Page 1

VEGASON 71 - D

TIB • Technical Information • Operating Instructions

Pulse-echo

measuring system

1

2

1 2 3

5.000

4

VEGASON

m

Single channel flow

measurement

Approvals for hazardous

areas, certificate acc. to

CENELEC

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone 0 78 36 / 50 - 0

Fax 0 78 36 / 50 201

Page 2

Contents

1 Introduction

1.1 Contents of the instruction manual .....................................................................................................................4

1.2 Safety information ...............................................................................................................................................4

1.3 Product description .............................................................................................................................................4

1.4 Approvals ............................................................................................................................................................4

2 Technical Information

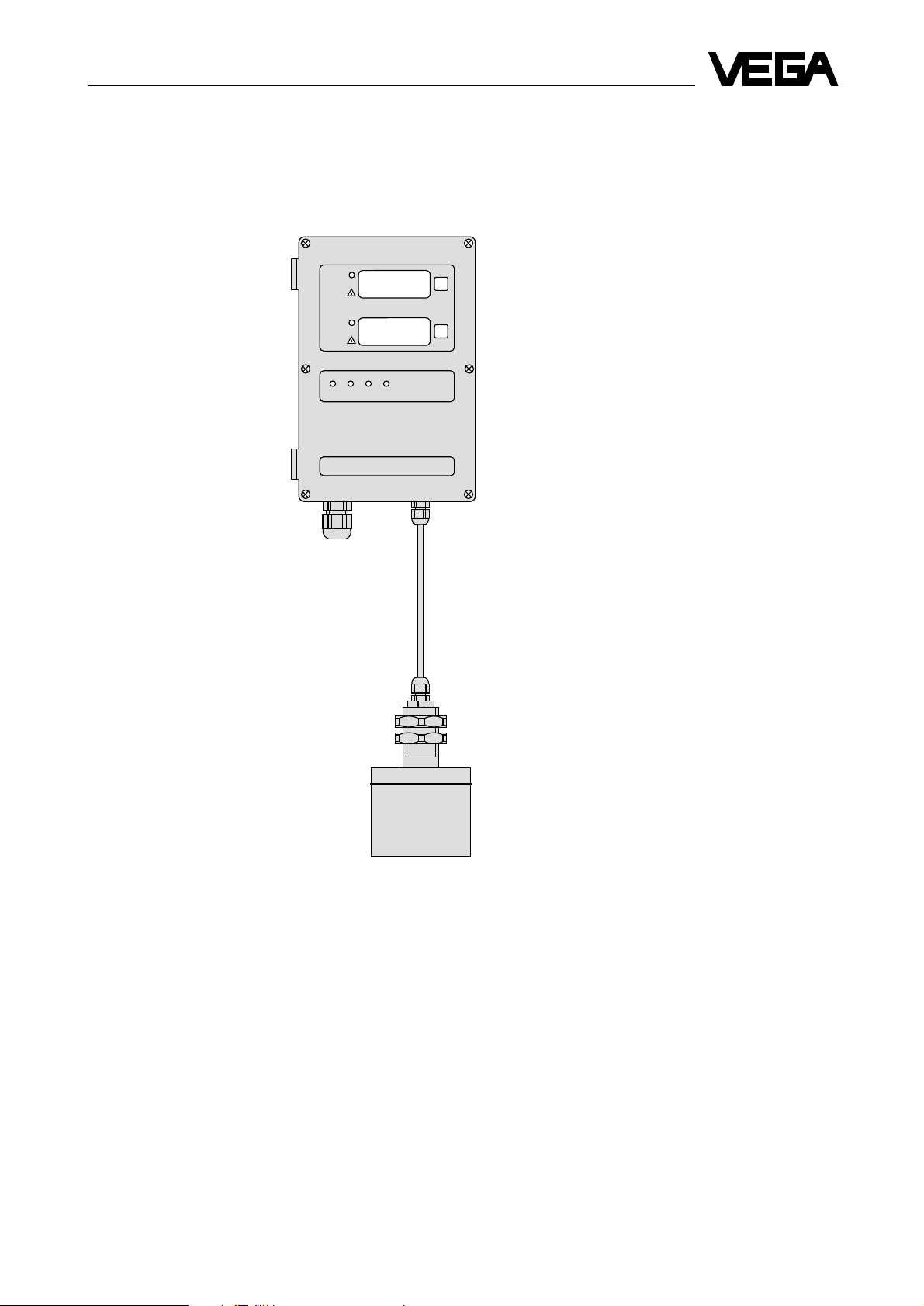

2.1 Configuration of a measuring system .................................................................................................................5

2.2 Technical data, VEGASON 71 - D.......................................................................................................................6

2.3 Technical data, transducer ..................................................................................................................................7

2.3 Dimensional drawings ......................................................................................................................................... 8

2.4 Measuring range .................................................................................................................................................8

2.5 General installation instructions ..........................................................................................................................9

2.6 Installation fault .................................................................................................................................................10

2.7 Electrical connection ......................................................................................................................................... 11

Contents

3 Operating surface

3.1 Indicating and operating elements ....................................................................................................................12

3.2 Operation .......................................................................................................................................................... 13

4 Set-up

4.1 Flow chart for set-up ......................................................................................................................................... 14

4.2 Mode range, general parameter adjustment, mode 0 - 00 … 0 - 99 ................................................................. 15

5 Adjustment

5.1 Empty / full adjustment in metres without flow change ..................................................................................... 18

5.2 Demonstration and programming example .......................................................................................................18

6 Flow measurement

6.1 Linearization......................................................................................................................................................19

6.1.1 Meter flume / weir .................................................................................................................................. 19

6.1.2 Enquiry of linearization curves 4 … 6 ....................................................................................................20

6.2 Linearity protocol...............................................................................................................................................22

2

VEGASON 71 - D

Page 3

Contents

7 Output results

7.1 Display ..............................................................................................................................................................23

7.1.1 Allocation of a multiplication factor.........................................................................................................23

7.1.2 Measuring unit .......................................................................................................................................23

7.1.3 Decimal point .........................................................................................................................................23

7.1.4 Integration time ......................................................................................................................................24

7.2 Adjustment max. flow ........................................................................................................................................24

7.3 Impulse value for flow relay ...............................................................................................................................24

7.4 Impulse value for sampling relay.......................................................................................................................24

7.5 Definition of the min. flow volume limit ..............................................................................................................25

7.6 Calculation examples of the max. flow ..............................................................................................................25

7.6.1 Khafagi-Venturi flume.............................................................................................................................26

7.6.2 Trapezoidal weir (Cipolletti) ....................................................................................................................27

7.6.3 Rectangular weir without throat .............................................................................................................28

7.6.4 Rectangular weir with throat ..................................................................................................................29

7.6.5 V-Notch .................................................................................................................................................. 30

7.6.6 Palmer-Bowlus-flume .............................................................................................................................31

7.7 Level module.....................................................................................................................................................32

7.7.1 Coordinations and their relations ...........................................................................................................32

7.7.2 Switching commands .............................................................................................................................32

7.8 Current module .................................................................................................................................................33

8 Supplementary programmings

8.1 Failure processing............................................................................................................................................. 33

8.2 Simulation .........................................................................................................................................................34

8.3 Basic adjustment, mode range general parameter adjustment.........................................................................34

8.4 Keyword ............................................................................................................................................................ 34

9 Optimization

9.1 Enquiry of the optimization................................................................................................................................35

9.2 Mode range optimization, mode 1 - 01 … 1 - 27...............................................................................................36

9.3 Definition of the operating range .......................................................................................................................37

9.4 Multiple echo reduction .....................................................................................................................................37

9.5 Adjustment of the max. gain .............................................................................................................................37

9.6 Fault signal........................................................................................................................................................ 38

9.8 Protocol of the optimization...............................................................................................................................38

9.7 Basic adjustment, mode range optimization .....................................................................................................38

10 Supplement

10.1 Error codes........................................................................................................................................................39

10.2 Error schedule...................................................................................................................................................39

VEGASON 71 - D

3

Page 4

1 Introduction

1 Introduction

1.1 Contents of the instruction manual

The Technical Information / Operating Instructions is

called TIB. It contains all necessary information for correct

- installation

- connection

- set-up

- linearization

- optimization

of the pulse-echo-measuring system VEGASON 71 - D.

VEGA regularly revises the contents of TIBs as technical

improvements are made to the instruments.

1.2 Safety information

The described module must only be installed and operated

as described in this TIB. Please note that other action can

cause damage for which VEGA does not accept

responsiblity.

1.3 Product description

The pulse-echo measuring system VEGASON 71 - D is

used for flow and level measurement.

A measuring system consists of

- a central electronics and

- a sensor.

The sensor is provided with a temperature sensor for

compensation of the temperature influence to the sound

running period. Measuring data and temperature

information are transmitted along the same coaxial cable.

All adjustment procedures, optimizations etc. can be

directly programmed via a keyboard on the central

electronics.

1.4 Approvals

If a measuring system is mounted acc. to the following

approval, the respective legal document has to be used

and the regulations have to be strictly observed.

Approvals for hazardous areas, certificate acc. to

CENELEC.

Consisting of:

- central electronics VEGASON 71 - D

- sensor SW 71 R Ex

defined in the conformity certificate PTB-no.

Ex-94.C.4066.

The running periods of periodically emitted sound impulse

packets which are reflected by the flow product to be

measured are evaluated.

The running period of sound is a measure of the distance

between sensor and liquid surface.

The control electronics determines this distance and

converts it into flow information.

The measuring results are indicated on the integral LCdisplay and acc. to the version, provided as relay and

current outputs.

The conformity certificate is included with the product on

delivery.

4

VEGASON 71 - D

Page 5

2 Technical Information

2 Technical Information

2.1 Configuration of a measuring system

Input Central electronics Outputs

Measuring data from the sensor 2 LC-display (multi-functional indication)

5.000

1

2

1 2 3

4

VEGASON

Flow module

- 1 relay output for flow

- 1 relay output for sampling

Level module

- 2 relay outputs

Current module

- 1 output flow proportional module

- 1 output level proportional module

Sensor

Central electronics consisting of:

- plastic housing with cover

- operating elements (5 keys)

- LED-display

- two LC-displays (multi-functional displays)

- power supply unit

- data memory (EEPROM, no buffer battery required)

- outputs: flow module, level module, current module

- terminals for power supply, inputs and outputs

VEGASON 71 - D

Sensor:

- in standard version or

- in Ex-version, certificate acc. to CENELEC

Accessories:

- swivelling holder for sensor mounting

Options:

- totalising counter (flow)

- indicator VEGADIS 171 A

- overvoltage arresters

5

Page 6

2.2 T echnical data, VEGASON 71 - D

Power supply

Operating voltage

- Standard U

- Option U

Power consumption at U

Fuse for version

and max-load 12 V A, 5 W

nenn

16 … 42 V AC or 16 … 60 V DC 2 A

90 … 250 V AC 500 mA

Measuring range

Min. distance 0.300 m

Max. distance 4.000 m (5.000 m)

Measuring data

Min. span 10 cm

Display in m (0.000 … 5.000 distance)

Resolution in mm

Scanning 3 mm

Measuring frequency 50 kHz

Measuring rate 0,4 sec.

Angle of reflection (at –3 dB) 8°

Linearity error after empty and full adjustment < 0,1 % of measuring range

Temperature error of the electronics 0,1 % / 10 k of measuring range

= 24 V AC (16 … 42 V), 50/60 Hz

nenn

U

= 24 V DC (16 … 60 V)

nenn

= 230 V AC (90 … 250 V), 50/60 Hz

nenn

2 T echnical Information

Central electronics

Inputs 1 (1 channel, for 1 sensor)

Outputs see section "output"

Housing material Polycarbonate

Electrical connection max. 1,5 mm

2

Cable entry 1 x Pg 7, 1 x Pg 13,5 (up to max. 5 x Pg 13,5)

Protection IP 65

Ambient temperature -20°C … +60°C

Storage and transport temperature -20°C … +80°C

Weight approx. 1,9 kg

Output

Indication

LC-display 2, 4-digit each

Flow module

1 flow relay output active, with status indication (LED)

- voltage impulse 24 V

- current impulse 20 mA

- pulse duration 200 ms

1 sampling relay output floating spdt, with status indication (LED)

- contact material AgCdO and Au plated

- min. turn-on voltage 10 mV

switching current 10 µA

- max. turn-on voltage 250 V AC, 60 V DC

switching current 2 A AC, 1 A DC

- max. breaking capacity 125 V A, 60 W

6

VEGASON 71 - D

Page 7

2 Technical Information

Level module

2 relay outputs floating spdts each

and 2 status indications (LEDs)

- contact material AgCdO and Au plated

- min. turn-on voltage 10 mV

switching current 10 µA

- max. turn-on voltage 250 V AC, 60 V DC

switching current 2 A AC, 1 A DC

- max. breaking capacity 125 V A, 60 W

Current module

2 current outputs

- range 0/4 … 20 mA

- resolution 0,05 % of range

- load max. 500 Ohm

- load dependent error at 0 … 500 Ohm, < 0,2 % related to the range

or module

as described above however with 2 floating outputs each

Fault signal

1 fail safe relay 1 floating spdt

contact data as described under relay outputs

2 failure-LEDs

2.3 Technical data, transducer

Transducer SW 71

Material of the transducer housing PVDF

Material of the fixing tube PVDF, thread G 1 A

Connection cable to central electronics standard coaxial cable type RG 58

Cable length 5 m, as option 300 m

Diameter of cable approx. 5 mm

Temperature sensor integrated in the transducer

Ambient temperature -20°C … +80°C

Storage and transport pressure -20°C … +80°C

Protection IP 68

Permissible ambient temperature 1 bar

Weight approx. 0,8 kg

Transducer SW 71 R Ex

Ex-approval PTB-no. Ex-94.C.4066

Flame proofing Casting "m"

Marking EEx m II T6 or T5 or T4

Material of the transducer housing PVDF

Material of the fixing tube PVDF, thread G 1 A

Connection cable to central electronics standard coaxial cable type RG 58

Cable length 5 m, as option up to 300 m

Diameter of cable approx. 5 mm

Temperature sensor integrated in the transducer

Temperature class T6 = 60°C, T5 = 75°C, T4 = 80°C

Storage and transport temperature -20°C … +80°C

Protection IP 68

Permissible ambient pressure 1 bar

Weight approx. 1,0 kg

VEGASON 71 - D

7

Page 8

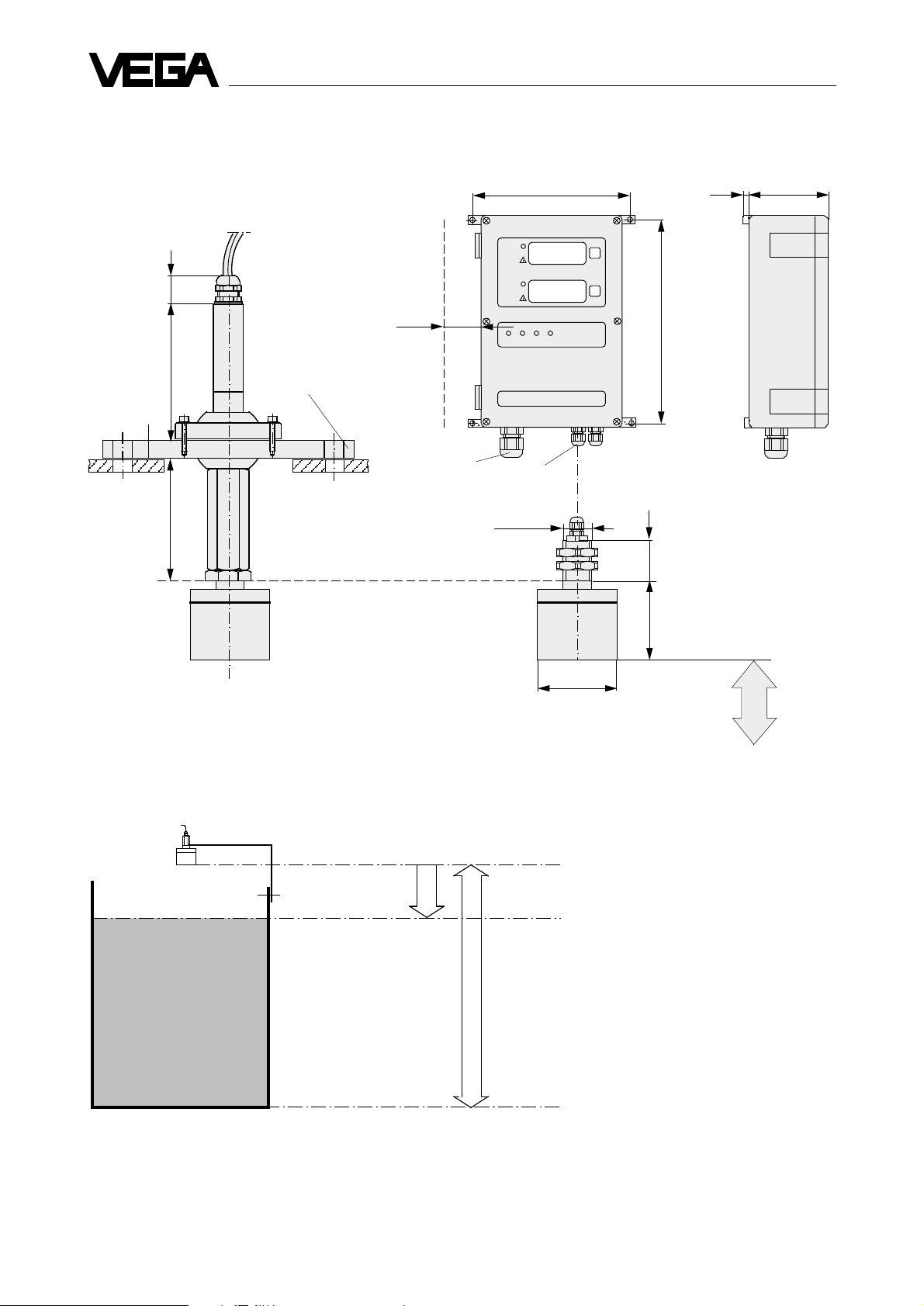

2.3 Dimensional drawings

(Dimensions in mm)

2 T echnical Information

Swivelling flange

28

138

Central electronics

Min. distance for

adjacent instrument

Flange

DN 150 PN 16

1

2

40

1 2 3

Pg 13,5 Pg 7

G 1 A

Sensor

*174

4

VEGASON

5

*229

* Mounting diemsnions

45

90

90

2.4 Measuring range

Reference plane

Min.-distance

Measuring range

ø95

Min.-distance

300 mm

0.000 m

0.300 m

max.

4.000 m (5.000 m)

8

VEGASON 71 - D

Page 9

2 Technical Information

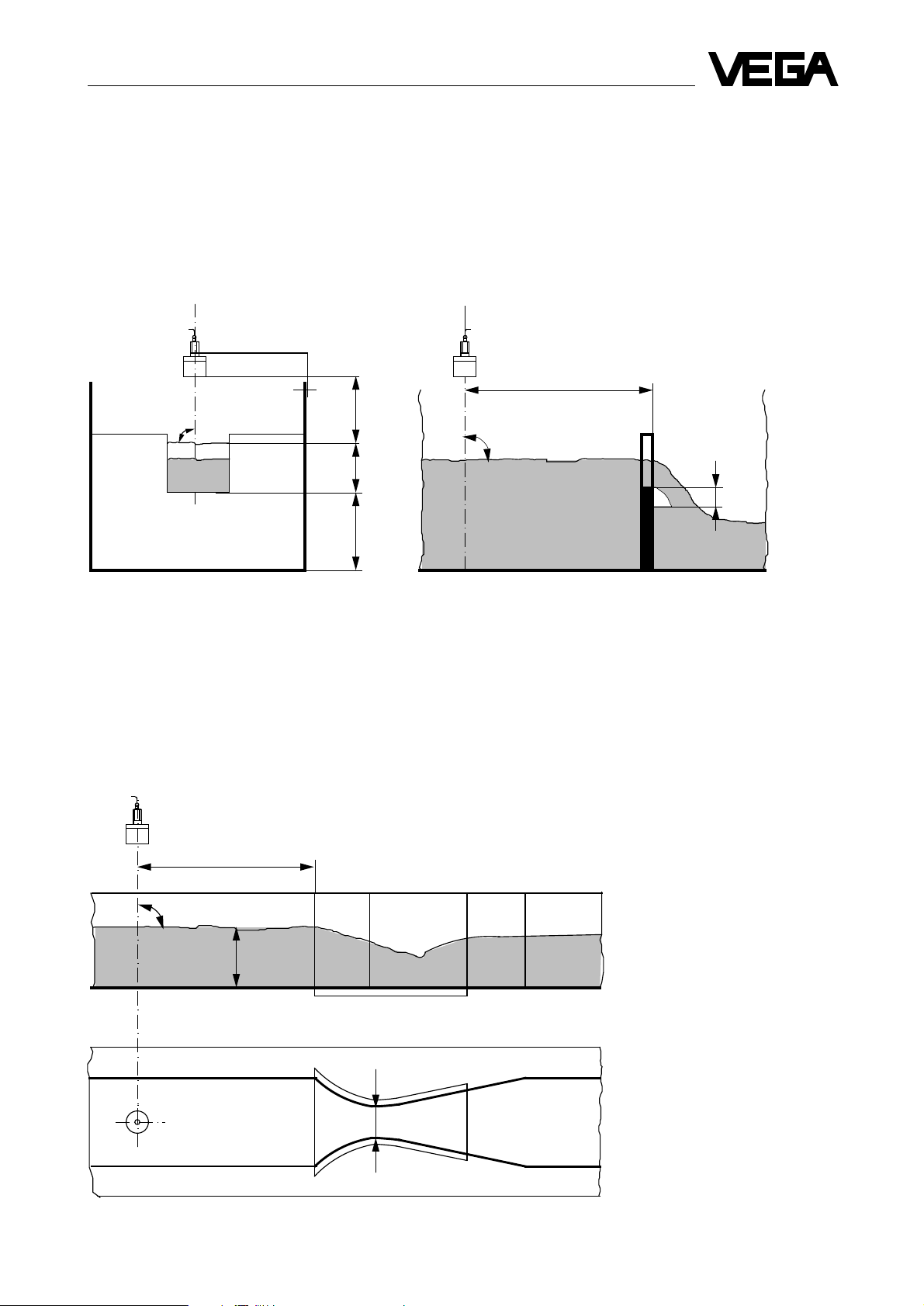

2.5 General installation instructions

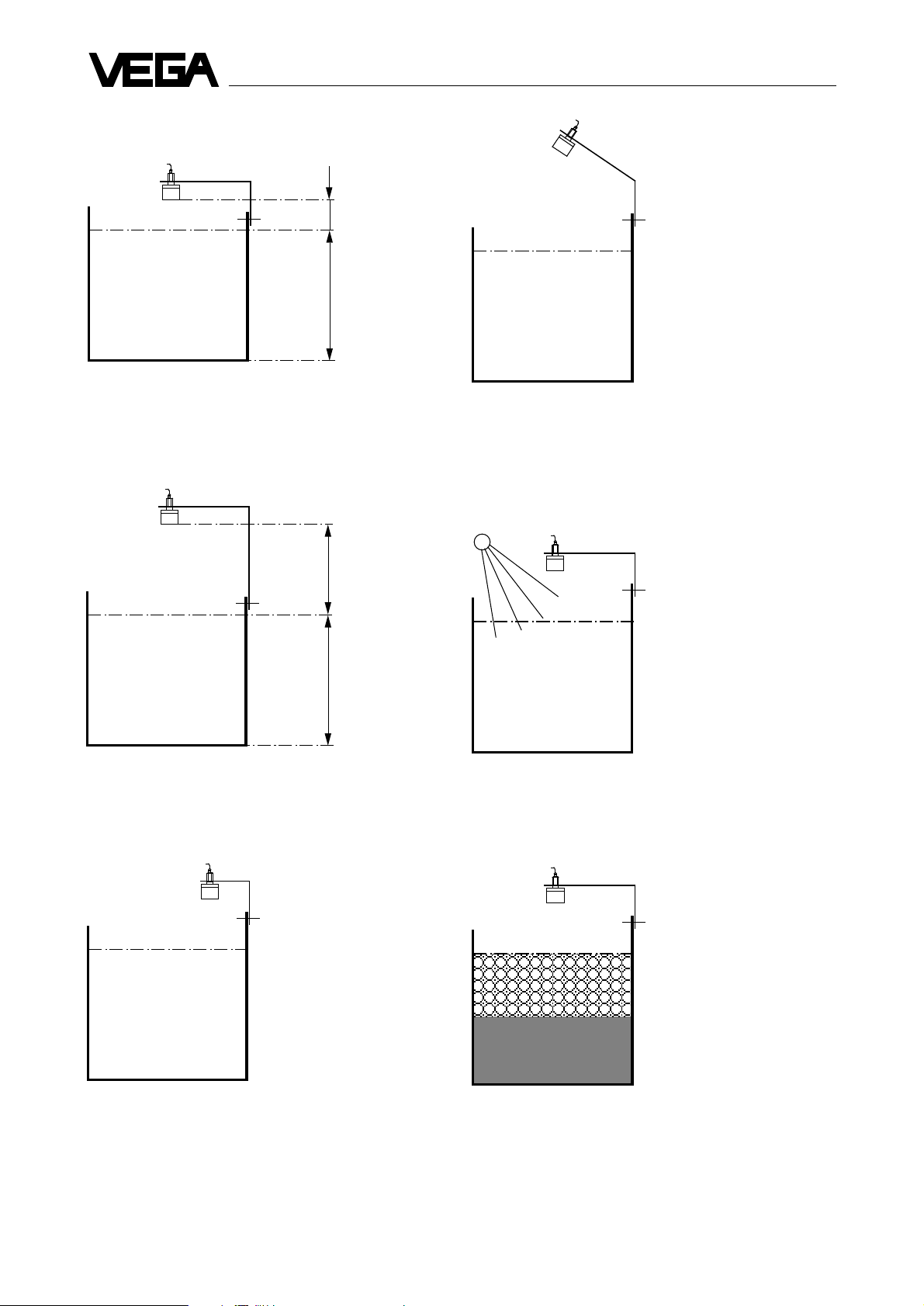

Open flume with weir (e.g. rectangular)

- Installation of the transducer upstream

- Observe distance to the weir (3 … 4 x h

- Installation if possible centered to the flume

- Installation vertical to the surface of the flow product

- Observe min. distance relating to h

- Min. distance diaphragm opening to downstream water ≥ 5 cm

90°

weir

max

max

)

≥ Min.-

max

h

max

≥ 2 x h

distance

3 - 4 x h

max

90°

upstream water

≥ 5 cm

downstream

water

Open flume with measuring channel (e.g. Khafagi-Venturi flume)

- Installation of the sensor at the inlet

- Observe distance to the Khafagi-Venturi flume (3…4xh

- Installation if possible centered to the flume

- Installation vertically to the surface of the flow product

- Min. distance relating to the height of damping h

max

Note

Otherwise follow the installation guidelines given by the channel manufacturer.

Sensor

3 - 4 x h

max

90°

h

max

max

)

Sensor

VEGASON 71 - D

B

9

Page 10

2.6 Installation fault

< 300 mm

max

h

2 T echnical Information

Fault: Min. distance from sensor to h

maintained.

max

not

Problem: The upper range cannot be measured.

Solution: Correct min. distance of the sensor to 0,3 m.

> 300 mm

max

h

Fault: Distance from sensor to h

Problem: Unreliable results due to very weak echoes.

too large.

max

Solution: Correct min. distance of the sensor to 0,3 m.

Fault: Sensor is not directed vertically to the surface.

Problem: Sensor receives weak echoes.

Solution: Mount sensor vertically.

Fault: Strong heat fluctuations, e.g. sun.

Problem: The measuring accuracy is not constant.

Solution: Install a sun shield in the respective position.

Fault: Sensor too close to the flume wall, i.e. not

mounted in the centre.

Problem: Build-up and rough flume walls cause

measuring problems.

Solution: Mount sensor in the centre of the flume.

10

Fault: Surface has foaming problem.

Problem: The surface of the foam is detected as level.

The measured value is wrong.

Solution: The used measuring principle is not suitable

and must be replaced e.g. by a hydrostatic

system (pressure transmitter).

VEGASON 71 - D

Page 11

2 Technical Information

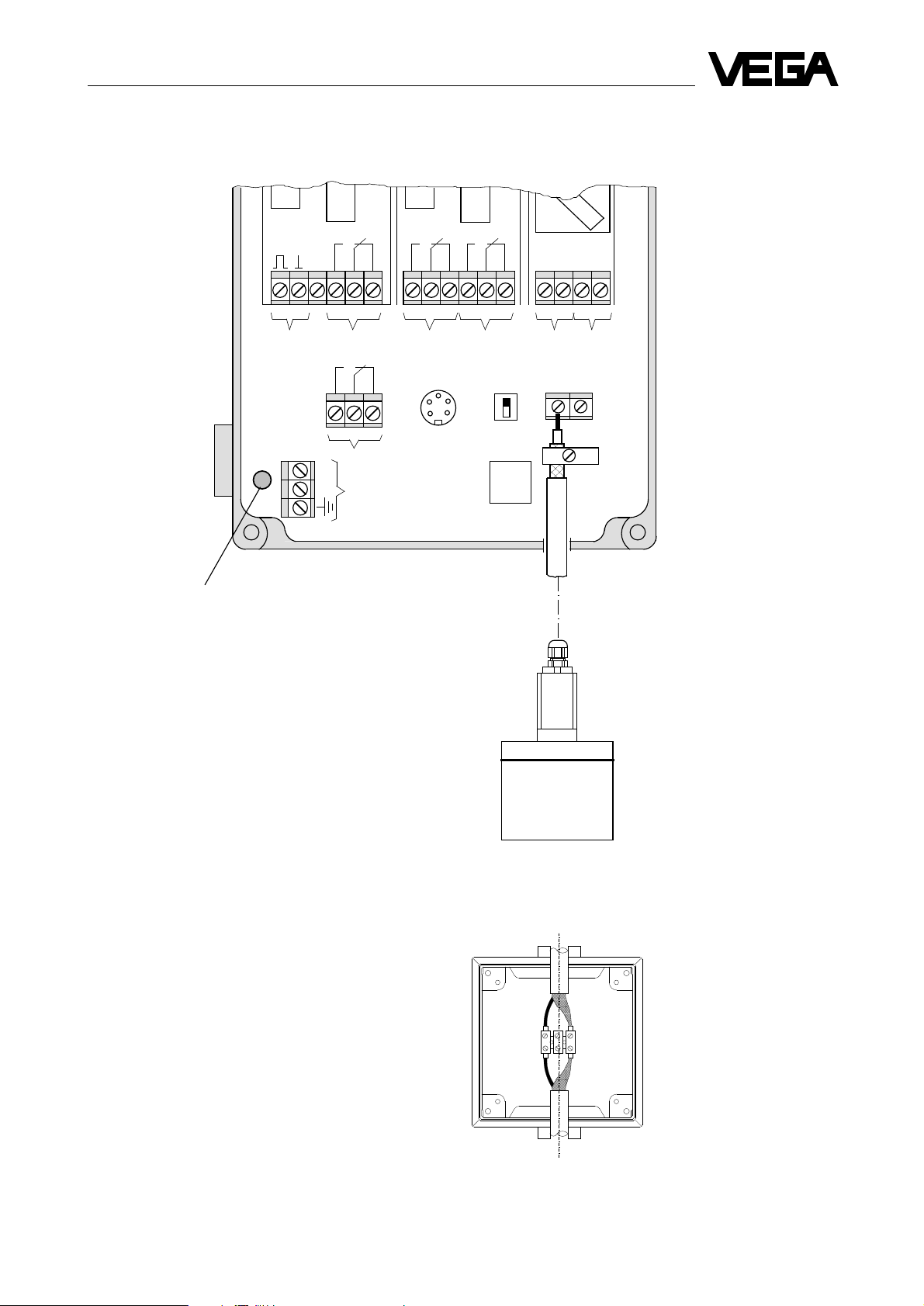

2.7 Electrical connection

Flow module

Flow module:

- Flow

Terminal 9 and 10

- Sampling

Terminal 12 … 14

91011

Relay output

-

+

Fuse type TR5

Manufacturer, e.g. Messrs. Wickmann,

Current value see 2.2 Technical Data

12

1 2

3

2

1

13 14

Service socket

4

5

Failure relay

output

Power supply

Level module

15 16

18

17

1 2

Relay output

Service switch

19

1

2

20

Attention!

High

voltage

Current module

+ - + -

23

21 22

1 2

Current output

6

24

7

8

standard coax cable

max. cable length = 300 mm

Current module:

- flow proportional

Terminal 21 and 22

- level proportional

Terminal 23 and 24

Note

During operation the sensor is clocked with highperformance impulses. It is therefore recommended to

provide all electrical connections first and then switch on

the power supply.

The connection line to the sensor can be extended as

shown. Therefore observe that a max. line length of 300 m

is not be exceeded.

Sensor

standard waterproof

distributor box

VEGASON 71 - D

11

Page 12

3 Operating surface

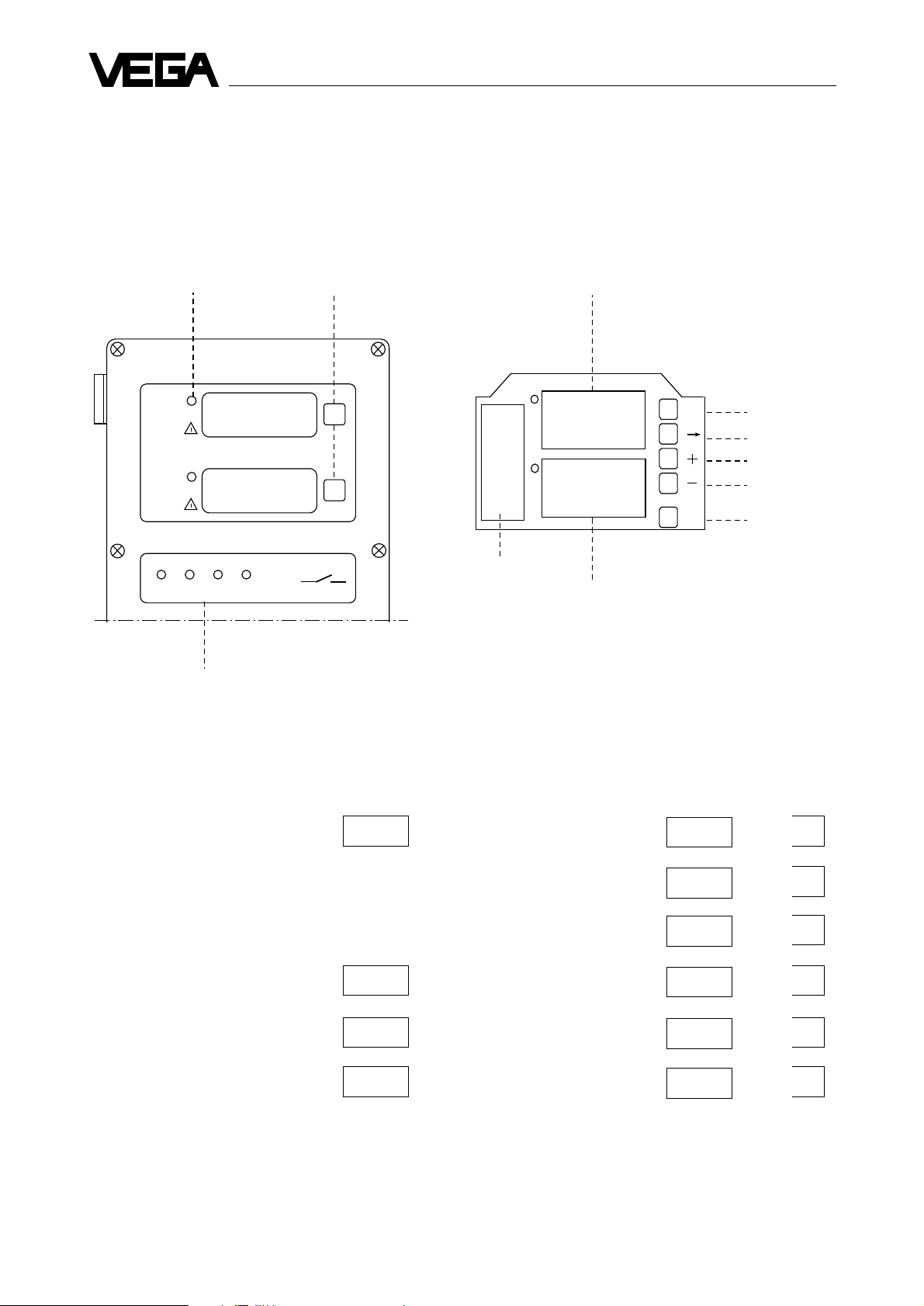

3.1 Indicating and operating elements

Outer view Inner view

3 Operating surface

LED-indication

Fault signal

1

8888

2

1 2 3

LED-indication of the relay

output 1 … 4

4

Measuring units as label in

the provided window

Scheme of

operation

Indication of measured

values

MODEFIELD

1

8888

2

8888

PARAMETER FIELD

MOD

STO

Selection of

mode

Cursor position

figures raise

figures lower

Memory

Indication of measured values

e.g. flow 00.00 … 75.00 11.25 m3/h

Demonstration after respective programming of

- Measuring unit

- Allocation of a multiplication factor

- Decimal point e.g.

Flow 0 … 100 % 50.0 %

Level 0 … 100 % 50.00 %

Distance 0.000 … 5.000 m 5.000 m

12

Mode range

General parameter adjustment 0 - 00 … 99

Optimization 1 - 01 … 27

Linearization curve 4 4.H.01 … 32

Linearization curve 5 5.H.01 … 32

Linearization curve 6 6.H.01 … 32

Fault signals E2.01 … .04

VEGASON 71 - D

Page 13

3 Operating surface

3.2 Operation

VEGASON 71 - D has 3 modes which can be enquired with the MOD-button (scrolling)

- indication of measured values

- mode range

- parameter adjustment.

After 60 mins. VEGASON 71 - D resets automatically to mode "Indication of measured values".

1. Indication

of measured

values

2. Mode

range

3. Parameter

adjustment

5.000

MOD

0Ê00 0Ê99

48.94

MOD

Cursor position

Figures raise

Figures lower

0 - 00

– – – – 0

Cursor position

MOD

Figures raise

Figures lower

+

-

+

-

STO

1. Indication of measured value

Flow in m

3

/h

Flow in %

Level in %

Distance in m

2. Mode range

Enquiry of the mode numbers in the MODEFIELD. The

parameters of the enquired mode numbers can be

checked or modified in mode 3.

3. Parameter adjustment

Programming of the parameters in the PARAMETER

FIELD. The parameter of the respectively enquired

mode can be modified and stored with the key STO.

Push the MOD-key if no modification is desired or if the

modified parameter should not be stored. In both cases

reset in mode 1.

In mode 99 the mode range of the general parameter adjustment can be quit and the optimization as well as the

linearization curve 4 … 6 can be enquired. Reset also in mode 99.

If after STO the actual mode range is enquired again within 60 mins., the last enquired mode number appears

automatically.

VEGASON 71 - D

13

Page 14

4 Set-up

4.1 Flow chart for set-up

Connect sensor to control electronics and

switch on the power supply .

4 Set-up

The software version is displayed and the

fault signal responds.

The measuring system is ready and starts

the self-check cycle. Preliminary indication:

0.000 m

Self-check cycle, i.e.:

1. Echo limitation from top to bottom.

2. Echo limitation from bottom to top.

3. Generation of a measuring window, within

which a preferred processing of the echo

is made.

Feeding

phase:

1.

2.

3.

5 6

4

Sensor

Flume

1

!

2

!

48.94

0.000 m

Echo

Measuring

window

After approx. 1 … 3 min. the measuring

system is in operating status. The fault signal

extinguishes. The measuring system has

finished the self-check and operates with the

parameters of the factory setting.

NO

?

YES

Flow measurement

(level measurement in flume)

14

5 6

1

!

4

2

!

Optimization required.

In the flume a distance of e.g.

0,600 m is determined.

0.600 m

VEGASON 71 - D

Page 15

4 Set-up

4.2 Mode range, general parameter adjustment, mode

0 - 000 - 00

0 - 00 …

0 - 000 - 00

0 - 990 - 99

0 - 99

0 - 990 - 99

Function Mode-no. Mode description Parameter Page

(bold = factory setting)

0 - 00 Software version .................................................... z.B. 48.94

0 - 01 … 10 not coordinated ...................................................... ––––

Adjustment 0 - 11 Empty adjustment

- distance in m ..................................................... 5.000 m … 0.000 m

- level in % ...........................................................

0.00.0

0.0 … 80.0 P. 18

0.00.0

0 - 12 Full adjustment

- distance in m ..................................................... 0.000 m … 5.000 m

- level in % ...........................................................

100.0100.0

100.0 … 20.0

100.0100.0

Display Allocation of a multiplication factor

function 0 - 13 - relating to 0 % ...................................................

0 - 14 - relating to 100 % ............................................... 0000 …

00000000

0000 … 9999

00000000

10001000

1000 … 9999

10001000

0 - 15 Measuring unit P. 23

- distance in m .....................................................

11

1

11

- level in % ........................................................... 2

- scaled value ...................................................... 3

0 - 16 Decimal point ......................................................... 0.000 …

0 - 17 Integration time ......................................................

00

0 … 900 P. 24

00

000.0 000.0

000.0 … 0000

000.0 000.0

Lineari- 0 - 18 Linearization curves

zation - linear ................................................................. 1

- not coordinated ................................................. 2

- not coordinated ................................................. 3

- individually programmable curve 4 .................... 4

- individually programmable curve 5 .................... 5

- individually programmable curve 6 .................... 6

- root function Q = K x h

- linear function Q = K x h

0,5

................................... 7

1,0

.................................

- Venturi flume

rectangular flume

rectangular weir

trapezoidal weir Q = K x h

- Palmer Bowlus Flume Q = K x h

- quadratic function Q = K x h

- V-Notch

Q = K x h

2,5

........................................................ 12

1,5

.............................. 9

1,86

................... 10

2,0

................................................

0 - 19 … 52 not coordinated ...................................................... ––––

Level 0 - 53 Coordination

module - measuring result in m ........................................ 1

Relay

output 1

0 - 54 not coordinated ...................................................... –––– P. 32

- measuring result in %........................................

Switching command

0 - 55 - on ...................................................................... 0.000 m … 5.000 m

0 - 56 - off ...................................................................... 0.000 m … 5.000 m

88

8 P. 20

88

11

22

2

22

VEGASON 71 - D

0 - 57 not coordinated ...................................................... ––––

15

Page 16

4 Set-up

4.2 Mode range, general parameter adjustment (continuation)

Function Mode-no. Mode description Parameter Page

(bold = factory settings)

(level 0 - 58 Coordination

module) - measuring result in m........................................ 1

Relay

output 2

Current Characteristics

module 0 - 65 - end ....................................................................

Current output 1 + 2

0 - 59 not coordinated ...................................................... –––– P. 32

0 - 60 - on ...................................................................... 0.000 m … 5.000 m

0 - 61 - off ...................................................................... 0.000 m … 5.000 m

0 - 62 … 64 not coordinated ...................................................... ––––

0 - 66 - begin ................................................................. 00.00 …

0 - 67 … 81 not coordinated ...................................................... ––––

- measuring result in %........................................

Switching command

22

2

22

20.0020.00

20.00 … 00.00 P. 33

20.0020.00

04.0004.00

04.00 … 20.00

04.0004.00

Max. 0 - 82 Flow (max. 4 positions) .......................................... 0001 … 9999 …

flow 0 - 83 Multiplier

(at level - flow x 1 ..............................................................

100 %) - flow x 10 ............................................................ 1

- flow x 100 .......................................................... 2 P. 24

- flow x 1000 ........................................................ 3

0 - 84 Time unit for above flow

- seconds .............................................................

- minutes.............................................................. 2

- hours ................................................................. 3

Flow

module

Pulse value 0 - 85 Flow quantity / impulse .......................................... 0001 … 9999 …

for flow 0 - 86 Multiplier

relay - flow quantity / impulse x 1 .................................

- flow quantity / impulse x 10 ............................... 1

- flow quantity / impulse x 100 ............................. 2

- flow quantity / impulse x 1000 ........................... 3

Pulse value 0 - 87 Flow quantity / impulse .......................................... 0001 … 9999 …

for samp- 0 - 88 Multiplier

ling relay - flow quantity / impulse x 1 ................................. 0

- flow quantity / impulse x 10 ...............................

- flow quantity / impulse x 100 ............................. 2 P. 25

- flow quantity / impulse x 1000 ........................... 3

- flow quantity / impulse x 10000 ......................... 4

- flow quantity / impulse x 100000 ....................... 5

- flow quantity / impulse x 1000000 ..................... 6

00

0

00

11

1

11

00

0 P. 24

00

11

1

11

10001000

1000

10001000

10001000

1000

10001000

10001000

1000

10001000

16

0 - 89 Time dependent controls in hours .........................

0 - 90 Min. flow volume limit in % .....................................

0 - 91 u. 92 not coordinated ...................................................... ––––

00

0 (off) … 100

00

0.00.0

0.0 … 100 P. 25

0.00.0

VEGASON 71 - D

Page 17

4 Set-up

4.2 Mode range, general parameter adjustment (continuation)

Function Mode-no. Mode description Parameter Page

(bold = factory settings)

0 - 93 Failure processing

- store actual current,

switching relay unchanged ................................

- current 0 mA, switching relay de-energized ...... 2 P. 33

- current corresponds to 0 %,

switching relay de-energized ............................. 3

- current corresponds to 100 %,

switching relay de-energized ............................. 4

0 - 94 Simulation .............................................................. 0.000 m … 9.999 m P. 34

0 - 95 u. 96 not coordinated ...................................................... ––––

0 - 97 Basic adjustment

- switched off .......................................................

- switched on ....................................................... 1

0 - 98 Keyword (= 0070)

- switched off .......................................................

- switched on ....................................................... 1

11

1

11

00

0 P. 34

00

00

0 P. 34

00

0 - 99 Change

- general parameter adjustment ..........................

- optimization ....................................................... 1 P. 20

- not coordinated ................................................. 2 and

- linearization curve 4 .......................................... 4 P. 35

- lineariztion curve 5 ............................................ 5

- linearization curve 6 .......................................... 6

00

0

00

VEGASON 71 - D

17

Page 18

5 Adjustment

5 Adjustment

5.1 Empty / full adjustment in metres without flow change

With this adjustment procedure two distances in m are defined which correspond to the levels of 0 % and 100 %.

5.2 Demonstration and programming example

Demonstration

m %

0.000

0.350

0.700

100

0

0.35 m distance ^ 100 %

0.7 m distance ^0%

Programming example

0.350 m distance ^ 100 %

• Enquire mode 0 - 12 in the MODEFIELD

• Program 0.350 m in the PARAMETER FIELD

• Then store with key STO

0.700 m distance ^ 0 %

• Enquire mode 0 - 11 in the MODEFIELD

• Program 0.700 m in the PARAMETER FIELD

• Then store with key STO

(The sequence of the empty and full adjustment is individual)

18

VEGASON 71 - D

Page 19

6 Flow measurement

6 Flow measurement

6.1 Linearization

6.1.1 Meter flume / weir

The system measures the level and calculates the flow.

The relationship between level and flow is linear in most

cases.

The level value (in %) must be therefore converted into a

flow porportional value.

The necessary mathematical functions depend on the

flumes and weirs used.

For the standard flumes and weirs the respective functions

are available as pre-programmed linearization curves and

can be directly enquired.

Flumes / weirs which do not correspond to the known

functions, can be imitated via three programmable

linearization curves.

Standard flumes / weirs

Pre-programmed

linearization curves

Enquire linearization

curves

0 - 18 = 1

7

bis

12

NO standard flumes /

weirs

Programmable

linearization curves

Enquire mode range

0 - 99 = 4

5

6

Program index markers

for linearization curves

4 - 01 … 32

5 - 01 … 32

6 - 01 … 32

Enquire linearization

curves

0 - 18 = 4

5

6

Processing results flow proportional

VEGASON 71 - D

19

Page 20

6 Flow measurement

6.1 Linearization (continuation)

6.1.2 Enquiry of linearization curves 4 … 6

In mode 0 - 99 linearization curves 4 … 6 can be enquired as well as the reset (mode 4 - 99, 5 - 99, 6 - 99) to the general

parameter adjustment can be made.

0 - 9 9

5 H . 0 1

4

4 H . 0 1

5

Enquiry linearization curve 4 … 6

6

Reset to general parameter adjustment

0 - 0 1

Programming example

Linearization curve 4

• Enquire mode 0 - 99 in the MODEFIELD

• Program figure 4 in the PARAMETER FIELD

• Then store with STO

• Push MOD-key for enquiry of the index markers

Reset is always made in mode 99 with figure 0 in the P ARAMETER FIELD.

Linearization curve 4

6 H . 0 1

32

4 - 9 9

0

Function Mode-no. Mode description Parameter

(bold = factory setting)

Index 4.H.01 1. index markers - level percent ................... 000.0 …

markers 4.L.01 - flow percent .................... 000.0 …

bis to

4.H.32 32. index markers - level percent ................... 000.0 …

4.L.32 - flow percent .................... 000.0 …

4 - 33 … 98 not coordinated .................................................... ––––

4 - 99 Change

- general parameter adjustment......................... 0

- optimization ..................................................... 1

- not coordinated ................................................ 2

- linearization curve 4 ........................................ 4

- linearization curve 5 ........................................ 5

- linearization curve 6 ........................................ 6

Linearization curve 5 as linearization curve 4, however 5.H.01 … 5.H.32

5.L.01 … 5.L.32 5 and 5 - 99

Linearization curve 6 as linearization curve 4, however 6.H.01 … 6.H.32

6.L.01 … 6.L.32 6 and 6 - 99

100.0100.0

100.0

100.0100.0

100.0100.0

100.0

100.0100.0

100.0100.0

100.0

100.0100.0

100.0100.0

100.0

100.0100.0

20

VEGASON 71 - D

Page 21

6 Flow measurement

Display

4 = no. of the linearization curve

4 = no. of the linearization curve

Change-over

Display 1

Display 2

Display 1

Display 2

H H

4 .

H . 0 1

H H

1 0 0 . 0

L L

4 .

L . 0 1

L L

1 0 0 . 0

H = indication for level percent

01 = 1. index markers

MODEFIELD

P ARAMETER FIELD

level percent value (factory setting)

L = indication for flow percent

01 = 1. index markers

MODEFIELD

PARAMETER FIELD

flow percent value (factory setting)

00

4 .

H

.

0 1

4 .

00

99

L

.

9 1

99

4 .

4 .

H H

H . 0 1

H H

L L

L . 0 1

L L

Example of a linearization curve

Flow

%

4.L.05

100.0

100

50

4 .

4 . L

H

. 0

. 0

11

1

11

99

9

99

scrolling with key –>

scrolling with key + or –

Example of a linearity protocol

Index marker Level percent Flow percent

no. (level)

01 30.0 % 10.0 %

02 50.0 % 15.0 %

03 75.0 % 40.0 %

04 90.0 % 70.0 %

05 100.0 % 100.0 %

4.L.01

010.0

VEGASON 71 - D

Level

0

50 100 %

4.H.01

030.0

4.H.05

100.0

21

Page 22

6 Flow measurement

6.1 Linearization (continuation)

Programming example

When programming the level and flow percent values,

observe the following:

- The starting point of the characteristics (index marker

00) is generated by the instrument itself and

coordinated with the values H = 0.0, L = 0.0.

- The end (last index marker) can be made individually

within the 32 value pairs.

- The last index marker must only consist of 100.0 level

percent and 100.0 flow percent.

Programming acc. to linearity protocol

(see e.g. page 21)

Index marker 01 (level percent)

• Enquire index marker 4.H.01 in the MODEFIELD

• Program 30 % in the PARAMETER FIELD acc. to the

linearization curve

• Then store with STO

Index marker 01 (flow percent)

• Enquire index marker 4.L.01 in the MODEFIELD

• Program 10 % in the PARAMETER FIELD acc. to the

linearization curve

• Then store with STO

etc. acc. to linearity protocol. After programming of all data

- reset to mode range 0

- change display indication to flow proportional indication,

i.e. mode 0 - 13 … 0 - 16

- here in the example activate the programmed

linearization curve, i.e. mode 0 - 18 = 4.

6.2 Linearity protocol

Linearization curve

Index Level percent Flow percent

marker no. (level)

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Date

Name

22

VEGASON 71 - D

Page 23

7 Output results

7 Output results

7.1 Display

7.1.1 Allocation of a multiplication factor

If an indication in flow m3/h is requested, first an allocation

of a multiplication factor to the measured level 0 % and

100 % must be carried out in mode 0 - 13 and 0 - 14.

This allocation of a multiplication factor is only valid for the

indication and does not influence the output results for the

relay and current outputs.

7.1.2 Measuring unit

In mode 0 - 15 first of all the level proportional indication is

converted to a linearized, flow percentage indication,

derived from the allocation of a multiplication factor.

Furthermore different measuring units can be inserted as

label into the respective window.

7.1.3 Decimal point

Furthermore the position of the decimal point can be

determined in mode 0 - 16.

Programming example

Allocation of a multiplier for 0 %

• Enquire mode 0 - 13 in the MODEFIELD

• Program the figure 0000 in the P ARAMETER FIELD

• Then store with STO

On display 1 the actual distance of 0.525 m is indicated at

the moment.

Allocation of a multiplier for 100 %

• Enquire mode 0 - 14 in the MODEFIELD

• Program the figure 7500 in the PARAMETER FIELD

• Then store with STO

On display 1 still the actual distance of 0.525 m is

indicated.

Measuring unit and label

• Enquire mode 0 - 15 in the MODEFIELD

• Program the figure 3 in the PARAMETER FIELD

• Then store with STO

On the display 15 % (linearized value) of the previously

programmed allocation of a multiplier are indicated (112.5).

Demonstration to the programming example

- adjustment see page 18

- linearization curve, page 21

Mode

0-15 = 1 0-15 = 2 0-15 = 3

distance level flow

in m in % in %

0.350

0.525

0.700

100

0

50

100

15

0

Position of the decimal point

• Enquire mode 0 - 16 in the MODEFIELD

• Shift with key –> the position of the decimal point to the

right until the requested position is reached

• Then store with STO

The desired form is indicated on the display (11.25). Insert

the label m

Flow acc. to

allocation of a

multiplier in m

0 - 14

= 75.00

= 00.00

0 - 13

3

/h into the window.

3

/h

11.25

11.25

VEGASON 71 - D

23

Page 24

7 Output results

7.1.4 Integration time

An integration time can be programmed in mode 0 - 17 to

damp probable fluctuations during the indication of

measured values.

Programming example

Integration time = 10 secs.

• Enquire mode 0 - 17 in the MODEFIELD

• Program figure 010 in the PARAMETER FIELD

• Then store with STO

7.2 Adjustment max. flow

The adjustment of the max. flow at 100 % is necessary to

enable the conversion of flow to flow volume.

The value given by the manufacturer of the weir or flume

at max. flow must be adjusted (this value must be reached

at 100 % of the adjustment carried out).

If the weir of flume is oversized or the data for max. flow

are not known, the required adjustment parameters can be

determined as described in chapter "7.6 Calculation

examples of the max. flow".

7.3 Impulse value for flow relay

It is possible to connect a counter to VEGASON 71 - D to

detect the flow quantity. When using a 24 V counter, it can

be directly connected to the flow module, terminal 9 and

10.

In mode 0 - 85 and 0 - 86 the multiplier of the step-down

ratio (flow volume/pulse) can be determined.

Note

The instrument automatically takes the measuring unit

selected for the adjustment of the max. flow.

Example

One impulse on the counter per 5 m

corresponds to 0005 x 1 m

- Mode 0 - 85, flow volume / impulse = 0005

- Mode 0 - 86, multiplier = 0

3

Programming

Flow volume / impulse = 0005

• Enquire mode 0 - 85 in the MODEFIELD

• Program figure 0005 in the PARAMETER FIELD

• Then store with STO

3

Note

The adjusted measuring unit is also valid for the following

programmings of the pulse rate.

Example

Max. flow acc. to manufacturers data = 364 m3/h

corresponds to 0364 x 1 m

- Mode 0 - 82, flow = 0364

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3 (h)

3

/h

Programming

Flow = 364

• Enquire mode 0 - 82 in the MODEFIELD

• Program figure 0364 in the PARAMETER FIELD

• Then store with STO

Multiplier = 0

• Enquire mode 0 - 83 In the MODEFIELD

• Program figure 0 in the PARAMETER FIELD

• Then store with STO

Time unit = 3

• Enquire mode 0 - 84 In the MODEFIELD

• Program figure 3 in the PARAMETER FIELD

• Then store with STO

Multiplier = 0

• Enquire mode 0 - 86 in the MODEFIELD

• Program figure 0 in the PARAMETER FIELD

• Then store with STO

7.4 Impulse value for sampling relay

A sampler can be connected to VEGASON 71 - D. The

sampling relay is provided for the connection of such an

instrument. The control for the sampler can be carried out

flow dependent, time dependent or combined.

Mode 0 - 87 and 0 - 88 for flow dependent control, mode

0 - 89 for time dependent control.

Note

For flow dependent control the instrument automatically

takes the measuring unit selected for the adjustment of

max. flow.

24

VEGASON 71 - D

Page 25

7 Output results

7.4 Impulse value for sampling relay

(continuation)

Example

One impulse on the sampler per 50000 m

corresponds to 5000 • 10 m

- Mode 0 - 87, flow volume / impulse = 5000

- Mode 0 - 88, multiplier = 1

- Mode 0 - 89, time dependent control

every 24 hours = 24

3

Programming

Flow volume / impulse = 5000

• Enquire mode 0 - 87 in the MODEFIELD

• Program figure 5000 in the PARAMETER FIELD

• Then store with STO

Multiplier = 1

• Enquire mode 0 - 88 in the MODEFIELD

• Program figure 1 in the PARAMETER FIELD

• Then store with STO

Time dependent control = 24

• Enquire mode 0 - 89 in the MODEFIELD

• Program figure 24 in the PARAMETER FIELD

• Then store with STO

3

7.6 Calculation examples of the max.

flow

The expression "Max. flow" considers the following flume

specific factors

- geometry

- flow rate

- flume material

The respectively valid value can therefore only be stated

exactly by the flume manufacturer .

If this information to an available flume or weir is not

available, it can be approximated.

Therefore the following schedules and fundamentals can

be used.

It must be observed that for the various types of flumes

and weir forms, different versions are possible, which are

however not considered in the formulars.

Supplementary it is recommended to determine and

observe the frame conditions defined in the literature for

flow measurement (surface of flume, flow rate etc.).

The own manufacture of flumes and weirs based on the

following versions is not possible.

7.5 Definition of the min. flow volume

limit

With open flumes sediment build-up can cause a zero

error. VEGASON 71 - D would therefore permanently

detect a low flow which will be considered for flow volume

counting.

A minimum flow volume limit can be set in mode 0 - 90 to

eliminate this problem. If the flow is below this limit, this

value is not considered for the determination of the flow

volume.

This parameter adjustment does not influence the level

proportional or flow proportional output via current outputs

or switching relays.

Programming example

Min. flow volume limit at 0,5 %

• Enquire mode 0 - 90 in the MODEFIELD

• Program figure 000.5 in the PARAMETER FIELD

• Then store with STO

For the following flumes, flow schedules and calculation

examples are stated

Page

- Venturi flume 26

- Trapezoidal weir (Cipoletti) 27

- Rectangular weir without throat 28

- Rectangular weir with throat 29

- V-Notch 30

- Palmer-Bowlus-flume 31

Conversion information

- Liter/sec • 3,6 = m3/h

1

3

-m

/h • ––– = Liter/sec

3,6

- Example 10 Liter/sec

^ 36 m3/h

VEGASON 71 - D

25

Page 26

7.6.1 Khafagi-Venturi flume

with rectangular cross-section and flat bottom

Sensor

3 - 4 x h

max

90°

h

max

Explanation:

Q

= max. flow in m3/h

max

B = flume width in mm or m

K = flume specific factor

h

= max. damming height in mm or m

max

7 Output results

Sensor

B

K (factor)

Selection of the actual flow (Q)

Flow schedule for usual V enturi flumes

BK Q

in mm (Factor) in m3/h in mm in m3/h in mm

max

45 605 80 260 4,8 40

120 838 124 280 9,3 50

160 1106 210 330 16,2 60

200 1383 363 410 25,6 70

240 1654 532 470 37,4 80

320 2178 864 540 58,8 90

640 4280 3776 920 383 200

If a V enturi flume acc. to above value is used, the value for

Q

can be taken out of the respective column and can be

max

used for programming of mode 0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 0864

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3 (h)

h

max

Q

min

= 864 m3/h

max

h

min

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow for liquid levels < h

Q = K • h

1,5

max

…>h

Q in m3/h

B in m

h in m

Assumed values for a calculation example

B = 0,16 m

K = 1106 (derived from B)

h = 0,25 m

Calculation example

Q = 1106 • 0,25

1,5

= 138,2 m3/h

Programming acc. to calculation example

Q

= 138,2 m3/h

max

- Mode 0 - 82, flow = 0138

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3 (h)

min

.

26

VEGASON 71 - D

Page 27

7 Output results

7.6.2 T rapezoidal weir (Cipolletti)

With sharp weir edge (Cipolletti)

≥ 2 x h

max

B

max

h

1

/4 h

max

max

Weir

K (Factor)

2 - 3 x h

Explanation:

Q

= max. flow in m3/h

max

B = weir width (bottom) in mm or m

K = weir specific factor

h

= max. weir height in mm or m

max

k = thickness of the weir in mm

Selection of the actual flow (Q)

Flow schedule for usual trapezoidal weir

BK Q

in mm (Factor) in m3/h in mm in m3/h in mm

max

300 2011 116,8 150 29,5 60

450 3014 354,4 240 44,3 60

600 4011 760,4 330 58,9 60

800 5353 1457,0 420 78,7 60

1000 6688 2581,0 530 93,3 60

1500 10043 6523,0 750 147,6 60

2000 13381 14397,0 1050 196,7 60

3000 20082 36893,0 1500 295,1 60

h

max

Q

min

h

min

3 - 4 x h

max

k ≈ 3 mm

or

k ≈ 3 mm

45°

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow for liquid levels < h

Q = K • h

1,5

max

…>h

Q in m3/h

B in m

h in m

Assumed values for a calculation example

B = 0,6 m

K = 4011 (derived from B)

h = 0,27 m

min

.

If a trapezoidal weir acc. to above value is used, the value

can be taken out of the respective column and can

for Q

max

be used for programming of mode 0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 3689

= 36893 m3/h

max

- Mode 0 - 83, multiplier = 1

- Mode 0 - 84, time unit = 3 (h)

VEGASON 71 - D

Calculation example

Q = 4011• 0,27

1,5

= 562,73 m3/h

Programming acc. to calculation example

= 562,73 m3/h

Q

max

- Mode 0 - 82, flow = 0563

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3 (h)

27

Page 28

7.6.3 Rectangular weir without throat

With sharp weir edge (without throat)

7 Output results

B

max

h

Weir edge

max

K = 6593

2 - 3 x h

Explanation:

Q

= max. flow in m3/h

max

B = weir width in mm or m

K = throat specific factor for above rectangular weir = 6593

h

= max. weir height in mm or m

max

k = thickness of the weir in mm

Selection of the actual flow (Q)

Flow schedule for usual rectangular weir

BQ

in mm in m3/h in mm in m3/h in mm

max

200 54,81 120 19,4 60

400 310,0 240 38,7 60

600 650,0 300 58,1 60

800 1592,0 450 77,5 60

1000 3064,0 600 96,9 60

1500 6423,0 750 145,3 60

If a rectangular weir acc. to above value is used, the value

for Q

can be taken out of the respective column and can

max

be used for programming of mode 0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 1592

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

h

max

Q

min

h

min

= 1592 m3/h

max

3 - 4 x h

max

k ≈ 3 mm

or

k ≈ 3 mm

45°

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow for liquid levels < h

Q = B • K • h

1,5

max

…>h

Q in m3/h

B in m

h in m

Assumed values for a calculation example

B = 0,4 m

K = 6593

h = 0,13 m

Calculation example

Q = 0,4 • 6593• 0,13

1,5

= 123,61 m3/h

Programming acc. to calculation example

= 123,61 m3/h

Q

max

- Mode 0 - 82, flow = 0124

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

min

.

28

VEGASON 71 - D

Page 29

7 Output results

7.6.4 Rectangular weir with throat

With sharp weir edge and throat

≥ 2 x h

max

Weir edge

B

max

h

max

K = 6290

2 - 3 x h

Explanation:

Q

= max. flow in m3/h

max

B = weir width in mm or m

K = throat specific factor for above rectangular weir = 6290

h

= max. weir height in mm or m

max

k = thickness of the weir in mm

Selection of the actual flow (Q)

Flow schedule for usual rectangular weir

BQ

in mm in m3/h in mm in m3/h in mm

max

200 52,3 120 18,5 60

300 109,6 150 27,7 60

400 295,8 240 37,0 60

500 441,2 270 46,2 60

600 620,0 300 55,5 60

800 1519 450 73,9 60

1000 2923 600 92,4 60

1500 6128 750 138,7 60

2000 13535 1050 184,9 60

3000 34666 1500 277,3 60

If a rectangular weir acc. to above value is used, the value

for Q

can be taken out of the respective column and can

max

be used for programming of mode 0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 1353

- Mode 0 - 83, multiplier = 1

- Mode 0 - 84, time unit = 3

h

max

Q

min

h

min

= 13535 m3/h

max

3 - 4 x h

max

k ≈ 3 mm

or

k ≈ 3 mm

45°

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow for liquid levels < h

Q = B • K • h

1,5

max

…>h

Q in m3/h

B in m

h in m

Assumed values for a calculation example

B = 0,4 m

K = 6290

h = 0,13 m

Calculation example

Q = 0,4 • 6290 • 0,13

1,5

= 117,9 m3/h

Programming acc. to calculation example

= 117,9 m3/h

Q

max

- Mode 0 - 82, flow = 0118

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

min

.

VEGASON 71 - D

29

Page 30

7.6.5 V-Notch

With sharp weir edge

7 Output results

≥ 2 x h

max

α

max

h

K (Factor)

max

2 - 3 x h

Explanation:

Q

= max. flow in m3/h

max

α = angle of beam

K = weir specific factor

h

= max. weir height in mm or m

max

k = thickness of the weir in mm

Selection of the actual flow (Q)

Flow schedule for usual V-Notch

α KQ

in ° (Factor) in m3/h in mm in m3/h in mm

max

90 4966 1385,0 600 4,4 60

60 2869 800,0 600 2,5 60

45 2056 573,3 600 1,8 60

30 1334 372,0 600 1,2 60

22,5 989 275,8 600 0,87 60

If a V -Notch acc. to above value is used, the value for Q

can be taken out of the respective column and can be

used for programming of mode 0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 0573

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

h

max

Q

min

= 573,3 m3/h

max

h

min

3 - 4 x h

max

k ≈ 3 mm

or

k ≈ 3 mm

45°

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow.

Q = K • h

α in °

Q in m

h in m

Assumed values for a calculation example

α =45°

K = 2056 (derived from α)

max

h = 0,33 m

Calculation example

Q = 2056 • 0,33

Programming acc. to calculation example

Q

- Mode 0 - 82, flow = 0129

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

2,5

3

/h

= 128,6 m3/h

max

2,5

= 128,6 m3/h

30

VEGASON 71 - D

Page 31

7 Output results

7.6.6 Palmer-Bowlus-flume

D

D/4

30°

Explanation:

Q

max

D = tube diameter in inch

K = flume specific factor

h

max

D/2 D/4

30°

K

= max. flow in m3/h

= max. height in mm or m

max

h

D/6

D/2

Selection of the actual flow (Q)

Flow schedule for usual flumes

DK Q

in inch (Factor) in m3/h in mm in m3/h in mm

6" 1952 37,82 120 2,9 30

max

8" 2338 68,60 150 7,3 45

10" 2712 148,8 210 12,3 55

12" 3046 214,3 240 18,9 65

15" 3519 374,8 300 32,1 80

18" 3943 501,4 330 54,4 100

24" 4745 1074,0 450 114,5 135

30" 5488 2122,0 600 192,3 165

Note:

The data of above schedule relate to Palmer-BowlusFlumes of Messrs. Plasti-Fab.

If a Palmer-Bowlus-Flume acc. to above values is used,

the value for Q

column and can be used for programming of mode

can be taken out of the respective

max

0 - 82 … 0 - 84.

Programming acc. to selection Q

- Mode 0 - 82, flow = 2122

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

h

max

Q

min

= 2122 m3/h

max

h

min

Calculation of the actual flow value (Q)

The following formula can be used for calculation of the

actual flow for liquid levels < h

Q = K • h

D in inch

Q in m

1,86

3

/h

max

…>h

h in m

Assumed values for a calculation example

D = 12"

K = 3046 (derived from D)

h = 0,1 m

Calculation example

Q = 3046 • 0,1

1,86

= 42,046 m3/h

Programming acc. to calculation example

= 42,042 m3/h

Q

max

- Mode 0 - 82, flow = 0042

- Mode 0 - 83, multiplier = 0

- Mode 0 - 84, time unit = 3

min

.

VEGASON 71 - D

31

Page 32

7 Output results

7.7 Level module

The pulse-echo measuring system can be equipped with a

level module. This module is provided with two relays.

Mode coordination

Relay Coordination Switching command

output ON OFF

1 Mode 0 - 53 Mode 0 - 55 Mode 0 - 56

2 Mode 0 - 54 Mode 0 - 60 Mode 0 - 61

7.7.1 Coordinations and their relations

For each relay or relay output the coordination can be

programmed separately .

Relay Measur- Measur- Coordination Linearization

1 Distance

2 as above, however 0 - 54 = … 0 - 18 = …

7.7.2 Switching commands

Mode 0 - 53 defines the measuring result and its

measuring unit coordinated to the relay output.

ing result ing unit Mode Mode

Level

proportional

Volume Flow

propor- in % 0 - 53 = 2 0 - 18 =

tional 4 … 12

in m 0 - 53 = 1 0 - 18 = 1

Level

in % 0 - 53 = 2 0 - 18 = 1

Diagram for overfill protection

Two point level switch: switching command of f above

switching command on means overfill protection

(function A)

% m

100

75

switching

command off

Mode 0 - 56

switching

command on

Mode 0 - 55

25

50

off

0

on

Diagram for protection against dry running of

pumps

Two point level switch: switching command of f above

switching command on means protection against dry

running of pumps (function B)

% m

100

75

switching

command on

Mode 0 - 55

switching

command off

Mode 0 - 56

25

50

on

0

off

Acc. to the sequence of the switching commands it is

possible to program the respective relay output as overfill

protection or protection against dry running of pumps

(A/B-function).

The min-∆ for the switching commands is 10 mm or 0,5 %.

Mode 0 - 55 means switching command on, i.e.

- the relay of output 1 is energized

- the LED-indication extinguishes

Mode 0 - 56 means switching command off, i.e.

- the relay of output 1 is de-energized

- the LED-indication lights

Same procedure for relay output 2, however mode 0 - 60

and 0 - 61.

32

Programming example for relay output 1

- coordination to measuring unit level in % corresponds

to 0 - 53 = 2

- two-point level switch as overfill protection

Coordination

• Enquire mode 0 - 53 in the MODEFIELD

• Program figure 2 in the PARAMETER FIELD

• Then store with STO

Switching command on

• Enquire mode 0 - 55 in the MODEFIELD

• Program 025.0 % in the PARAMETER FIELD

• Then store with STO

Switching command off

• Enquire mode 0 - 56 in the MODEFIELD

• Program 050.0 % in the PARAMETER FIELD

• Then store with STO

Same procedure for relay output 2, however mode 0 - 60

and 0 - 61.

VEGASON 71 - D

Page 33

7 Output results / 8 Supplementary programmings

7.8 Current module

The pulse-echo measuring system can be equipped with

another module. The module is provided with two current

outputs.

Current output 1 is automatically coordinated to the flow

proportional output result and current output 2 to the level

proportional output result.

The course of characteristics of the current output is fixed

by an initial and final point.

The factory setting defines a course of 4 … 20 mA

corresponding to 0 … 100 %.

Within the whole range of 0.00 … 20.00 mA, each current

value can be programmed for a raising or falling

characteristics.

The current-∆ between initial and final value must be min.

1 mA.

Programming example

Factory setting Programming example

% mA

100

80

60

40

Mode 0 - 65

20

End of

characteristics

mA

16

8 Supplementary programmings

8.1 Failure processing

In mode 0 - 93 the reaction of the relay and current outputs

in case of failure can be defined.

Programming possibilites

Mode Current outputs Relay outputs

0 - 93 LED

= 1 actual currents are no change

stored

= 2 current - 0 mA

= 3 current corresp. to 0 % operated relay de-energize

= 4 current corresp. to 100%

Programming example

Change-over to failure processing

e.g. 0 - 93 = 4

• Enquire mode 0 - 93 in the MODEFIELD

• Program figure 4 in the PARAMETER FIELD

• Then store with STO

Note

For adjustment of the failure processing observe

additionally the schedule of error codes in the supplement.

20

Mode 0 - 66

0

4

Begin of

characteristics

0

End of characteristics 100 % ^ 16 mA

• Enquire mode 0 - 65 in the MODEFIELD

• Program 16.00 mA in the PARAMETER FIELD

• Then store with STO

Begin of characteristics 0 % ^ 0 mA

• Enquire mode 0 - 66 in the MODEFIELD

• Program 00.00 mA in the PARAMETER FIELD

• Then store with STO

VEGASON 71 - D

33

Page 34

8 Supplementary programmings

8.2 Simulation

By this mode it is possible to simulate the outputs along

the whole range of the distance in m, to test the functions

of the connected process control. The simulation

influences the relay outputs, the current outputs and the

indication (display 2).

Operation

The key "+" increases and the key "–" reduces the outputs.

First of all the simulation is made in 5 mm steps and is

accelerated after approx. 10 secs. to 25 mm steps.

Relay outputs

Current outputs

Measured

Sensor

Simulation

Note

The simulation is marked by

- enquiry of mode 0 - 94

- flashing of all figures,

e.g. 0.700 m

value

Indication

0 - 94

0.700

8.3 Basic adjustment, mode range

general parameter adjustment

After parameter adjustment of one or several modes it is

perhaps necessary to reset the parameters of this mode to

factory setting.

Mode 0 - 97 offers this possibility, therefore the proviously

adjusted parameters are cancelled. During the

cancellation, CAL is displayed (approx. 5 sec.).

Programming example

• Enquire mode 0 - 97 in the MODEFIELD

• Program figure 1 in the P ARAMETER FIELD

• Then store with STO, CAL is displayed for approx.

5 secs. in the PARAMETER FIELD

8.4 Keyword

Acc. to the factory setting the keyword is switched off and

the data input is released.

All mentioned modes can be now enquired and their

parameters can be indicated on the display of the

measuring system and modified if necessary, as described

above.

The activation of the keyword (mode 0 - 98 = 1) protects the

parameters from unauthorized and undesired

modifications.

Warning

During simulation the measured values from the sensor

are NOT transferred for processing. Mode 0 - 94 must be

therefore quit immediately after simulation is finished. The

timer reset (after 60 mins.) should be only seen as kick-off.

After simulation, all outputs are up-dated with the valid

measured value.

Programming example

Simulation example

• Enquire mode 0 - 94 in the MODEFIELD

• Activate simulation with key MOD, at the moment the

actual measuring result flashes in the PARAMETER

FIELD

• Modify the outputs respectively with key "+" or "–"

• After having finished the test procedures quit the

simulation again with MOD or STO-key.

Another release of the data input is only possible after

programming of the keyword (overwriting of the indicated

key symbol).

The programming of the keyword can be made in any

mode and is effective for the whole mode range (mode 98

is 0).

The keyword is: 0070

Programming

Activate keyword

• Enquire mode 0 - 98 in the MODEFIELD

• Program figure 1 in the P ARAMETER FIELD

• Then store with STO

Adjust keyword

• Enquire the desired mode no. for parameter adjustment

in MODEFIELD, here in the example mode 0 - 53

• Enquire data input, the key symbol 0––n is displayed

in the P ARAMETER FIELD

• Program 0070 as keyword

• Then store with STO

• The programming of e.g. mode 0 - 53 can be continued

34

VEGASON 71 - D

Page 35

9 Optimization

9 Optimization

When dispatched the measuring system is provided with all experience and practical parameters, so that generally no

optimization is necessary.

9.1 Enquiry of the optimization

In mode 0 - 99 the optimization as well as the reset (mode 1 - 99) to the general parameter adjustment can be carried out.

0 - 9 9

1

Optimization

Reset to general parameter adjustment

0 - 0 1

Programming example

Optimization

• Enquire mode 0 - 99 in the MODEFIELD

• Program figure 1 in the PARAMETER FIELD

• Then store with STO

• For enquiry of the optimization, push MOD-key

The reset is made in mode 99 with figure 0 in the PARAMETER FIELD.

1 - 0 1 0 - 9 9

27

0

VEGASON 71 - D

35

Page 36

9 Optimization

9.2 Mode range optimization, mode

Mode-no. Mode description Parameter Page

1 - 01 u. 02 not coordinated ........................................................... – – – –

1 - 03 Instrument version ...................................................... 71 - D

1 - 04 not coordinated........................................................... ––––

1 - 05 Indication, distance in m

1 - 06 Indication, gain in dB

Operating range P. 37

1 - 07 - being of operating range

1 - 08 - end of operating range

1 - 09 … 11 not coordinated ........................................................... ––––

Multiple echo reduction

1 - 12 - reduction ..................................................................

1 - 13 - optimization ..............................................................

1 - 14 … 19 not coordinated ........................................................... ––––

Max. gain

1 - 20 - Indication, echo gain

1 - 21 - limitation ...................................................................

1 - 22 - optimization ..............................................................

1 - 011 - 01

1 - 01 …

1 - 011 - 01

1 - 271 - 27

1 - 27

1 - 271 - 27

(bold = factory setting)

0.0000.000

0.000 m

0.0000.000

6.0006.000

6.000 m

6.0006.000

0.000.00

0.00 … 1.25 V P. 37

0.000.00

0.000.00

0.00 … 1.25 V

0.000.00

0.030.03

0.03 … 4.95 V P. 37

0.030.03

0.030.03

0.03 … 4.95 V

0.030.03

1 - 23 not coordinated........................................................... ––––

1 - 24 Fault signal

switch off / switch on...................................................

1 - 25 u. 26 not coordinated ........................................................... ––––

Basic adjustment (factory setting)

1 - 27 switch off / switch on...................................................

1 - 51 … 75 Service activities......................................................... PASS

1 - 99 Change

- general parameter adjustment ................................

- optimization ............................................................. 1 P. 20

- not coordinated ....................................................... 2 and

- linearization curve 4 ................................................ 4 P. 35

- linearization curve 5 ................................................ 5

- linearization curve 6 ................................................ 6

00

0 / 1 P. 38

00

00

0 / 1 P. 38

00

00

0

00

36

VEGASON 71 - D

Page 37

9 Optimization

9.3 Definition of the operating range

The operating range can be limited in this mode by

programming of

- operating range begin and

- operating range end.

Echoes outside this limitation are ignored.

Note

The operating range end should always be programmed

10 % > than the flume end.

9.4 Multiple echo reduction

It is possible to reduce the echo gain by an offset function

to gate out possible multiple echoes.

Reduction range (offset range) = 0.00 … 1.25

Practical values = 0.00 … 0.20

Useful echo

Multiple echoes

9.5 Adjustment of the max. gain

The pulse-echo measuring system tries to detect an echo

by using the whole gain. This means, that in case of an

empty flume the gain can be bigger than required for the

useful echo when the flow is available.

This causes that sound reflections (false echoes) are

detected as useful echoes. It is useful to limit the control

range of the gain to avoid this.

Note

- The limitation can be adjusted from 0.03 V to 4.50 V, as

optimization up to 4.95 V .

- The optimum adjustment of this mode is only possible

when the flume is empty.

- For orientation a d is indicated on the display of the

measuring system, as long as with the actual gain, an

echo (false echo) is detected.

Programming example

Indication of the echo gain

• Enquire mode 1 - 20 in the MODEFIELD

• e.g. 2.00 is indicated in the P ARAMETER FIELD, i.e. in

case of an obviously wrong indication of measured

values, a false echo is detected with a gain of 2.000

The reduction (offset) depends on the

function and starts with the end of the

measuring window.

Programming example

Reduction and optimization to e.g. 0.20

Reduction

• Enquire mode 1 - 12 in the MODEFIELD

• Program reduction 0.12 (V) in the PARAMETER FIELD

• Then store with STO

Optimization

• Enquire mode 1 - 13 in the MODEFIELD