do not aim the gun at, or spray any person or animal.

•NEVER allow any part of the body to touch the fluid stream. DO NOT allow body to touch a leak in the fluid hose.

•NEVER put your hand in front of the gun. Gloves will not provide protection against an injection injury.

•ALWAYS lock the gun trigger, shut the pump off, and release all pressure before servicing, cleaning the tip or guard, changing tip, or leaving unattended. Pressure will not be released by turning off the motor. The PRIME/SPRAY knob must be turned to PRIME to relieve the pressure. Refer to the Pressure Relief Procedure (page 7) described in the pump manual.

•ALWAYS keep the tip guard in place while spraying. The tip guard provides some protection but is mainly a warning device.

•ALWAYS remove the spray tip before flushing or cleaning the system.

•Paint hose can develop leaks from wear, kinking and abuse. A leak can inject material into the skin. Inspect the hose before each use. Do not use hose to lift or pull equipment.

•NEVER use a spray gun without a working trigger lock and trigger guard in place.

•All accessories must be rated at or above 3000 PSI/207 BAR.

This includes spray tips, guns, extensions, and hose.

note to physician:

Injection into the skin is a traumatic injury. It is important to treat the injury as soon as possible. DO NOT delay treatment to research toxicity. Toxicity is a concern with some coatings injected directly into the blood stream. Consultation with

a plastic surgeon or reconstructive hand surgeon may be advisable.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

•Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be sure it will provide the necessary protection.

• Wear protective eyewear.

•Wear protective clothing as required by coating manufacturer.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property damage and/or severe injury can occur.

PREVENTION:

•Provide extensive exhaust and fresh air introduction to keep the air within the spray area free from accumulation of flammable vapors. Solvent and paint fumes can explode or ignite.

•Do not spray in a confined area.

•Avoid all ignition sources such as static electric sparks, open flames, pilot lights, electrical appliances, and hot objects. Connecting or disconnecting power cords or working light switches can make sparks. Paint or solvent flowing through the equipment is able to result in static electricity.

•Do not smoke in spray area.

•Fire extinguisher must be present and in good working order.

•Place pump at least 20 feet (6.1 meters) from the spray object in a well ventilated area (add more hose if necessary). Flammable vapors are often heavier than air. Floor area must be extremely well ventilated. The pump contains arcing parts that emit sparks and can ignite vapors.

•The equipment and objects in and around the spray area must be properly grounded to prevent static sparks.

•Keep area clean and free of paint or solvent containers, rags and other flammable materials.

•Use only conductive or grounded high pressure fluid hose. Gun must be grounded through hose connections.

•Power cord must be connected to a grounded circuit.

•Always flush unit into a separate metal container, at low pump pressure, with spray tip removed. Hold gun firmly against side of container to ground container and prevent static sparks.

•Follow the material and solvent manufacturer’s warnings and instructions. Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets (MSDS) and container labels provided with the paints and solvents. Follow the paint and solvent manufacturer’s safety instructions.

•Use extreme caution when using materials with a flashpoint below 70ºF (21ºC). Flashpoint is the temperature that a fluid can produce enough vapors to ignite.

•Plastic can cause static sparks. Never hang plastic to enclose a spray area. Do not use plastic drop cloths when spraying flammable materials.

•Use lowest possible pressure to flush equipment.

•Do not spray onto pump assembly.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

•Do not use materials containing bleach or chlorine.

•Do not use halogenated hydrocarbon solvents such as bleach, mildewcide, methylene chloride and 1,1,1 - trichloroethane. They are not compatible with aluminum.

•Contact your coating supplier about the compatibility of material with aluminum.

English |

2 |

|

|

|

|

Important Safety Information · Read all safety information before operating the equipment. Save these instructions.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

•Read all instructions and safety precautions before operating equipment.

•Follow all appropriate local, state, and national codes governing ventilation, fire prevention, and operation.

•The United States Government Safety Standards have been adopted under the Occupational Safety and Health Act (OSHA). These standards, particularly part 1910 of the General Standards and part 1926 of the Construction Standards should be consulted.

•Use only manufacturer authorized parts. User assumes all risks and liabilities when using parts that do not meet the minimum specifications and safety requirements of the pump manufacturer.

•Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover. Check for damage or movement of couplings. Immediately replace the hose if any of these conditions exist.

Never repair a paint hose. Replace it with another grounded high-pressure hose.

•All hoses and fittings must be secured before operating spray pump. Unsecured parts can eject at great force or leak a high pressure fluid stream causing severe injury.

•All hoses, swivels, guns, and accessories must be pressure rated at or above 3000 PSI/207 BAR.

•Do not spray outdoors on windy days.

•Wear clothing to keep paint off skin and hair.

•Do not operate or spray near children. Keep children away from the equipment at all times.

•Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

•Stay alert and watch what you are doing.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

Important Electrical Information

notice - Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that will accept the plug on the product. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A 14 or 12 gauge cord is recommended (see chart below). If an extension cord is to be used outdoors, it must be marked with the suffix W-A after the cord type designation. For example, a designation of SJTW-A would indicate that the cord would be appropriate for outdoor use.

Cord gauge |

Maximum cord length |

12 |

200 feet |

14 |

100 feet |

|

|

Do not use more than 100 feet of spray hose. If you need to spray further than 100 feet from your power source, use more extension cord, not more spray hose.

NOTE - the 9145 and 9155 series units are provided with a non-resetable thermal overload. THE 9175 and 9195 series UNITS ARE PROVIDED WITH A REPLACEABLE FUSE.

•Always disconnect the motor from the power supply before working on the equipment.

The cause of the overload should be corrected before restarting. Take to Service Center.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the green grounding wire to either flat blade terminal. The wire with insulation having a green outer surface with or without yellow stripes is the grounding wire and must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if you are in doubt as to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not fit the outlet, have the proper outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a grounding plug that looks like the plug illustrated below. Make sure that the product is connected to an outlet having the same configuration as the plug. No adapter should be used with this product.

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

If you experience problems with your sprayer at any time during assembly, operation, or cleanup, please refer to the Troubleshooting section of this manual (page 22), or call customer service at:

1-800-880-0993

3 |

English |

|

Components and Description

Components

The shipping carton for your painting system contains the following:

•Suction tube and return tube

•Pump cleaning adapter

•Spray gun with filter

•Spray tip assembly (see chart on next page)

•25’ (9145, 9155) or 50’ (9175, 9195), 1/4” diameter pressure hose

•Instruction manual

Tools Needed for Assembly

•Two adjustable wrenches

•Extension cord (refer to Important Electrical Information, page 3).

Controls and Functions

ON/OFF Switch The ON/OFF switch turns the power to the sprayer on and off (O=OFF, l=ON).

Suction tube Fluid is drawn through the suction tube into the pump.

Fluid Section A piston in the fluid section moves up and down to create the suction that draws fluid through the suction tube.

Spray Gun The spray gun controls the delivery of the fluid being pumped. The gun model you have depends on your sprayer model (refer to Spray Gun/Tip Chart, next page).

Spray Hose |

The spray hose connects the gun to the pump. |

Return Tube |

Fluid is sent back out through the return tube to the original container when PRIME/SPRAY knob is |

|

in PRIME position. |

Pump Cleaning Adapter The adapter allows you to attach a garden hose to the suction tube for easy cleanup (latex materials only).

PRIME/SPRAY Knob The PRIME/SPRAY knob directs fluid to the spray hose when set to SPRAY or the return tube when set to PRIME. The arrows on the PRIME/SPRAY knob shows the rotation directions for PRIME and SPRAY.

|

The PRIME/SPRAY knob is also used to relieve pressure built up in the spray hose (see Pressure |

|

Relief Procedure, page 7). |

Pressure Control Dial |

The pressure control dial regulates the amount of force the pump uses to push the fluid. |

Oiler |

(9155, 9175, and 9195 only) The oiler is designed to provide lubrication to the fluid section of the |

|

pump. |

Pusher Stem The pusher stem is designed to keep the inlet valve open and from sticking due to dried materials.

Specifications

Capacity:

9145 Up to .25 gallon (0.95 liter) / minute 9155 Up to .29 gallon (1.10 liters) / minute 9175 Up to .33 gallon (1.25 liters) / minute 9195 Up to .42 gallon (1.60 liters) / minute

Power source:

9145 1/2 Hp universal motor

9155 5/8 Hp universal motor

9175 3/4 Hp permanent magnet DC motor

9195 7/8 Hp permanent magnet DC motor

Power requirement:

15 amp minimum circuit on 115 VAC, 60 Hz current

Generator power requirement:

8000 Watt

Safety features:

Spray gun trigger lock and pressure diffuser; built-in tip safety guard; PRIME/SPRAY knob for safe pressure release.

Capability:

Sprays a variety of paints, primers, stains, preservatives and other nonabrasive materials, including pesticides and liquid fertilizers.

This pump should not be used with textured materials, block filler, or asphalt sealer.

English |

4 |

|

|

|

|

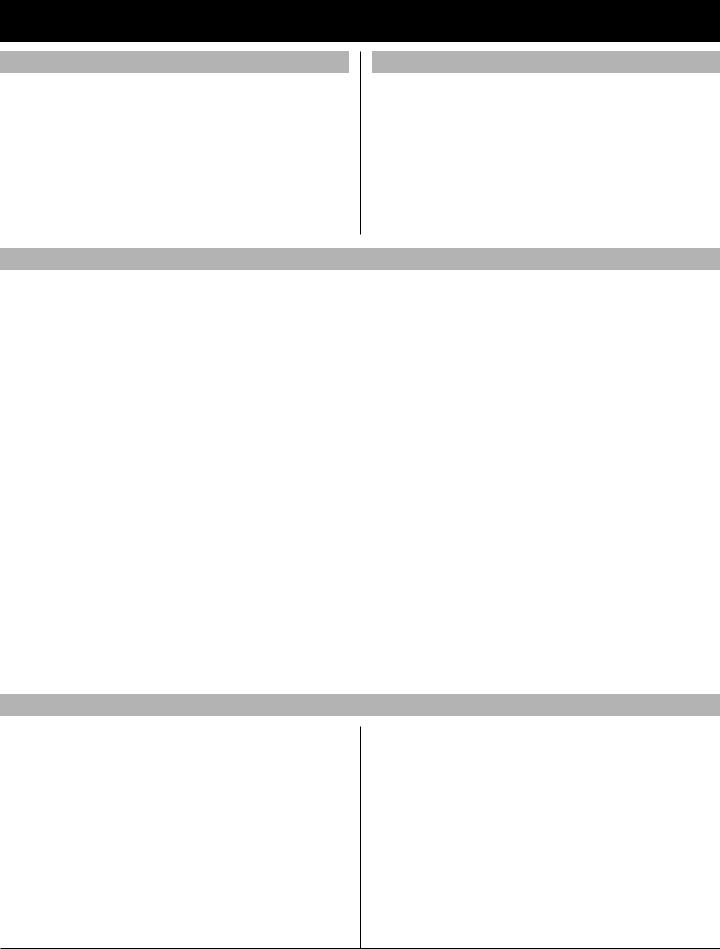

Components and Description

This pump is available in two models: a stand model (9145) and cart models (9155, 9175 shown below, and 9195). All information given for the stand model applies to the cart models except where indicated.

notice

Some of the graphics in this manual may not exactly match your sprayer and spray gun. All information and instructions given in this manual applies to all models except where noted.

9145 |

GX-05 |

415 |

415 |

Yellow (fine) |

25 feet |

9155 |

GX-07 |

415 |

517 |

Yellow (fine) |

25 feet |

9175 |

GX-07 |

517 |

519 |

White (medium) |

50 feet |

9195 |

GX-08 |

517 |

521 |

White (medium) |

50 feet |

Hose bracket |

|

|

Pressure control dial |

|

|

(rear of sprayer) |

|

|

Oiler (9155, 9175 |

|

|

and 9195 only) |

|

|

Spray hose port |

|

|

(reverse side) |

ON / OFF switch |

|

Oiler button (9155, |

||

PRIME/SPRAY knob |

||

9175 and 9195 only) |

||

Pail bracket |

Cord wrap / Tip holder (9155, |

|

Pusher stem |

9175 and 9195 only) |

|

Toolmate™ Tool box |

||

Return tube |

||

(9175 and 9195 only) |

||

Suction tube |

||

|

*The pump cleaning adapter can be clipped to the spray hose port

Clip |

|

|

Suction set filter |

|

|

*Pump cleaning |

|

Spray hose |

adapter |

|

|

|

|

|

Spray Gun Assembly |

|

|

|

Washer** |

Spray gun (see chart above |

|

for models, GX-07 shown) |

|

|

|

|

|

Saddle seat** |

|

Spray |

** Saddle seat and washer come |

|

guard |

pre-assembled inside spray guard |

|

Spray tip |

|

|

5 |

English |

|

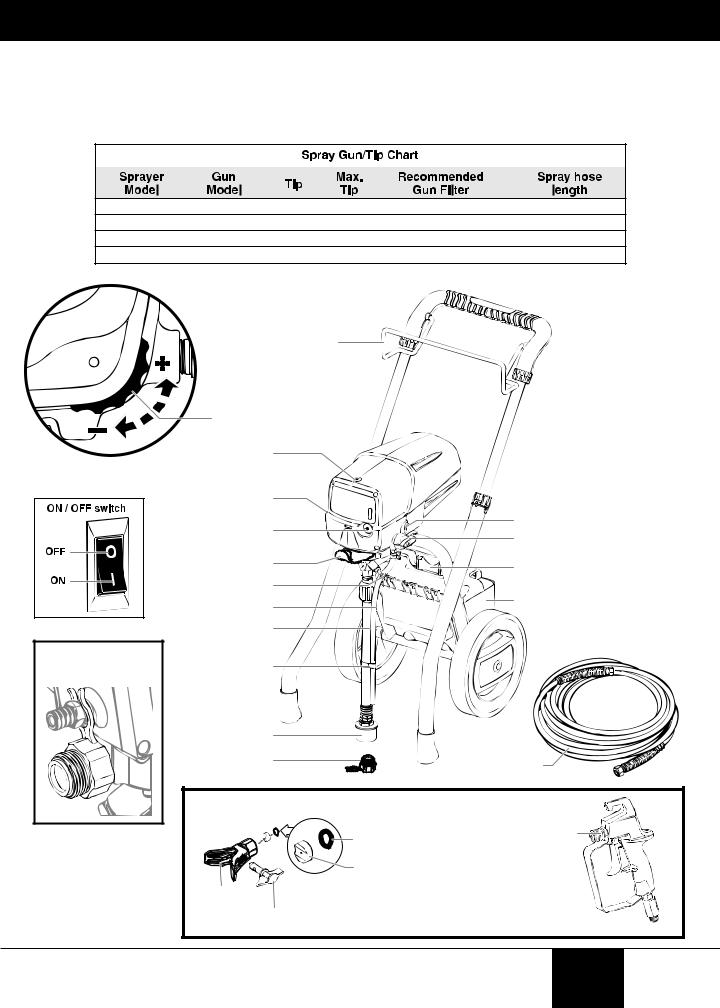

Assembly

Do not plug in the power cord until assembly is complete.

If you have one of the cart models, follow these assembly instructions. If you have the model 9145 sprayer, skip to item 4, below.

1.Twist the knobs on either side of the handle counterclockwise to unlock the handle. Pull the handle out fully, and turn knobs clockwise to lock into place.

2.Insert the ends of the hose bracket into the holes of the handle as shown.

3.Attach the pail bracket. Line up the holes in the bracket with the holes in the sprayer. Insert and tighten the screws using a 3/16” allen wrench.

4.Thread one end of the high pressure spray hose to the spray hose port. Hold the port with an adjustable wrench, and tighten the hose with the other.

5.Thread the other end of the hose to the spray gun. Hold the gun with one adjustable wrench, and tighten the hose nut with the other.

The spray tip should not be attached until after the

sprayer and spray hose have been purged and primed.

6.Thread the suction tube onto the inlet valve and tighten firmly by hand. Be sure that the threads are straight so that the fitting turns freely.

7.Press the return tube onto the return tube fitting. Squeeze clip over the return tube fitting to secure the return tube.

8.Verify that the seal is present inside the suction tube. Thread the inlet filter into the end of the suction tube.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

English |

6 |

||

|

|

|

|

|

|

|

|

|

|

Before you Begin - This section contains instructions that will be repeated throughout this manual.

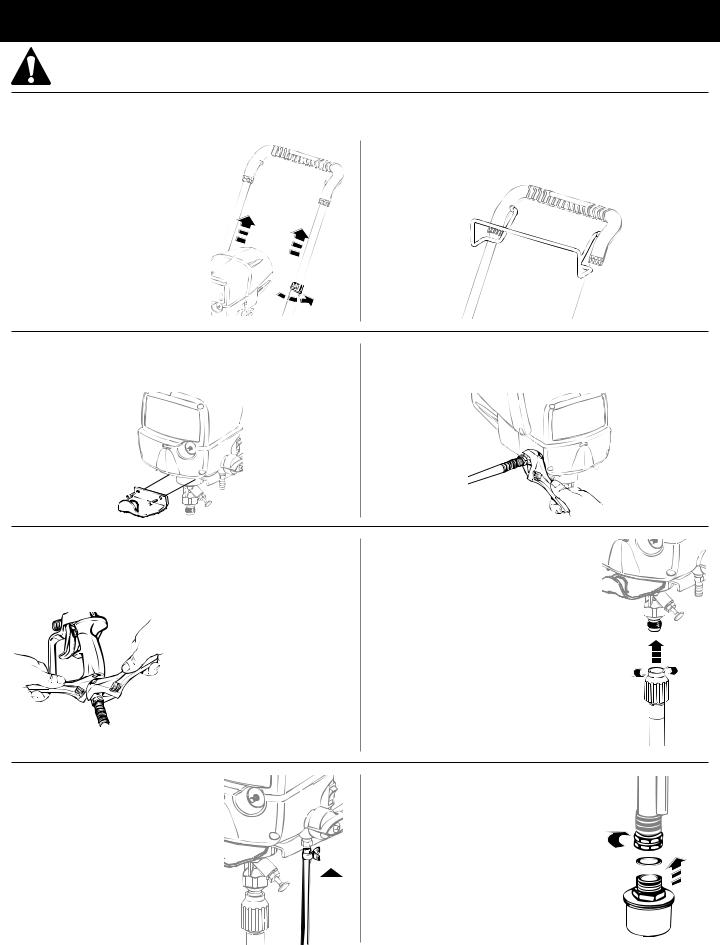

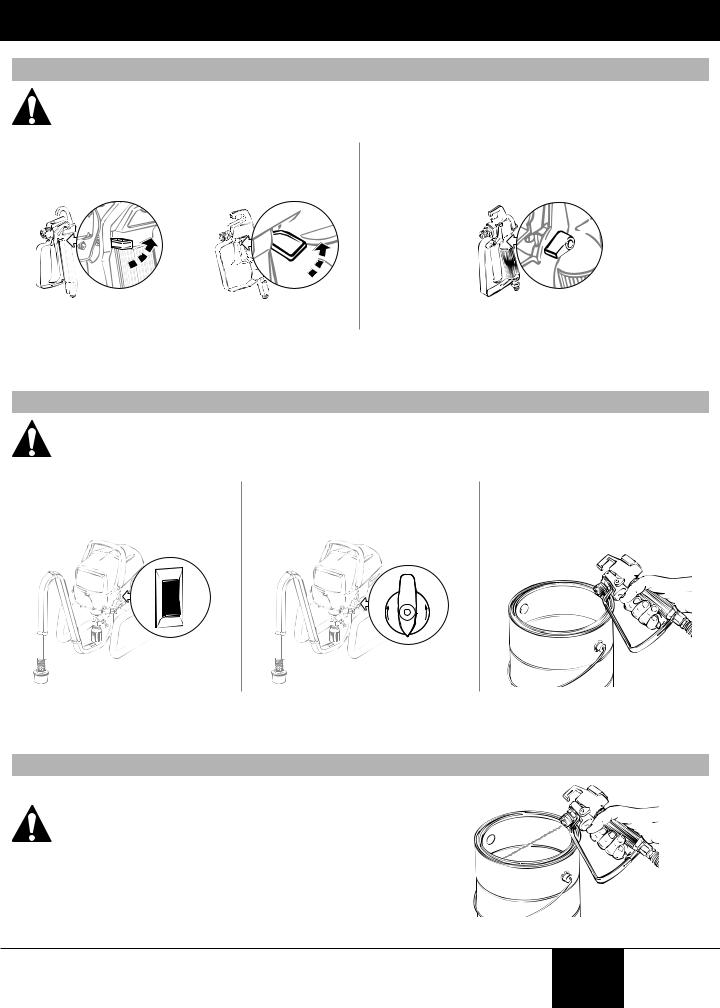

Locking the Spray Gun

Always lock the trigger off when attaching the spray tip or when the spray gun is not in use.

GX-05 / GX-07 |

GX-08 |

The gun is locked when the trigger lock is at a 90º angle |

To lock the gun, turn the trigger lock forward and slightly down |

(perpendicular to the trigger in either direction). |

until it stops. |

GX-05 |

GX-07 |

GX-08 |

Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when shutting the unit off for any purpose. This procedure is used to relieve pressure from the spray hose.

1.Lock the spray gun off (see directions above). Flip the ON/

OFF switch to the OFF position.

O

O

2.Turn the PRIME/SPRAY knob to PRIME.

SPRAY |

PRIME |

3.Unlock the spray gun and trigger spray gun into the side of the material bucket. Lock the spray gun.

Grounding the Spray Gun (oil-based materials only)

If spraying or cleaning with with oil-based materials, the spray gun must be grounded while preparing the spray hose or cleaning.

Ground the gun by holding it against the edge of a metal container while purging. Failure to do so may lead to a static electric discharge which may cause a fire.

Keep hands clear of the fluid stream.

7 |

English |

|

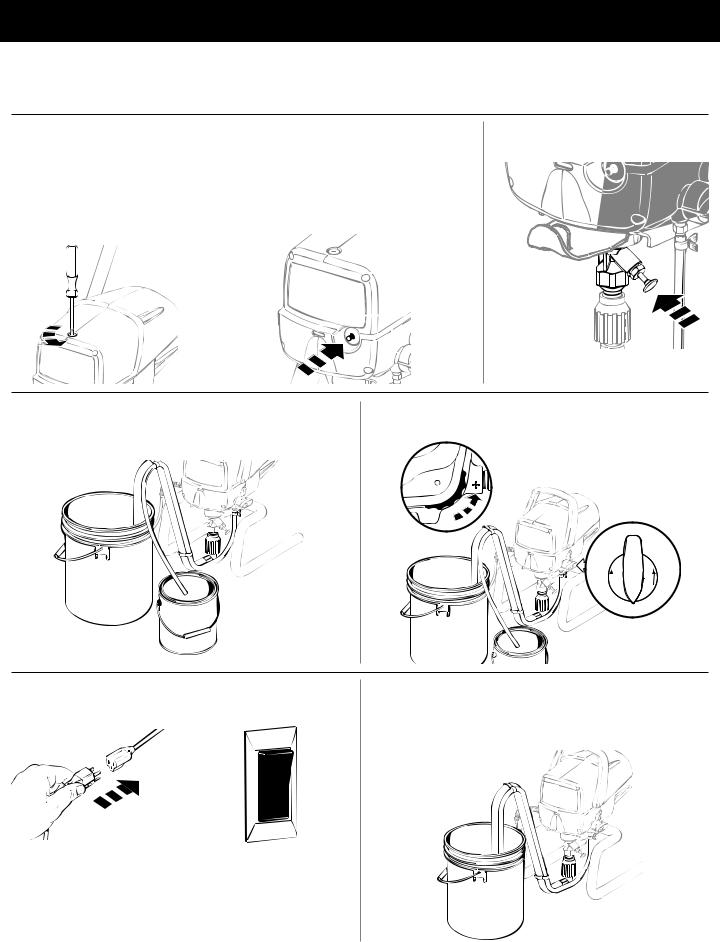

Preparing the Sprayer

All new units are performance-tested at the factory and are shipped with test fluid in the fluid section to prevent corrosion during shipment and storage. If you have already used your pump, some water or solvent used in cleaning may remain in the fluid section. Whether your sprayer is new or if you have already used it, this fluid must be purged and thoroughly cleaned out of the system prior to use. Follow the steps below.

9155, 9175 and 9195 only.

1.Remove oiler cap using a straightslot screwdriver. Squirt separating oil P/N 0516913 supplied with your sprayer into the oiler (approximately 1 ounce). Light household oil can be substituted if necessary. Replace cap.

2.After filling, push button on front of face plate 2-5 times to lubricate the fluid section. Press once for every eight hours of usage. Be sure to check reservoir level (a) and refill as necessary.

3.Fully depress the pusher stem to make sure the inlet ball is free.

(a)

(a)

4.Place a full container of spraying material underneath the suction tube (a). Secure the return tube (b) into a waste container.

5.Turn the pressure control dial to maximum pressure (+).

Turn the PRIME/SPRAY knob to PRIME.

(a)

(b)

(b)

SPRAY

SPRAY

PRIME

6.Plug in the sprayer and move the ON/OFF switch to the ON (l) position.

l

l

The unit will begin to draw material up the suction tube, into the pump, and out the return tube. Let the unit cycle long enough to remove test fluid from the pump, or until spray material is coming from the return tube.

7.Switch the pump OFF (O). Remove the return tube from the waste container and place it in its operating position above the container of spraying material. Use the metal clip to bind the two hoses together.

|

English |

8 |

|

|

|

|

|

|

Preparing the Spray Hose and Spray Gun

The spray tip assembly should not be attached to the spray gun when purging the spray hose. Failure to comply could result in an injection injury.

1.Unlock the spray gun and turn the PRIME/SPRAY knob to PRIME.

2.PULL the trigger and aim the spray gun at the side wall of a waste container.

If using oil-based materials, the spray gun must be grounded (see Grounding the Spray Gun, page 7).

SPRAY |

PRIME |

3.While pulling the trigger, switch the pump ON (l), and turn the PRIME/SPRAY knob to Spray. Hold the trigger until all air, water, or solvent is purged from the spray hose and material is flowing freely.

+ |

|

+ |

SPRAY |

l |

|

||

|

|

PRIME |

|

|

|

|

Whenever the PRIME/SPRAY knob is still on SPRAY, there will be high pressure in the hose and spray gun until the PRIME/SPRAY knob is turned to PRIME.

4.Release trigger and perform the Pressure Relief Procedure, page 7).

5.Lock the spray gun trigger.

6.Make sure the saddle seat and black seal are in place inside the tip guard nut (see Components and Description, page 5).

7.Insert spray tip (a) into the side of the spray guard (b).

The pointed end (c) of the spray tip should be facing forward as shown.

(c)

(b)

(b)

(a)

8.Thread the spray tip guard assembly onto the gun. Tighten by hand.

Begin |

|

. . .to achieve |

|

||

tightening |

|

the desired |

the tip at |

|

spray angle |

this angle |

|

when tight. |

9 |

English |

|

Loading...

Loading...