Volkswagen V10-TDI User Manual

The Touareg

V10-TDI Engine

Design and Function

Self-Study Program

Course Number 89N303

Volkswagen of America, Inc.

Service Training

Printed in U.S.A.

Printed 03/2004

Course Number 89N303

©2004 Volkswagen of America, Inc.

All rights reserved. All information contained in

this manual is based on the latest information

available at the time of printing and is subject to

the copyright and other intellectual property

rights of Volkswagen of America, Inc., its

affiliated companies and its licensors. All rights

are reserved to make changes at any time

without notice. No part of this document may

be reproduced, stored in a retrieval system, or

transmitted in any form or by any means,

electronic, mechanical, photocopying, recording

or otherwise, nor may these materials be

modified or reposted to other sites without the

prior expressed written permission of the

publisher.

All requests for permission to copy and

redistribute information should be referred to

Volkswagen of America, Inc.

Always check Technical Bulletins and the

Volkswagen Worldwide Repair Information

System for information that may supersede any

information included in this booklet.

Trademarks: All brand names and product

names used in this manual are trade names,

service marks, trademarks, or registered

trademarks; and are the property of their

respective owners.

Contents

Introduction .............................................................................................................. 1

The V10-TDI, Specifications, Power/Torque Diagram

Engine Mechanics..................................................................................................... 4

Cylinder Block,Endbracket, Cylinder Head, Connecting Bolt Principal, Crankshaft,

Crank Pin Offset, Pistons and Connecting Rods, Balancing, Auxilary Drive and Components

Oil Circulation, Coolant Circulation, Fuel System, Exhaust System,

Overview of Engine Management

Service ..................................................................................................................... 40

Service Tools

The Self-Study Program provides you with

information regarding designs and functions.

The Self-Study Program is not a Repair Manual.

For maintenance and repair work, always refer

to the current technical literature.

New!

Caution/Note

i

ii

Introduction

“...Easy to recognize, the beauty of the classical lines,

the calm but predominantly powerful charisma

of intelligent and sensible engine activity, simple and elegant -

in short, ladies and gentlemen, the world’s top performer!

A milestone...”

With the V10-TDI engine, Volkswagen once again sets new standards in diesel

technology. Due to a multitude of innovative techniques, the highest demands in terms

of performance, torque and emissions of a diesel engine are fulfilled for the luxury

vehicle class.

The V10-TDI engine crowns 25 years of diesel engine development at Volkswagen.

It is the most powerful series passenger-vehicle diesel engine in the world.

1

Introduction

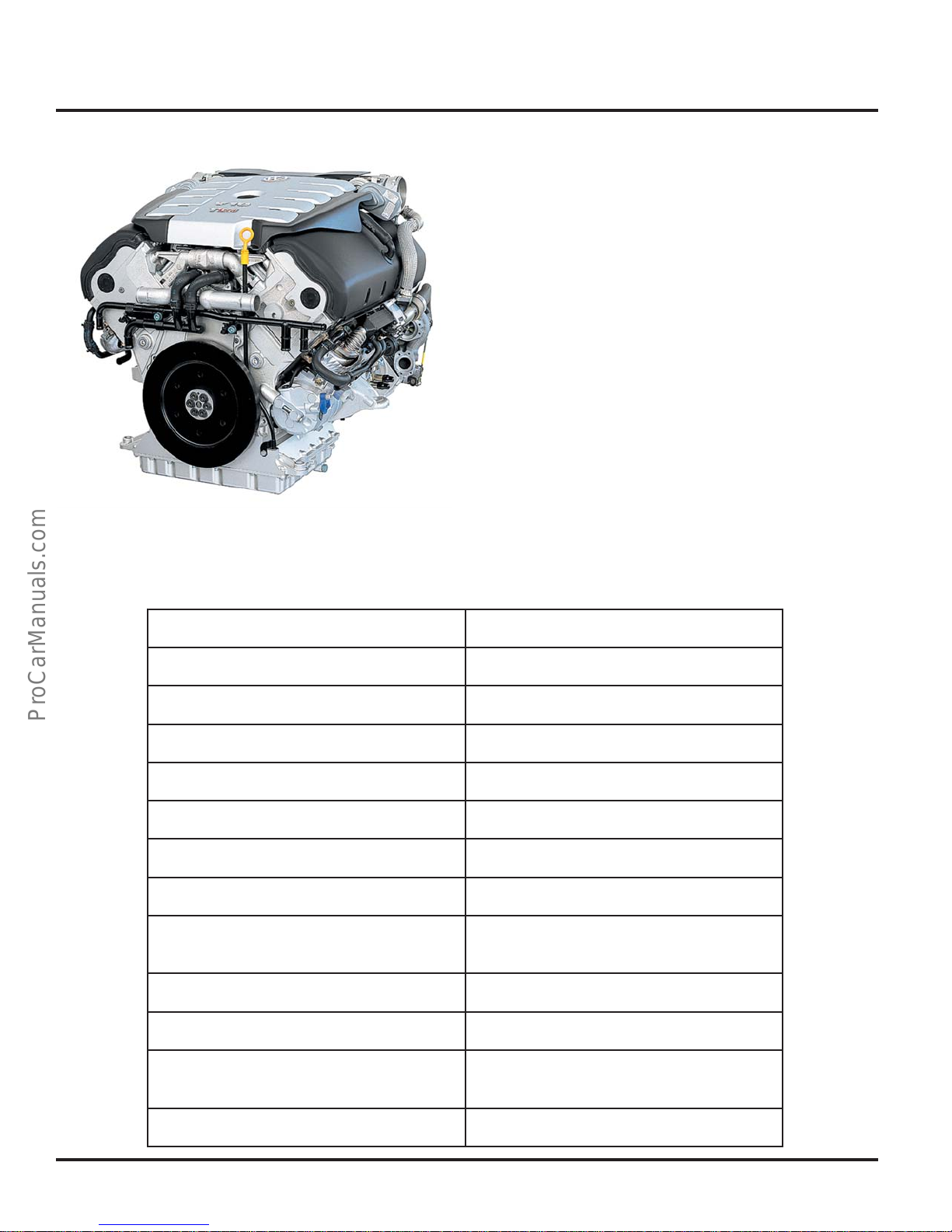

The V10-TDI Engine

The V10-TDI engine is a newly developed diesel

engine in which innovative lightweight

construction and enormous power are united

within compact dimensions.

It has a 900 aluminum cylinder block with 5

cylinders in each bank of the block. The control

and auxiliary drive are gear-driven. The fuel

injection system uses solenoid controlled unit

injectors to ensure a high performance yield at

low exhaust emissions.

303_001

noitcurtsnoC09,srednilyC01

eroB)mm18(.nI91.3

ekortS)mm5.59(.nI67.3

oisserpmoC1:81

rewopesroHMPR0573@)Wk032(ph803

euqroT

riuqeRleuFmuminimZC94leseiD

edoCenignEWKB

tnemecalpsiD)cc1294(sehcnIcibuC003

rednilyC-rep-sevlaV2

oitaRn

tnemeganaMenignE61CDEhcsoB

stneme

tnemtaerTtsuahxE

0

tfbl355

elgnA-V

MPR0522@)mN057(

dnanoitalucricersagtsuahxE

retrevnoccitylatacnoitadixo

niriF9-4-8-3-7-2-01-5-6-1

redrOg

2

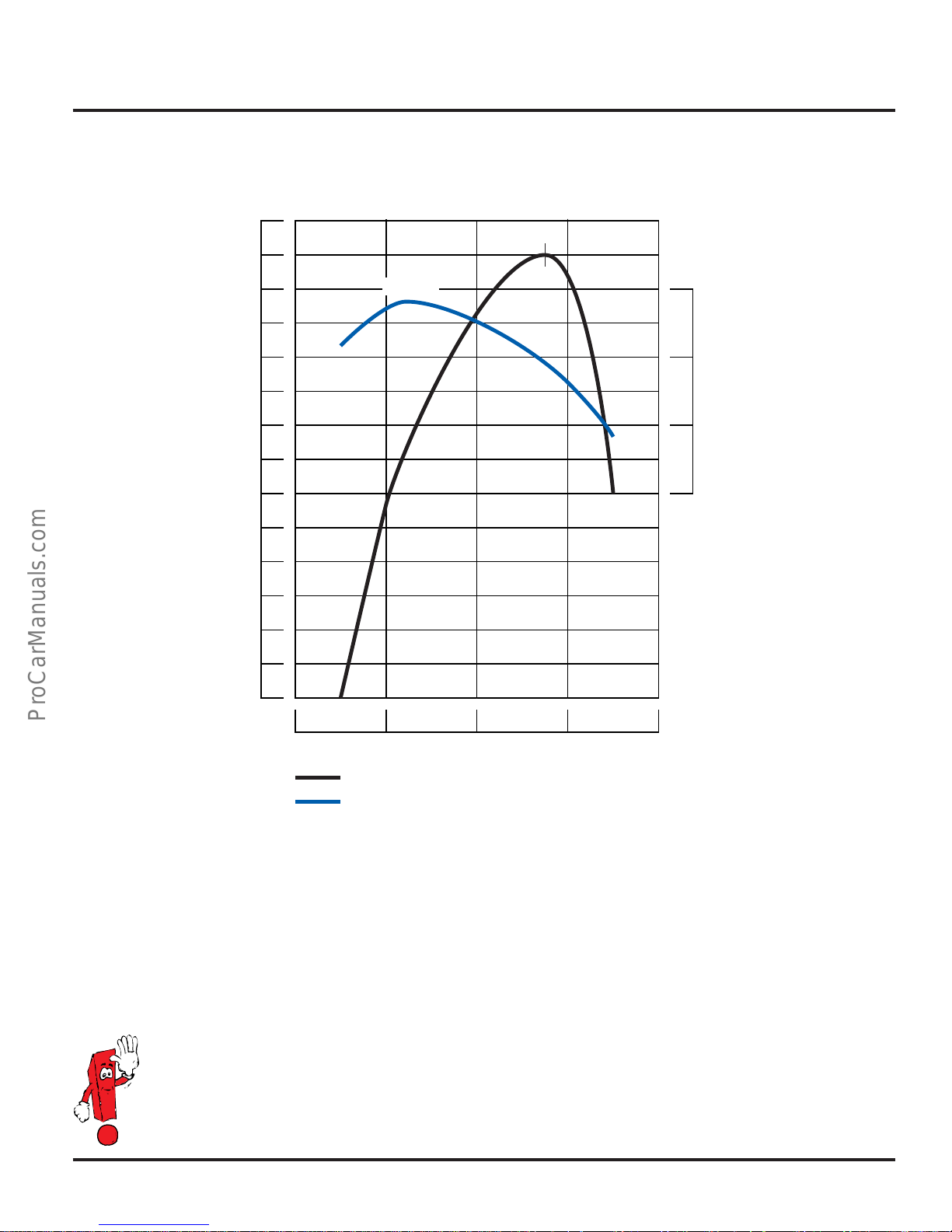

240

Introduction

Power Output / Torque

5.0 I - V10 - TDI - 308 hp (230 kW) @ 3750 RPM

533 lb ft (750 Nm) @ 2250 RPM

3,750

220

200

180

160

140

120

100

2,250

800

600

400

200

Torque

(Nm)

1000 2000 3000 4000 5000

Power Output

(kW)

Engine Mechanics Technical Features

• Cylinder block made of aluminum with an

end bracket made of cast-iron

• Joining of cylinder head and cylinder block

with tie-rod bolt connection

• Control and auxiliary drive unit are gear-driven

• Balancer shaft to reduce vibrations

A detailed description of the engine management system can be found in Self-Study Program No.

89P303 “Touareg Electronic Diesel Control EDC 16”, design and function.

= Power Output

= Torque

Engine (RPM)

Engine Management Technical Features

• EDC 16

• Two Engine Control Modules

• Pneumatic controlled exhaust gas

recirculation with electric motor operated

intake manifold flaps

• Oxygen sensors for controlling exhaust gas

recirculation

3

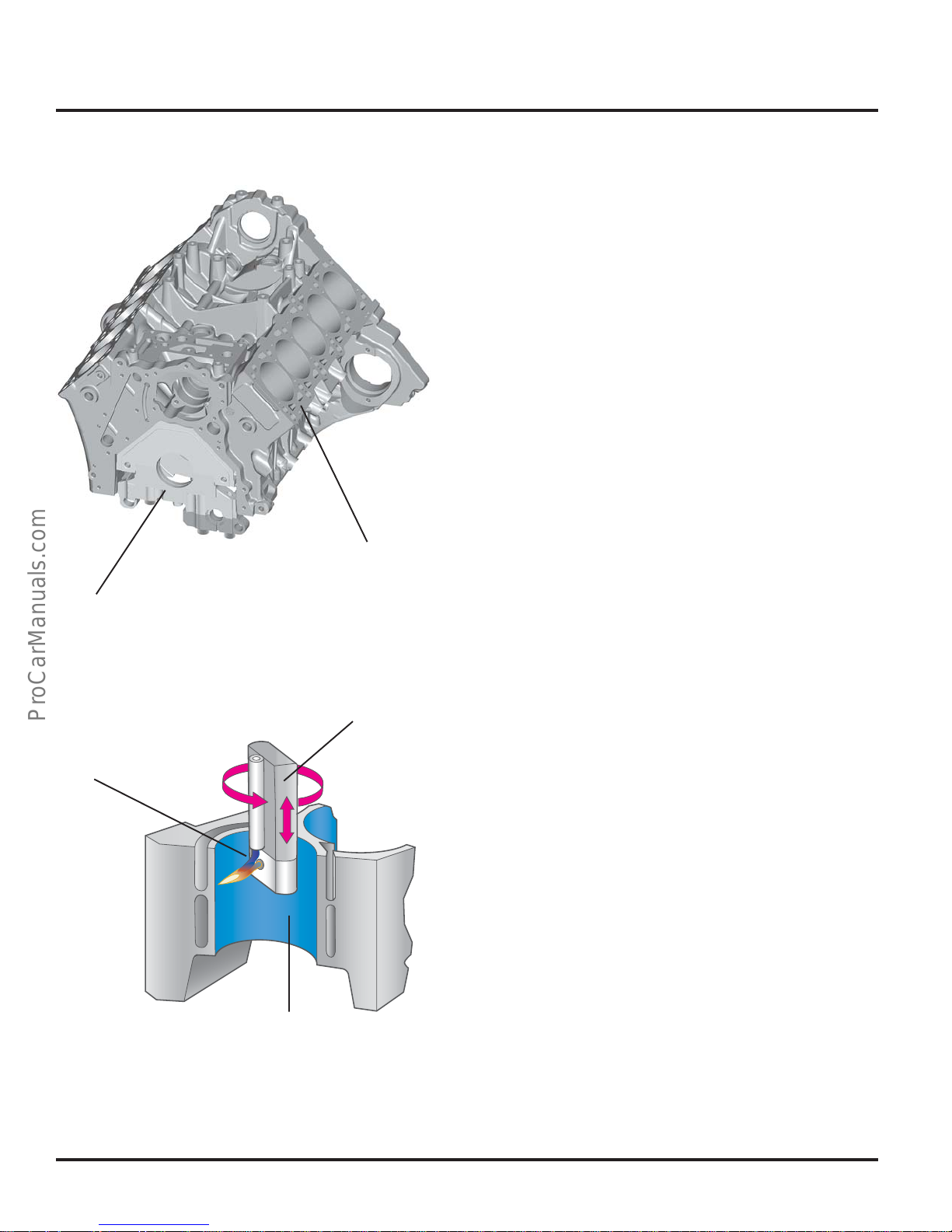

Engine Mechanics

Cylinder Block

The cylinder block assembly consists of three

components; an aluminum cylinder block, upper

and a lower end brackets. The aluminum

cylinder block provides a significant weight

reduction for the 90° cylinder banks. The high

tensile cast iron end brackets give the assembly

a rigid platform.

303_031

End Brackets

Plasma Jet

Cylinder Wall

Top Portion of

Cylinder Block

Plasma Burner

Plasma-Sprayed Cylinder Walls

For the first time in diesel engines, a plasmasprayed running film is applied to the cylinder

walls. As a result, the use of cylinder liners in

the aluminium cylinder block is no longer

necessary. This reduces the weight of the

engine and permits compact dimensions due to

a short distance between the cylinder bores.

303_069

4

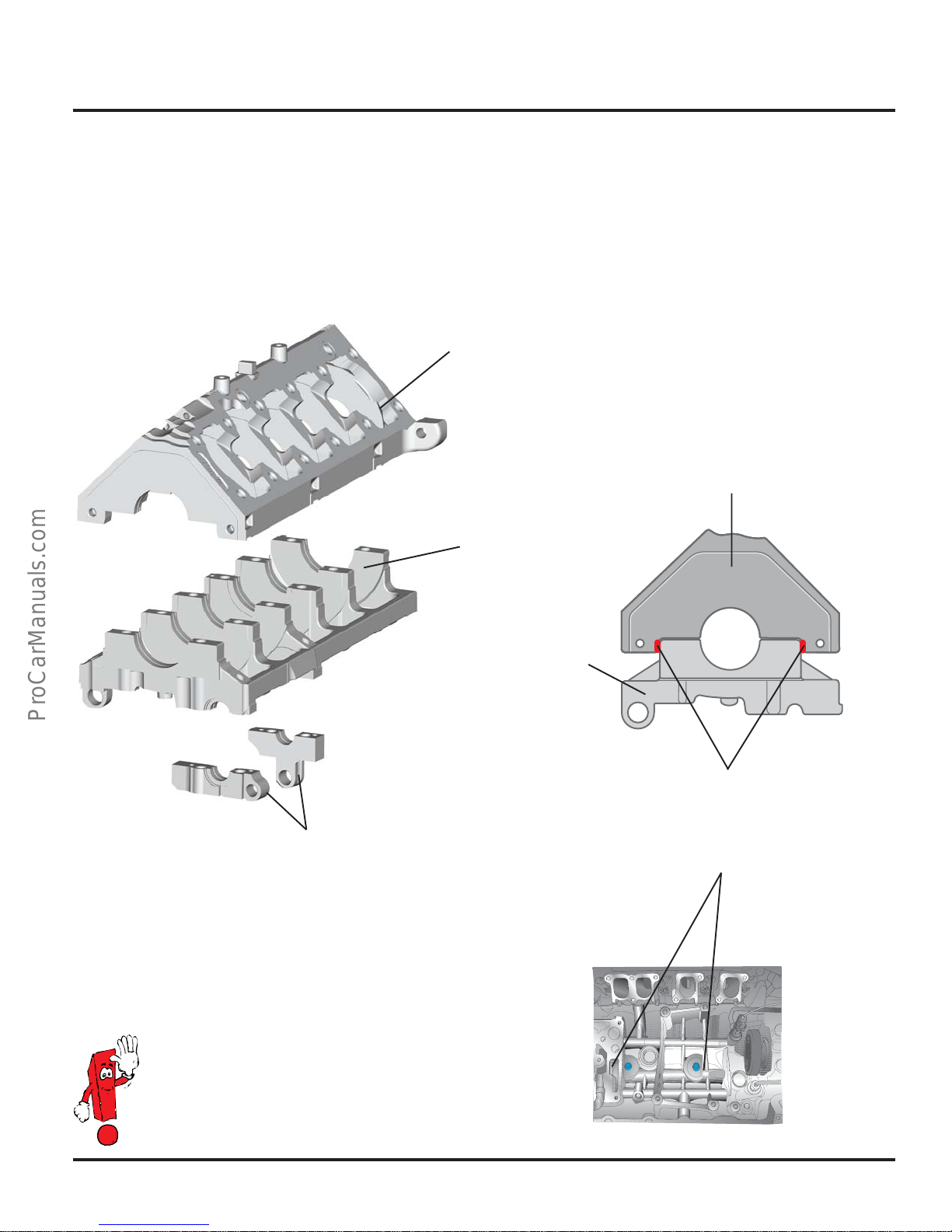

Engine Mechanics

End Bracket

The upper and lower end brackets are manufactured from high tensile cast iron. The upper and

lower portions of the end brackets use a press fit; and 4 bolts per main journal to provide the

crankshaft with a strong and rigid structure to contain the high combustion forces of the diesel

engine.

End Bracket,

Upper Portion

Crankshaft Bracket

Upper Portion

End Bracket,

Lower Portion

Balancer Shaft Thrust Bearing

The cylinder block will be damaged or

deformed by loosening the bolts

connecting the cylinder block with the

upper portion of the end bracket .

End Bracket ,

Lower Portion

303_077

303_087

Press Fit

Bolted Connection

303_022

5

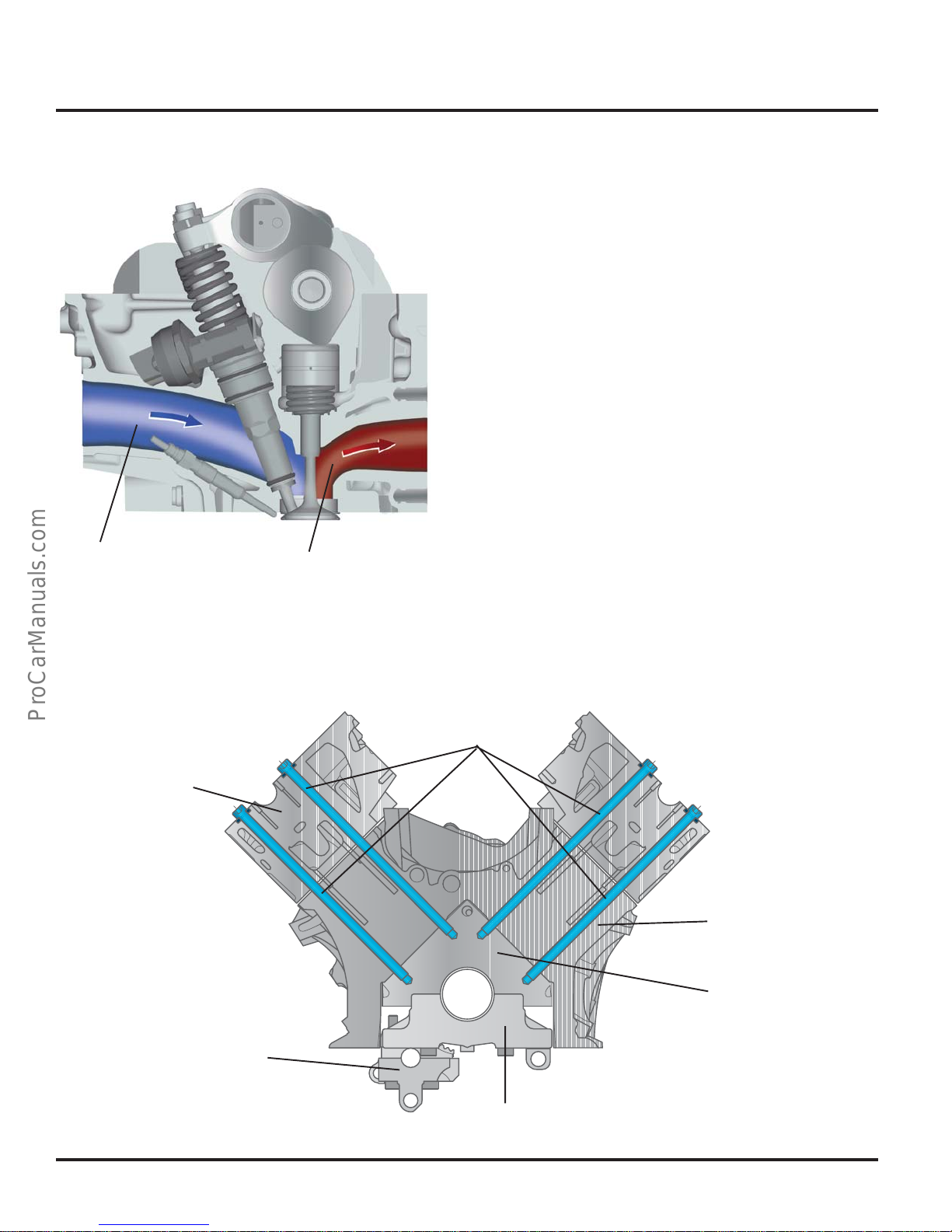

Engine Mechanics

Intake Port

Exhaust Port

Cylinder Head

The V10-TDI engine has two aluminium-alloy

cylinder heads. The intake and exhaust ports are

arranged according to the crossflow principle;

that is, the intake and exhaust ports are located

on opposite sides of the cylinder head. This

arrangement provides good gas exchange and

thus good cylinder filling. The intake ports are

located in the V space of the engine, while the

exhaust ports are on the engine exterior.

303_025

Connecting Bolt Principle

To prevent tension in the cylinder block, the

cylinder heads, cylinder block, and upper portion

of the end bracket are bolted to each other

using connecting bolts.

Cylinder Head

Connecting Bolts

Cylinder Block

End Bracket,

Upper Portion

Balancer Shaft Bearing

6

303_049

End Bracket,

Lower Portion

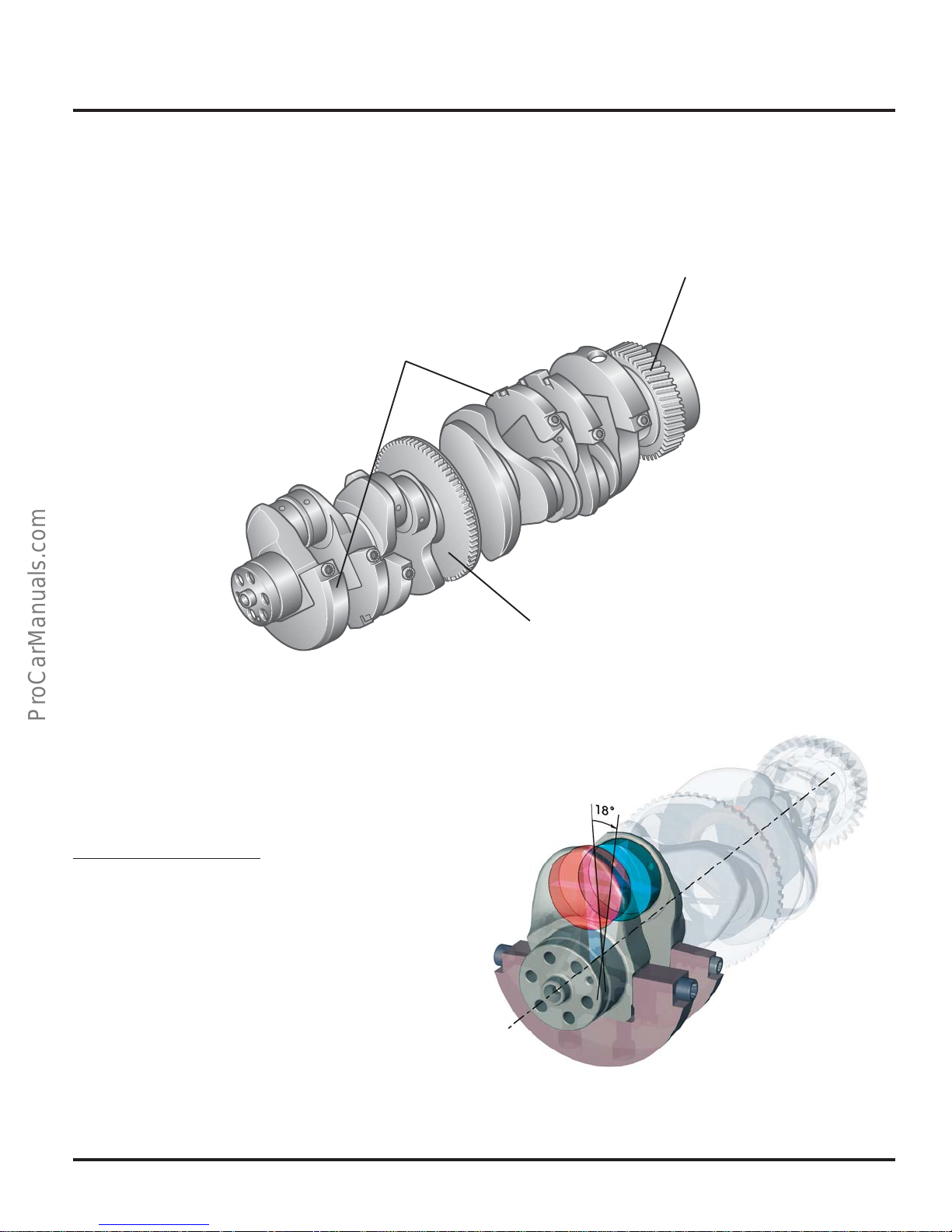

Crankshaft

The crankshaft of the V10-TDI engine is made of

tempered steel; forged from one piece. The

auxiliary drive gear, engine speed sensor wheel,

and bolted-on counterweights are located on

the crankshaft.

Bolted-on Counterweights

Engine Mechanics

Auxiliary Drive Gear

Crank Pin Offset

The cylinders of a 4-stroke engine fire within

two complete revolutions of the crankshaft

(720°). To attain uniform ignition, the ignition

angle for a 10 cylinder engine must be 72°.

720° crankshaft angle

10 cylinders

A 10 cylinder V-engine must therefore have a Vangle of 72°:

Since the V10-TDI engine has a V-angle of 90°,

the crank pin must be offset by 18° to attain

uniform ignition:

= 72° ignition angle

303_023

Engine Speed Sensor Wheel

90° V-angle – 72° ignition angle = 18° crank pin offset

303_107

7

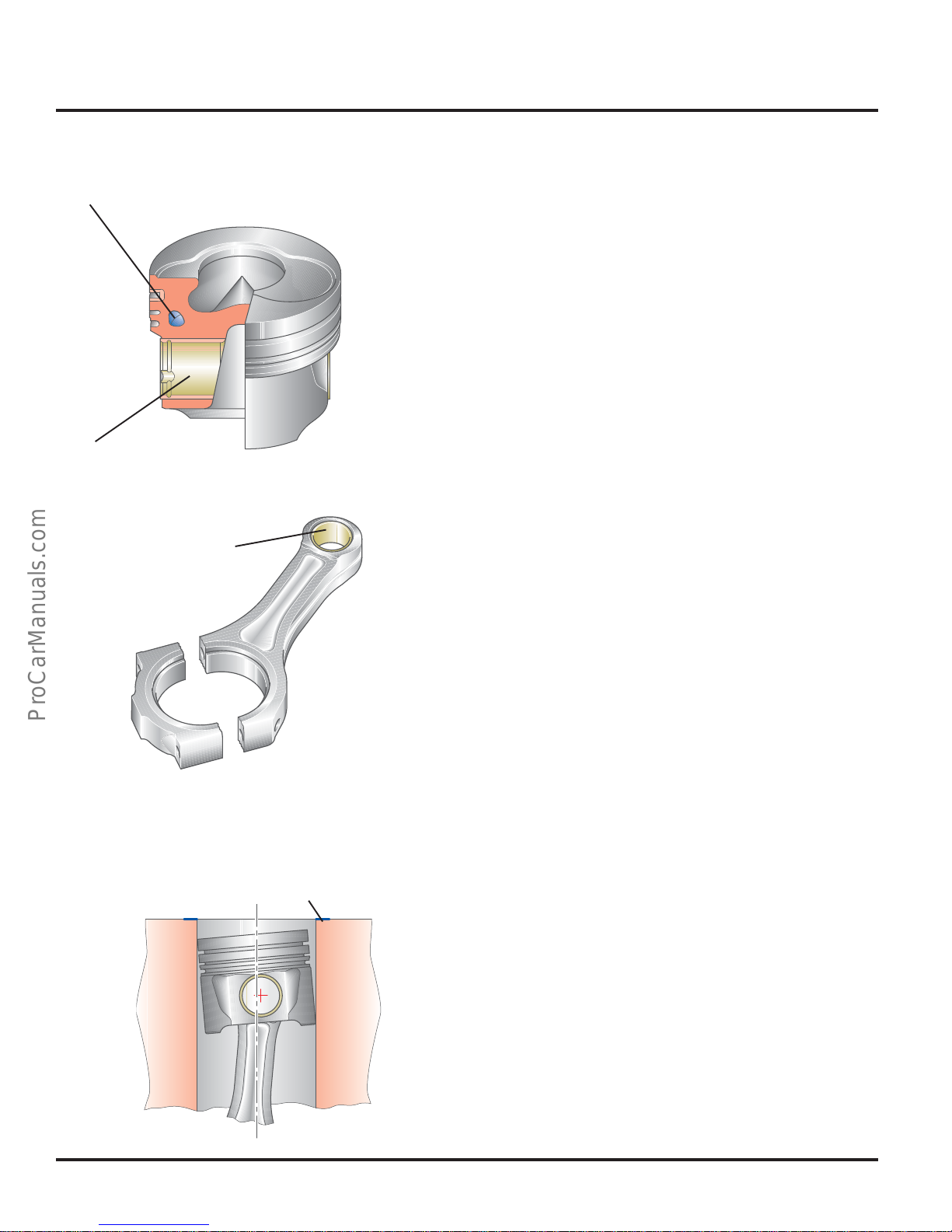

Engine Mechanics

Cooling Channel

Brass Bearing

303_097

Pistons and Connecting Rods

To keep the demands on the piston and

connecting rods low at high combustion

pressures, the piston pin bosses and the

connecting rod boss have a trapezoidal shape.

This distributes the combustion forces over a

broader area. The piston pin bosses are also

strengthened by brass bearings.

A cooling channel is infused into the piston to

cool the piston ring zone. Oil is injected into this

cooling channel from the oil-spraying jets as

soon as the piston is located at bottom dead

center.

Connecting Rod

Brass Bearing

303_098

Top Dead Center

The connecting rod is forged from a high

density sintered metal. To separate the cap

from the rod a procedure called “Cracking” is

required.

Piston Pin Axis Offset

The piston pin axis is offset to prevent noise

from the tilting of the piston at top dead center.

Each time the connecting rod is in a sloping

position, lateral piston forces occur which

alternately press the piston against the cylinder

walls.

The lateral piston force changes direction at top

dead center. The piston is tilted to the opposite

cylinder wall there, thus resulting in noise.

To prevent this, the piston pin axis is offset.

8

Due to the offset arrangement of the piston pin

axis, the piston changes sides before it reaches

top dead center and then supports itself on the

opposite cylinder wall.

303_099

Engine Mechanics

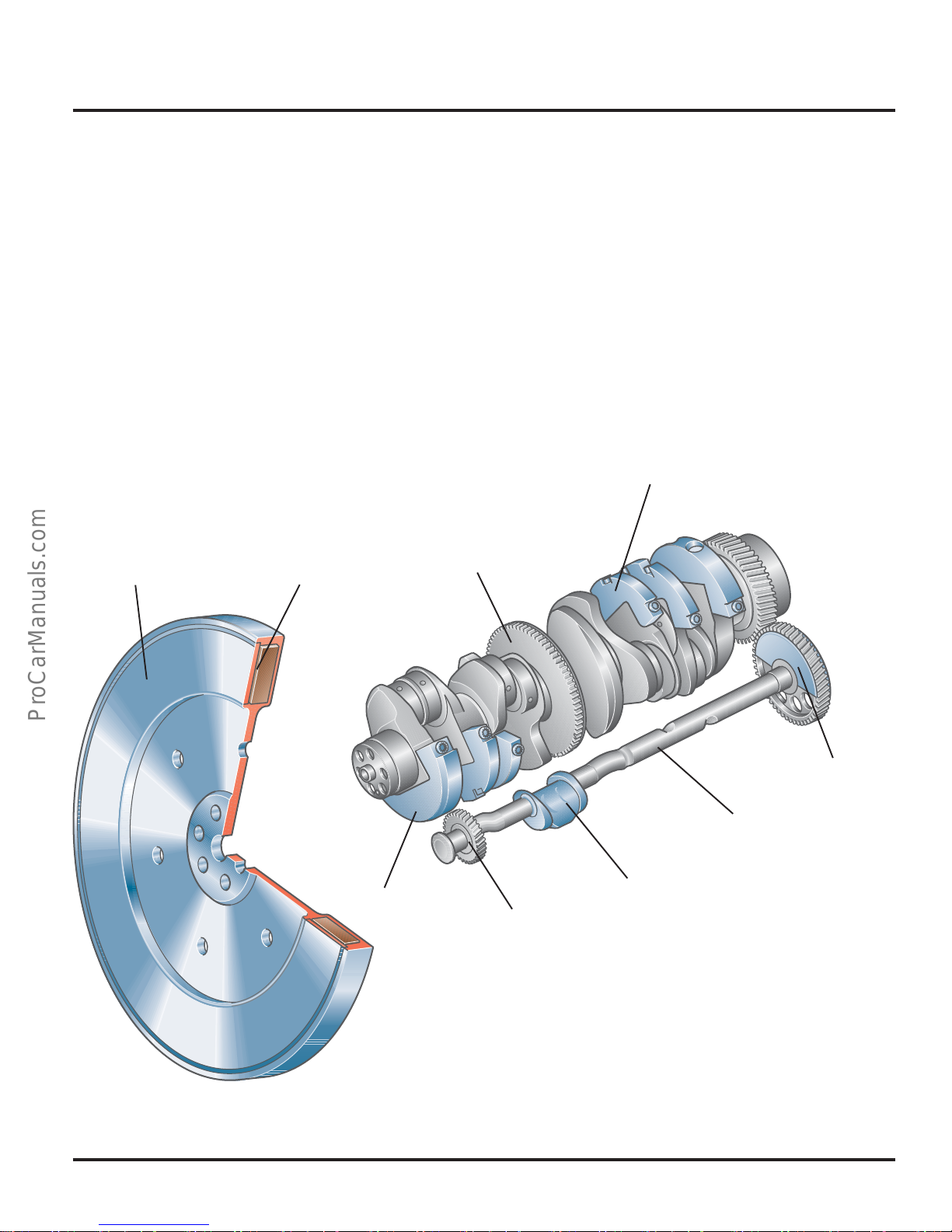

Balancing

To attain low vibration running of the engine, the

moments of inertia must be balanced.

For this, 6 counterweights are attached to the

crankshaft. In addition, a counter rotating

balancing shaft and a weight located in the drive

wheel of the balancing shaft eliminate the

moments of inertia. The balancing shaft is driven

by the crankshaft and serves as a driveshaft for

the oil pump.

The counterweights are made of a tungsten

alloy. As tungsten has a high density, the

weights be small in size, which saves space.

Engine Speed

Vibration Damper

Silicone Oil

Sensor Wheel

Vibration Damper

The vibration damper reduces the rotational

vibrations of the crankshaft. It is filled with a

silicone oil.

The rotational vibrations of the crankshaft are

eliminated by the shear force of the silicone oil.

Counterweight

303_008

Crankshaft

Oil Pump

Drive Gear

Counterweight

Counterweight

Balancing Shaft

303_024

9

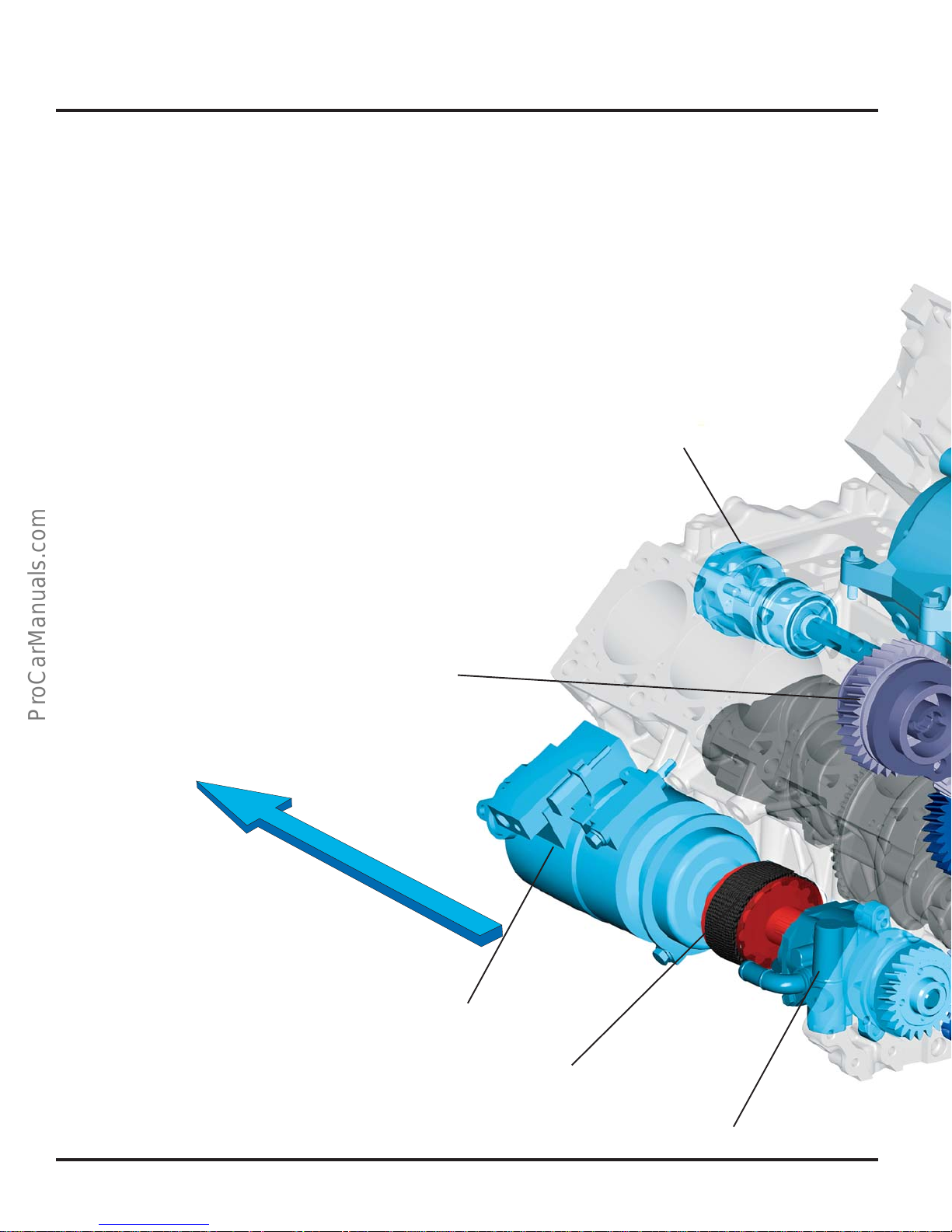

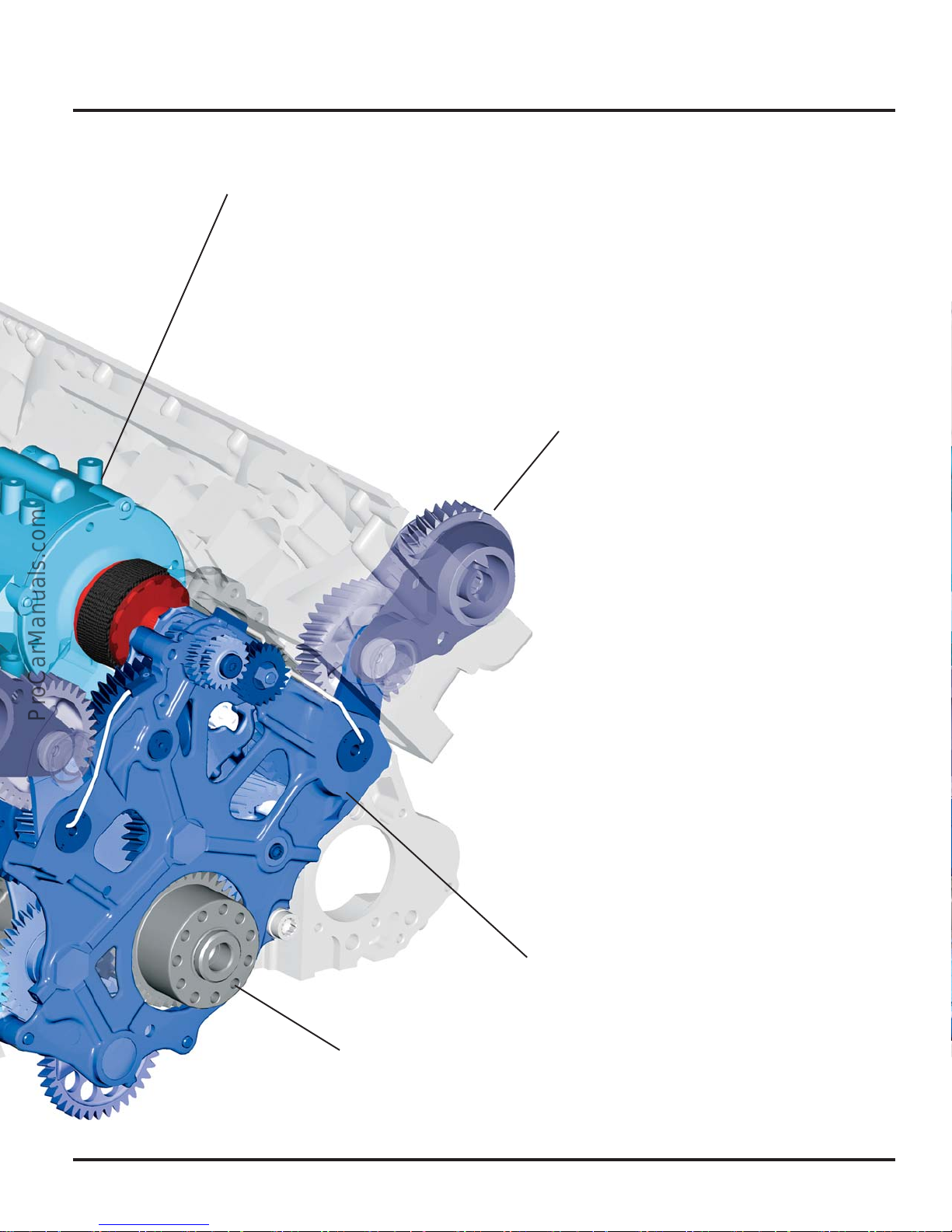

Engine Mechanics

Auxiliary Drive and Components

The auxiliary drive is located on the flywheel

side.

The camshafts and the auxiliary components are

driven by the crankshaft by helical gears.

The advantage of a gear drive over a toothed

belt is that larger forces can be transferred while

the size of the gears remains the same as the

sprockets used for toothed belt. In addition, a

toothed belt will stretch with age, changing cam

timing.

The auxiliary drive is also maintenance-free.

Coolant Pump

Camshaft Drive

Direction of Tr a ve l

Air Conditioning (A/C)

Compressor

Gates Drive

10

Power Steering Pump

Alternator

Engine Mechanics

Camshaft Drive

Drive Module

Crankshaft

303_016

11

Loading...

Loading...