Page 1

SECTION 01: ENGINE

CONTENTS

1.

VOLVO D13 ENGINE............................................................................................................................3

1.1 SYSTEM OVERVIEW..................................................................................................................... 3

1.2 ENGINE OVERVIEW...................................................................................................................... 6

1.3 ENGINE OIL ...................................................................................................................................7

1.3.1 General....................................................................................................................................7

1.3.2 Oil Quality ................................................................................................................................ 7

1.3.3 Oil Change Intervals................................................................................................................8

1.3.4 Oil Filters .................................................................................................................................9

1.3.5 Synthetic Lubrication ............................................................................................................... 9

1.3.6 Oil Viscosity ............................................................................................................................. 9

1.3.7 Oil Additives............................................................................................................................. 9

1.3.8 Oil Consumption......................................................................................................................9

1.3.9 Oil Change.............................................................................................................................10

1.3.10 Oil Filters Change..................................................................................................................10

1.3.11 Checking The Oil Level .........................................................................................................11

1.4 POWER PLANT ASSEMBLY REMOVAL.....................................................................................11

1.5 POWER PLANT ASSY. INSTALLATION...................................................................................... 14

1.6 ENGINE MOUNTS .......................................................................................................................14

2. DETROIT DIESEL SERIES 60 ENGINE ............................................................................................. 16

2.1 DDEC VI SYSTEM........................................................................................................................ 16

2.2 HARNESSES................................................................................................................................16

2.3 ENGINE OVERVIEW.................................................................................................................... 17

2.4 DDEC VI SENSORS.....................................................................................................................18

2.5 PREVOST INSTALLED SENSORS ............................................................................................. 19

2.6 MOTOR CONTROL MODULE (MCM).......................................................................................... 19

2.7 COMMON POWERTRAIN CONTROLLER (CPC) ....................................................................... 19

2.8 DDEC VI DIAGNOSTICS.............................................................................................................. 19

2.8.1 Diagnostic system .................................................................................................................19

2.8.2 Check Engine Telltale Light (AWL) ....................................................................................... 20

2.8.3 Stop Engine Warning Light (RSL) ......................................................................................... 20

2.8.4 Stop Engine Override Switch (SEO) ..................................................................................... 20

2.8.5 Diagnostic Data Link (DDL) Connectors ............................................................................... 20

2.9 READING DIAGNOSTIC CODES – FLASHING LIGHT METHOD: .............................................20

2.10 DDEC VI CPC DIAGNOSTIC CODES LIST .................................................................................21

2.11 DDEC VI MCM DIAGNOSTIC CODES LIST ................................................................................28

2.12 ENGINE OIL LEVEL .....................................................................................................................39

2.13 ENGINE OIL AND FILTER CHANGE ........................................................................................... 40

2.14 RECOMMENDED ENGINE OIL TYPE ......................................................................................... 41

2.15 POWER PLANT ASSEMBLY REMOVAL.....................................................................................41

2.16 POWER PLANT ASSY. INSTALLATION...................................................................................... 45

2.17 JAKE BRAKE................................................................................................................................45

2.18 ENGINE MOUNTS .......................................................................................................................45

3. ELECTRONIC FOOT PEDAL ASSEMBLY (EFPA) & THROTTLE POSITION SENSOR ................46

4. ENGINE TROUBLESHOOTING GUIDE.............................................................................................47

5. SPECIFICATIONS............................................................................................................................... 49

5.1 SERIES 60 ENGINE ..................................................................................................................... 49

5.2 VOLVO D13 ENGINE ................................................................................................................... 50

PA1561 1

Page 2

Section 01: ENGINE

ILLUSTRATIONS

FIGURE 1: D13F ENGINE, ALTERNATOR SIDE (TYPICAL) ....................................................................................... 6

FIGURE 2: D13F ENGINE, TURBO SIDE (TYPICAL) ................................................................................................7

FIGURE 3: D13F OIL FILTERS.............................................................................................................................9

FIGURE 4: OIL FILTER WRENCH........................................................................................................................ 10

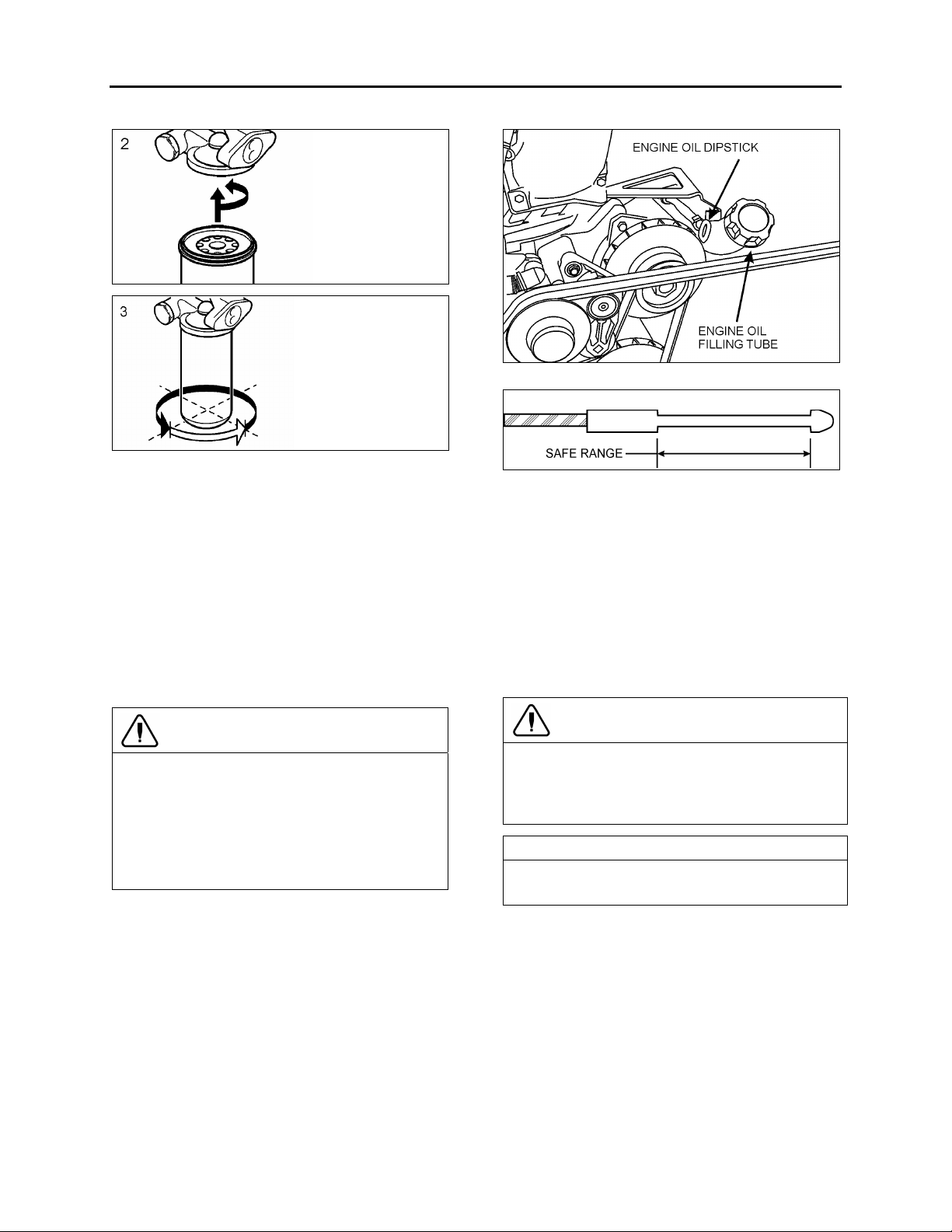

FIGURE 5: OIL FITER REPLACEMENT................................................................................................................. 11

FIGURE 6: ENGINE OIL FILLING TUBE ................................................................................................................11

FIGURE 7: ENGINE OIL LEVEL DIPSTICK ............................................................................................................ 11

FIGURE 8: BELT TENSIONER VALVE..................................................................................................................12

FIGURE 9: ENGINE COMPARTMENT H3 COACHES (TYPICAL) ............................................................................... 14

FIGURE 10: VOLVO ENGINE POWER PLANT CRADLE INSTALLATION .....................................................................15

FIGURE 11: VEHICLE INTERFACE HARNESS (GENERAL APPLICATION SHOWN)...................................................... 16

FIGURE 12: DETROIT DIESEL 2007 SERIES 60 ENGINE (TYPICAL ........................................................................ 18

FIGURE 13: MOTOR CONTROL MODULE (MCM)..................................................................................................19

FIGURE 14: CPC............................................................................................................................................. 19

FIGURE 15: THE CPC COMMUNICATES OVER THE J1587 AND J1939 DATA LINKS TO THE VEHICLE ........................19

FIGURE 16: FLASHING FAULTS CODES ............................................................................................................. 21

FIGURE 17: ENGINE OIL LEVEL DIPSTICK .......................................................................................................... 39

FIGURE 18: OIL RESERVE TANK ....................................................................................................................... 39

FIGURE 19: UNDER VEHICLE VIEW ...................................................................................................................40

FIGURE 20: ENGINE COMPARTMENT ................................................................................................................42

FIGURE 21: ENGINE COMPARTMENT H3 COACHES (TYPICAL) ............................................................................. 44

FIGURE 22: ENGINE COMPARTMENT VIP (TYPICAL)............................................................................................ 44

FIGURE 23: POWER PLANT CRADLE INSTALLATION............................................................................................45

FIGURE 24: ELECTRONIC FOOT PEDAL ASSEMBLY............................................................................................. 46

PA1561 2

Page 3

Section 01: ENGINE

1. VOLVO D13 ENGINE

1.1 SYSTEM OVERVIEW

NOTE

The “Premium Tech Tool” (PTT) is the

preferred tool for performing diagnostic work.

Contact your local dealer for more information.

The Engine Management System (EMS)

controls many engine functions such as: fuel

timing and delivery, engine protection functions,

engine brake operation, EGR valve function and

the turbocharger nozzle function. The Engine

Electronic Control Unit (EECU) along with other

supporting control units and sensors are

responsible for monitoring and controlling these

functions. These control units communicate

through the J1939 high speed serial data line to

share data.

In addition to their control functions, the modules

have on-board diagnostic capabilities. The onboard diagnostics are designed to detect faults

or abnormal conditions that are not within their

operating parameters. When the system detects

a fault or abnormal condition, the fault will be

logged in one or both of the modules’ memory.

The vehicle operator will be advised that a fault

has occurred by the illumination of a malfunction

indicator lamp and a message in the driver

information display, if equipped. The module

may initiate the engine shutdown procedure if

the system determines that the abnormal

condition could damage the engine. In some

situations, the system will enter the "limp home"

mode. Limp home mode allows continued

vehicle operation but, the system may substitute

a sensor or signal value that may result in

reduced engine performance.

Fault codes logged in the system memory, can

later be read to aid in diagnosing the fault.

These faults can be read via a diagnostic

computer or through the instrument cluster

display, if equipped. The “Premium Tech Tool”

(PTT) is the preferred tool for performing

diagnostic work. Using a diagnostic computer

(or PTT) connected to the Serial

Communication Port, expands the technicians

diagnostic capabilities with additional data and

tests.

For diagnostic software, contact your local

dealer.

The following is a list of engine sensors that

provide input to the EMS:

• Ambient Air Temperature Sensor

• Ambient Pressure sensor

• Boost Air Pressure (BAP) Sensor

• Camshaft Position (Engine Position) Sensor

• Crankshaft Position (Engine Speed) Sensor

• Differential Pressure DPF Sensor

• EGR Differential Pressure Sensor

• EGR Temperature Sensor

• Engine Coolant Level (ECL) Sensor

• Engine Coolant Temperature (ECT) Sensor

• Engine Oil Pressure (EOP) Sensor

• Engine Oil Level (EOL) Sensor

• Engine Oil Temperature (EOT) Sensor

• Exhaust Temperature Sensor (DPF

Sensors)

• Fuel Pressure Sensor

• Intake Air Temperature And Humidity (IATH)

Sensor

• Intake Manifold (Boost) Temperature Sensor

• Throttle Position (TP) Sensor

• Turbo Speed Sensor

• Variable Geometry Turbocharger (VGT)

Position Sensor

Sensors

Ambient Air Temperature Sensor

The Ambient Air Temperature Sensor is used to

detect the outside air temperature. The sensor

modifies a voltage signal from the ECM. The

modified signal returns to the ECM as the

ambient air temperature. The sensor uses a

thermistor that is sensitive to the change in

temperature. The electrical resistance of the

thermistor decreases as temperature increases.

The Ambient Air Temperature Sensor is located

in the front of the vehicle.

Ambient (Atmospheric) Pressure Sensor

The Ambient (Atmospheric) Pressure Sensor

contains a pressure sensitive diaphragm and an

electrical amplifier. Mechanical pressure applied

PA1561 3

Page 4

Section 01: ENGINE

to the diaphragm causes the diaphragm to

deflect and the amplifier to produce an electrical

signal proportional to the deflection.

The Ambient (Atmospheric) Pressure Sensor is

built into the Engine Management System

(EMS) Module.

Camshaft Position Sensor

The Camshaft Position (Engine Position) Sensor

is located in the rear face of the timing gear

cover at the rear of the engine, near the bottom

of the valve cover. It uses magnetic induction to

generate a pulsed electrical signal. It senses the

passage of seven (7) timing bumps on the edge

of the camshaft dampener. Six of the holes

correspond to the phasing of the electronic unit

injectors, while the seventh hole indicates the

top dead center position.

Crankshaft Position (Engine Speed) Sensor

The Crankshaft Position (Engine Speed) Sensor

uses magnetic induction to generate a pulsed

electrical signal. Notches are machined into the

edge of the flywheel. When one of the notches

passes close to the sensor, electric pulses

result.

The Crankshaft Position (Engine Speed) Sensor

also indicates when the crankshaft is at the top

dead center position.

EGR Temperature Sensor

The EGR temperature sensor detects exhaust

gas temperature for EGR system. The sensor

modifies a voltage signal from the control unit.

The modified signal returns to the control unit as

the exhaust temperature of the EGR system to

confirm EGR operation. The sensor uses a

thermistor that is sensitive to the change in

temperature.

The EGR Temperature Sensor is located near

the EGR valve.

Engine Coolant Level (ECL) Sensor

The Engine Coolant Level (ECL) Sensor is a

switch. If engine coolant level falls below a

calibrated point the contacts open and the driver

will be notified of the low coolant level.

The Engine Coolant Level (ECL) Sensor is

located in the cooling system reservoir tank.

Engine Coolant Temperature (ECT) Sensor

The Engine Coolant Temperature Sensor is

located at the front of the engine. The sensor

will indicate a high coolant temperature caused

by problems like radiator blockage, thermostat

failure, heavy load, or high ambient

temperatures. This sensor is also used for cold

start enhancement and for fan clutch

engagement.

Differential Pressure DP Sensor

The differential pressure sensor is used for flow

measurement of the Diesel Particulate Filter

(DPF). This sensor has two pressure ports and

senses the difference in pressure between the

two ports. Measurement of the pressure before

and after the DPF is used to calculate diesel

filter regeneration.

The Differential Pressure DPF Sensor is located

on the side of the Diesel Particulate Filter (DPF).

EGR Differential Pressure Sensor

The EGR differential pressure sensor is used for

flow measurement of the Exhaust Gas

Recirculation (EGR) valve. This sensor has two

pressure ports and senses the difference in

pressure between the two ports. Measurement

of the pressure before and after the EGR valve

is used to calculate EGR flow.

The EGR Differential Pressure Sensor is located

on the left or right side of the engine.

Engine Oil Pressure (EOP) Sensor

The Engine Oil Pressure Sensor contains a

pressure sensitive diaphragm and a electrical

amplifier. Mechanical pressure applied to the

diaphragm causes the diaphragm to deflect and

the amplifier to produce an electrical signal

proportional to the deflection.

The Engine Oil Pressure Sensor is located on

the oil filter assembly. The sensor monitors

engine oil pressure to warn of lubrication system

failure.

Engine Oil Level (EOL) Sensor

The Engine Oil Level Sensor is located in the oil

pan.

Engine Oil Temperature (EOT) Sensor

The Engine Oil Temperature Sensor is a

thermistor whose resistance varies inversely to

temperature. The sensor has a negative

PA1561 4

Page 5

Section 01: ENGINE

temperature coefficient, which means the sensor

resistance will decrease as the engine oil

temperature increases.

The Engine Oil Temperature Sensor is located

in the oil pan.

Exhaust Temperature Sensor (DPF Sensors)

The exhaust gas temperature sensor detects

exhaust gas temperature for DPF protection as

well as DPF regeneration control. The sensor

modifies a voltage signal from the control unit.

The modified signal returns to the control unit as

the exhaust temperature at that specific location

of the exhaust. The sensor uses a thermistor

sensitive to the change in temperature.

that is

The Exhaust Temperature Sensors are located in

the DPF assembly.

Fuel Pressure Sensor

The fuel pressure sensor contains a diaphragm

that senses fuel pressure. A pressure change

causes the diaphragm to flex, inducing a stress

or strain in the diaphragm. The resistor values in

the sensor change in proportion to the stress

applied to the diaphragm and produces an

electrical output.

The Fuel Pressure Sensor is located on top of

the fuel filter housing.

air temperature increases.

The Intake Manifold (Boost) Temperature

Sensor is located in the intake manifold.

Intake Manifold Pressure Sensor

The Intake Manifold Pressure Sensor contains a

pressure sensitive diaphragm and an electrical

amplifier. Mechanical pressure applied to the

diaphragm causes the diaphragm to deflect and

the amplifier to produce an electrical signal

proportional to the deflection.

The Intake Manifold Pressure Sensor is located

on the air inlet pipe before the intake manifold.

Throttle Position (TP) Sensor

The Throttle Position Sensor is a potentiometer

that is mechanically linked to the accelerator

pedal. A potentiometer is a variable resistor

whose resistance will change as the pedal is

pressed. As the resistance changes, the signal

voltage of the sensor changes indicating the

accelerator pedal position.

The Throttle Position Sensor is located above

the accelerator pedal. The sensor is designed to

improve the driver’s control by reducing

sensitivity to chassis motion. This sensor

provides the driver’s fuel request input to the

VECU.

Intake Air Temperature and Humidity (IATH)

Sensor

The Intake Air Temperature and Humidity (IATH)

Sensor contains a thermistor and a capacitive

sensor. The resistance of the thermistor varies

inversely to temperature. The output of the

capacitive sensor increases as the humidity of

the surrounding air increases. By monitoring the

signals from both portions of the sensor, the

Engine Management System (EMS) Module

calculates the temperature and humidity of the

air passing through the air filter housing.

The Intake Air Temperature and Humidity (IATH)

Sensor is located in the air intake tube just

downstream from the air filter canister.

Intake Manifold (Boost) Temperature Sensor

The Intake Manifold (Boost) Temperature

Sensor is a thermistor whose resistance varies

inversely to temperature. The sensor has a

negative temperature coefficient, which means

the sensor resistance will decrease as the inlet

Turbo Speed Sensor

The Turbo Speed Sensor informs the EMS of

the turbo shaft speed. The sensor does not read

from the vanes, but reads from the shaft. The

Engine Management System (EMS) Module

uses this signal in conjunction with the VGT

position sensor signal to control the speed of the

turbocharger and therefore optimize the intake

manifold pressure.

The Turbo Speed Sensor is mounted in the

center of the turbocharger.

Variable Geometry Turbocharger Smart

Remote Actuator (VGT SRA)

The Variable Geometry Turbocharger Smart

Remote Actuator (VGT SRA) takes the position

commands from the EMS, moves the nozzle of

the turbocharger to the desired position, and

performs all of the diagnostics and self checks

on the actuator.

PA1561 5

Page 6

Section 01: ENGINE

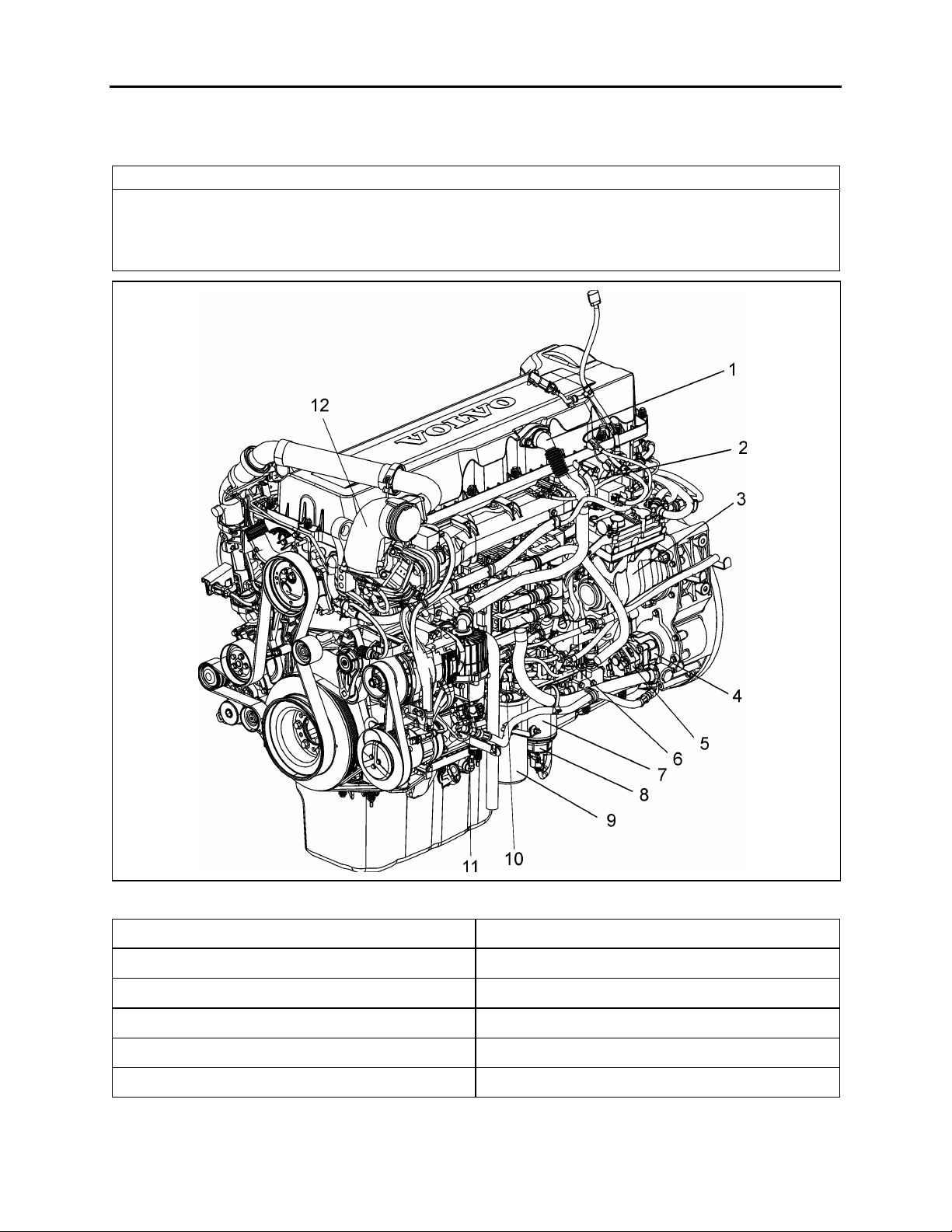

1.2 ENGINE OVERVIEW

NOTE

For additional information concerning Volvo D13 engine components or engine-related components,

consult Volvo Trucks Canada or Volvo Trucks North America Web Site under: Parts & Service. On

Volvo web site, you will find detailed service procedures for parts replacement, repair and

maintenance.

FIGURE 1: D13F ENGINE, ALTERNATOR SIDE (TYPICAL)

1. Breather Tube 7. Fuel Filter

2. Intake Manifold 8. Fuel/Water Separator

3. Air Compressor 9. Fuel Filter

4. Power Steering Pump 10. Hand-Priming Pump

5. Fuel Pump 11. Crankcase Ventilator

6. Engine Electronic Control Unit (EECU) 12. EGR Mixing Chamber

PA1561 6

Page 7

Section 01: ENGINE

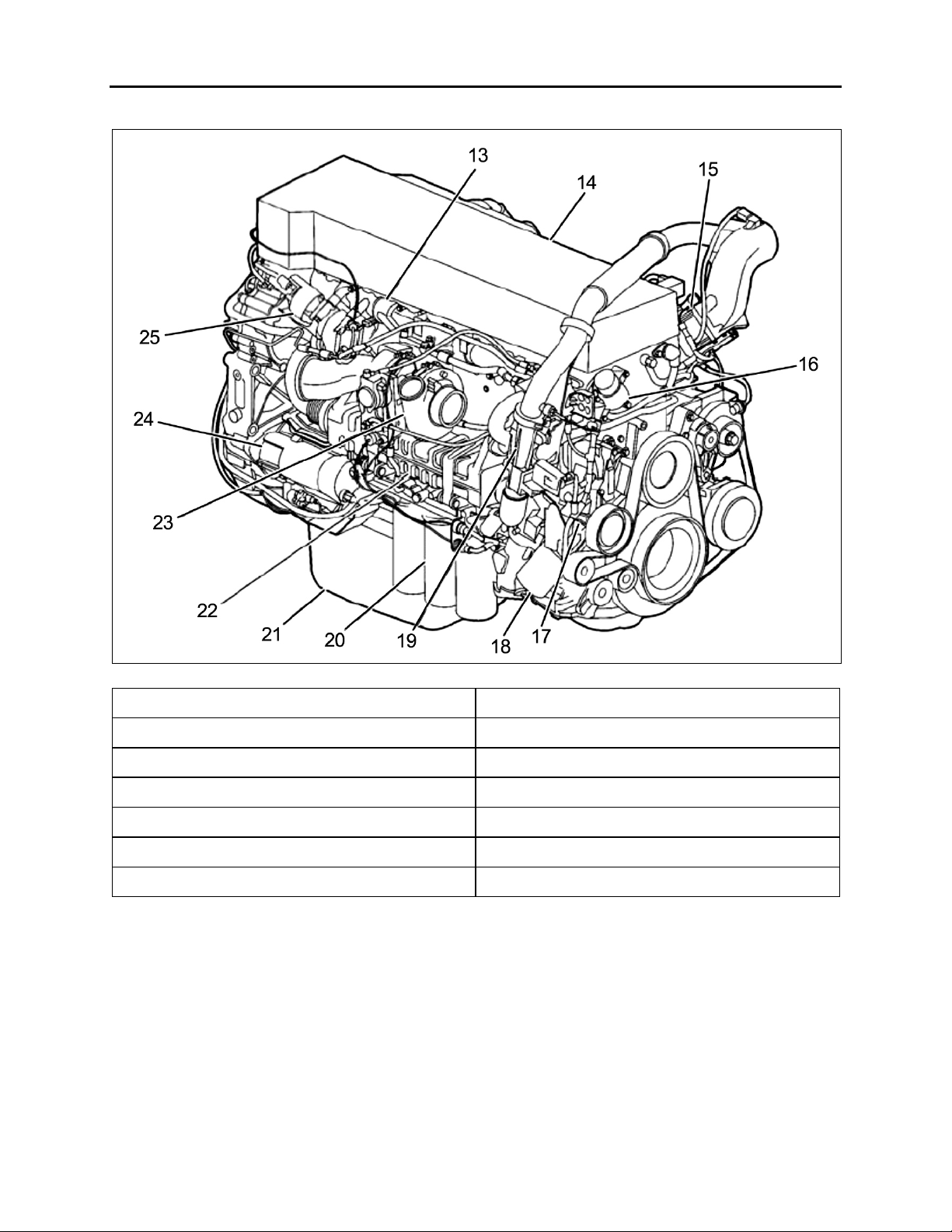

FIGURE 2: D13F ENGINE, TURBO SIDE (TYPICAL)

13. Exhaust Manifold 20. Oil Filters

14. Valve Cover 21. Oil Pan

15. Engine Pre-Heater Element (Optional) 22. EGR Cooler

16. DRV Valve 23. Turbocharger

17. Coolant Pump 24. Starter Motor

18. Coolant Filter 25. EGR Valve

19. Venturi Pipe

1.3 ENGINE OIL

1.3.1 General

Keep the engine oil at the proper level and change it at the recommended intervals. Always replace the

oil filters at the same time as when the oil is changed.

1.3.2 Oil Quality

Volvo North America recognizes engine oils that meet or exceed the standards given by American

Petroleum Institute (API) for the oil classifications listed in this manual. Only oils licensed to carry the API

PA1561 7

Page 8

Section 01: ENGINE

symbol should be used. Lubricants meeting API standards have provided maximum engine life when

used together with the recommended oil and oil filter change intervals.

EO-O Premium Plus (or VDS-4) diesel engine oil is mandatory for use in all 2007 emission compliant

Volvo engines. Chassis equipped with a 2007 emission compliant engine, which can be identified by the

presence of a Diesel Particulate Filter (DPF), also require the use of Ultra Low Sulfur Diesel (ULSD) fuel.

EO-O Premium Plus oils exceed the new API service category CJ-4.

CAUTION

DO NOT add extra oil additives. Additives such as break-in oils, top oils, graphitizers, and frictionreducing liquids are not necessary and can harm the engine.

1.3.3 Oil Change Intervals

The length of time an engine can operate before an oil change depends on the quality oil used, the type

of fuel used, fuel consumption, engine oil consumption, vehicle application, level of dust in the air, and

fuel consumption. The change intervals given in this manual are maximum intervals. If the vehicle is

operating in heavy-duty operation, dusty or off-road conditions, etc., reduce the intervals for more

frequent oil changes.

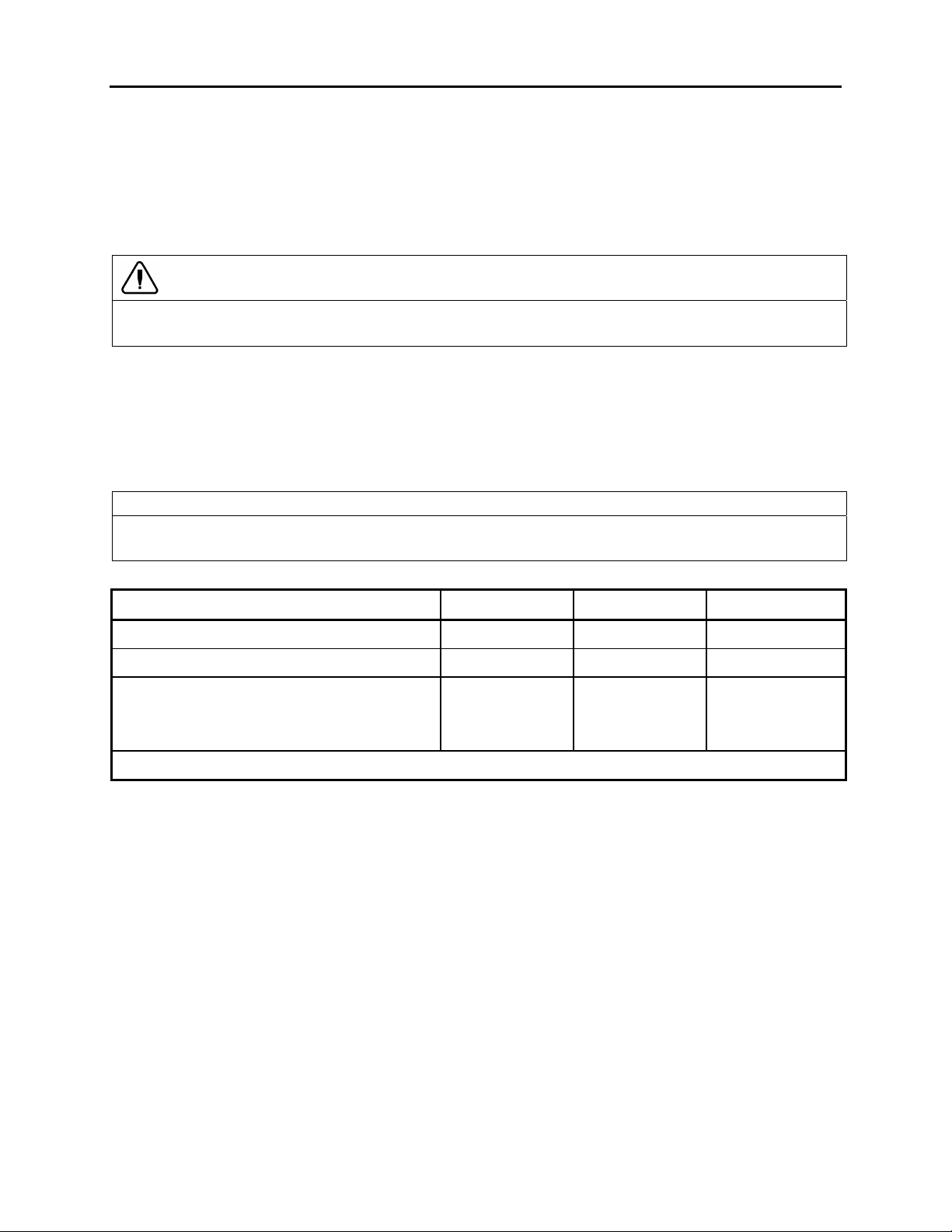

NOTE

Use the information in the table below to determine the operating condition and usage applicable to your

vehicle.

Engine Operating Condition Medium Heavy Severe

Total Fuel Consumption (mpg) More than 6 More than 4.7 More than 3.7

Total Fuel Consumption (L/100 KM) Less than 39 Less than 50 Less than 64

Engine Oil and Filter Change

Interval, miles (km) – 41 U.S. quarts (39L)

Oil capacity

NOTE: If idle time is greater than 25%, use the next lower drain interval.

35,000 (55 000) 25,000 (40 000) 15,000 (24 000)

PA1561 8

Page 9

Section 01: ENGINE

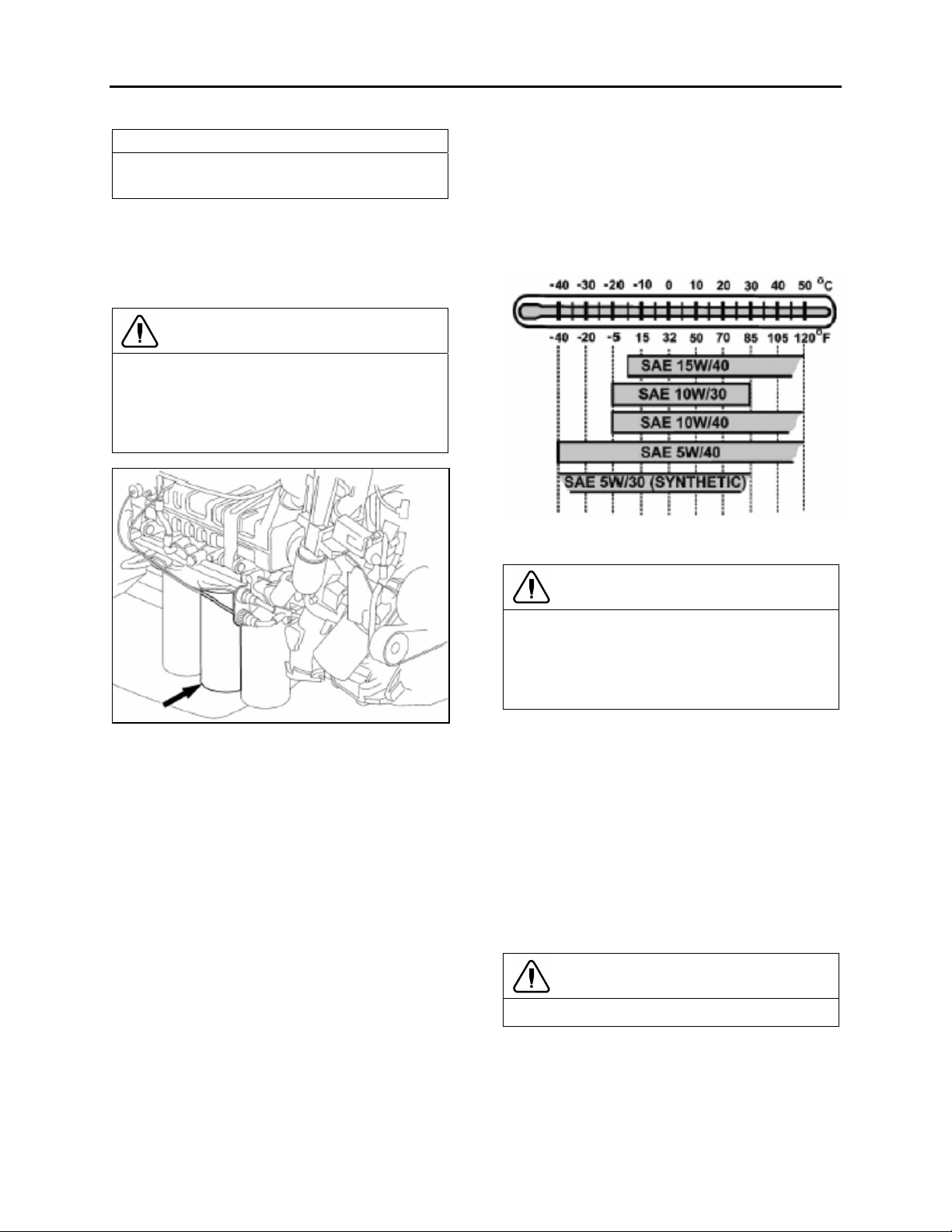

NOTE

Oil filters should always be changed when

changing the oil.

1.3.4 Oil Filters

There are three filters on the engine, one of

which is a bypass filter. This should be changed

at the same time as the full-flow filter(s).

CAUTION

Volvo branded oil filters are designed to

provide the proper level of filtration and

protection for Volvo engines. Filters that do

not meet the same stringent requirements

may void engine warranty.

Choose the viscosity grade for the typical

ambient temperature for the application.

Multigrade oils have a broad range that suit

operation in changing temperature.

Volvo North America recommends the

viscosities shown in the viscosity/temperature

table for Volvo engines.

1.3.7 Oil Additives

FIGURE 3: D13F OIL FILTERS

1.3.5 Synthetic Lubrication

Synthetic oils are offered by some oil suppliers

as an alternative to the traditional, petroleum

based oils for engines. These oils may be used

in Volvo engines, provided they meet the quality

levels specified on the previous pages, that is:

both VDS-4 and EO-O Premium Plus.

The use of synthetic oils does not permit the

extension of the recommended oil change

intervals.

1.3.6 Oil Viscosity

The viscosity grade defines the thickness of the

oil. The oil must be thin enough at low

temperatures for easy cold starts and thick

enough to protect at high temperatures. An oil is

not fully defined until both the API quality

classification and the viscosity grade are

specified.

CAUTION

Extra oil additives must never be added to

any engine oil used. Additives such as breakin oils, top oils, graphitizers, and friction

reducing liquids are not necessary and may

even harm the engine.

Using oils to the quality standards

recommended in this manual makes the use of

extra oil additives unnecessary, as these oils

already contain a balanced treatment of

additives.

1.3.8 Oil Consumption

Once the engine is stopped, check the oil level

daily. If the engine has just been stopped and it

is warm, wait approximately five minutes to allow

the oil to drain back to the oil pan before

checking. Add oil as necessary.

CAUTION

DO NOT overfill engine with oil.

All diesel engines are designed to consume

some oil, so it is normal to add oil periodically.

An engine used in heavy-duty operation will

consume more oil than one in normal operation.

PA1561 9

Page 10

Section 01: ENGINE

1.3.9 Oil Change

WARNING

A hot engine or engine oil can be dangerous.

Serious burns can result from contact with a

hot engine or oil. Take precautions when

draining the oil. Wear gloves or let the engine

cool down before draining.

WARNING

When draining the oil, use the proper tools

and keep away as far as possible. Raise the

elbow so the forearm is parallel to the ground

to prevent oil running down the arm, causing

burns.

CAUTION

Always dispose of all lubricants (motor oil,

coolant, gear box oils, etc) and filters

according to Federal or local regulations.

Used oil disposed of in nature or waterways

contaminates our drinking water and kills

wildlife.

1.3.10 Oil Filters Change

WARNING

Hot oil can cause severe burns. DO NOT

allow hot oil to contact the skin. When

changing oil, wear protective gloves.

CAUTION

Volvo-branded oil filters are designed to

provide the proper level of filtration and

protection for Volvo engines. Filters that do

not meet the same stringent requirements

may cause unsatisfactory results.

• Clean around the oil filter housing and

remove the filters using the oil filter

wrench or the oil filter socket.

WARNING

Prolonged contact with used engine oil may

be harmful. Use rubber gloves when handling

used oil. Wash skin thoroughly if it comes in

contact with used oil.

It is important to drain as much oil as possible.

Try to change oil immediately after driving, when

the oil is warm. Always replace the oil filters

when changing the oil.

Component Capacity (L)

Oil pan 24 min - 32 max

Engine block 4.5

Filters (3) 6

Total oil fill (empty) 42.5

NOTE

Since about 1 liter of oil remains in the engine

after draining, approximately 38 liters will be

needed for a complete oil change.

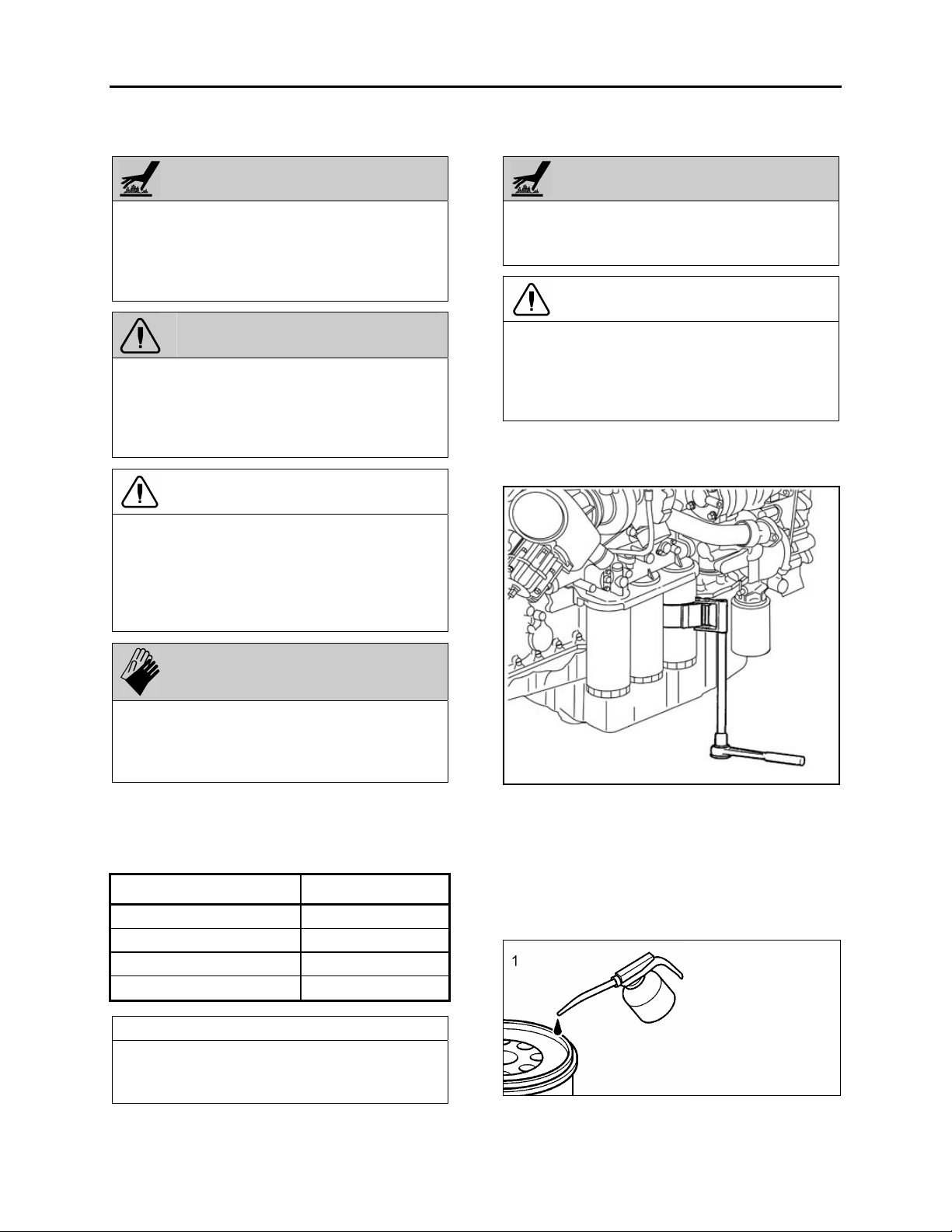

FIGURE 4: OIL FILTER WRENCH

• Prefill the new oil filters with approved

engine oil. Also, lubricate the filter gaskets

with engine oil (1). Hand tighten the oil

filters until they contact the sealing surface

of the oil filter housing (2). Manually

tighten the oil filters an additional ¾ to 1

full turn (3).

PA1561 10

Page 11

Section 01: ENGINE

FIGURE 5: OIL FITER REPLACEMENT

• Start the engine and check for leaks

around the oil filter housing and filters.

• Check the oil level. Add approved engine

oil to the recommended level, if

necessary. Do not overfill.

1.3.11 Checking the Oil Level

Ensure that the vehicle is parked on level

ground before checking the oil level. Wait five

minutes after shutting off the engine and then

proceed with checking the oil.

CAUTION

DO NOT let the oil level fall below the marking

on the dipstick. DO NOT overfill so the level is

above the upper marking on the dipstick. This

could lead to excessive oil temperature and/or

poor crankcase breather performance. Add oil

through the oil filler pipe as required in order

to maintain level within the safe range.

FIGURE 6: ENGINE OIL FILLING TUBE

FIGURE 7: ENGINE OIL LEVEL DIPSTICK

1.4 POWER PLANT ASSEMBLY REMOVAL

To access the engine or engine-related

components, the vehicle power plant assembly

must be removed as a whole unit by means of a

slide-out cradle. The power plant assembly

includes the engine, transmission (including

retarder if so equipped), air compressor,

alternator and transmission oil cooler.

Remove the power plant assembly as follows:

CAUTION

Tag hoses and cables for identification before

disconnecting in order to facilitate reinstallation.

Plug all openings to prevent dirt from entering

the system.

NOTE

No parts within the EECU are serviceable. If

found defective, replace the EECU as a unit.

PA1561 11

• Preparation

1. Close the heater lines shut-off valves.

2. Disconnect the battery or batteries from the

starting system by removing one or both of

the battery cables from each battery system.

With the electrical circuit disrupted,

accidental contact with the starter button will

not produce an engine start.

Page 12

Section 01: ENGINE

WARNING

Due to the heavy load of the rear bumper

assembly, it must be adequately supported

before attempting to remove it.

3. Remove the rear bumper assembly from the

vehicle. Refer to Section 18

"Rear Bumper Removal".

4. If applicable, disconnect the block heater

connector located near the EGR mixing

chamber.

BODY, under

9. Disconnect and remove the air intake duct

mounted between the turbocharger outlet

and the air cooler inlet.

10. Disconnect and remove section of coolant

pipe assembly mounted between the radiator

outlet and the water pump inlet.

11. Disconnect and remove a section of coolant

pipe assembly mounted between the

thermostat housing and the radiator inlet, if

applicable.

12. Disconnect the electric fan-clutch connector

located near the cooling fan right angle

gearbox.

13. Disconnect the cooling fan drive shaft.

CAUTION

To avoid damage to cooling fan right angle

gearbox, make sure the power plant cradle

clears the gearbox when pulling the engine out.

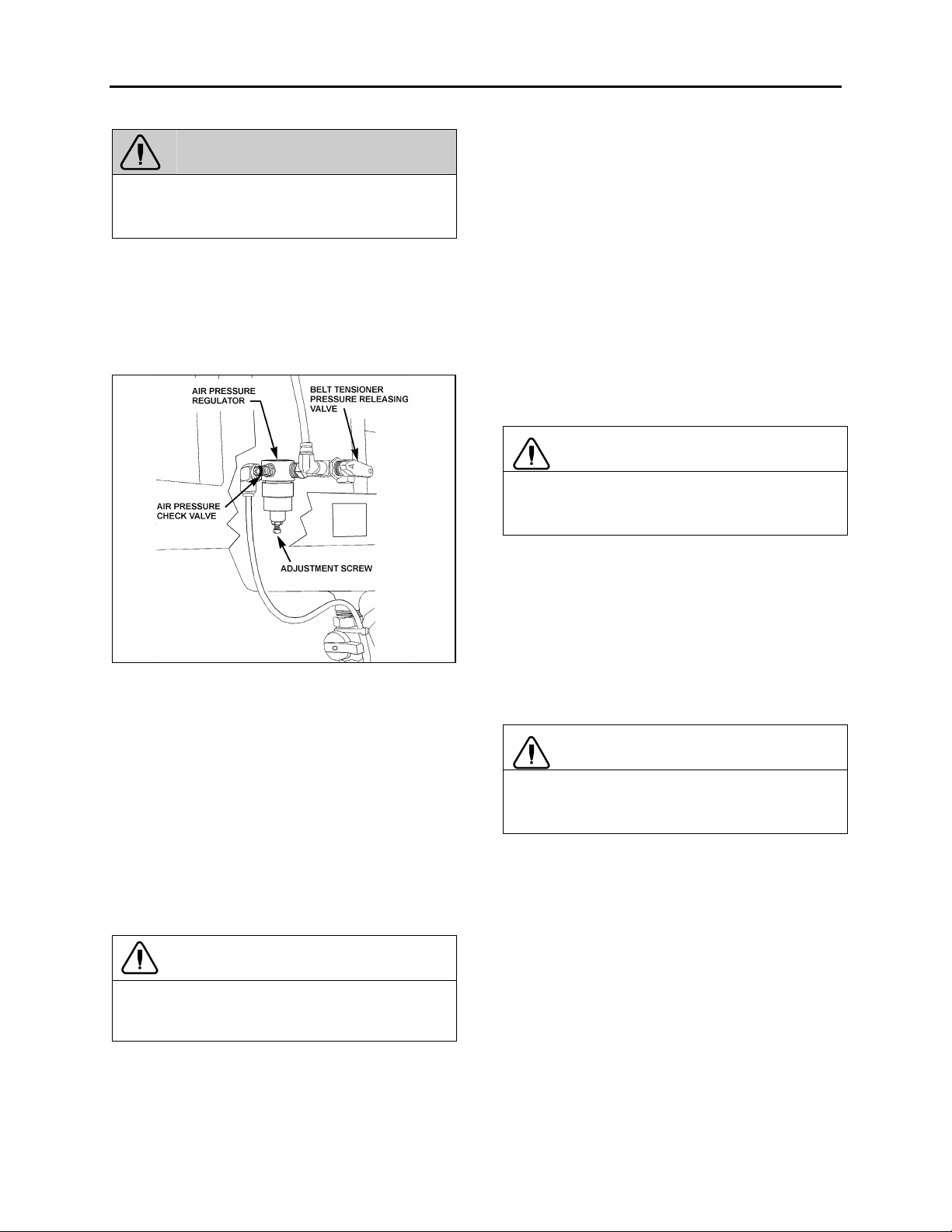

FIGURE 8: BELT TENSIONER VALVE

5. Locate the A/C compressor belt tensioner

pressure releasing valve (Fig. 8). Turn

pressure releasing valve handle

counterclockwise in order to release pressure

in belt-tensioner air bellows and loosen belt.

Remove the A/C compressor belt.

6. To release all pressure from the air system.

Refer to Section 12, BRAKES & AIR

SYSTEM for instructions.

7. Disconnect and remove the engine-air intake

duct mounted between air cleaner housing

and turbocharger inlet.

CAUTION

To avoid damage to turbocharger, cover the

turbocharger inlet opening to prevent foreign

material from entering.

8. Disconnect and remove the air intake duct

mounted between the air cooler outlet and

the engine intake.

12200

14. Disconnect surge tank hoses connected to

the thermostat housing, the pump inlet and to

the transmission oil cooler.

15. Disconnect and remove the exhaust pipe

mounted between the flexible coupling and

the pipe going to the Aftertreatment Device

(ATD). If necessary, refer to Section 04

EXHAUST

and Installation".

SYSTEM under “Muffler Removal

CAUTION

To avoid damage to turbocharger, cover the

turbocharger outlet opening to prevent foreign

material from entering.

16. Remove the power steering pump.

17. Close engine fuel supply shutoff valve on

primary fuel filter or Fuel Pro. Disconnect the

fuel line located above fuel filters and

connected to inlet port. On vehicles equipped

with the optional fuel filter/water separator,

disconnect the connector and remove cable

ties from cradle.

• With Vehicle Raised

18. Using the quick-connect drain hose, drain

the engine cooling system. Refer to Section

COOLING under "Draining Cooling System".

05

PA1561 12

Page 13

Section 01: ENGINE

19. From under the vehicle, disconnect the

propeller shaft as detailed in Section 09,

under heading "Propeller Shaft Removal".

20. On vehicles equipped with an automatic

transmission provided with a hydraulic output

retarder, disconnect steel-braided airline from

pressure regulator output. The pressure

regulator is mounted in the upper section of

engine compartment backwall and is

accessible through the engine compartment

R.H. side door.

21. Remove the retaining bolts, washers and

nuts securing the power plant cradle to the

vehicle rear subframe.

22. Disconnect transmission harness from

transmission housing.

• With Vehicle Lowered

23. Disconnect the air compressor discharge,

governor steel-braided airlines and manual

filling airlines from compressor. Remove

retaining clips.

24. Disconnect the hose connecting the

compressor head to the sump tank, if

applicable.

25. Disconnect ground cables from rear

subframe ground-stud located close to the

starter motor.

26. Disconnect alternators cooling duct and put

aside.

27. Inside rear electrical compartment,

disconnect starter, alternators and heater

cables. Also disconnect AFSS cable if

applicable.

28. Disconnect Aftertreatment Device (ATD)

control cable.

29. Disconnect VIH (vehicle interface harness)

connector.

30. Disconnect fuel return line from bulkhead

fixed on engine cylinder head end.

31. Unfasten and put aside engine compartment

lighting fixture and turbocharger fire

suppression nozzle if applicable.

32. Disconnect turbo boost pressure gauge

airline from engine air intake, if applicable.

33. Disconnect the engine coolant hose near the

starter.

34. On partition wall, disconnect connector C397

located between engine compartment and

main power compartment.

35. Inspect the power plant assembly to ensure

that nothing will interfere when sliding out the

cradle. Check for connections or hoses not

mentioned in this list as some vehicles are

equipped with special or aftermarket

components.

NOTE

Check if any spacer(s) have been installed

between power plant cradle and vehicle rear

subframe, and if so, note position of each

washer for reinstallation purposes.

36. Using a forklift, with a minimum capacity of

4,000 lbs (1 800 kg), slightly raise the power

plant cradle.

37. Pull engine out slowly from the engine

compartment. Make sure all lines, wiring and

accessories are disconnected and are not

tangled.

CAUTION

Due to the minimum clearance between the

power plant equipment and the top of the

engine compartment, extreme care should be

used to raise the power plant cradle, just

enough to free the cradle. Clearance between

power plant cradle and mounting rail should

range between ¼" and ½" (6-12 mm).

PA1561 13

Page 14

Section 01: ENGINE

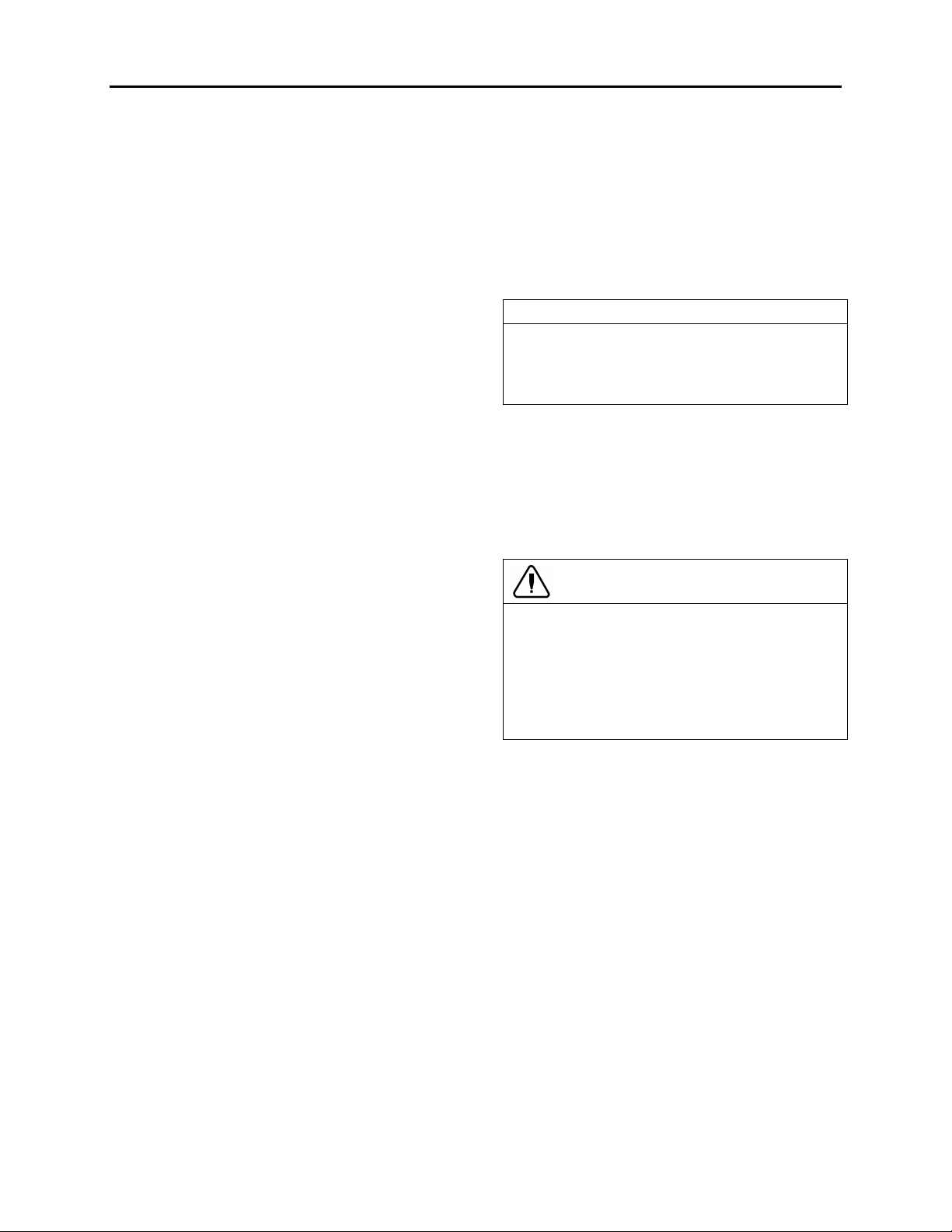

FIGURE 9: ENGINE COMPARTMENT H3 COACHES (TYPICAL) 01193

1.5 POWER PLANT ASSY. INSTALLATION

It is recommended that new rubber mounts be

installed at each major overhaul.

To install a power plant assembly, follow the

same procedure as in "Power Plant Assembly

Removal" except in reverse order, then proceed

with the following:

1. Torque the power plant cradle mounting

NOTE

Refer to the table on the following page for

engine cradle tightening torques.

bolts to 190 lbf-ft (255 Nm).

2. Refill cooling system with saved fluid (refer

to Section 05

COOLANT SYSTEM).

3. Once engine fuel system has been drained,

it will aid restarting if fuel filters are filled with

fuel oil (refer to Section 03

FUEL SYSTEM).

4. Start engine for a visual check. Check fuel,

oil, cooling, pneumatic and hydraulic system

connections for leakage. Test operation of

engine controls and accessories.

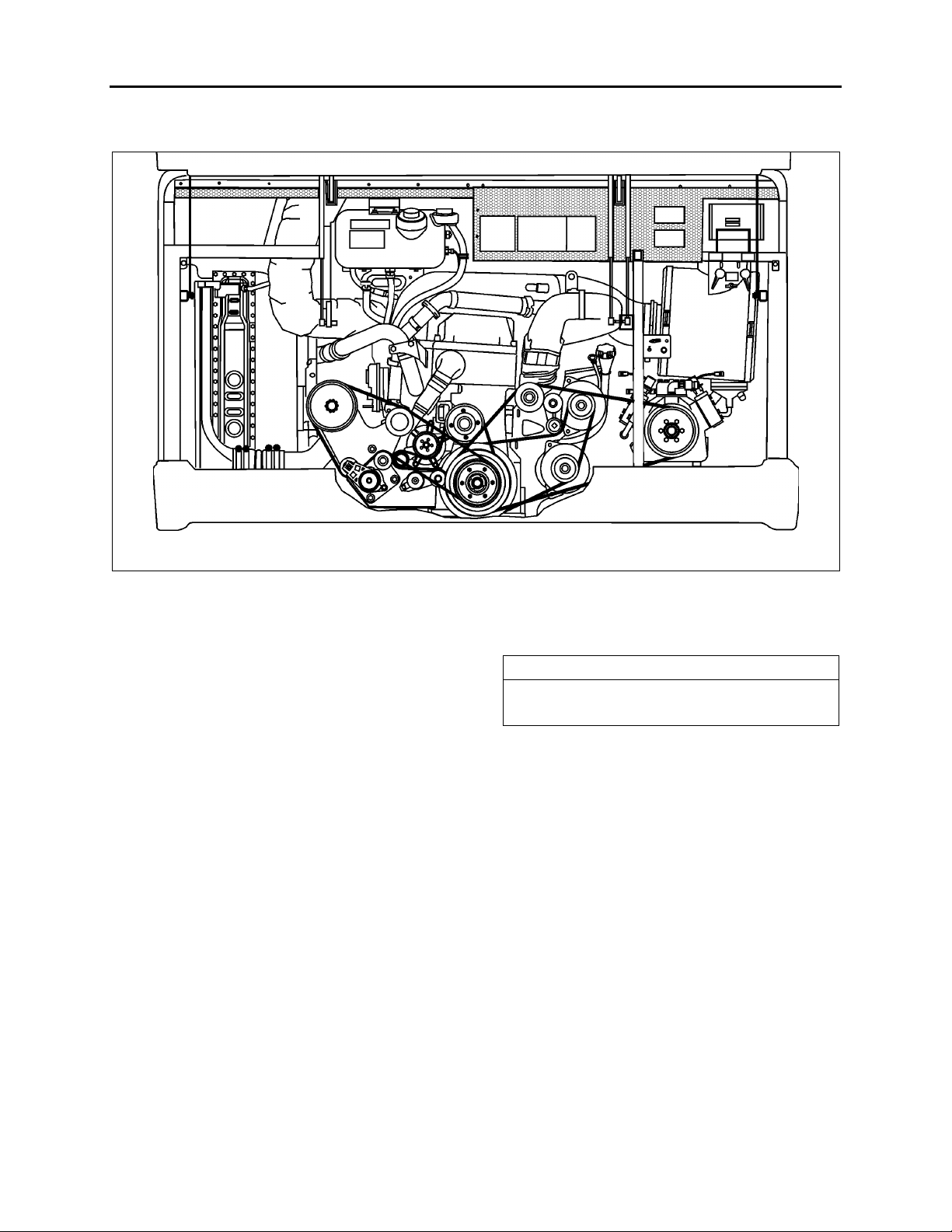

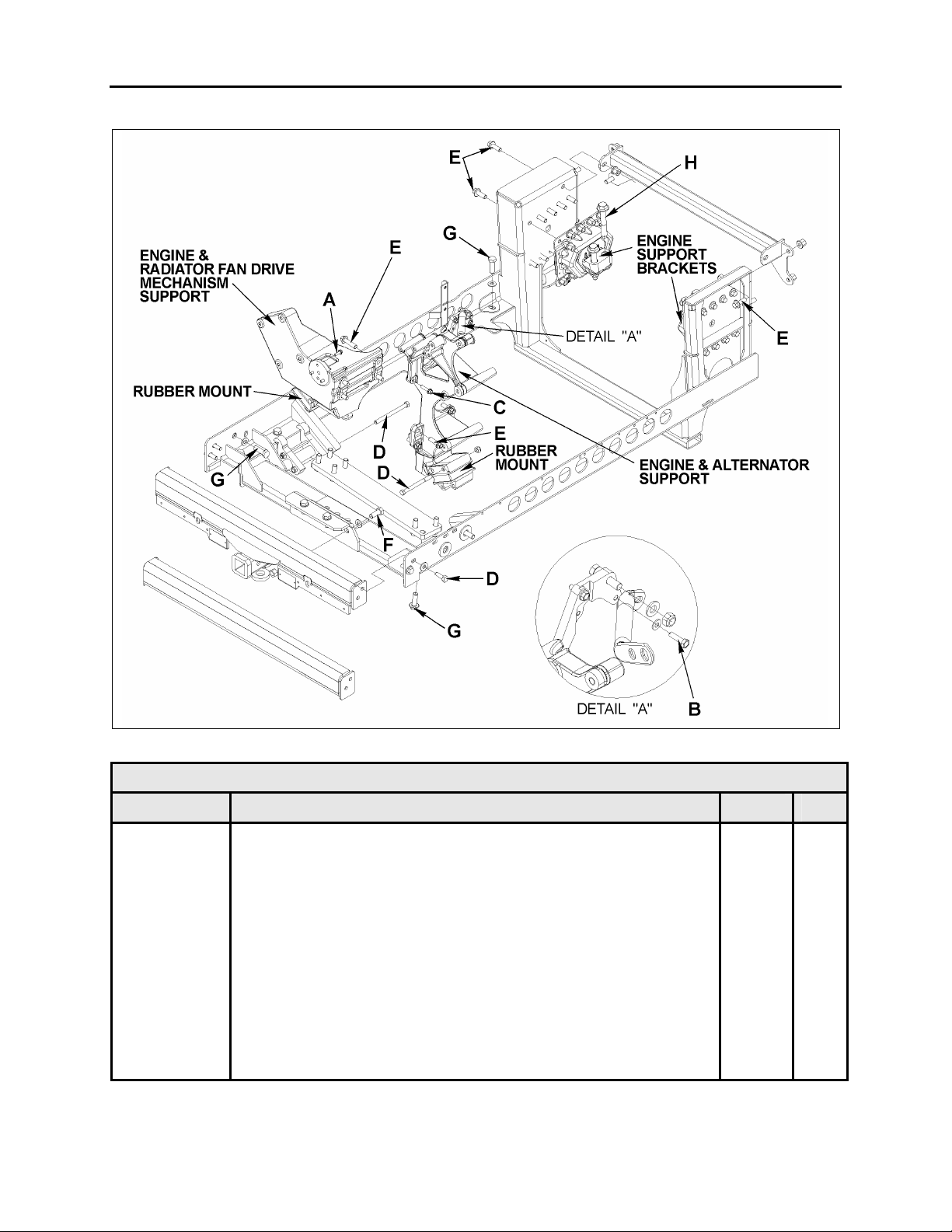

1.6 ENGINE MOUNTS

The power plant assembly is mounted to the

cradle by means of rubber mounts and supports.

Two engine support brackets are used at the

front of the engine while two rubber mounts are

mounted underneath the engine & radiator fan

drive mechanism support and the engine &

alternator support (Fig. 10).

PA1561 14

Page 15

Section 01: ENGINE

FIGURE 10: VOLVO ENGINE POWER PLANT CRADLE INSTALLATION

DRY TORQUES

REFERENCE DESCRIPTION Lbf-ft Nm

A SCREW, CAP HEXAGONAL HEAD M8 – 1.25 G8.8 16 22

B SCREW, CAP HEXAGONAL HEAD M8 – 1.25 G10.9 22 30

C SCREW, CAP HEXAGONAL HEAD M10 – 1.5 G10.9 43 58

D SCREW, CAP HEXAGONAL HEAD M12 – 1.75 G8.8 60 81

E SCREW, CAP HEXAGONAL HEAD M14 – 2.0 G8.8 90 122

F SCREW, CAP HEXAGONAL HEAD M16 – 2.0 G8.8 140 190

G SCREW, CAP HEXAGONAL HEAD M16 – 2.0 G10.9 190 258

H SCREW, CAP HEXAGONAL HEAD M20 – 2.5 G10.9 450 610

PA1561 15

Page 16

Section 01: ENGINE

2. DETROIT DIESEL SERIES 60 ENGINE

The DDC series 60 engine is a 6-cylinder, fourcycle, 14.0 liters Detroit Diesel series 60 engine,

equipped with an electronic control system

(DDEC VI).

Complete maintenance and repair information

on the engine will be found in the current

DETROIT DIESEL SERIES 60 2007 ONHIGHWAY SERVICE MANUAL 6SE2007. This

essential

manual contains complete instructions

on operation, adjustment (tune-up), preventive

maintenance and lubrication, parts verification,

repair or replacement. This manual’s sections

cover complete systems such as:

• Engine main assembly;

• Fuel system;

• Lubrication system;

• Cooling system;

• Fuel, lubricating oil and coolant;

• Air intake system;

• Exhaust system;

• Exhaust gas recirculation components;

• Electrical equipment;

• Operation and verification;

• Engine tune-up;

system has a chassis-mounted control unit for

vehicle engine management, the Common

Powertrain Controller (CPC). The connection to

the vehicle is made via a CAN interface which

digitally transmits the nominal values (e.g.

torque, engine speed specification, etc.) and the

actual values (e.g. engine speed, oil pressure,

etc.).

DDEC VI controls the timing and amount of fuel

injected by the electronic unit injectors (EUI).

The system also monitors several engine

functions using electrical sensors, which send

electrical signals to the Motor Control Module

(MCM). The MCM computes the electrical

signals and determines the correct fuel output

and timing for optimum power, fuel economy

and emissions. The MCM also has the ability to

display warnings or shut down the engine

completely (depending on option selection) in

the event of damaging engine conditions, such

as low oil pressure or high engine temperature.

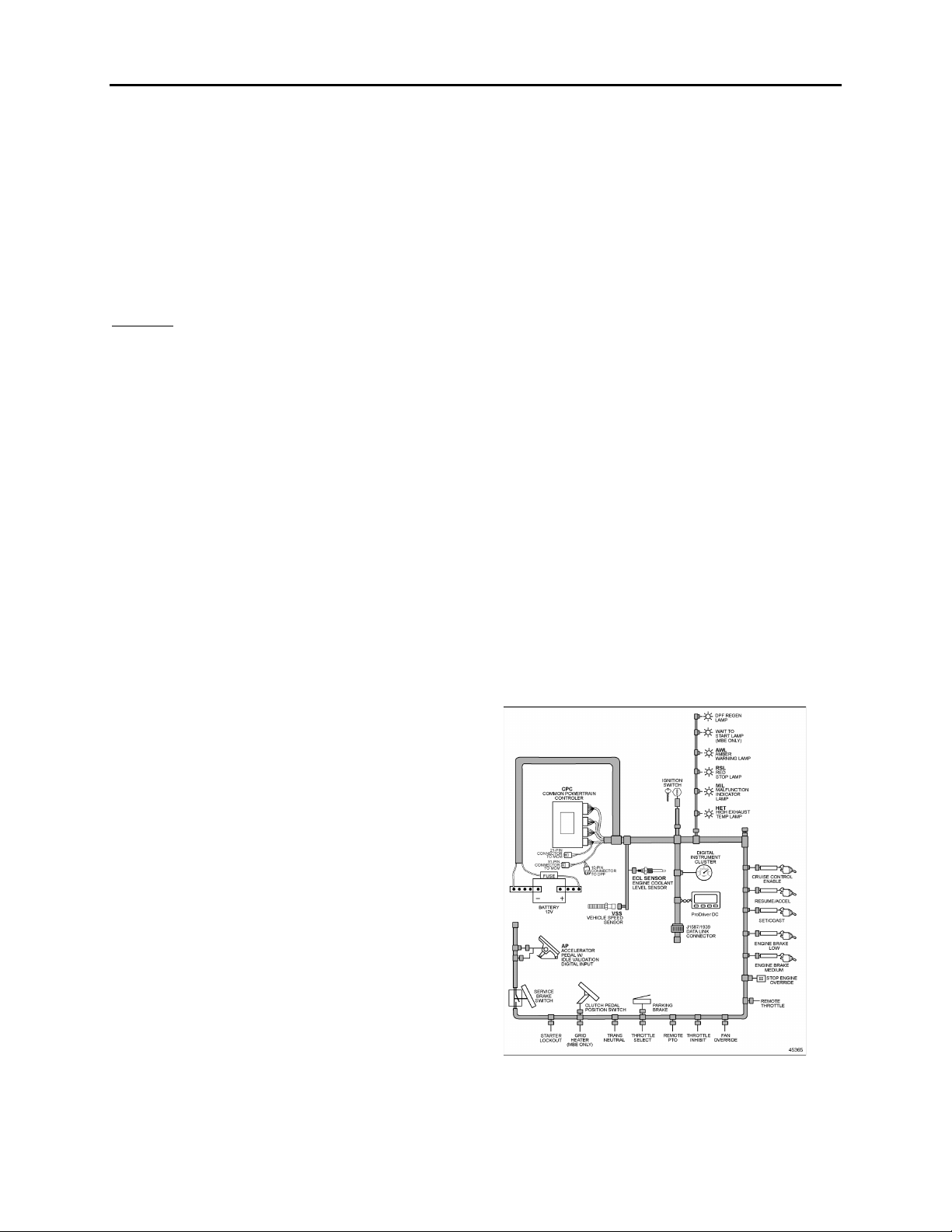

2.2 HARNESSES

There are two major harnesses: the Engine

Harness (EH) and the Vehicle Interface Harness

(VIH). The Engine Harness is installed at the

Detroit Diesel factory and is delivered connected

to all engine sensors, the fuel injection system,

and the MCM.

The OEM supplied Vehicle Interface Harness

connects the CPC to other vehicle systems.

• Preventive maintenance;

• Storage;

Refer to Series 60 DDEC VI Troubleshooting

Guide published by Detroit Diesel for more

complete information on diagnosis of

components and system problems.

Procedures for engine removal and installation

are given at the end of this section. The DDEC

system is self-diagnostic. It can identify faulty

components and other engine-related problems

by providing the technician with diagnostic

codes.

2.1 DDEC VI SYSTEM

DDEC VI (Detroit Diesel Electronic Control) is a

system that monitors and determines all values

required for the operation of the engine. A

diagnostic interface is provided to connect to an

external diagnosis tester. Besides the engine

related sensors and the engine-resident control

unit, the Motor Control Module (MCM), this

PA1561 16

FIGURE 11: VEHICLE INTERFACE HARNESS (GENERAL

APPLICATION SHOWN)

Page 17

2.3 ENGINE OVERVIEW

Section 01: ENGINE

1- Starter motor

2- Oil pan drain plug

3- Primary fuel-filter/waterseparator

4- MCM (DDEC VI Electronics)

5- Secondary fuel filter shutoff

valve

6- Secondary fuel filter

7- Fuel pump

8- Air compressor

9- Engine oil filling tube

10- Bosch alternators (2)

11- Engine oil dipstick

12- EGR delta pressure sensor

18- Thermostat housing

19- Turbo compressor outlet

20- Actuator coolant return line

21- Electrically controlled actuator

22- HC doser

23- Closed-crankcase breather/oil separator

13- EGR valve

14- Intake throttle

15- EGR mixer

16- Intake manifold

17- Engine Harness

PA1561 17

Page 18

Section 01: ENGINE

24- Water pump

25- EGR cooler

26- Oil filter (2)

27- Crankcase breather tube

28- EGR tube

FIGURE 12: DETROIT DIESEL 2007 SERIES 60 ENGINE (TYPICAL) 01179

2.4 DDEC VI SENSORS

• Engine Oil Pressure Sensor (EOP

Sensor): Senses gallery oil pressure for

• Camshaft Position Sensor (CMP Sensor):

Indicates a specific cylinder in the firing

order.

• Crankshaft Position Sensor (CKP Sensor):

Senses crankshaft position and engine

speed for functions such as fuel control

strategy.

• DPF Inlet Pressure Sensor Measures

pressure between the Diesel Oxidation

Catalyst (DOC) and the Diesel Particulate

Filter (DPF) in the aftertreatment assembly.

• DPF Outlet Pressure Sensor: Measures

pressure on the outlet of the aftertreatment

device in the exhaust system of the vehicle.

• DPF Outlet Temperature Sensor:

Temperature measured at the outlet of the

after-treatment system that is installed within

the exhaust system of the vehicle.

• DOC Inlet Temperature Sensor:

Temperature measured at the outlet of the

after-treatment.

• DOC Outlet Temperature Sensor:

Temperature measured between the DOC

and the DPF in the aftertreatment assembly.

• EGR Delta Pressure Sensor: Senses EGR

pressure for EGR control.

• EGR Temperature Sensor: Senses EGR

exhaust temperature after EGR cooler. Used

for EGR system diagnosis.

• Engine Coolant Temperature Sensor (ECT

functions such as engine protection.

• Engine Oil Temperature Sensor (EOT

Sensor): Senses oil temperature for

functions such as reducing variation in fuel

injection and fan control.

• Fuel Line Pressure Sensor: Senses fuel

line pressure.

• Fuel Compensation Pressure Sensor:

Compensates fuel line pressure.

• Intake Manifold Pressure Sensor (IMP

Sensor): Senses turbo boost for functions

such as smoke control and engine protection.

• Intake Manifold Air Temperature Sensor

(IMT Sensor): Senses pressure. The MCM

uses this information to compute the amount

of air entering the engine.

• Supply Fuel Temperature Sensor (SFT

Sensor): Senses fuel temperature for

functions such as engine fueling.

• Turbo Compressor Temperature Out

Sensor: Senses turbo out air temperature.

• Turbo Speed Sensor (TSS): Monitors

turbo

speed for overspeed conditions.

• VGT Position Sensor/EGR Valve Position

Sensor.

• Intake Air Throttle Valve Sensor.

• Exhaust Valve Recirculation Valve (EGR)

Sensor.

Sensor): Senses coolant temperature for

functions such as engine protection, fan

control and engine fueling.

PA1561 18

Page 19

Section 01: ENGINE

2.5 PREVOST INSTALLED SENSORS

• Engine Coolant Level Sensor (ECL

Sensor): Senses coolant level for engine

protection (mounted on coolant surge tank).

• Turbo Compressor In Temperature

Sensor: Senses the air temperature at the

turbo compressor inlet.

• Vehicle Speed Sensor (VSS): Provides a

vehicle speed signal (connected to

transmission).

2.6 MOTOR CONTROL MODULE (MCM)

The Motor Control Module is mounted, on the

starter side of the engine (Fig. 13). Considered

the "Brain" of the DDEC VI system, it provides

overall monitoring and control of the engine. It

does so by comparing input data from the

various sensors to a set of calibration data

stored in the EEPROM (Electrically Erasable,

Programmable, Read-Only Memory) within the

Motor Control Module. After comparing the

input data with the calibration data, the MCM

sends high-current command pulses to the

Electronic Unit Injectors (EUI) to initiate fuel

injection. The MCM also receives feedback

regarding the start and end of injection for a

given cylinder. The EEPROM within the Motor

Control Module is factory programmed by

Detroit Diesel. Reprogramming must be done at

a Detroit Diesel authorized service center.

However, some changes may be performed to

the cruise control and road speed limiter using a

diagnostic data reader (see paragraph "DDEC

VI Diagnostic Codes" in this section).

2.7 COMMON POWERTRAIN CONTROLLER

(CPC)

The CPC is the interface between the MCM and

the vehicle/equipment for engine control and

manages other vehicle/equipment functions.

Within the CPC, sets of data for specific

applications are stored. These include idle

speed, maximum running speed, and speed

limitation. Customer programmable parameters

are also stored here. The CPC receives data

from the operator (accelerator pedal position,

switches and various sensors) and other

electronic control units. From this data,

instructions are computed for controlling the

engine and transmitted to the MCM via the

proprietary data link.

FIGURE 14: CPC

FIGURE 13: MOTOR CONTROL MODULE (MCM)

01145

PA1561 19

FIGURE 15: THE CPC COMMUNICATES OVER THE

J1587 AND J1939 DATA LINKS TO THE VEHICLE

2.8 DDEC VI DIAGNOSTICS

2.8.1 Diagnostic system

Diagnostics is a standard feature of DDEC VI.

The purpose of this feature is to provide

information for problem identification and

Page 20

Section 01: ENGINE

problem solving in the form of a code. The MCM

and CPC continuously perform self diagnostic

checks and monitor the other system

components. Information for problem

identification and problem solving is enhanced

by the detection of faults, retention of fault codes

and separation of active from inactive codes.

The engine-mounted MCM includes control logic

to provide overall engine management. System

diagnostic checks are made at ignition on and

continue throughout all engine operating modes.

Sensors provide information to the MCM and

CPC regarding various engine and vehicle

performance characteristics. The information is

used to regulate engine and vehicle

performance, provide diagnostic information,

and activate the engine protection system.

The DDEC VI on-board diagnostic system

accessories include the following:

• Check Engine telltale light (AWL);

• Stop Engine telltale light (RSL);

• Stop Engine Override switch (SEO);

• Diagnostic Data Link (DDL) connectors.

The AWL is illuminated and a code is stored if

an electronic system fault occurs. This indicates

the problem should be diagnosed as soon as

possible. The CPC illuminates the AWL and

RSL and stores a malfunction code if a

potentially engine damaging fault is detected.

These codes can be accessed in one of four

ways:

• Commercially available J1587/J1939

diagnostic tools.

• Detroit Diesel Diagnostic Link® (DDDL 7.0).

• Flashing the AWL and RSL with the

SEO/Diagnostic Request Switch.

• Dashboard’s Message Center Display

(MCD).

2.8.2 Check Engine Telltale Light (AWL)

The CPC illuminates the Check Engine telltale,

mounted on the telltale light panel to indicate

that a problem has been detected and that a

code has been stored in the MCM memory.

This light also has a 5-second bulb check when

the ignition is first turned on.

2.8.3 Stop Engine Warning Light (RSL)

This light, also mounted on the telltale light

panel, illuminates to indicate that a major engine

problem is occurring (with the exception of a 5second bulb check when the ignition is first

turned on).

2.8.4 Stop Engine Override Switch (SEO)

This switch, mounted on the dashboard, may be

used to extend the 30-second delay period

before engine shutdown when the Stop engine

telltale light is illuminated. This switch can be

repeatedly depressed in order to move the

vehicle out of traffic.

NOTE

The stop engine override switch will be

operative only if it has been depressed before

the end of the 30 second delay period.

CAUTION

The OVERRIDE switch must be used only in

emergency cases, such as to move the

vehicle out of traffic. Excessive use of this

switch can cause serious damage to the

engine.

This switch is also used for DDEC diagnostic

code requests. Press this switch with the engine

at idle or off but with the ignition in the "ON"

position and active codes will be flashed on the

CHECK ENGINE and STOP ENGINE telltale

lights alternately.

2.8.5 Diagnostic Data Link (DDL) Connectors

A connector is mounted on the L.H. footwell

wall. Another connector is located in the rear

electric compartment. They allow the connection

of the Diagnostic Data Reader (DDR) to read

the codes or to access pertinent data on the

condition of the engine. This enables a more

complete analysis of any defect found in the

DDEC system operation. For more information,

see Detroit Diesel Troubleshooting Guide

#6SE492.

2.9 READING DIAGNOSTIC CODES –

FLASHING LIGHT METHOD:

DDEC VI makes use of two types of codes:

Active and inactive. The difference between the

two types of codes is as follows:

PA1561 20

Page 21

Section 01: ENGINE

Active Codes: Codes that are currently

keeping the Check Engine or Stop Engine

telltale light illuminated. Active codes are flashed

via the Stop Engine Light when checked with the

stop-engine-override switch.

Inactive Codes: These are all the codes

logged in the CPC, which have previously

occurred, (whether or not they are currently

turning on the Stop or Check Engine Light).

Inactive codes are flashed via the Check Engine

telltale light when checked with the stop-engineoverride switch.

In most instances, only the DDR can provide the

information necessary for a quick diagnosis of

the problem. If you just need to read out codes,

however, and do not have a DDR available, the

following procedure will let you read out codes.

Make sure the rear-starting switch (located in

the engine compartment) is in the normal

position. With the ignition ON, the engine idling

or engine shut-off, momentarily depress the

Stop Engine Override (SEO) switch. Active

codes will be flashed on the stop engine telltale,

followed by the inactive codes being flashed on

the check-engine telltale panel. The cycle

repeats itself until the operator depresses the

stop engine override switch again.

Flashing codes provide a four digit number.

Each fault code is flashed twice in order to help

with counting the flashes. If there are no active

faults or if there are no inactive faults the

number “3” is flashed once followed by an ~3s

delay.

FIGURE 16: FLASHING FAULTS CODES

Refer to DDEC Troubleshooting Manual 6SE567

for more information and SAE codes.

NOTE

Active codes are flashed in ascending

numerical flash code order. Inactive codes are

flashed in most recent to least recent order.

NOTE

Fault codes can only be cleared using the

DDR.

NOTE

The listed codes may not be used in all

applications. A default value in the normal

operating range is used by the MCM to

provide for engine operation if a sensor failure

is present.

2.10 DDEC VI CPC DIAGNOSTIC CODES LIST

SPN FMI PID/SID

70 2 PID 70 2111 Park Brake Status Not Plausible (Vehicle Moving)

70 19 SID 234 2112 J1939 Park Brake Switch Signal from Source #1 is

70 13 SID 234 2112 J1939 Park Brake Switch Signal from Source #1 is

70 19 SID 234 2112 J1939 Park Brake Switch Signal from Source #2 is

70 13 SID 234 2112 J1939 Park Brake Switch Signal from Source #2 is

70 19 SID 234 2112 J1939 Park Brake Switch Signal from Source #3 is

70 13 SID 234 2112 J1939 Park Brake Switch Signal from Source #3 is

84 21 PID 84 2113 Vehicle Speed Failure

PA1561 21

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

erratic

missing

erratic

missing

erratic

missing

Page 22

Section 01: ENGINE

SPN FMI PID/SID

84 3 PID 84 2113 Vehicle Speed Sensor Circuit Failed High

84 4 PID 84 2113 Vehicle Speed Sensor Circuit Failed Low

84 2 PID 84 2113 VSS Anti Tamper Detection via Virtual Gear Ratio

84 8 PID 84 2113 VSS Anti Tamper Detection via Fixed Frequency

84 6 PID 84 2113 VSS Anti-Tamper Detection via ABS Vehicle Speed

84 19 PID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 13 PID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 19 SID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 13 PID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 19 PID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 13 PID 84 2113 J1939 Wheel-Based Vehicle Speed Signal from

84 20 PID 84 2113 Vehicle Speed Sensor Drifted High Error (VSS

91 13 PID 91 2114 Accelerator Pedal Learn Error

91 3 PID 91 2114 Accelerator Pedal Circuit Failed High

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

Device

Comparison

Source#1 is erratic

Source#1 is missing

Source#2 is erratic

Source#2 is missing

Source#3 is erratic

Source#3 is missing

signal not plausible)

91 4 PID 91 2114 Accelerator Pedal Circuit Failed Low

91 8 PID 91 2114 Pwm Accelerator Pedal Signal 1 Frequency Out Of

Range

91 14 PID 91 2114 Pwm Accelerator Pedal Not Learned

91 7 PID 91 2114 Pwm Accelerator Pedal Idle Not Recognized

91 31 PID 91 2114 Pwm Accelerator Pedal Learned Range to Large

91 3 PID 91 2114 Accelerator Pedal Signal Circuit Failed High

91 9 SID 231 2615 J1939 EEC2 Message is missing

98 0 PID 98 2115 Oil Level High

98 18 PID 98 2115 Oil Level Low

98 1 PID 98 2115 Oil Level Very Low

100 18 PID 100 2121 Oil Pressure Low

100 1 PID 100 2121 Oil Pressure Very Low

107 0 PID 107 2122 Air Filter Restriction High

107 4 PID 107 2122 Air Filter Signal Circuit Failed Low

107 3 PID 107 2122 Air Filter Signal Circuit Failed High

110 16 PID 110 2123 Coolant Temperature High

PA1561 22

Page 23

Section 01: ENGINE

SPN FMI PID/SID

110 0 PID 110 2123 Coolant Temperature Very High

111 18 PID 111 2124 Coolant Level Low

111 3 PID 111 2124 Coolant Level Circuit Failed High

111 4 PID 111 2124 Coolant Level Circuit Failed Low

111 1 PID 111 2124 Coolant Level Very Low

168 0 PID 168 2125 Battery Voltage Very Low

168 0 PID 168 2125 Battery Voltage High

168 18 PID 168 2125 Battery Voltage Low

168 14 PID 168 2125 Opt Idle Detected Charging System or Battery

168 14 PID 168 2125 ECU powerdown not completed (Main Battery

171 2 PID 171 2131 Ambient Temperature Sensor Data Erratic

171 14 PID 171 2131 J1587 Ambient Air Temp Sensor Data Not

171 9 PID 171 2131 J1587 Ambient Air Temp Sensor Data Message

191 9 SID 231 2615 J1939 ETC1 Message is missing

191 19 SID 231 2132 J1939 Transmission Output Shaft Speed Signal is

191 13 SID 231 2132 J1939 Transmission Output Shaft Speed Signal is

247 9 PID 247 2615 MCM Engine Hours Data not received or stopped

247 10 PID 247 2615 MCM Engine Hours Data increasing at an

247 0 PID 247 2615 MCM Engine Hours Data higher than expected

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

Failure

Terminal Possibly Floating)

Received This Ign Cycle

Stopped Arriving

erratic

missing

arriving

implausible rate

247 1 PID 247 2615 MCM Engine Hours Data lower than expected

523 19 PID 163 2133 J1939 Transmission Current Gear Signal is erratic

523 13 PID 163 2133 J1939 Transmission Current Gear Signal is missing

524 9 SID 231 2615 J1939 ETC2 Message is missing

527 9 SID 231 2615 J1939 CCVS Message from Source #1 is missing

527 9 SID 231 2615 J1939 CCVS Message from Source #2 is missing

527 9 SID 231 2615 J1939 CCVS Message from Source #3 is missing

558 2 SID 230 2134 Idle Validation Switch Inputs Reversed

558 5 SID 230 2134 Idle Validation Switch 2 Circuit Failed Low

558 6 SID 230 2134 Idle Validation Switch 2 Circuit Failed High

558 4 SID 230 2134 Idle Validation Switch 1 Circuit Failed Low

558 3 SID 230 2134 Idle Validation Switch 1 Circuit Failed High

PA1561 23

Page 24

Section 01: ENGINE

SPN FMI PID/SID

596 19 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

596 13 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

596 19 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

596 13 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

596 19 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

596 13 SID 244 2135 J1939 Cruise Control Enable Switch Signal from

597 2 SID 246 2141 Service Brake Status Not Plausible

597 19 SID 246 2141 J1939 Service Brake Switch Signal from Source #1

597 13 SID 246 2141 J1939 Service Brake Switch Signal from Source #1

597 19 SID 246 2141 J1939 Service Brake Switch Signal from Source #2

597 13 SID 246 2141 J1939 Service Brake Switch Signal from Source #2

597 19 SID 246 2141 J1939 Service Brake Switch Signal from Source #3

597 13 SID 246 2141 J1939 Service Brake Switch Signal from Source #3

599 4 SID 243 2142 Cruise Control SET and RESUME Circuits Failed

600 19 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

600 13 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

600 19 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

600 13 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

600 19 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

600 13 SID 243 2143 J1939 Cruise Control Coast Switch Signal from

602 19 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

602 13 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

602 19 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

602 13 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

Source #1 is erratic

Source #1 is missing

Source #2 is erratic

Source #2 is missing

Source #3 is erratic

Source #3 is missing

is erratic

is missing

is erratic

is missing

is erratic

is missing

Low

Source #1 is erratic

Source #1 is missing

Source #2 is erratic

Source #2 is missing

Source #3 is erratic

Source #3 is missing

from Source #1 is erratic

from Source #1 is missing

from Source #2 is erratic

from Source #2 is missing

PA1561 24

Page 25

Section 01: ENGINE

SPN FMI PID/SID

602 19 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

602 13 SID 242 2144 J1939 Cruise Control Accelerate Switch Signal

608 14 SID 250 2145 J1708 Data Link Failure

609 12 SID 233 2145 CPC2 Hardware Failure

615 9 SID 231 2615 J1939 DM1 Message from Transmission is missing

625 13 SID 248 2151 ECAN ID_1629 Diagnostic Message Not Received

625 9 SID 248 2151 ECAN ID_1629 Diagnostic Message No Longer

625 10 SID 248 2151 ECAN ID_1629 Reporting Inconsistent Number of

625 2 SID 248 2151 ECAN ID_1629 Diagnostic Message Reporting

625 14 SID 248 2151 ECAN ID_1629 Diagnostic Message Reporting an

625 9 SID 248 2151 Incorrect MCM System ID Received

625 9 SID 248 2151 MCM System ID Not Received or Stopped Arriving

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

from Source #3 is erratic

from Source #3 is missing

This Ignition Cycle

Being Received

Frames

Data Not Available

Unknown MUID

625 4 SID 248 2151 ECAN Link Circuit Failure

628 14 SID 254 2151 XFLASH Static Fault Code Memory Page Read

Write Failure

628 13 SID 155 2615 20ms ECU OS Task Locked in an Endless Loop

628 13 SID 155 2615 20ms ECU OS Task Timed out Prior to Completion

628 13 SID 155 2615 1000ms ECU OS Task Locked in an Endless Loop

628 13 SID 155 2615 1000ms ECU OS Task Timed out Prior to

Completion

629 2 SID 254 2151 CPC Hardware/Software Mismatch

629 12 SID 254 2151 DDEC Data Xflash Write Error. Replace CPC2.

630 2 SID 253 2152 EEPROM Checksum Failure

630 2 SID 253 2152 EEPROM Checksum Failure for the SCR Block

630 13 SID 253 2152 SCR Number Out of Range

630 14 SID 155 2615 MCM Fault Codes Unavailable via J1939 and

J1587

630 14 SID 155 2615 MCM Fault Code Table Inconsistant - Upgrade

MCM Software

630 14 SID 155 2615 Insufficient Static Fault Code Storrage Memory -

Upgrade CPC Software

PA1561 25

Page 26

Section 01: ENGINE

SPN FMI PID/SID

630 14 SID 155 2615 MCM Fault Code Table Inconsistant - Upgrade

639 14 SID 231 2153 J1939 Data Link Failure

701 3 SID 26 2211 Digital Output 4 09 Circuit Failed High

701 4 SID 26 2211 Digital Output 4 09 Circuit Failed Low

702 3 SID 40 2212 Digital Output 3 17 Circuit Failed High

702 4 SID 40 2212 Digital Output 3 17 Circuit Failed Low

703 3 SID 51 2213 Digital Output 3 09 Circuit Failed High

703 4 SID 51 2213 Digital Output 3 09 Circuit Failed Low

704 3 SID 52 2214 Digital Output 4 07 Circuit Failed High

704 4 SID 52 2214 Digital Output 4 07 Circuit Failed Low

705 3 SID 53 2215 Digital Output 1 13 Circuit Failed High

705 4 SID 53 2215 Digital Output 1 13 Circuit Failed Low

706 3 SID 54 2221 Digital Output 3 10 Circuit Failed High

706 4 SID 54 2221 Digital Output 3 10 Circuit Failed Low

707 3 SID 55 2222 Digital Output 2 10 Circuit Failed High (CEL / AWL

707 4 SID 55 2222 Digital Output 2 10 Circuit Failed Low (CEL / AWL

708 3 SID 56 2223 Digital Output 3 12 Circuit Failed High

708 4 SID 56 2223 Digital Output 3 12 Circuit Failed Low

709 3 SID 257 2224 Digital Output 3 16 Circuit Failed High

709 4 SID 257 2224 Digital Output 3 16 Circuit Failed Low

710 3 SID 258 2225 Digital Output 4 06 Circuit Failed High

710 4 SID 258 2225 Digital Output 4 06 Circuit Failed Low

711 3 SID 259 2231 Digital Output 1 05 Circuit Failed High

711 4 SID 259 2231 Digital Output 1 05 Circuit Failed Low

712 3 SID 260 2232 Digital Output 1 04 Circuit Failed High

712 4 SID 260 2232 Digital Output 1 04 Circuit Failed Low

713 3 SID 261 2234 Digital Output 3 07 Circuit Failed High

713 4 SID 261 2234 Digital Output 3 07 Circuit Failed Low

713 5 SID 261 2234 Digital Output 3 07 Open Circuit

713 7 SID 261 2234 TOP2 Shift Failure

714 3 SID 262 2235 Digital Output 3 08 Circuit Failed High

714 4 SID 262 2235 Digital Output 3 08 Circuit Failed Low

714 5 SID 262 2235 Digital Output 3 08 Open Circuit

715 3 SID 263 2241 Digital Output 4 10 Circuit Failed High

904 9 SID 231 2615 J1939 EBC2 Message from ABS is missing

904 19 SID 231 2242 J1939 Front Axle Speed Signal is erratic

904 13 SID 231 2242 J1939 Front Axle Speed Signal is missing

972 2 SID 203 2243 Throttle inhibit switch signal not plausible due to

973 9 SID 231 2615 J1939 EBC1 Message is missing

973 13 SID 231 2244 J1939 Engine Retarder Selection Signal Missing

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

MCM Software

Lamp)

Lamp)

excess vehicle speed

PA1561 26

Page 27

Section 01: ENGINE

SPN FMI PID/SID

973 19 SID 231 2244 J1939 Engine Retarder Selection Signal Erratic

974 2 PID 372 2245 Remote Accelerator Pedal Supply Voltage Out of

974 3 PID 372 2245 Remote Accelerator Pedal Circuit Failed High

974 4 PID 372 2245 Remote Accelerator Pedal Circuit Failed Low

981 0 SID 155 2311 PTO CC+ and CC- Switches Pressed

986 9 SID 231 2615 J1939 CM1 Message is missing

1267 4 SID 123 2312 Digital Output 4 10 Circuit Failed Low

1267 3 SID 123 2312 Digital Output 4 10 Circuit Failed Open

1321 4 SID 128 2314 Starter Lockout Output Shorted to Ground

1321 3 SID 128 2314 Starter Lockout Output Open Circuit

1590 19 SID 155 2615 Adaptive Cruise Control Message Not Received

1590 9 SID 231 2615 Adaptive Cruise Control Device Reporting Error

1624 9 SID 231 2615 J1939 TCO1 Message is missing

1624 19 SID 231 2315 J1939 Tachograph Vehicle Speed Signal is erratic

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

Range

Simultaneously

1624 13 SID 231 2315 J1939 Tachograph Vehicle Speed Signal is missing

1663 7 SID 123 2321 Optimized Idle Safety Loop Faulted

1716 9 SID 231 2615 J1939 ERC1 Message is missing

1845 9 SID 231 2615 J1939 TCFG2 Message is missing

2623 14 PID 91 2322 Pwm Accelerator Pedal GAS1 and GAS2 Signal

Missing

2623 8 PID 91 2322 Pwm Accelerator Pedal Signal 2 Frequency Out Of

Range

2900 9 SID 231 2615 J1939 ETC7 Message is missing

3510 3 SID 211 2333 Accelerator Pedal Supply Voltage Circuit Failed

High

3510 4 SID 211 2333 Accelerator Pedal Supply Voltage Circuit Failed

Low

3510 4 SID 211 2333 Pwm Accelerator Pedal Supply Voltage Missing

3510 3 SID 211 2333 Accelerator Pedal Supply Voltage Circuit Failed

High

3606 9 SID 231 2615 J1939 ESS Message is missing

3695 2 SID 155 2334 Manual DPF Regen and DPF Inhibit Switch

Rationality Fault

3695 19 SID 155 2334 DPF Regen Inhibit MUX Switch Message Contains

Data Error Indicator

3695 13 SID 155 2334 DPF Regen Inhibit MUX Switch Message Contains

SNV Indicator

3695 9 SID 155 2334 DPF Regen Inhibit MUX Switch Message Stopped

Arriving

PA1561 27

Page 28

Section 01: ENGINE

SPN FMI PID/SID

PID/SID

ID

FLASH

CODES

FAULT DESCRIPTION

3695 14 SID 155 2334 DPF Regen Inhibit MUX Switch Message Not

Received this Ign Cycle

3696 19 SID 155 2335 DPF Regen Force MUX Switch Message Contains

Data Error Indicator

3696 13 SID 155 2335 DPF Regen Force MUX Switch Message Contains

SNV Indicator

3696 9 SID 155 2335 DPF Regen Force MUX Switch Message Stopped

Arriving

3696 14 SID 155 2335 DPF Regen Force MUX Switch Message Not

Received this Ign Cycle

2.11 DDEC VI MCM DIAGNOSTIC CODES LIST

SPN FMI PID/SID

27 4 PID 27 1111 EGR Valve Position Circuit Failed Low

27 3 PID 27 1111 EGR Valve Position Circuit Failed High

27 2 PID 27 1111 EGR Valve Position Feedback Failed

27 0 PID 27 1111 EGR Valve Position Feedback Failed (High Box)

27 1 PID 27 1111 EGR Valve Position Feedback Failed (Low Box)

27 14 PID 27 1111 EGR Valve Position Positive Torque Error

27 7 PID 27 1111 EGR Valve Stuck Open

27 19 PID 27

51 4 SID 51 1112 Intake Air Throttle Circuit Failed Low

51 3 SID 51 1112 Intake Air Throttle Circuit Failed High

51 2 PID 51 1112 Intake Throttle Position Deviation Error

51 0 PID 51 1112 Intake Air Throttle Position High

51 1 PID 51 1112 Intake Air Throttle Position Low

51 7 PID 51 1112 Intake Throttle Auto Calibration Error

94 4 PID 94 1112 Fuel Compensation Pressure Sensor Circuit Failed Low

94 3 PID 94 1112 Fuel Compensation Pressure Sensor Circuit Failed High

94 1 PID 94 1112 Fuel Pressure Too High/Too Low

97 4 PID 97 1615 Water in Fuel Circuit Failed Low

97 3 PID 97 1615 Water in Fuel Circuit Failed High

98 1 PID 98 1114 Oil Level Circuit Failed Low

98 0 PID 98 1114 Oil Level Circuit Failed High

98 13 PID 98 1634 Oil Level Mesaurement, Configuration Error

98 14 PID 98 1634 Oil Level Mesaurement, Oil Level Too Low or Too High

100 4 PID 100 1114 Engine Oil Pressure Circuit Failed Low

100 3 PID 100 1114 Engine Oil Pressure Circuit Failed High

100 1 PID 100 1114 Engine Oil Pressure Low

100 2 PID 100 1114 Oil Pressure Plausibility - Engine Running

100 2 PID 100 1114 Oil Pressure Plausibility - Stop

103 2 PID 103 1115 Turbocharger Speed Not Plausible

103 1 PID 103 1115 Turbo Charger Speed Below Threshold (High Box)

103 0 PID 103 1115 Turbo Charger Speed Above Threshold (Low Box)

103 4 PID 103 1115 Turbo Charger Speed Sensor Circuit Failed Low

103 3 PID 103 1115 Turbo Charger Speed Sensor Circuit Failed High

108 4 PID 108 1211 Barometric Pressure Circuit Failed Low

108 3 PID 108 1211 Barometric Pressure Circuit Failed High

108 2 PID 108 1211 Ambient Pressure Plausibility Fault (Low Box)

108 20 PID 108 1211 Ambient Pressure Plausibility Fault (High Box)

PID/SID

ID

FLASH

CODE FAULT DESCRIPTION

1521

Smart Actuator Indicates EGR Position Error

PA1561 28

Page 29

Section 01: ENGINE

SPN FMI PID/SID

110 4 PID 110 1212 Engine Coolant Outlet Temperature Circuit Failed Low

110 3 PID 110 1212 Engine Coolant Outlet Temperature Circuit Failed High

110 0 PID 110 1212 Coolant Temperature High

110 14 PID 110 1212 Coolant Temperature / Engine Oil Temperature Plausibility Fault

110 2 PID 110 1212 Engine Coolant Sensor (OUT), General Temp. Plausibility Error

132 7 PID 132 1213 Intake Air Throttle Valve Closure Detection- Positive Torque

132 14 PID 132 1213 Intake Air Throttle Valve Closure Detection -Braking Condition

132 14 PID 322 1635 HC-Doser Fuel Pressure Not Plausible

132 1 PID 322 1213 Air Mass Flow Too Low

132 13 PID 132

158 2 PID 43 1214 Ignition Switch Not Plausible

164 4 PID 164 1215 Rail Pressure Governor Sensor Circuit Failed Low

164 3 PID 164 1215 Rail Pressure Governor Sensor Circuit Failed High

164 0 PID 164 1215 Rail Pressure Governor (High Side) Error

164 0 PID 164 1215 Rail Pressure Governor (Low Side) Error

168 1 PID 168 1221 Battery Voltage Low

168 0 PID 168 1221 Battery Voltage High

171 4 PID 171 1222 Ambient Temperature Circuit Failed Low

171 3 PID 171 1222 Ambient Temperature Circuit Failed High

174 4 PID 174 1223 Fuel Temperature Circuit Failed Low

174 3 PID 174 1223 Fuel Temperature Circuit Failed High

174 2 PID 174 1223 Fuel Temperature Sensor, General Temp. Plausibility

174 0 PID 174 1223 Fuel Temperature Too High

175 4 PID 175 1224 Engine Oil Temperature Circuit Failed Low

175 3 PID 175 1224 Engine Oil Temperature Circuit Failed High

175 14 PID 175 1224 Engine Oil Temperature Sensor Plausibility Fault

175 2 PID 175 1224 Engine Oil Temperature Sensor, General Temp. Plausibility

190 2 PID 190 1225 Engine Speed High

354 4 PID 354 1231 Relative Humidity Circuit Failed Low

354 3 PID 354 1231 Relative Humidity Circuit Failed High

411 4 PID 411 1232 EGR Delta Pressure Sensor Circuit Low

411 3 PID 411 1232 EGR Delta Pressure Sensor Circuit High

411 0 PID 411 1232 EGR Differential Pressure Failed (High Box)

411 1 PID 411 1232 EGR Differential Pressure Failed (Low Box)

411 5 PID 411 1232 EGR Sampling Range Failed

411 13 PID 411 1232 EGR Delta Pressure Sensor Out Of Calibration

411 13 PID 411 1232 EGR Delta Pressure Sensor Out Of Calibration

412 3 PID 412 1233 EGR Temperature Sensor Circuit Failed High

412 4 PID 412 1233 EGR Temperature Sensor Circuit Failed Low

412 20 PID 412 1233 EGR Temperature Drift (High Box)

412 21 PID 412 1233 EGR Temperature Drift (Low Box)

412 2 PID 412 1233 EGR Temperature Sensor, General Temp. Plausibility Error

412 0 PID 412 1512 EGR Temperature Very High

412 16 PID 412 1233 EGR Temperature Sensor / Temperature Too High

615 4 SID 155 1615

615 3 SID 155 1615

615 4 SID 155 1615