Page 1

®

S

E I

D F

GB

NL DK

F230

Airless Sprayer

Owner’s Manual • Betriebsanleitung • Manuel d'utilisateur

Manual de usuario • Manuale dell'utente • Gebruikshandleiding

Ejermanual • Användarmanual

English p. 2

Deutsch p. 14

Français p. 26

Español p. 38

Printed in the U. S.

Italiano p. 50

Nederlands p. 62

Dansk p. 74

Svenska p. 86

. All rights reserved. Form No. 0508296A

agner

2006 W

©

A.

0106

Page 2

Table of Contents

WARNING

CAUTION

CAUTION

WARNING

R

GB

Safety Precautions.................................................................2

General Description ...............................................................3

Specifications .........................................................................3

Preparing to Paint ..................................................................4

Priming ....................................................................................4

Preparing to Prime................................................................4

Mounting the Paint Hopper...................................................5

Attaching the Suction Set .....................................................5

Priming the Pump .................................................................5

Pressure Relief Procedure ....................................................5

Spraying .................................................................................6

Cleanup ...................................................................................7

Maintenance............................................................................8

Troubleshooting ...................................................................10

Parts Listing..........................................................................11

Main Assembly — Hopper Unit...........................................11

Main Assembly — Suction Set Unit....................................11

Diaphragm Pump................................................................12

Pump Head Assembly ........................................................13

Hopper Assembly................................................................13

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to an

area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information

will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which should

This unit is provided with a thermally protected automatic

reset. If an overload occurs the thermally protected

automatic reset disconnects the motor from the power

supply.

HAZARD: Injection injury - A high pressure stream

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE

CUT! Injection can lead to amputation. See a physician

immediately.

be given special attention.

The motor will restart without warning when the protector

•

automatically resets.

• Always disconnect the motor from the power supply

before working on the equipment.

When the thermally protected automatic reset disconnects

•

the motor from the power supply

turning the priming valve to PRIME.

• Turn the ON/OFF switch to OFF.

produced by this equipment can pierce the

skin and underlying tissues, leading to serious

injury and possible amputation.

, relieve pressure by

The maximum operating range of the unit is 20.7 MPa

(3000 PSI) fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the fluid pump off and

release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure will

not be released by turning off the engine. The

PRIME/SPRAY valve or pressure bleed valve must be

turned to their appropriate positions to relieve system

pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

• ALWAYS keep tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• The paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect

the hose before each use.

• NEVER use a spray gun without a working trigger lock

and trigger guard in place.

• All accessories must be rated at or above the maximum

operating pressure range of the sprayer. This includes

spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

PREVENTION:

• Provide extensive exhaust and fresh air introduction to

• Avoid all ignition sources such as static electricity sparks,

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

• Place sprayer at least 6.1 m (20 feet) from the spray object

• The equipment and objects in and around the spray area

•

• Power cord must be connected to a grounded circuit

•

•

• The unit must be connected to an earthed object. Use the

can explode or ignite. Severe injury and/or

property damage can occur.

keep the air within the spray area free from accumulation

of flammable vapors.

electrical appliances, flames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

order.

in a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area

must be extremely well ventilated. The pump contains

arcing parts that emit sparks and can ignite vapors.

must be properly grounded to prevent static sparks.

Use only conductive or earthed high pressure fluid hose.

Gun must be earthed through hose connections.

(electric units only).

Always flush unit into separate metal container, at low

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

Follow material and solvent manufacturer's warnings and

instructions.

green earthing wire to connect the unit to a water pipe,

steel beam, or other electrically earthed surface.

2 © Wagner. All rights reserved.

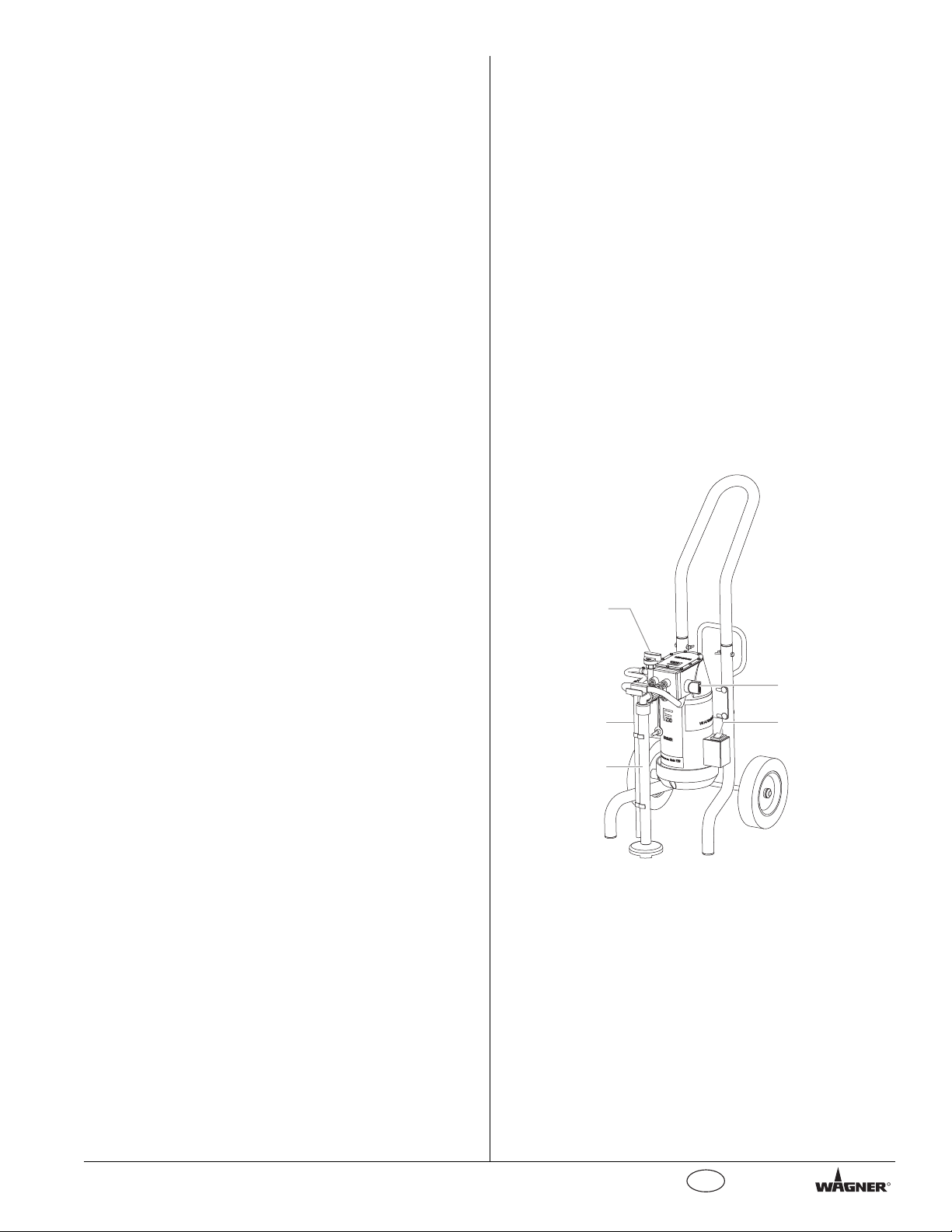

Page 3

Always place sprayer outside of structure in fresh air. Keep all

Return Tube

PRIME/SPRAY

Valve

Suction Tube

Motor ON/OFF

Switch

Pressure Control

Knob

GB

R

solvents away from engine exhaust. Never fill fuel tank with a

running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump to a grounded object.

Refer to engine owner’s manual for complete safety

information.

• Do not use materials with a flashpoint below 21° C (70°

F). Flashpoint is the temperature at which a fluid can

produce enough vapors to ignite.

Plastic can cause static sparks. Never hang plastic to

•

nclose spray area. Do not use plastic drop cloths when

e

praying flammable materials.

s

• Use lowest possible pressure to flush equipment.

GAS ENGINE (WHERE APPLICABLE)

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read

• Wear protective eyewear.

• Wear protective clothing as required by coating

HAZARD: GENERAL - This product can cause severe

PREVENTION:

• Read all instructions and safety precautions before

• Follow all appropriate local, state, and national codes

• Pulling the trigger causes a recoil force to the hand that is

•

• Before each use, check all hoses for cuts, leaks, abrasion

• ALWAYS follow the material manufacturer’s instructions

• Do not use this unit in workshops that are covered under

• Clean up all material and solvent spills immediately.

• Always unplug cord from outlet before working on

• Wear ear protection. This unit can produce noise levels

•

• Do not spray on windy days.

© Wagner. All rights reserved. 3

MATERIALS - Will cause severe injury or

property damage.

methylene chloride and 1,1,1 - trichloroethane. They are

not compatible with aluminum and may cause an

explosion. If you are unsure of a material’s compatibility

with aluminum, contact your coating's supplier.

insecticides, and other materials can be

harmful if inhaled or come in contact with body.

Vapors can cause severe nausea, fainting, or

poisoning.

all instructions supplied with the mask to be sure it will

provide the necessary protection.

manufacturer.

injury or property damage.

operating equipment.

governing ventilation, fire prevention, and operation.

holding the spray gun. The recoil force of the spray gun is

particularly powerful when the tip has been removed and

a high pressure has been set on the airless pump. When

cleaning without a spray tip, set the pressure control knob

to the lowest pressure.

Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specifications and safety devices of the

pump manufacturer.

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it

with another earthed high-pressure hose.

for safe handling of paint and solvents.

the explosion prevention regulations.

equipment (electric units only).

above 85 dB(A).

Never leave this equipment unattended. Keep away from

children or anyone not familiar with the operation of airless

equipment.

Earthing Instructions

Electric models must be earthed. In the event of an electrical

short circuit, earthing reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having an earthing wire with an

appropriate earthing plug. The plug must be plugged into an

outlet that is properly installed and earthed in accordance with

all local codes and ordinances.

DANGER — Improper installation of the earthing plug can

result in a risk of electric shock. If repair or replacement

of the cord or plug is necessary, do not connect the green

earthing wire to either flat blade terminal. The wire with

insulation having a green outer surface with or without

yellow stripes is the earthing wire and must be connected

to the earthing pin.

Check with a qualified electrician or serviceman if the earthing

instructions are not completely understood, or if you are in

doubt as to whether the product is properly earthed. Do not

modify the plug provided. If the plug will not fit the outlet, have

the proper outlet installed by a qualified electrician.

General Description

This high performance airless sprayer is a precision power tool

used for spraying many types of materials. Read and follow

this instruction manual carefully for proper operating

instructions, maintenance and safety information.

Specifications

Weight:

Hopper unit ...................17 kg (37 lbs.)

Suction set unit .............20 kg (44 lbs.)

Capacity ...........................Up to 1.25 liters (.35 gallons) per

Power source ...................Electric motor, totally enclosed, fan

.............................

oltage

V

Spraying pressure ............Up to 20.7 MPa (3000 PSI)

Capabilities

.......................Sprays a variety of oil-based and

minute

cooled

220–240 VAC, 50/60 Hz, 6.2 A or

100–120 VAC, 50/60 Hz, 11.0 A

latex paints, primers, and stains

Page 4

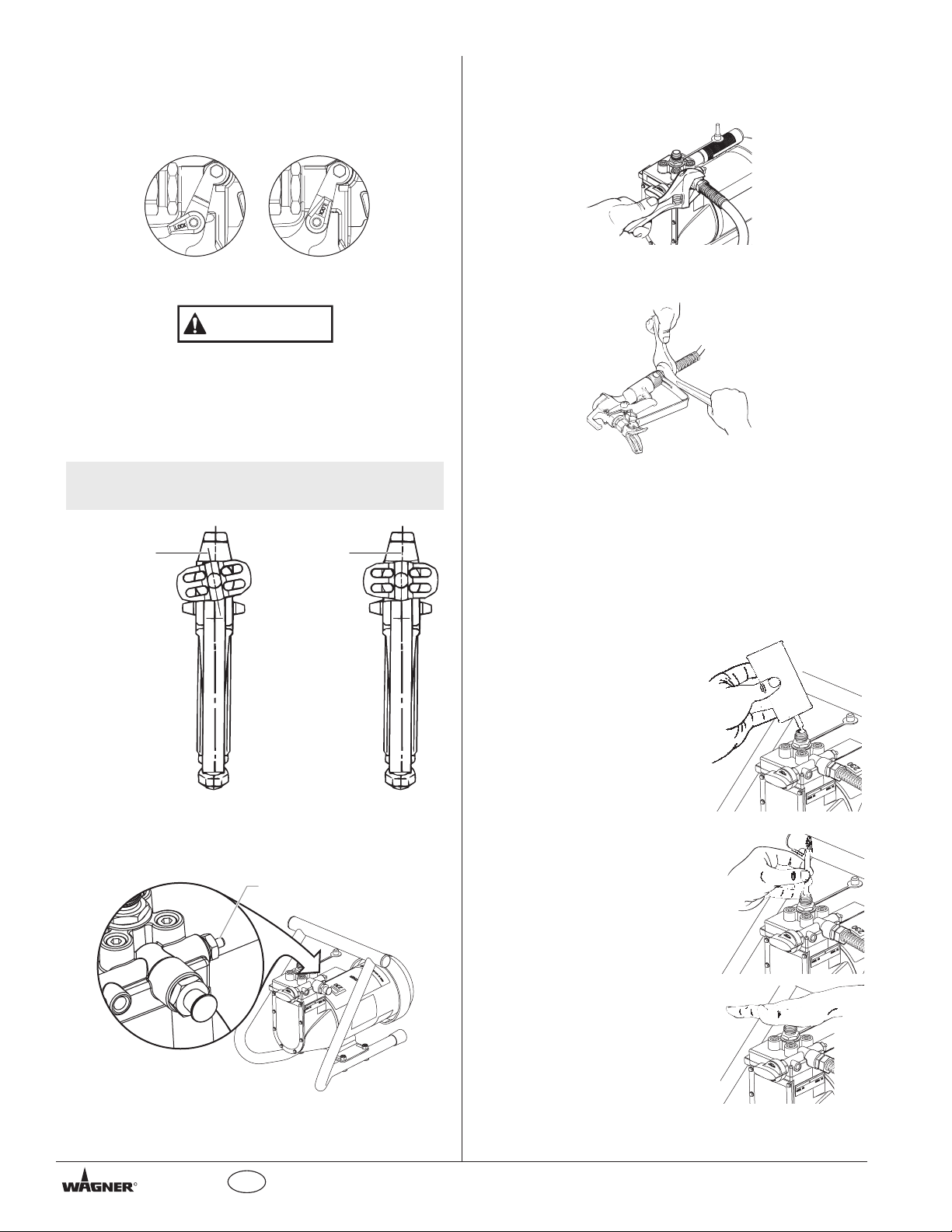

Preparing to Paint

Pusher Valve Button

(optional)

Begin

tightening

the tip guard

at this angle

to achieve

the desired

spray angle

when tight.

WARNING

Trigger locked

(gun will not spray)

Trigger unlocked

(gun will spray)

R

GB

Attaching the Tip to the Gun

1. Lock the trigger by rotating the trigger lock forward until it

stops.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position. Always engage

the gun trigger lock before removing, replacing or

cleaning tip.

2. Thread the tip guard onto the gun. Tighten the nut first by

hand, then tighten more firmly with a wrench.

NOTE: When attaching the tip guard to the gun, align

the tip guard as shown in the figure below,

then tighten with a wrench.

Attaching the Paint Hose

. Attach the high pressure hose to the paint sprayer. Use a

1

rench to tighten the paint hose securely.

w

2. Attach the spray gun to the other end of the high pressure

hose. Tighten the hose securely to the gun using two

wrenches.

3. Plug the sprayer into a properly grounded outlet or heavy

duty grounded extension cord. Do not use more than 100

feet of cord. If you must spray a long distance from a

power source, use more paint hose, not more extension

cords. Use a minimum size of 16 gauge extension cord

for up to 50 feet in length, or 12 to 14 gauge for extension

cords between 50 and 100 feet in length.

Checking the Outlet Valve (optional)

1. Firmly press the optional pusher valve button on the side

of the pump housing to make sure the outlet ball valve

moves freely.

Priming

Preparing to Prime

1. Fill the inlet valve with water or

with a light household oil.

2. Make sure the PRIME/SPRAY

valve is set to PRIME and that

the pressure control knob is

turned counterclockwise to the

lowest pressure setting.

Move the motor ON/OFF switch

3.

to ON.

4. Increase the pressure by turning

the pressure control knob

clockwise 1/2 turn.

5. Force the inlet valve to open and

close by pushing on it with a

screwdriver or the eraser end of a

pencil. It should move up and

down about 1/16 of an inch.

Continue until water or oil is

sucked into the sprayer. This will

wet the moving parts and break

loose any old paint residue.

6. Put the palm of your hand over the

inlet. Turn the pressure control

knob clockwise to its maximum

setting. You should feel suction

coming from the inlet valve. If you

do not, see the section on

cleaning and servicing the outlet

valve.

7. Turn the pressure control knob

counterclockwise to the minimum pressure setting.

8. Move the motor ON/OFF switch to OFF.

4 © Wagner. All rights reserved.

Page 5

Mounting the Paint Hopper

Return Tube

Paint Hopper Cover

Return Tube Fitting

Return Tube

WARNING

Trigger locked

(gun will not spray)

Pressure Control

Knob

PRIME/SPRAY

Valve

CAUTION

CAUTION

Pressure Control Knob

P

RIME/SPRAY Valve

GB

R

Use the following procedure to mount the paint hopper and

attach the return tube on a hopper unit.

1. Align the bottom of the paint hopper with the threaded

inlet valve on the paint pump block.

2. Turn the paint hopper clockwise to thread it onto the inlet

valve. Continue to turn the paint hopper until it is secure

on the inlet valve.

NOTE: Make sure the threads are straight and the

3. Place the filter screen into the bottom of the paint hopper

. Make sure that the motor ON/OFF switch is turned to

4

. Screw the return tube fitting found

5

NOTE: Do not over-tighten.

6. Place the straight end of the

7. Thread the nut on the return tube

8. Place the hook end of the return tube into the hole in the

hopper turns freely on the inlet valve. Do not

cross-thread.

and snap it in position.

FF.

O

in the literature set into the return

tube port on the side of the pump.

Hand-tighten only. Some

threads will be visible

even when fully

tightened.

return tube into the return tube

fitting.

onto the return tube fitting and

tighten until the return tube is

secure.

paint hopper cover.

Priming the Pump

1. Turn the pressure control knob counterclockwise to its

lowest pressure setting.

. Remove the paint hopper cover and fill the paint hopper

2

ith material or place the suction set into a bucket of

w

material.

3. Turn the PRIME/SPRAY valve to PRIME.

4. Move the motor ON/OFF switch to ON.

5. Turn the pressure control knob clockwise to between half

and full pressure. Let the unit prime 1 to 2 minutes after

material begins to flow through the return tube.

Always reduce the pressure to zero before changing the

position of the PRIME/SPRAY valve. Failure to do so may

cause damage to the paint pump diaphragm.

If the pressure control knob is reduced to zero and the

PRIME/SPRAY valve is still on SPRAY while the sprayer is

operating, there will be high pressure in the hose and

spray gun until the PRIME/SPRAY valve is turned to

PRIME or until the spray gun is triggered to relieve the

pressure.

Attaching the Suction Set

Use the following procedure to attach the suction set to a

suction set unit.

1. Align the nut on the suction set with the threaded inlet

valve on the paint pump block.

2. Turn the nut clockwise to thread it onto the inlet valve.

Continue to turn the nut until it is secure on the inlet valve.

NOTE: Make sure the threads are straight and the

3. Screw the return tube fitting found in the literature set into

the return tube port on the side of the pump.

NOTE: Do not over-tighten. Hand-tighten only.

4. Place the straight end of the return tube into the return

tube fitting.

5. Slide the return tube clamp onto the return tube fitting and

tighten until the return tube is secure.

nut turns freely on the inlet valve. Do not

cross-thread.

Some threads will be visible even when fully

tightened.

Pressure Relief Procedure

Follow this procedure after the unit is assembled and before

any operation which involves the spray gun such as cleaning

and maintenance or changing tips or accessories.

1. Turn the pressure control knob counterclockwise to its

lowest setting.

2. Turn the PRIME/SPRAY valve to PRIME.

3. Trigger the gun to remove any pressure that may still be in

the hose.

4. Lock the trigger by rotating the trigger

lock forward until it stops.

Injection hazard. Do not spray without

the tip guard in place. NEVER trigger

the gun unless the tip is completely

turned to either the spray or the unclog

position. ALWAYS engage the gun

trigger lock before removing, replacing or cleaning tip.

© Wagner. All rights reserved. 5

Page 6

Spraying

Approximately

10 to 12 inches

Right way

Wrong way

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

H

eavy Coat

Do not flex wrist while spraying.

L

ight Coat Light Coat

Good spray pattern

Paint tailing pattern

Pressure Control Knob

PRIME/SPRAY Valve

P

roper way to trigger the spray gun

Aproximately

1

0 to 12 inches

Keep stroke

e

ven

Start stroke End strokePull trigger Release triggerKeep steady

R

GB

Spraying Technique

he key to a good paint job is an even coating over the entire

T

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying distance

is 10 to 12 inches between the spray tip and the surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Overlap each stroke by about 30%. This will ensure an even

coating.

When you stop painting, lock the gun trigger lock, turn the

pressure control knob counterclockwise to its lowest setting

and set the PRIME/SPRAY valve to PRIME. Move the motor

ON/OFF switch to OFF and unplug the sprayer.

If you expect to be gone more than 1 hour, follow the short

term clean up procedure described in the CLEANUP section of

this manual.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and of

each stroke. This will save material and avoid material buildup

at the end of the stroke. Do not trigger the gun during the

middle of a stroke. This will result in an uneven spray and

splotchy coverage.

3. Turn the PRIME/SPRAY valve to SPRAY.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as material begins

to flow through it.

5. Unlock the gun trigger

lock by turning the

switch so that it is

parallel to the handle.

Trigger the spray gun to

6.

bleed air out of the

hose.

7. When material reaches

the spray tip, spray a

test area to check the

spray pattern.

f with

8. Use the lowest pressure setting necessary to get a good

spray pattern. If the pressure is set too high, the spray

pattern will be too light. If the pressure is set too low,

tailing will appear or the paint will spatter out in blobs

rather than in a fine spray.

6 © Wagner. All rights reserved.

Page 7

Cleanup

Trigger locked

(gun will not spray)

Trigger locked

(gun will not spray)

Trigger locked

(gun will not spray)

CAUTION

WARNING

GB

R

Overnight Storage

Long-Term Storage

Shutdown

. Turn the pressure control knob counterclockwise to the

1

inimum setting.

m

2. Turn the PRIME/SPRAY valve to PRIME to release

system pressure.

3. Trigger the gun to remove any pressure that may still be in

the hose.

. Lock the trigger by rotating the trigger

4

ock forward until it stops.

l

5. Move the motor ON/OFF switch to

OFF and unplug the sprayer.

6. For latex materials only, pour 1/2 cup

water slowly on the top of the paint to

prevent the paint from drying. For

other materials, seal the material

container or paint hopper (with the

hopper cover) keeping the return tube

in the material.

7. Wrap the spray gun assembly in a damp cloth and place it

in a plastic bag. Seal the bag shut.

8. Place the sprayer in a safe place out of the sun for shortterm storage.

Startup

Remove the gun from the plastic bag.

1.

2. Stir the water into the paint for latex materials. Remove

the cover from the paint hopper or material container and

stir the paint for all other materials.

valve is set to

3. Check to be sure that the PRIME/SPRA

PRIME and that the pressure is completely reduced.

4. Plug sprayer in and Move the motor ON/OFF switch to

ON.

5. After the sprayer is primed, turn the PRIME/SPRAY valve

to SPRAY and gradually turn the pressure control knob

clockwise to increase the pressure.

est the sprayer on a practice piece and begin spraying.

T

6.

Y

Do not allow material to build up on the motor or the

motor will overheat. Do not allow flammable solvents to

come in contact with the motor or they could ignite.

NOTE: You will need a bucket, cleaning solution, a

Do not use mineral spirits or paint thinner on latex paint,

or the mixture will turn into a jelly-like substance which is

difficult to remove.

toothbrush, a wrench and cleaning rags.

Clearing the Paint Hopper

Use the following procedure to clear the material out of the

paint hopper of a hopper unit.

1. Lock the gun trigger by rotating the

trigger lock forward until it stops.

2. Turn the pressure control knob

counterclockwise to the minimum

setting.

3. Turn the PRIME/SPRAY valve to

PRIME.

4. Move the motor ON/OFF switch to

OFF.

5. Direct the return tube into the original

material container.

6. Move the motor ON/OFF switch to ON.

7. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining material in the paint hopper

through the pump, up the return tube, and into the

material container.

8. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

9. Trigger the gun to relieve pressure and lock the gun.

10. Remove the spray tip and guard and place them into a

container of water or appropriate solvent for the type of

material with which you are painting.

11. Fill the paint hopper with water or an appropriate solvent

for the type of material with which you are painting.

12. Direct the return tube into a waste bucket.

13. Increase the pressure to 1/2 the maximum pressure. Let the

water or solvent circulate for 2-3 minutes to flush material

out of the pump, the paint hopper, and the return tube.

Clearing the Suction Set

Use the following procedure to clear the material out of the

suction tube of a suction set unit.

1. Turn the pressure control knob counterclockwise to the

minimum setting.

urn the PRIME/SPRAY valve to PRIME.

2. T

3. Move the motor ON/OFF switch to OFF.

ait a couple seconds, then trigger

W

4.

the gun into the material container to

release built up fluid pressure from the

pump.

5. Lock the gun trigger by rotating the

trigger lock forward until it stops.

6. Remove the suction hose from the

material and hold it above a bucket of

water or solvent. Leave the return

hose in the material container

7. Move the motor ON/OFF switch to ON.

urn the pressure control knob to 1/2 maximum pressure.

T

8.

This will draw the remaining material in the suction tube

through the pump, down the return hose and into the

material container

.

.

© Wagner. All rights reserved. 7

Page 8

. Turn the pressure control knob counterclockwise to the

R

GB

9

inimum setting.

m

10. Place the attached suction tube and return hose into the

container of water or appropriate solvent.

11. Remove the spray tip and guard and place them into a

container of the appropriate solvent.

12. Increase the pressure to 1/2 the maximum pressure. Let

the water or solvent circulate for 2-3 minutes to flush paint

out of the pump, the suction tube and the return hose.

Clearing the Paint Hose

1. To save material left in the hose, release the gun trigger

lock and carefully trigger the gun with the spray tip

removed against the inside of the material container.

2. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

3. Turn the PRIME/SPRAY valve to SPRAY.

4. Turn the pressure control knob slowly until material starts

to flow into the bucket. As soon as the water or solvent

starts to come into the bucket, release the trigger.

5. Change to clean water or solvent, point the gun to the

side of the waste bucket, and continue circulating for

another 5 minutes to thoroughly clean the hose, pump

and spray gun.

6. Turn the pressure control knob counterclockwise to its

lowest setting.

7. Turn the PRIME/SPRAY valve to PRIME.

8. Trigger the gun to remove any pressure which may still be

in the hose.

9. Lock the gun trigger by rotating the trigger lock forward

until it stops.

10. Move the motor ON/OFF switch to OFF.

11. Cover the material container and set it aside.

Clearing the Gun

1. Remove the spray gun from the paint hose using two

adjustable wrenches.

2. Remove the filter housing from the gun. Place the gun

and the filter assembly into a container of water or solvent

to soak.

3. Clean the spray tip and gun filter with a soft brush.

4. Reassemble the gun and filter. Assemble the spray tip in

the cleaning position with the arrow pointing to the back of

the gun.

5. Attach the paint hose to the gun and tighten using two

wrenches.

6. Move the motor ON/OFF switch to ON.

. Unlock gun trigger by turning the gun trigger lock so that it

7

s parallel to the gun handle.

i

8. Turn the PRIME/SPRAY valve to SPRAY and point the

gun to the side of the waste bucket.

9 Trigger the gun and gradually turn the pressure control

knob clockwise to 1/2 pressure. Continue to trigger the

gun for approximately 30 seconds.

0. Turn the pressure control knob counterclockwise to its

1

lowest setting.

11. Turn the PRIME/SPRAY valve to PRIME.

12. Trigger the gun to remove any pressure which may still be

in the hose.

13. Lock the gun trigger by rotating the trigger lock forward

until it stops.

14. Move the motor ON/OFF switch to OFF.

Final Cleanup

1. Remove the tip assembly.

2. Move the motor to ON.

3. Turn the PRIME/SPRAY valve to SPRAY.

4. Turn the pressure control knob clockwise to 1/2 power.

5. Trigger the gun into the cleaning bucket until the hopper

or solvent bucket is empty.

6. Refill the hopper or solvent bucket and continue flushing

the system until the solution coming out of the gun

appears clean.

7. Lock the gun and turn the pressure control knob

counterclockwise to its lowest setting.

8. Turn the PRIME/SPRAY valve to PRIME.

9. Remove the hopper or suction set from the inlet valve.

10. Clean the threads of the inlet valve with a damp cloth.

11. Fill the inlet valve with a light

household oil.

12. Turn the PRIME/SPRAY valve to

SPRAY to distribute the oil.

NOTE: Proper cleaning and

13.

14. Turn the PRIME/SPRAY valve to PRIME.

15. Trigger the gun to remove any pressure that may still be in

16. Lock the gun trigger by rotating the trigger lock forward

17. Move the motor ON/OFF switch to OFF.

18.

19. Return the hopper filter to its position in the hopper.

20.

21. Wipe the entire unit, hose, and gun with a damp cloth to

oiling of the pump after

use are the most

important steps you can

take to insure proper

operation after storage.

urn the pressure control knob

T

counterclockwise to its lowest setting.

the hose.

until it stops.

Remove the hopper filter and clean in clean water or the

appropriate solvent. Use a soft brush.

Replace the hopper or suction set on the inlet valve.

remove accumulated material.

8 © Wagner. All rights reserved.

Page 9

Maintenance

Valve Body

O-ring

Seal

Seat

Ball

Spring

Ball Stop

GB

R

ollow these procedures when encountering problems

F

ndicated in the troubleshooting section.

i

Removing and Cleaning the Inlet Valves

1. Perform the Pressure Relief Procedure, turn off and

unplug the unit.

2. Remove the inlet valve assembly using a 27 millimeter

socket or box end wrench.

3. Test movement of the valve by pushing on it from the

open end of the valve housing with a screwdriver or the

eraser end of a pencil. It should move about 1/16 of an

inch (0,15 mm). If it does not move, it should be cleaned

or replaced.

NOTE: The inlet valve must be oiled after every job.

4. Thoroughly clean the valve assembly with water or the

5. If the valve has been properly cleaned and water drips out

6. Install a new or cleaned valve in the pump block and then

This will reduce or eliminate priming problems

the next time the sprayer is used.

appropriate solvent. Use a small brush.

of the bottom, the valve is worn and needs to be replaced.

A properly seated valve filled with water and held vertically

will not drip.

fill the valve with light oil or solvent.

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve body with a wrench.

2. Remove and clean the ball stop and small spring inside

the valve using a wire hook or tweezers. Replace the

spring if it is broken or worn.

NOTE: This spring is manufactured to a very specific

tension. Do not put in an unauthorized

substitute. See the paint pump assembly

parts diagram for the proper replacement part

number.

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any

sign of wear or damage, replace them with new parts.

This carbide ball must seal tightly against its seat for the

valve to function properly.

5. Cover all parts with a thin coat of light oil before

reassembling.

NOTE: You will need to align the ridge on the seat

with the groove in the pump housing when

reassembling.

6. Drop in the valve ball.

7. Insert the ball stop and spring and replace the valve body.

Be sure that the o-ring is positioned properly and that the

tongue on the cap fits inside the spring.

8. Tighten the valve body securely with an adjustable

wrench. Do not over-tighten.

© Wagner. All rights reserved. 9

Cleaning the Hopper Screen

The screen at the bottom of the paint hopper

may need cleaning periodically. Check it

every time you add paint. Remove the

screen by pulling it out of the hopper with a

pliers. Clean the screen with water or

solvent and a soft-bristle brush, if necessary.

Page 10

R

GB

P

roblem

The sprayer does not start up.

Troubleshooting

C

ause

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. Low or no voltage is coming from the

wall plug.

4. The sprayer was turned off while still under

pressure.

5. The extension cord is damaged or has too

low a capacity.

6. The thermal overload on the sprayer is

tripped.

7. There is a problem with the motor.

S

olution

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Properly test the power supply voltage.

4. Turn the PRIME/SPRAY valve to PRIME.

5. Replace the extension cord.

6. Allow the motor to cool and move the sprayer to

a cooler spot.

7. Take the sprayer to a WagnerAuthorized Service

Center.

The sprayer starts up but does not

draw in paint when the

PRIME/SPRAY valve is set to

PRIME.

The sprayer draws up paint but

the pressure drops when the gun

is triggered.

The sprayer will not shut off.

The spray gun leaks.

The tip assembly leaks.

1. The unit will not prime properly or has lost prime.

2. The paint hopper is empty

3. The hopper filter is clogged.

4. The inlet valve is stuck.

5. The outlet valve is stuck.

6. The PRIME/SPRAY valve is plugged.

7. The inlet valve is worn or damage.

8. There is a problem with the diaphragm.

9. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The hopper filter is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The inlet or outlet valve ball or ball seat is

worn.

2. Foreign matter or paint has built up between

the ball and the seat.

1. Internal parts of the gun are worn

or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. Try to prime the unit again.

2. Fill the paint hopper with paint.

3. Clean the hopper filter.

4. Clean the inlet valve.

5. Clean the outlet valve and replace any

worn parts.

6. Take the sprayer to a WagnerAuthorized Service

Center.

7. Replace the inlet valve.

8. Take the sprayer to a WagnerAuthorized Service

Center.

9. Take the sprayer to a WagnerAuthorized Service

Center.

1. Replace the spray tip with a new tip.

2. Clean the hopper filter.

3. Clean or replace the proper filter. Always keep

extra filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Take the sprayer to a WagnerAuthorized Service

Center.

2. Take the sprayer to a WagnerAuthorized Service

Center.

1. Take the sprayer to a WagnerAuthorized Service

Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.

The spray gun will not spray.

The paint pattern is tailing.

The thermal overload tripped and

shut off the sprayer.

1. The spray tip, the gun filter or the tip filter is

plugged.

2. The spray tip is in the CLEAN position.

The pressure is set too low

1.

2. The gun, the tip, or the hopper filter

is plugged.

3. The tip is worn.

4. The paint is too thick.

1. The motor overheated.

The extension cord is too long or is too

2.

small a gauge.

3. Paint has built up on the motor.

4. The motor was started while the sprayer

was under pressure.

5. The sprayer was sitting in the hot sun.

.

1. Clean the spray tip, gun filter or tip filter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

Clean the filters.

2.

3. Replace the spray tip.

4. Thin the paint.

Allow to cool for 30 minutes.

1.

2. Allow to cool for 30 minutes and replace the

extension cord with a shorter extension or a

thicker gauge cord.

3. Clean the paint from the motor.

4. Restart the sprayer in the PRIME mode.

5.

Move the sprayer out of the sun.

NOTE: When the PRIME/SPRAY valve is on SPRAY and there is flow through the return tube, remove the

PRIME/SPRAY valve and clean or replace it.

NOTE: The electric motor should always be kept clean and dry. Paint acts as an insulator. Too much paint on the

motor will cause the motor to overheat.

10 © Wagner. All rights reserved.

Page 11

GB

R

Parts Listing

1

2

3

5

6

7

8

4

1

2

3

4

5

6

7

10

9

8

11

12

13

15

14

Main Assembly — Hopper Unit

Main Assembly — Suction Set Unit

Item Part # Description Quantity

1 0288144 Hopper assembly..................................1

2 ---------- Pump head assembly...........................1

3

4 0278310 Stand ....................................................1

5 9811122 Lock nut ................................................4

6 0294635 Plug.......................................................2

7 0270343 Tube cap...............................................2

8

0555126

1200 Diapragm pump, 100–120 V

031

9805213 Carriage bolt .........................................4

Diaphragm pump, 220–240 V

AC..........

AC

1

Item Part #

1 0508251 Handle ..................................................1

2 9811122 Lock nut ................................................4

3 0512396 Wheel....................................................2

4 0508255 Frame ...................................................1

5 0088715 Return hose fitting ................................1

0327226

6

7 0278147 Suction set assembly............................1

8 9810111 Wing nut................................................2

9800108

9

10 9810113 Axle cap................................................2

11 0555126 Diaphragm pump, 220–240 VAC..........1

12 ---------- Pump head assembly...........................1

13 9802533 Carriage bolt .........................................4

14

15 9802519 Screw....................................................2

0311200 Diaphragm pump, 100–120 VAC

0278364 Pail hook...............................................1

Description

Return hose clamp ...............................1

....................................................

Screw

Quantity

2

© Wagner. All rights reserved. 11

Page 12

R

GB

Diaphragm Pump

13

17

18

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

19

20

21

22

23

25

24

26

AS-3112

0270 405

220V~240V

0508111

110V~120V

9952995

220V~240V

0275503

100V

BS-546 CEE 7/7 NEMA 5-15P

(P/N 0555126 / 220–240 VAC or P/N 0311200 / 100–120 VAC)

Item Part # Description Quantity

1 0311215 Pump head .................................................1

2 0270494 Diaphragm ring ...........................................1

3

4

0270201

9801

Diaphragm

109 Set screw ....................................................2

..................................................1

5 0288775 Pressure control knob.................................1

6 0270529 Valve stem..................................................1

7 0047373 Pressure regulating spring..........................1

8 0089518 O-ring..........................................................1

9 0089475 Pressure valve needle................................1

10 0278345 Hydraulic piston ..........................................1

11 0005311 Piston spring ...............................................1

0270550

12

0047393 Retainer ......................................................2

13

14 0278359 Gasket ........................................................1

0278341

15

Piston washer

Hydraulic cover

.............................................

...........................................

16 9800049 Screw ..........................................................9

17 0090031 Eccentric sleeve and bearing assembly .....1

Item Part # Description Quantity

18 0089829 Shaft key.....................................................1

19 9900355 Socket screw ..............................................4

20

9921601

Lock washer

................................................4

21 0508295 Motor, 220–240 VAC

0278469

(includes items 27 and 28)

Motor, 100–120 VAC

.........................

(includes items 27 and 28)

22 0270524 Seal.............................................................1

23 0270490 Ball bearing.................................................2

24 0311400 Snap ring ....................................................1

25 9870117 Plug seal .....................................................1

26 0278238 Hydraulic housing assembly

1

(includes items 22–25) ...............................1

0270462

27

0270612 Fan cover (not shown)................................1

28

1

----------

Fan (not shown)

Power cord (not shown, see above)

..........................................

...........

1

1

1

12 © Wagner. All rights reserved.

Page 13

GB

R

Pump Head Assembly

2

1

3

5

6

7

8

9

10

11

4

12

13

14

1

5

16

1

2

3

4

6

5

7

Item Part # Description Quantity

1 0278242 Inlet valve assembly (includes item 2)........1

2 0089482 Sealing washer, nylon.................................1

3 0278334 Paint pump..................................................1

4 0555901 PRIME/SPRAY valve assembly..................1

5 0278362 Outlet seal...................................................1

6 0278241 Ball seat......................................................1

7 0093635 Ball..............................................................1

8 0047485 Outlet spring ...............................................1

9 0278361 Ball guide....................................................1

10 9871114 O-ring..........................................................1

11 0278335 Outlet fitting.................................................1

12 0278337 Pusher body................................................1

13 0278250 Pusher stem assembly ...............................1

0278368 Pusher spring..............................................1

14

15 0156646 Seal.............................................................1

16 0278340 Pusher washer............................................1

Hopper Assembly

Item Part # Description Quantity

1 0279591 Cover, hopper.......................................1

2 0089917 Filter screen, fine (shown) ....................1

0088871 Filter screen, coarse

3 0090283 Hopper ..................................................1

4 0093865 Return tube...........................................1

5 0090617 Fitting ....................................................1

6 0090560 Return tube assembly

(includes items 4 and 5) .......................1

7 0288144 Hopper complete

(includes items 1 – 6) ...........................1

© Wagner. All rights reserved. 13

Loading...

Loading...