Viking Pump TSM143 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

CONTENTS

Introduction 1

Special Information 2

Maintenance 2

Packed Pumps 4

Mechanical Seal Pumps 8

Optional PTFE Seal 12

Thrust Bearing Adjustment 13

Installation of Carbon Graphite Bushings 13

Pressure Relief Valve Instructions 14

Warranty 15

HEAVY DUTY PUMPS

SERIES 335 AND 4335

SIZES N, R, AND P

SECTION TSM 143

PAGE 1 OF 15

ISSUE E

FIGURE 1

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and cannot be used for ordering parts. Obtain

a parts list from the factory or a Viking® representative.

Always give the complete name of the part, part number

and material with the model number and serial number of

the pump when ordering repair parts. The unmounted pump

or pump unit model number and serial number are on the

nameplate.

In the Viking model number system, basic size letters are

combined with the series number (335 and 4335) indicating

both unmounted or mounted pump unit.

MODEL NUMBER CHART

UNMOUNTED PUMP

PACKED

N335 N4335

R335 R4335

P335 P4335

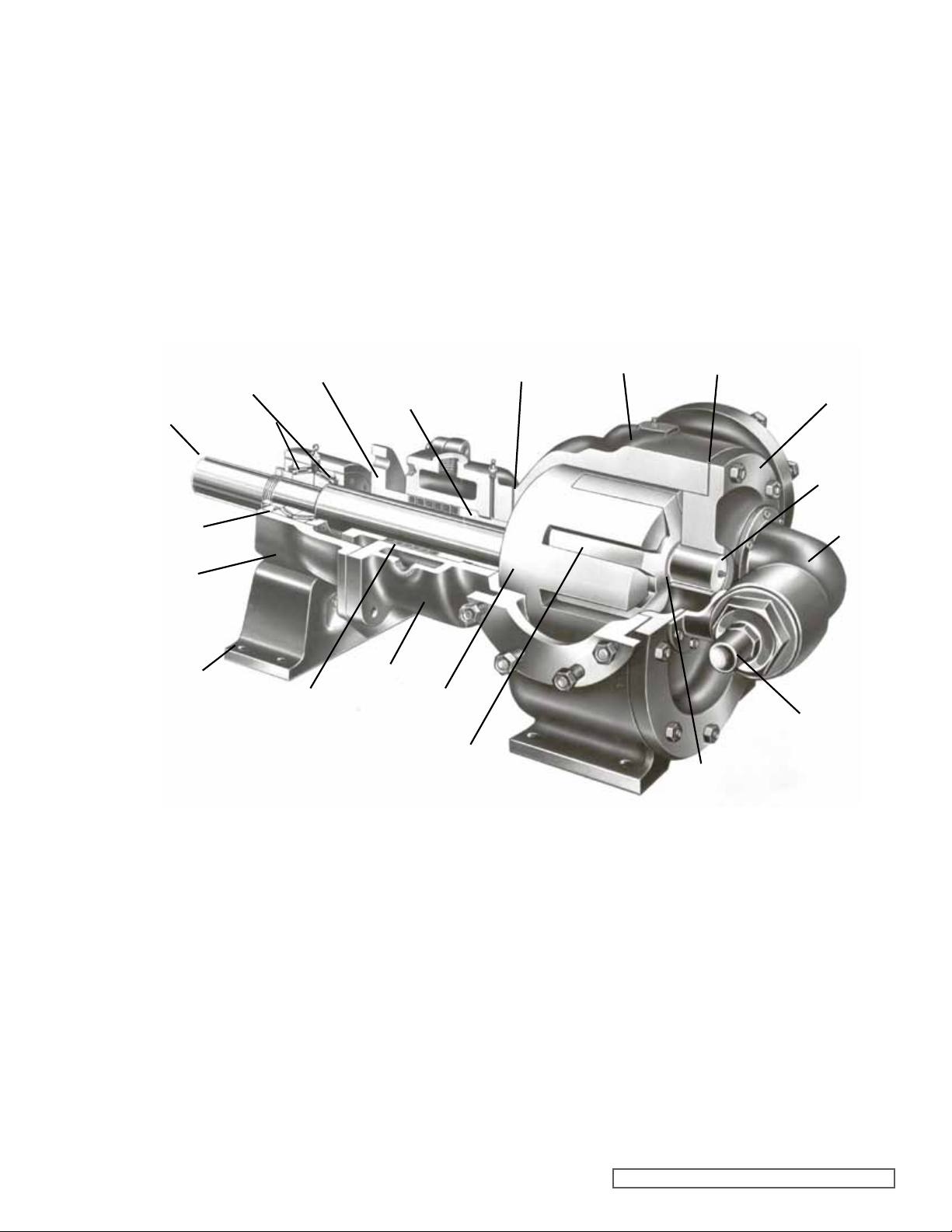

This manual deals only with Series 335 and 4335 HeavyDuty Pumps. Refer to Figures 1 through 20 for general

configuration and nomenclature used in this manual. Pump

specifications and recommendations are listed in Catalog

Section 143, for series 335 and 4335 Heavy-Duty Pumps.

MECH.

SEAL

Units are designated by the unmounted pump model numbers

followed by a letter indicating drive

style.

P =Commerical Speed Reducers

UNITS

DANGER !

Before opening any Viking pump liquid chamber (pumping chamber, reservoir, relief valve

adjusting cap fitting etc.) be sure:

1. That any pressure in chamber has been

completely vented through the suction

or discharge lines or other appropriate

openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or made

non- operational so that it cannot be started

while work is being done on the pump.

3. That you know what liquid the pump

has been handling and the precautions

necessary to safely handle the liquid.

Obtain a material safety data sheet (msds)

for the liquid to be sure these precautions

are understood.

Failure to follow the above listed precautionary measures may result in serious injury or

death.

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

SPECIAL INFORMATION

ROTATION: Viking pumps operate equally well in a clockwise

or counterclockwise rotation. Shaft rotation determines which

port is suction and which is discharge. The suction port

location is where pumping elements (gear teeth) come out

of mesh.

CIRCULATION LINES: are standard equipment (N & R size

only) and must be properly connected. Packed pumps have

a line connected from the packing chamber to the discharge

port. Mechanical seal pumps have a line connected from

the seal chamber to the suction port. If the pump rotation is

reversed be sure the circulation lines are connected to the

suction or discharge port as noted above to avoid excessive

leakage or damage to pump. If the pump is handling heated

product be sure the circulation line is insulated to assure

continued flow.

The jacketed head (R & P only, optional on N size) and

rotor bearing sleeve provide large chambers at both ends

of the pumping chamber for temperature control of product

in the pump. These features do not alter basic steps in the

disassembly and assembly of your pump.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive placement pumps and must

be provided with some sort of pressure protection. This

may be a relief valve mounted directly on the pump, an

inline pressure relief valve, a torque limiting device or a

rupture disk.

2. A non-jacketed relief valve is standard on these pumps.

Options include plain and jacketed relief valves. N size

pumps with a jacketed head with a relief valve is not

available . R size pumps are standard with a jacketed

head but also have both plain and jacketed relief valve

available as options. P size pumps are standard with a

jacketed head and non-jacketed relief valve.

3. If the pump rotation is to be reversed during operation,

pressure protection must be provided on both sides of

pump.

4. The relief valve adjusting screw cap must always point

towards suction side of pump. If pump rotation is

reversed, remove the pressure relief valve and turn end

for end. Refer to Figure 2.

5. Pressure relief valves cannot be used to control the pump

flow or regulate the discharge pressure.

For additional information on pressure relief valves, refer to

Technical Service Manual TSM000 and Engineering Service

Bulletin ESB-31.

INLET

OR

SUCTION

OUTLET

OR

DISCHARGE

SPECIAL MECHANICAL SEALS: can be installed in a

modified stuffing box.

Extra care must be taken in the repair of pumps with

mechanical seals. Read and follow all special information

supplied with the pump.

MAINTENANCE

The Series 335 and 4335 pumps are designed for long

trouble free life under a wide variety of application conditions

with a minimum of maintenance. The points listed below will

help provide long service life.

LUBRICATION: External lubrication must be applied slowly

with a handgun to all lubrication fittings every 500 hours of

operation with multi-purpose grease, NLGI # 2. Do not overgrease. Applications involving very high or low temperatures

will require other types of lubrication. Refer to Engineering

Service Bulleting ESB-515. Consult factory with specific

lubrication questions.

PACKING ADJUSTMENT: New packed pumps require an

initial packing adjustment to control leakage as the packing

“runs in”. Make initial adjustments carefully and do not

over-tighten the packing gland. After the initial adjustment,

inspection will reveal the need for packing gland adjustment

or packing replacement. Refer to instructions under

DISASSEMBLY, page 4, and ASSEMBLY, page 6, regarding

repacking the pump.

CLEANING PUMP: Keep the pump as clean as possible.

This will facilitate inspection; adjustment and repair work and

help prevent overlooking a dirt covered grease fitting.

STORAGE: If the pump is to be stored, or not used for six

months or more, the pump must be drained and a light coat

of non-detergent SAE 30 weight oil must be applied to all

internal pump parts. Lubricate fittings and apply grease to

the pump shaft extension. Viking suggests rotating the pump

shaft by hand one complete revolution every 30 days to

circulate the oil.

SUGGESTED REPAIR TOOLS: The following tools must

be available to properly repair Series 335 and 4335 pumps.

These tools are in addition to standard mechanics’ tools such

as open end wrenches, pliers, screwdrivers etc. Most of the

listed items can be obtained from an industrial supply house.

1. Soft Headed Hammer

2. Allen Wrenches (for some mechanical seals and set

collars)

3. Packing hooks, flexible (packed pumps)

Large for 0.375 inch and up cross section packing

4. Bearing locknut spanner wrench

(Source: #471 J.H. Williams & Co. or equal)

5. Spanner wrench (Supplied with pump)

Viking Part Number 3-810-009-631

RELIEF VALVE

ADJUSTING

SCREW CAP

FIGURE 2

SECTION TSM 143 ISSUE E PAGE 2 OF 15

6. Brass Bar

7. Arbor Press

SHAFT

ROLLER

BEARINGS

PACKING

GLAND

ROTOR BEARING

SLEEVE BUSHING

ROTOR BEARING

SLEEVE GASKET

CASING

HEAD GASKET

HEAD

IDLER PIN

END CAP

THRUST

BEARING

HOUSING

BEARING

HOUSING

STAND

PACKING

ROTOR

BEARING

SLEEVE

ROTOR

IDLER

FIGURE 3

CUTAWAY OF PACKED PUMP MODEL N335

RELIEF

VALV E

RELIEF VALVE

ADJUSTING

SCREW CAP

IDLER

BUSHING

SECTION TSM 143 ISSUE E PAGE 3 OF 15

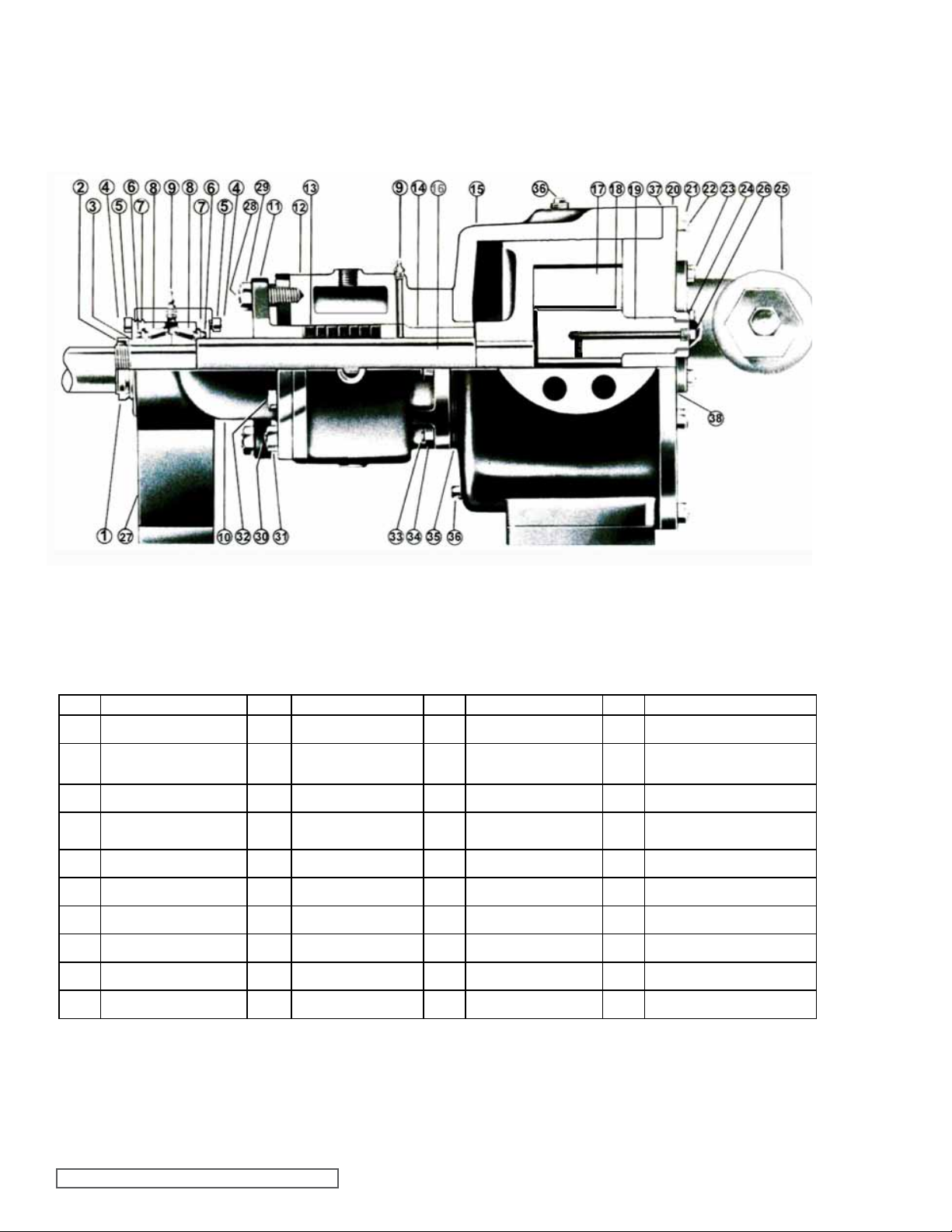

PACKED PUMPS

Model N, R, and P335

FIGURE 4 DETAILS FOR SECTIONAL VIEW - MODELS N, R AND P335

ITEM NAME OF PART ITEM NAME OF PART ITEM NAME OF PART ITEM NAME OF PART

1 Locknut 11 Packing Gland 21 Nut For Head 31 Bearing Housing Nut

2 Lockwasher 12

3 Bearing Spacer Collar 13 Packing 23 Capscrew For Valve 33

Capscrew for Adjusting

4

Locknut

5 End Cap Lock 15 Casing 25 Internal Relief Valve 35 Rotor Bearing Sleeve Gasket

6 Lip Seal 16 Rotor and Shaft 26 Pipe Plug 36 Pipe Plug

7 End Cap 17 Idler and Bushing 27 Bearing Housing Stand 37 Head Gasket

8 Roller Bearing 18 Idler Bushing 28 Packing Gland Stud 38 Relief Valve Gasket

9 Grease Fitting 19 Idler Pin 29 Packing Gland Nut * Suck Back line Not Illus.

10 Thrust Bearing Housing 20 Head and Idler Pin 30 Bearing Housing Stud

Rotor Bearing Sleeve

& Bushing

Bushing, Rotor

14

Bearing Sleeve

22 Stud For Head 32 Bearing Housing Capscrew

Stud For Rotor Bearing

Sleeve

24 Idler Pin Nut (Not N) 34 Nut For Rotor Bearing Sleeve

SECTION TSM 143 ISSUE E PAGE 4 OF 15

DANGER !

Before opening any Viking pump liquid chamber (pumping chamber, reservoir, relief valve

adjusting cap fitting etc.) Be sure:

1. That any pressure in the chamber has been

completely vented through the suction

or discharge lines or other appropriate

openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or made

non- operational so that it cannot be started

while work is being done on the pump.

3. That you know what liquid the pump

has been handling and the precautions

necessary to safely handle the liquid.

Obtain a material safety data sheet (MSDS)

for the liquid to be sure these precautions

are understood.

Failure to follow above listed precautionary measures may result in serious injury or

death.

DISASSEMBLY

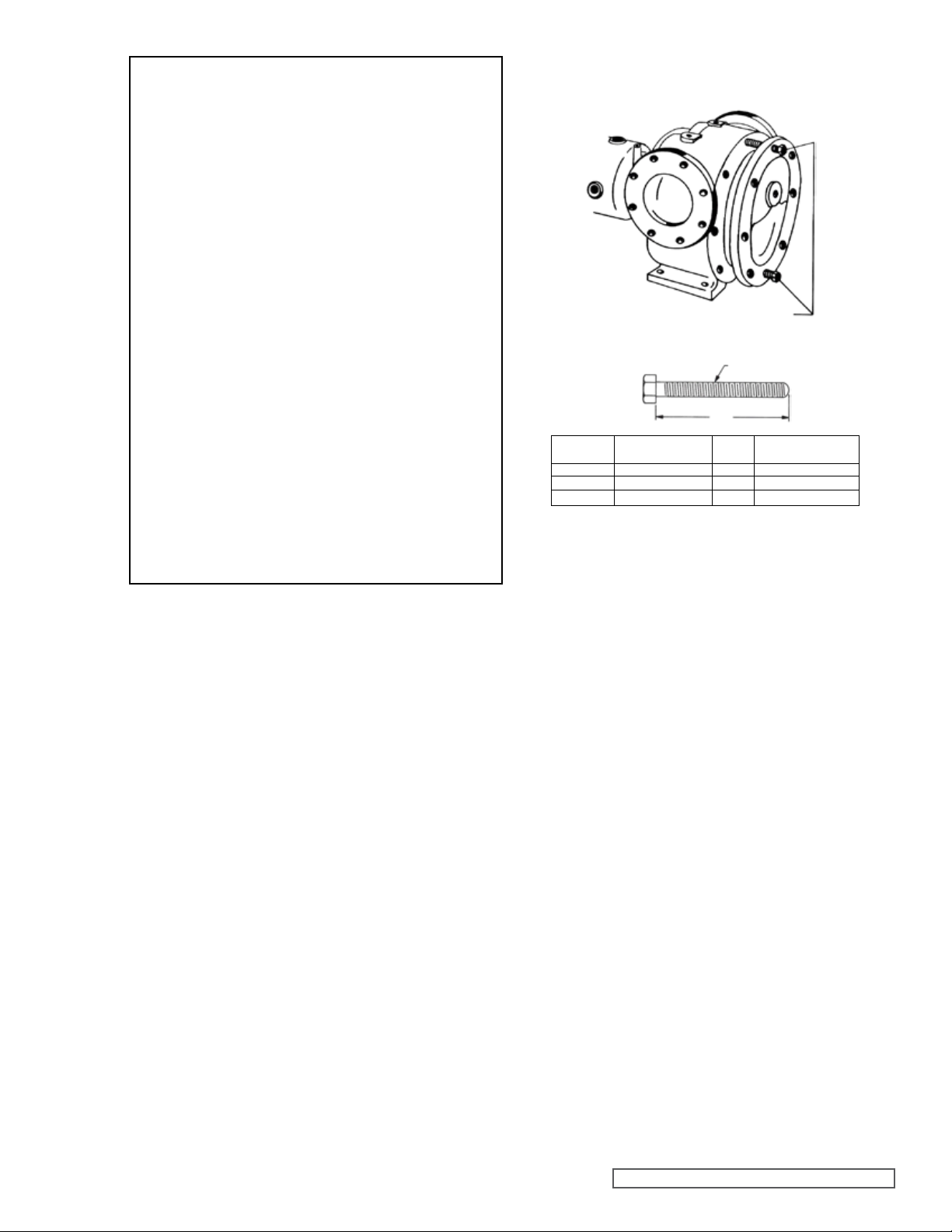

1. Mark the head and casing before disassembly to ensure

proper reassembly. The idler pin, which is offset in pump

head, must be positioned towards and equal distance

between the port connections to allow for proper flow of

liquid through the pump.(Refer to figure 5)

It is not necessary to remove the relief valve to take the

head off the pump; however, removing the relief valve

will lessen the total weight of the part. Do not use chain

or cable around the relief value body to support the

head during removal. For PRESSURE RELIEF VALVE

INSTRUCTIONS, refer to page 14.

Remove all nuts from the head. Jackscrews should be

used to back the head away from the casing as shown

in Figure 5. For proper size and length of jackscrews for

pump size refer to the table in Figure 6. The use of a hoist

to support head will facilitate its removal.

Back the head away from casing. Do not allow the idler

to fall from the idler pin. To prevent this, tilt the top of the

head back when removing. Remove the head from pump.

If a hoist is not available, cribbing or blocking can be used

to support head. This will eliminate having to lift the head

into position when reassembling the pump.

2. Remove the head gasket, idler and bushing assembly.

3. Remove the pipe plug from the drain hole in the casing,

this breaks the vacuum behind rotor.

JACKSCREWS

FIGURE 5

THREAD SIZE

A

PUMP

SIZE

N 2 4.00 0.50” - 13 NC

R 2 4.50 0.63” - 11 NC

P 3 5.00 0.50” - 13 NC

4. Remove the packing gland nuts and slide the gland out

of the rotor bearing sleeve.

5. Insert a length of hard wood or brass bar through the

port opening between the rotor teeth to keep the shaft

from turning.

6. Bend the tang on the lock washer up, and with a spanner

wrench remove the locknut and lockwasher from the

shaft. Refer to Figure 7.

7. Remove the length of hardwood or brass bar from the

port opening.

8. Cushion the end of the shaft with a hardwood block or

piece of brass and drive the rotor out of casing, being

careful to avoid damaging the rotor bearing sleeve

bushing. Support the weight of rotor with a hoist. A cable

sling can be used around the shaft, or around rotor

teeth, to carry the weight of the part.

9. Remove the end cap lockscrews, disengage the end cap

locks and with a spanner wrench remove the end caps.

Remove the roller bearings.

10. Remove the nuts and capscrews and take off the thrust

bearing housing. Remove the packing from the rotor

bearing sleeve. NOTE: Model P335 has a lantern ring.

11. Check the rotor bearing sleeve bushing while the rotor

bearing sleeve is mounted on the casing. If worn, the

bushing must be replaced.

Disconnect the circulation line and remove the rotor

bearing sleeve from casing. A press must be used to

remove the old bushing. If the bushing has a shoulder

on the stuffing box end, it must be pressed out through

NO. SCREWS

USED

FIGURE 6

MINIMUM JACKSCREW LENGTH

SECTION TSM 143 ISSUE E PAGE 5 OF 15

A

THREAD SIZE

(INCH)

Loading...

Loading...