Page 1

®

GB

Owner’s Manual

FineCoat Coating System

Model 0524016

FineCoat 9900

Edition 10 / 2010 0524 834B

Page 2

GB

Contents

Attention

i

Page

Safety regulations for FineCoat spraying ............................... 3

Introduction to spraying using the FineCoat procedure ....... 4

Description of functions ........................................................... 4

Applications ...............................................................................4

What kind of spraying materials can be applied? ..................4

Technical data............................................................................ 4

System diagram ......................................................................... 4

Preparing the coating material ................................................. 5

Table of viscosities and nozzle sets ............................................ 5

Starting operation ......................................................................5

Setting the FineCoat spray gun ............................................5/6

Spray pattern selection ................................................................ 5

Setting the required spray pattern ............................................... 5

Setting the spray jet width ...........................................................6

Setting the amount of material..................................................... 6

Setting the amount of air .............................................................6

Setting the ascending feed pipe .................................................. 6

Spraying technique ................................................................... 7

Breaks in work ........................................................................... 7

Finishing work and cleaning the unit ................................... 7/8

Changing the nozzle .................................................................... 8

Spray gun accessories and spare parts.................................. 9

Nozzle sets .................................................................................. 9

Table of nozzle sets..................................................................... 9

Hose whip .................................................................................... 9

Valve plate set ............................................................................. 9

Service set ................................................................................... 9

Page

Turbo-blower maintenance .......................................................9

Changing the air lter ..................................................................9

Carbon brushes ........................................................................... 9

Special accessories ................................................................10

RN 30 Extension tip ................................................................... 10

WSL 50 Spray lance .................................................................. 10

WSL 60 Spray lance .................................................................. 10

1.9 L Remote pressure tank ...................................................... 10

Power Cart................................................................................. 10

Troubleshooting ...................................................................... 11

Spare parts list, FineCoat spray gun ......................................... 12

Spare parts list, turbo-blower FineCoat 9900 ............................ 14

Spare parts list, air hose FineCoat 9900 ................................... 16

Connection Diagram ...............................................................17

WAGNER-Service companies ................................................18

Important notes on product liability ...................................... 19

3+2 years guarantee for professional nishing ................... 19

CE Declaration of conformity ................................................. 20

Safety Regulations for FineCoat Spraying

This manual contains information that must be read and understood

before using the equipment. When you come to an area that has one of

the following symbols, pay particular attention and make certain to heed

the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety

information will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to

prevent damage to the equipment or how to avoid

causes of minor injuries will follow.

A hazard symbol such as this one refers to a specific,

task-related risk. Be sure to heed the safeguard.

Notes give important information which should be given

special attention.

2

HAZARD: GENERAL

This product can cause severe injury or property

damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• Use only manufacturer authorized parts. User

assumes all risks and liabilities when using parts that

do not meet the minimum specications and safety

devices of the pump manufacturer.

• Before each use, check all hoses for cuts, leaks,

abrasion or bulging of cover. Check for damage or

movement of couplings. Immediately replace the hose

if any of these conditions exist. Never repair a hose.

Replace it with an identical replacement hose.

• NEVER aim the gun at any part of the body.

• Wear clothing to keep paint off skin and hair.

• Do not spray outdoors on windy days.

• Never leave this equipment unattended. Keep away

from children or anyone not familiar with the operation

of HVLP equipment.

Page 3

GB

HAZARD: EXPLOSION OR FIRE

PE

i

PE

Solvent and paint fumes can explode or ignite. Severe

injury and/or property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction

to keep the air within the spray area free from

accumulation of ammable vapors.

• Avoid all ignition sources such as static electricity

sparks, electrical appliances, ames, pilot lights, hot

objects, and sparks from connecting and disconnecting

power cords or working light switches.

• Plastic can cause static sparks. Never hang plastic

to enclose spray area. Do not use plastic drop cloths

when spraying ammable materials.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Power cord must be connected to a grounded circuit

(electric units only).

• Follow material and solvent manufacturer’s warnings

and instructions. Be familiar with the coating material’s

MSDS sheet and technical information to ensure safe

use.

• Use extreme caution when using materials with a

ashpoint below 70° F (21° C). Flashpoint is the

temperature that a uid can produce enough vapors to

ignite.

HAZARD: SKIN BURN INJURY

Heated parts can cause severe skin burn injury.

PREVENTION:

• Quick disconnect ttings on the hose and spray gun

become hot during use. Avoid skin contact with quick

disconnect ttings when they are hot. Allow quick

disconnect ttings to cool before disconnecting the

spray gun from the hose.

Earthing Instructions

Electric models must be earthed. In the event of an

electrical short circuit, earthing reduces the risk of electric

shock by providing an escape wire for the electric current.

This product is equipped with a cord having an earthing

wire with an appropriate earthing plug. The plug must be

plugged into an outlet that is properly installed and earthed

in accordance with all local codes and ordinances.

DANGER — Improper installation of the earthing plug

can result in a risk of electric shock. If repair or

replacement of the cord or plug is necessary, do not

connect the green earthing wire to either blade

terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the earthing

wire and must be connected to the earthing pin.

Check with a qualied electrician or serviceman if the earthing

instructions are not completely understood, or if you are in doubt as to

whether the product is properly earthed. Do not modify the plug provided.

If the plug will not t the outlet, have the proper outlet installed by a

qualied electrician.

Caution – The power cord for this equipment acts as an

emergency stop/emergency switching off device. The

power cord must be placed near an easily accessible,

unobstructed socket-outlet.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause severe injury or property damage.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such

as methylene chloride and 1,1,1 - trichloroethane.

They are not compatible with aluminum and may

cause an explosion. If you are unsure of a material’s

compatibility with aluminum, contact your coating’s

supplier.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact with

body. Vapors can cause severe nausea, fainting, or

poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be sure

it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is

assumed for incorrect installation.

Power cord replacement must be performed by the manufacturer, its

service agent, or a similarly qualied person.

Operating Temperature

This equipment will operate correctly in its intended ambient, at a

minimum between +10°C and +40°C.

Relative Humidity

The equipment will operate correctly within an environment at 50% RH,

+40°C. Higher RH may be allowed at lower temperatures.

Measures shall be taken by the Purchaser to avoid the harmful effects of

occasional condensation.

Altitude

This equipment will operate correctly up to 3000 m above mean sea level.

Transportation and Storage

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -25°C to +55°C and for short

periods up to +70°C.

It has been packaged to prevent damage from the effects of normal

humidity, vibration and shock.

A list of the materials used in the construction of the

equipment will be made available on request to validate

compatibility with the coating materials to be used.

3

Page 4

GB

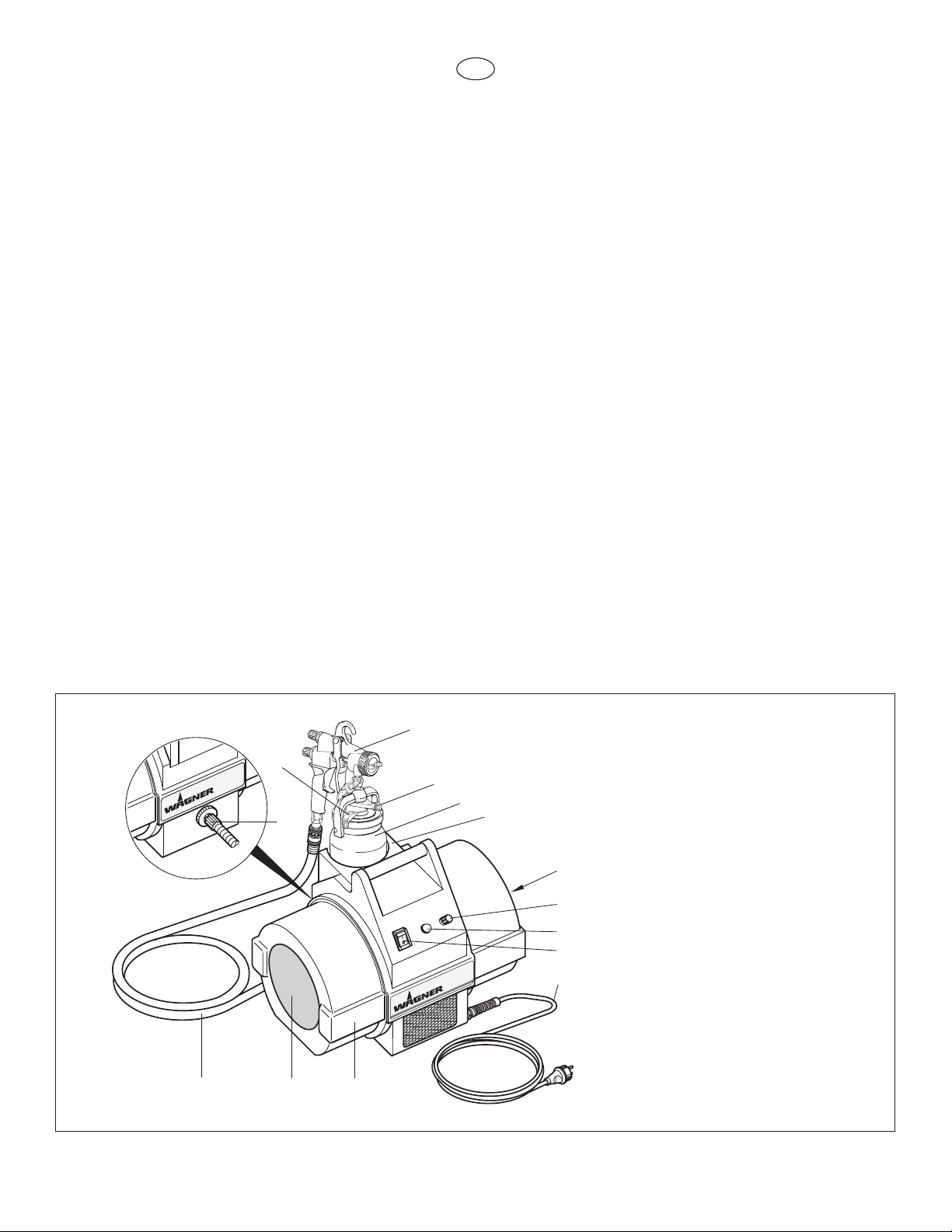

Introduction to spraying using the

1

14

10

13

2

3

4

5

6

7

8

9

12 11

FineCoat procedure

FineCoat is a low pressure spraying technique which operates

with a high volume of air at low air pressure.

The essential advantage of this system is the reduced formation

of spray mist. The material required to cover a given surface is

thus reduced to a minimum.

The FineCoat system is particularly suitable for repairing and

renovating.

Compared to conventional coating applications, an economical

and superior surface finish is achieved with an environmentally

friendly application.

Description of Functions

The “FineCoat 9900” spray application system consists of a

turbo-blower which supplies a FineCoat paint spray gun with

atomizing air via an air hose.

In the spray gun, part of the atomizing air is used to increase the

pressure in the paint container. This pressure is used to convey

coating material through the ascending feed pipe to the tip where

it is mixed with the rest of the atomized air.

Applications

• Renovation and repair work

• Interior wall decoration

What kind of spraying materials can be

applied?

• Water-soluble and solvent-containing coating materials

• Wood preservatives

• Multi-color effect materials

• Multi-color paint

• Texture and effect paints

Technical Data

FineCoat 9900

Voltage : 230V~, 50/60 Hz

Power consumption P1 : 1500 W

Max. current comsumption : 7.5 A

Max. air ram pressure : 0.68 bar

Rpm : 21 000 rpm

Weight (turbo-blower,

air hose and spray gun) : 15 kg

Mains cable : 3 m

Container capacity : 1 liter

Air hose : 7.5 m

Nozzle set (standard) : No. 4 (1.8 mm)

Max. permissible

coating temperature : 43ºC

Typical coating flow rate : 0.35 l/min

Max. noise level

turbo-blower : 75 dB (A) *

paint spray gun : 80 dB (A) **

System Diagram

* Measuring location: 1 m in distance from the unit 1.60 m

above the oor, reverberant oor.

** Measuring location: 2.5 m distance from the unit 1.60 m

above the oor.

1 FineCoat paint spray gun

2 Closing lever for paint container

3 Paint container (contents: 1 liter)

4 Spray gun holder

5 Air lter

6 Fine wire fuse

7 Indicator lamp for air lter

contamination

8 ON/OFF switch

9 Mains cable

10 Turbo-blower

11 Motor air lter

12 Air hose

13 Air hose connection

14 Rotating lever for ascending

feed pipe

4

Page 5

GB

Preparing the coating material

Coating material

Solvent-based

lacquer paints

Water-soluble

lacquer paints

Wood preservatives

(scumble, mordants, etc).

Multi-color effect materials,

multi-color paint

Texture and effect

paints

Viscosity DIN-s

(4 mm DIN cup)

15 - 45

observe manufacturer’s

instructions

undiluted

observe manufacturer’s

instructions

observe manufacturer’s

instructions

3 - 4

4 - 5

2 - 3

6 - 7

5 - 6

Nozzle set

No.

ABC

2

1

3

Observe the manufacturer’s instructions for the use of the coating

material on the paint tin or on the technical instruction sheet.

Coating material purity:

An absolute pre-condition for the trouble-free operation of the

ne-spray system is that the coating material is uncontaminated.

If you have doubts as to the purity of the coating material, we

recommend that you rst lter it through a ne sieve.

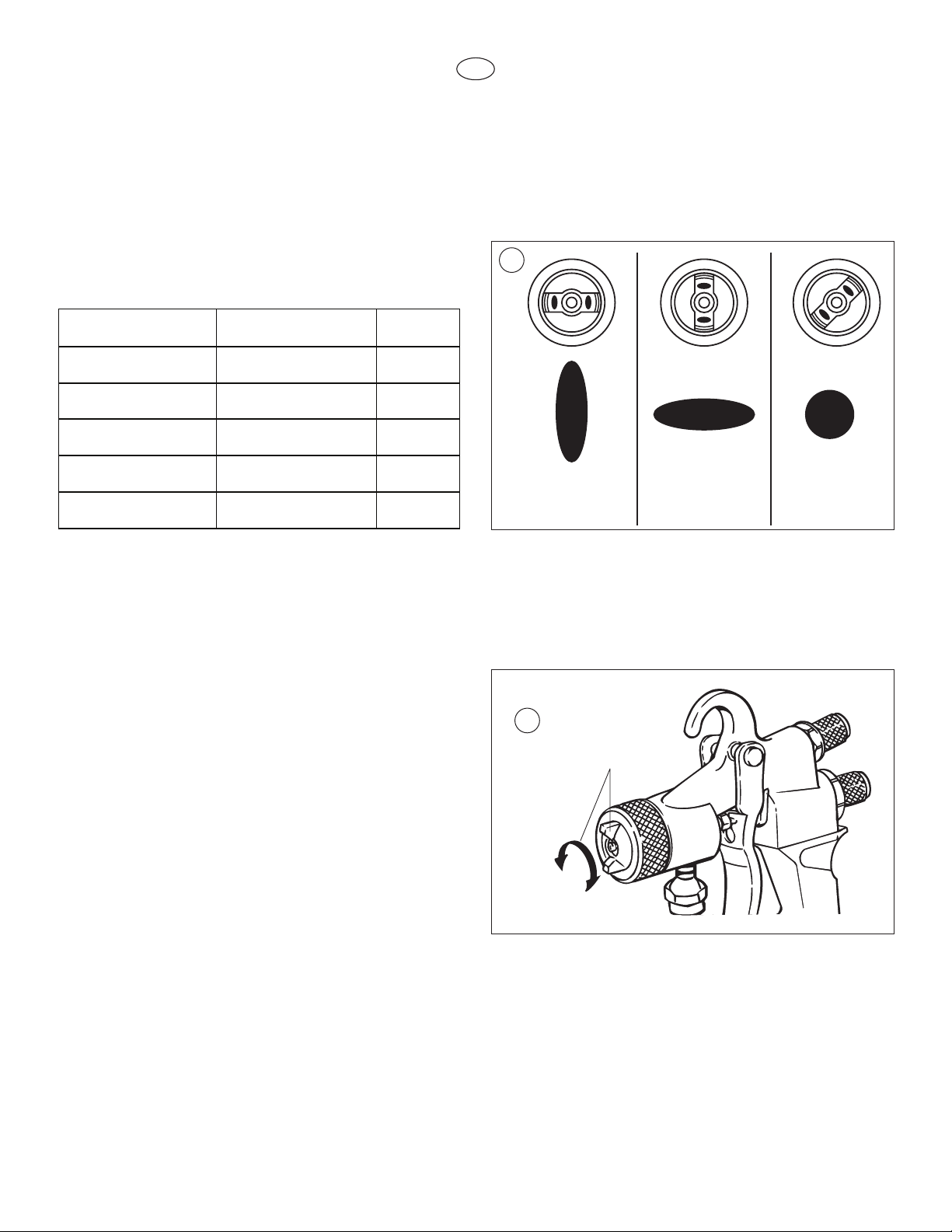

Table of viscosities and nozzle sets

Setting the FineCoat Spray Gun

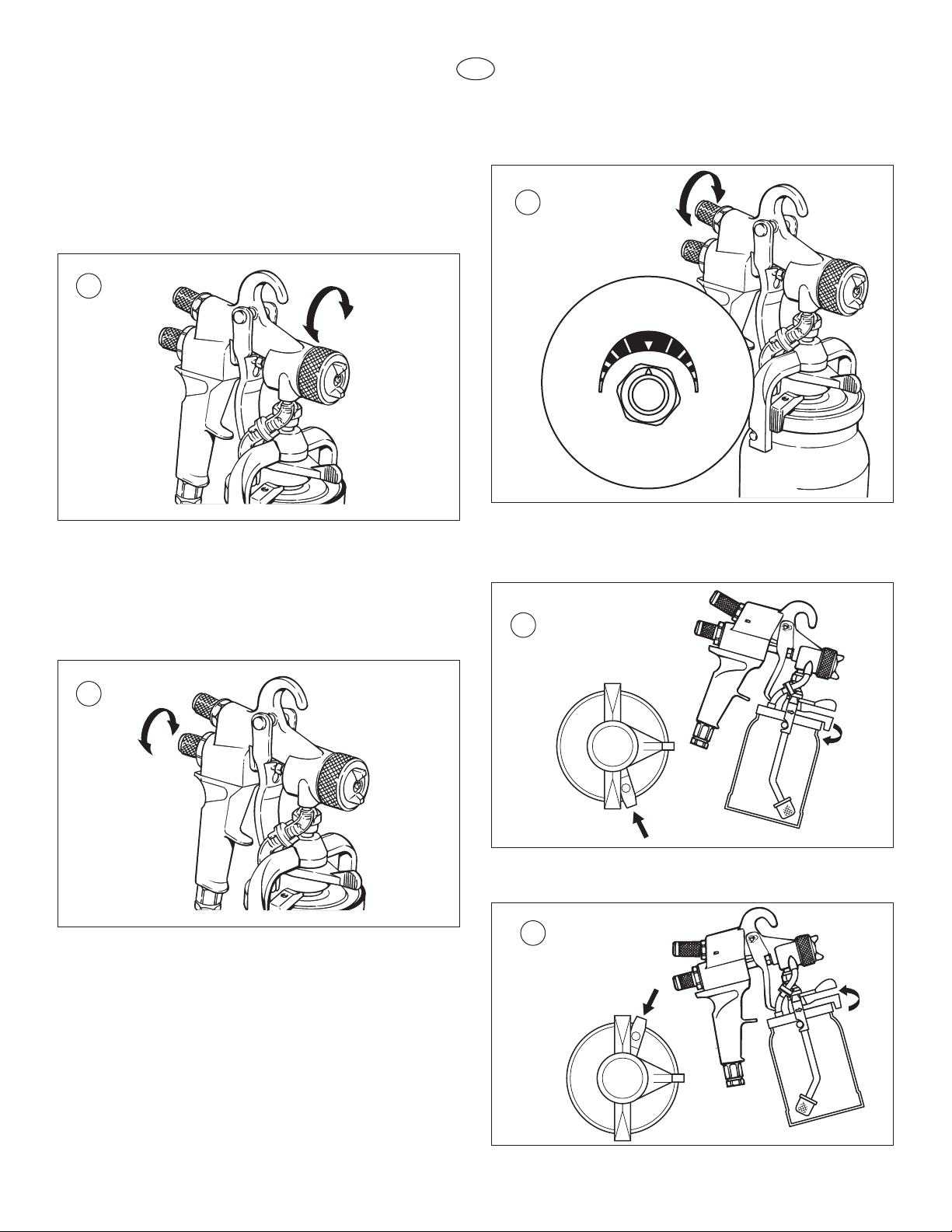

Spray pattern selection (g. 2)

A = vertical at jet for horizontal surfaces

B = horizontal at jet for vertical surfaces

C = Round jet for corners and edges and places difcult to

access.

Starting operation

Before connecting to the mains supply make sure that the mains

voltage corresponds to the operating voltage on the rating plate.

The unit must be connected with a properly earthed shockproof

socket.

1. Screw air hose end (anti-kink spring) onto the turboblower.

Couple air hose to the paint spray gun.

2. Open closing lever on the paint container, remove paint

container.

3. Fill paint container with coating material.

4. Check that the paint container seal is clean and is seated

correctly.

5. Clip the container onto the spray gun and secure with the

closing lever.

6. Switch the turbo-blower on.

7. Point the paint spray gun at the object to be sprayed.

8. Determine the settings for the spray pattern, spray

jet width, amount of material, amount of air and

ascending feed pipe settings, see g. 2 - 8 and the

description page 5/6.

9. Operate trigger on the paint spray gun.

5

Setting the required spray pattern (g. 3)

Turn the air cap (1) to the required spray pattern position.

Attention:

Never pull trigger while adjusting the air cap settings.

Page 6

GB

Setting the spray jet width (fig. 4)

4

5

Maximum

Minimum Minimum

6

7

8

Adjusting ring

Turn to the right = wider spray jet

Turn to the left = narrower spray jet

Note:

The adjusting ring does not fasten the air cap!

Setting the amount of material (fig. 5)

Set the amount of material by turning the material adjustment

knob.

Turn to the left = more material

Turn to the right = less material

Setting the amount of air (fig. 6)

The correct setting for the amount of air is decisive for the

atomization and formation of paint mist.

Setting the ascending feed pipe

Spraying object lying on oor (g. 7)

Turn rotating lever clockwise as far as it will go.

Spraying object over head (g. 8)

Turn rotating lever anti-clockwise as far as it will go.

6

Page 7

GB

Spraying technique

3 - 20 cm

9

10

11

Hold the paint spray gun upright and maintain a constant

distance of about 3 - 20 cm to the object being sprayed.

Move the paint spray gun evenly either from side to side or up

and down. If the gun is moved evenly, it will produce an even

surface nish. No runs will occur if the speed is correct.

Always start spraying away from the object and avoid stopping

spraying whilst still on the object.

Note: If the round jet setting is used, the distance may be

increased according to the size of the object being sprayed.

• In case of excessive paint mist formation, adjust

the air and material ow respectively and alter the

distance from the object.

Right

Wrong

Excessive paint mist formation, uneven surface nish.

Breaks in work

• Turn the material regulating knob to the right as far as it

will go (g. 11).

This will secure the paint spray gun against unintentional

operation.

• Switch the unit off.

Finishing work and cleaning the unit

1. Switch the unit off.

2. Hold the paint spray gun in the original container. Press

the trigger to release the pressure in the spray gun

container.

3. Undo the paint container closing lever and remove the

container.

4. Empty the remaining coating material into the original

container.

5. Fill the spray gun container with solvent or water and t

onto the spray gun.

Only use solvents with a ash point above 21 °C.

6. Shake the paint spray gun well.

7. Switch the unit on and spray the solvent or water into an

open container.

Caution! Never spray into a container with only a

small opening (bunghole)! See safety regulations.

8. Repeat this procedure until the solvent or water coming

out of the tip is clear.

Then empty the paint container completely.

Caution! Never leave solvents in the spray gun

container; this may cause pressure to build up in the

container.

Always keep the paint container seal clean of left over

coating material and check regularly for signs of damage.

7

Page 8

GB

9. Switch the unit off.

12

13

2

3

4

1

14

5

15

16

10. Clean the outer surfaces of the paint container and paint

spray gun with a cloth soaked in solvent or water.

Note: Do not leave the FineCoat spray gun immersed

in solvent for extended periods! (The seals and air pipe

on non-return valve may swell, preventing them from

functioning properly.)

11. Unscrew adjusting ring, remove air cap and spring plate

(g. 13). Unscrew nozzle. Clean air cap, tip and needle

with brush and solvent or water.

Note: Never use sharp metal objects to clean the nozzles

or air channels of the FineCoat spray gun.

12. Apply a ne coat of silicone-free oil to the marked areas

(g 12).

3. Remove the needle (g. 15,5).

13. If the paint spray gun is not used for any length of time, it

should be cleaned and protected by applying a ne coat of

silicone-free oil..

Changing the nozzle

Note: Make sure that the air cap, the tip and the needle have

identical markings.

1. Remove the adjusting ring, the air cap and the spring

plate (g. 13).

4. Remove the tip with the enclosed special socket wrench

(g. 16).

2. Fig. 14 – Loosen the needle seal with the open-end

wrench (g. 14,1). Remove the material adjusting knob

(g. 14,2) and the pressure spring (g. 14,3). Open trigger

of the spray gun to facilitate needle removal (g. 14,4).

Reassemble with the new nozzle set in reverse order.

Attention: The needle seal screw connection must be

readjusted after reassembly.

8

Page 9

GB

Spray gun accessories and spare parts

Air cap

Tip

Needle

4

4

4

17

2

1

3

18

Nozzle sets:

The spray nozzle set consists of an air cap, a tip and a needle

(g. 17).

Table of nozzle sets

Set (complete)

Marking Part No. Tip size

2 0276 254 Ø 0,8 mm

3 0276 227 Ø 1,3 mm

4 0276 228 Ø 1,8 mm (Standard)

5 0276 229 Ø 2,2 mm

6 0276 245 Ø 2,5 mm

7 0524 211 Ø 2,7 mm

8 0261 021 Ø 3,0 mm

9 0261 022 Ø 4,0 mm

Turbo-blower maintenance

1. Changing air lter and motor air lter

The indicator lamp (1) shows that the air lter (2) and the

motor air lter (3) need cleaning or exchanging.

Turn off turbo-blower.

Remove the air lter (2) and motor air lter (3) from the

turbo-blower.

Depending on how dirty the lters are, either clean by

blowing through compressed air or exchange the lters.

Care must be taken when retting the air lter (2) that the

green side is on the inside.

Hose whip 152 cm long

Part No. 0524 405

Valve plate set for non-return valve

10 pcs. Part No. 0277 919

Service-Set

consisting of seal item 5, page 12, seal item 8, seal item 17,

needle seal item 27, air pipe item 32, non-return valve item 34,

air pipe item 35, paint container seal item 49.

Part No. 0295 981

Air lter and motor air lter

Part No. 0279 938

2. Carbon brushes

The carbon brushes of the turbo-blower must be replaced

once per year or every 500 hours of operation.

Please contact your WAGNER service center.

9

Page 10

GB

Special accessories

19

20

21

22

RN 30 Extension Tip (g. 19)

for ribbed radiators, length 30cm.

Part No. 0261 020

WSL 50 Spray lance (g. 20)

Area of application

Removating and repair work

For ceilings and walls

Material supply by means of a commercially available pressure

tank.

Part No. 0261 023

WSL 60 Spray lance (fig. 21)

When coating materials can be used?

Coating materials which, due to their properties, cannot be used

with a paint spray gun, e.g., liquid wood chip, multi-color effect

coating, ornamental plaster, texture and spray ller, etc.

Part No. 0261 024

Power Cart

Part No. 0524 001

1.9 L Remote Pressure Tank (fig. 22)

Part No. 0524 230

10

Page 11

GB

Troubleshooting

Problem

A. The unit will not start.

B. No coating material ow from

the tip.

C. Tip drips.

D. Spray pattern sickle-shaped.

E. Spray jet utters.

F. Leaks around the needle (3)*.

Cause

1. No mains voltage.

2. Carbon brushes in motor worn.

3. Fine-wire fuse defect.

4. ON/OFF switch defect.

5. Motor defect.

1. Tip clogged.

2. Non-return valve (34)* clogged.

3. Paint container seal damaged.

4. Filter (48)* clogged.

5. Paint container empty.

6. Adjusting ring (30)* open too far.

7. Material adjusting knob (1)* closed.

1. Worn tip.

2. Contamination in tip.

3. Material adjusting knob open too far.

4. Needle seal screw connection (20)* overtightened.

1. Air cap holes plugged.

1. Coating material in paint container is

running out.

2. Filter clogged.

1. Needle seal screw connection (20)* loose.

2. Needle seal (26)* worn.

Solution

1. Check.

2. Replace.

3. Have checked and replaced by a specialist

electrician.

4. Have replaced by a specialist electrician.

5. Call WAGNER service.

1. Clean tip.

2. Unscrew non-return valve and clean or exchange

valve plate. Pay attention to the direction of the

arrow during assembly.

3. Replace.

4. Clean or replace.

5. Rell.

6. Adjust.

7. Adjust.

1. Replace.

2. Clean.

3. Adjust material adjusting knob accordingly (see page

6).

4. Adjust.

1. Clean.

1. Rell coating material.

2. Clean or replace.

1. Tighten screw connection for needle seal (20)*

loosely with open-end wrench.

2. Tighten or replace the needle seal (26).

*see page 12-13

11

Page 12

GB

34

33

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

28

29

23

22

21

20

16

19

26

17

25

30

32

50

49

48

47

45

44

43

46

42

41

40

39

38

3

3

35

18

24

52

27

Spare Parts List, FineCoat spray gun

12

Page 13

GB

Item Part No. Description

Item Part No. Description

0277 035 FineCoat paint spray gun

1 0277 502 Material adjusting knob

2 0295 575 Pressure spring

3 0276 228 Nozzle set no. 4 (consists of air cap, tip

and needle)

4 0277 510 Housing

5 0275 501 Seal

6 0275 578 Pressure spring

7 0277 536 Tappet

8 0277 486 Seal

9 0277 489 Retaining ring

10 9811 119 Hexagon nut

11 9805 205 Screw

12 0277 491 Knob

13 9894 242 Spring washer

14 0277 498 Valve housing

15 0277 493 Valve

16 0277 488 Seal

17 0277 506 Double socket

18 0277 185 Housing

19 0277 515 Retaining ring

20 0277 508 Screw connection

21 0277 445 Handle

22 0277 230 Pipe

23 0277 231 Hexagon nut

24 0276 481 Nipple

25 0277 505 Nipple

26 0275 579 Needle seal

27 0277 198 Trigger

28 0277 514 Axle

29 0275 250 Spring plate

30 0277 507 Adjusting ring

32 0277 482 Air pipe

33 0277 919 Valve plate set - 10 pcs.

34 0276 248 Non-return valve

35 0277 483 Air pipe

38 0277 509 Nipple

39 0277 511 Nut

40 0277 451 Bridge

41 0277 467 Closing lever

42 0277 460 Lid

43 9805 206 Screw

44 0277 448 Rotating lever

45 0277 449 Guide

46 9871 049 O-ring

47 0277 178 Ascending feed pipe

48 0295 600 Filter

49 0277 495 Paint container seal

50 0275 573 Paint container

52 0261 889 Socket wrench

0295 981 Service set

13

Page 14

GB

Spare Parts List, turbo-blower FineCoat 9900

1

2

4

5

13

14

15

16

17

18

19

20

21

14

15

16

22

23

24

25

26

29

30

27

28

10

11

12

7

8

9

6

33

35

34

36

32

31

39

40

41

37

38

42

43

44

46

45

47

13

3

14

Page 15

GB

Item Part No. Description

Item Part No. Description

1 0277 979 Ring, air outlet retaining

2 0277 439 Threaded pipe

3 9803 103 Screw (2)

4 0277 443 Lid

5 0277 442 Housing

6 0277 402 Seal

7 0524 396 Bottom housing

8 0090 628 Foot (4)

9 9802 222 Screw (4)

10 9802 544 Screw (4)

11 0277 419 Cable attachment

12 0276 595 Mains cable

13 9805 285 Screw (12)

14 0277 366 Filter can, large (2)

15 0279 938 Filter replacement kit

16 0277 367 Filter holder (2)

17 0277 371 Fan noise foam

18 0277 369 Lid

19 0277 396 Nut (6)

20 0276 598 Foam disk

21 0277 501 Clip

22 0277 368 Foam Insert

23 0277 159 Sound insulation

24 9805 316 Bolt (3)

25 0277 469 Foam disk

26 0277 997 Lid

27 0277 669 Spacer (3)

28 0524 231 Motor with turbine 230 V~, 50/60 Hz

29 9821 512 Lock washer (3)

30 9810 108 Nut (3)

31 0524 458 Angled hose connector

32 0524 461 Hose

33 0524 598 Interference suppression lter

34 0529 300 Mounting plate

35 9803 104 Screw (6)

36 0277 379 Spray gun holder

37 9850 936 Switch

38 0277 194 Indicator lamp

39 0277 565 Fuse holder

40 0277 567 Fine-wire fuse 8 A

41 0277 591 Top housing

42 0277 389 Insert (2)

43 0277 532 Handle

44 0277 372 Seal (2)

45 9902 205 Screw (3)

46 0279 426 Air ow switch

47 0277 475 Air hose

15

Page 16

GB

2

4

1

3

Spare Parts List, air hose FineCoat 9900

Item Part No. Description

1 0276 439 Seal quick-release coupling

2 0275 625 Hose quick-release coupling

3 0277 234 Air hose, 7,5 m

4 0524 405 Hose whip 152 cm long

16

Page 17

GB

Connection Diagram

(P/N 0277 194, 230V)

(P/N 0277 193, 110V)

(P/N 0279 426)

(P/N 9850 936)

(P/N 0508 103, 230V)

(P/N 9850 937, 110V)

(P/N 0277 940, 230V)

PE

(P/N 0277 938, 110V)

(P/N 0276 595, 230V)

(P/N 0277 207, 110V)

(P/N 0524 598)

(P/N 9850 577)

1

2

2

3

4

4

4

4

4

3

1

1

1

1

1

Black

1

Blue

2

Brown

3

Green / yellow

4

17

17

Page 18

GB

DeutschlandJ. Wagner GmbH • Otto-Lilienthal-Straße 18 • 88677 Markdorf

Tel. 0043/07544/5050 • Fax: 0043/07544/505/200 • info@wagner-group.com

Tel. 0043/2235/44 158 • Fax: 0043/2235/44 163 • office@wagner-group.at

ÖsterreichJ. Wagner Ges.m.b.H • Ottogasse 2/20 • 2333 Leopoldsdorf

Tel. 0041/71/7572211 • Fax: 0041/71/7572222 • wagner@wagner-group.ch

Schweiz J. Wagner AG • Industriestrasse 22 • 9450 Altstätten

Tel. 728/743562 • Fax: 728/744684

JapanWagner Spraytech Japan/Ltd. • 2-35, Shinden-Nishimachi • Osaka/Japan

Tel. 0086/2166521858 • Fax: 0086/2166529819 • wagnersh@public8.sta.net.cn

China Wagner Spraytech Shanghhai Co LTD • 4th Floor, No. 395 • Jianchang Xi Road

Shibei Industrial Zone • Shanghai, 200436 China

Tel. 001/763/553-7000 • Fax: 001/763/553-7288 • info@wagnersystemsinc.com

USAWagner Spraytech Corp. • P.O. Box 279 • Minneapolis, MN 55440 USA

Tel. +33/1/825 011 111 • Fax: +33/1/698 172 57 • division.batiment@wagner-france.fr

France J. Wagner France S.A.R.L. • Parc de Gutenberg - Bâtiment F • 8 voie la Cardon •

91127 Palaiseau Cedex

0844/335/0517 • Fax: 0044/1295/269861 • enquiry@wagnerspraytech.co.uk

Great Britain Wagner Spraytech (UK) Ltd. • The Coach House • 2 Main Road •

Middleton Cheney • OX17 2ND • Great Britain

Tel. 0039/039/625021 • Fax: 0039/039/6851800 • info@wagnercolora.com

Italia Wagner Colora S.R.L. • Via Fermi, 3 • 20040 Burago Molgora • Milano

Tel. 0032/2/2694675 • Fax: 0032/2/2697845 • info@wagner-group.be

Belgie Wagner Spraytech • Belgium SA • Veilinglaan 58 • 1861 Meise-Wolvertem

Tel. 0031/30/2414155 • Fax: 0031/30/2411787 • info@wagner-group.nl

NederlandWagner Spraytech Benelux B.V. • Zonnebaan 10 • 3542 EC Utrecht

Tel. 03/95872000 • Fax: 03/95809120 • wagner@wagnerspraytech.cm.au

Australia Wagner Spraytech Australia Pty. Ltd. • POB 286 • Braeside, Vic., 3195 Australia

Tel. 0045/43/271818 • Fax: 0045/43/430528 • wagner@wagner-group.dk

DanmarkWagner Spraytech Scandinavia A/S • Helgeshøj Allé 28 • DK2605 Taastrup • Denmark

Tel. 0046/42/150020 • Fax: 0046/42/150020 • mailbox@wagner.se

Sverige Wagner Spraytech Scandinavia A/S • Helgeshøj Allé 28 • DK2605 Taastrup • Denmark

Tel. 0034/93/6800028 • Fax: 0034/93/6800555 • info@wagnerspain.com

EspañaWagner Spraytech Ibérica S.A. • P.O. Box 132, Crta. N-340 • KM 1.245,4 •

08750 Molins de Rey - Barcelona Spain

18

Page 19

GB

Important notes on product liability

As a result of an EC regulation being effective as from January 1, 1990, the manufacturer shall only be liable for his product if all parts come from him or

are released by him, and if the devices are properly mounted and operated.

If the user applies outside accessories and spare parts, the manufacturer´s liability can fully or partially be inapplicable; in extreme cases usage of the

entire device can be prohibited by the competent authorities (employer´s liability insurance association and factory inspectorate division).

Only the usage of original WAGNER accessories and spare parts guarantees that all safety regulations are observed.

3+2 years guarantee for professional nishing

Wagner professional guarantee

(Status 01.02.2009)

1. Scope of guarantee

All Wagner professional colour application devices (hereafter referred

to as products) are carefully inspected, tested and are subject to strict

checks under Wagner quality assurance. Wagner exclusively issues

extended guarantees to commercial or professional users (hereafter

referred to as “customer”) who have purchased the product in an

authorised specialist shop, and which relate to the products listed for that

customer on the Internet under www.wagner-group.com/pro-guarantee.

The buyer’s claim for liability for defects from the purchase agreement

with the seller as well as statutory rights are not impaired by this

guarantee.

We provide a guarantee in that we decide whether to replace or repair

the product or individual parts, or take the device back and reimburse

the purchase price. The costs for materials and working hours are our

responsibility. Replaced products or parts become our property.

2. Guarantee period and registration

The guarantee period amounts to 36 months. For industrial use or equal

wear, such as shift operations in particular, or in the event of rentals it

amounts to 12 months.

Systems driven by petrol or air are also guaranteed for a 12 month

period.

The guarantee period begins with the day of delivery by the authorised

specialist shop. The date on the original purchase document is

authoritative.

For all products bought in authorised specialist shops from 01.02.2009

the guarantee period is extended to 24 months providing the buyer of

these devices registers in accordance with the following conditions within

4 weeks of the day of delivery by the authorised specialist shop.

Registration can be completed on the Internet under www.wagner-group.

com/pro-guarantee. The guarantee certicate is valid as conrmation,

as is the original purchase document that carries the date of the

purchase. Registration is only possible if the buyer is in agreement with

having the data being stored that is entered during registration.

When services are carried out under guarantee the guarantee period for

the product is neither extended nor renewed.

Once the guarantee period has expired, claims made against the

guarantee or from the guarantee can no longer be enforced.

3. Handling

If defects can be seen in the materials, processing or performance of

the device during the guarantee period, guarantee claims must be made

immediately, or at the latest within a period of 2 weeks.

The authorised specialist shop that delivered the device is entitled to

accept guarantee claims. Guarantee claims may also be made to the

service centres named in our operating instructions. The product has to

be sent without charge or presented together with the original purchase

document that includes details of the purchase date and the name of

the product. In order to claim for an extension to the guarantee, the

guarantee certicate must be included.

The costs as well as the risk of loss or damage to the product in transit

or by the centre that accepts the guarantee claims or who delivers the

repaired product, are the responsibility of the customer.

4. Exclusion of guarantee

Guarantee claims cannot be considered

- for parts that are subject to wear and tear due to use or other

natural wear and tear, as well as defects in the product that

are a result of natural wear and tear, or wear and tear due to

use. This includes in particular cables, valves, packaging, jets,

cylinders, pistons, means-carrying housing components, lters,

pipes, seals, rotors, stators, etc. Damage due to wear and tear

that is caused in particular by sanded coating materials, such as

dispersions, plaster, putty, adhesives, glazes, quartz foundation.

- in the event of errors in devices that are due to non-compliance

with the operating instructions, unsuitable or unprofessional use,

incorrect assembly and/or commissioning by the buyer or by a

third party, or utilisation other than is intended, abnormal ambient

conditions, unsuitable coating materials, unsuitable operating

conditions, operation with the incorrect mains voltage supply/

frequency, over-operation or defective servicing or care and/or

cleaning.

- for errors in the device that have been caused by using

accessory parts, additional components or spare parts that are

not original Wagner parts.

- for products to which modications or additions have been

carried out.

- for products where the serial number has been removed or is

illegible

- for products to which attempts at repairs have been carried out

by unauthorised persons.

- for products with slight deviations from the target properties,

which are negligible with regard to the value and usability of the

device.

- for products that have been partially or fully taken apart.

5. Additional regulations.

The above guarantees apply exclusively to products that have been

bought by authorised specialist shops in the EU, CIS, Australia and are

used within the reference country.

If the check shows that the case is not a guarantee case, repairs are

carried out at the expense of the buyer.

The above regulations manage the legal relationship to us concludingly.

Additional claims, in particular for damages and losses of any type,

which occur as a result of the product or its use, are excluded from the

product liability act except with regard to the area of application.

Claims for liability for defects to the specialist trader remain unaffected.

German law applies to this guarantee. The contractual language is

German. In the event that the meaning of the German and a foreign text

of this guarantee deviate from one another, the meaning of the German

text has priority.

J. Wagner GmbH

Division Professional Finishing

Otto Lilienthal Strasse 18

88677 Markdorf

Federal Republic of Germany

19

Page 20

GB

Note on disposal:

In observance of the European Directive 2002/96/

EC on waste electrical and electronic equipment

and implementation in accordance with national law,

this product is not to be disposed of together with

household waste material but must be recycled in an

environmentally friendly way!

Wagner or one of our dealers will take back your

used Wagner waste electrical or electronic equipment

and will dispose of it for you in an environmentally friendly way.

Please ask your local Wagner service centre or dealer for details or

contact us direct.

Signature - Person responsible for documentation Signature - Authorised Representative

Declaration of conformity

Directive: Machinery Directive on machinery safety, 2006/42/EC, Low

Voltage Directive, 2006/95/EC, EMI Directive, 2006/108/EC, European

directive 2002/96/EC on waste electrical and electronic equipment

Conforming Machinery: WAGNER FC9900

Serial number: As marked on nameplate

We hereby certify that the machinery described above conforms with

the essential health and safety requirements of council directives

2002/96/EC, 2006/95/EC, 2006/108/EC, 2006/42/EC

on the approximation of the laws of the member states relating to the

safety of the machinery.

Applied harmonized standards, in particular:

EN 1953:1998+A1:2009, EN 55014-1:2001, BS EN 61000-32:2006+A2:2009, BS EN 61000-3-3:2008, EN 60204-1:2006, BS EN

ISO 12100-1:2003+A1:2009, BS EN ISO 12100-2:2003+A1:2009, AS/

NZS 3100:2009, CISPR 14-1

-------------------Date: 23.9.2010

Manufacturer:

Wagner Spray Tech

1770 Fernbrook Lane

Plymouth, MN 55447

USA

J. Wagner GmbH

Division Professional Finishing

Otto Lilienthal Strasse 18

88677 Markdorf

République fédérale d’Allemagne

20

Loading...

Loading...