Volkswagen VAS 5051 User Manual

g

V

g

Volkswagen Phaeton

Стр. 1 из 6Front suspension, servicin

40 - 2

Front suspension, servicin

AS 5051, connecting and selecting functions

Special tools, equipment, testers, measuring

instruments and auxiliary items required

VAS 5051 Vehicle diagnosis, testing and information

system

Diagnostic cable VAS 5051/1 or VAS 5051/3

Warning!

During a test drive you must always secure

testing and measuring equipment on the back

seat.

These devices may be operated only by a

passenger during a test drive.

g

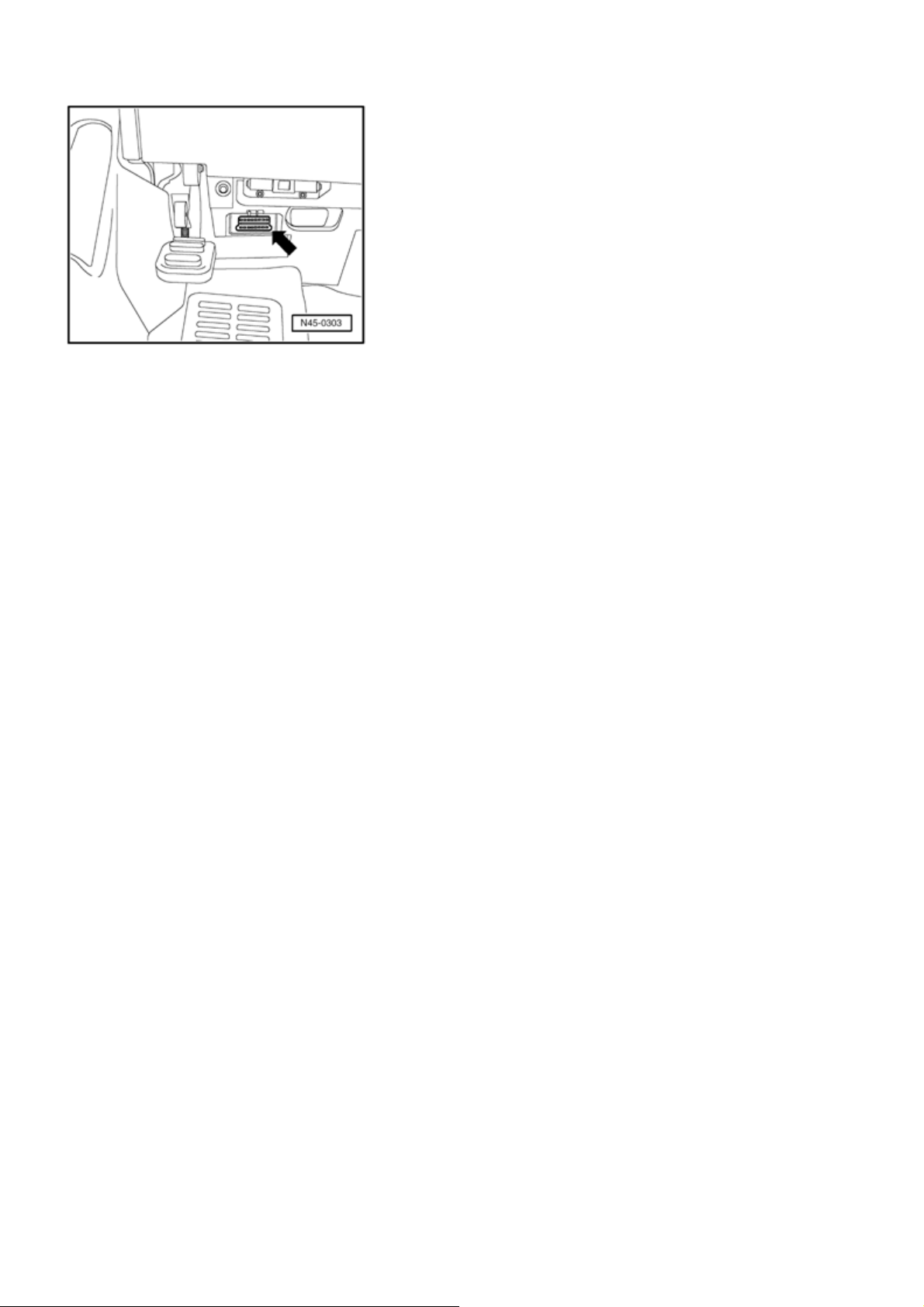

- Connect diagnosis cable connector VAS 5051/1 or VAS

5051/3 to diagnosis connection.

Стр. 2 из 6Front suspension, servicin

- Switch on tester

- arrow -

.

The tester is operational when it displays a picture of a car.

- Switch on ignition.

- Touch button/field for "Guided Fault Finding" on screen.

- Select one after another:

Brand

Type

Model year

Version

Engine code

- Confirm data entered.

Note:

Wait until tester has checked all control modules in

vehicle.

- Press Goto button and select "Function/component

selection" function

Follow information given on screen to start the desired

functions.

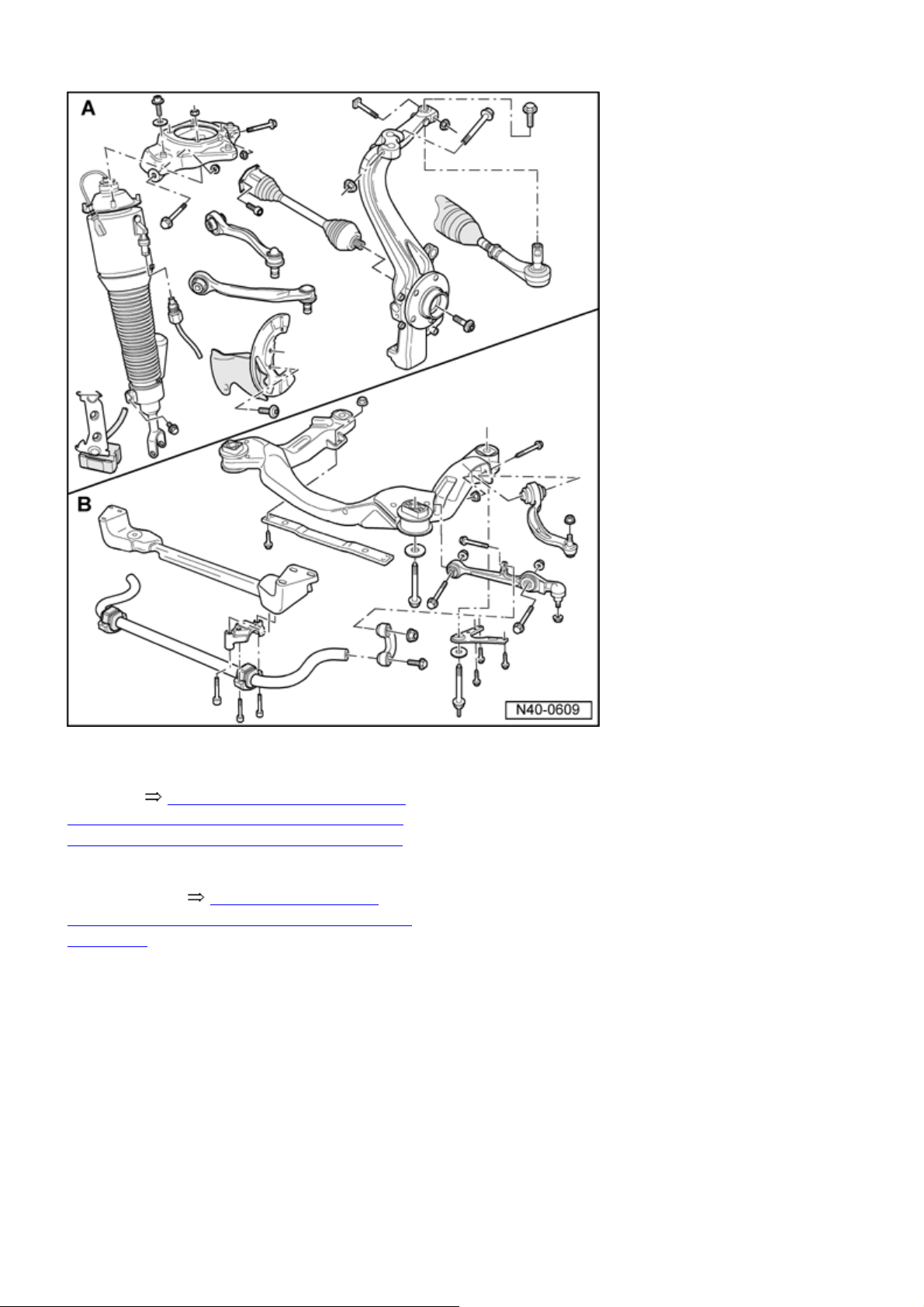

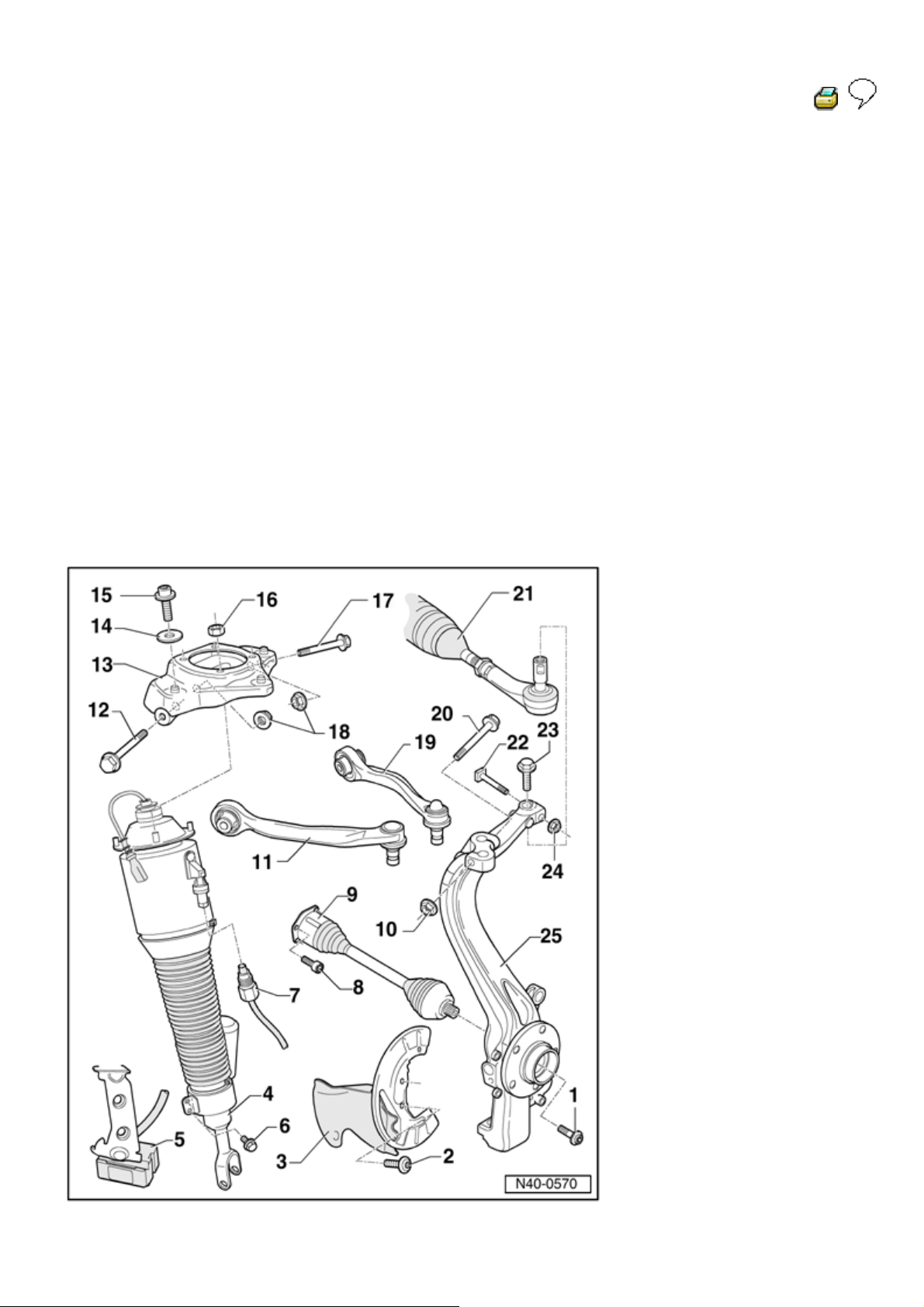

Front axle, overview

Стр. 3 из 6Front suspension, servicin

g

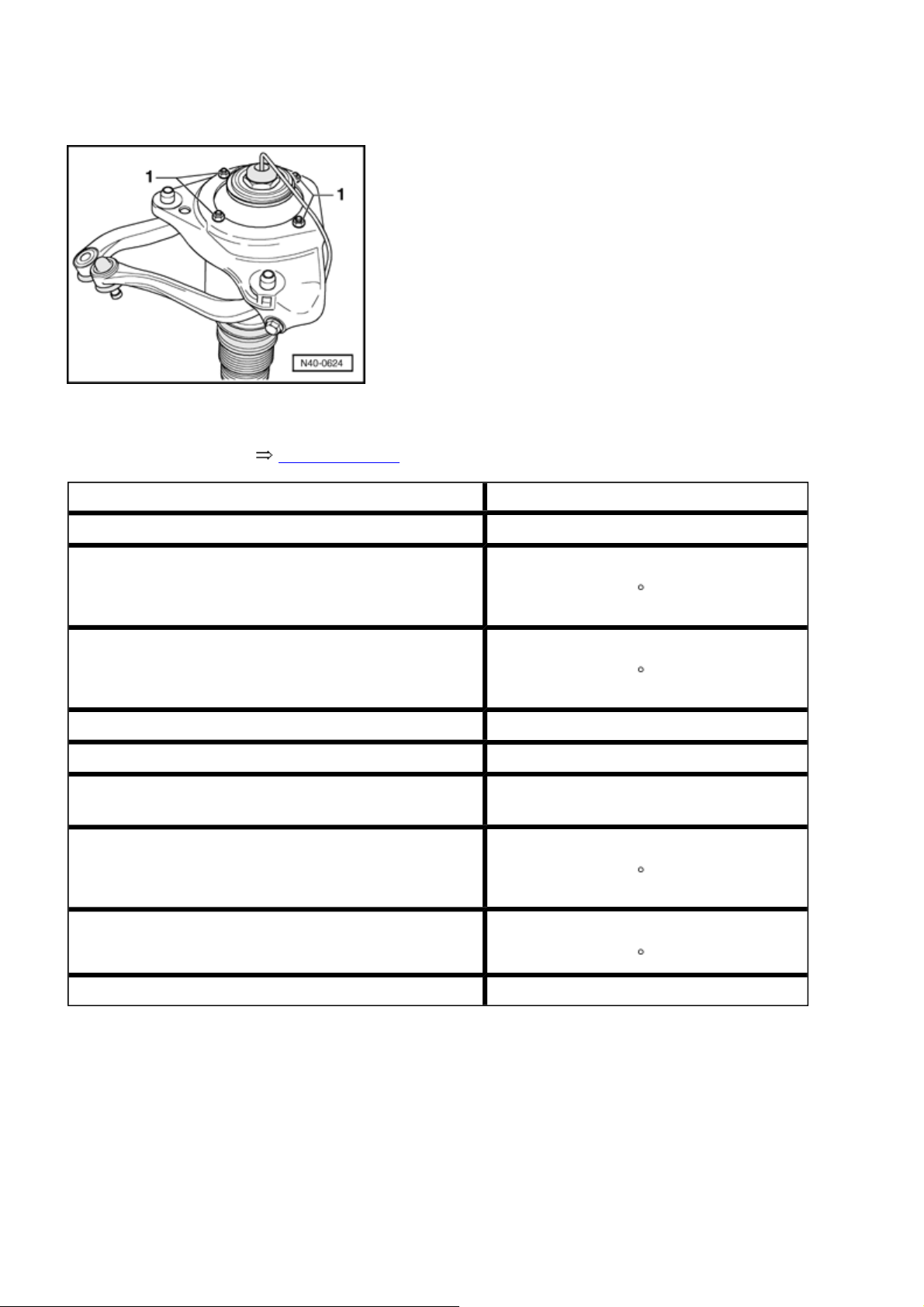

A - Mounting bracket, upper links, air

spring strut, and wheel bearing

housing 40

-3, A - Mounting bracket,

upper links, air spring strut and wheel

bearing housings, assembly overview

B - Subframe, lower links, and

stabilizer bar 40-4, B - Subframe,

lower link, and stabilizer bar, assembly

overview

Note:

If vehicles with drive axle removed must be moved,

an outer joint must be installed first. Tighten outer

joint to 50 Nm, otherwise the wheel bearings will be

damaged.

Welding and straightening work on supporting or

wheel carrying components of suspension is not

permitted.

Стр. 4 из 6Front suspension, servicin

g

Always replace self-locking nuts.

Always replaced corroded nuts/bolts.

Wheel bearing, lifting to curb weight position

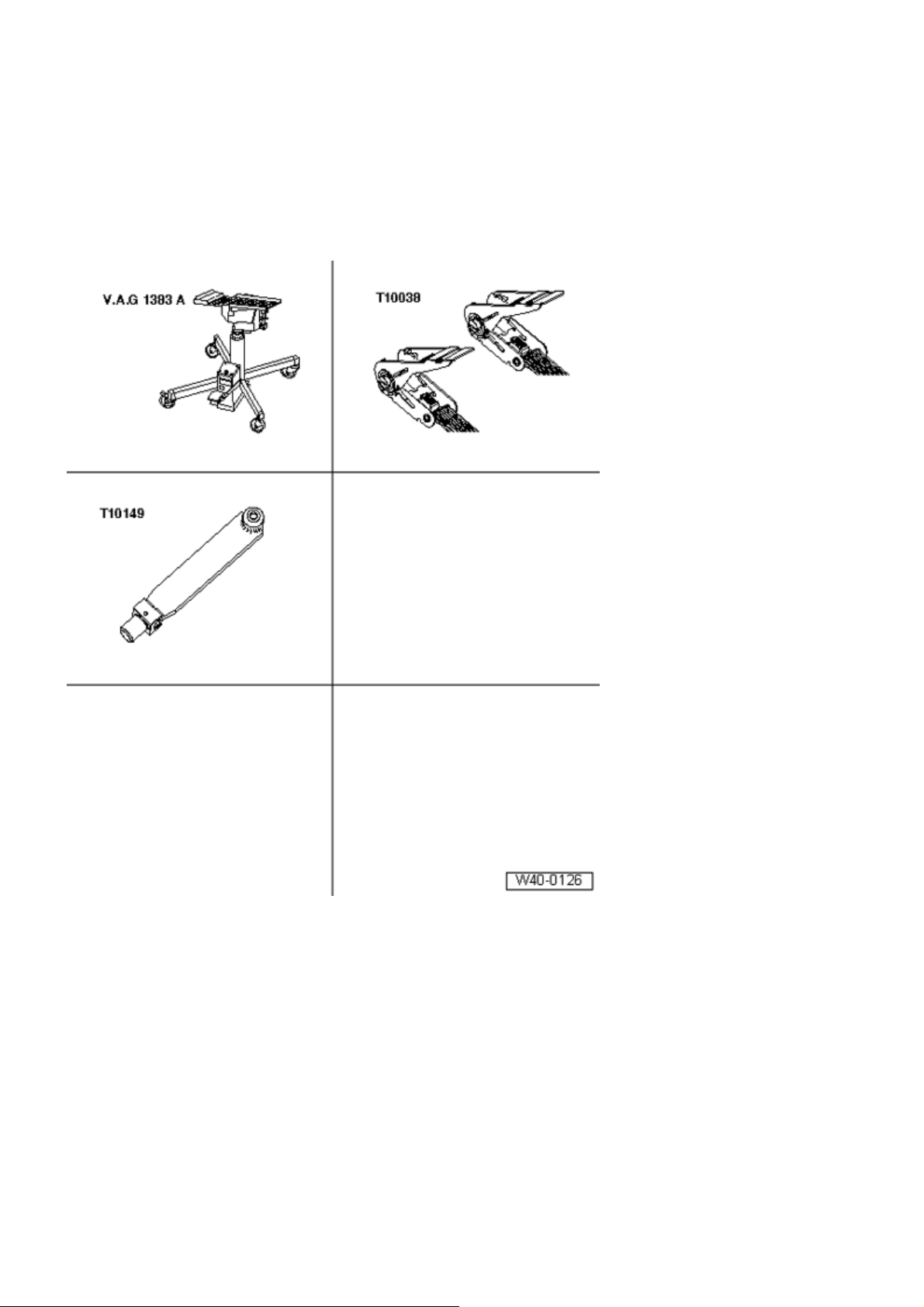

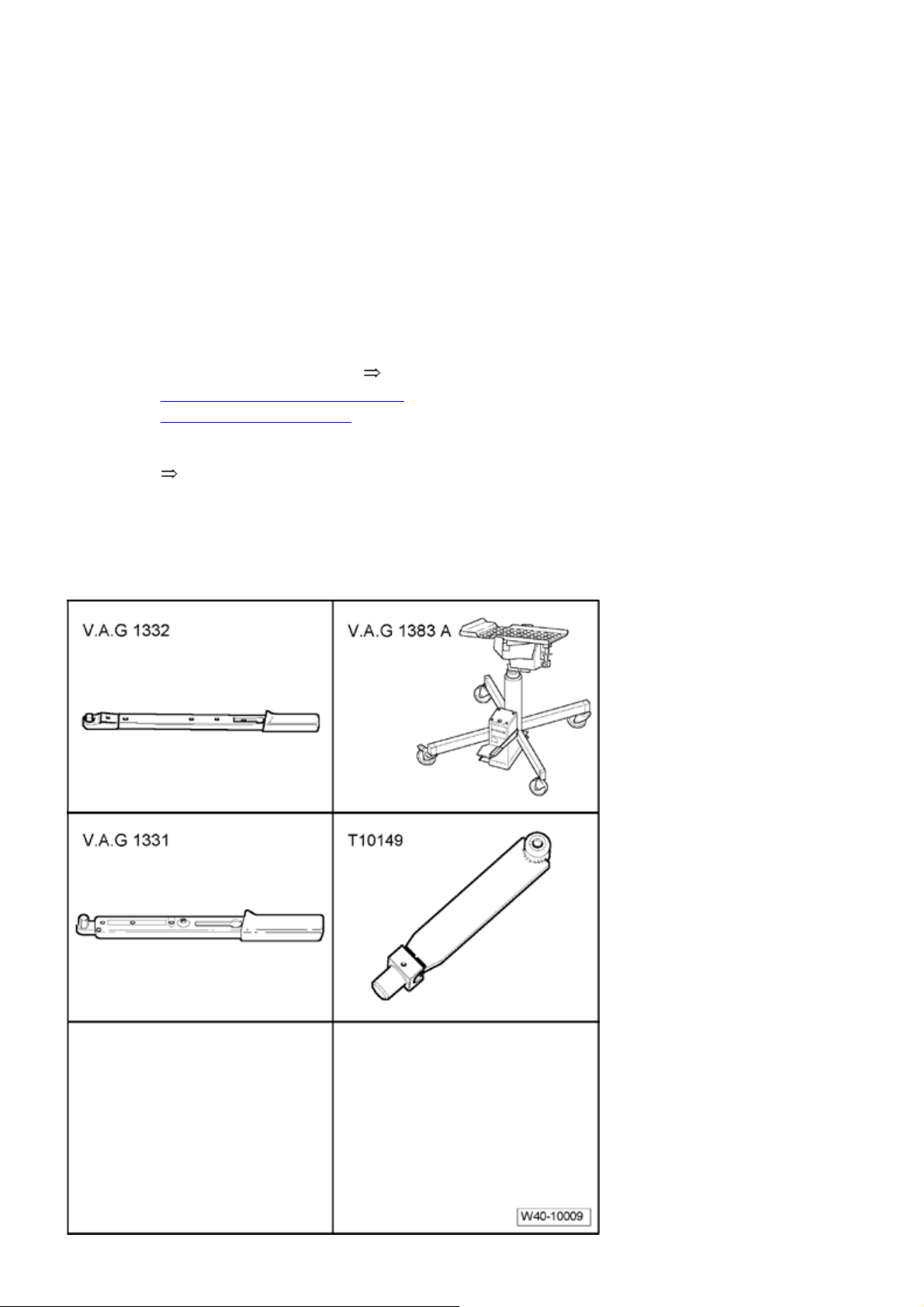

Special tools, testers and auxiliary items

required

engine/transmission jack V.A.G

1383 A

Tightening strap T10038

Wheel hub support T10149

Note:

Always tighten all connecting bolts to suspension

p

y

!

g

g

parts with bonded rubber bushings in curb weight

position (unloaded).

Bonded rubber bushings have a limited twisting range.

Axle components with bonded rubber bushings must be

brought into installation position before tightening, which

corresponds to curb weight position when driving.

Otherwise, if you stress the bonded rubber bushing it will

lead to a shorter life span.

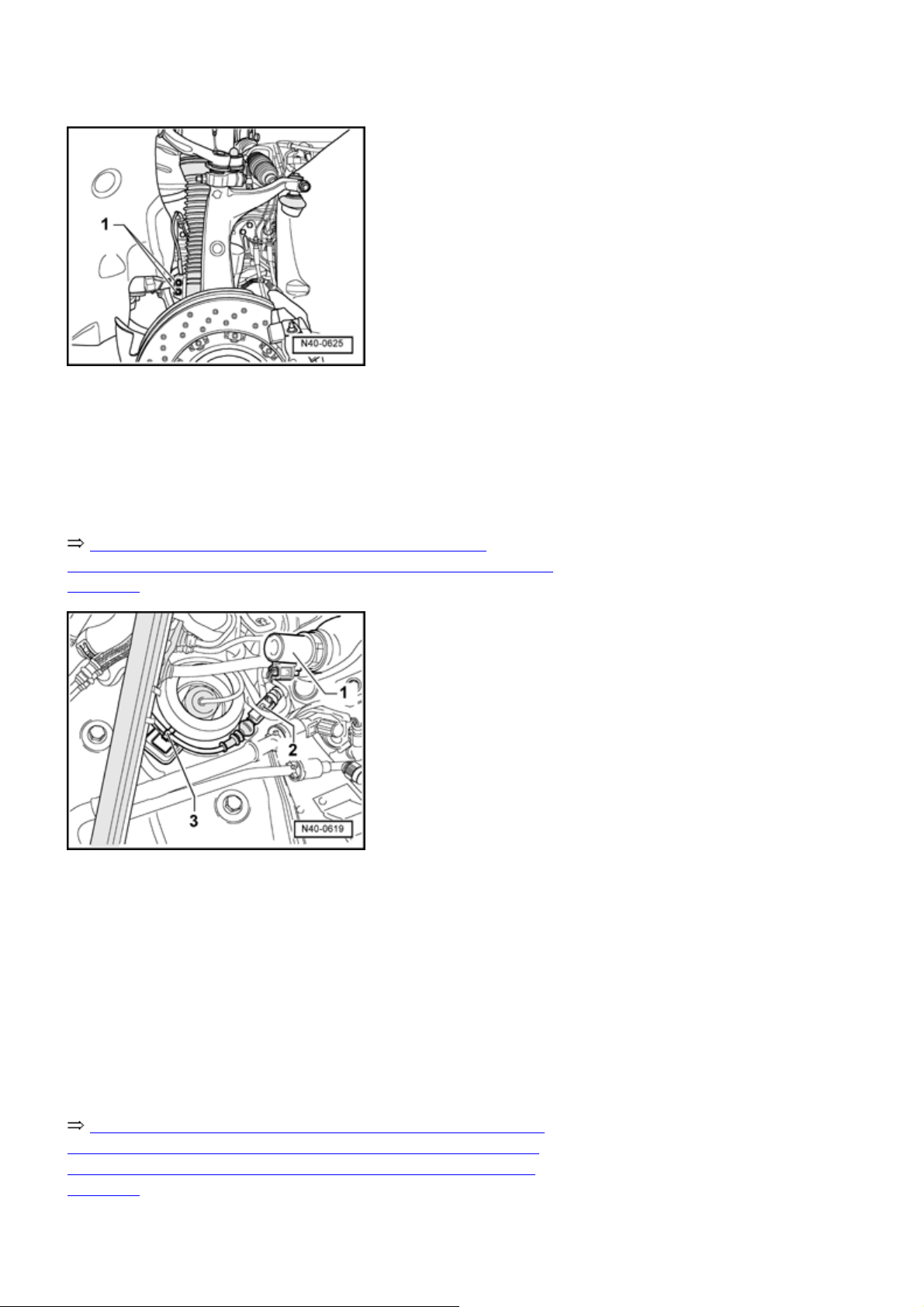

By raising the suspension on one side using the

engine/transmission jack V.A.G 1383 A and support

T10149 , this position will be simulated on the hoist.

Стр. 5 из 6Front suspension, servicin

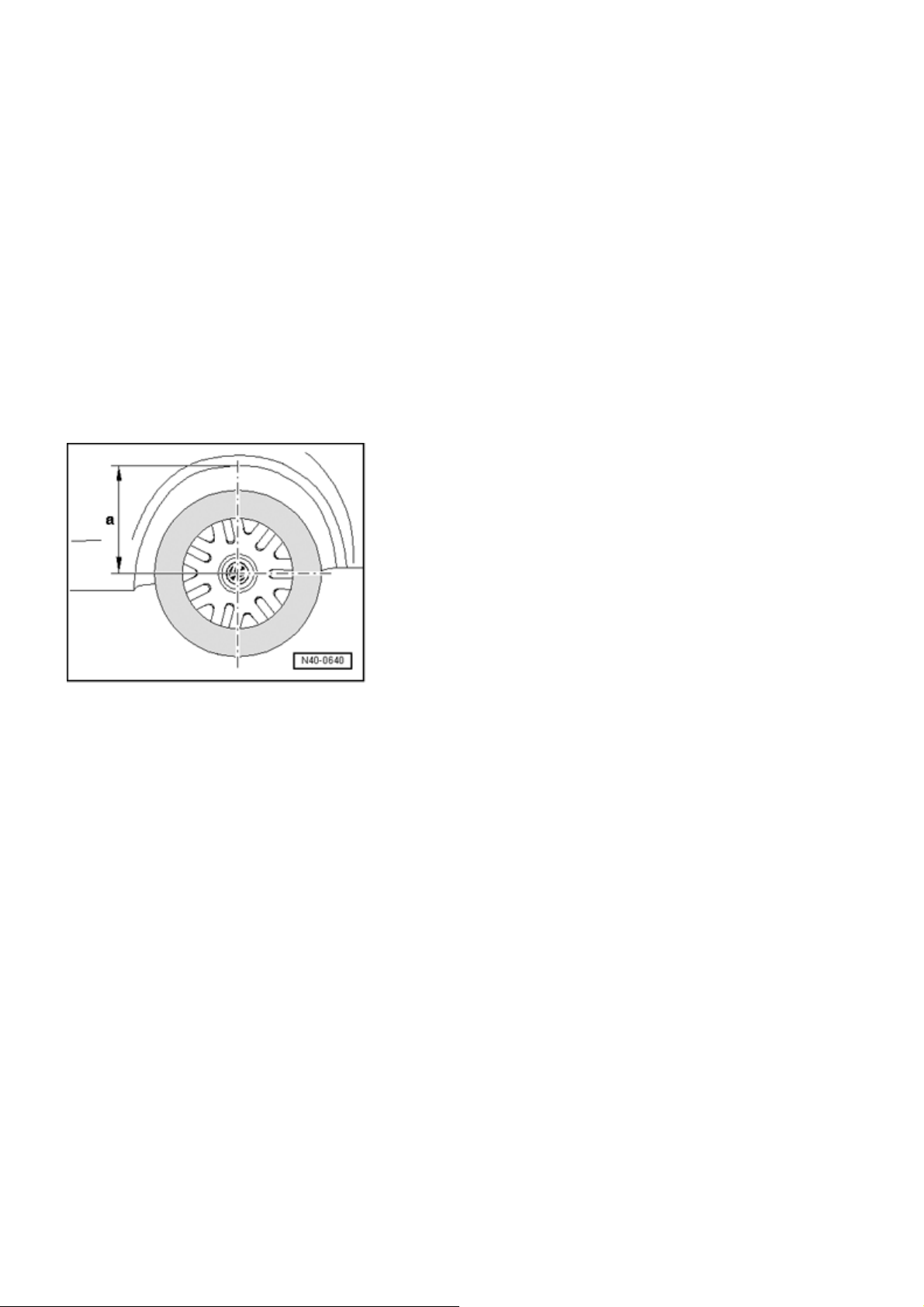

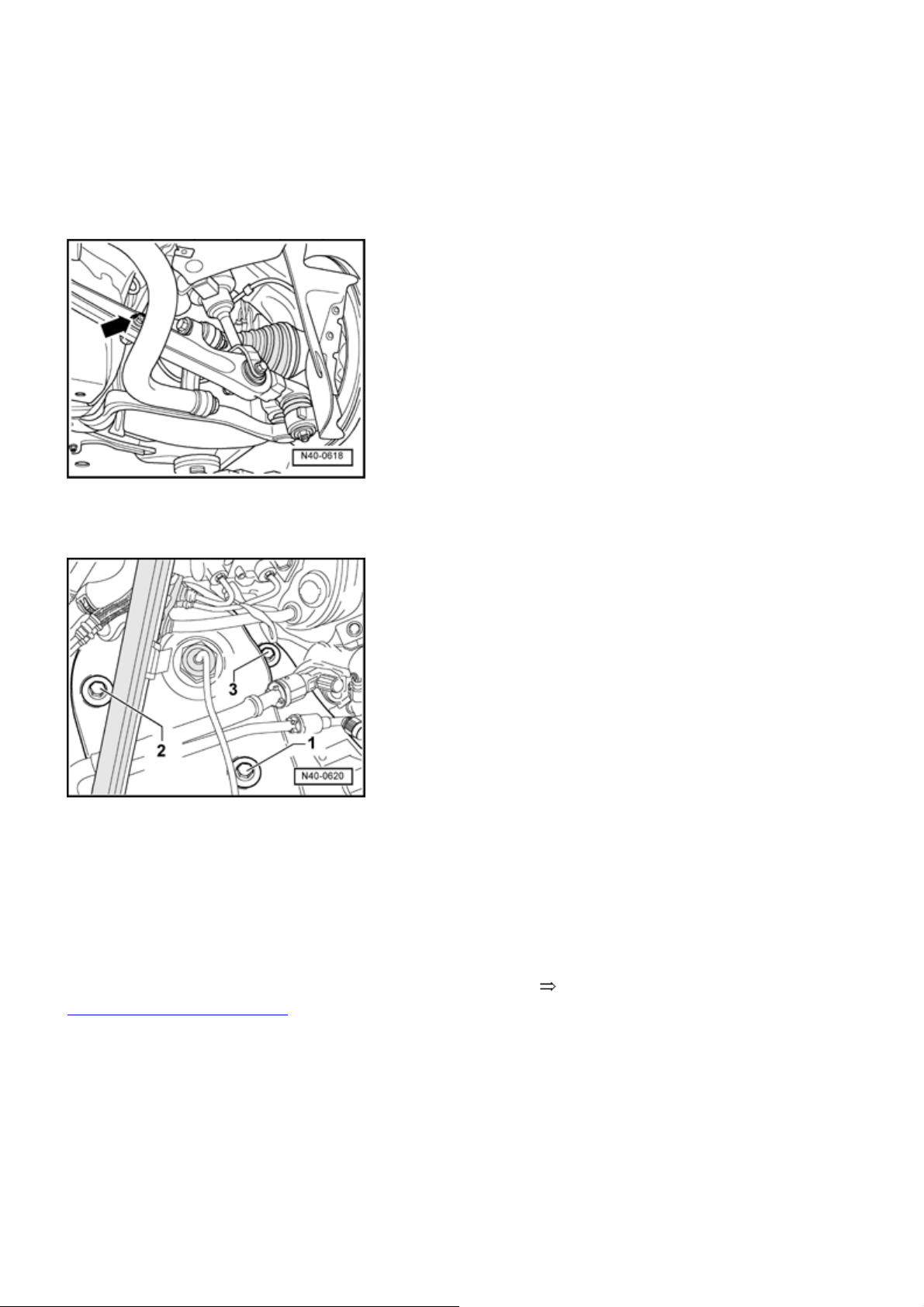

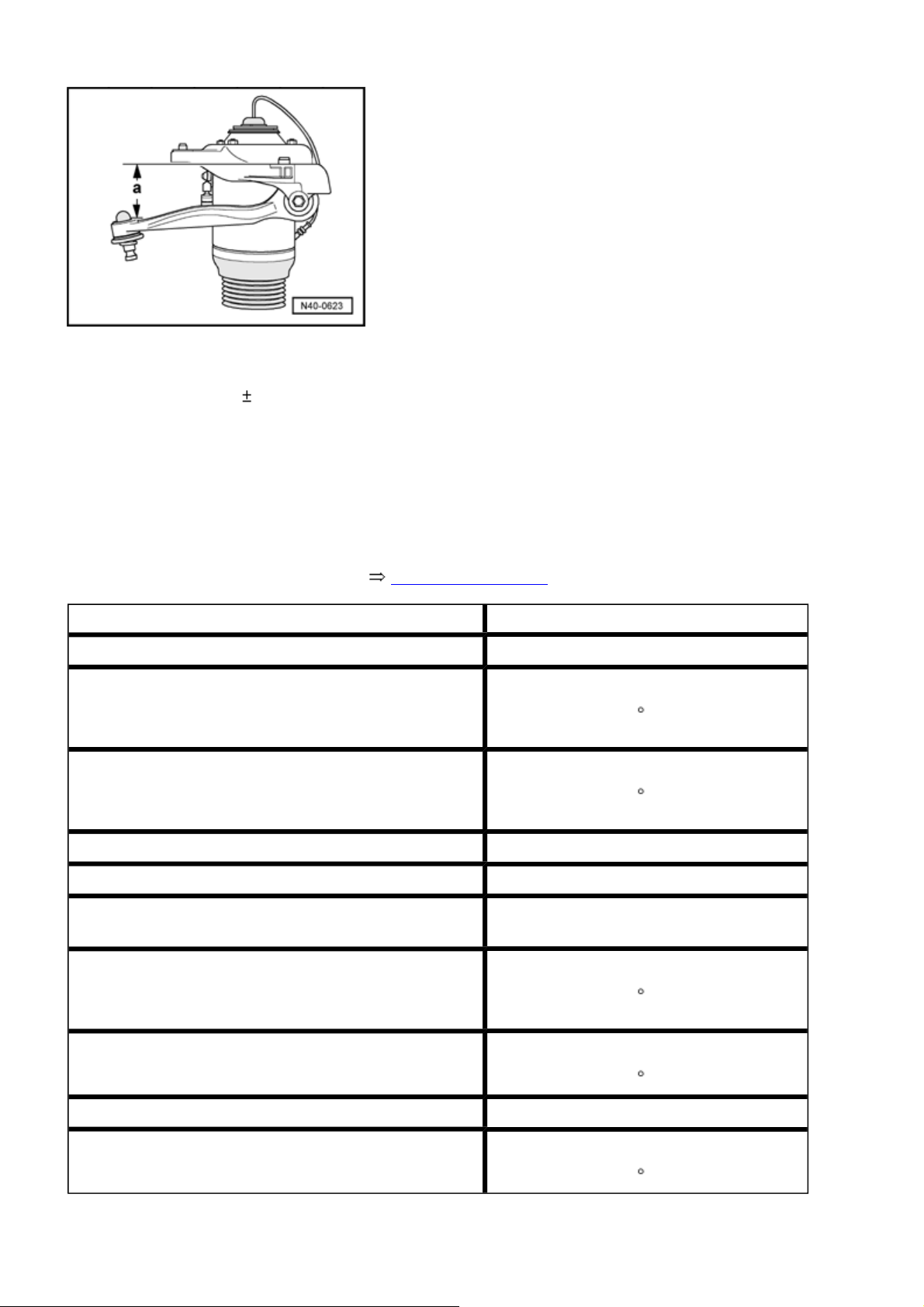

- Before beginning assembly, measure dimension

- a -

from

center of wheel to lower edge of wheelhousing using a tape

measure.

The measurement must be taken in the curb weight

osition (unloaded).

- Note measured value. This is needed for tightening bolts

and nuts.

Before the individual suspension is raised on one side, the

vehicle must be secured to the lifting arms on the hoist

using tensioning straps T10038 .

Caution!

If the vehicle is not secured, it ma

slip off the hoist

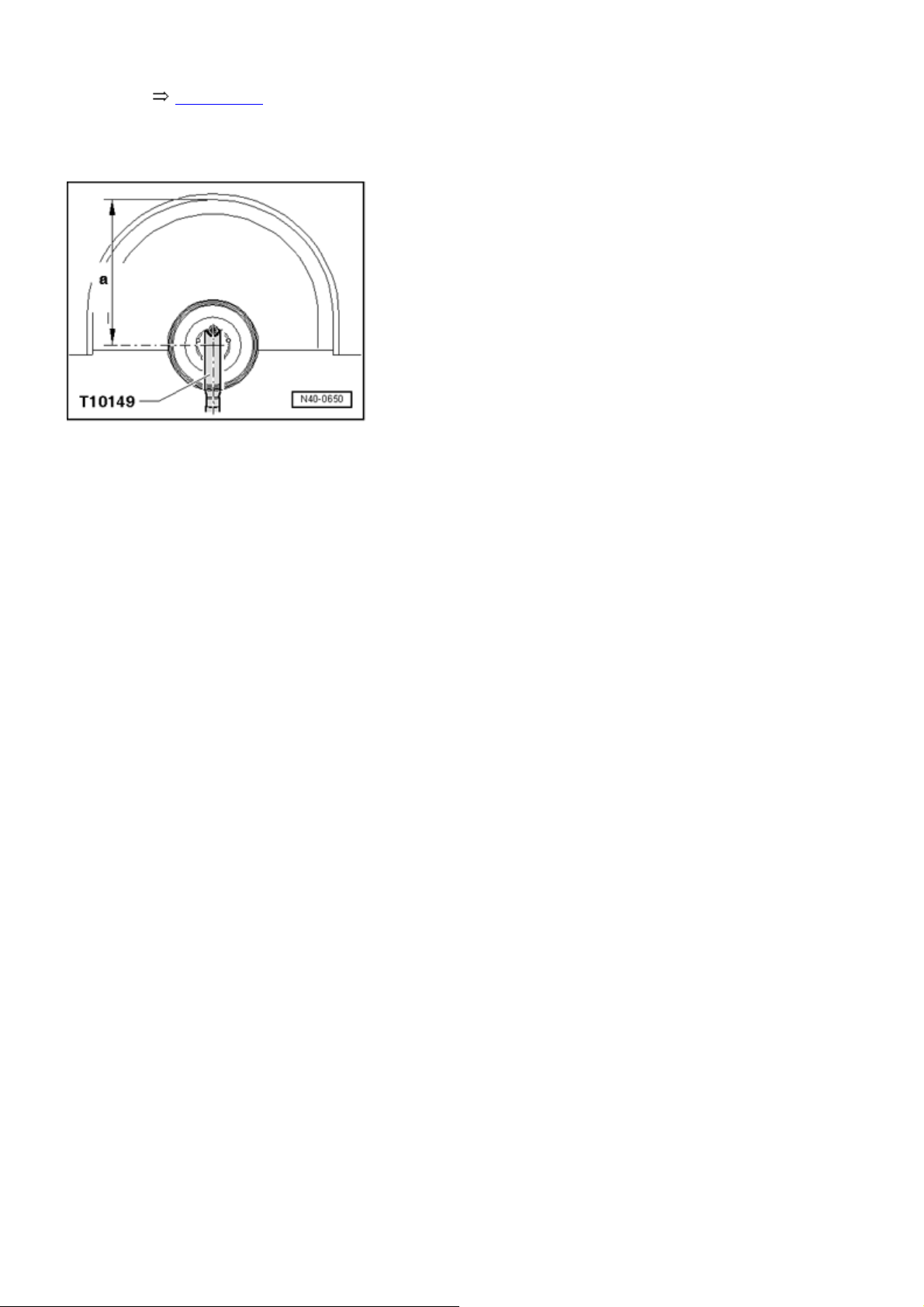

- Turn wheel hub until one of the wheel bolt holes is at 12

o'clock position. .

- Attach Wheel Hub Support T10149 to wheel hub with a

wheel bolt.

Only tighten respective bolts and nuts after dimension

- a - between wheel hub center and lower edge of wheel

housin

, measured before beginning of assembly, is

j

g

Стр. 6 из 6Front suspension, servicin

g

achieved

Topic 40-2

.

- Raise wheel bearing housing using engine/transmission

ack V.A.G 1383 A until dimension

is achieved.

- a -

Lift wheel bearing housin

Caution!

Do not raise or lower the hoist if the

engine/transmission jack is under the vehicle.

Do not leave engine/transmission jack V.A.G 1383

A under vehicle any longer than necessary.

- Tighten respective nuts/bolts.

- Lower wheel bearing housing.

- Move engine/transmission jack V.A.G 1383 A below

vehicle away.

- Remove wheel hub support T10149 .

A - Mounting bracket, upper links, air spring strut

g

and wheel bearin

housings, assembly overview

Note:

If a vehicle has to be moved after removing the drive

axle, first install an outer joint and tighten this to 50

Nm, otherwise you will damage the wheel bearings.

Welding and straightening work on supporting or

wheel carrying components of the suspension is not

permitted.

Always replace self-locking hex head nuts.

Стр. 1 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

40 - 3

Always replaced corroded bolts and nuts.

Hex socket head bolt

200 Nm plus an additional

g

1

180 (

Always replace

/ 2 turn)

Vehicle must not be raised

when tightenin

Torx bolt

9 Nm

Cover plate

Air spring strut

Стр. 2 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

Protective boot must not have

any indentations (be pressed

inward)

Removing and installing

40-3, Air spring strut removing

and installing

Wheel acceleration sensor

Left front wheel acceleration

sensor G337

Right front wheel acceleration

sensor G338

Check with Vehicle Diagnosis,

Testing and Information

System VAS 5051 in "Guided

Fault Finding"

Hex bolt

10 Nm

Air supply line

5 Nm

Clean connection before

loosening

Air escapes when

connections are loosened

Protect threaded connection

from dirt

Multi-point socket head bolt

70 Nm

M 10 x 20

Pre-tighten to 10 Nm in

diagonal sequence

Drive axle

Hex nut

50 Nm

Self-locking

Стр. 3 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

Always replace

Upper front link

Can only be removed

together with mounting

bracket

Mounting bracket, removing

and installing 40-3,

Mounting bracket, removing

and installing

Bonded rubber bushings,

replacing 40-3, Upper link

bonded rubber bushing,

replacing

Hex bolt

Always replace

Mounting bracket

Removing and installing

40-3, Mounting bracket,

removing and installing

Washer

Multi-point socket head bolt

Observe tightening sequence

40-3, Tightening sequence,

Hex nut

23 Nm

Hex bolt

Always replace

Hex nut

50 Nm and 90 (

air spring damper to body

50 Nm plus an additional 90

( 1 / 4 turn)

Always replace

1

/ 4 turn)

Стр. 4 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

Self-locking

Replace after every removal

Upper rear link

Can only be removed

together with mounting

bracket

Mounting bracket, removing

and installing 40-3,

Mounting bracket, removing

and installing

Bonded rubber bushings,

replacing 40-3, Upper link

bonded rubber bushing,

replacing

Hex bolt

On aluminum wheel bearing

Tie rod

Hex bolt

Hex bolt

7 Nm

housings, tighten against

driving direction

Always replace

g

Hex nut

50 Nm

Self-locking

Always replace

Wheel bearing housing

Removing and installing

40-3, Wheel bearing housing,

removing and installing

Aluminum or steel, application

Parts catalog

Стр. 5 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

Air spring strut removing and installin

Special tools, testers and auxiliary items

required

Стр. 6 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

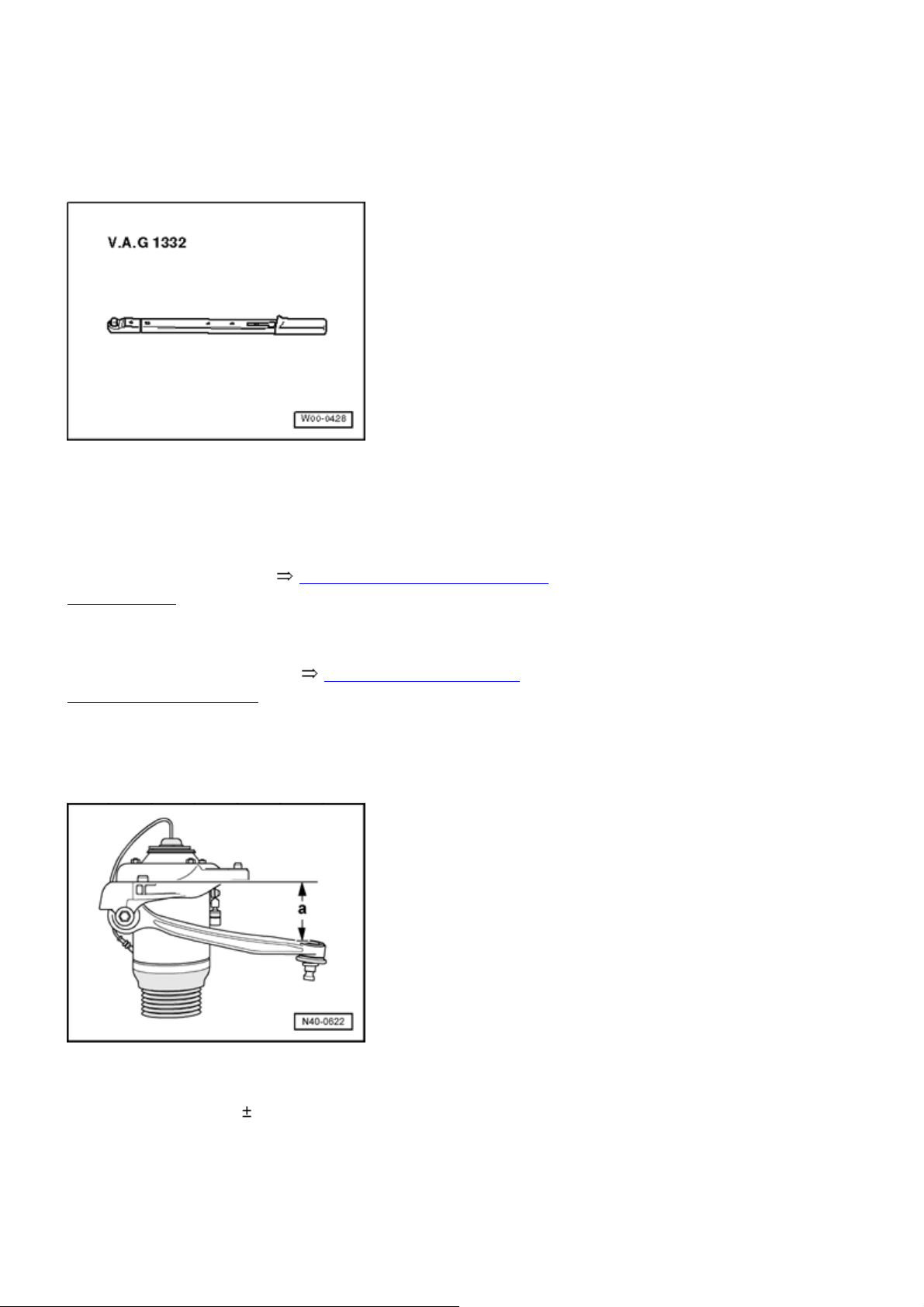

Torque wrench V.A.G 1331

Torque wrench V.A.G 1332

Engine/transmission jack V.A.G

1383 A

Wheel hub support T10149

Removing

Remove air spring strut together with mounting

bracket and upper links.

During assembly work, make sure that no indentations

form on boot of air spring strut!

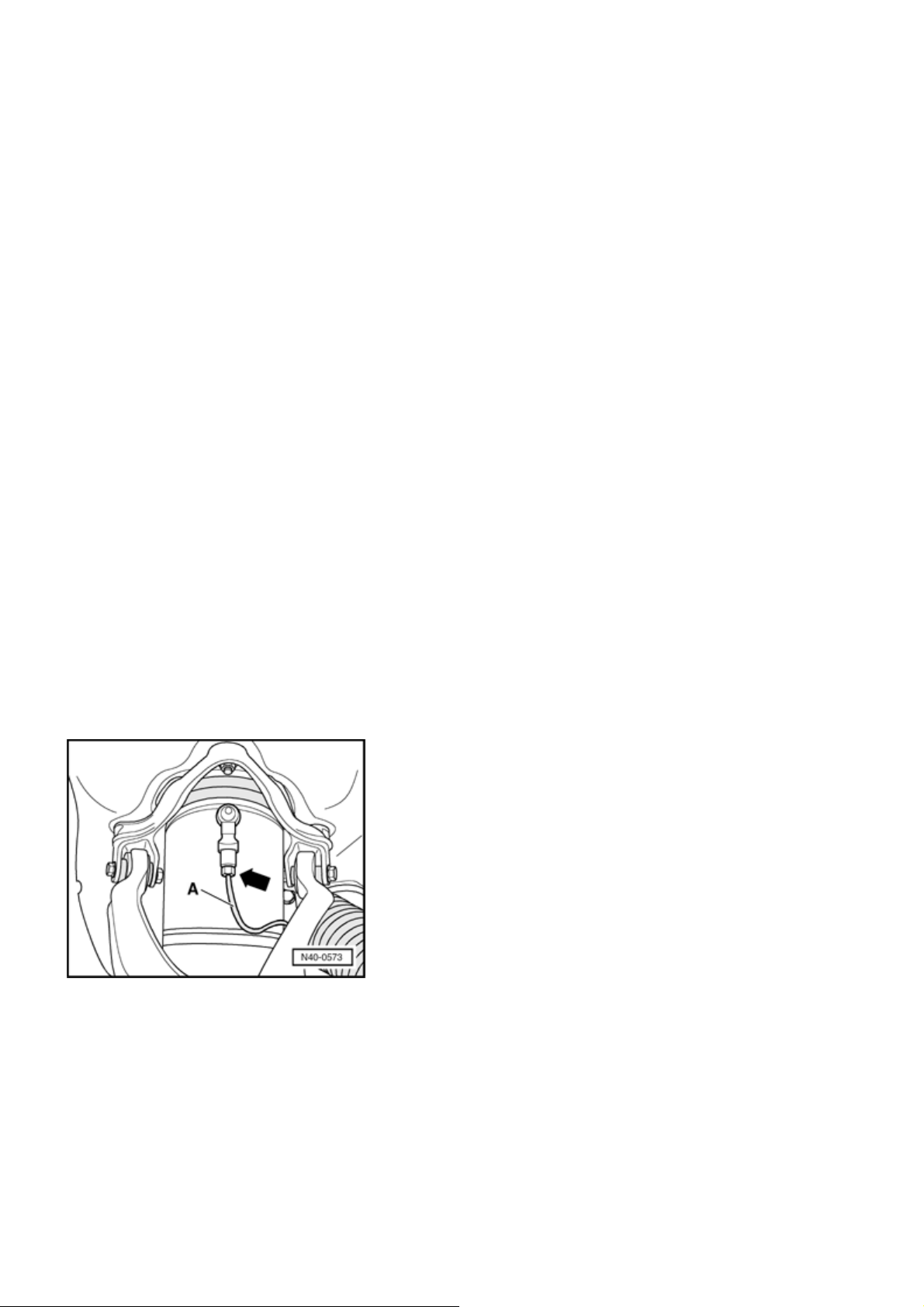

- Remove front wheel.

- Clean air line connection

- Remove air line

from air spring strut and then seal off

- A -

- arrow -

to air spring strut.

both connections.

- Open air line cable ties at air spring strut.

j

Стр. 7 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

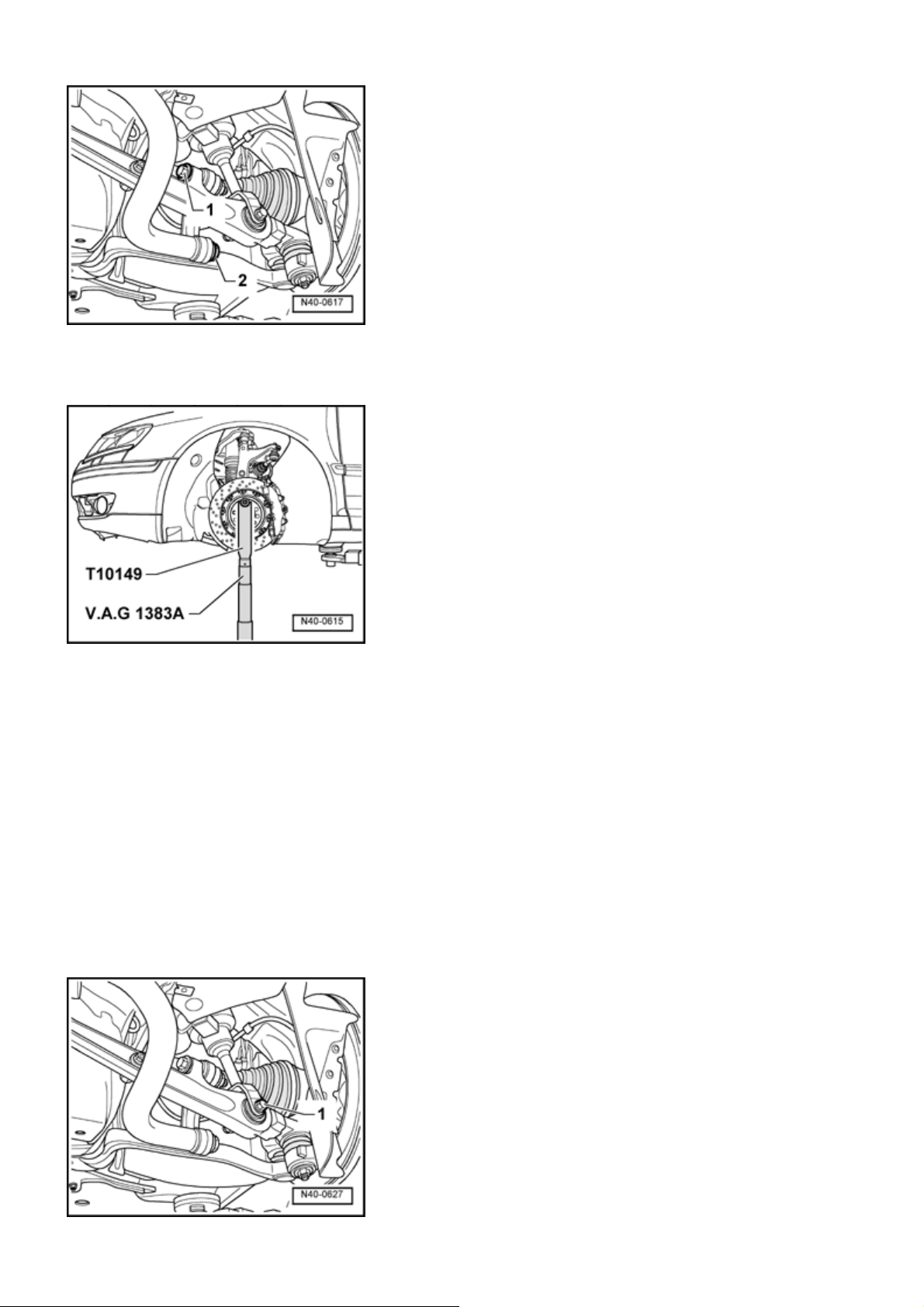

- Loosen connecting link to stabilizer bar

link

- Attach Wheel Hub Support T10149 to wheel hub with a

wheel bolt.

- Raise wheel bearing housing with engine/transmission

ack V.A.G 1383 A and Wheel Hub Support T10149 until

connecting link is "stress free" .

- 1 -

.

and to lower

- 2 -

- Remove connecting link from stabilizer bar.

- Lower wheel bearing housing.

- Move engine/transmission jack V.A.G 1383 A away from

under vehicle.

- Remove both upper links from wheel bearing housing.

V

g

Стр. 8 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

- Remove air spring strut from lower link

- Remove Wheel Acceleration Sensor

strut.

- Remove plenum chamber cover.

Repair Manual, Body Exterior, Repair Group 64,

Stationary windows; Plenum chamber cover, removing and

installing

- 1 -

.

-1-

from air spring

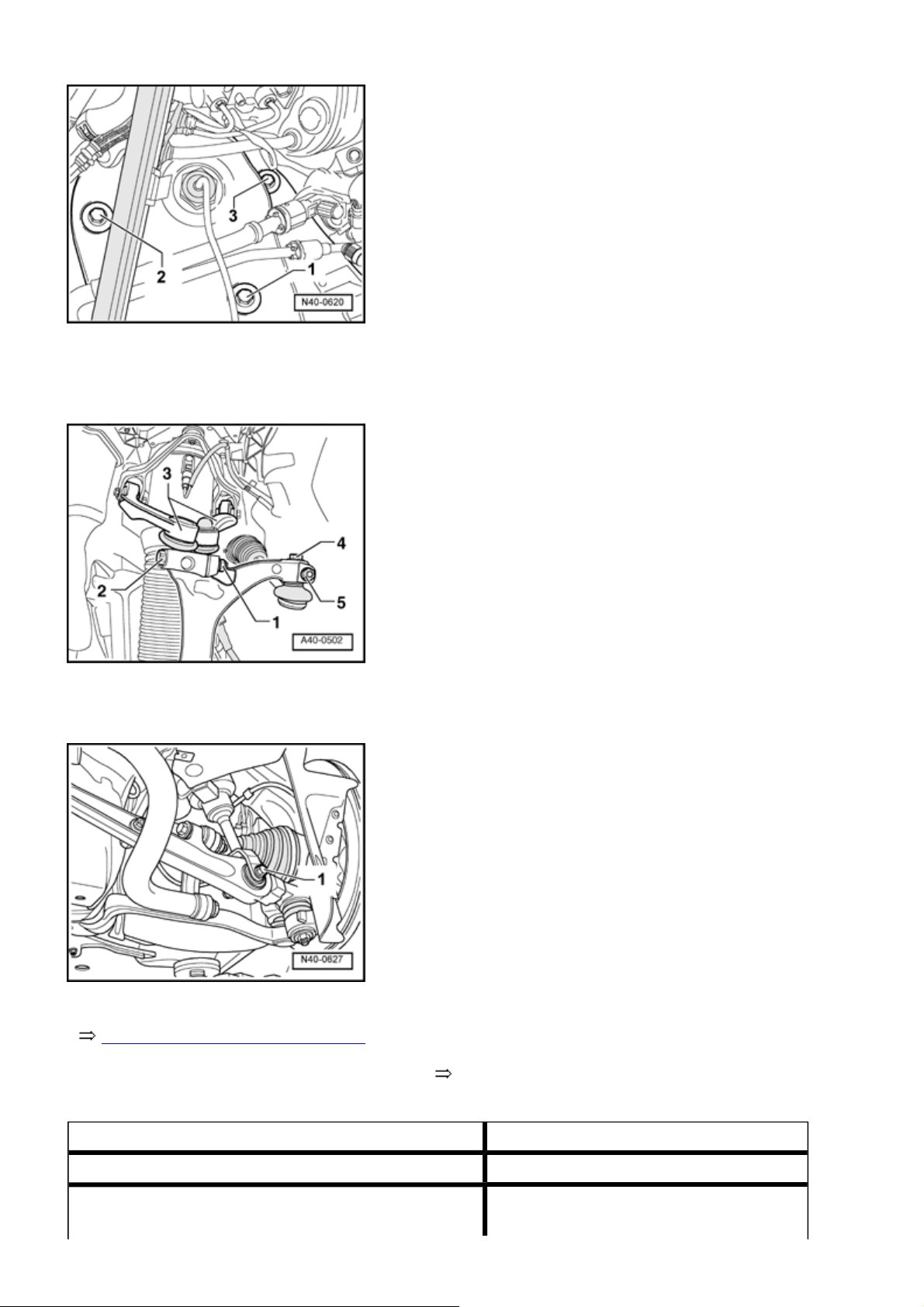

- Unclip cable

- Disconnect strut adjustment switching valve electrical

connector

ehicles with Adaptive Cruise Control

- Remove Brake Booster Membrane Position Sensor G420

.

- 1 -

Repair Manual, Brake System, Repair Group 47, Brake

booster/brake master cylinder, assembly overview; Brake

Booster Membrane Position Sensor G420, removing and

installing

Left side air spring strut, removin

- 2 -

- 3 -

.

.

Стр. 9 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly over...

- Turn steering gear left to stop.

Continue removing air spring strut on right side

- Turn steering gear right to stop.

Continue for both sides

- Remove Level Control System Sensor connecting link

arrow -

from lower link.

-

- Remove air spring strut multi-point socket head bolts

from air spring strut.

2, 3 -

- 1,

- Pull wheel bearing housing as far downward as possible

and then remove from air spring strut.

- Remove mounting bracket from air spring strut.

If air spring strut is to be replaced, first read the following

40

-3, Air spring strut, filling .

Installing

Installation is in reverse order of removal. Note the

following:

- Check threaded bushings (3 pieces, as part of mounting

bracket) are located properly in body.

- Observe tightening sequence for multi-point socket head

bolts.

y

Tightening sequence, air spring damper to bod

Стр. 10 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

- Push upper link

tightening.

- Raise wheel bearing housing and then tighten hex bolt

40-2, Lift wheel bearing housing

-

- Check basic setting of level control system Vehicle

Diagnosis, Testing and Information System VAS 5051 .

as far down as possible when

- 3 -

- 1

Tightening torques

Air line to air spring strut 5 Nm

Connecting link to stabilizer bar

90 Nm plus an additional 1 / 4 turn (90

1)

g

2)

Стр. 11 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

)

Connecting link to lower link

1)

2)

90 Nm plus an additional 1 / 4 turn (90

)

Upper link to wheel bearing housing 50 Nm

Wheel acceleration sensor to air spring strut 10 Nm

Connecting link from vehicle level sensor to lower

8 Nm

link

Air spring strut to lower link

1)

2)

Mounting bracket to body

1)

90 Nm plus an additional 1 / 4 turn (90

)

50 Nm plus an additional 1 / 4 turn (90

)

Air spring strut to mounting bracket 20 Nm

1)

Use new bolts/nuts

2)

Tighten bolts/nuts in curb weight position

Air spring strut, fillin

Special tools, testers and auxiliary items required

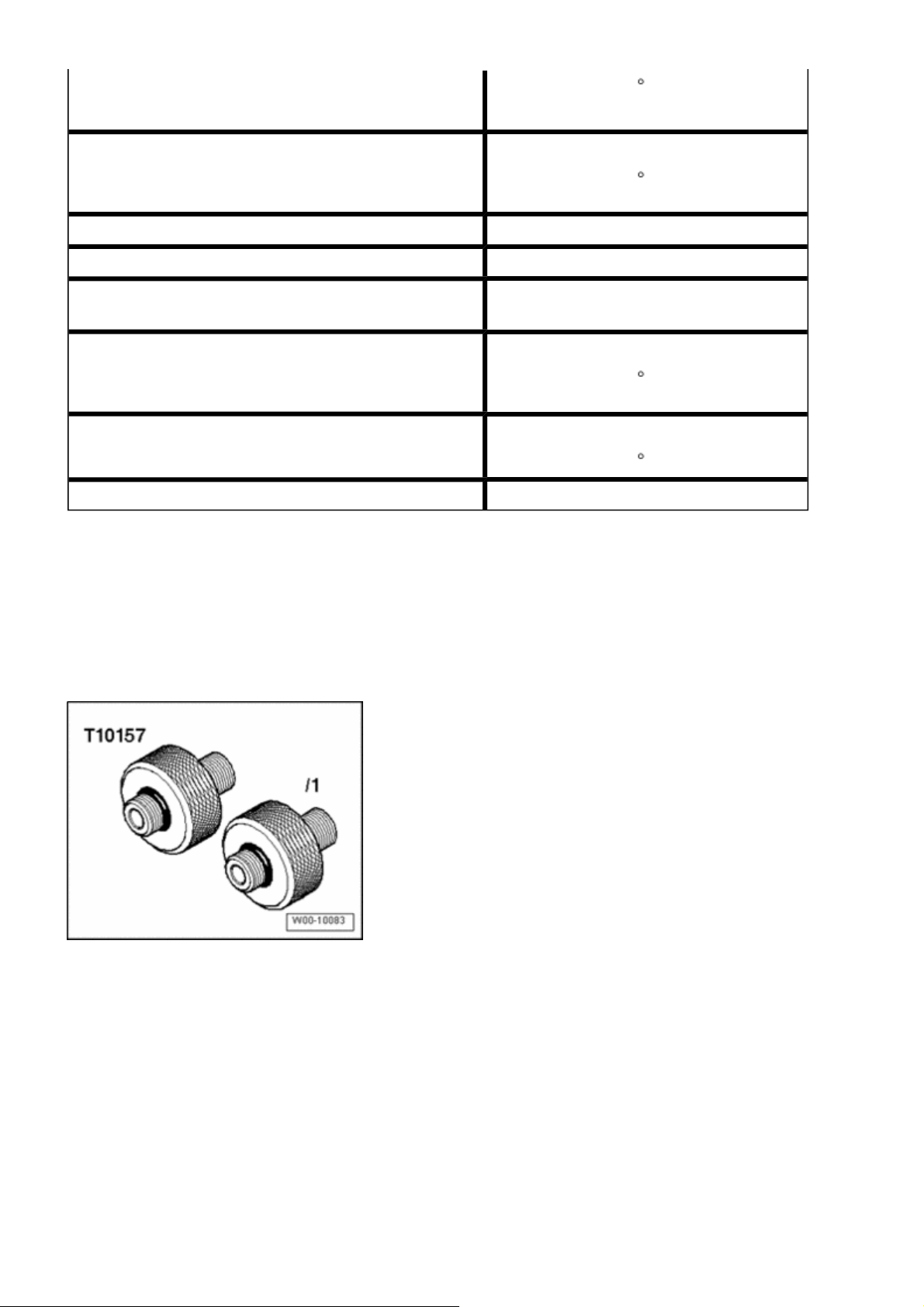

Adapter T10157

Air suspension strut charger VAS 6231 , not depicted

Steel gas cylinder filled with Argon or Corgon, not

illustrated

Note:

Air spring struts are supplied as replacement parts

with a minimum pressure. By sitting in storage for

extended periods this minimum pressure can

diminish (just like a tire). Before the air spring strut is

removed from its packaging, this minimum pressure

must be controlled and restored by "refilling" . Without

this necessary refilling, folds can form in the underfilled air spring boot. These folds cause damage

which can lead to premature failure.

- Remove cover from packaging.

Стр. 12 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

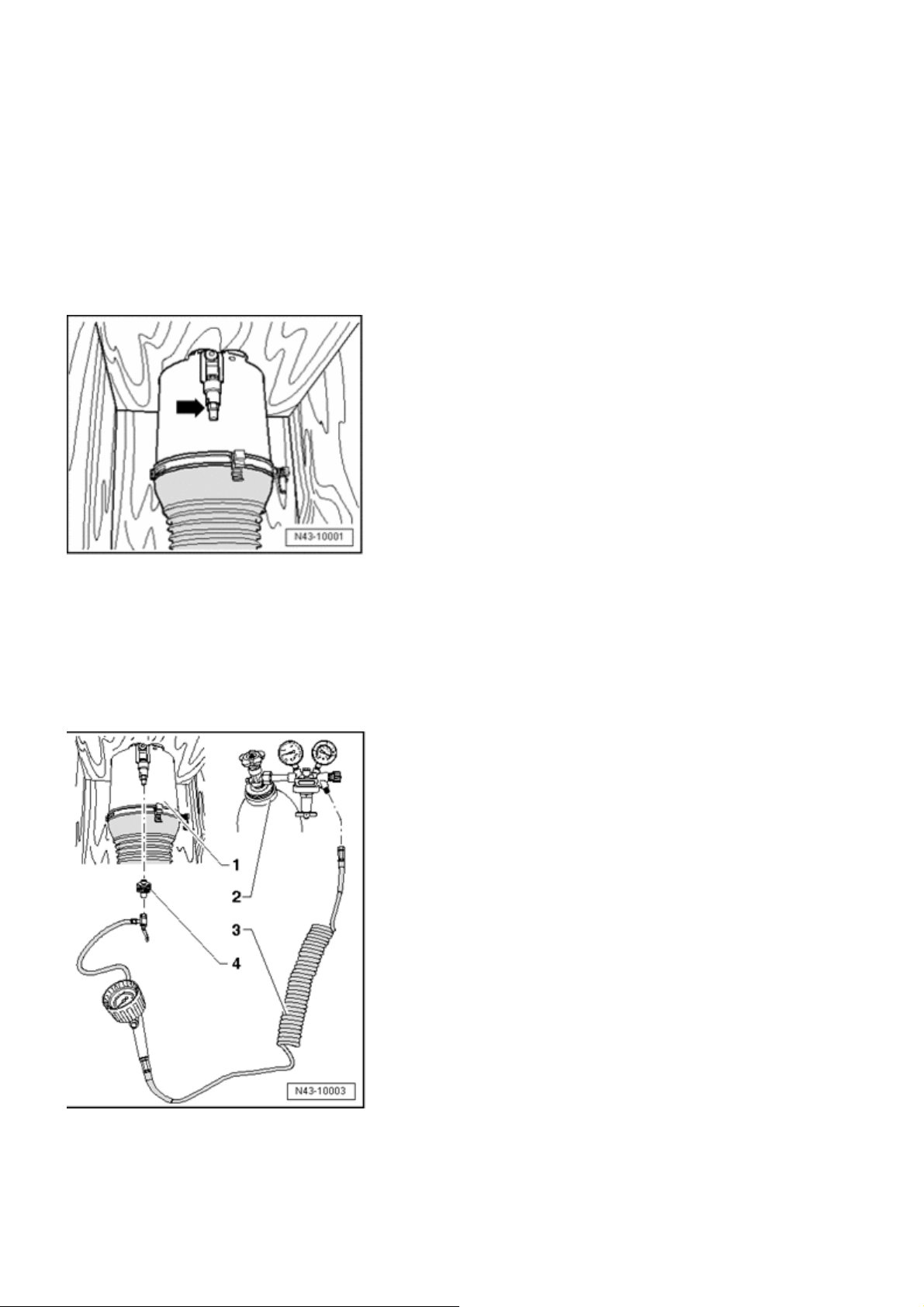

- Remove bolt

- arrow -

from residual pressure retaining

valve.

- Close steel gas bottle pressure valve.

- Become familiar with the relevant rules for prevention of

accidents for pressurized containers and technical gases.

- Connect air spring filler unit VAS 6231 and adapter

T10157 as shown in the illustration.

Air spring strut with packaging

Steel gas bottle for argon, corgon with gauges

Air spring filler unit VAS 6231

Adapter T10157

Стр. 13 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

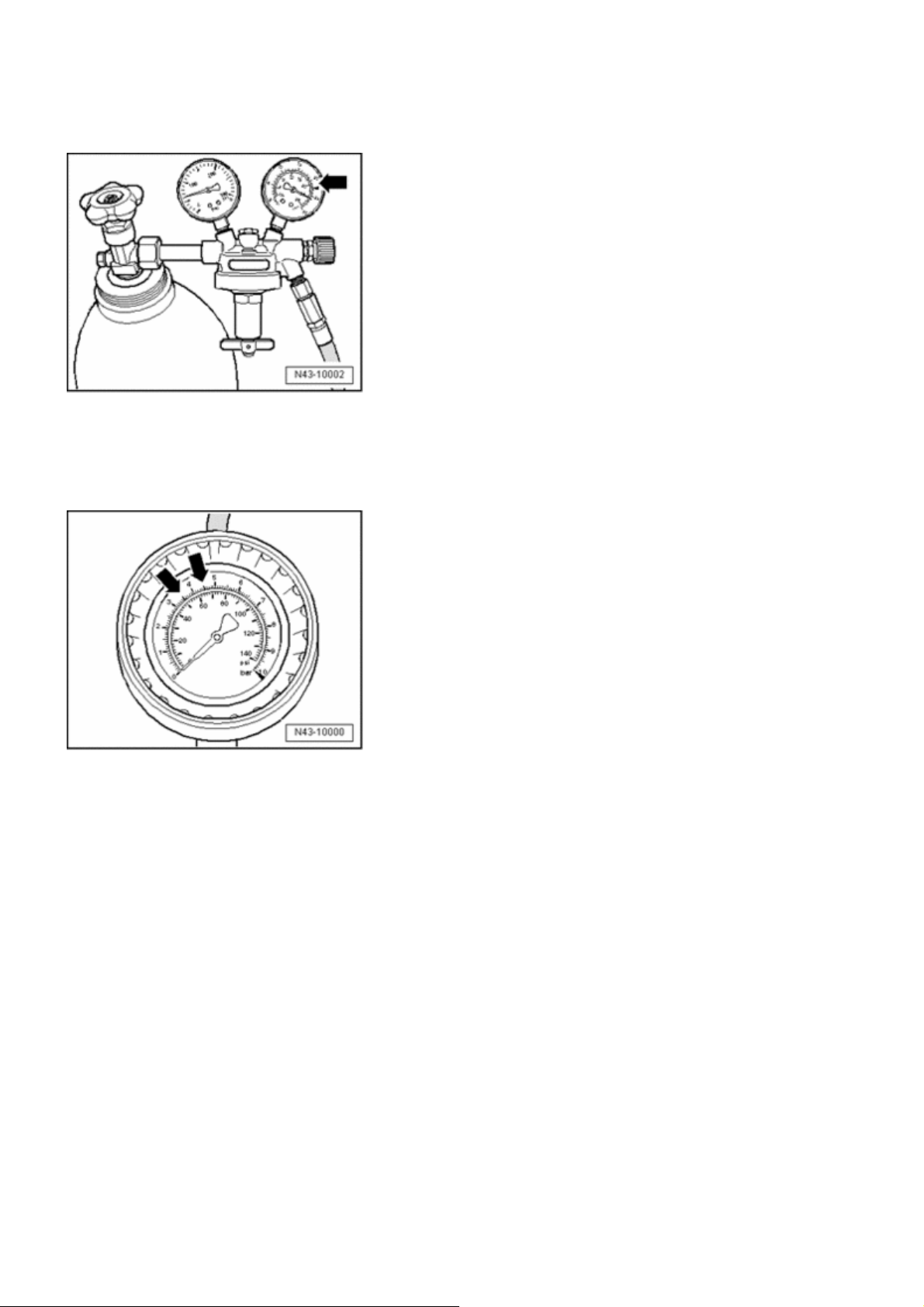

- Set flow rate limiter gauge to 2.0 L/min

-arrow-

.

- Fill gas into air spring strut using several individual

pressure bursts.

The display only shows a correct gas pressure if the

"oscillatory pressure" of the residual pressure retaining

valve is overcome. The "oscillatory pressure" is at approx.

3.5 bar. When the display reaches 3.5 to 4.5 bar, air spring

damper is sufficiently filled with gas.

- Make sure display does not climb over 4.5 bar when

filling.

- Disconnect air spring filler unit VAS 6231 from adapter

T10157 . This dissipates gas above an internal pressure of

3.5 bar.

Minimum pressure is now set. Remove air spring strut from

packaging.

- After installation, first drive the vehicle at high ride height

and then at normal ride height. Repeat this sequence once

more.

Move twice to different ride heights, the gas is replaced

with cleaned air from air supply unit.

- Install air spring strut 40-3, Installing .

g

Mounting bracket, removing and installin

Special tools, testers and auxiliary items required

Стр. 14 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

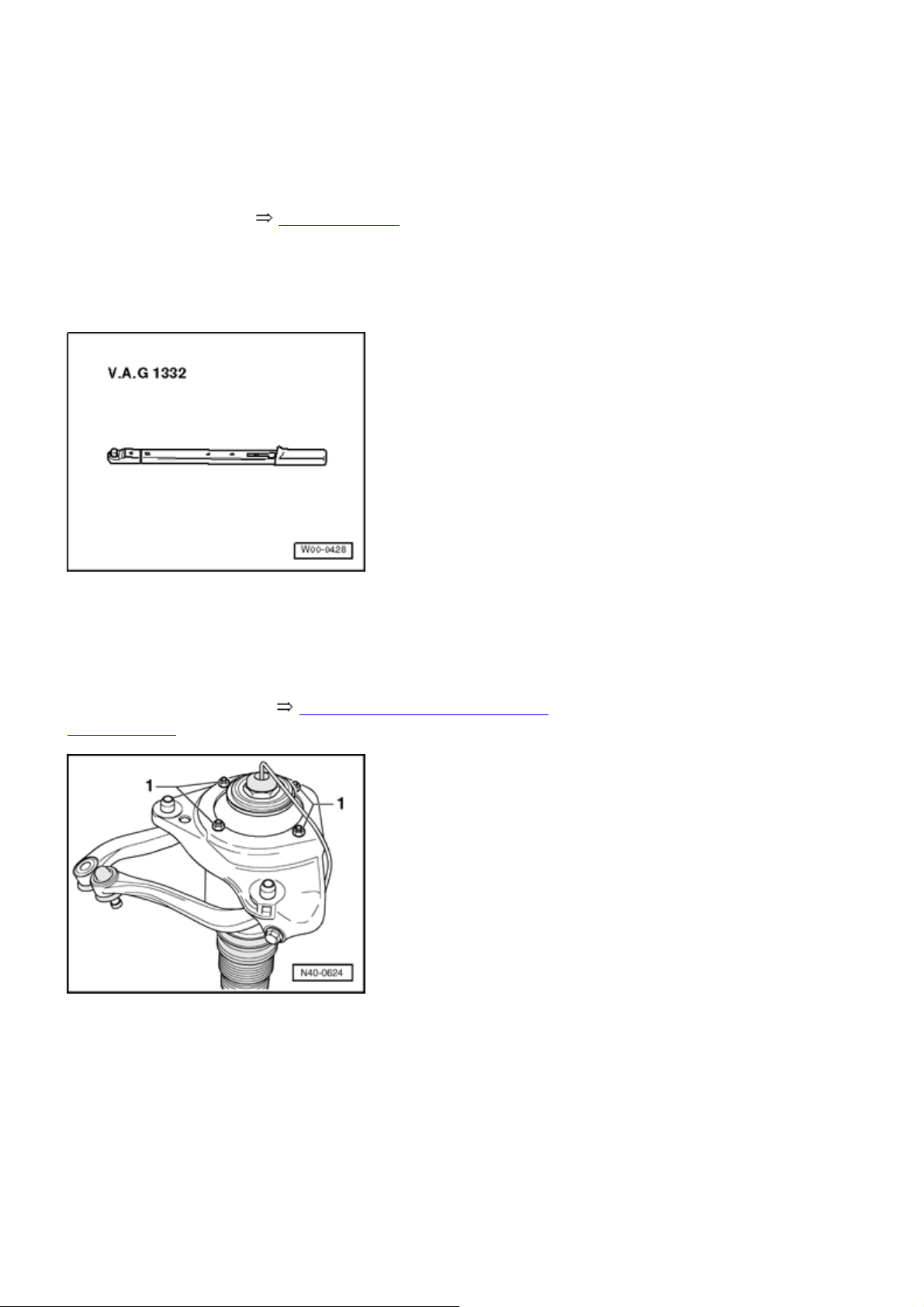

Torque wrench V.A.G 1332

Removing

- Remove air spring strut 40-3, Air spring strut removing

and installing .

- Remove mounting bracket from air spring strut

Installing

Installation is in reverse order of removal.

-1-

.

Стр. 15 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

- Install mounting bracket to air spring strut

-1-

.

- Install air spring strut 40-3, Installing .

Tightening torque

Air line to air spring strut 5 Nm

Connecting link to stabilizer bar

1)

2)

Connecting link to lower link

1)

2)

90 Nm plus an additional 1 / 4 turn (90

)

90 Nm plus an additional 1 / 4 turn (90

)

Upper link to wheel bearing housing 50 Nm

Wheel acceleration sensor to air spring strut 10 Nm

Connecting link from vehicle level sensor to lower

8 Nm

link

Air spring strut to lower link

1)

2)

90 Nm plus an additional

)

1

/ 4 turn (90

Mounting bracket to body

1)

50 Nm plus an additional 1 / 4 turn (90

)

Air spring strut to mounting bracket 20 Nm

1)

Always use new nuts and bolts

2)

Tighten bolts and nuts in curb weight position

Upper link, removing and installing

Special tools, testers and auxiliary items required

Стр. 16 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

Torque wrench V.A.G 1332

Removing

- Remove air spring strut 40-3, Air spring strut removing

and installing .

- Compress air spring strut in a vise with protective covers.

- Remove mounting bracket 40-3, Mounting bracket,

removing and installing .

- Remove both links from mounting bracket.

Links, setting

- Set upper front link to dimension

Dimension

= 81 2 mm

- a -

and tighten.

- a -

Стр. 17 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

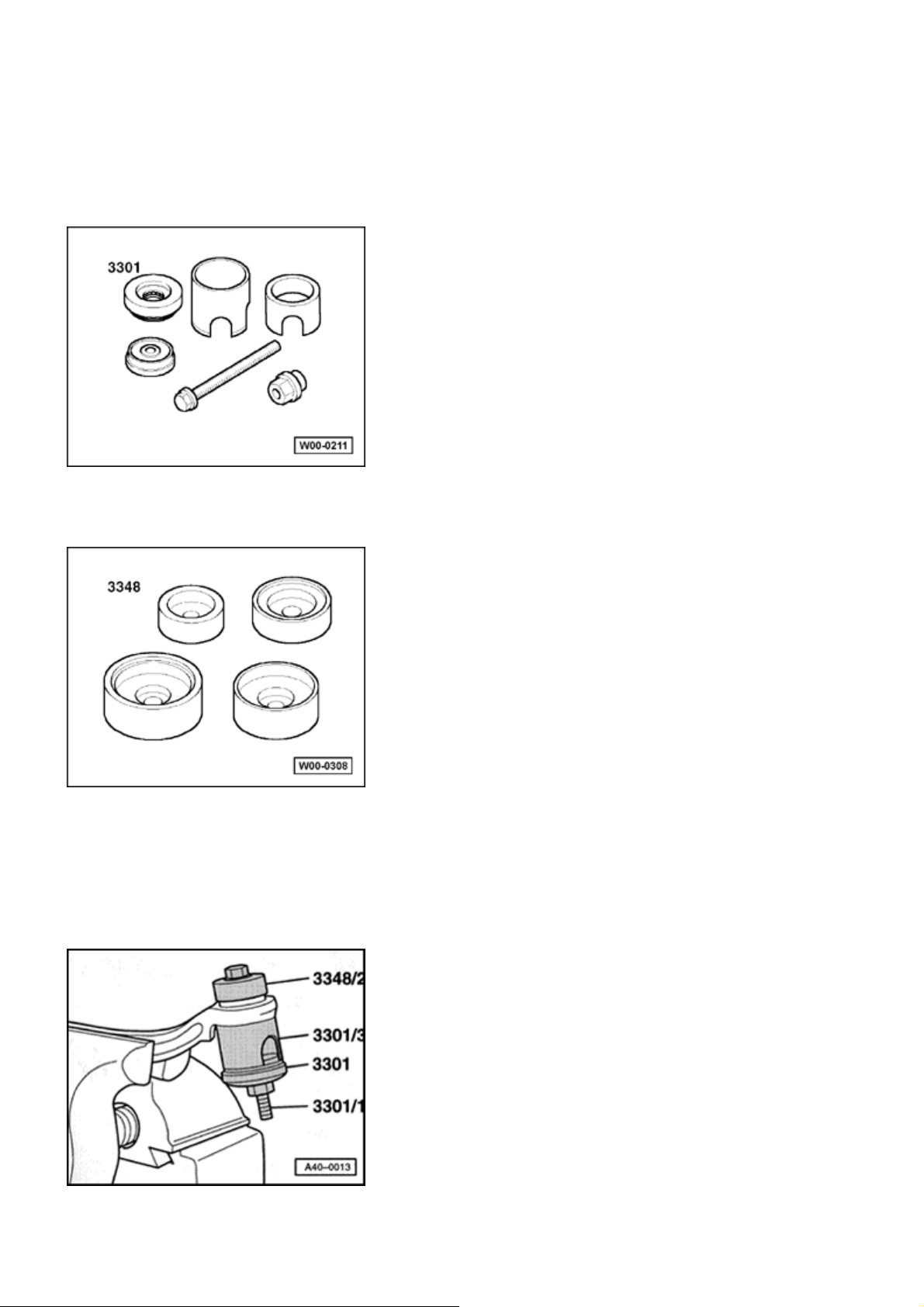

- Set upper rear link to dimension

Dimension

Installing

= 69 2 mm

- a -

and tighten.

- a -

Installation is in reverse order of removal, note the

following:

- Attach both links to mounting bracket.

- Adjust both links before tightening. 40-3, Links, setting

Tightening torque

Air line to air spring strut 5 Nm

Connecting link to stabilizer bar

1)

2)

Connecting link to lower link

1)

2)

90 Nm plus an additional 1 / 4 turn (90

90 Nm plus an additional 1 / 4 turn (90

)

)

Upper link to wheel bearing housing 50 Nm

Wheel acceleration sensor to air spring strut 10 Nm

Connecting link from vehicle level sensor to lower

8 Nm

link

Air spring strut to lower link

1)

2)

Mounting bracket to body

1)

90 Nm plus an additional 1 / 4 turn (90

)

50 Nm plus an additional 1 / 4 turn (90

)

Air spring strut to mounting bracket 20 Nm

Upper link to mounting bracket

1)

1)

Use new bolts and nuts

50 Nm plus an additional 1 / 4 turn (90

)

2)

g

p

g

Tighten bolts in curb weight position

Upper link bonded rubber bushing, replacin

Special tools, testers and auxiliary items required

Стр. 18 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

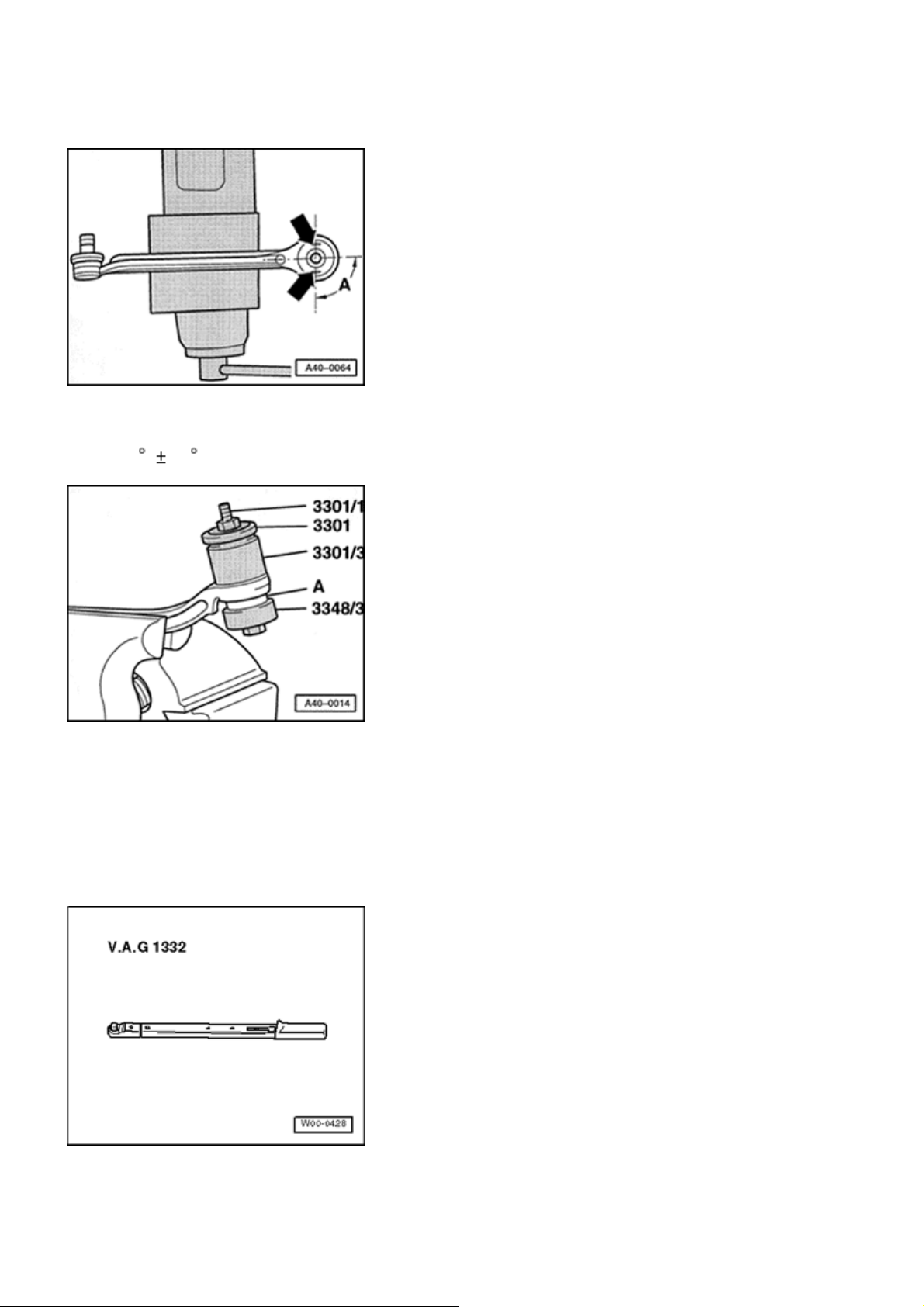

Assembly tool 3301

Front and Rear Bearing Tool 3348

Bonded rubber bushing, removing

Clam

link only in vise with protective covers!

Removing bonded rubber bushin

Стр. 19 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

Bonded rubber bushing, seating

Bonded rubber bushing installation location

A =90 5

Seating bonded rubber bushing

Bushing

- A -

Wheel bearing housing, removing and installing

Special tools, testers and auxiliary items required

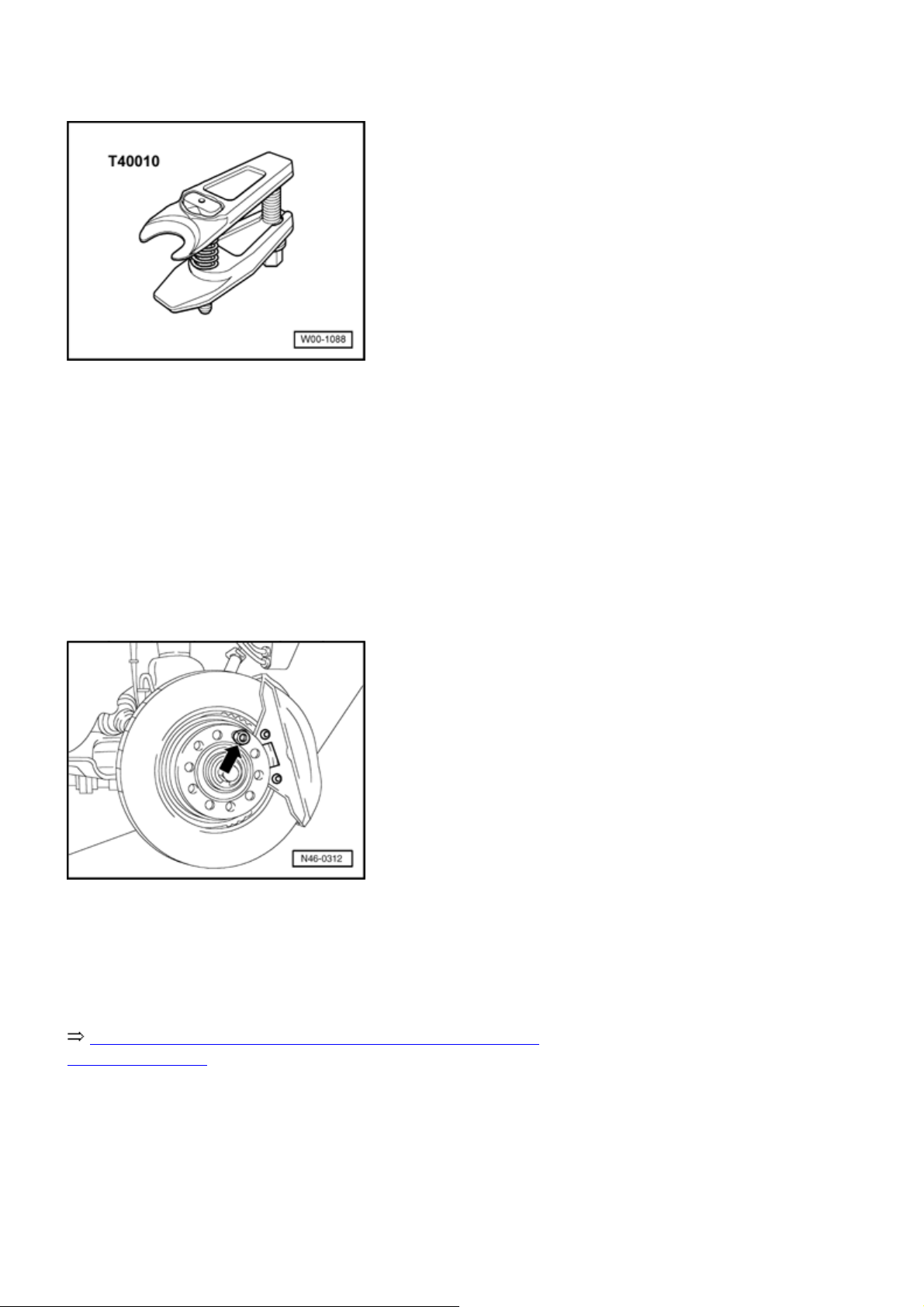

Torque wrench V.A.G 1332

Стр. 20 из 29A - Mounting bracket, upper links, air spring strut and wheel bearing housings, assembly o...

Ball joint puller T40010

Removing

During assembly work, make sure that no indentations

form on boot of air spring strut!

- Remove drive axle hex bolt. Vehicle must be on ground to

do this

- risk of accident -

- Remove front wheel.

.

- Secure brake disc using wheel bolt

- arrow -

.

- Remove brake caliper and disengage from wire to body

Repair Manual, Brake System, Repair Group 46, Front

brakes, servicing

.

- Remove brake disc and cover plate.

- Loosen lower link hex nut and guide link on wheel bearing

housing 2 turns.

Loading...

Loading...