Page 1

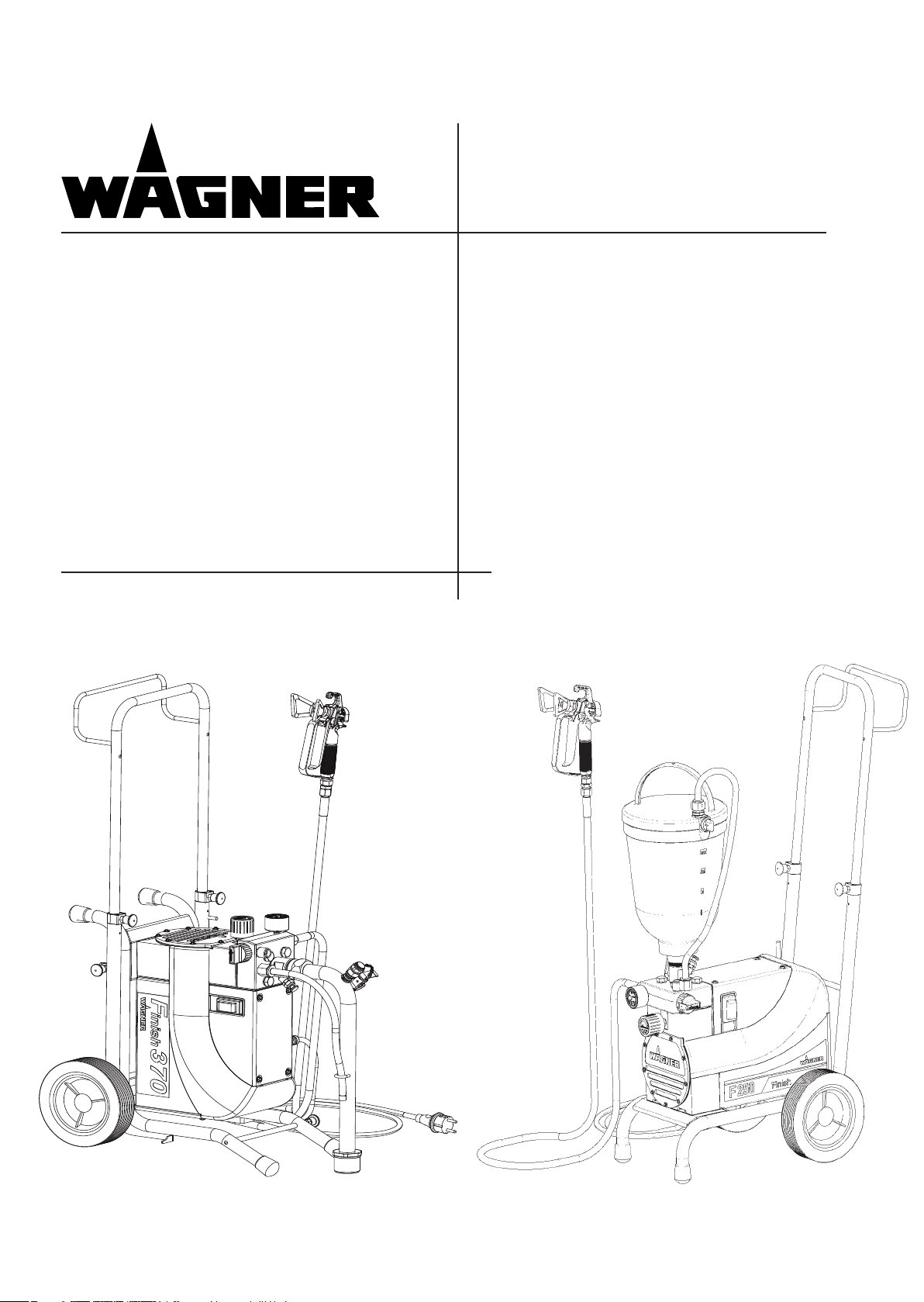

Airless high-pressure spraying unit

Finish 370

Finish 250

Operating manual 2

0252 882

11 / 2007

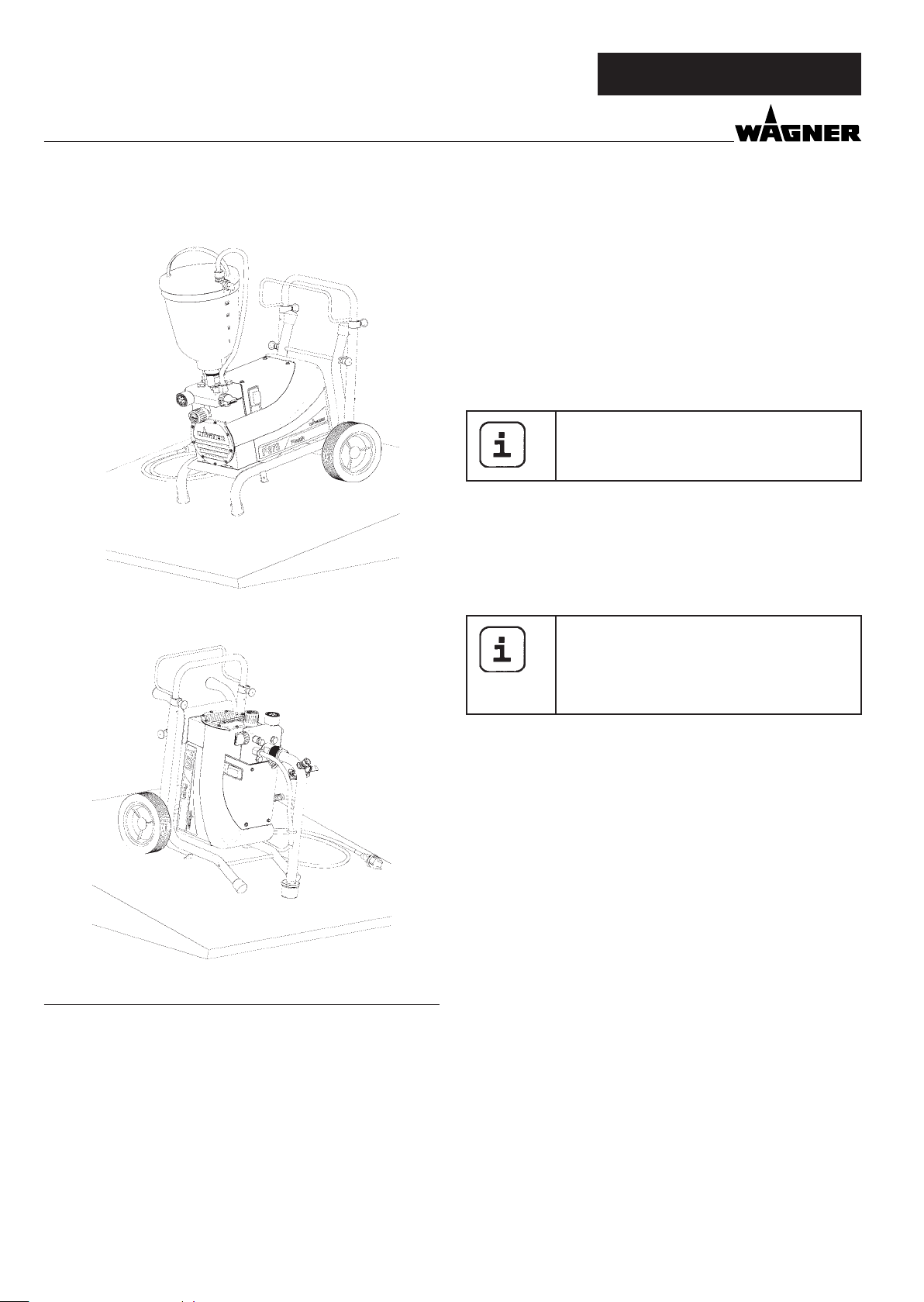

Finish 370

Finish 250

Page 2

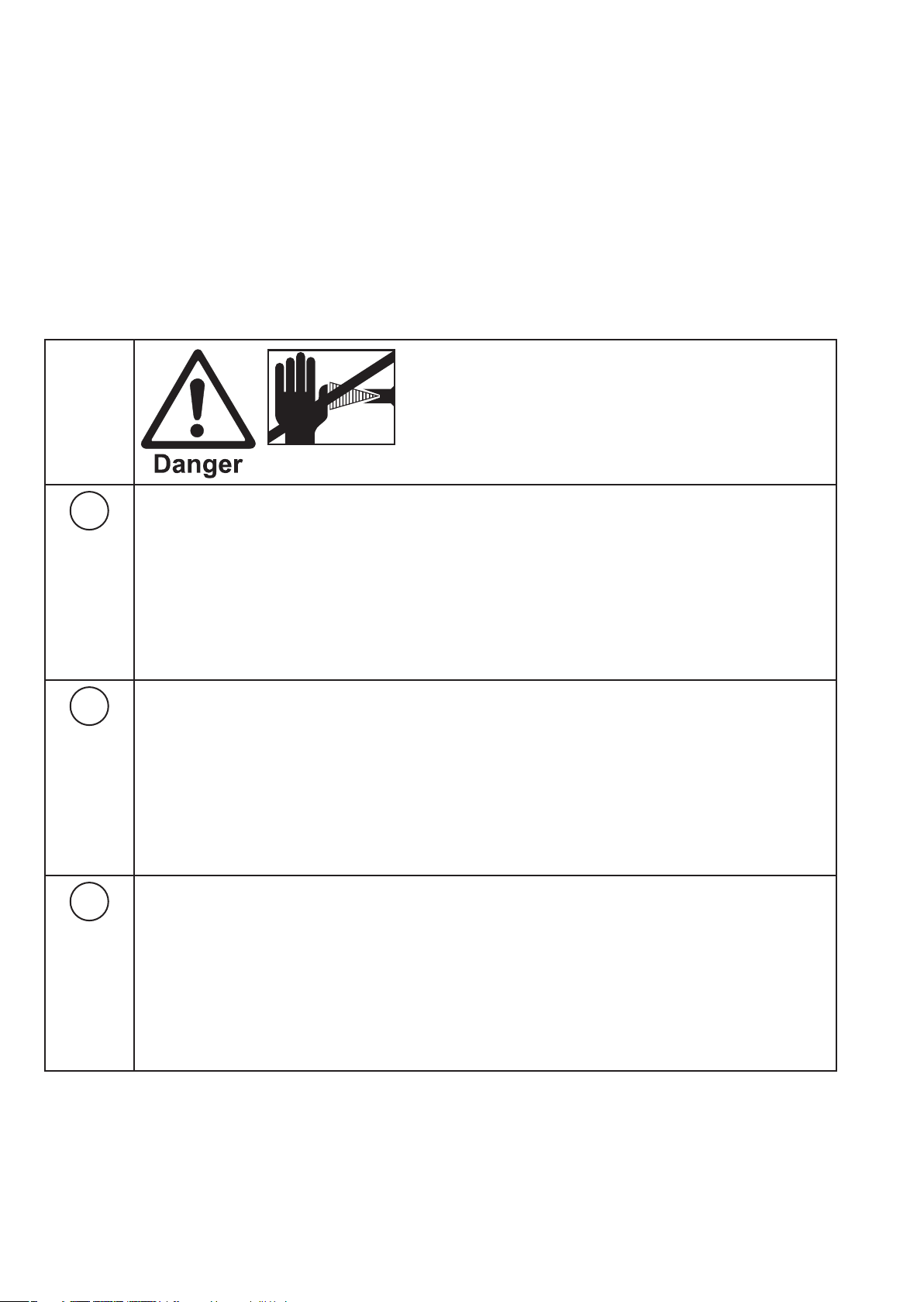

WARNING!

Attention, danger of injury by injection!

Airless units develop extremely high spray pressures.

1

2

3

Never bring ngers, hands or other body parts into contact with the spray jet!

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without spray jet safety guard.

Do not treat a spray injury as a harmless cut. In case of injury to the skin by coating material

or solvents, consult a doctor for quick and correct treatment. Inform the doctor about the

coating material or solvent used.

The following points are to be observed in accordance with the operating manual

before every start-up:

1. Faulty units may not be used.

2. Secure a Wagner spray gun with the securing lever at the trigger guard.

3. Ensure earthing.

4. Check the permissible operating pressure of the high-pressure hose and spray gun.

5. Check all the connecting parts for leaks.

Instructions for regular cleaning and maintenance of the unit are to be observed

strictly.

Observe the following rules before any work on the unit and at every working

break:

1. Relieve the pressure from the spray gun and high-pressure hose.

2. Secure a Wagner spray gun with the securing lever at the trigger guard

3. Switch the unit o .

Ensure safety!

Page 3

Finish 370 / 250

Contents

GB

CONTENTS

1 SAFETY REGULATIONS FOR AIRLESS SPRAYING 4

1.1 Flash point ___________________________________4

1.2 Explosion protection ___________________________4

1.3 Danger of explosion and re from sources of ignition

during spraying work __________________________4

1.4 Danger of injury from the spray jet _______________4

1.5 Secure spray gun against unintended operation ____4

1.6 Recoil of spray gun ____________________________4

1.7 Breathing equipment as protection against solvent

vapors ______________________________________4

1.8 Prevention of occupational illnesses ______________5

1.9 Max. operating pressure ________________________5

1.10 High-pressure hose (safety instructions) ___________5

1.11 Electrostatic charging (formation of sparks or ames) 5

1.12 Use of units on building sites and workshops _______5

1.13 Ventilation when spraying in rooms ______________5

1.14 Suction installations ___________________________5

1.15 Earthing of the object __________________________5

1.16 Cleaning the unit with solvents __________________5

1.17 Cleaning the unit _____________________________5

1.18 Work or repairs at the electrical equipment ________5

1.19 Work at electrical components ___________________5

1.20 Setup on an uneven surface _____________________6

2 GENERAL VIEW OF APPLICATION _____________ 6

2.1 Application __________________________________6

2.2 Coating material ______________________________6

2.2.1 Coating materials with sharp-edged additional materials __________________________________________6

2.2.2 Filtering _____________________________________6

3. DESCRIPTION OF UNIT ______________________ 7

3.1 Airless process ________________________________7

3.2 Functioning of the unit _________________________7

3.3 Explanatory diagram ___________________________8

3.4 Transportation ________________________________8

3.5 Trolley back tting (only Finish 370) _______________8

3.6 Technical data Finish 250 _______________________9

3.7 Technical data Finish 370 _______________________9

4 STARTUP _________________________________ 10

4.1 Unit with suction system _____________________ 10

4.2 unit with upper hopper (5 litres) _______________ 10

4.3 high pressure hose and spray gun ______________ 10

4.4 Connection to the mains network ______________ 10

4.5 Cleaning preserving agent when starting-up of

operation initially ___________________________ 11

4.6 Ventilate unit (hydraulic system) if the sound of inlet

valve is not audible __________________________ 11

4.7 Taking the unit into operation with coating material 11

5 SPRAYING TECHNOLOGY ___________________ 12

6 HANDLING THE HIGHPRESSURE HOSE _______ 12

6.1 High-pressure hose __________________________ 12

7 INTERRUPTION OF WORK ___________________ 12

8 CLEANING THE UNIT _______________________ 13

8.1 Cleaning the unit from the outside _____________ 14

8.2 Suction lter _______________________________ 14

8.3 High-pressure lter __________________________ 14

8.4 Cleaning the Airless spray gun _________________ 15

9 SERVICING ________________________________ 15

9.1 General servicing ___________________________ 15

9.2 High-pressure hose __________________________ 15

10 REPAIRS AT THE UNIT ______________________ 16

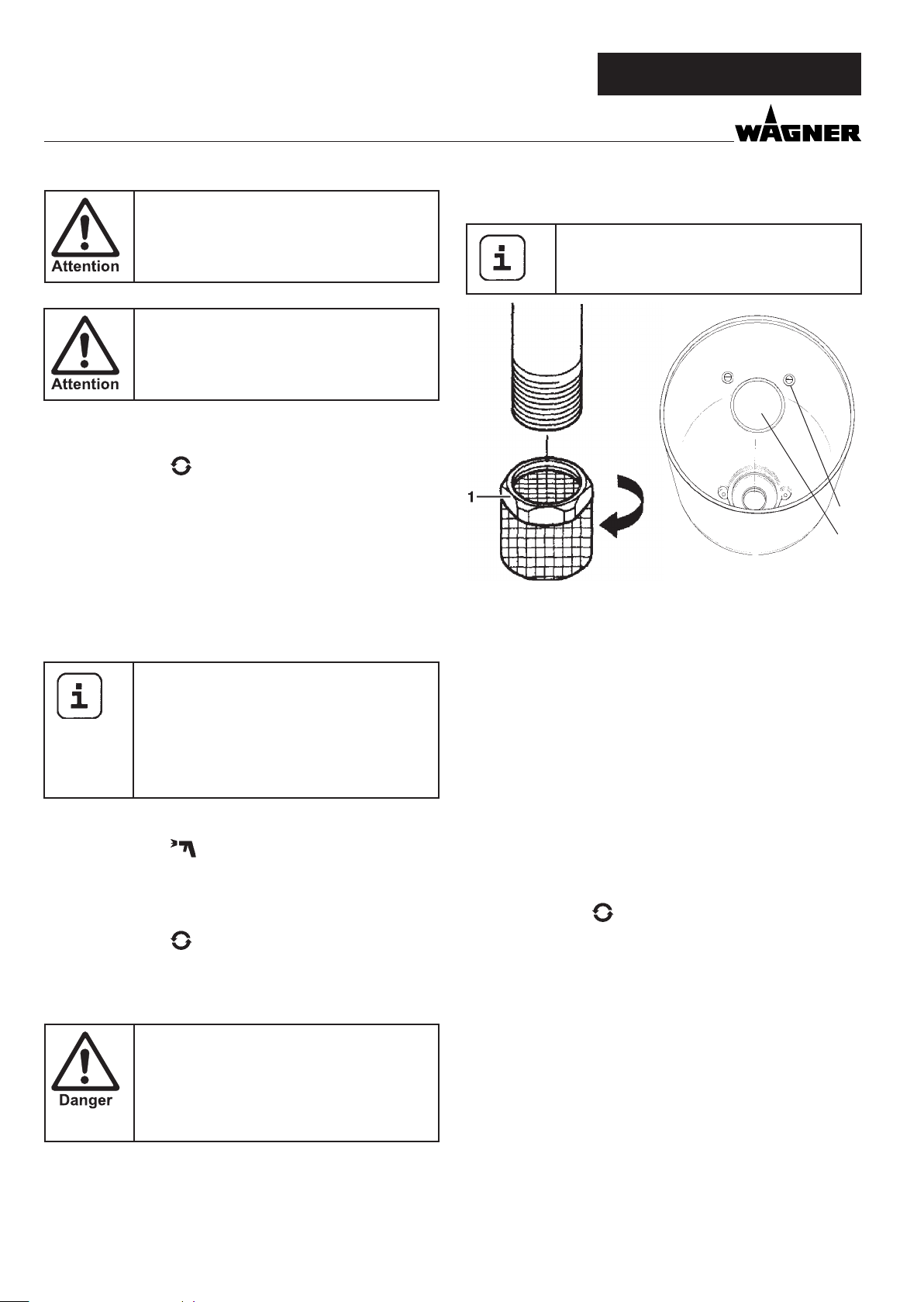

10.1 Inlet valve Pusher ___________________________ 16

10.2 Inlet valve _________________________________ 16

10.3 Outlet valve ________________________________ 16

10.4 Pressure control valve ________________________ 17

10.5 Relief valve ________________________________ 17

10.6 Replacing the diaphragm _____________________ 17

10.7 Replacing the power cable ___________________ 18

10.8 Typical wear parts ___________________________ 18

10.9 Connection diagram _________________________ 19

10.10 Remedy in case of faults ______________________ 20

11 SPARE PARTS AND ACCESSORIES ____________ 21

11.1 Finish 370 / 250 accessories ___________________ 21

11.2 Spare parts list Pump head ___________________ 22

11.3 Spare parts list Pump-Aggregate ______________ 23

11.4 Spare parts list high-pressure lter _____________ 25

11.5 Spare parts List Trolley _______________________ 25

11.6 Spare parts list suction system (rigid) ___________ 26

11.7 Spare parts list hopper 5l _____________________ 27

11.8 Spare parts list hopper with TopClean ___________ 27

CE-declaration ____________________________________28

Service network __________________________________ 29

Testing of the unit ________________________________ 30

Important information on product liability_____________ 30

Guarantee declaration _____________________________ 30

3

Page 4

GB

SAFETY REGULATIONS

Finish 370 / 250

1 SAFETY REGULATIONS FOR

AIRLESS SPRAYING

The safety-speci c requirements for Airless spraying are speci ed in:

a) The European Standard „Spray equipment for coating ma-

terials – safety regulations „ (EN 1953: 1998).

b) The regulations of the German employer‘s liability insu-

rance association („Berufsgenossenschaft“) „Using liquid

jets“ (BGV D15) and „Processing coating materials „ (BGV

D25).

c) Guidelines for construction and implementation require-

ments for liquid jets (spraying units) of the German industrial employer‘s liability insurance association (ZH1/406).

The following safety regulations are to be observed in order

to ensure safe handling of the Airless high-pressure spraying

unit.

.

1.1 FLASH POINT

1.4 DANGER OF INJURY FROM THE SPRAY JET

Attention, danger of injury by injection!

Never point the spray gun at yourself, other

persons or animals.

Never use the spray gun without spray jet

safety guard.

The spray jet must not come into contact

with any part of the body.

In working with Airless spray guns, the high

spray pressures arising can cause very dangerous injuries. If contact is made with the

spray jet, coating material can be injected

into the skin. Do not treat a spray injury as a

harmless cut. In case of injury to the skin by

coating material or solvents, consult a doctor

for quick and correct treatment. Inform the

doctor about the coating material or solvent

used.

1.5 SECURE SPRAY GUN AGAINST UNINTENDED

OPERATION

Only spray coating materials with a ash point

of 21 °C or higher.

The ash point is the lowest temperature at

which vapors develop from the coating material. These vapors are su cient to form an

in ammable mixture over the air above the

coating material.

1.2 EXPLOSION PROTECTION

Do not use the unit in work places which are

covered by the explosion protection regulations.

The unit is not designed to be explosion protected.

1.3 DANGER OF EXPLOSION AND FIRE FROM

SOURCES OF IGNITION DURING SPRAYING

WORK

Always secure the spray gun when mounting or dismounting

the tip and in case of interruption to work.

1.6 RECOIL OF SPRAY GUN

When using a high operating pressure, pulling

the trigger guard can e ect a recoil force up

to 15 N.

If you are not prepared for this, your hand can

be thrust backwards or your balance lost. This

can lead to injury.

1.7 BREATHING EQUIPMENT AS PROTECTION

AGAINST SOLVENT VAPORS

Wear breathing equipment during spraying work.

A breathing mask is to be made available to the user (regulations of the German employer‘s liability insurance association

(„Berufsgenossenschaft“) „Rules for the use of breathing masks“ (BGR 190), „Using liquid jets“ (BGV D15) and „Processing

coating materials „ (BGV D25).

There must be no sources of ignition such as,

for example, open res, lit cigarettes, cigars or

tobacco pipes, sparks, glowing wires, hot surfaces, etc. in the vicinity.

4

Page 5

Finish 370 / 250

GB

SAFETY REGULATIONS

1.8 PREVENTION OF OCCUPATIONAL ILLNESSES

Protective clothing, gloves and possibly skin protection cream

are necessary for the protection of the skin.

Observe the regulations of the manufacturer concerning coating materials, solvents and cleaning agents in preparation,

processing and cleaning units.

1.9 MAX. OPERATING PRESSURE

The permissible operating pressure for the spray gun, spray

gun accessories, unit accessories and high-pressure hose

must not fall short of the maximum operating pressure of 25

MPa (250 bar or 3625 psi).

1.10 HIGHPRESSURE HOSE SAFETY

INSTRUCTIONS

An electrostatic charging of spray guns and the high-pressure

hose is discharged through the high-pressure hose. For this

reason the electric resistance between the connections of the

high-pressure hose must be equal to or lower than 1 MΩ.

Only use WAGNER original-high-pressure

hoses in order to ensure functionality, safety

and durability.

1.14 SUCTION INSTALLATIONS

The are to be provided by the unit user in accordance with the

corresponding local regulations.

1.15 EARTHING OF THE OBJECT

The object to be coated must be earthed.

(Building walls are usually earthed naturally)

1.16 CLEANING THE UNIT WITH SOLVENTS

When cleaning the unit with solvents, the

solvent should never be sprayed or pumped

back into a container with a small opening

(bunghole). An explosive gas/air mixture can

arise. The container must be earthed.

1.17 CLEANING THE UNIT

Danger of short-circuits caused by water ingression!

Never spray down the unit with high-pressure or high-pressure steam cleaners.

1.11 ELECTROSTATIC CHARGING FORMATION OF

SPARKS OR FLAMES

Electrostatic charging of the unit may occur

during spraying due to the ow speed of

the coating material. These can cause sparks

and ames upon discharge. The unit must

therefore always be earthed via the electrical

system. The unit must be connected to an

appropriately-grounded safety outlet.

1.12 USE OF UNITS ON BUILDING SITES AND

WORKSHOPS

The unit may only be connected to the mains network via a

special feeding point with a residual-current device with INF

≤ 30 mA.

1.13 VENTILATION WHEN SPRAYING IN ROOMS

Adequate ventilation to ensure removal of the solvent vapors

has to be ensured.

1.18 WORK OR REPAIRS AT THE ELECTRICAL

EQUIPMENT

These may only be carried out by a skilled electrician. No liability is assumed for incorrect installation.

1.19 WORK AT ELECTRICAL COMPONENTS

Unplug the power plug from the outlet before carrying out

any repair work.

5

Page 6

GB

SAFETY REGULATIONS

1.20 SETUP ON AN UNEVEN SURFACE

The front end must always point downwards in order to avoid

sliding away.

If possible do not use the unit on an inclined surface since the

unit tends to wander through the resulting vibrations.

Finish 370 / 250

Both units are able for all common varnishing jobs like

doors, door frames, balustrades, furniture, woodencladding,

fences, radiators (heating) and steel parts.

2.2 COATING MATERIAL

Diluting lacquers and paints or those containing solvents, twocomponent coating materials, dispersion and latex paints.

No other materials should be used for spraying without

WAGNER‘s approval.

Pay attention to the Airless quality of the coating materials to be processed.

The unit is able to process coating materials with up to

15,000 mPas. If highly viscous coating materials cannot be taken in or the performance of the unit is to low, the paint must

be diluted in accordance with the manufacturer‘s instructions.

Attention: Make sure, when stirring up with

motor-driven agitators that no air bubbles

are stirred in. Air bubbles disturb when spraying and can, in fact, lead to interruption of

operation.

2 GENERAL VIEW OF APPLICATION

2.1 APPLICATION

Finish 370 / 250 is an electric driven unit for the airless atomization of di erent painting materials. Also it is able to feed the

internal feeded paint roller, which is available as accessory.

Finish 370 /250 is made for jobs in the workshop and on the

building site

The unit performance is conceived so that its use is possible

on building sites for small- to middle-area dispersion work.

Finish 250 is designed for varnishing jobs. Small jobs with dispersion work are possible.

2.2.1 COATING MATERIALS WITH SHARPEDGED

ADDITIONAL MATERIALS

These particles have a strong wear and tear e ect on valves

and tips, but also on the heating hose and spray gun. This impairs the durability of these wearing parts considerably.

2.2.2 FILTERING

Su cient ltering is required for fault-free operation. To this

purpose the unit is equipped with a suction lter (Item 1) and

an insertion lter in the spray gun (Item 2). Regular inspection

of these lters for damage or soiling is urgently recommended.

A high-pressure lter (Item 3) -available as accessory- is rising

up the ltering surface and will make the work more comfortable.

6

Page 7

Finish 370 / 250

2

3

GB

GENERAL VIEW OF APPLICATION

3.2 FUNCTIONING OF THE UNIT

The following section contains a brief description of the technical construction for better understanding of the function:

Finish 370 / 250 is an electrically driven high-pressure paint

spraying equipment.

The motor (Item 1) drives directly the hydraulic pump.

A piston (2) is moved up and down so that hydraulic oil is moved under the diaphragm (3) which then moves.

In detail:

The downwards movement of the machine opens the disk inlet valve (4) automatically and coating material is sucked in.

During the upwards movement of the diaphragm, the coating

material is displaced and the outlet valve opens while the inlet

valve is closed.

1

3. DESCRIPTION OF UNIT

3.1 AIRLESS PROCESS

The main area of application are thick layers of highly viscous

coating material.

At the Finish 370 / 250 unit a diaphragm pump takes in the

coating materials and transports it via a high-pressure hose

to the spray gun with the airless tip. Here the coating material

atomizes since it is pressed through the tip core at a maximum

pressure of 25 MPa (250 bar, 3625 psi). This high pressure has

the e ect of micro ne atomisation of the coating material.

As no air is used in this process, it is described as an AIRLESS

process.

This method of spraying has the advantages of nest atomisation, cloudless operation (depending of a correct unit adjustment) and a smooth, bubblefree surface. As well as these,

the advantages of the speed of work and convenience must

be mentioned.

The coating material ows under high pressure through the

high-pressure hose to the spray gun and is atomized when it

exists from the tip.

The pressure control valve limits the set pressure in the hydraulic oil circuit and thus also the pressure of the coating

material.

A pressure change when the same tip is used also leads to a

change in the amount of paint atomized.

4 3 2 1

7

Page 8

GB

DESCRIPTION OF UNIT

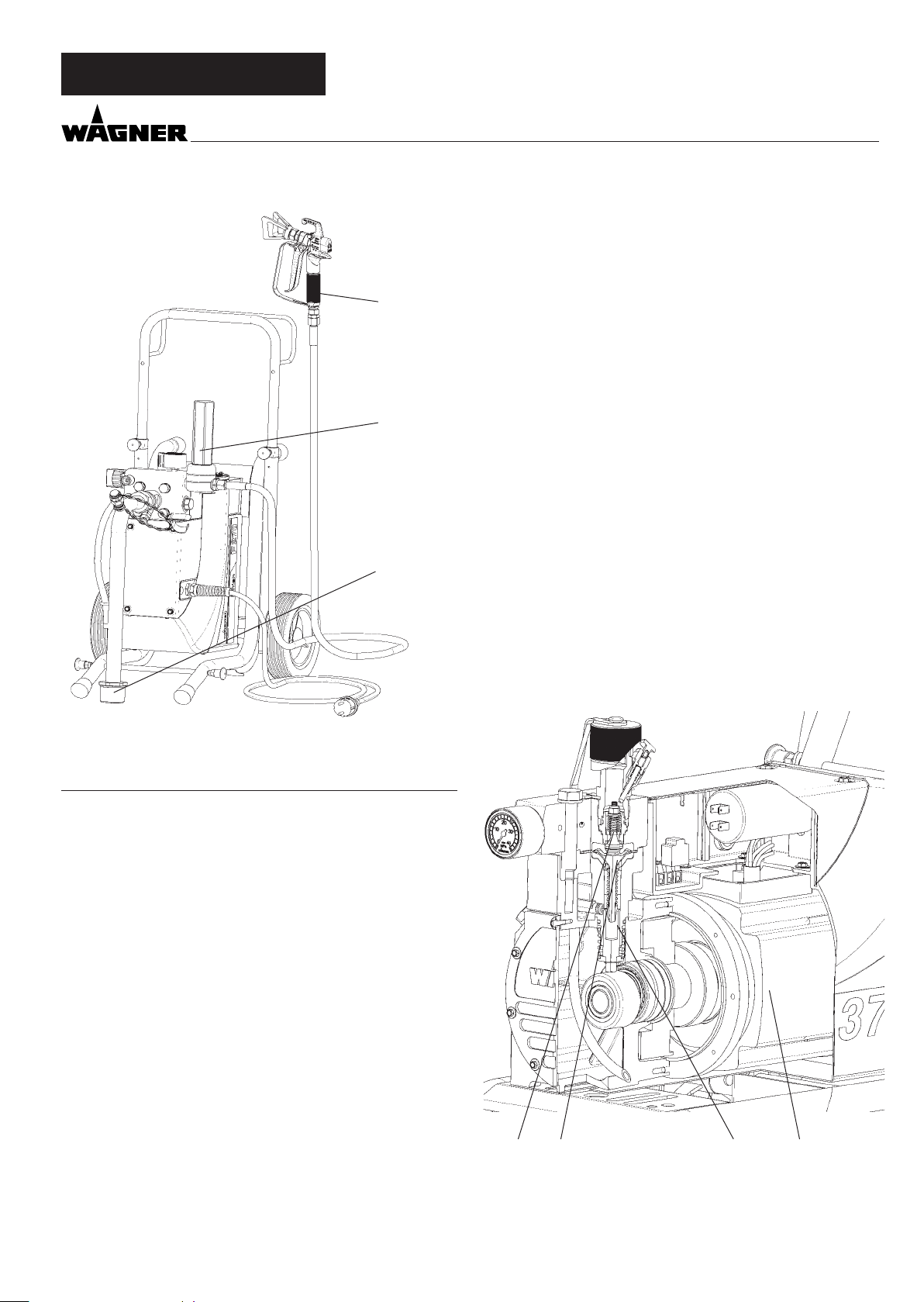

3.3 EXPLANATORY DIAGRAM

1 Tip guard with airless tip

2 Spray gun

3 High-pressure hose

4 Connection for high-pressure hose

5 Pressure gage

6 Pressure control valve

7 Pressure relef valve

Finish 370 / 250

1

2

3

6

Symbols: Spraying

Circulation

8 ON / OFF switch

9 Return tube

10 Suction tube

11 Connection for cleaning with the spray gun

12 Hopper

13 Cleaning ring (TopClean) for hopper (accessory)

14 Inlet valve button

15 Outlet valve

16 Oil measuring stick under the oil screw plug

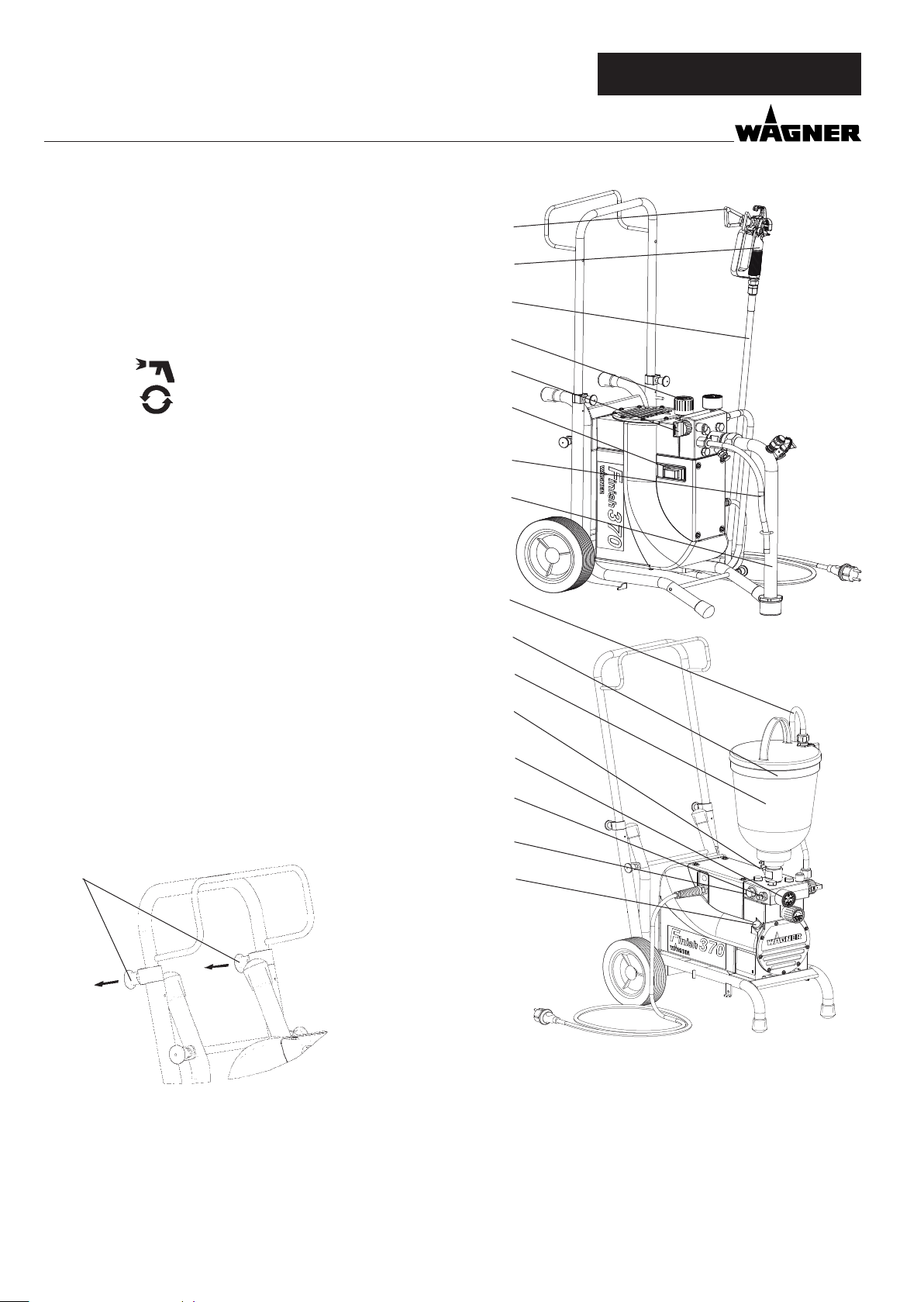

3.4 TRANSPORTATION

Unroll high-pressure hose and lay it over the shaft.

Pull the locking pins (Item 1) on both sides of shaft. The locking pins can be arrested by a small turn (left or right). Pull

the shaft out and deblock the locking pins. A light pull or push

will help to lock the pins well.

7

8

9

10

9

13

12

14

5

4

15

1 16

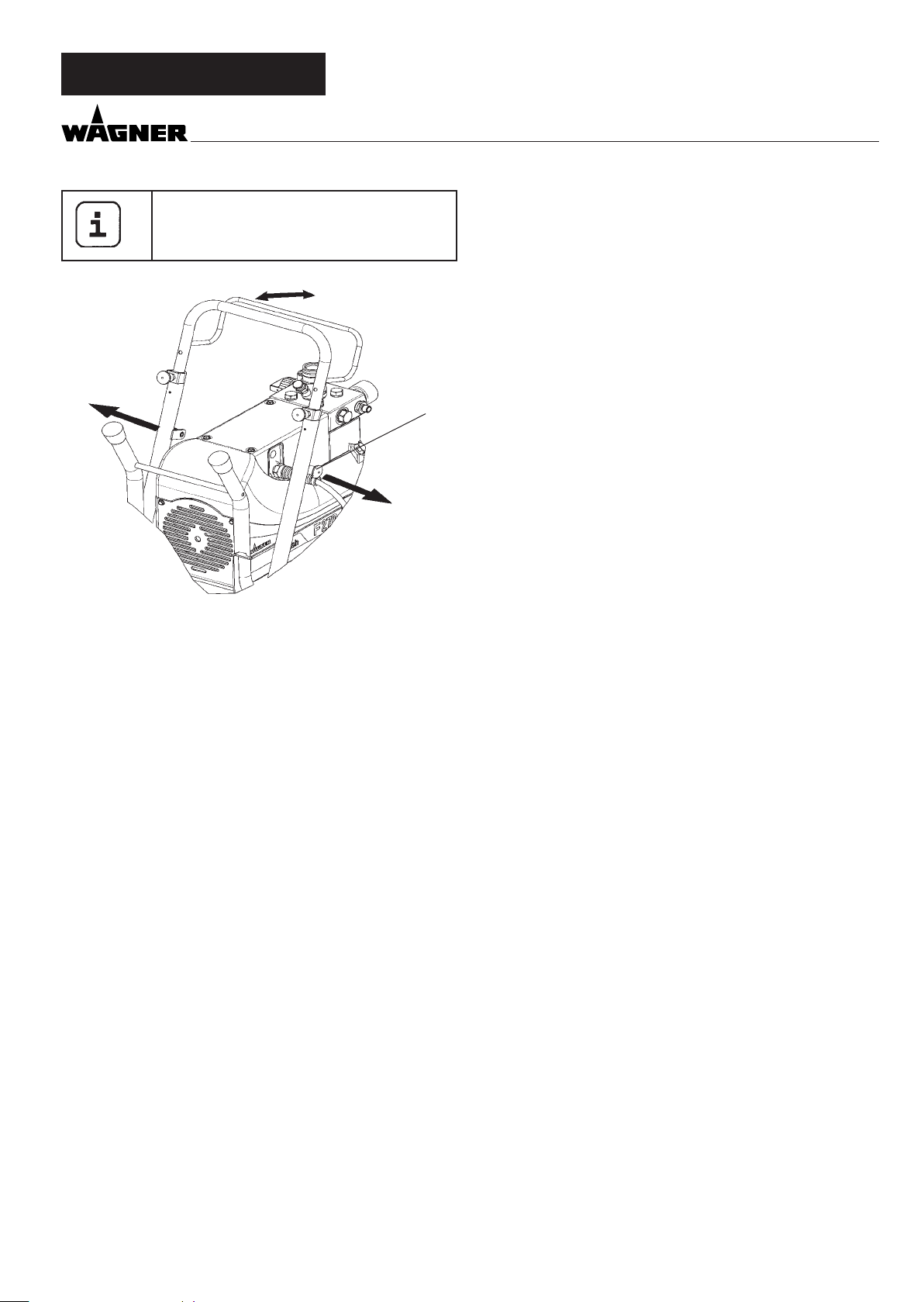

3.5 TROLLEY BACKFITTING ONLY FINISH 370

Transportation in vehicle

Secure the unit in the vehicle by means of suitable fasteners.

8

Pull locking pins (Item 1) on both sides of frame. The locking

pins can be arrested by a small turn (left or right). Move frame

into the other position. Deblock both locking pins so that they

t well in the rest position.

Page 9

Finish 370 / 250

plug of socket, disassemble suction system

and high pressure hose

GB

DESCRIPTION OF UNIT

3.7 TECHNICAL DATA FINISH 370Before start with the back tting, pull of main

Voltage : 230 V AC, 50 Hz

Fuses : 16 A time-lag

Unit connecting line : 6 m long, 3 x 1.5 mm

Max. current consumption

hose heating : 6.0 A

Degree of protection : IP 54

3.6 TECHNICAL DATA FINISH 250

Voltage : 230 V AC, 50 Hz

Fuses : 16 A time-lag

Unit connecting line : 6 m long, 3 x 1.5 mm

Max. current consumption

hose heating : 4,6 A

Degree of protection : IP 54

Acceptance capacity : 1,1 kW

Max. operating pressure : 25 MPa (250 bar)

1

Acceptance capacity : 1.3 kW

Max. operating pressure : 25 MPa (250 bar)

Max. volume ow : 2.9 l/min

Volume ow at 12 MPa

(120 bar) with water : 2.3 l/min

Max. temperature of the

coating material : 43 °C

Max. viscosity : 15,000 mPas

Empty weight pump : 29.5 kg

Hydraulic oil lling

quantity : 0.65 liter

Max. vibration at the spraygun: lower than 2.5 m/s

Max. sound pressure level: 74 dB (A)*

*Place of measurement: 1 m distance from unit and 1.60

m above oor, 12 Mpa (120 bar) operating pressure,

reverberant oor

Max. volume ow : 2.2 l/min

Volume ow at 12 MPa

(120 bar) with water : 1.8 l/min

Max. temperature of the

coating material : 43 °C

Max. viscosity : 15,000 mPas

Empty weight pump : 28 kg

Hydraulic oil lling

quantity : 0.65 liter

Max. vibration at the spraygun: lower than 2.5 m/s

Max. sound pressure level: 74 dB (A)*

*Place of measurement: 1 m distance from unit and 1.60

m above oor, 12 Mpa (120 bar) operating pressure,

reverberant oor

9

Page 10

GB

STARTUP

Finish 370 / 250

4 STARTUP

4.1 UNIT WITH SUCTION SYSTEM

1. Unscrew the dust protective cap (Item 1).

2. Ensure that the sealing surfaces of the connections are

clean.

Ensure that the red inlet (2) is inserted in the coating ma-

terial inlet (5).

3. Use the enclosed 41 mm wrench to screw the union nut

(3) at the suction hose (4) onto the coating material inlet

(5) and tighten it.

4. Screw the union nut (6) at the return hose (7) to the connection (8) (22mm).

4.2 UNIT WITH UPPER HOPPER 5 LITRES

1. Unscrew the dust protective cap (Item 1).

2. Ensure that the sealing surfaces of the connections are

clean.

Ensure that the red inlet (2) is inserted in the coating ma-

terial inlet (5).

3. Screw the union nut (6) on the return pipe (7) onto the

connection (8).

3. Hang the return pipe (7) into the hopper and screw the

upper hopper (9) onto the coating material inlet (5).

if using hopper with cleaning ring (TopClean) step 5 and 6

5. Fix TopClean on hopper upside

6. Plug in return pipe into TopClean and screw on union nut

4.3 HIGH PRESSURE HOSE AND SPRAY GUN

1. Screw the high pressure hose (10) onto the hose connection

2. Screw the spray gun (11) onto the high pressure hose

3. Tighten all union nuts on high pressure hose so that no

coating material can escape.

4. Screw the tip holder with the selected tip onto the spray

gun, align tip and tighten union nut.

When unscrewing the high pressure hose,

hold rmly on the hose connection with a

22mm wrench.

4.4 CONNECTION TO THE MAINS NETWORK

Connection must always be carried out via

an appropriately grounded safety outlet with

residual-current-operated circuit-breaker.

Before connecting the unit to the mains supply, ensure that

the line voltage matches that speci ed on the unit’s rating

plate.

11

10

9

8

7

6

1

3

2

5

8

7

4

10

Page 11

Finish 370 / 250

4.5 CLEANING PRESERVING AGENT WHEN

STARTINGUP OF OPERATION INITIALLY

Unit with suction tube

1. Immerse the suction system into a container lled with a

suitable cleaning agent (recommendation: water).

Unit with hopper

2. ll up hopper with a suitable cleaning agent (recommendation: water).

3. Switch on unit.

4. Turn the pressure regulating knob (1) to the right until

the stop is reached.

5. Open relief valve (2)

valve position (circulation)

6. Wait until cleaning agent is emitted from the return hose.

7. Turn the pressure regulating knob (1) back approx. one

rotation.

8. Close relief valve (2)

valve position (spraying), pressure is rising up inside

the high pressure hose (visble at pressure gage)

9. Point the tip of the spray gun into an open collecting container and pull the trigger guard at the spray gun.

10. The pressure is increased by turning the pressure regulating knob (1) to the right. Set approx. 10 MPa at the pressure gage.

11. Spray the cleaning agent out of the unit for approx.

1 - 2 min. (~5 liters) into the open collecting container.

GB

STARTUP

4

3

1

2

4.7 TAKING THE UNIT INTO OPERATION WITH

COATING MATERIAL

4.6 VENTILATE UNIT HYDRAULIC SYSTEM IF THE

SOUND OF INLET VALVE IS NOT AUDIBLE

1. Switch on the unit.

2. Turn pressure regulating knob (1) three revolutions to

the left.

3. Open relief valve (2)

valve position (circulation)

The hydraulic system is ventilated. Leave the unit on for

two or three minutes.

4. Then turn pressure regulating knob (1) to the right until

stop.

5. Press inlet valve pusher (4).

Sound of the inlet valve is audible.

6. If not, repeat points 2 and 4

Unit with suction tube

1. Immerse the suction system into a container lled with

coating material.

Unit with hopper

2. ll coating material into the hopper.

3. Press inlet valve pusher (4) several times to release possibly clogged inlet valve

4. Open relief valve (2)

valve position (circulation)

5. Switch on unit.

6. Turn the pressure regulating knob (1) to the right until

the stop is reached.

When the noise of the valves changes, the unit is bled and

takes in coating material.

7. If coating material exits from the return hose, turn the

pressure regulating knob (1) back approx. 1 rotation.

8. Close relief valve (2)

valve position (spraying), pressure is rising up inside

the high pressure hose (visble at pressure gage (3))

9. Pull of the spray gun and spray into an open collecting

container in order to remove the remaining cleaning

agent from the unit. When coating materials exits from

the tip, close the spray gun.

10. Pull of the spray gun and adjust the spraying pressure by

turning the pressure regulating knob (1).

11. The unit is ready to spray.

11

Page 12

GB

SPRAYING TECHNIQUE / HANDLING THE HIGH-PRESSURE HOSE / INTERRUPTION OF WORK

Finish 370 / 250

5 SPRAYING TECHNOLOGY

Move the spray gun evenly during the spraying process. If this

is not observed, an irregular spraying appearance will be the

result. Carry out the movement with the arm, not with the

wrist. A parallel distance of approx. 30 cm between the tip and

the surface to be coated should always be observed. The lateral limitation of the spray fan should not to be too distinct. The

edge of spraying should be gradual to facilitate overlapping of

the next coat. The spray gun should always be held at an angle

of 90° to the surface to be coated. A spray fan aimed obliquely

at the surface to be coated leads to an unwanted spray cloud.

To achieve perfect surfaces at varnishing works, special accessories are available at Wagner, e.g. FineFinish tips or an AirCoat

gun set. Your Wagner dealer will advise you.

6 HANDLING THE HIGHPRESSURE

HOSE

The high-pressure hose is to be handled with care. Avoid sharp

bending or kinking. The smallest bending radius amounts to

about 20 cm.

Do not drive over the high-pressure hose. Protect against

sharp objects and edges.

7 INTERRUPTION OF WORK

1. Turn pressure regulating knob three revolutions to the

left.

2 Open relief valve (2)

valve position (circulation)

3. Switch o the unit

4. Pull trigger guard of spray gun to decrease the pressure of

the high pressure hose and the spray gun.

5. Secure the spray gun, refer to the operating manual of the

spray gun.

6. Remove tip from tip holder and store the tip in a small vessel with suitable cleaning agent.

7. Leave the suction system immersed in the coating material or immerse it in the corresponding cleaning agent. The

suction lter and unit should not dry out.

8. Cover the material container in order to prevent the paint

from drying.

In using quick-drying or two-component

coating materials, do not fail to rinse unit

through with a suitable cleaning agent during the processing period.

Danger of injury through leaking highpressure hose. Replace any damaged highpressure hose immediately.

Never repair defective high-pressure hoses

yourself!

When using the high-pressure hose while

working on sca olding, it is best to always

guide the hose along the outside of the scaffolding.

6.1 HIGHPRESSURE HOSE

The unit is equipped with a high-pressure hose specially suited for diaphragm pumps.

Only use WAGNER original-high-pressure

hoses with internal heating in order to ensure

functionality, safety and durability.

12

Page 13

Finish 370 / 250

GB

DISPLAYS AT THE UNIT / CLEANING THE UNIT

8 CLEANING THE UNIT

A clean state is the best method of ensuring operation without problems. After you have nished spraying, clean the

unit. Under no circumstances may coating material rests dry

and harden in the unit. The cleaning agent used for cleaning

(only with a ash point above 21 °C) must be suitable for the

coating material used.

• Secure the spray gun, refer to the operating manual of

the spray gun.

Remove and clean the tip.

• Unit with suction system

1. Open relief valve

valve position (circulation) and switch on unit

2. Remove suction tube from the material container, the return tube remains over the material container.

3. Immerse the suction system into a container lled with a

suitable cleaning agent

4. Turn the pressure control valve back in order to set a minimal spraying pressure.

5. Close relief valve,

valve position (spraying)

6. Pull the trigger guard of the spray gun in order to pump

the remaining coating material from the suction hose,

high-pressure hose and the spray gun into an open container (if appropriate, increase the pressure at the pressure control valve slowly in order to obtain a higher material

ow).

The container must be earthed in case of

coating materials which contain solvents.

14. Rinse in the circuit – Open relief valve

valve position (circulation).

15. Close the spry gun.

16. When cleaning with water repeat the procedure about 3

minutes long with clear water.

17. Remove spray gun from suction tube, close spray gun

connection at suction tube with closure nut.

The cleaning e ect is increased by alternatively opening and closing the spray gun.

Caution! Do not pump or spray in container

with small opening (bunghole)!

See safty regulations.

7. Open relief valve

valve position (circulation)

8. Pump suitable cleaning agent in the circuit for several minutes.

with in exible suction system (tube) step 9 up to 17

9. Screw the spray gun to the suction tube with both enclosed 22 mm wrenches.

10. Pump a suitable cleaning agent in the circuit for about

1 minute.

11. Pull the trigger guard of the spray gun and lock it with a

clamp.

12. Close relief valve,

valve position (spraying)

13. Clean the suction tube about 3 minutes long.

18. Close relief valve,

valve position (spraying)

19. Pump the remaining cleaning agent into an open container until the pump is empty.

20. Switch o the unit

Warm water improves the cleaning e ect in

the case of water-dilutable coating materials.

• Unit with upper hopper

1. Open relief valve

valve position (circulation) and switch on unit

2. Turn the pressure control valve back in order to set a minimal spraying pressure.

3. Close relief valve,

valve position (spraying)

4. Pull the trigger guard of the spray gun in order to pump

the remaining coating material from the hopper, highpressure hose and the spray gun into an open container (if

appropriate, increase the pressure at the pressure control

valve slowly in order to obtain a higher material ow).

13

Page 14

GB

CLEANING THE UNIT

Finish 370 / 250

The container must be earthed in case of

coating materials which contain solvents.

Caution! Do not pump or spray in container

with small opening (bunghole)!

See safty regulations.

5. Fill up hopper with suitable cleaning agent.

6. Open relief valve

valve position (circulation)

7. Pump suitable cleaning agent in the circuit for several minutes.

with cleaning ring (TopClean) step 8 up to 12

8. Switch reverser knob into a horizontal position.

The cleaning agent will ow around the circumference of

the inner hopper wall and will clean it in some minutes,

depending of the fouling

9. Switch reverser knob into the upright position.

Cleaning agent is owing directly into the hopper

Do not switch the reverser knob at the cleaning ring into the horizontal position when

the pump is load with coating material. The

devider holes can be plugged.

Than the cleaning work of cleaning ring is

reduced, and it will take more time up to the

cleaning ring has cleaned themself.

10. Close relief valve,

valve position (spraying)

11. Pump the remaining cleaning agent from the hopper,

high-pressure hose and the spray gun into an open container

12. Open relief valve

valve position (circulation)

13. Switch o unit

8.1 CLEANING THE UNIT FROM THE OUTSIDE

First unplug the power plug from the outlet.

Danger of short-circuits caused by water

ingression! Never spray down the unit with

high-pressure or high-pressure steam cleaners.

Wipe down unit externally with a cloth which has been immersed in a suitable cleaning agent.

8.2 SUCTION FILTER

Clean lters always ensure maximum volume,

constant spray pressure and problem-free

functioning of the unit.

2

1

suction tube 5l hopper

Unit with suction system

1. Unscrew the lter (Item 1) from the suction tube.

2. Clean or replace the lter.

Carry out cleaning with a hard brush and a corresponding

cleaning agent.

Unit with hopper

1. Release screws with a screwdriver (Item 2).

2. Lift and remove lter disk with a screwdriver

3. Clean or replace the lter disk.

Carry out cleaning with a hard brush and a corresponding

cleaning agent.

8.3 HIGHPRESSURE FILTER

1. Open relief valve

valve position (circulation) - Switch the unit o .

2. Open the high-pressure lter and clean the lter insert. To

do so:

3. Unscrew the lter housing (1) by hand.

4. Remove the lter insert (2) and pull out the bearing spring

(3).

5. Clean all the parts with the corresponding cleaning agent.

If compressed air is available – blow through the lter insert and bearing spring.

6. When mounting the lter ensure that the bearing ring (4)

in the lter insert is positioned correctly and check the Oring at the lter housing for damage.

7. Screw on the lter housing by hand until it stops (a higher

tightening force only impedes later dismantling).

14

Page 15

Finish 370 / 250

8.4 CLEANING THE AIRLESS SPRAY GUN

1. Rinse the Airless spray gun with a suitable cleaning agent

under lower operating pressure.

2. Clean the tip thoroughly with a suitable cleaning agent so

that no suitable coating material rests remain.

3. Do not store the tip in solvent because this reduces the

durability considerably.

4. Clean the outside of the Airless spray gun thoroughly.

GB

CLEANING THE UNIT / SERVICING

9 SERVICING

9.1 GENERAL SERVICING

An annual expert check is higly recomended

to be sure to have an safe unit

You can servicing of the unit carried out by

the Wagner Service. Favorable conditions can

be agreed with a service agreement and/or

maintenance packages.

Minimum check before every startup:

1. Check the high-pressure hose, spray gun with rotary joint,

power supply cable with plug for damage.

2. Check whether the pressure gage can be read.

1

3

2

Insertion lter in the Airless spray gun

Removal

1. Pull the protective bracket (1) forwards.

2. Screw the grip (2) out of the gun housing. Pull out the insertion lter (3).

3. If the insertion lter is clogged or defective, replace it.

check at periodical intervals:

1. Check inlet-, outlet-, relief valve according wear. Clean it

and replace worn out parts.

2. Check all lter inserts (spray gun, suction system) clean it

and replace if necessary.

9.2 HIGHPRESSURE HOSE

Inspect the high-pressure hose visually for any notches or

bulges, in particular at the transition in the ttings. It must be

possible to turn the union nuts freely. A conductivity of less

than

1 MΩ must exist across the entire length.

Have all the electric tests carried by the Wagner Service.

Installation

1. Slide the insertion lter (3) with the longer cone into the

gun housing.

2. Screw the grip (2) into the gun housing and tighten it.

3. Latch in the protective bracket (1).

15

Page 16

GB

REPAIRS AT THE UNIT

Finish 370 / 250

10 REPAIRS AT THE UNIT

Switch the unit o .

Before all repair work: Unplug the power

plug from the outlet.

10.1 INLET VALVE PUSHER

1. Use a 17 mm spanner to screw out the inlet valve button.

2. Replace the wiper (1) and O-ring (2).

2

1

Installation

1. Insert the inlet valve (2) into the trigger housing (1) and

secure with the clasp (3). Ensure that the (black) seal (5) is

mounted in the trigger housing.

2. Screw the unit from the trigger housing and the inlet valve into the paint section. The same (black) seal (7) has to

be mounted in the paint section.

3. Tighten the trigger housing with the 30 mm wrench and

tighten with three light blows of the hammer on the end

of the wrench. (Corresponds to approx. 90 Nm tightening

torque).

3

1

5

10.2 INLET VALVE

1. Place the enclosed 30 mm wrench on the trigger housing

(1).

2. Loosen the trigger housing (1) with light blows of a hammer on the end of the wrench.

3. Screw out the trigger housing with the inlet valve (2) from

the paint section.

4. Pull of the clasp (3) using the enclosed screwdriver.

5. Place the enclosed 30 mm wrench on the inlet valve (2).

Turn out the inlet valve carefully.

6. Clean the valve seat (4) with a cleaning agent and brush

(ensure that no brush hairs are left behind).

7. Clean the seals (5, 6) and check for damage. Replace, if necessary.

8. Check all the valve parts for damage. In case of visible

wear replace the inlet valve.

2

4

6

10.3 OUTLET VALVE

1. Use a 22 mm wrench to screw the outlet valve from the

paint section.

2. Carefully pull of the clasp (1) using the enclosed screwdriver. The compression spring (2) presses ball (4) and valve

seat (5) out.

3. Clean or replace the components.

4. Check the O-ring (7) for damage.

5. Check the installation position when mounting the spring

support ring (3) (clipped onto spring (2)), outlet valve seat

(5) and seal (6), refer to gure.

16

Page 17

Finish 370 / 250

GB

REPAIRS AT THE UNIT

10.5 RELIEF VALVE

Replace a fault re ef valve (1) as a single unit.

Only the O-ring (2) may be replaced as a single part

564

10.4 PRESSURE CONTROL VALVE

Only have the pressure control valve (1) replaced by the customer service.

The max. operating pressure has to be reset

by the customer service.

1

32

1

7

1

10.6 REPLACING THE DIAPHRAGM

Switch the unit o .

Before all repair work: Unplug the power

plug from the outlet.

2. Screw the trigger housing with inlet valve out of the paint

section as described in Section 10.2 Inlet valve, Items 1 to

3. (disassembling of hexagon nuts will become easier)

3. Turn back the pressure control valve, rotary knob completely (anti-clockwise).

(Note: If the unit is still warm, open the oil screw plug (6)

brie y in order to compensate the pressure and close it

again.)

4. Use a 19 mm wrench to screw the hexagonal bolt (Item 1)

out of the pressure insert (2).

5. Remove the paint section (3).

6. Remove the insert (4) and the diaphragm (5).

7. The diaphragm can only be used once. Always replace the

diaphragm.

2

17

Page 18

GB

REPAIRS AT THE UNIT

Finish 370 / 250

1. Remove the cover (1) (a screwdriver may be helpfull to

move the cover back from the box).

2. Loosen the cable threaded joint (2).

3. Loosen the wires in the mains terminal (3) .

4. Replace the unit connecting line.

1

(only an approved power cable with the designation H07-

RNF with a splash-proof plug may be used).

5. Connect the green/yellow wire to the contact with the PE

sign.

6. Connect the cover again with the earthing plug for the

heating hose and mount it carefully (do not squeeze any

cables!)

3

4

5

2

6

Before mounting the new diaphragm, clean the insert as well

as the grooved surface at the pressure insert (2) and the paint

section (3) and wipe o any oil.

Mounting is carried out in the reverse order.

1. First tighten all the hexagonal bolts (1) crosswise with

30Nm, then crosswise with 70Nm.

2. Before starting up leave the pressure control valve in the

open position for about 2 minutes while the motor is running (bleeds the unit). Only then close it until the noise of

the inlet valve can be heard.

10.7 REPLACING THE POWER CABLE

Switch the unit o .

Before all repair work: Unplug the power

plug from the outlet.

18

1

2

3

10.8 TYPICAL WEAR PARTS

Despite the use of high-quality materials the highly abrasive

e ect of the paints means that wear can occur at the following

parts:

Inlet valve (spare part Order No.: 0344700)

For replacing refer to Section 10.2

(failure becomes noticeable through performance loss and/or

poor or no suction)

Outlet valve (spare part Order No.: 0341702)

For replacing refer to Section 10.3

(failure becomes noticeable through performance loss and/

or poor suction) The outlet valve is usually considerably more

durable than the inlet valve. Thorough cleaning may already

help here.

Relief valve (spare part Order No.: 0169248)

For replacing refer to Section 10.5

(failure is noticeable through performance loss. Furthermore

material arrives constantly at the return hose although the

multifunction switch is set to spraying.

This part is relatively seldom a wear part.

Page 19

Finish 370 / 250

10.9 CONNECTION DIAGRAM

GB

REPAIRS AT THE UNIT

Switch 8A

blue 0252481

white

white

black 0252480

black 0340380black

gree-yellow

brown

Capacitor 35 µF

blue

Cover

blue

brown

green-yellow

Plug

19

Page 20

GB

Finish 370 / 250

REPAIRS AT THE UNIT

10.10 REMEDY IN CASE OF FAULTS

TYPE OF MALFUNCTION WHAT ELSE? POSSIBLE CAUSE MEASURES FOR ELIMINATING THE MALFUNCTION

Unit does not start Motor switch can not

switched on

Unit does not suck in Air bubbles exit from

the return hose

Air bubbles do not exit

at the return hose

Unit does not generate pressure

Unit has sucked in Air in the oil circuit Bleed the oil circuit in the unit by turning the

Unit reached pressure, but the pressure

collapses, also at the

pressure gage, during

spraying.

Unit reached pressure,

but the pressure collapses during spraying.

pressure gage still

shows high pressure

No voltage applied Check voltage supply

Unit fuse has triggered Let the motor cool down

Unit is sucking in outside

air

Inlet valve clogged Press the inlet valve button until the stop is

Inlet/outlet valve soiled

/ foreign bodies (e.g.

threads) drawn in / worn

Pressure control valve turned down completely

Suction lter clogged Check the suction lter. If necessary, clean/

Paint cannot be worked in

this state. Due to its properties the paint clogs the

valves (inlet valve) and the

delivery rate is too low.

Clogged lter do not let

enough paint pass

Tip clogged Clean the tip (-> refer to Section 10.1)

Check: Suction system tightened properly?

Cleaning connection at rigid suction tube

screwed tight and not leaking? Inlet valve

button leaky? -> Replace wiper and O-ring (->

refer to Section 10.1)

reached several times by hand

Remove the valves and clean then (-> refer to

Section Pkt.10.2/10.3) / replace worn parts

Turn the pressure control valve to the right until the stop is reached

pressure control valve completely to the left

(until overturning) and let it run approx. 2 – 3

min. Then turn the pressure control valve to

the right and set the spraying pressure (repeat

process several times, if necessary). Process is

assisted by positioning the unit vertically.

replace

Dilute the paint

Check/clean the (high-pressure lter) gun lter

20

Unit does not generate

the max. pressure possible. Paint nevertheless exits at the return

hose.

Relief valve defective Clean or replace the relief valve (-> refer to

Section 10.5)

Page 21

Finish 370 / 250

11 SPARE PARTS AND ACCESSORIES

GB

PARE PARTS AND ACCESSORIES

11.1 FINISH 370 / 250 ACCESSORIES

1

2

3

5

6

11 12

78

9

10

13

4

Accessories:

ITEM DESIGNATION ORDER NO.

1 Spray gun AG-14

(stainless steel)

Spray gun AG-08

(aluminium made)

2 AirCoat spray gun GM-3000 0364 005

3 Double hose 9984 564

HP hose DN-3, 7.5 m 9984 583

4 AirCoat-controler set 0252 910

5 Pole gun

Length 100 cm

Length 150 cm

Length 370 cm

6 Inline Roller 0345 010

7 Hopper 5l 0341 265

8 Hopper cleaning ring (TopClean) 0340 930

0502 166

0296 388

0096 019

0096 005

0096 006

14

ITEM. DESIGNATION ORDER NO.

9 Tip extension

Length 15 cm

Length 30 cm

Length 45 cm

Length 60 cm

10 Tip extension with

Slewable knee joint

Length 100 cm

Length 200 cm

Length 300 cm

11 Suction system ( exible)

for dispersionen

12 Cleaning container for suction system

Holder for container (only F250)

13 Suction system (rigid) for dispersi-

onen

14 Filter bag, mesh width 0,3 mm 0097 531

0556 051

0556 052

0556 053

0556 054

0096 015

0096 016

0096 017

0034 630

0055 553

0252 264

0341 264

21

Page 22

GB

REPAIRS AT THE UNIT

11.2 SPARE PARTS LIST PUMP HEAD

Finish 370 / 250

ITEM ORDER-NO DESIGNATION

1 0252 290 Pump head

2 0252 442 Pressure insert D18 (Finish 370)

2 0252 443 Pressure insert D16,5 (Finish 250)

3 0252 440 Piston D18 (Finish 370)

3 0252 441 Piston D16,5 (Finish 250)

4 0187 308 Spring plate

5 9922 516 Snap ring 12x1

6 0005 311 Pressure spring

7 3050 916 O-ring 25x3

8 0252 289 Diaphragm with inlet

9 9971 395 O-ring 10x1,25

10 0169 248 Re ef valve (item 9,10)

11 0341 702 Outlet valve, service set

12 0252 469 Outlet valve housing

0252 470 End part (to order with item12)

13 0344 700 Inlet valve

14 0341 331 Sealing ring (2x)

15 0252 279 Trigger housing

16 0341 336 Clasp

17 0340 339 Inlet

18 9990 865 Dust protective cap M36x2

19 0341 241 Inlet valve button (item19, 20, 21)

20 0341 316 Wiper

21 9971 486 O-ring 4x2 (FFPM)

22 0047 432 Double socket 1/4“ NPS/M16x1,5

23 9970103 Sealing ringg

24 0252 475 Pressure gage

25 0252 478 Cap

26 9970 218 Sealing ring

27 0252 295 Suction pipe

28 0252 294 Pressur control valve (item 28, 29)*

29 9971 365 O-ring 9,25x1,78*

30 0010 861 Pressure spring*

31 0010 859 Stop sleeve*

32 0010 858 Clip*

33 0158 250 Pressure regulating knob*

34 9951 072 Cap

35 0252 493 Label, plate

36 0158 383 Label Wagner

37 9993 105 Hose nozzle M5

38 3051 678 O-ring 9x3

39 0252 316 Return pipe

40 9900 217 Hexagon head screw M12x90 (4)

41 9906 035 Cylinder head screw M12x50 (2)

42 9920 204 Washer 13 (6)

* When these parts are replaced the operating pressure has to

be set again by the customer service.

22

Spare parts diagram pump head

Page 23

Finish 370 / 250

11.3 SPARE PARTS LIST PUMPAGGREGATE

GB

SPARE PARTS AND ACCESSORIES

ITEM ORTDER-NO DESIGNATION

1 0252 280 Motor assy. (item 1 to 10)

2 0252 431 Flange ring

3 3057 379 O-ring 30x2,5

4 0252 429 Inner ring

5 9922 603 Snap ring 52x2

6 0252 428 Shaft sealing ring

7 0252 430 Needle bearing

8 0252 450 Housing

9 0252 432 Fan

10 0252 433 Fan cowl

11 0340 354 Gasket

12 0252 435 Frame, fan

13 9903 348 Hex self drilling screw (8)

14 9971 536 sealing disk (4)

15 9900 248 Hex washer head screw M4x12 (13)

16 9900 313 Cylinder head screw M8x25 (2)

17 9920 102 Washer 8,4 (2)

18 9900 249 Hex washer head screw M5x12 (4)

19 9904 306 Screw plug BSP 1/8“

20 9970 127 Sealing ring

21 0252 453 Oil cap screw

22 9971 146 O-ring

23 0252 452 Oil dipstick

24 0252 351 Front cover

25 0252 305 Seal

26 9960 429 Roller bearing

27 0252 385 Gasket

28 9953 696 Motor protection switch

29 0252 434 Electric box

30 0252 504 Label F370

0252 502 Label F250 (left)

0252 503 Label F250 (right)

31 9952 876 Capacitor 35µF

32 0341 520

33 9952 685 Cable threaded joint M20x1,5

34 9952 686 Hexagon nut M20x1,5

Mains cable

H07RN-F3G1.5 6m long

35 9990 571 Plug (2)

36 9950 244 Terminal strip

37 0252 293 Cover

23

Page 24

GB

SPARE PARTS AND ACCESSORIES

Finish 370 / 250

Spare parts diagram pump-aggregate

24

Page 25

Finish 370 / 250

GB

SPARE PARTS AND ACCESSORIES

11.4 SPARE PARTS LIST HIGHPRESSURE FILTER

ITEM ORDER NO. DESIGNATION

1 0097 121 High-pressure lter HF- 01 compl.

2 0097 301 Filter block

3 0097 302 Filter housing

4 0097 303 Hollow screw

5 0097 304 Seal ring

6 9970 110 Seal ring

7 9974 027 O-ring 30x2 (PTFE)

8 9971 401 O-ring 16x2 (PTFE)

9 0508 749 Bearing spring

10 0508 603 Bearing ring

0508 748

11

0508 450

0508 449

12 9994 245 Pressure spring

Filter insert 60 meshes

Optional:

Filter insert 100 meshes

Filter insert 30 meshes

11.5 SPARE PARTS LIST TROLLEY

ITEM ORDER-NO. DESIGNATION

1 0252 291 Trolley assy. (for F-370)

2 9994 961 Wheel (2)

3 9994 950 Wheel cap (2)

4 0252 455 Locking pin (4)

5 0252 454 Spacer ring (2)

6 9910 106 Hexagon nut M5 (4)

7 0252 464 Sheet (2)

8 9900 142 Hexagon screw M5x12 (4)

9 9990 861 Plug (6)

10 9990 866 Rubber cap (4)

Spare parts diagram high-pressure lter

Spare parts diagram trolley F-370

25

Page 26

GB

SPARE PARTS AND ACCESSORIES

Finish 370 / 250

ITEM ORDER-NO DESIGNATION

1 0252 292 Trolley assy. (for F-250)

2 9994 961 Wheel (2)

3 9994 950 Wheel cap (2)

4 0252 455 Locking pin (4)

5 9990 861 Plug (2)

6 9990 866 Rubber cap (2)

11.6 SPARE PARTS LIST SUCTION SYSTEM RIGID

ITEM ORDER-NO DESIGNATION

1 0341 264 Suction system assy..

0344 341

2

0250 245

3 0341 275 Return pipe

4 0341 260 Hex screw cap with chain and clamp

5 0341 367 Sealing

4

5

Filter, mesh width 1 mm

Optional:

Filter, mesh width 0,8 mm

Spare parts diagram trolley F-250

3

2

Spare parts diagram suction system (rigid)

26

Page 27

Finish 370 / 250

GB

11.7 SPARE PARTS LIST HOPPER 5L

ITEM ORDER-NO DESIGNATION

- 0341 265 Hopper 5l, assy.

1 0340 901 Cover

0037 607

2

0003 756

3 9902 306 Sheet metal screw 3,9x13 (2)

4 0340 904 Hopper

5 0340 908 Return pipe

1

Filter disk, mesh width 0,8 mm

Optional:

Filter disk, mesh width 0,4 mm

11.8 SPARE PARTS LIST HOPPER WITH TOPCLEAN

ITEM ORDER-NO DESIGNATION

- 0341 268 Hopper 5l with TopClean, assy.

1 0340 904 Hopper 5l ( lter disc see 11.7)

2 0340 901 Cover

3 0340 271 TopClean, assy.

4 0340 270 Return pipe

5 0340 499 Screwing

6 0340 466 Distributor ring

7 0340 500 Rotary valve shaft

8 9971 486 O-ring 4x2 (FFPM)

2

4

5

7

2

4

3

5

Spare parts diagram hopper

8

3

6

1

Spare parts diagram hopper with TopClean

27

Page 28

GB

CE-DECLARATION

Finish 370 / 250

28

Page 29

Finish 370 / 250

TESTING OF THE UNIT

GB

TESTING OF THE UNIT / INFORMATION ON PRODUCT LIABILITY / GUARANTEE DECLARATION

in accordance with the guidelines for liquid jets (spraying

units) of the German industrial employer‘s liability insurance

association.

The unit has to be tested when appropriate, however at least

every 12 months. by experts whether safe operation continues to be ensured.

In case of non-operative units the test can be postponed until

the next start-up.

The operator is obliged to make an appointment for the unit

test.

Please contact the WAGNER customer service centers

(This guideline only applies for Germany)

IMPORTANT INFORMATION ON PRODUCT LIABILITY

An EU directive valid since 01.01.1990 speci es that the manufacturer is only liable for his products if all the parts originate from the manufactured or are approved by him, and if the

units are mounted and operated properly.

If accessories or spare parts from third parties are used, liability can be partially or completely inapplicable. In extreme

cases the responsible authorities can prohibit the use of the

entire unit (German industrial employer‘s liability insurance

association and factory inspectorate).

case of single-shift operation, 12 months in case of two-shift

operation or 6 months in case three-shift operation since the

point of handing over to the buyer due to a circumstance lying

before this handing over – in particular due to faulty design,

bad building materials or poor execution – are improved or

supplied new as we choose without costs.

The guarantee is given in the form that the unit or individual

parts of it are replaced as we decide. The costs required to this

purpose, in particular transportation, road, working or material costs, are borne by us unless the costs increase because the

unit has been brought subsequently to a place that is not the

location of the customer.

We do not accept any guarantee for damage that has been

caused by the following reasons:

Unsuitable or incorrect usage, faulty mounting or starting-up

by the buyer or by third parties, natural wear, faulty handling

or maintenance, unsuitable coating materials, substitute materials and chemical, electrochemical or electrical in uences,

in as far as damage is not due to our fault. Abrasive coating

materials, such as minium, dispersions, glazes, liquid abrasive

materials, etc. reduce the durability of valves, packings, spray

guns, tips, cylinders, pistons, etc. Any resulting signs of wear

are not covered by this guarantee.

With original WAGNER accessories and spare parts, compliance with all safety regulations is guaranteed.

NOTE ON DISPOSAL

In observance of the European Directive 2002/96/EC on waste

electrical and electronic equipment and implementation in

accordance with national law, this product is not to be disposed of together with household waste material but must be

recycled in an environmentally friendly way!

Wagner or one of our dealers will take back your used Wagner

waste electrical or electronic equipment and will dispose of

it for you in an environmentally friendly way. Please ask your

local Wagner service centre or dealer for details or contact us

direct.

GUARANTEE DECLARATION

24 months, at two-shift operation 12 months, at threeshift operation 6 months

We give a works guarantee to the following extent for this

unit:

All those parts that prove to be unserviceable or to be considerably impaired in their serviceability within 24 months in

Components that were not manufactured by Wagner are subject to the original manufacturer warranty.

The replacement of a part does not extend the guarantee period of the unit.

The unit has to be examined immediately after receipt.

Obvious faults are to be reported in writing within 14 days after receipt of the unit in order to avoid loss of the rights arising

from faults.

We reserve the right to have the guarantee ful lled by a contractual company.

Ful lling of the guarantee depends on proof being provided

by invoice and delivery note. If the check shows that the case

is not a guarantee case, repairs are carried out at the expense

of the buyer.

We make it clear that the guarantee declaration does not

represent a limitation of the statutory rights or of the rights

agreed contractually through our general terms of business.

J. Wagner GmbH

Subject to modi cations Printed in Germany

29

Page 30

GB

SERVICE NETWORK

SERVICENETZ / SERVICE NETWORK / RÉSEAU DE SERVICE APRÈSVENTE

RETE DI ASSISTENZA /SERVICENETWERK

Finish 370 / 250

AUSAWagner SprayTech

Australia PTY LTD.

POB 286

14-16 Kevlar Close

Braeside, VIC. 3195

Phone: +61/ 03/ 9587 2000

Fax: +61/ 03/ 9580 9120

wagner@wagnerspraytech.com.au

J. Wagner Ges.m.b.H.

Ottogasse 2/20

2333 Leoplodsdorf

Österreich

Tel. +43/ 2235 / 44 158

Telefax +43/ 2235 / 44 163

Gerhard.Poisinger@wagner-group.at

B Wagner Spraytech

Benelux b.v.

Veilinglaan 56

1861 Wolvertem-Meise

Belgium

Tel. +32/2/269 46 75

Telefax +32/2/269 78 45

info@wagner-wsb.be

DK Wagner Spraytech

Scandinavia A/S

Helgeshøj Allé 28

2630 Taastrup

Denmark

Tel. +45/43/ 27 18 18

Telefax +45/43/ 43 05 28

wagner@wagner-group.dk

E Wagner Spraytech

Iberica S.A.

Apartado 132

08750 Molins de Rey

Barcelona / Espania

Tel. +34/93/6800028

Telefax +34/93/66800555

info@wagnerspain.com

F J. Wagner France S.A.R.L

5 avenue du 1er mai, B.P. 47

91122 Palaiseau-Cedex

France

Tel. +33/1/825 011 111

Telefax +33/1/698 172 57

division.batiment@wagnerfrance.fr

I Wagner Colora

Via Fermi, 3

20040 Burago di Molgora (MI)

Italia

Tel. +39/ 039 / 625 021

Telefax +39/ 039 / 685 18 00

info@wagnercolora.com

NL Wagner Spraytech

Benelux b.v.

Zonneban 10,

3542 EC Utrecht

Netherlands

Tel. +31/ 30/241 41 55

Telefax +31/ 30/241 17 87

info@wagner-wsb.nl

NZ

SprayTech New Zealand Ltd.

P.OB 10353

unit 6/671 Te Rapa Road

Hamilton

Phone: +64/ 07/ 849 1329

Fax: +64/ 07/ 849 3185

sales@spraytech.co.nz

CH Wagner International AG

Industriestrasse 22

9450 Altstätten

Schweiz

Tel. +41/71 / 7 57 22 11

Telefax +41/71 / 7 57 22 22

wagner@wagner-group.ch

D

J. Wagner GmbH

Otto-Lilienthal-Straße 18

D-88677 Markdorf

Postfach 11 20

D-88669 Markdorf

Deutschland

Tel.: +49 / 75 44 / 505 - 540

Fax: +49 / 75 44 / 505 -169

wagner@wagner-group.com

www.wagner-group.com

30

CZ

GB

Wagner, spol.s r.o.

Nedasovská str. 345

155 21 Praha 5 -Zlicín

Czechia

Tel. +42/ 2 / 579 50 412

Telefax +42/ 2 / 579 51 052

info@wagner.cz

Wagner Spraytech (UK) Ltd.

Unit 3 Haslemere Way

Tramway Industrial

Estate

Banbury, Oxfordshire OX 16 5RN

Great Britain

Tel. +44/ 12 95 / 265 353

Telefax +44/ 12 95 / 269 861

enquiry@wagnerspraytech.co.uk

S

Wagner Spraytech

Scandinavia A/S

Helgeshøj Allé 28

2630 Taastrup

Denmark

Tel. +45/43/ 21 18 18

Telefax +45/43/ 43 05 28

wagner@wagner-group.dk

Loading...

Loading...