Page 1

Dampf-Tapetenablöser

2 Jahre

Garantie

2 years

Guarantee

2 ans de

garantie

2 jaar

garantie

Steam wallpaper stripper

Décolleuse du papier peint

Behangafstoom-apparaat

DTS 5800

D / GB/ F/ NL

Page 2

DTS 5800

+ +

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

D

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 8

GB

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 12

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 - 16

NL

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

GB

5

DTS 5800

Translation of the original operating instructions

The operating instructions are part of the unit. Keep them in a safe place!

Read these operating instructions carefully and in full before using the unit.

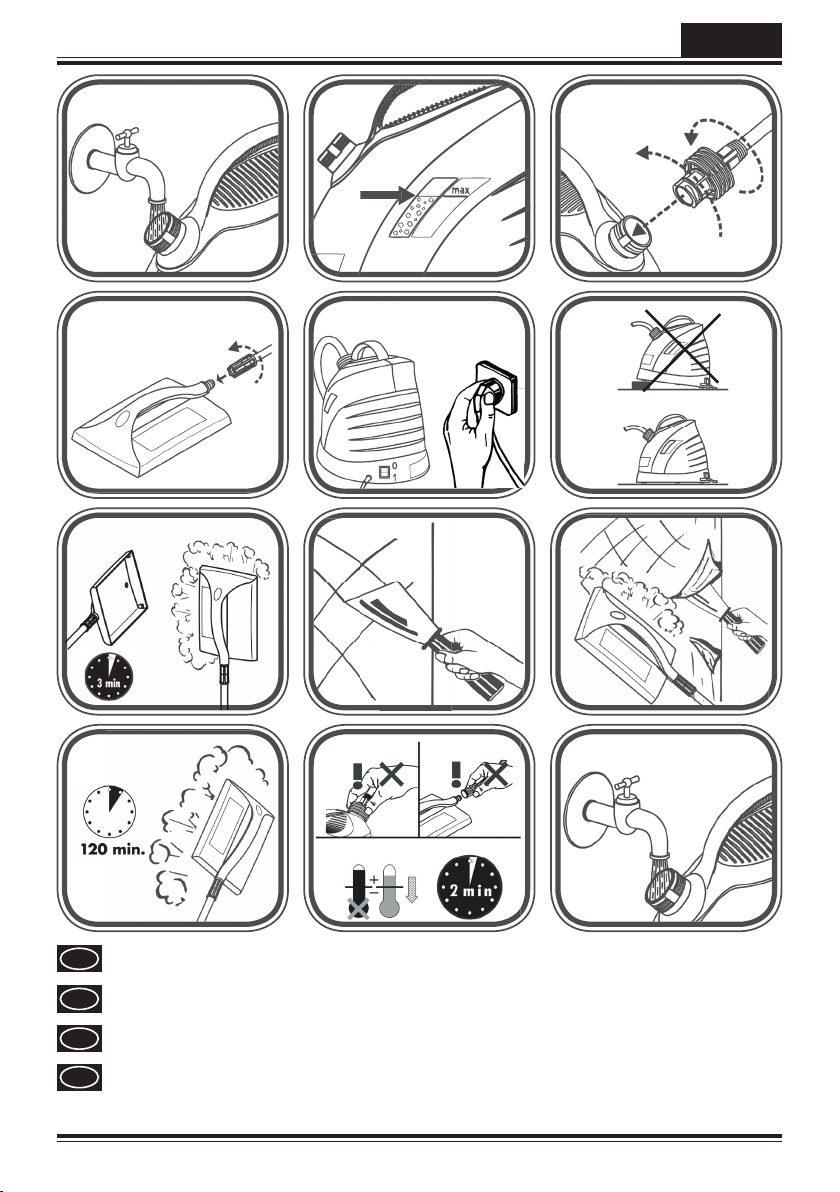

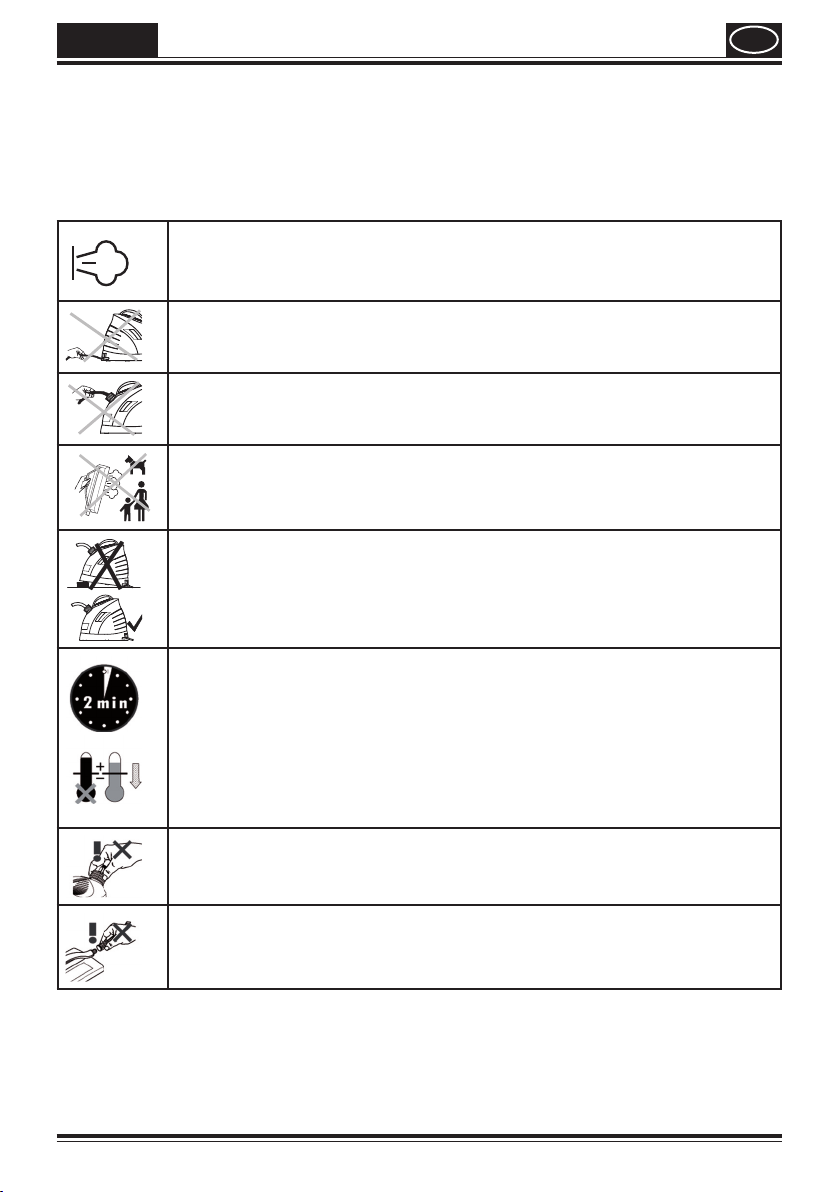

Explanation of symbols used

Discharged steam is hot

Do not pull on the power cord

Do not pull on the hose

Do not point steam plate towards people and pets

Position device upright and level

Allow device to cool for 2 minutes before refilling

Detach steam hose only from the device after the cooling phase

Detach steam hose from the steam plate only after the cooling phase

Intended use

The steam wallpaper remover is solely suited to remove wallpaper and for cleaning with

genuine Wagner special accessories.

To ensure long life of the steam wallpaper remover, clean your unit immediately and

thoroughly after each use.

Page 4

GB

6

DTS 5800

2 ans de

garantie

2 jaar

garantie

2 years

Guarantee

2 Jahre

Garantie

DTS 5800

D / GB/ F/ NL

Dampf-Tapetenablöser

Steam wallpaper stripper

Décolleuse du papier peint

Behangafstoom-apparaat

Scope of delivery

1 Basic unit

1

2

4

2 Steam hose

3 Steam plate

4 Operating instructions

3

Safety instructions

Attention

Never point the steam plate / bar at people, animals or at objects sensitive to

temperature.

Always ensure that the unit is standing securely in a horizontal position (on the

oor).

Do not stand on or place objects onto the unit or steam hose. Never over-twist or make

kinks in the steam hose, and never block the valve. Only carry the unit by its handle – and

in particular, never pull on the steam hose or mains cable.

Never submerge the unit in liquid. Every time the accessory is changed for, when lling /

relling and emptying or when the steam unit is not in use (including work pauses), pull

the mains plug out of the socket. Never overll the unit. Unplug the mains plug in the

event of overlling or a fault.

Do not use the device near combustible liquids and vapors.

Use only WAGNER original spare parts and accessories!

Caution! Danger of short-circuits! Cover sockets and switches and do not subject them

to steam.

Before connecting to the mains supply, be sure that the supply voltage is identical with the

value given on the rating plate.

When using an extension cable: max.10m long – the cable cross section must be at least 3 x 1 mm2.

Avoid damage! When working in the vicinity of wood / gypsum bases and coated materials

these can be impaired by heat or steam. Remedy: Use a heat / steam shield made of

cardboard or metal. The unit switches o automatically in case of overheating. After

approx.12 minutes, the unit switches itself back on automatically.

The steam time is approximately 120 minutes. Never leave a unit unattended that is on.

Keep the unit away from children and animals. Never let the container steam until it is

completely empty.

When working with hot steam (approx.100°), there is a risk of serious

scalding.

If you change position during use, be very careful because the steam unit,

hose and plate can be very hot.

Always wear suitable protective clothing / gloves.

Operate the unit only with pure water without agents or additives. Do not

switch the unit on when it is not lled with water.

Before loosening the screw connections always allow the unit cool down

for at least 2 minutes. Caution! Risk of scalding!

Heated water can leak from the steam plate during the heating-up phase. Hot

water can drip during overhead work.

Page 5

GB

7

DTS 5800

i

Regular descaling is key to your steamer functioning properly.

Descale the steam wallpaper remover after 10 – 20 hours of operation,

depending on the water hardness. Use a customary descaling agent

according to the manufacturer's speci cation or household vinegar.

Devices which are defective due to a lack of descaling are excluded

from the warranty!

Store emptied, upright and dry.

Technical data

Power source: 230 V ~ Power consumption: 2000 W

Steaming time: max. 120 min. Steaming power: 50 g/min.

Reservoir capacity: 5.8 l Hose length: 3.5 m

Weight of the steam plate: 310 g

Spare parts

Pos. Name Order No.

1 Steam hose 0419 222

2 Steam plate 0419 221

Special accessories

0339 700 Convert your DTS 5800 to a universalcleaning unit with WAGNER cleaning

kit

0338 702 Perforation roller – With it you can score and strip in one operation.

0235 701 Small steam plate

0419 348 Cap closure

1

2

0339 700 0338 702

0235 701

0419 348

Disposal instructions

The appliance and accessories should be recycled in an environmentally friendly

way. Do not dispose of the appliance with household waste. Support environmental

protection by taking the appliance to a local collection point or obtain information

from a specialist retailer..

Page 6

GB

8

DTS 5800

Important Note regarding Product Liability!

Due to an EC ordinance in e ect since 01.01.1990, the manufacturer is liable for his product

only if all parts originate from or were approved by the manufacturer and the devices

are assembled and operated correctly. The use of other accessories and spare parts can

partially or completely invalidate the liability.

2 years guarantee

The guarantee runs for two years, counting from the date of sale (sales slip). It covers

and is restricted to free-of-charge recti cation of faults which are demonstrably

attributable to the use of faulty materials in manufacture, or assembly errors; or freeof-charge replacement of the defective parts. The guarantee does not cover incorrect

use or commissioning or tting or repair work which is not stated in our operating

instructions. Wearing parts are also excluded from the guarantee. The guarantee

excludes commercial use. We expressly reserve the right to ful l the guarantee. The

guarantee expires if the tool is opened up by persons other than WAGNER service

personnel. Transport damage, maintenance work and loss and damage due to faulty

maintenance work are not covered by the guarantee. Under any guarantee claim,

there must be proof of purchase of the tool through submission of the original receipt.

Wherever legally possible, we exclude all liability for injury, damage or consequential

loss, especially if the tool has been used for a purpose other than that stated in the

operating instructions, commissioned or repaired other than in accordance with our

operating instructions or if repairs are performed by someone who is unquali ed.

We reserve the right to perform any repairs in excess of those stated in our operating

instructions. In case of guarantee or repair, please refer to your point of sale.

Warning

If the supply cord of this appliance is damaged,

it must only be replaced by a repair shop

appointed by the manufacturer, because

special purpose tools are required.

The wires in this mains lead are coloured in

accordance with the following code:

green/yellow = earth

blue = neutral brown = live

As the colours of the wires in the mains lead

of this appliance may not correspond with the

coloured markings identi ying the terminals

in your plug, proceed as follows:

The wire which is coloured green and

•

yellow must be connected to the terminal in the plug which is marked with the letter E or by

the earth symbol or coloured green or green and yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the

•

letter N or coloured black.

The wire which is coloured brown must be connected to the terminal which is marked with the

•

letter L or coloured brown.

Should the moulded plug have to be replaced, never re-use the defective plug or attempt to

•

plug it into a di erent 13 A socket. This could result in an electric shock.

Should it be necessary to exchange the fuse in the plug only use fuses approved by ASTA in

•

accordance with BS 1362. Only 13 Amp fuses may be used.

To ensure that the fuse and fuse carrier are correctly mounted please observe the provided

•

markings or colour coding in the plug.

After changing the fuse, always make sure that the fuse carrier is correctly inserted. With out the

•

fuse carrier, it is not permissible to use the plug.

The correct fuses and fuse carriers are available from your local electrical supplies stockist.

•

Page 7

DTS 5800

CE Konformitätserklärung

D

Wir erklären in alleiniger Verantwortung, dass dieses Produkt den folgenden

einschlägigen Bestimmungen entspricht:

2006/95/EG, 2004/108/EG, 2002/95/EG, 2002/96/EG

Angewandte harmonisierte Normen:

EN 60335-1:2006 , EN 60335-2-15:2008 , EN 55014-1:2009,

EN 55014-2 :2008, EN 61000-3-2:2009, EN 61000-3-3:2008

GB

CE Declaration of Conformity

We declare under sole responsibility that this product conforms

to the following relevant stipulations:

2006/95/EG, 2004/108/EG, 2002/95/EG, 2002/96/EG.

Applied harmonised norms:

EN 60335-1:2006 , EN 60335-2-15:2008 , EN 55014-1:2009,

EN 55014-2 :2008, EN 61000-3-2:2009, EN 61000-3-3:2008

CE Déclaration de conformité

F

Nous déclarons sous notre responsabilité que ce produit est

en conformité avec les réglementations suivantes :

2006/95/EG, 2004/108/EG, 2002/95/EG, 2002/96/EG.

Conforme aux normes et documents normalisés :

EN 60335-1:2006 , EN 60335-2-15:2008 , EN 55014-1:2009,

EN 55014-2 :2008, EN 61000-3-2:2009, EN 61000-3-3:2008

NL

CE Conformiteitsverklaring

Wij verklaren dat dit product voldoet aan de volgende normen:

2006/95/EG, 2004/108/EG, 2002/95/EG, 2002/96/EG.

En normatieve dokumenten:

EN 60335-1:2006 , EN 60335-2-15:2008 , EN 55014-1:2009,

EN 55014-2 :2008, EN 61000-3-2:2009, EN 61000-3-3:2008

i.V. T. Jeltsch i. V. J. Ulbrich

Vice President Development Manager

Product Strategy & Planning

Dokumentationsverantwortlicher

Responsible person for documents

Responsable de la documentation

Documentatieverantwoordelijke

J. Wagner GmbH Otto-Lilienthal-Str. 18 D-88677 Markdorf

17

Page 8

DTS 5800

NL

Wagner Spraytech Benelux B.V.

Zoonebaan 10

3542 EC Utrecht

+31/30/2 41 41 55 +31/30/2 41 17 87

AUS

Wagner Spraytech

Australia Pty. Ltd.,

14-16 Kevlar Close,

Braeside, VIC 3195/Australia

+61/3/95 87 20 00 +61/3/95 80 91 20

HR

Adresa servisa:

EL-ME-HO

Horvatinčićev put 2

10436 Rakov Potok/Kroatien

/ +385(-1)65 86 - 028

SK

Phobos Corporation Spol.r.o

Stanicna 6, 92700 Sala

Slowakei

+421/31/7 70 78 84 +421/31/7 70 22 42

PL

PUT Wagner Service

ul. E. Imieli 14

41-605 Swietochlowice

+48/32/2 45 06 19 +48/32/2 41 42 51

CH

J. Wagner AG

Industriestraße 22

9450 Altstätten

+41/71/7 57 22 11 +41/71/7 57 23 23

H

Magyarországi szerviz

Hondimpex KFT.

Kossuth L. u. 48-50

8060 Mór

+36(-22)/407 321 +36(-22)/407 852

DK/S

Wagner Spraytech

Scandinavia A/S

Helgeshøj Allé 28

DK-2630 Tåstrup

+45/43 27 18 18 +45/43 43 05 28

E

J. Wagner Spraytech Ibérica S.A.

Ctra. N-340, Km 1245,4

08750 Molins de Rei (Barcelona)

+34/93/6 80 00 28 +34/93/6 68 01 56

B

Wagner Spraytech Belgie

Veilinglaan 58

1861 Meise-Wolvertem

+32/2/2 69 46 75 +32/2/2 69 78 45

SLO

Adresa servisa:

GMA Elektromehanika d.o.o.

Cesta Andreja Bitenca 115,

Ljubljana 1000/Slowenien

+386(1)/583 83 04 +386(1)/518 38 03

GB

Wagner Spraytech (UK) Ltd.

The Coach House

2 Main Road

Middleton Cheney OX17 2ND

UK-Helpline 0844 335 0517

5 p per minute (landline)

D

J. Wagner GmbH

Otto-Lilienthal-Str. 18

D-88677 Markdorf

Hotline 0180/1000 227

+49/ (0) 75 44/ 505-1169

CZ

E-Coreco s.r.o.

Na Roudné 102

301 00 Plzen

+420 739 359 518 +420 227 077 364

F

Wagner France S.a.r.l.

Parc de Gutenberg - Bâtiment F8

8 voie la Cardon

91127 Palaiseau Cedex

0 825 011 111 0169 81 72 57

Part. No. 041 9850 02/2011_RS

© Copyright by J.Wagner GmbH

18

www.wagner-group.com

Irrtümer und Änderungen vorbehalten.

Not responsible for errors and changes.

Sous réserves d’erreurs et de modications.

Fouten en wijzigingen voorbehouden.

Loading...

Loading...