Page 1

Originalbetriebsanleitung

2 Jahre

Garantie

2 years

Guarantee

2 ans de

garantie

2 jaar

garantie

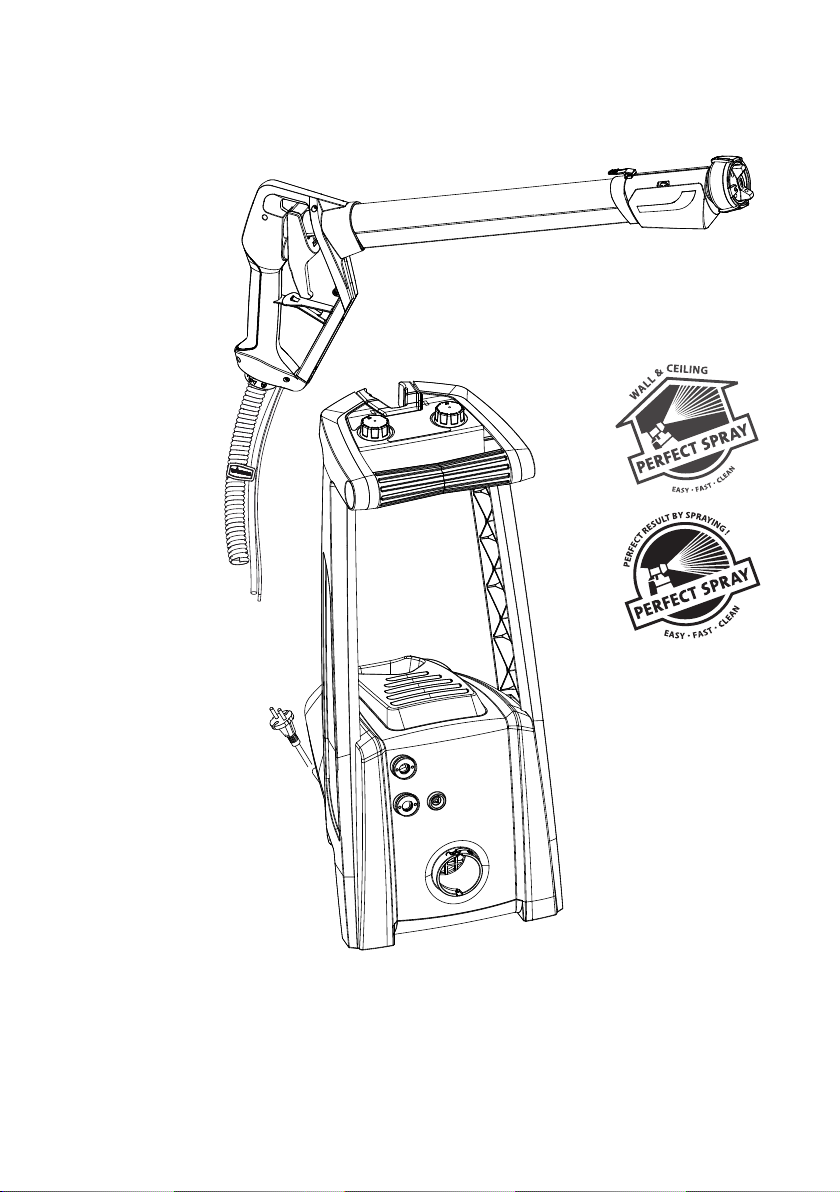

WallPerfect

Flexio 995

D/GB/F/NL

Page 2

WallPerfect Flexio 995

D

GB

F

NL

..........................................1 - 31

.........................................32 - 62

.........................................63 - 94

........................................95 - 124

+ +

........... 126

Page 3

D

GB

WallPerfect Flexio 995

WallPerfect Flexio 995

Translation of the original operating instructions

MANY THANKS FOR PLACING YOUR TRUST IN US

We would like to congratulate you on purchasing this brand product from Wagner;

General

we are sure that you will enjoy working with it greatly.

Please read the Operating Manual carefully and observe the safety information

before starting the device. Store the Operating Manual in a safe place close to the

product in case it needs to be used by someone else.

We would be happy to be of assistance if you have any questions, suggestions or requests.

Please contact us via the phone number included on the back page or via our homepage,

www.wagner-group.com/service.

Contents

1. Explanation of symbols used ................................................... 33

2. General Safety Instructions

3. Safety instructions for colour application devices

4. Scope of delivery

5. Field of application

6. Coating Materials Suitable for Use

7. Coating Materials Not Suitable for Use

8. Preparation of the Coating Material

9. Preparation of the workplace (for interior wall paint)

10. Assembling the spray lance (g. 2) ............................................40

11. Connecting the hoses (g.3) ..................................................41

12. Multifunction switch settings (g. 4, A)

13. Setting the ow rate when working with the spray lance (g. 4, B) .............. 42

14. Setting the width of the spray jet on the spray lance (Fig. 5) .................... 42

15. Starting your work with the spray lance

16. Spraying technique when using the spray lance ...............................43

17. Interruption of Work

18. Switching o and cleaning the spray lance .................................... 44

19. Rectifying errors when working with the spray lance ...........................48

20. Starting work with the spray attachment ......................................50

21. Setting the spray pattern you require when working with the spray attachment 51

22. Setting the ow rate for the spray attachment (g. 22). ........................ 52

23. Spraying technique when using the spray attachment .........................52

24. Interruption of Work

25. Switching o and cleaning the spray attachment ..............................53

26. Correction of Malfunctions

27. Maintenance

28. Storage

29. Spare Parts

......................................................................57

..............................................................37

............................................................38

.................................................................57

...................................................................58

....................................................33

...............................36

.............................................. 38

.......................................... 38

............................................39

............................ 39

........................................42

.......................................43

.......................................................... 44

.......................................................... 53

....................................................56

32

32

Page 4

WallPerfect Flexio 995

i

WallPerfect Flexio 995

30. Accessories ................................................................... 59

31. Technical Data

................................................................ 60

D

GB

1. Explanation of symbols used

This symbol indicates a potential danger for you or for the device.

Under this symbol you can nd important information on how to

avoid injuries and damage to the device.

Danger of electrical shock

Indicates tips for use and other particularly useful information.

Wide spray jet setting

Narrow spray jet setting

Devices and accessories marked with this symbol are suitable for

processing high-viscosity materials such as e.g. interior wall paints

(dispersions and latex paints).

If a material bears this logo, it is particularly well suited for use with

the relevant device.

Devices and accessories marked with this symbol are suitable for

processing low-viscosity materials such as paints, glazes and wall

paints specically designed for this purpose.

If a material bears this logo, it is particularly well suited for use with

the relevant device.

General

2. General Safety Instructions

WARNING! Read all safety notications and instructions. Failure to comply with the safety

notications and instructions provided may result in electric shock, re and/

or serious injury. The term "power tool" used below covers both mains-operated

power tools (with mains lead) and accumulator-operated power tools (without

mains lead).

1. Safety at the workplace

a) Keep your workplace clean and well lit. Disorder or unlit workplaces may result in

accidents.

33

33

Page 5

D

GB

b) Never use the tool in hazardous areas that contain ammable liquids, gases

or dusts. Power tools generate sparks that can ignite the dust or vapors.

c) Keep children and other persons away when using the power tool. You can

General

lose control of the tool if you are distracted.

WallPerfect Flexio 995

WallPerfect Flexio 995

2. Electrical Safety

a) The tool plug must t into the socket. The plug may not be modied in any

form. Do not use adaptor plugs together with protective-earthed tools.

Unmodied plugs and suitable sockets reduce the risk of an electric shock.

b) Avoid physical contact with earthed surfaces such as pipes, heating

elements, stoves and refrigerators. The risk through electric shock increases if

your body is earthed.

c) Keep the equipment away from rain and moisture. The risk of an electric shock

increases if water penetrates electrical equipment.

d) Do not misuse the mains lead by carrying the tool by the lead, hanging it

from the lead or by pulling on the lead to remove the plug. Keep the lead

away from heat, oil, sharp edges or moving tool parts. Damaged or twisted

leads increase the risk of an electric shock.

e) If you work outdoors with a power tool, only use extension cables suitable

for outdoor use. The use of an extension lead that is suitable for outdoors reduces

the risk of an electric shock.

f) If you cannot avoid using the tool in a damp environment, use a residual

current operated circuit-breaker. Using a residual current operated circuit-breaker

avoids the risk of electric shock.

3. Safety of Persons

a) Be attentive. Pay attention to what you are doing and work sensibly with

a power tool. Do not use the tool if you are tired or under the inuence of

drugs, alcohol or medication. Just a moment of inattentiveness while using the

tool can lead to serious injuries.

b) Wear personal safety equipment and always wear safety goggles Wearing

personal protective equipment, such as dust mask, non-slip safety shoes, safety helm

or ear protection, depending on the type of power tools, reduces the risk of injury.

c) Avoid accidental starting-up. Make sure that the electric tool is switched o

before you connect it to the power supply, pick it up or carry it. Accidents can

occur if you carry the power tool while your nger is on the switch or if you connect

the power tool to the power supply which it is on.

34

34

Page 6

WallPerfect Flexio 995

WallPerfect Flexio 995

d) Remove setting tools or wrenches before switching on the power tool. A tool

or wrench that is in a rotating tool part can lead to injuries.

e) Avoid an unnatural posture. Ensure that you are standing securely and

have your balance at all times. This ensures that you can control the tool better in

unexpected situations.

f) Wear suitable clothing. Do not wear wide clothing or jewellery. Keep your

hair, clothes and gloves away from moving parts. Loose clothing, jewellery or

long hair can be caught in moving parts.

g) This device can be used by children over the age of 8 as well as by people

with restricted physical, sensory or mental abilities or who have little

experience or knowledge about it, providing they are supervised or

instructed on how to use the device safely and what risks are involved.

Children may not play with the device. User maintenance and cleaning may not be

carried out by children unattended.

4. Usage and treatment of the electric tool

a) Do not overload the tool. Use the power tool designed for the work that you

are doing. You work better and safer in the specied performance range if you use

the suitable power tool.

b) Do not use power tools whose switch is defective. A power tool that cannot be

switched on or o is dangerous and has to be repaired.

D

GB

General

c)

Remove the plug from the socket before carrying out tool settings, changing

accessories or putting the tool away. This precautionary measure prevents

unintentional starting of the tool.

d) Store unused power tools so that they are inaccessible to children. Do not

let persons use the tool who are not familiar with it or who have not read

these instructions. Power tools are dangerous when they are used by inexperienced

persons.

e) Take proper care of your tools. Check whether the moving parts

functiontrouble-free and do not jam, whether parts are broken or damaged

so that the tool function is impaired. Have damaged parts repaired before

using the tool. Many accidents have their origin in power tools that have been

maintained badly.

f) Use the power tool, accessories, insert tools, etc. in accordance with these

instructions and in a fashion specied for this special tool type. Take the

working conditions and the activity to be carried out into consideration. The

use of power tools for purposes other than the intended ones can lead to dangerous

situations.

35

35

Page 7

D

GB

5. Service

a) Have your tool repaired only by qualied specialist personnel and only with

General

original spare parts. This ensures that the tool safety is maintained.

b) If the supply cord is damaged, it must be replaced by the manufacturer or it’s

service agent or a similarly qualied person in order to avoid a safety hazard.

WallPerfect Flexio 995

WallPerfect Flexio 995

3. Safety instructions for colour application devices

Caution! Wear breathing equipment: Paint mist and solvent vapors are damaging to

•

health. Always wear breathing equipment and only work in well ventilated rooms or

using supplementary ventilating equipment. It is advisable to wear working clothing,

safty glasses, ear protection and gloves.

CAUTION: DANGER OF INJURY!

Never point the spray lance at people or animals.

Sockets and plugs must be masked. Risk of an electric shock as a

consequence of sprayed material entering the socket!

Flammable agents may not be used for spraying with this device.

•

The device may not be cleaned using ammable solvents.

•

Caution against dangers that can arise from the sprayed substance and observe the

•

text and information on the containers or the specications given by the substance

manufacturer.

Do not spray any liquid of unknown hazard potential.

•

The device may not be used in establishments that are subject to explosion

•

prevention regulations.

In order to avoid risk of an explosion during spray operations, excellent natural or

•

articial ventilation must be provided.

While spraying there may be no ignition source in the surrounding area, for example,

•

open re, cigarette smoke, sparks, red-hot wires and hot surfaces.

Ensure that no solvent vapors are sucked in by the unit. Do not spray onto the unit!

•

The device is not a toy. For this reason do not allow children to handle or play with the

•

device.

Before working on the device, remove the power plug from the socket.

•

Mask all areas that are not going to be sprayed. When working keep

•

in mind that wind, for example, may transport paint mist over great

distances and cause damage.

Always switch o the device before placing the spray lance in the holder.

•

The spray attachment for varnish paints and glazes may only be

•

operated in conjunction with a fully functioning valve. If paints rises in

the ventilating hose (A) do not operate the unit further! Dismantle

and clean the ventilating hose, valve and diaphragm and replace the

diaphragm if necessary.

A

36

36

Page 8

WallPerfect Flexio 995

Materialnr. 2314149 1008EBMA

WallPerfect Flexio 995

Do not lay the spray gun.

•

D

GB

With original WAGNER accessories and spare parts, you have the guarantee that all

safety regulations are fullled.

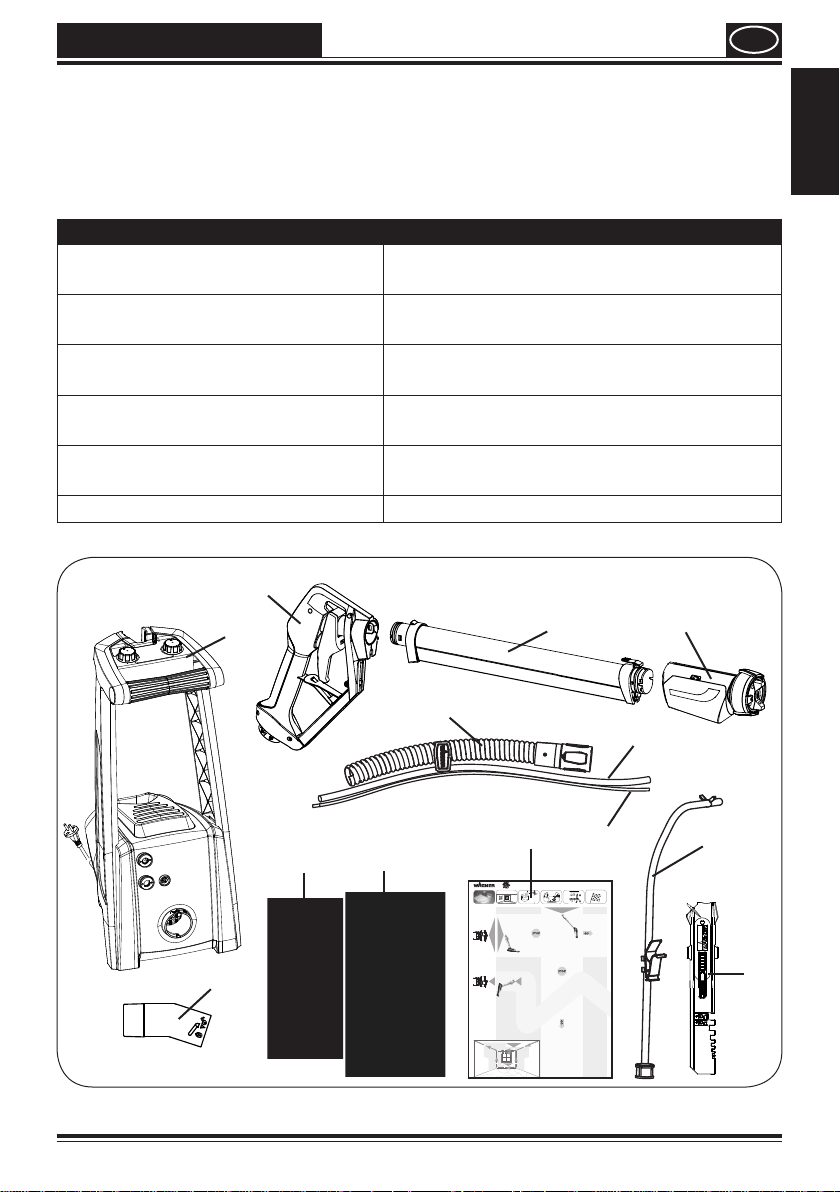

4. Scope of delivery

Scope of delivery (Fig. 1)

1 Basic device, Flexio 995 2 Spray lance (dismantled) comprising: Grab

handle (a), air pipe (b) and spray head (c)

3 Replacement nozzle seal for spray

head (2 pcs., no g.)

5 Suction hose 6 Adapter to connect the Click&Paint grab

7 Grab handle for Click&Paint spray

attachments

9 Practice poster 10 Replacement nozzle seal for spray

11 Lubricating grease (no g.) 12 Stirring rod

4 Hose package comprising: Air hose (d),

material hose (e) and control hose (f)

handle to the air hose

8 Perfect Spray 800 spray attachment for

varnish paints and glazes.

attachment(no g.)

General

a

2a

1

2b 2c

4d

4e

7

8

A B C D E F

Cover up !

+ 0 - 10%

9

4f

Testposter

1 – 4

10-30 cm

OFF

A B

6

1

1

2

1

3

33

4

3

5

12

37

37

Page 9

D

GB

WallPerfect Flexio 995

WallPerfect Flexio 995

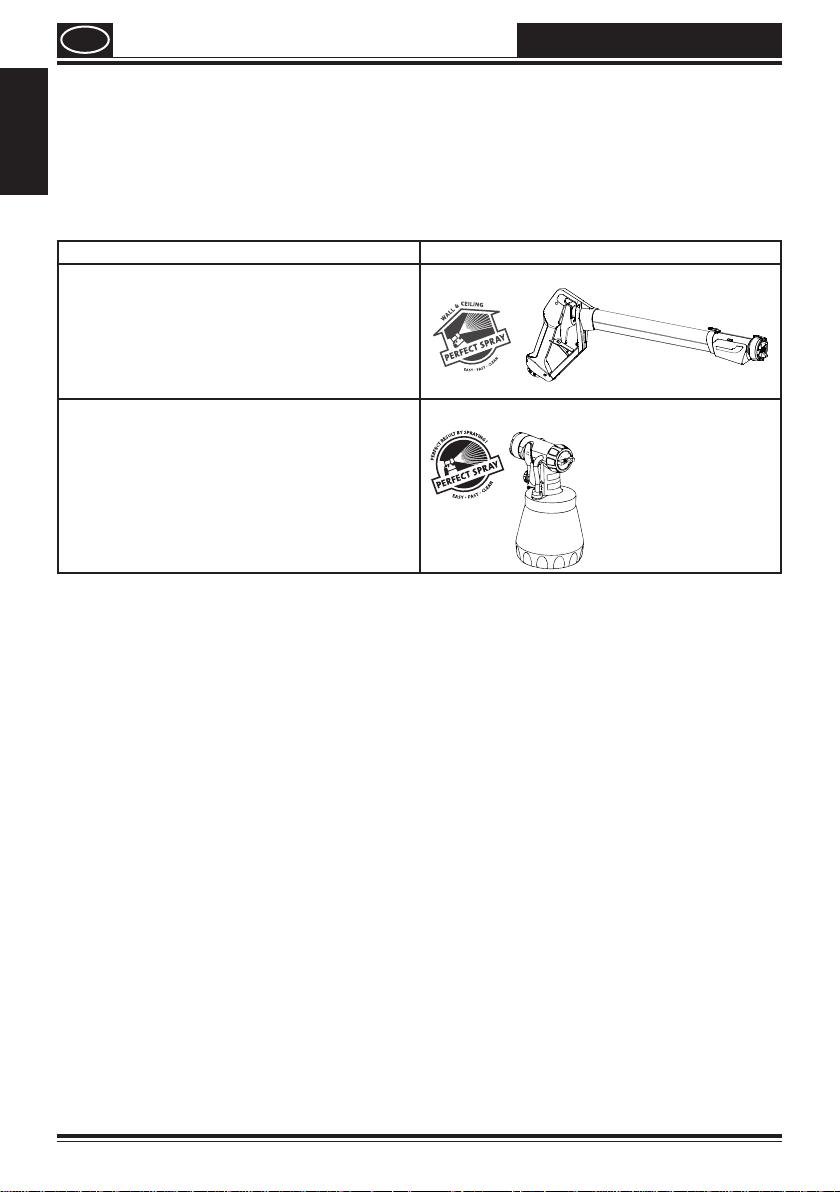

5. Field of application

With the Flexio 995, interior wall paints can be applied right from the bucket. And that

is not all, for the Click&Paint adapter enables all Wagner spray attachments to be used

General

for processing varnish paints and glazes.

Depending on which material you want to use, you must ax either the spray lance or

the spray attachment.

Coating Materials Application tools

Water-soluble interior wall paint

(dispersions and latex paint)

Spray lance

Water- and solvent-based paints, nishes,

primers, 2-component paints, clear

nishes, automotive nishes, staining

sealers and wood sealer-preservatives.

All coating materials with the red Perfect

Spray logo

Perfect Spray spray attachment

6. Coating Materials Suitable for Use

Water-soluble interior wall paint (dispersions and latex paint)

Water- and solvent-based paints, nishes, primers, 2-component paints, clear nishes,

automotive nishes, staining sealers and wood sealer-preservatives.

Attention! Never suck solvent-based materials directly via the suction system.

Pumps and hoses are not solvent resistant and could be damaged.

7. Coating Materials Not Suitable for Use

Materials that contain highly abrasive components, facade paint, caustic solutions and

acidic coating substances. Flammable materials.

The following materials can only be processed with optional

accessories

Solvent-based wall paints (WallPerfect I-Spray spray attachment, order no. 2326 477)

38

38

Page 10

WallPerfect Flexio 995

WallPerfect Flexio 995

8. Preparation of the Coating Material

D

GB

Mix the material well in the original container. When using interior wall paint, an agitator

is recommended.

WallPerfect Flexio 995 has been developed for use with all conventional paints in

their undiluted form. If the surface is smooth and the paint you are using is very

i

thick and gel-like, dilute it by 10%. Dilution can be necessary if the atomisation

is coarse or if the ow rate is too low even at the maximum setting.

Detailed information about the various materials and the maximum permitted

dilution can be found on the manufacturers' technical data sheets (e.g. available

on the Internet).

Spray material that is at least at room temperature provides a better spray

result.

i

The following chapters 9-19 discuss using the Flexio 995 as a wall paint

spraying system.

i

Read chapters 20-26 if you want to use varnish paints and glazes with the

Flexio 995.

9. Preparation of the workplace (for interior wall paint)

General

Wall paint

Sockets and plugs must be masked. Risk of an electric shock as a

consequence of sprayed material entering the socket!

Mask all the areas and objects that are not to be spray painted, or

remove them from the work area. No liability is assumed for damage

due to overspray. Silicate paint corrodes glass and ceramic surfaces

upon contact! All such surfaces must therefore be completely covered.

Pay attention to the quality of the adhesive tape used.

Do not use excessively strong adhesive tape on wallpaper and painted

i

surfaces, in order to avoid damaging these surfaces when removing the

tape. Remove adhesive tape slowly and evenly; do not use jerky movements.

Do not leave adhesive tape on surfaces any longer than necessary, in order

to minimise the possibility of residues when removing.

Also observe the adhesive tape manufacturer's instructions.

39

39

Page 11

D

GB

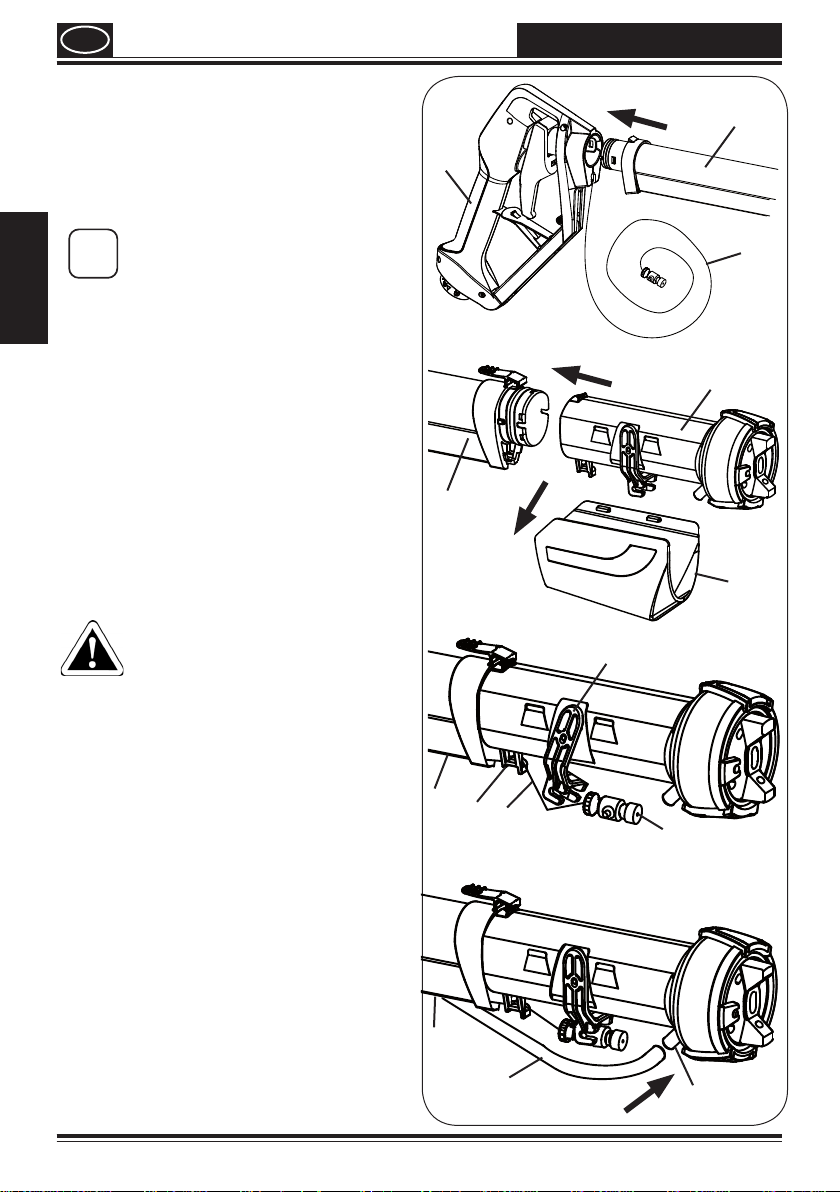

10. Assembling the spray lance

(g.

2)

Take the rolled-up pull wire (g. 2, 1) out

•

of the grab handle (2) and unwind it.

Put air pipe (3) in grab handle (2).

•

After assembly, the air pipe and

grab handle can no longer be

i

separated.

Wall paint

Put together the spray head (4) and air

•

pipe (3).

Remove the cover (5) from the spray head

•

(4).

Insert the pull wire (6) into the guide rail

•

(7) on the bottom side of the air pipe and

pull it over the guide hook (8) to the spray

head.

Push back the trigger (9) and connect the

•

pull wire. Set the pull wire at a tension

using the adjustment screw (10).

Push the end of the material hose (11),

•

without the securing clip, into the slot (12)

on the spray head.

Guide the material hose close along the

•

spray head along to the grab handle and

push it into the guide rail (7).

Clip the cover (5) back on to the spray

•

head.

Do not try to disassemble them

by force!

Attention! Do not tighten the

adjustment screw (10) too

much. The nozzle opening has

to remain closed at this point,

as otherwise material might

leak out.

2

3

7

WallPerfect Flexio 995

WallPerfect Flexio 995

3

1

4

5

9

8

6

10

40

40

7

11

12

Page 12

WallPerfect Flexio 995

WallPerfect Flexio 995

11. Connecting the hoses

(g

.3)

Insert the control hose (1) into the grab

•

handle (2).

Insert the thin end of the black air hose

•

(3) into the grab handle (2) (watch out

for marking) and x it into position by

turning it to the right.

Insert the thick end of the air hose (3) into

•

the air-hose connection (4) on the basic

device (watch out for marking) and x it

into position by turning it to the right.

Connect the material hose (5) to the

•

material hose connection socket (6) and

secure with securing clip.

Connect the control hose (1) to the

•

control hose connection socket (7).

Connect the suction hose (8) to the

•

suction hose connection socket (9)and

secure with securing clip.

Plug the attachment clip on the suction

•

hose (10) to the edge of the paint

container.

Push the suction hose down to the base

•

of the paint container.

Do not push the hose too far into

the paint container, as it might

i

otherwise bend upwards and suck

in air.

3

3

8

D

GB

2

Wall paint

1

4

9

10

7

1

6

5

41

41

Page 13

D

GB

12. Multifunction switch settings (g. 4, A)

WallPerfect Flexio 995

WallPerfect Flexio 995

FILL/

CLEAN

OFF

ON

i

Wall paint

Settings for cleaning and

pre-lling the system

System is o

Operating setting

When using the spray

attachment for varnish paints

and glazes, the FILL/CLEAN

functions may not be used!

Fill/

CLEAN

OFF

A

13. Setting the ow rate when working with the spray

lance (g. 4, B)

The material quantity is set depending on the characteristics of the material (viscosity)

and the working speed of the operator.

This setting can be made variably with the material ow limiter:

lower material

higher material

We recommend starting with a low material ow setting and then gradually

i

adjusting this to suit needs. .

turn to the left

turn to the right

B

14. Setting the width of the spray jet on the spray lance

(Fig. 5)

A = wide spray jet

(green)

B =

narrow spray

jet (red)

42

42

For coating larger surfaces

Working with a large ow

rate (green area on quantity

scale)

For coating smaller areas,

corners and edges

Working with a small ow

rate (red area on quantity

scale)

A

B

Page 14

WallPerfect Flexio 995

WallPerfect Flexio 995

In order to reduce overspray and to improve the sprayed result, the colour on

the quantity scale (red or green) should match the colour of the width of the

i

spray jet (red or green).

15. Starting your work with the spray lance

Put the machine down only on a level, clean surface.

•

Before connecting to the mains supply, be sure that the supply voltage is identical

•

with the value given on the rating plate.

Attention! Before switching on the device, check that the trigger is not

pulled/held. A held trigger can result in paint being sprayed by accident.

Only put the trigger on hold when cleaning.

Plug in the power cable.

•

Set the multifunction switch (g. 6, A) to "FILL/CLEAN".

•

Hold the spray lance over the paint container.

•

Keep the trigger kept pressed down until paint starts to come

•

out of the nozzle.

Now the system is lled with paint and ready to be operated.

Hold the spray lance away from the paint container.

•

Set the multifunction switch (g. 6, A) to "ON".

•

Fill/

CLEAN

OFF

D

GB

Wall paint

16. Spraying technique when using the

spray lance

Mask all areas that are not going to be sprayed.

•

It can be valuable to do a test spray on a piece of cardboard or similar surface to work

•

out what the most suitable settings are.

Important: Start at the edge of the spray area. Start the spray movement rst of

all, and then press the trigger. Avoid

interrupting the spraying process

inside the spray area.

Work at a distance of between 10-30 cm.

•

Fig. 7 A: CORRECT Even distance to the object.

Fig. 7 B: INCORRECT An uneven distance will

result in uneven paint application.

Move the spray lance up and down evenly .

•

To work in a horizontal direction, turn the spray

•

lance by 90°.

Even guidance of the splash lance will produce a

•

consistent surface quality.

If nozzle and air cap are soiled, clean both parts

•

with water.

10-30 cm

A

B

A

43

43

Page 15

D

GB

The spray jet can pulsate when very liquid materials are being used.

However, this does not usually have a negative eect on the results.

i

If the work being performed is of a sophisticated nature (e.g. the borders

around plugs) do not pull the trigger through completely. This prevents the

i

feed pump from being switched on and the only material that is sprayed is

the material that is already in the system. If this starts to run out, briey pull

Wall paint

the trigger completely in order to rell the system.

"Cross spray" when using paint with a

poor covering capacity or if the surface

i

is highly absorbent (Fig. 8).

Interior wall paint in strong colour

shades should be applied at least twice

i

(allow rst paint coat to dry rst). This

will ensure good coverage.

WallPerfect Flexio 995

WallPerfect Flexio 995

17. Interruption of Work

Turn the machine o. (Set the multifunction switch to "OFF")

•

Put the spray lance in the holder.

•

Wet paint surface in paint container with a little water to prevent a skin from forming.

•

Clean nozzle openings after an interruption in operation.

•

18. Switching o and cleaning the spray lance

Proper cleaning is the prerequisite for problem-free operation of the paint application

device. No warranty claims are accepted in case of improper or no cleaning.

We recommend using hot water for cleaning purposes.

i

Turn the machine o. (Set the multifunction switch to "OFF")

•

Remove the suction hose from the paint container.

•

Set the multifunction switch to "FILL/CLEAN".

•

44

44

Page 16

WallPerfect Flexio 995

WallPerfect Flexio 995

Hold the spray lance over the material

•

container and pull the trigger to pump the

remaining paint out of the system into the

material container.

Turn the machine o. (Set the multifunction

•

switch to "OFF")

Place a container with water in front of the

•

device and attach the suction hose.

Click the spray lance into the holder and

•

slew it over the container with water. (Fig. 9)

Attention! During automatic

cleaning of the pump do not

leave the device unattended. The

hoses could disconnect during

the cleaning operation leading to

water damage.

Set the multifunction switch to "FILL/CLEAN".

•

Pull the trigger (g. 10, 1) and push the stop

•

(2) upwards to secure the trigger. Allow water

to circulate through the machine for about 10

minutes in order to clean the pump and hoses.

If necessary renew the water.

Release the stop by pulling the trigger.

•

Turn the machine o. (Set the multifunction

•

switch to "OFF")

Take the spray lance out of the holder and

•

remove the cover (g. 11, 1) from the spray

head.

Detach the material hose (g. 11, 2) from the

•

slot on the spray head.

1

D

GB

Wall paint

2

2

1

45

45

Page 17

D

GB

Loosen the pull wire by the adjustment

•

screw (g. 12, 1). Pull the trigger (g. 12, 2)

disengage the pull wire.

Remove the spray head (g. 12, 3) by

•

pressing the lever (g. 12, 4).

Remove the adjustment ring (g. 13, 1)

•

carefully from the connecting nut (g. 13,

2). Loosen the connecting nut. Remove

the air cap (3), air screen (4), nozzle (5) and

nozzle seal (6) from the spray head.

Wall paint

Clean the air cap; air screen, nozzle and

•

nozzle seal thoroughly.

Attention! Never clean the seals,

nozzle- or air-holes with pointy metal

objects.

Remove the suction hose and thoroughly

•

rinse the suction lter in owing water.

If necessary wipe the exterior of the spray

•

lance.

WallPerfect Flexio 995

WallPerfect Flexio 995

4

3

2

1

1

2

3

46

46

4

5

6

Page 18

WallPerfect Flexio 995

WallPerfect Flexio 995

Reconstruction

Push the nozzle seal (g. 14, 6) over the

•

needle (8); the groove (slot) should point

towards you.

Insert the nozzle (g. 14, 5), keeping an

•

eye on the grooves.

Put the air screen (4) in the air cap (3). Put

•

both on the nozzle (5) and secure with the

connecting nut (2).

Snap the adjustment ring (g. 15, 1) into

•

the connecting nut enabling the loop on

the peg to be positioned in the air cap.

8

D

GB

7

6

Wall paint

5

5

4

3

2

1

47

47

Page 19

D

GB

WallPerfect Flexio 995

WallPerfect Flexio 995

19. Rectifying errors when working with the spray lance

Problem Cause Remedy

No coating material

emerges from the

nozzle

Wall paint

Coating material

drips from the

nozzle

Atomisation too

coarse

Nozzle clogged

•

Material volume setting

•

turned too far to the left

When trigger is not

•

completely pushed through,

the feed pump is not

switched on

Control hose blocked or

•

damaged

Container empty

•

Suction hose is blocked

•

The suction hose is

•

disconnected from the basic

device

The suction hose is not in

•

the paint

Pull wire is disconnected or

•

not tight enough

The material hose is

•

disconnected from the spray

head or basic device

Pump is defect

•

Coating material assembly

•

at air cap, nozzle or needle

Nozzle loose

•

Nozzle seal worn

•

Nozzle worn

•

Pull wire is too tight

•

Material volume too large

•

Material volume setting

turned too far to the right

Nozzle contaminated

•

Viscosity of coating material

•

too high

Air lter heavily soiled

•

At high quantity of material,

•

narrow spray jet selected

(red)

➞ Clean

➞ Turn to the right

➞ Push trigger through

completely

➞ Clean or replace

➞ New paint container

➞ Clean suction hose

➞ Reattach the suction hose

➞ Immerse the suction hose

➞ Connect and tighten the

pull wire

➞ Reattach the material hose

➞ Please contact Wagner

Service

➞ Clean

➞ Union nut tighten

➞ Change

➞ Change

➞ Reduce tension

➞ Turn the material volume

setting to the left

➞ Clean

➞ Dilute further

➞ Change

➞ Switch to wide spray jet

(green)

48

48

Page 20

WallPerfect Flexio 995

WallPerfect Flexio 995

Problem Cause Remedy

Spray jet pulsates

Coating material

causes "paint tears"

Too much fog of

coating material

(Overspray)

Width of paint

spray cannot be

adjusted

Poor covering

capacity on the wall

Coating material

cannot be atomised

Coating material in

•

container running out

Nozzle seal worn

•

Air lter heavily soiled

•

Filter clogged at suction

•

hose

Too much coating material

•

applied

Viscosity of coating material

•

too low

Distance to the object too

•

large

Too much material quantity

•

At a low quantity of material,

•

wide spray jet selected

(green)

Adjustment ring is not

•

connected to the peg on the

air cap

Air screen is clogged up

•

Spray material is too cold

•

Highly absorbent surface

•

or paint with poor covering

capacity

Distance too large

•

The material quantity and

•

spray jet do not correspond

with each other

Multifunction switch is set to

•

"Clean"

Turbine is defect

•

➞ Rell

➞ Replace

➞ Change

➞ Clean lter

➞ Turn the material volume

setting to the left

Spray excess material on the

wall using the inking roller

➞ Reduce the quantity of

material and apply in several

layers

➞ Reduce distance

➞ Turn the material volume

setting to the left

➞ Switch to narrow jet spray

(red)

➞ Connect adjustment ring

and peg

➞ Disassemble and clean the

spray head

➞ The material you are

spraying should be at room

temperature

➞ Cross spray (Fig. 8)

➞ Closer to the object

➞ Optimise the settings

➞ Set the multifunction switch

to "ON"

➞ Please contact Wagner

Service

D

GB

Wall paint

49

49

Page 21

D

GB

The following chapters 20-26 describe working with vinyls and lacquers with

the spray attachment.

i

Read chapters 9-19 if you want to use wall paint with the Flexio 995.

20. Starting work with the spray attachment

Put the machine down only on a level,

•

clean surface.

Before connecting to the mains supply, be

•

sure that the supply voltage is identical

with the value given on the rating plate.

Plug in the power cable.

•

Aligning suction tube. (Fig. 16)

•

If the suction tube is positioned correctly,

the container contents can be sprayed

without almost any residue.

When working on lying objects: Turn

the suction tube forwards. (Fig. 16 A)

Spraying work when working on overhead

objects: Turn the suction tube rearwards.

Varnish paints and glazes

(Fig. 16 B)

Set the container on a sheet of paper, pour

•

in the prepared coating material.

Screw the container tightly onto the spray

•

gun

Connect gun handle and spray attachment

•

together. (g 17).

If already attached, remove the air hose from

•

the grab handle of the spray lance.

Only the air hose is required for

operating a spray attachment

i

with the Flexio 995. To facilitate

handling, the material hose can

therefore be removed from the

air hose and the suction hose

can be detached from the basic

unit.

A

A

WallPerfect Flexio 995

WallPerfect Flexio 995

B

50

50

click

Page 22

WallPerfect Flexio 995

WallPerfect Flexio 995

Attach the Click&Paint adapter (Fig. 18, 2) with the bayonet coupling to the thinner end

•

of the air hose (1).

Insert the other end of the adapter into the gun handle (3).

•

Set the multifunction switch (g. 19, A) to "ON".

•

D

GB

1 2

3

Fill/

CLEAN

OFF

A

21. Setting the spray pattern you require when working

with the spray attachment

WARNING! Danger of injury! Never pull the trigger guard while adjusting

the air cap.

With the union nut (g. 20, 1) slightly unscrewed, turn the air cap (2) to the desired

spraysetting position (arrow). Then tighten the union nut.

Fig. 21 A = vertical at jet

Fig. 21 B = horizontal at jet

Fig. 21 C = circular jet

for horizontal surfaces

for vertical surfaces

for corners, edges and hard-to-reach surfaces

Varnish paints and glazes

1

2

51

51

Page 23

D

GB

WallPerfect Flexio 995

WallPerfect Flexio 995

22. Setting the ow rate for the spray attachment (g. 22).

Set the material volume by turning the regulator

on the trigger of the spray gun.

lower material volume

higher material volume

turn anti-clockwise

(-)

turn clockwise (+)

23. Spraying technique when using the spray attachment

Cover all surfaces not to be sprayed.

•

Varnish paints and glazes

Cover screw threads or similar parts of the target object.

•

The spray movement should come from the

•

arm, not just from the wrist. This ensures that

a uniform distance is maintained between the

spray gun and the spray surface during the

spray operation. Select a distance of 5 - 15 cm,

depending on the desired spray jet width.

Fig. 23 A: CORRECT: Even distance to

Fig. 23 B: INCORRECT: An uneven

Move the spray gun evenly cross-wise or up-and-

•

down, depending on the spray pattern setting.

An even movement of the spray gun results in an

•

even surface quality.

The spray result depends heavily on the smoothness and cleanliness of the

surface to be sprayed. Therefore the surface should be carefully prepared and

i

kept free of dust.

Important: Start at the edge of the area to be sprayed. Start the spray

movement rst of all, and then press the trigger. Avoid interruptions

i

within the area to be sprayed.

A

the object.

distance will result in uneven

paint application.

B

52

52

Page 24

WallPerfect Flexio 995

WallPerfect Flexio 995

D

GB

24. Interruption of Work

Turn the machine o. (Set the multifunction switch to "OFF")

•

Put the spray attachment on the oor.

•

When processing 2-component varnishes, clean the device immediately.

•

Clean nozzle openings after an interruption in operation.

•

25. Switching o and cleaning the spray attachment

Proper cleaning is the prerequisite for problem-free operation of the paint application

device. No warranty claims are accepted in case of improper or no cleaning.

The Clean function on the multifunction

switch may not be used when cleaning the

i

spray attachment.

Turn the machine o. (Set the multifunction switch

•

to "OFF")

Press the hook (Fig. 24 "click") slightly downwards.

•

Turn the spray attachment and grab handle

towards each other and detach.

Unscrew the container. Empty any remaining

•

coating material back into the material tin.

Preclean the container and feed tube with a brush.

•

Clean the ventilating bore (Fig.25,1)

Pour water or solvent into the container. Screw the

•

container back on.

Do not use ammable materials for cleaning

purposes.

Re-connect the spray attachment and the grab

•

handle.

Turn on the machine and spray the water or

•

solvent into a container or a cloth.

Repeat the above procedure until the water or

•

solvent emerging from the nozzle is clear.

Turn o the machine and remove the plug.

•

Press the hook (Fig. 24 "click") slightly downwards.

•

Turn the spray attachment and grab handle

towards each other and detach.

Screw of the container and empty it. Pull out the

•

suction tub with container seal.

CAUTION! Never clean seals, diaphragm and nozzle

or air holes of the spray gun with metal objects.

The ventilation hose and diaphragm are only solvent-resistant to a limited extent. Do

not immerse in solvent, only wipe.

1

click

Varnish paints and glazes

53

53

Page 25

D

GB

Pull the ventilating hose (Fig. 26, 1) at the

•

top from the gun body. Screw o the valve

cover (2). Remove the diaphragm (3). Clean

all the parts carefully.

Unscrew the union nut (Fig. 27, 1) and

•

remove the air cap (2) and nozzle (3). Clean

the air cap, nozzle seal (4) and nozzle with a

brush and solvent or water.

Clean the spray attachment and the

•

exterior of the container with a cloth that

has been soaked in water or a solvent.

Assemble the parts again (see “Assembly”).

•

Assembly

The unit may only be operated with an integer

diaphragm (Fig. 26, 3).

Place the diaphragm (Fig. 26 ,3) with the

•

pin facing upwards on the bottom section

of the valve. Also see the marking on the

gun body.

Varnish paints and glazes

Place on the valve cover (Fig. 26 ,2) and

•

screw it closed.

Place the ventilating hose (Fig. 26, 1) on the

•

valve cover and on the nipple at the gun

body.

Push the nozzle seal (g. 28, 4) over the

•

needle (5); the groove (slot) should point

towards you.

Put the nozzle (Fig. 28 ,3) onto the gun

•

body and nd the correct position by

turning it.

Put the air cap (Fig. 27, 2) onto the nozzle

•

and tighten it using the union nut (1).

WallPerfect Flexio 995

WallPerfect Flexio 995

1

2

3

4

3

2

5

4

1

54

54

3

Page 26

WallPerfect Flexio 995

WallPerfect Flexio 995

Place the container seal (Fig. 29, 1) from

•

below on the suction tube (2) and slide it

over the collar, while turning the container

seal slightly.

Insert the suction tube (Fig. 29, 2) with

•

container seal in the gun body (3).

D

GB

3

1

2

Varnish paints and glazes

55

55

Page 27

D

GB

26. Correction of Malfunctions

Problem Cause Remedy

No coating material

emerges from the

nozzle

Coating material

drips from the

nozzle

Atomisation too

coarse

Varnish paints and glazes

Spray jet pulsates

Coating material

causes "paint tears"

Too much fog of

coating material

(Overspray)

Paint in the

ventilating hose

Nozzle clogged

•

Material volume setting turned

•

too far to the left

Suction tube clogged

•

Suction tube loose

•

No pressure build-up in container

•

Ventilating bore (Fig. 25,1)

•

clogged

Coating material assembly at air

•

cap, nozzle or needle

Nozzle loose

•

Nozzle seal is missing or worn

•

Nozzle worn

•

Material volume too large

•

Material volume adjusting screw

turned too far to the right

Nozzle contaminated

•

Coating material too thick

•

Air lter heavily soiled

•

Too little pressure build-up in

•

container

Coating material in container

•

running out

Nozzle seal is missing or worn

•

Air lter heavily soiled

•

Too much coating material

•

applied.

Distance to the object too large

•

Too much coating material

•

applied

Diaphragm soiled

•

Diaphragm defective

•

WallPerfect Flexio 995

WallPerfect Flexio 995

➞ Clean

➞ Turn to the right

➞ Clean

➞ Insert

➞ Tighten container

➞ Clean

➞ Clean

➞ Tighten

➞ Insert an intact nozzle

seal

➞ Change

➞ Turn material volume

adjusting screw to the

left

➞ Clean

➞ Dilute

➞ Change

➞ Tighten container

➞ Rell

➞ Insert an intact nozzle

seal

➞ Change

➞ Turn material volume

adjusting screw to the

left

➞ Reduce distance

➞ Turn material volume

adjusting screw to the

left

➞ Clean the diaphragm

➞ Replace the diaphragm

56

56

Page 28

WallPerfect Flexio 995

WallPerfect Flexio 995

Problem Cause Remedy

Poor covering

capacity on the wall

Spray material is too cold

•

Highly absorbent surface or paint

•

with poor covering capacity

Distance too large

•

➞ The material you are

spraying should be at

room temperature

➞ Cross spray (Fig. 11)

➞ Closer to the object

27. Maintenance

Check the air lter (g. 30, 1) after use and

replace depending on how soiled it is.

Insert a new air lter (order no. 2310 812) and

replace the lid (2).

WARNING! Never operate the

i

machine without the air lter;

dirt could be sucked in and

interfere with the function of

the machine.

To make assembly easier, apply lubricant

(enclosed) to the specied areas after

cleaning (g. 31).

D

GB

General

2

1

Varnish paints and glazes

28. Storage

After assembly, the air pipe

i

and grab handle can no

longer be separated.

Do not try to disassemble

them by force!

Store the device only when cleaned

•

properly.

Release the pull wire.

•

Release the trigger stop.

•

57

57

Page 29

D

GB

29. Spare Parts

WallPerfect Flexio 995

WallPerfect Flexio 995

General

The pictures of spare parts can be found on the page that folds out at the end

of the operating manual.

i

Spare Parts List: Spray lance (Fig. A1)

Pos. Designation Order No.

1,2 Spray jet adjustment ring, union nut * 2310 811

3,4,5,6 Nozzle set * 2310 810

6 Nozzle seal (2 pcs.) 2304 433

1-7 Complete spray head * 2344 435

8 Spray head cover 2308 176

9 O-ring 2308 158

9,10 Spray lance * 2344 436

Spare Parts List: Perfect Spray spray attachment (Fig. A2)

Pos. Designation Order No.

Perfect Spray spray attachment complete with 800 ml

container

1 Union nut 0417 319

2 Air cap 2305 129

3 Nozzle 2305 131

4 Nozzle seal 0417 706

5 O-ring of spray attachment 0417 308

6 Ventilating hose, valve cover, diaphragm 2304 027

7 Suction tube 0417 357

8 Container seal 0417 358

9 Container with cover 800 ml 0413 909

0417 914

Spare Parts List: Flexio 995 (Fig. A3)

Pos. Designation Order No.

1 Air hose 2308 127

2 Securing clip 2308 123

3 Material hose and control hose * 2314 168

4 Complete suction hose 2308 116

5 Air lter cover 2308 132

6 Air lter (2pcs.) 2310 812

7 Grab handle for Click&Paint spray attachments 0414 240

8 Adapter for Click&Paint grab handle 2344 437

58

58

Page 30

WallPerfect Flexio 995

WallPerfect Flexio 995

D

GB

Spare Parts List: Flexio 995 (Fig. A3)

9 Stirring rod 2304 419

Lubricating grease 2315 539

* Denotes parts that can only be purchased together and not individually.

30. Accessories

The CLICK&PAINT SYSTEM with additional spray attachments and accessories oers

the right tool for each work.

Accessories (not included in the delivery)

Name Order No.

Brilliant spray attachment incl. 600 ml container

Optimised nozzle and air guidance for brilliant paint results

Small-scale spray attachment incl. 250 ml container

For ligree objects, detailed and creative work.

Perfect Spray spray attachment incl. 1400 ml container

Rapid working at larger objects such as timber houses, garage doors, etc. 0417 917

Detail / Radiator spray attachment incl. 600 ml container

For inaccessible places, such as radiators, cupboard corners, recesses etc. 0417 915

WallPerfect I-Spray spray attachment incl. 1800 ml container

For processing solvent-based interior wall paint.

0417 932

0417 918

2326 477

General

Further information about the WAGNER range of products for renovating is available

under www.wagner-group.com

59

59

Page 31

D

GB

31. Technical Data

WallPerfect Flexio 995

WallPerfect Flexio 995

Max. viscosity:

General

Interior wall paint

Power source: 230 V ~ , 50 Hz

Power consumption: 630 W

Atomizing output: 200 W

Max. ow rate:

nterior wall paint

Double insulation:

Sound pressure level*: 76 dB (A); Uncertainty K = 4 dB

Sound pressure output*: 89 dB (A); Uncertainty K = 4 dB

Oscillation level*: < 2,5 m/s²; Uncertainty K = 1,5 m/s²

Luftschlauchlänge: 3,5 m

Gewicht: 5,8 kg

* Measured in accordance with EN 60745

Technical Data

4000 mPas

525 ml/min

Information about the oscillation level

The specied oscillation level has been measured according to a standard test

procedure and can be used to compare against electric tools.

The oscillation level is also for determining an initial assessment of the vibrational strain.

Attention! The vibration emission value can dier from the specied value when the

electric tool is actually in use, depending on how the electric tool is being used. It is

necessary to specify safety measures to protect the operating personnel. These measures

are based on an estimated shutdown during the actual conditions of use (all parts of the

operating cycle are taken into consideration here, for example periods when the electric

tool is switched o, and, when it is switched on but running without any load).

Environmental protection

The device and all accessories and packaging have to be recycled in an

environmentally friendly manner. Do not dispose of the appliance with

household waste. Support environmental protection by taking the appliance

to a local collection point or obtain information from a specialist retailer.

Leftover paint and solvents may not be emptied into drains, the sewage system

or disposed of as household rubbish. It has to be disposed of separately as special

waste. Please pay special attention to the instructions on the product packaging.

60

60

Page 32

WallPerfect Flexio 995

WallPerfect Flexio 995

D

GB

Important Note regarding Product Liability!

According to an EU directive, the manufacturer is only liable without limitation for faults

in the product if all parts come from the manufacturer or have been approved by the

manufacturer and have been mounted to the device and are operated properly. If thirdparty accessories or spare parts are used, the manufacturer is exonerated wholly or partly

from his/her liability if use of the third-party accessories or spare parts have caused a

defect in the product.

2 years guarantee

The guarantee runs for two years, counting from the date of sale (sales slip). It covers and

is restricted to free-of-charge rectication of faults which are demonstrably attributable

to the use of faulty materials in manufacture, or assembly errors; or free-of-charge

replacement of the defective parts. The guarantee does not cover incorrect use or

commissioning or tting or repair work which is not stated in our operating instructions.

Wearing parts are also excluded from the guarantee. The guarantee excludes commercial

use. We expressly reserve the right to full the guarantee. The guarantee expires if the

tool is opened up by persons other than WAGNER service personnel. Transport damage,

maintenance work and loss and damage due to faulty maintenance work are not covered

by the guarantee. Under any guarantee claim, there must be proof of purchase of the

tool through submission of the original receipt. Wherever legally possible, we exclude

all liability for injury, damage or consequential loss, especially if the tool has been used

for a purpose other than that stated in the operating instructions, commissioned or

repaired other than in accordance with our operating instructions or if repairs are

performed by someone who is unqualied. We reserve the right to perform any repairs

in excess of those stated in our operating instructions. In case of guarantee or repair,

please refer to your point of sale.

General

61

61

Page 33

WallPerfect Flexio 995

PD

CE Konformitätserklärung

Wir erklären in alleiniger Verantwortung, dass dieses Produkt den folgenden

einschlägigen Bestimmungen entspricht:

2006/42/EG; 2004/108/EG; 2011/65/EG; 2002/96/EG

Angewandte harmonisierte Normen:

EN 60335-1:2012; EN 50580:2012; EN 55014-1:2006 + A1:2009 + A2:2011;

EN 55014-2:1997 + Corrigendum 1997 + A1:2001 + A2:2008;

EN 61000-3-2:2006 + A1:2009 + A2:2009; EN 61000-3-3:2008; EN 62233:2008

PGB

CE Declaration of Conformity

We declare under sole responsibility that this product conforms to the following

relevant stipulations:

2006/42/EG; 2004/108/EG; 2011/65/EG; 2002/96/EG

Applied harmonised norms:

EN 60335-1:2012; EN 50580:2012; EN 55014-1:2006 + A1:2009 + A2:2011;

EN 55014-2:1997 + Corrigendum 1997 + A1:2001 + A2:2008;

EN 61000-3-2:2006 + A1:2009 + A2:2009; EN 61000-3-3:2008; EN 62233:2008

PF

CE Déclaration de conformité

Nous déclarons sous notre responsabilité que ce produit est en conformité avec les

réglementations suivantes :

2006/42/EG; 2004/108/EG; 2011/65/EG; 2002/96/EG

Conforme aux normes et documents normalisés :

EN 60335-1:2012; EN 50580:2012; EN 55014-1:2006 + A1:2009 + A2:2011;

EN 55014-2:1997 + Corrigendum 1997 + A1:2001 + A2:2008;

EN 61000-3-2:2006 + A1:2009 + A2:2009; EN 61000-3-3:2008; EN 62233:2008

PNL

CE Conformiteitsverklaring

Wij verklaren dat dit product voldoet aan de volgende normen:

2006/42/EG; 2004/108/EG; 2011/65/EG; 2002/96/EG

En normatieve dokumenten:

EN 60335-1:2012; EN 50580:2012; EN 55014-1:2006 + A1:2009 + A2:2011;

EN 55014-2:1997 + Corrigendum 1997 + A1:2001 + A2:2008;

EN 61000-3-2:2006 + A1:2009 + A2:2009; EN 61000-3-3:2008; EN 62233:2008

i.V. T. Jeltsch i. V. J. Ulbrich

Senior Vice President Vice President Engineering

Global Product Strategy & Planning

Dokumentationsverantwortlicher

Responsible person for documents

Responsable de la documentation

Documentatieverantwoordelijke

J. Wagner GmbH Otto-Lilienthal-Str. 18 D-88677 Markdorf

125

Page 34

A1

WallPerfect Flexio 995

ÜBERSICHT / OVERVIEW / APERÇU GÉNÉRAL / OVERZICHT

A2

5

1

2

3

5

4

7

6

9

8

10

A3

34

6

7

8

12

2

1

3

4

5

6

7

9

8

9

Page 35

WallPerfect Flexio 995

D

GB

F

NL

Auf der Rückseite dieser Ausklappseite benden sich die

Ersatzteilbilder.

Die dazugehörigen Ersatzteillisten nden Sie in Kapitel 29.

The pictures of spare parts can be found on the back of this fold-out

page.

The related spare part lists can be found in chapter 29.

Les illustrations des pièces de rechange se trouvent au dos de cette

page dépliante.

Vous trouverez les listes de pièces de rechange correspondantes au

chapitre 29.

Op de achterkant van deze uitklappagina bevinden zich de

afbeeldingen van de reserveonderdelen.

De bijbehorende reserveonderdelenlijsten vindt u in hoofdstuk 29.

Page 36

WallPerfect Flexio 995

J. Wagner GmbH

D

Otto-Lilienthal-Str. 18

D-88677 Markdorf

Hotline 0180 5 59 24 637

+49/ (0) 75 44/ 505-1169

Wagner Spraytech Belgie

B

Veilinglaan 56-58

1861 Meise-Wolvertem

+32/2/2 69 46 75 +32/2/2 69 78 45

Wagner France S.a.r.l.

F

12 Avenue des Tropiques

Z.A. de Courtaboeuf

91978 Les Ulis Cedex

0 825 011 111 +33 (0) 1 69 81 72 57

Wagner Spraytech

DK/S

Scandinavia A/S

Helgeshøj Allé 28

DK-2630 Tåstrup

+45/43 27 18 18 +45/43 43 05 28

J. Wagner AG

CH

Industriestraße 22

9450 Altstätten

+41/71/7 57 22 11 +41/71/7 57 23 23

Phobos Corporation Spol.r.o

SK

Stanicna 6, 92700 Sala

Slowakei

+421/31/7 70 78 84 +421/31/7 70 22 42

E-Coreco s.r.o.

CZ

Na Roudné 102

301 00 Plzeň

+420 734 792 823 +420 227 077 364

J. Wagner Spraytech Ibérica S.A.

E

Ctra. N-340, Km 1245,4

08750 Molins de Rei (Barcelona)

+34/93/6 80 00 28 +34/93/6 68 01 56

Adresa servisa:

SLO

GMA Elektromehanika d.o.o.

Cesta Andreja Bitenca 115,

Ljubljana 1000/Slovenija

+386(1)/583 83 04 +386(1)/518 38 03

Magyarországi szerviz

H

Hondimpex KFT.

Kossuth L. u. 48-50

8060 Mór

+36(-22)/407 321 +36(-22)/407 852

PUT Wagner Service

PL

ul. E. Imieli 14

41-605 Swietochlowice

+48/32/2 45 06 19 +48/32/2 41 42 51

Adresa servisa:

HR

EL-ME-HO

Horvatinčićev put 2

10436 Rakov Potok/Kroatien

/ +385(-1)65 86 - 028

Wagner Spraytech Benelux B.V.

NL

De Heldinnenlaan 200

3543 MB Utrecht

+31/30/2 41 41 55 +31/30/2 41 17 87

Wagner Spraytech (UK) Ltd.

GB

The Coach House

2 Main Road

Middleton Cheney OX17 2ND

01295 714200 01295 710100

Part. No. 2343 903 12/2013_RS

© Copyright by J.Wagner GmbH

Wagner Spraytech

AUS

Australia Pty. Ltd.,

14-16 Kevlar Close,

Braeside, VIC 3195/Australia

+61/3/95 87 20 00 +61/3/95 80 91 20

www.wagner-group.com

Irrtümer und Änderungen vorbehalten.

Not responsible for errors and changes.

Sous réserves d’erreurs et de modications.

Fouten en wijzigingen voorbehouden.

Loading...

Loading...