Page 1

Diaphragm Pumps

1150

Piston Pumps

EP2105

EP2205

EP2300

EP2300se

EP2400

EP2510

GP2605

GP2905

HVLP

CS5100

CS8100

CS9100

Maxum II Gun

Diaphragm Pumps

1150

Piston Pumps

EP2105

EP2205

EP2300

EP2300se

EP2400

EP2510

GP2605

GP2905

HVLP

CS5100

CS8100

CS9100

Maxum II Gun

Page 2

Page 3

Plus

ED1150 Airless Sprayer

Owner's Manual

Model no. 0294059

Form no. 0294968C

1

© 1996 Wagner Spray Tech. All rights reserved.

Page 4

CAUTION

THIS UNIT IS PROVIDED WITH A THERMALLY PROTECTED AUTOMATIC RESET. IF AN OVERLOAD

OCCURS THE THERMALLY PROTECTED AUTOMATIC RESET DISCONNECTS THE MOTOR FROM THE

POWER SUPPLY.

• Motor will restart without warning when protector automatically resets.

• Always disconnect motor from power supply before working on equipment.

• When thermally protected automatic reset disconnects the motor from the power supply, relieve pressure by

turning priming valve to “prime” .

• Turn ON-OFF switch to OFF.

CAUTION: THE CAUSE OF THE OVERLOAD SHOULD BE CORRECTED BEFORE RESTARTING.

CAUTION

Be sure to read, understand and observe all safety

precautions and warnings. See pages 3 thru 6.

Read product labels—follow manufacturer’s recommendations

All procedures and recommendations presented in this manual are based on information which SprayTECH believes

to be reliable. However, such procedures and recommendations are to be implemented and used by persons reading this

manual at their own discretion and risk.

Label directions, procedures and precautions set forth by the manufacturers of finishing products are to be considered

the best source of information on those products. No attempt has been made in this manual to provide complete data on

all the various materials which may be used in your airless sprayer.

Application procedures are presented here as suggestions only, and are not to be construed as representations or

warranties as to safety, performance, results or fitness for any intended use ot the various types of products mentioned.

BEFORE YOU CALL

Have the following information available:

Model #____________

Serial #____________

Purchase Date________________________

© 1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

2

Page 5

SAFETY PRECAUTIONS

This manual contains information which must be read and understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular attention and make certain to heed the safeguard.

WARNING

Important safety information indicates a hazard which may cause serious injury or loss of life.

CAUTION

Important information that tells how to prevent damage to equipment or how to avoid causes of minor injuries.

Note: Gives important information which should be given special attention.

IMPORTANT

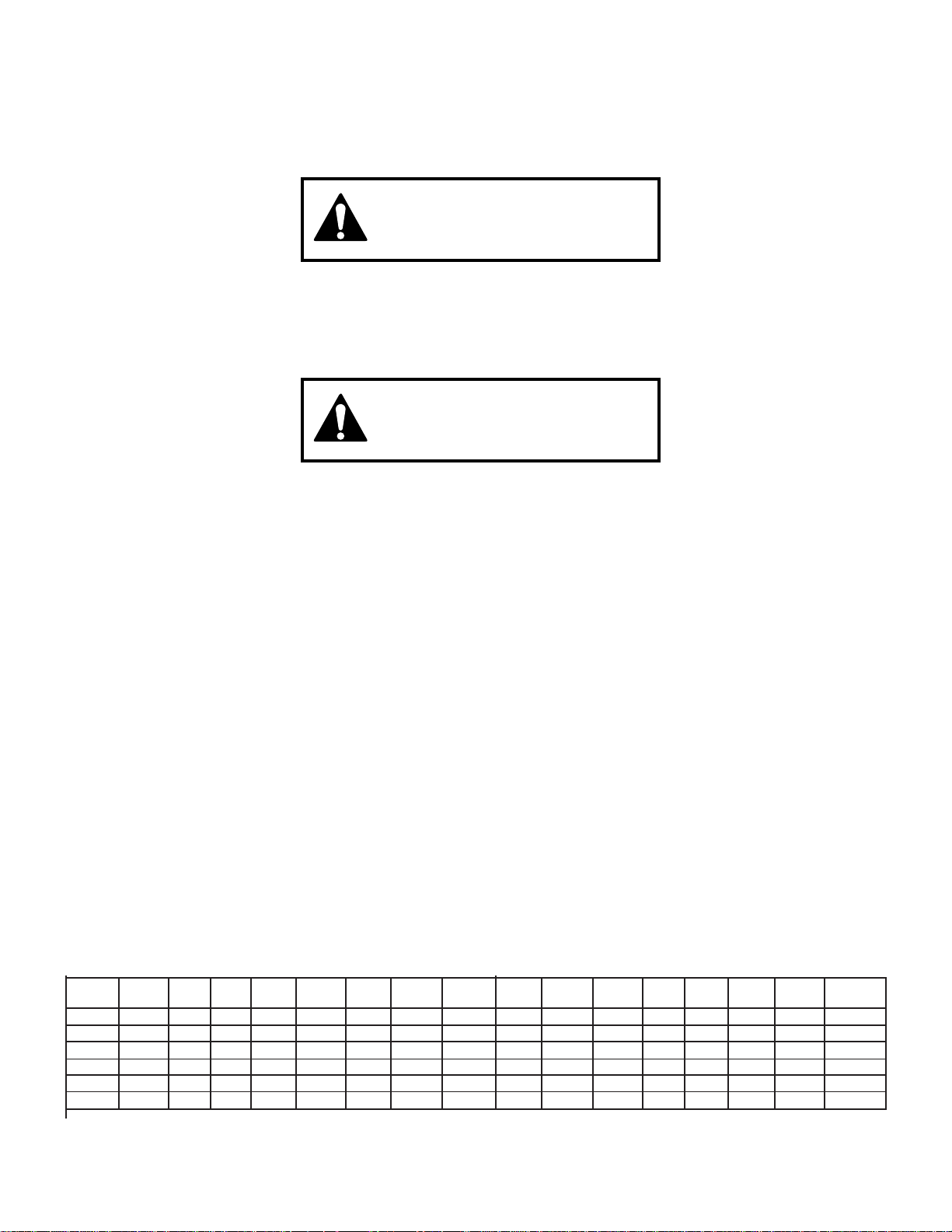

EXTENSION CORD SELECTION

If an extension cord is used, make sure it is of the three-conductor type with NEMA connectors so a continuous grounding circuit is

provided from tool to power circuit receptacle. Also, be sure that the conductor size is large enough to prevent excessive voltage drop

which will cause loss of power. A table of recommended extension cord sizes will be found below.

For nameplate ampere ratings which are between those given, use the extension cord recommended for the NEXT HIGHER ampere

rating.

If an extension cord is to be used outdoors it must be marked with the suffix W-A following the cord type designation. For example —

SJTW-A to indicate it is acceptable for outdoor use.

RECOMMENDED EXTENSION CORD SIZES FROM SERVICE ENTRANCE TO PUMP MOTOR.

NAMEPLATE AMPERE RATING

Cord

Lgth. 0 to 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

25Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12

50Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12I

25Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12

100Ft. 18 18 18 16 16 16 16 16 14 14 14 14 14 14 12 12

125Ft. 18 18 16 16 16 14 14 14 14 14 14 12 12 12 12 12

150Ft. 18 16 16 16 14 14 14 14 14 12 12 12 12 12 12 12

3

Page 6

WARNING

HAZARD

Injection Injury - A high pressure stream of paint pro-

duced by this equipment can pierce the skin and

underlying tissues, leading to serious injury and possible amputation.

PREVENTION

• Maximum operating range of the gun - 3000 PSI fluid

pressure.

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to come in contact

with the fluid stream. DO NOT come in contact with a

fluid stream created by a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut fluid pump off and

release all pressure before servicing, cleaning tip guard,

changing tips, or leaving unattended. Simply turning off

the electrical power will not release pressure in the

system. The Prime Spray Valve must be turned to the

position to relieve the pressure.

• ALWAYS have the tip guard in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

DO NOT TREAT AS A SIMPLE CUT! Injectioncan lead to amputation. See a physician immediately.

NOTE TO PHYSICIAN: Injection into the skin

is a traumatic injury. It is important to treat the

injury surgically as soon as possible. DO

NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings

injected directly into the blood stream. Consultation with a plastic surgeon or reconstructive hand surgeon may be advisable.

ALWAYS remove spray tip before flushing or cleaning

•

the system.

• Paint hose can develop leaks from wear, kinking, abuse,

etc. A leak is capable of injecting material into the skin.

The paint hose should be inspected before each use.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• All accessories must be rated at or above 3000 P.S.I.

(Includes spray tips, guns, extensions, and hose).

• In case of skin injection see physician immediately.

4

Page 7

WARNING

HAZARD PREVENTION

Explosion or fire - Solvent and paint fumes can explode or

ignite causing property damage and/or severe injury.

• Exhaust and fresh air introduction must be provided to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electricity sparks

open flames such as pilot lights, hot objects such as

cigarettes, and sparks from connecting and disconnecting power cords and working light switches.

• Fire extinguishing equipment must be present and in

working order.

• Keep the pump away from spray area to avoid solvent

and paint fumes. The pump contains arcing parts which

emit sparks.

• High velocity flow of material through equipment may

develop static electricity. The equipment being used,

and objects in and around the spray area, must be

properly grounded to prevent static discharge and sparks.

• Use only conductive or grounded high pressure fluid

hoses for airless applications. Be sure that gun is

grounded through hose connections.

• Power cord must be connected to a grounded circuit.

• Follow the material and solvent manufacturer's safety

precautions and warnings.

• WHEN FLUSHING EQUIPMENT use lowest possible

pressure.

5

Page 8

WARNING

HAZARD

Explosion hazard incompatible materials - May cause

property damage or severe injury.

Hazardous vapors - Paints, solvents, insecticides, and

other materials may be harmful if inhaled causing severe nausea, fainting, or poisoning.

PREVENTION

• Halogenated hydrocarbon solvents such as methylene

chloride and 1,1,1 - Trichlorethane are not compatible

with aluminum and may cause an explosion. If unsure of

a material’s compatibility with aluminum, contact your

coatings supplier.

• Some spray guns and accessories cannot be used with

halogenated hydrocarbon solvents. Be certain of compatibility before use with halogenated hydrocarbon solvents.

• The SprayTECH ED1150 pump is not compatible for

use with halogenated hydrocarbon solvents. The

SprayTECH G-05, G-09, and G-10 guns must NOT be

used with halogenated hydrocarbon solvents.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to insure that it will provide the necessary protection

against the inhalation of harmful vapors.

General - May cause property damage or severe injury.

• Read all instructions and safety precautions before

operating.

• Comply with all appropriate local, state and national

codes governing ventilation, fire prevention and

operation.

• The United States Government Safety Standards have

been adopted under Occupational Safety and Health

Act. These standards, particularly the General Standards, Part 1910 and construction Standard, Part 1926,

should be consulted.

• This high pressure airless pump is designed to be used

with authorized SprayTECH parts only. When using this

pump with parts that do not comply with the minimum

specifications and safety devices of the pump manufacturer, the user assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover or damage or movement of

couplings. If any of these conditions exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another grounded hose.

• All hoses, swivels, guns, and accessories used with this

unit must be pressure rated at or above 3000 PSI.

6

Page 9

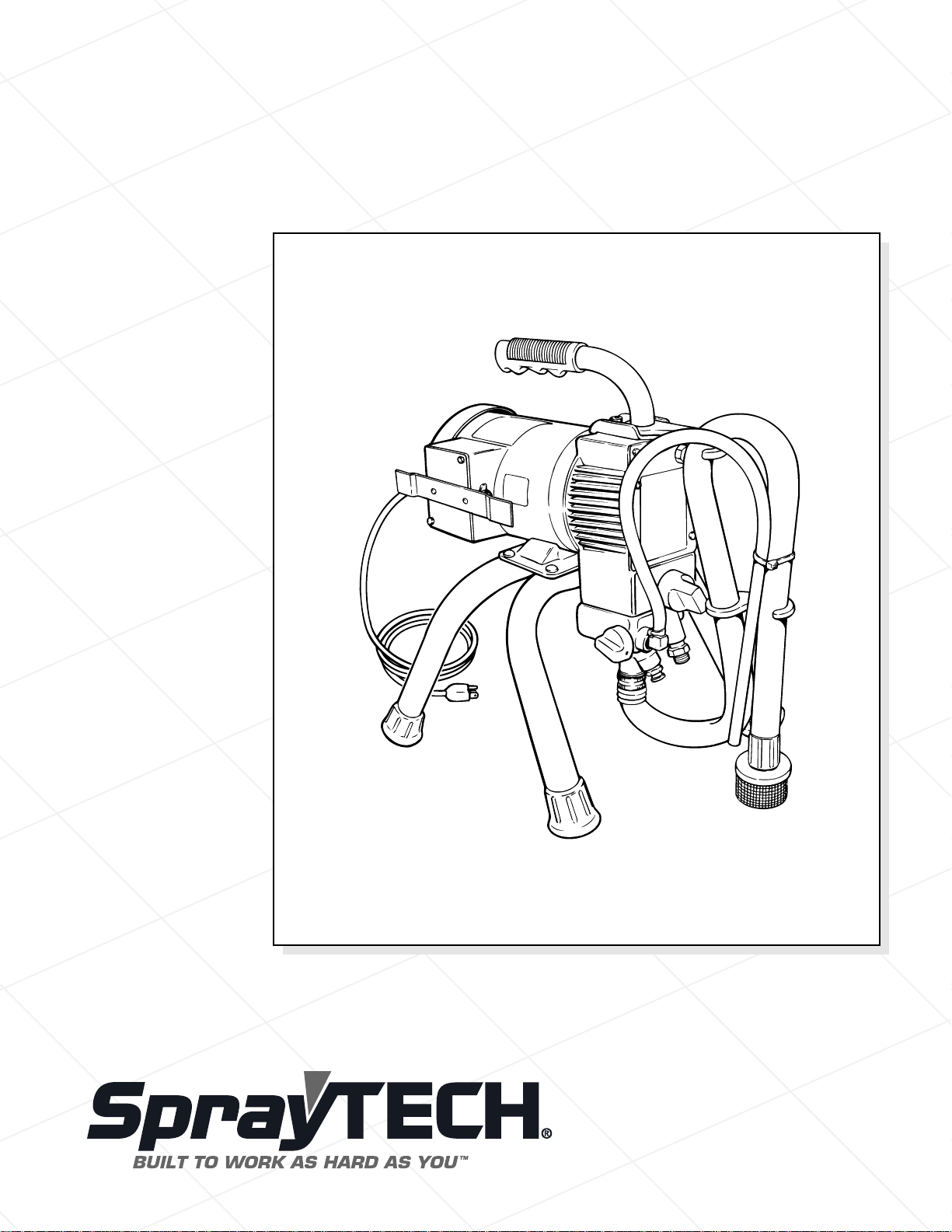

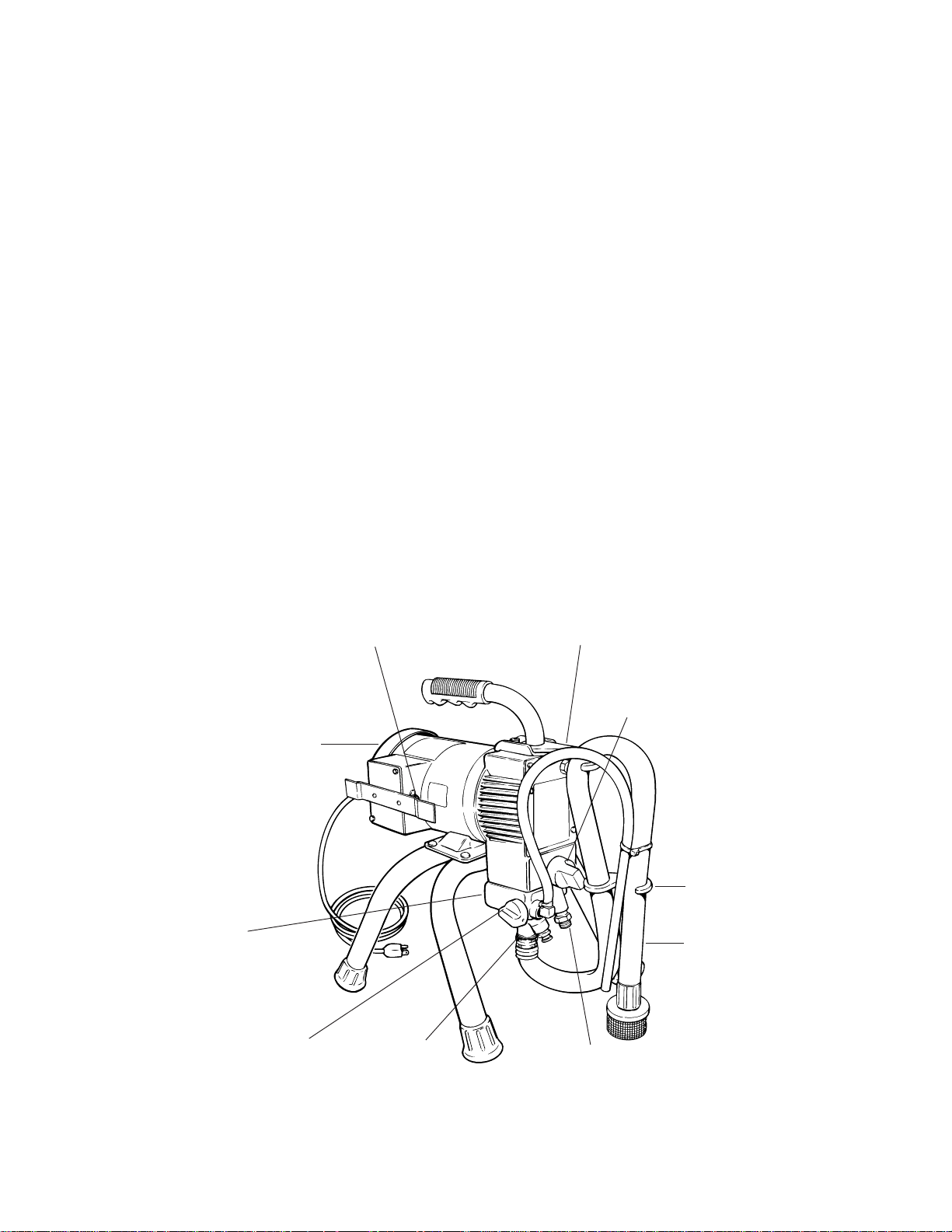

GENERAL DESCRIPTION

Be sure to read the IMPORTANT SAFETY INFORMATION on pages 3 thru 6 before using this sprayer.

Your SprayTECH sprayer is a powerful, easy to operate

and easy to service machine. Since it operates on the

airless principle, no air compressor is needed.

Power is supplied by a 3/4 horsepower, TEFC electric

motor. The flow rate is 0 to .50 gallons a minute. The

pressure is adjustable from 0 to 3000 pounds per square

inch.

COMPONENT FUNCTIONS

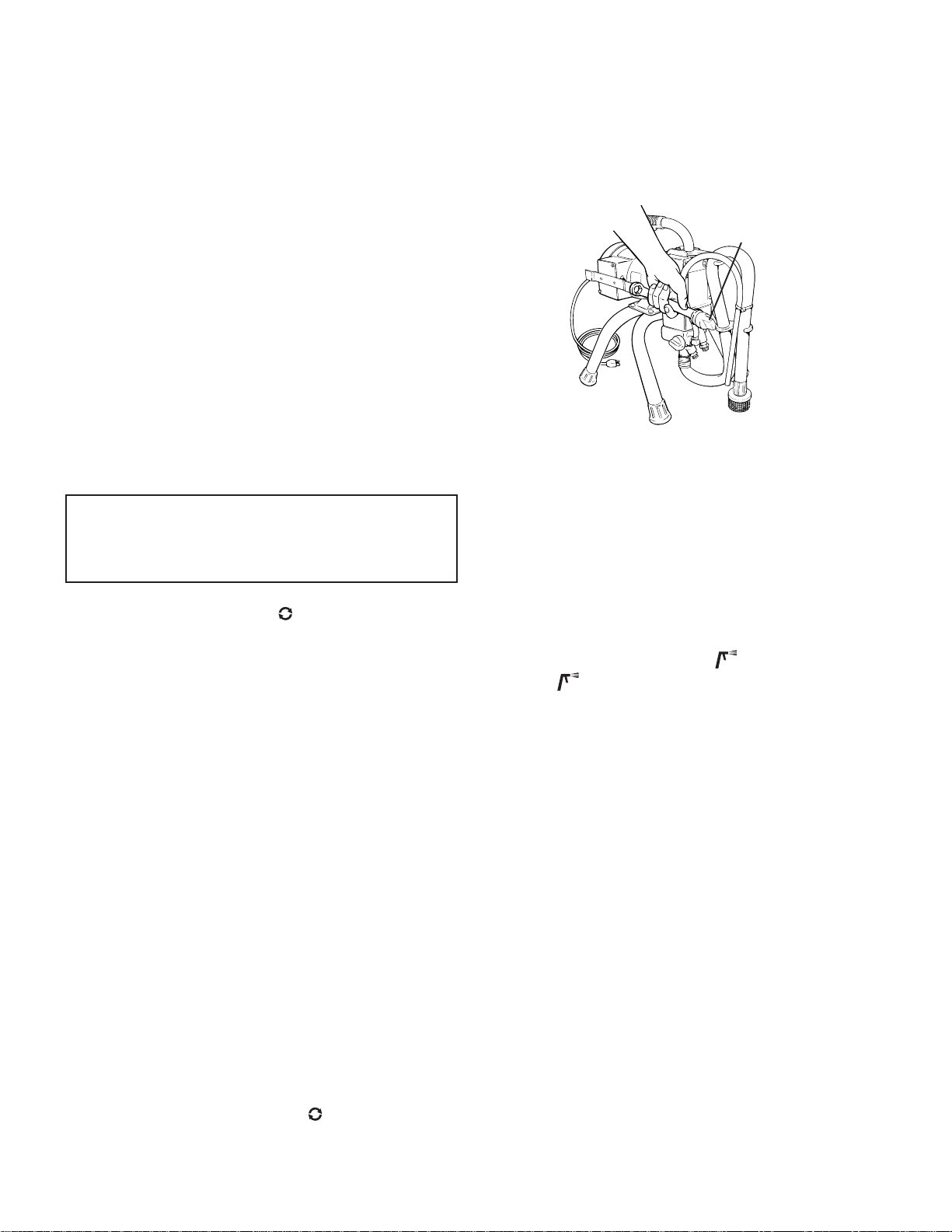

See Figure 1 for component locations.

Power for the sprayer is supplied by a 3/4 horsepower,

TEFC electric motor (see Figure 1). It is located at the rear

of the sprayer and is connected to the hydraulic pump. The

motor is furnished with a 3-wire electric cord. The third wire

(ground) should never be cut off. Any extension cords used

must also be 3-wire and 3-wire plug that will plug into a 3wire grounded electrical outlet. Do not use 2-wire extension

cords. Shorter extension cords will assure maximum

electrical power for proper operation, use more paint hose,

not more extension cords. Refer to page 3 for extension

cord selection.

Cords and extension cords should be protected from

vehicle traffic and sharp cutting edges or objects. Any worn

or damaged cords should be replaced promptly.

The motor has an automatic overload protective switch.

This switch disconnects the motor from electrical supply if

overload occurs. The motor can be started again after 5

minutes. The cause of the overload should be corrected

before restarting.

The motor should always be kept clean and dry. Paint acts

as an insulator. Therefore, too much paint on the motor will

cause it to overheat.

ON-OFF SWITCH

The ON-OFF switch is located on the side of the electric

motor (see Figure 1).

Paint

Pump

Motor

Priming

Knob

On/Off Switch

Inlet

Valve

Hydraulic Pump

Pressure

Control

Knob

Hook

Suction Set

Outlet

Valve

Figure 1.-Sprayer Component Locations

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

7

Page 10

HYDRAULIC PUMP

For the hydraulic pump location, see Figure 1. It operates

as follows: The electric motor is connected to the eccentric

bearing, which is inside the hydraulic pump. The piston

rests on the bearing. The movement of the bearing causes

the piston to move up and down. When the trigger on the

gun is pulled back, this action moves the pump diaphragm.

Diaphragm movement forces the paint through the outlet

valve and out the paint hose and spray gun. The paint goes

through the spray gun at high pressure, causing it to breakup (atomize) into fine particles. This gives a smooth and

even paint coating. Pressure and delivery rate are regulated by the pressure control knob and spray tip size.

PRESSURE CONTROL KNOB

The pressure control knob controls the pressure control

valve. It is manually operated. It is located on the front of the

hydraulic pump near the bottom of the sprayer (see Figure

1). When the knob is turned cIockwise, more hydraulic

pressure is directed toward the diaphragm. When the knob

is turned counterclockwise, less hydraulic pressure is

directed toward the diaphragm. The pressure control knob

regulates the pressure on the diaphragm from 0 PSI when

turned fully counterclockwise to 3000 PSI when turned

fully clockwise.

NOTE

DO NOT START PUMP UNDER PRESSURE. REDUCE PRESSURE TO ZERO BY TURNING PRIMING

KNOB TO PRIME POSITION . FAILURE TO DO SO

WILL DECREASE MOTOR LIFE.

PAINT PUMP

The paint pump is located below the hydraulic pump (see

Figure 1). The two pumps are bolted together by four

socket head capscrews. The diaphragm separates the

pumps. The paint pump operates as follows: The piston in

the hydraulic pump forces hydraulic oil toward and away

from the diaphragm. This action moves the diaphragm up

and down. Diaphragm movement forces paint through the

spray gun at high pressure.

INLET V ALVE

The inlet valve is located on bottom of the paint pump at the

front of the sprayer (see Figure 1). The suction nut end of

the suction tube screws onto this valve. The valve operates

automatically. It controls the flow of paint from the paint

container into the paint pump. It does this by opening up

when the piston and diaphragm are on the downstroke,

allowing a “gulp” of paint to enter the paint pump. The inlet

valve then closes when the piston and diaphragm are on

the upstroke. This closing prevents paint from going back

through the inlet valve into the paint container (inlet valve

acts as a check valve). Instead, the paint is directed out the

spray hose and spray gun by the outlet valve.

The inlet valve is a one-piece configuration. It contains a

device to dislodge a stuck valve by simply pushing the

plunger button on the side of the valve body.

DIAPHRAGM

The diaphragm is the heart of the sprayer. In addition to

pumping paint, it also serves as a gasket between the

hydraulic pump and paint pump. As such, it prevents the

paint and oil from mixing. The sprayer operates at 1725

strokes per minute. This means that the diaphragm forces

a “gulp” of paint out of the spray gun 1725 times every

minute.

An insert fits in the inlet hole on the underside of the paint

pump. This insert reduces wear by protecting the diaphragm from the metal edges of the inlet hole.

The diaphragm is made of flexible, tough plastic. It is not

harmed by common solvents.

NOTE

The diaphragm should be replaced whenever the paint

pump is removed. Using the old diaphragm will result in

limited diaphragm life and fluid leaks.

CAUTION

The plunger button should never be pushed during

operation as this may cause premature failure of the

inlet valve.

OUTLET VALVE

The outlet valve is also located on bottom of the paint pump

at the front of the sprayer (see Figure 1). It operates

automatically, serving as a check valve. When the priming

valve is on (spray) position, the outlet valve directs the

flow of paint out into the spray hose and into the spray gun.

When the diaphragm and piston act to “gulp” more paint,

the outlet valve closes. The closed valve prevents (checks)

paint in the spray hose and spray gun from returning to the

paint pump.

8

Page 11

The outlet valve also contains a device to dislodge a stuck

valve. Simply push the plunger button located on the side

of the paint block before starting the pump.

CAUTION

The plunger button should never be pushed during

operation as this may cause premature failure of the

outlet valve.

You can see that the inlet valve and outlet valve work in

harmony with the diaphragm and piston. As a" team" they

pump paint.

PRIMING KNOB

The priming knob controls the priming valve. It is located on

the right front of the paint pump at the front of the sprayer

(see Figure 1). It can be manually turned to the or

position. When on (prime) it serves to rid the sprayer of

air by directing the initial air volume of the inlet valve back

into the paint container. It will continue to do this until paint

comes through and it is manually switched to the

(spray) position. It then directs the paint out the outlet fitting

to the spray hose and on to the spray gun.

The priming valve also serves to relieve pressure on the

system during shutdown and cleanup. The pressure is

relieved by turning the priming knob to .

SUCTION SET

The complete suction set consists of (1) the suction tube

with a suction filter on one end and (2) the return tube (see

Figure 1). Both suction and return tube are chemical and oil

resistant. One end of the suction tube and one end of the

return tube screw onto the paint pump (see Figure 1).

These two fittings need to be tight enough to keep air from

being drawn in. The other two ends go in the paint con-

tainer. When the priming knob is turned to (prime), paint

is drawn up the suction tube into the paint pump. The paint

pump then routes the paint through the return tube back to

the paint container. This primes the painting system. When

the priming knob is turned to (spray), flow is shut off

through the return tube and the sprayer can spray.

NOTE:

DO NOT USE THE SPRAYER UNLESS

THE SUCTION FILTER IS IN PLACE!

HIGH PRESSURE OUTLET FITTING

The high pressure outlet fitting is located on the front side

of the paint pump (see Figure 1). The paint hose is connected to it. The outlet fitting connections must be very tight.

Otherwise, fluid will leak out the connections when pressure builds up in the system.

PAINT HOSE

The high pressure paint hose (see Figure 1) has permanently swaged fittings. It is grounded with a static conductor. This conductor serves to “drain off” any static charge,

preventing shock. The conductor is sandwiched between

two insulating sheaths which resist breaking and abrasion.

CAUTION

CHANGE THE POSTION OF THE PRIMING KNOB

SLOWLY. THIS WILL PREVENT BREAKING ANY VALVE

PARTS. ALWAYS REDUCE THE PRESSURE WITH

THE PRESSURE CONTROL KNOB BEFORE TURNING

THE PRIMING KNOB.

WARNING

DO NOT IMMERSE THE PAINT HOSE IN ANY

SOLVENTS.

The paint hose and the electric cord should always be

protected from vehicle traffic and sharp cutting edges

or objects. If the paint hose is cut, worn, or damaged it

must be replaced with another high pressure grounded

hose.

The paint hose can develop leaks from wear, kinking,

abuse, etc. A leak is capable of injecting spray material

into the skin. Therefore, the paint hose should be

inspected periodically. Never repair a paint hose —

replace it with another high pressure grounded hose.

9

Page 12

SPRAY GUN

The spray gun is connected to the sprayer by the paint

hose. The gun will spray when the unit is running, the

suction and return tubes are in the spray material, the

priming knob is turned to the pressure control valve

is adjusted, and the spray gun trigger is pulled back.

WARNING

THE SPRAYTECH ED1150 PUMP IS NOT COMPATIBLE

FOR USE WITH HALOGENATED HYDROCARBON SOLVENTS. THE WAGNER G-05, G-09 AND G-10 GUNS

MUST NOT BE USED WITH HALOGENATED HYDROCARBON SOLVENTS.

Spray Pattern

Width = 2 x Spray Pattern Width Number

e.g. 0153319 = 2 X 3 = 6” Spray Pattern 1 Foot

from Work

0153419= 2 x 4 = 8” Spray Pattern 1 Foot

from Work

See Figure 2 for example of a spray pattern.

WIDTH OF SPRAY

PATTERN IN INCHES

ASSEMBLY OF A NEW SPRAYER

1. Screw the return fitting into the elbow on the front side

of the paint pump. Both fittings should be hand tight only,

but tight enough to prevent air from being drawn in.

2. Screw the paint hose, wrench tight, onto the outlet fitting

on the front side of the paint pump.

SPRAY GUN TIP SELECTION

Select a spray gun tip as follows:

LACQUERS &

STAINS ENAMELS LATEX

0153315 0153317 0153319

0153415 0153417 0153419

1'

Figure 2.-Example of Spray Pattern

ASSEMBLY OF SPRAY GUN

NOTE

Follow the Assembly Instructions that came with

your gun if it is a brand other than Wagner.

After you have selected the proper spray tip, assemble it

onto the spray gun as explained in Steps 1 through 4.

1. lnsert the spray tip and sealing washer into the tip guard

so that the flats of the spray tip are seated perfectly into

the tip guard. See Figure 3.

2. Hand tighten the tip nut onto the diffuser.

SPRAY GUN

DIFFUSER

SEALING WASHER

SPRAY TIP

TIP NUT

Example 0153 3 19

0153 3 19

Prefix Spray Pattern Size of Spray Tip

Width In Degrees Holes In Inches

(In this case, 30°) (In this case,.019")

TIP GUARD

Figure 3.-Spray Tip Assembly Sequence.

10

Page 13

3. Loosen the tip nut slightly. Turn the tip guard about

1/16 turn counterclockwise from desired spray angle.

See Figure 4.

TIGHTEN WITH

WRENCH FROM

THIS POINT

DESIRED SPRAY

ANGLE

TRIGGER SAFETY

LEVER

LOCKED ON

(CLEANING ONLY)

SPRAY GUN

HOUSING

TENSION NUT

LOCKED OFF

(WILL NOT

SPRAY)

SEALING

WASHER

FILTER

UNLOCKED

(SPRAY AS DESIRED)

Figure 4.- Spray Gun Tip Guard Postion Before

Tightening.

4. Tighten tip nut. The tip guard should now be in the proper

position. See Figure 5.

TIP GUARD

TIP NUT

Figure 5.-Tightening Spray Gun Tip.

HANDLE

CONNECT SPRAY GUN HOSE

Figure 6.-Spray Gun Filter Assembly and Trigger Safety

Lever position.

6. Test the trigger tension by unlocking the trigger safety

lever and pulling back trigger. To increase tension, turn

tension nut (see Figure 6) clockwise. To decrease

trigger tension, turn tension nut counterclockwise. After

adjusting trigger tension, lock trigger safety lock in

locked off position as shown in Figure 6.

7. Connect the paint hose to the spray gun. This connection should be tight.

PAINT STRAINING AND THINNING

NOTE

Do not try to change the angle of the tip guard

unless the tip nut has been loosened.

5. Put the spray gun filter on the gun as shown in Figure 6.

First remove the handle from the spray gun housing.

Stick the small end of the filter firmly in the spray gun

housing. Then screw the handle back on. See Page 26

for Optional Filters.

When a container of paint is exposed to the air for a period

of time, “skin” may form on top. This “skin” should be

removed. If necessary, the paint should be strained

through a strainer.

Under normal conditions, paints used with this airless

sprayer do not have to be thinned. However, it is possible

that you may use paint that is too thick to be sprayed. In this

case you will have to thin the paint.

When thinning paint to spraying consistency (viscosity),

use the right thinner — water for latex paints, mineral spirits

for oil base paints (or, see the instructions on the paint

container for proper thinner).

11

Page 14

OPERATION

START UP PROCEDURE

1. CHECK TO BE SURE THE MOTOR SWITCH IS

OFF— play it safe.

2. LOCK SPRAY GUN—The spray gun will not spray

when the trigger lock is locked.

a few minutes. It is sometimes helpful to turn ON-OFF

switch ON and OFF to assit in bleeding.

B. Now turn pressure control knob clockwise to prime

the pump. When sprayer is primed, paint will come out

of the return tube. This may take 2-3 minutes. If

sprayer does prime, turn pressure control knob

counterclockwise and repeat procedure.

3. CHECK THE HYDRAULIC OIL— The sprayerer was

shipped with the proper amount of hydraulic oil in the

hydraulic pump. However, the oil should be checked

before starting. Look at oil level in oil fill port. When the

unit is level, oil level should be at bottom of fill port. Use

only hydraulaic oil part number 0088009 - 1 quart or

part number 0088010 - 1 gallon. Oil capacity is 19

ounces.

4. CHECK FITTINGS—Check to see that these fittings

are tight: inlet valve, return tube, outlet valve, outlet

fitting, high pressure airless hose, spray gun and allen

head paint pump screws.

NOTE

DO NOT TIGHTEN PAINT PUMP SCREWS TO MORE

THAN 15 FOOT-POUNDS TORQUE (180 INCHPOUNDS)

5. TURN PRIMING KNOB TO (PRIME) POSITION— A

will appear in the priming knob window. The sprayer

must be primed before it will spray.

6. Make sure the suction tube is immersed in paint.

PRESSURE CONTROL

VALVE KNOB

Figure 7.-Bleeding Air Out of the Sprayer.

You will also have to follow the above bleeding procedure when you change hydraulic oil, if you remove the

paint pump or work on the hydraulic housing, or if the

sprayer loses prime due to rough handling.

11. MAKE SURE PRESSURE IS REDUCED BY TURNING THE PRESSURE CONTROL KNOB COUNTER

CLOCKWlSE.

12. TURN PRIMING KNOB TO (SPRAY) POSITION

— will appear in the knob window.

7. PLUG ELECTRIC CORD INTO OUTLET— Electric

service must be 115 VAC, 60 Hz. REMEMBER: More

than 100 feet of extension cord is not recommended.

Use additional airless paint hose, not more electric

cord.

8. TURN THE MOTOR SWITCH ON.

9. PRIME THE PUMP—Let the paint circulate until no air

bubbles show in the paint (aboutt 2-3 minutes). Turn

the pressure control valve at least 1/2 turn clockwise

from fully decreased postion to prime the pump with

paint.

10. BLEED THE AIR—If unit fails to prime when started up,

it may be necessary to bleed (vent) the air out of the

hydraulic system. Bleed the air as follows:

A. Turn pressure control knob all the way counter-

clockwise, turn priming knob to , and let sprayer run

© 1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

13. UNLOCK SPRAY GUN TRIGGER — When the trigger

is unlocked, the trigger safety lever will point in the

same direction as the trigger (see Figure 6).

14. ADJUST PRESSURE — Adjust the pressure control

knob on the sprayer to lowest pressure needed for good

operation. Pull spray gun trigger back and spray a test

area to check spray pattern.

15. YOU ARE NOW READY TO SPRAY — See “SPRAY

PAINTING” for tips on how to spray.

SPRAY PAINTING

You can learn to spray paint as easy as you can learn to

paint with a brush or roller. You can get a professional

looking job in a safe manner by following the spray painting

tips below.

1. Heed all WARNINGS and CAUTIONS that are listed on

pages 2 thru 6 at the front of this manual. Take time out

now to reread them.

12

Page 15

2. Avoid sharp bending and kinking of the paint hose. The

paint hose and electric cord should be kept clear of traffic

and sharp cutting edges or objects.

3. Use the lowest pressure possible when spraying. Too

much pressure shortens equipment life. It also causes

faster than normal wear on the spray tip.

4. Determine the best spraying distance (distance from

spray tip on the spray gun to the work). If the spray gun

is held too close to the work, you will have paint buildup

that will cause sags and runs. If the spray gun is held too

far from the work, “fogging” will result.

The correct distance should be about 10 to 12 inches.

Keep this distance for the entire length of the stroke. Of

course, the shape of some work surfaces will not permit

this. However, the same spraying distance should be

kept whenever possible.

6. Keep the spray gun perpendicular to the work as shown

in Figure 10.

APPROXIMATELY

10 TO 12 INCHES

RIGHT

WAY

WRONG

WAY

Figure 10.-Right and Wrong ways to Hold Spray Gun

Toward Work.

5. Do not move the spray gun by flexing your wrist. The

result of this is shown in Figure 8. Rather, move the

spray gun with a smooth stroke of the entire arm and

shoulder. Maintain the same arm speed all the way

through the stroke. The result of this is shown in Figure

9.

LIGHT

COAT

HERE

HEAVY

COAT

HERE

WRONG

WAY TO SPRAY

LIGHT

COAT

HERE

Figure 8.-Result of Flexing Wrist While Spraying.

EVEN COAT ON WORK THROUGH

STROKE MOVEMENT OF ENTIRE ARM

7. The spray gun should be triggered (turned off and on) on

each stroke. This will save paint and avoid paint buildup

at the end of the stroke. However, do not trigger during

the middle of a stroke. This will result in an uneven spray

and splotchy work. See Figure 11 for proper triggering

on a left-to-right stroke. Reverse for a right-to-left stroke.

8. Move the spray gun at a rate of speed that is comfortable

for you. If you have to move your arm too fast in order

to prevent excessive paint buildup, either (1) lower the

pressure by turning the pressure control knob counterclockwise, or (2) use a spray tip with a smaller hole. If

you have to move your arm too slow in order to get a

good coating, either (1) raise the pressure by turning the

pressure control knob clockwise, or (2) use a spray tip

with a larger hole. You should always keep the spray

gun moving when making a stroke. Slowing down in one

place will cause sags or runs.

APPROXIMATELY

10 TO 12 INCHES

WORK

APPROXIMATELY

10 TO 12 INCHES

WORKING

DISTANCE

STEADY

RIGHT

ARM

SPEED

WAY TO SPRAY

Figure 9.-Result of Smooth Arm Stroke and Steady,

Even Speed While Spraying

EVEN

STEADY

PULL

TRIGGER

STROKE

RELEASE

TRIGGER

Figure11 -Proper Way to Trigger Spray Gun.

9. Overlap each stroke by about 40% to 50%. The overlap

will insure a paint coating that is uniform across the work.

One way to get good overlap is to point the spray

gun at the edge of the last stroke.

13

Page 16

SPRAY TIP PLUGGING

The spray tip can be plugged by foreign matter and “skin”

in the paint. Excessively large paint pigments can also plug

the tip. If the tip becomes plugged while spraying, proceed

as follows:

1. Lock spray gun trigger OFF so that the spray gun can't

spray.

To remove and replace the filter, proceed as follows:

1. Lock spray gun trigger OFF.

2. Turn sprayer ON-OFF switch OFF.

TOP OF FILTER

2. Turn sprayer ON/OFF switch OFF.

3. Reduce pressure by turning the pressure control knob

counterclockwise. Turn priming valve knob to to

bleed pressurized paint in paint hose and spray gun

back into paint container.

4. Remove tip guard assembly with spray tip and sealing

washer from spray gun as shown in Figure 3, page 10.

5. Remove spray tip and sealing washer from tip guard

assembly.

6. Soak tip guard assembly, spray tip, and sealing washer

in solvent. Then clean them with a stiff brush. A toothpick, wood chip, or sharpened matchstick can be used

to clean the spray tip hole.

CAUTION

Never clean the spray tip hole with a wire or metal

object as these items will cause damage.

PIN HOLE

Figure 12.-Example of Pinhole in Spray Gun Filter.

3. Reduce pressure by turning the pressure control knob

counterclockwise. Turn priming knob to . This will

drain the pressurized paint in the paint hose and spray

gun back into the paint container.

4. Remove the paint hose from the spray gun as shown in

Figure 13.

5. Remove the handle from the spray gun.

6. Remove the old filter. Use a new filter, or clean the old

filter.

7. Stick small end of new or cleaned filter into spray gun

housing.

8. Screw handle back on spray gun.

9. Connect paint hose to spray gun.

7. Reassemble the spray tip, sealing washer, and tip guard

assembly onto the spray gun the same way you did

when you assembled the unit. See “ASSEMBLY OF

SPRAY GUN”, page 10.

SPRAY GUN FILTER CLEANING AND CHANGING

Clean or change the spray gun filter at least once per

painting day, some types of latex paint may require filter

cleaning or changing more often.

The filter is best cleaned with a brush dipped in appropriate

solvent. Never poke the filter with a sharp instrument.

If the filter is not cleaned or changed at the proper time, it

will plug from the top down. When there is about 1 inch or

so of the filter left that isn’t plugged, the heavy flow of paint

will blow pinholes in the filter. An example of this is shown

in Figure 12.

Extra spray gun filters should be kept on hand.

SPRAY GUN HOUSING

HANDLE WASHER

FILTER

HANDLE

PAINT HOSE

Figure 13.-Spray Gun Filter Removal and

Replacement.

14

Page 17

SHUTDOWN AND CLEANUP

CAUTION

You should clean and oil your sprayer as soon as you finish

a job. Do not store the sprayer unless it has been

cleaned and oiled.

10. Remove suction hose from inlet valve and let valve

suck in a small amount of light oil. This will oil pump parts

and keep them from corroding.

When you shut down, clean up with water if you were using

latex paint and clean up with solvent if you were using oil

base paint.

If you are going to stop spraying for an hour or two just

relieve the pressure in the sprayer by turning the priming

knob to , cover your paint container to keep dirt out and

place tape over the spray tip to keep air from drying paint in

the tip.

Shut down and clean up as follows:

1. Reduce pressure by turning pressure control knob counterclockwise. Turn priming knob to . Remove suction

hose only from paint container, hold it above container

and allow sprayer to pump itself dry. Remove tip guard,

spray tip and washer and let soak clean.

2. Have container of hot soapy water for cleaning after

spraying with latex paint or suitable solvent for oil base

paints. Do not clean with mineral spirits if using latex

paint because it makes jelly.

3. Place suction and return tubes in the solvent or warm

soapy water. Increase pressure and let circulate for

2-3 minutes.

4. To save remaining paint in spray hose, carefully trigger

gun into and against side of paint container. Be careful

of splashing. Turn priming knob to . Turn pressure

up and watch inside of container for cleaning solvent to

come through, then shut off gun and place in cleaning

container.

5. Trigger gun and let cleaning solvent circulate for approximately 2-3 minutes.

It is very important that you oil the inlet valve as stated

in step 10 above. Oil inlet valve after EVERY job.

11.Turn ON-OFF Switch OFF.

MAINTENANCE

Check the hydraulic oil level before each use and after

every 20 run hours. To check hydraulic oil level, see

number 3, 'CHECK THE OIL", Page 12.

Change the hydraulic oil after the first 20 run hours and

every 200 hours thereafter. To change hydraulic oil, proceed as follows:

1. Remove the oil filler plug from the hydraulic housing face

plate.

2. Drain out the old hydraulic oil.

3. Fill hydraulic housing with approximately 19 ounces of

hydraulic oil. Use only hydraulic oil part number 0088009

(1 quart) or part number 0088010 (1 gallon). Replace oil

fill plug.

4. Since air may enter the system when the oil is changed,

the sprayer may have to be vented (bled). To bleed out

the air, see number 10, 'BLEED THE AIR", Page 12.

You will also have to bleed the air out of the system if

you remove the paint pump or go into the hydraulic

housing, or if the sprayer loses prime due to rough

handling.

6. Turn priming knob to and shut unit off. Unscrew gun

handle. Remove and clean filter. Install filter in gun and

reassemble spray tip, washer and guard.

7. With priming knob on , remove suction tube from

cleaning container to allow sprayer to pump dry.

8. Take a clean container of water or solvent and using low

pressure pump through system until clear. If cleaning

with water, turn to and pump lacquer thinner through

pump. This will clean any paint particles still in the

system and remove water.

9. Take suction tube out of container and let sprayer run

itself dry.

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

IMPORTANT!

Tighten the (4) Pump Block Bolts after the first 20 hours

of use.

D

C

To tighten, use the 6mm allen wrench supplied in the

literature kit. Use a criss cross pattern when tightening.

First A, then C, then B, then D. If you have a torque wrench

use 13-15 Ft./Lbs.

15

A

B

Page 18

SUCTION FILTER CLEANING

CAUTION

The suction filter is located on the end of the suction tube.

A clean suction filter gives full delivery capacity and a

constant level of spraying pressure. Clean the suction filter

as needed with a brush dipped in solvent.

CHECKING OPERATION OF INLET VALVE

CHECKING OPERATION OF OUTLET VALVE

The outlet valve should be checked if the sprayer draws up

little or no paint, or draws up paint, but doesn’t build

pressure. It is a good practice to check outlet valve operation before spraying. If the sprayer has been in storage, the

outlet valve may be sticky.

See Figure 14 for location of inlet valve. The inlet valve

should be checked if the sprayer draws up little or no paint.

It is a good practice to check inlet valve operation before

spraying. If the sprayer has been in storage, the inlet valve

may be sticky.

To check inlet valve operation, proceed as follows:

1. Turn priming knob to .

2. Turn ON-OFF switch ON.

3. Let inlet valve suck against the palm of your hand. If little

or no suction is felt repeatedly move the plunger in and

out to lift inlet valve stem, as shown in Figure 14. Put in

a few drops of light oil or cleaner.

INLET VALVE PLUNGER

To check outlet valve operation, proceed as follows:

1. Turn priming knob to .

2. Turn ON-OFF switch to ON.

3. If above symptoms occur during priming of pump simply:

• Reduce pressure to 0.

• Push the plunger in and out to lift the ball off the seat.

See Figure 14.

THE PLUNGER DEVICE MUST BE LOOSENED PRIOR

TO ANY SERVICE OF THE OUTLET VALVE.

NOTE

Your sprayer was shipped with two extra outlet valve

springs. Periodic replacement is necessary to maintain

top performance. Suggested replacement is every 35 to

50 hours of operation for best performance. Perodic

replacement of the outlet valve spring also increases the

life of the inlet valve.

OUTLET VALVE

PLUNGER

Figure 14.-Inlet & Outlet Valve Plungers

16

Page 19

REPLACING DIAPHRAGM OR DIAPHRAGM PARTS

The diaphragm is the only separation between the paint

pump and the hydraulic pump. It pumps paint, but it also

serves as a gasket between the hydraulic pump and paint

pump. If the diaphragm membrane ruptures, paint will

probably get into the hydraulic housing. If adequately

cleaned up soon enough, the parts (bearing, piston, etc.)

can be saved. If the hydraulic housing is not cleaned up

soon enough, you may have internal freeze-up.

When the diaphragm or diaphragm parts have to be replaced, proceed as follows:

5. Install the new diaphragm. Put the membrane stem and

nut side of the diaphragm in the hydraulic pump housing

hole.

6. Put the paint pump back on. Before installing the 4 paint

pump screws, put Anti-Seize Lubricant on the screw

threads. (This prevents the steel screws from galling

and seizing in the aluminum hydraulic pump). Now

install the 4 new paint pump washers and 4 screws using

a 6 millimeter allen wrench (see Figure 17).

PAINT

D

B

A

PUMP

SCREW

1. Remove the 4 paint pump screws with a 6 millimeter

alIen wrench. As you remove the 4 screws, also remove

the 4 washers that may remain in the holes.

Figure 15. - Remove paint pump screws

2. Take the paint pump housing off the hydraulic pump

housing.

3. Remove the old diaphragm and the old insert ring.

DIAPHRAGM

C

Figure 17-Tightening Paint Pump Screws.

7. Tighten opposite screws in turn as shown. (A-B, C-D).

Tighten screws evenly to 13-15 ft lbs. (156-180 inchpounds) torque. Begin at screw A tightening to 10 ft lbs.

continue to screw D. Repeat this step until all screws

have attained a torque of 10 ft. lbs. Repeat sequence

tightening to 14 ft lbs. and repeat one more time tightening to 14 ft lbs. Following this tightening sequence will

assure proper seating of the diaphgram.

NOTE:

Improper torquining sequence of the paint pump screws may

cause damage to diaphragm and inefficient pump performance.

Proper torque also prevents hydraulic oil from leaking out

between the paint pump and the hydraulic housing. It is

recommended that a new unit be re-torqued after the first 20

hours of operation. Thereafter, tighten the paint pump screws

after every 3 or 4 operations. One lockwasher should always be

used with each of the four paint pump screws.

PAINT PUMP

PAINT PUMP SCREW

Figure 16.-Diaphragm Parts and Their Relationship to

Other Parts of the Sprayer.

4. When a new diaphragm is installed, a new insert ring

(see Figure 16) should also be installed. Install the new

Insert. Be sure to put the flat surface of the insert ring into

the flat surface of the paint pump.

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

8. After replacing or repairing the diaphragm, the sprayer

will have to be bled. See Number 9, “BLEED THE AIR,”

page 12.

USE OF ANTI-SEIZE LUBRICANT

You should use Anti-Seize Lubricant (part number 0093930)

any time you are screwing dissimilar metal thread connections together. On your sprayer these connections are; (1)

steel outlet valve into paint pump, (2) steel inlet valve into

paint pump, (3) steel priming valve into paint pump, (4) steel

paint pump screws into aluminum hydraulic pump, and (6)

steel pressure control valve into iron pressure vessel/hydraulic pump.

17

Page 20

TROUBLESHOOTING

Provided you have followed the instructions, the sprayer will operate efficiently and give trouble-free service. Should any

unexpected problem arise you can, in most cases, remedy the problem by following the chart below.

Problom

Cause

Remedy

Sprayer does not startup

Sprayer starts up but

does not draw up paint

1. Sprayer not plugged in

2. Blown fuse in circuit

3. No voltage or low voltage at

wall plug

4. Bad sprayer ON-OFF switch

5. Damaged cord or extension

cord, or cord capacity too low

6. Defective motor

1. No paint or suction tube not

totally immersed in paint

2. Suction filter clogged

3. Suction tube loose at inlet

valve

4. Suction tube damaged or defective

5. Priming valve plugged

6. Hydraulic oil level very low or

empty

7. Inlet valve stuck

8. Inlet valve damaged (paint is

drawn up and leaks through

inlet valve)

9. Outlet valve stuck

10. Diaphragm membrane

ruptured, broken diaphragm

spring, cracked diaphragm

disk, or loose diaphragm nut

11. Loose oil suction tube in hydraulic housing

12. Scored piston or cylinder

13. Wrong grade of hydraulic oil, or

using fluid other than hydraulic

oil

14. Rear motor fan cover bent

1. Plug in

2. Replace fuse

3. Test power supply voltage

4. Replace switch

5. Replace with 3-prong cord. Any extension cord

used must be 3-wire, 12 gauge minimum, with a 3wire plug that will plug into a 3-wire electrical outlet.

6. Repair or replace. Take to SprayTECH Authorized

Service Center.

1. Add more paint or immerse suction tube in paint

2. Clean or replace filter

3. Clean connection and tighten firmly

4. Replace tube

5. Take valve off and clean it

6. Fill only with hydraulic oil part number 0088009

(quart) or 0088010 (gallon). Caution: do not

overfill

7. Push Inlet Valve Plunger to free stuck valve

8. Replace inlet valve

9. Push Outlet Valve Plunger to free stuck valve

10. Clean hydraulic housing if needed (blown diaphragm may cause internal freezeup). Replace

defective diaphragm parts or tighten nut if loose

11. Replace tube

12. Replace piston. If cylinder is scored, replace

hydraulic housing

13. Use only hydraulic oil part number 0088009

(quart) or 0088010 (gallon). Change initial fill after

first 20 hours of operation. Change every 200

hours there after. Bleed after changing

14. Remove fan cover and straighten

Sprayer draws up paint

but pressure does not

build up

1. Priming valve defective (paint

runs back via return hose)

2. Hydraulic oil level low

3. Diaphragm membrane

ruptured, cracked diaphragm

disk, broken diaphragm spring,

or loose diaphragm nut

4. Outlet valve stuck, dirty, or has

worn parts

5. Defective suction tube

6. Scored piston or cylinder

7. Cracked hydraulic housing or

paint pump housing

18

1. Replace valve

2. Fill to appropriate level using only hydraulic oil part

number 0088009 (quart) or 0088010 (gallon)

3. Clean hydraulic housing if needed. Replace

defective diaphragm parts or tighten nut if loose

4. Dismantle valve. Clean or replace valve spring first.

If this does not work, replace ball

5. Replace tube

6. If piston is scored, replace piston. If cylinder is

scored, replace hydraulic housing

7. Replace housing

Page 21

TROUBLESHOOTING (Continued)

Problem

Sprayer draws up paint,

pressure builds up, but

drops away markedly

when gun is opened (low

performance)

Pressure fluctuation

.

Cause

1. No spray tip on gun

2. Spray tip hole too large

3. Suction filter clogged

4. Gun filter plugged

5. Gun filter too fine for

coarse paint being

sprayed

6. Suction tube not firmly

tightened to inlet valve

7. Leaky suction tube

8. Leaky priming valve

9. Worn paint pump outlet

valve seat, ball, or

spring

10. Worn Inlet valve

11. Pressure control valve

worn or damaged

1. Loose suction tube at

inlet valve

2. Leaky suction tube at

inlet valve

3. Leaky or dirty priming

valve

4. Leaky, worn, or damaged inlet valve

5. Outlet valve may be

stuck, dirty, or have

worn parts

6. Dirty pressure control

valve

7. Worn or damaged pressure control valve

8. Pinhole in diaphragm

membrane

9. Loose oil suction tube,

causing air in hydraulic

system. Or, oil suction

tube may be partly

plugged

10. Eroded paint pump

block

11. Cracked hydraulic

housing

Remedy

1. Put on correct tip

2. Select smaller tip or try newer tip

3. Clean or replace filter

4. Clean or replace filter every 4 hours. Keep

extra filters on hand

5. Use correct filter or strain/thin paint

6. Clean connection thoroughly and tighten

7. Clean connection thoroughly and tighten

or replace tube

8. Replace valve

9. Replace defective part(s)

10. Replace valve

11. Replace valve - Take to Authorized

SprayTECH Service Center

1. Clean connection thoroughly and tighten

2. If tightening doesn’t work, replace suction

nut and adapter

3. Clean or replace valve

4. Replace valve

5. Dismantle valve. Clean or replace valve

spring first. If this doesn’t work, replace

ball

6. Take to Authorized SprayTECH Service

Center

7. Take to Authorized SprayTECH Service

Center

8. Replace diaphragm membrane

9. Clean oil suction tube if necessary and

reglue

10. Replace block

11. Replace housing

Paint in hydraulic housing

Spray gun won't shut off

1. Ruptured diaphragm

membrane

1. Insufficient trigger

spring pressure on gun

2. Worn ball or diffuser

seat or gun

3. Foreign matter or paint

buildup between ball

and diffuser on gun

19

1. Take to Authorized SprayTECH Service

Center

1. Increase trigger spring pressure by

adjusting rear tension nut

2. Replace ball or diffuser or gun

3. Disassemble gun and clean

Page 22

TROUBLESHOOTlNG (Concluded)

Problem

Spray gun leaks

Spray gun won't spray

Low paint output from spray

gun

Spray gun sprays without

trigger being pulled back

Cause

1. Worn valve ball holder on

gun

1. Out of spray material

2. Spray tip or gun filter

plugged

1. Partially plugged spray tip or

filter

1. Valve ball holder not in

correct position

NOTE1: If a return line that is completely submerged in

paint causes bubbles after priming, you probably have a

vacuum leak in the suction set. To remedy, tighten suction

set.

NOTE 2: Should oil seep through the face of the hydraulic

and paint pump sections, firmly tighten the four sockethead capscrews. Use the 6 millimeter alIen wrench. Follow

the procedure described in Item 8, page 17.

Remedy

1. Replace valve ball holder

1. Get more spray material

2. Clean spray tip. Clean or replace gun filter

1. Clean or replace gun filter. Clean spray tip

1. Adjust rear tension nut. If this doesn’t work, examine

valve ball holder and replace if necessary

NOTE 3: More than 100 feet of extension cord is not

recommended. Use more paint hose, not more extension

cord. Shorter extension cords will assure maximum electrical power for proper operation.

NOTE 4: When the priming valve is on (spray) and you

are getting flow back through the return tube, remove

priming valve and clean or replace.

NOTE 5: The electric motor should always be kept clean

and dry. Paint acts as an insulator. Therefore, too much

paint on the motor will cause it to overheat.

BEFORE YOU CALL

Have the following information available:

Model #____________

Serial #____________

Purchase Date________________________

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

20

Page 23

43

42

41

40

39

38

37

6

11

3

4

5

2

7

8

9

1

10

17

20

18

19

36

23

21

22

12

16

13

14

15

35

24

33

34

5

32

31

1

30

FINAL ASSEMBLY — Figure 18

ITEM PART NO. DESCRIPTION QTY.

1 0288478 Grip, 1

2 0294511 Handle 1

3 0088328 Washer, Lock, 5/16" 4

4 9800325 Screw, Soc. Hd. 8mm x 16mm Lg. 1

5 0089935 Elbow, Barb 2

6 0270504 Tubing, 5/16" O.D., 3/16" I.D. 1

7 0294656 Filter 1

8 9822515 Ring, Retaining 1

9 0270501 Washer 1

10 0005311 Spring 1

11 0089937 Gasket 1

12 0294513 Cover 1

13 9800049 Screw 1

14 0034307 Cap, Filter 1

15 9871044 O-Ring 1

16 0270488 Piston 1

17 0047393 Ring, Retaining 1

18 0288775 Knob, Pressure Valve 1

19 0089504 Valve, Pressure Assembly 1

(Includes Item 21)

20 294265 Bearing with Eccentric 1

21 0089501 O-Ring 1

22 0089829 Key, Woodruff 1

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

25

26

27

28

29

ITEM PART NO. DESCRIPTION QTY.

23 0047487 Washer, Copper 1

24 0089934 O-Ring 3

25 - - - - - - - Diaphragm Assembly, See Fig. 19 1

26 9885552 Elbow 1

27 - - - - - - - Paint Pump Assembly 1

(See Figure 19)

28 0089945 Screw, Soc. Hd. Cap, M8 x 80 4

29 0294533 Foot, Rubber 4

30 0090497 Nut, Hex. 5/16"- 18 1

31 0090559 Cord, Power 1

32 0089726 Clamp, Cord Locking 1

33 9802533 Bolt, Carriage, 5/16" x 18 x 1 1

34 0294495 Vessel, Pressure 1

35 0089932 O-Ring 1

36 0270490 Bearing, Ball 2

37 0270524 Seal, Tip 1

38 - - - - - - - Nut, (Included with Item 43) 1

39 0089986 Plate, On-Off 1

40 0089985 Washer, Internal Tooth 1

41 0294530 Motor 1

42 0089453 Switch, Electric 1

43 0089799 Terminal, Insulated 1

21

Page 24

1

17

19

20

21

22

23

25

24

26

15

16

‰

13

12

2

3

5

6

7

4

8

18

17

14

11

10

Paint Pump Assembly — Figure 19

9

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

22

Page 25

PAINT PUMP ASSEMBLY — Figure 19

ITEM PART NO. DESCRIPTION QTY.

1 0270201 Diaphragm assy. 1

2 0270494 Ring, diaphragm 1

3 0294216 Pusher assy, outlet valve 1

(Includes O-ring P/N 9971327)

4 0294672 Kit, repair outlet valve 1

5 0010778 Seal, ball seat 1

6 0294264 Housing assy., outlet seat 1

7 0270491 Ball 1

8 0278907 Kit, Repair, Outlet Spring

9 0294508 Outlet fitting 1

10 0253218 Pusher assy., inlet valve 1

11 0294213 Inlet valve assy. 1

(Includes Item 15)

12 9885552 Elbow 1

ITEM PART NO. DESCRIPTION QTY.

13 9885553 Fitting, Hose,1/8 nptm x 3/8 1

14 0089945 Screw, soc hd cap M8x89 4

15 0089482 Washer, Sealing, Nylon 1

16 0088328 Washer, lock 5/16 9

17 9801103 Screw, set 2

18 0288748 Knob 1

19 0154375 Cam 1

20 0090512 Washer, star 1

21 0036352 Spring 1

22 0281317 Stem/ball assy., prime valve 1

23 0090523 O-Ring 1

24 0281316 Seat, ball assy., prime valve 1

25 0294494 Paint pump block 1

26 0294673 Kit, Repair, Diaphragm 1

BEFORE YOU CALL

Have the following information available:

Model #____________

Serial #____________

Purchase Date________________________

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

23

Page 26

ACCESSORIES

Part No. Description

0153--- Tungsten C arbide Flat Tips

0153003 Tip Guard, Flat Tip

0093641 Hopper Assembly, 6 gallon

0291004 Hose, Whip End, 3' x 3/16''

0291003 Hose, Whip End, 5' x 3/16"

0291002 Hose, Wireless, 25' x 1/4''

0291000 Hose, Wireless, 50' x 1/4''

0093896 Hose Connector, 1/4'' x 1/4''M

0088154 Pressure Gauge

0153043 Tip Extension, 6''

0153042 Tip Extension, 12''

5

4

3

2

1

0152001 Power Roller Gun Attachment

0152308 Roller Cover, 3/8'' Nap

0152307 Roller Cover, 1/2'' Nap

0152309 Roller Cover, 3/4'' Nap

0152310 Roller Cover, 1 1/2'' Nap

0152235 Roller Cover, 1/2" Nap

0152236 Roller Cover, 3/8" Nap

0152237 Roller Cover, 3/4" Nap

0152238 Roller Cover, 1-1/4" Nap

0152700 Adapter, Power Roller Extension

0088009 Hydraulic Oil, quart

0088010 Hydraulic Oil, gallon

0270188 G-10 Airless Spray Gun

0093930 Anti-Seize Compound

0152900 R-10 Telescoping Roller, 12" x 3/8" nap

0152909 R-10 Telescoping Roller, 9" x 3/8" nap

0294672 Kit, Repair Outlet valve

0294673 Kit, Repair diaphragm

0294218 SUCTION SET ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 0279305 Filter, housing 1

2 0294217 Suction Hose 1

3 9871047 O-ring 1

4 0294665 Clip, hose 1

5 0269321 Return tube 1

Filter Mesh Color of

Part No. Application Type Number Filter Body

Synthetic resin

0089960 Enamels, clean Extrafine 0.084 mm Red

varnishes, stains

azures

Base coat enamels,

0089959 Primer enamels, Fine 0.140 mm Yellow

fillers, marking

paints, textured

enamels

Emulsions,

0089958 Latex paints, Medium 0.315 mm White

acrylic paints

Filler paints,

0089957 large area Coarse 0.560 mm Green

surfaces

©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

VERSATIP™ GUARD

Includes Seal. fits 11/16" thread 0270177

VERSATIP™ GUARD

Includes Seal. fits 7/8" thread 0270178

VERSATIP™ ASS'Y

Includes guard, seal, 517 reversible tip.

Fits 11/16" thread 0270175

VERSATIP™ ASS'Y

Includes guard, seal, 517 reversible tip.

Fits 7/8" thread 0270176

VERSATIP™Sizes… 313 through 319 0299----

411 through 431 0299---511 through 543 0299---617 through 623 0299---715 through 723 0299----

819 through 823 0299---ORDER BY USING PREFIX 0299--- AND FAN AND TIP

SIZE FOR LAST 3 DIGITS ( I.E. FOR 0.013 TIP WITH

6" FAN ORDER P/N 0299313 )

24

Page 27

Limited Warranty

Contractor Airless Spray Equipment

What Is Covered By This Warranty:

This product, manufactured by SprayTech Corporation (SprayTech), is warranted against defects in material and workmanship for one

(1) year following date of purchase if operated in accordance with SprayTech's printed recommendations and instructions.

For SprayTech EP and GP (piston) sprayers: In addition, for SprayTech models EP2100, EP2300 and EP2510 SprayTech

warrants non-wear parts of the fluid section, drive train and mechanical pressure control components against defects in material and

workmanship for two (2) years from the date of purchase. For SprayTech models EP2505, GP2605, GP2905 SprayTech warrants nonwear parts of the fluid section, speed reducer, drive train and electronic pressure control components, transducer and circuit board against

defects in material and workmanship for three (3) years from the date of purchase. SprayTech warrants the electric motor or gasoline

engine for all piston models (EP and GP sprayers) against defects in material and workmanship for two (2) years from the date of purchase.

For SprayTech ED or GD (diaphragm) series sprayers: In addition, SprayTech warrants the diaphragm for the lifetime of the

sprayer against defects in material and workmanship; and warrants the electric motor for three (3) years from the date of purchase.

Within the applicable warrant period, SprayTech will repair or replace, at our option, defective parts without charge if such parts are

returned with transportation charges prepaid to the nearest Authorized Service Center or to SprayTech Corporation, 1770 Fernbrook

Lane, Minneapolis, MN 55447. If SprayTech is unable to repair this product as to conform to this Limited Warranty after a reasonable

number of attempts, SprayTech will provide, at our option, either a replacement for this product or a full refund of the purchase price of

this product.

What is Not Covered By This Warranty:

1. This Warranty does not cover any defects or damages caused by either:

a) the use or installation of repair or replacement parts or accessories not manufactured by SprayTech, or

b) repair performed by anyone other than a SprayTech Authorized Service Center.

These remedies are the sole and exclusive remedies available for breach of express and implied warranties.

2. The Warranty does not cover equipment and accessories supplied to SprayTech from an original equipment manufacturer,

including but not limited to: hoses, tips, or accessories. SprayTech will provide the purchaser with copies of the original

equipment manufacturer’s express warranties provided to SprayTech along with the name and address of the appropriate

manufacturer.

3. This Warranty does not cover damage or defects caused by or related to abrasion, corrosion, abuse, misuse, negligence,

accident, normal wear, faulty installation or tampering in a manner which impairs normal operation.

Limitation of Remedies:

IN NO CASE SHALL SPRAYTECH BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS,

INCLUDING TRANSPORTATION COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS OR IMPLIED

WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer Of Implied Warranties:

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABlLlTY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer:

This warranty is extended to the original purchaser only and is not transferable.

Your Rights Under State Law:

Some states do not allow limitations on how long an implied warranty lasts or the exclusion of incidental or consequential damages, so

the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Tough Customer™

To validate the Tough Customer™ Program, the completed Tough Customer card included with each sprayer must be mailed

immediately. (In the event you did not receive a Tough Customer™ registration card with your sprayer, call 1-800-292-4637, or

write us at the address below). The return of this card is not required for you to exercise your rights under the limited warranty.

1770 Fernbrook Lane

Minneapolis, Minnesota 55447

Telephone 1-800-292-4637

Printed in U.S.A.

28

Loading...

Loading...