Page 1

VEGA Grieshaber KG

Electronic level measurement

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach

Phone 0 78 36/50-0

Fax 0 78 36/50-201

4

1

1 2 3

2

VEGASON

VEGASON

71 - 2 … 75 - 2

TIB • Technical Information • Operating Instructions

Pulse-Echo

measuring system

Two channel operation

2-wire level measurement or

differential measurement

Operating range up to

-5 m

- 10 m

- 20 m

- 30 m

Compact unit with modules

for relay and current outputs

Linearization

Sensor optimization

VEGASON 71 - 2 and 73 - 2

approved in hazardous areas

of Ex - zone 1

5.00

5.00

Page 2

Contents

2 71 - 2 … 75 - 2

Introduction Contents of the instruction manual .....................................................4

Safety information ...............................................................................4

Special instructions for use in Ex-Zone 1 ...........................................4

Product description .............................................................................4

Technical Information Configuration of measuring system ....................................................5

Technical data ....................................................................................6

Dimensional drawing ..........................................................................8

Measuring range .................................................................................9

Installation examples - for liquid tanks ..........................................10

- for solids ..................................................11

Installation errors (tanks or silos) ......................................................11

Electrical connections .......................................................................12

Operating surface Indication and operating elements ....................................................13

Operating ..........................................................................................14

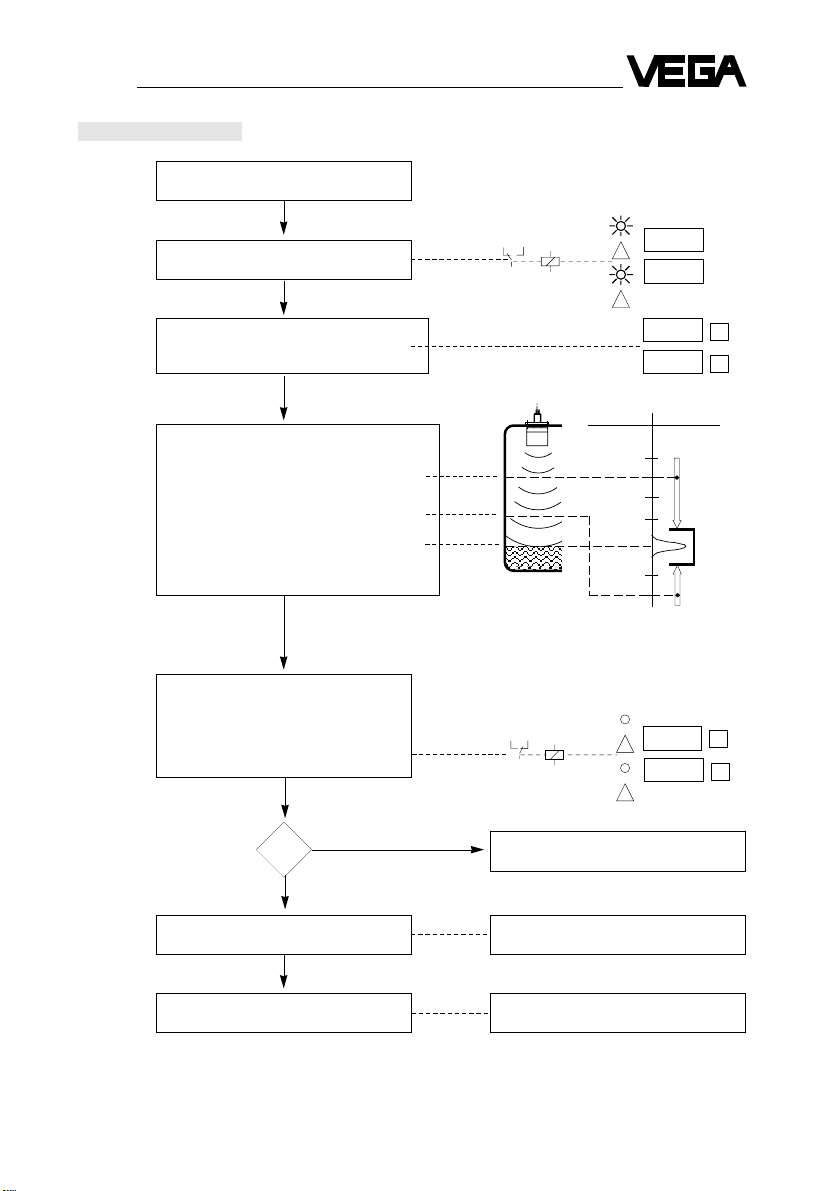

Start-up Flow diagram for start-up ..................................................................15

Mode listing 0, general parameter adjustments ................................16

Adjustment Level measurement ........................................................................20

Selection of the adjustment procedure .............................................20

Adjustment in m without level change ..............................................21

Adjustment in % with level change ...................................................21

Differential measurement ..............................................................22

Selection of the adjustment procedure .............................................22

Adjustment in m without level change ..............................................23

Linearization Adapting to the vessel geometry ......................................................24

Selection of the linearization curves 4 … 6 ......................................24

Mode listing 4 (5 and 6) ....................................................................25

Display demonstration ......................................................................25

Operation ..........................................................................................25

Determination of the index markers ..................................................26

Linearity protocol ..............................................................................27

Programming example .....................................................................28

Outputs Display function

Allocation of a multiplication factor ........................................29

Measuring units and pattern ..................................................29

Decimal point ........................................................................29

Module for relay outputs 1 … 4

Two-point level switch ...........................................................31

Pump function .......................................................................33

Tendency determination ........................................................35

Module for current output 1 and 2

Coordination and course of characteristics ...........................37

Page 3

Contents

71 - 2 … 75 - 2 3

Supplementary

programming

Failure processing ............................................................................38

Simulation .........................................................................................39

Basic adjustment ..............................................................................40

Keyword ............................................................................................40

Sensor optimization Selection of sensor optimization .......................................................41

Mode listing 1 (2) sensor optimization ..............................................41

Information for sensor optimization ..................................................43

Limitation of the operating range

Start of operating range / end of operating range .............................44

Adapting

to the

product type ..........................................................................45

to the vessel geometry (liquid) ..........................................................45

to solids ............................................................................................46

Reduction of echo amplification

Multiple false echo reduction ............................................................47

Storage

of a false echo profile

False echo learn ....................................................................48

Profile interpolation ...............................................................49

Adapting

to filling and emptying speed

Rate of product level change ................................................50

Limitation

of the echo amplification

Max. gain ...............................................................................51

Supplementary optimization

Measuring window ............................................................................52

Fail safe ............................................................................................52

Real distance ....................................................................................53

Basic adjustment ..............................................................................53

Supplement

Protocol of sensor optimization ........................................................54

Error codes .......................................................................................55

Page 4

Product description

Introduction

4 71 - 2 … 75 - 2

Contents of the instruction manual

The Technical Information / Operating Instruc-

tions is just called TIB. It contains all necessary

information for correct:

- installation

- connection

- start-up

- linearization

- optimization

the Pulse-Echo-measuring system

VEGASON 71 - 2 … 75 - 2.

This TIB is supplied as part of the order. Knowledge

of the contents is important for correct operation of

the indicating instrument.

This TIB accompanies the product and is

addressed to technical qualified staff which are

trained or have knowledge of the use of level

measurement and control equipment.

Safety information

The described module must only be inserted and

operated as described in this TIB. Please note that

other action can cause damage for which VEGA

does not take liability.

VDE-regulations and the security measures valid

for the respective applications should be observed.

Special instructions for the use in Ex-Zone 1

The transducers SW 71 … SW 73 (SW 71 applied)

are also available in the Ex-flame proofing encapsulation "m". With the type designation SW 72 R

and SW 73 R they have the flame proofing

EEx m II T6 and can be used in Ex-Zone 1.

For these applications the regulations of the conformity certificate PTB-no. Ex–92.C.2113 as well as

the special regulations acc. to VDE have to be

observed. The above mentioned conformity certificate accompanies the instrument.

The Pulse-Echo-measuring system VEGASON

71 – 2 … 75 – 2 enables

- two channel level measurement or

- one differential measurement.

The running periods of reflected sound impulse are

evaluated.

The running period is a measure of the distance

between sensor (transducer) and product.

The central electronics determines these distances

for each channel and converts them into the

respective level.

Measurements are indicated on two integral LCdisplays and are either available as current or relay

outputs.

A measuring system consists of

- one central electronics and

- two sensors (transducer).

Each sensor has its own temperature sensor for

compensation of the temperature influence on the

running period. The measuring data and temperature information are conducted via coax connection

cable.

The measuring system is provided with factory-set

parameters so that immediate use is possible for

most applications.

The adjustment procedures and sensor optimizations etc. can be programmed directly via a

keyboard on the central electronics.

Page 5

Technical Information

71 - 2 … 75 - 2 5

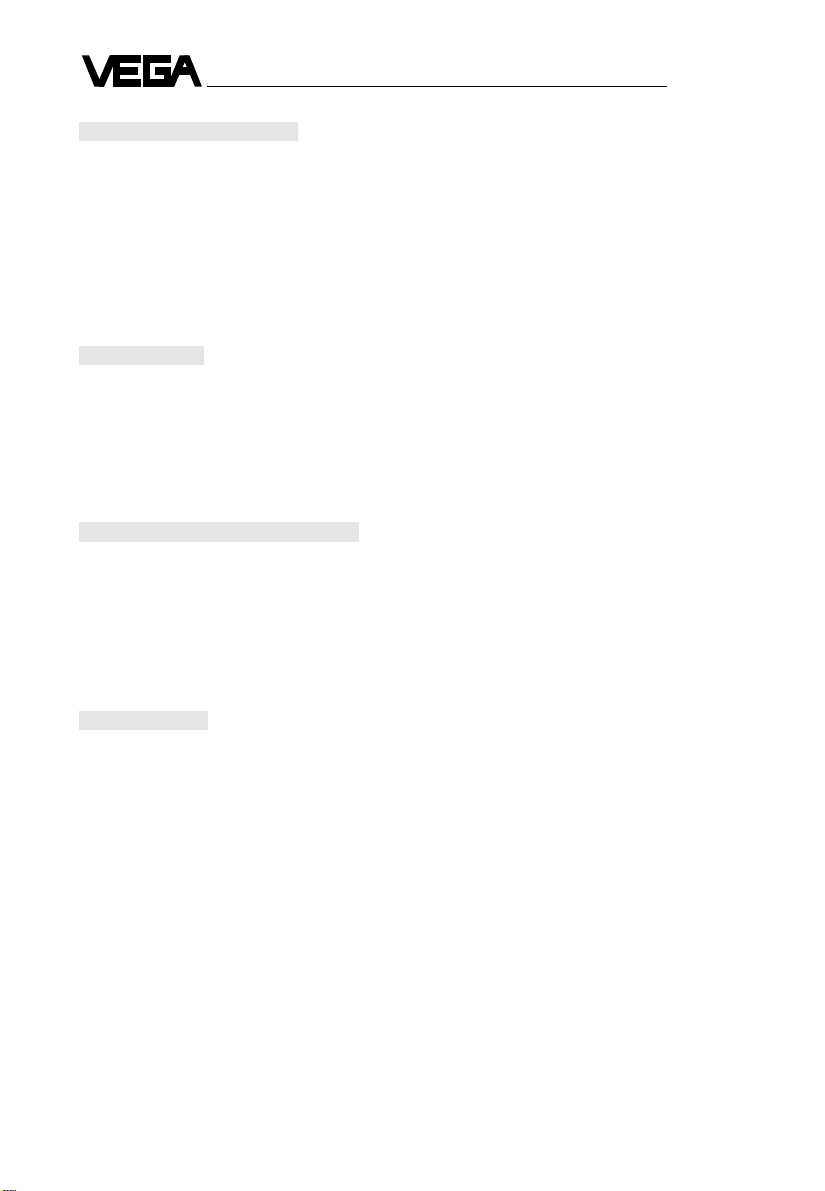

Configuration of a measuring system

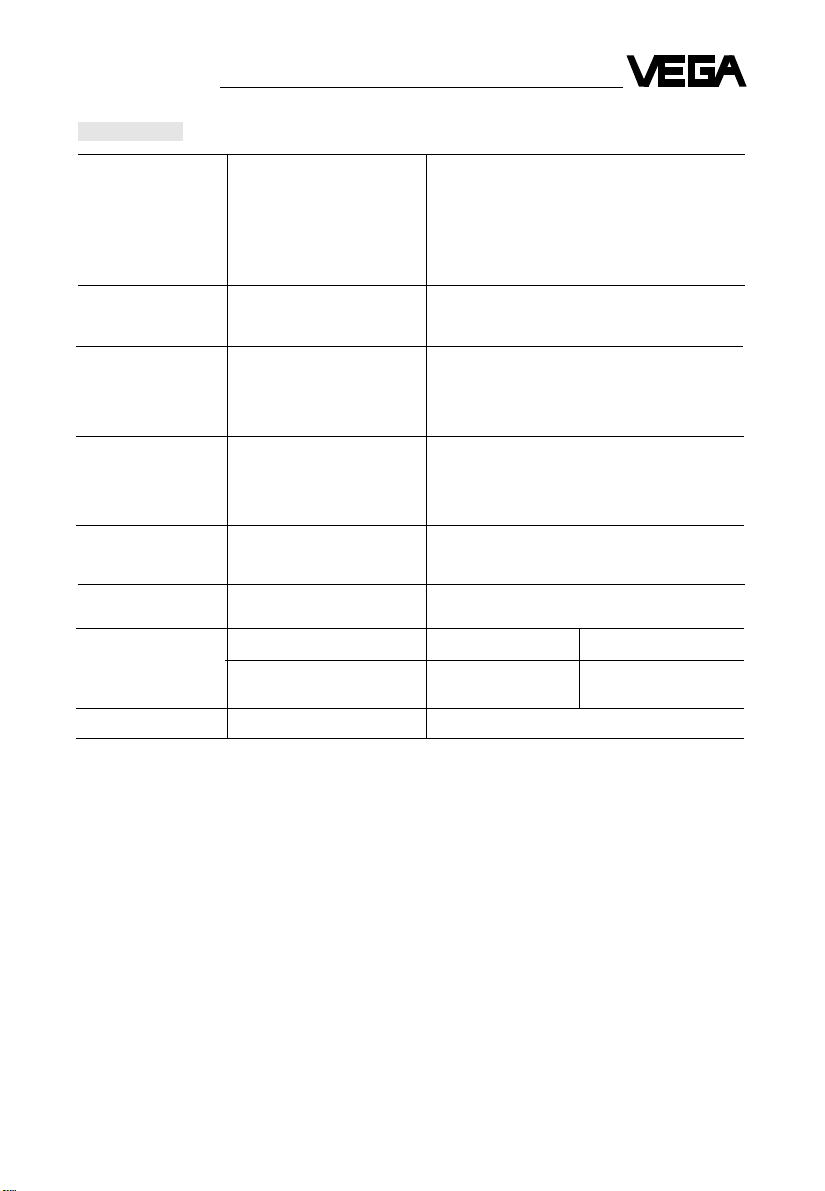

Inputs Central electronics Outputs

Measuring data of

transducer 1

channel 1

Measuring data of

transducer 2

channel 2

Multi function indicator

Module for relay output 1 and 2

Module for relay output 3 and 4

Module for current output 1 and 2

0 … 20 mA

Fail safe relay and

fail safe-LEDs

4

1

1 2 3

2

VEGASON

Central electronics consists of:

- plastic housing with cover and integral

- operating elements (5 buttons)

- diodes (LED-indication)

- two multi function indications (LC-displays)

- power supply

- memory (EEPROM, no buffer battery required)

- outputs as modules (see above)

- terminals for power supply, inputs and outputs

Further instruments (option):

- indicating instrument VEGADIS 171 A

(connection to 0 … 20 mA)

- overvoltage arrester

Transducer

Page 6

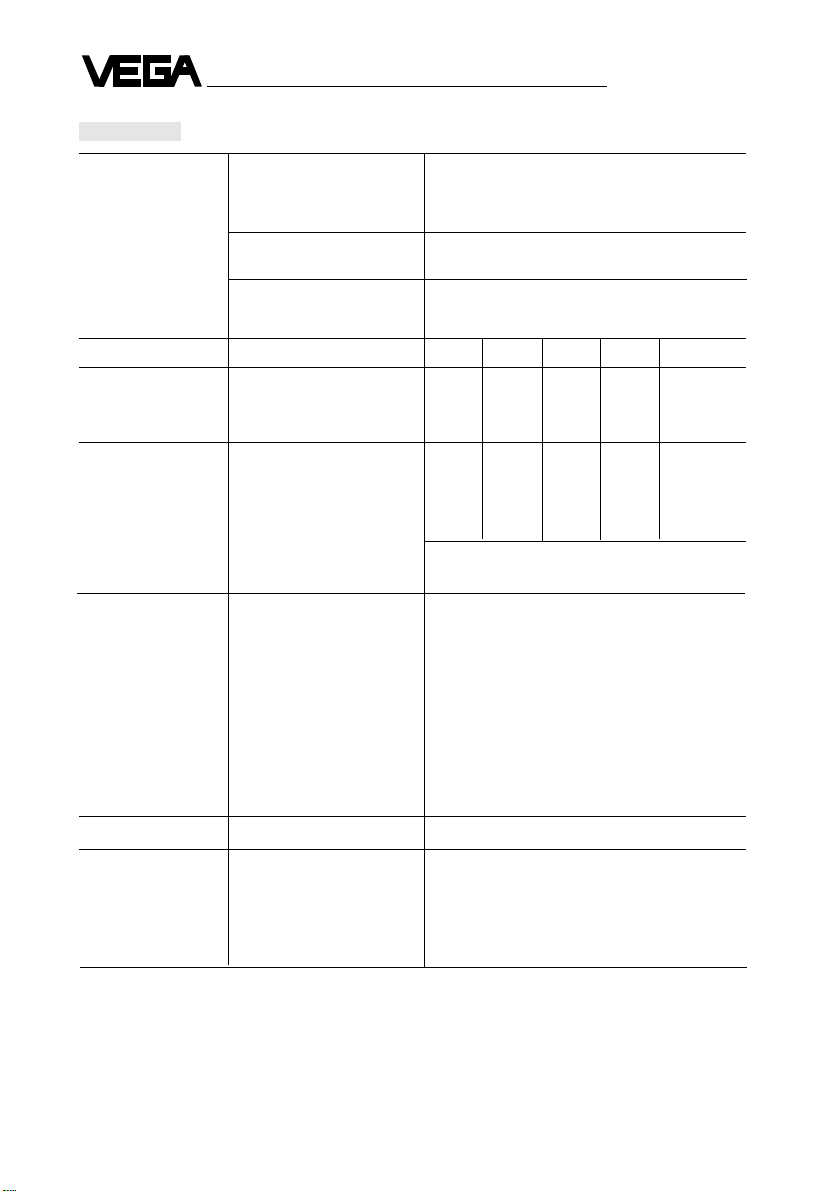

Technical data

Power supply operating voltage

standard U

nenn

= 24 V AC (16 … 42 V), 50 / 60 Hz

= 24 V DC (16 … 60 V)

option U

nenn

= 230 V AC (90 … 250 V), 50 / 60 Hz

power consumption

at U

nenn

and at max. load 12 VA / 5 W

fuse

for version 16 … 42 V AC or 16 … 60 V DC = 2 A

for version 90 … 250 V AC = 500 mA

Type VEGASON 71 - 2 72 - 2 73 - 2 74 - 2 75 - 2

Minimum distance at liquids or 0,3 m 0,5 m –– –– ––

solids particle size ≥ 5 mm –– –– 0,8 m 0,8 m 1,0 m

particle size ≤ 5 mm –– –– 1,0 m 1,1 m 1,2 m

Maximum distance product and process dependent 5 m 5 m 10 m 20 m 30 m

Input data min. measuring distance 10 cm 10 cm 10 cm 10 cm 10 cm

display in mm cm cm cm cm

scanning 3 mm 3 mm 3 mm 3 mm 3 mm

measuring frequency 50 kHz 40 kHz 33 kHz 22 kHz 16 kHz

measuring rate 0,4 sec. 0,4 sec. 0,4 sec. 0,5 sec. 0,7 sec.

angle of reflection at –3 dB) 7° 9° 12° 12° 12°

linearity error acc. to

empty / full adjustment < 0,1 % of measuring range

temperature error of electronics 0,1 % / 10 k of measuring range

Sensor data number of transducer 2

transducer housing PVDF

impedance adapter PE

mounting tube type 71 … 73 PVDF, thread 1" BSP

type 74 and 75 RCH 1000, thread 1" BSP

temperature sensor integrated in transducer

permissible excess pressure

in the vessel

- transducer 71 … 75 max. 1 bar

- transducer 71 R … 73 R max. 1 bar

connection cable coax line type RG 58

line length standard 5 m

maximum 300 m

cable diameter approx. 5 mm

Indication LC-display 2, 4-digits each

Relay output max. 2 modules 2 relay 1 spdt per relay each

contact material AgCdO and Au plated

min. turn-on voltage 10 mV

switching current 10 µA

max. turn-on voltage 250 V AC, 60 V DC

switching current 2 A AC, 1 A (DC)

max. breaking capacity 125 VA, 60 W

Technical Information

6 71 - 2 … 75 - 2

Page 7

Current outputs module - with 2 outputs

- range 0/4 … 20 mA

- resolution 0,05 % of range

- load max. 500 Ohm

- load dependent

failure at 0 … 500 Ohm, < 0,2 % related to the range

or

module - as above however with 2 floating outputs each

Fail safe function 1 relay for both channels 1 spdt

contact data as described under relay outputs

2 fail safe-LEDs separately per channel

Ambient ambient temperature on

conditions - transducer 71 … 75 –20°C … +80°C / -4 … 176°F

- transducer 71 R … 73 R –20°C … +55°C / -4 … 131°F

- central electronics –20°C … +60°C / -4 … 140°F

storage and transport temperature –20°C … +80°C / -4 … 176°F

Environmental protection

protection - transducer 71 … 75 IP 68

- transducer 71 R … 73 R IP 68

- housing of central electronics IP 65

protection class II

Electrical terminals for max. 1 x 1,5 mm

2

connection cable entry 2 x Pg 7

1 x Pg 13,5, max. 5 x Pg 13,5

Material transducer PVDF

housing of central electronics Polycarbonate

Weight VEGASON 71 … 73 74 and 75

1 transducer (without cable) approx. 0,8 kg approx. 1,5 kg

central electronics approx. 1,9 kg approx. 1,9 kg

Dimensions see dimensional drawing on following page

Technical Information

71 - 2 … 75 - 2 7

Technical data

(continuation)

Page 8

Technical Information

8 71 - 2 … 75 - 2

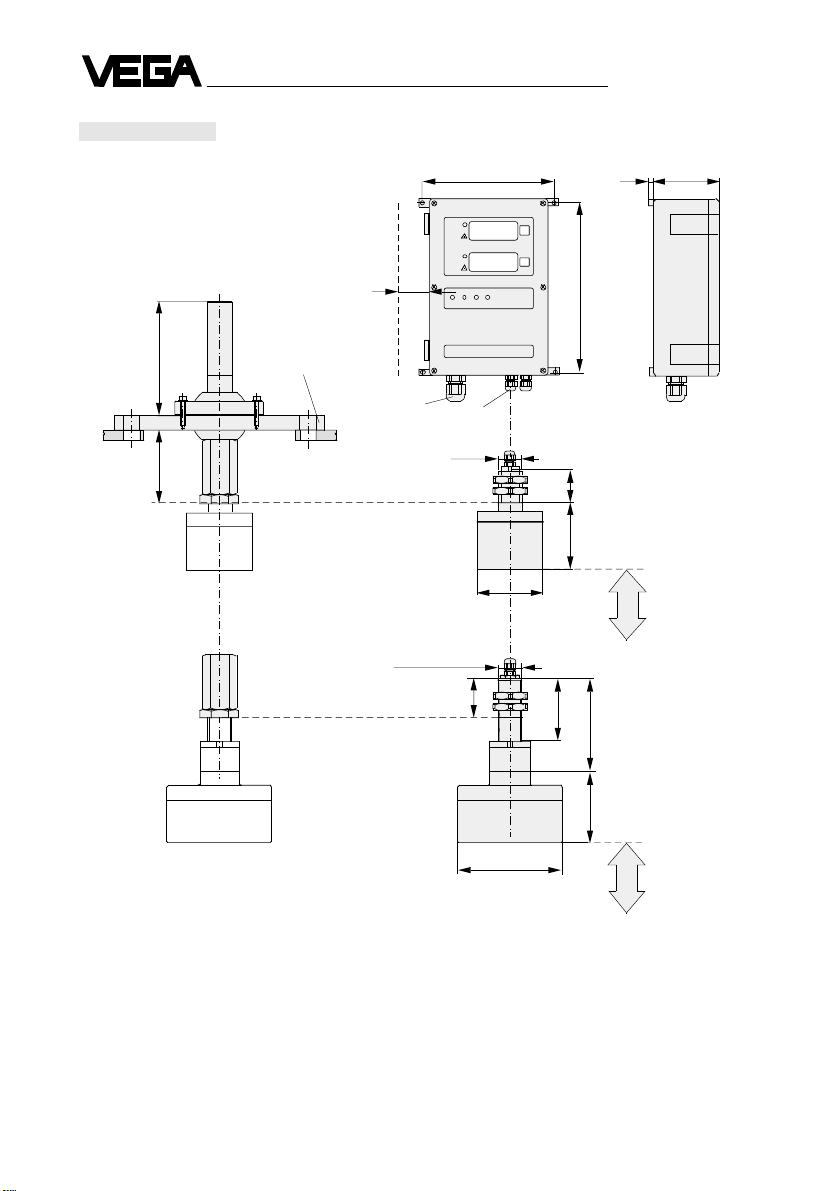

Dimensional drawing

(dimensions in mm)

411 2 3

2

VEGASON

*174

* Mounting dimensions

45

91

90

*229

Min. distance for

further instruments

40

5

ø95

appr. 100

Flange

DN 150

PN 16

appr. 155

133

93

ø145

Sensor

SW 72 / 73

Pg 13,5

Pg 7

Central electronics

G 1 A

Thread

1" BSP

0,5…0,8 m

90

0,8…1,2 m

Sensor

SW 74 / 75

54

Flanged

gimbal

Min. distance

Min. distance

Sensor SW

71 … 73

71 R … 73 R

Page 9

Technical Information

71 - 2 … 75 - 2 9

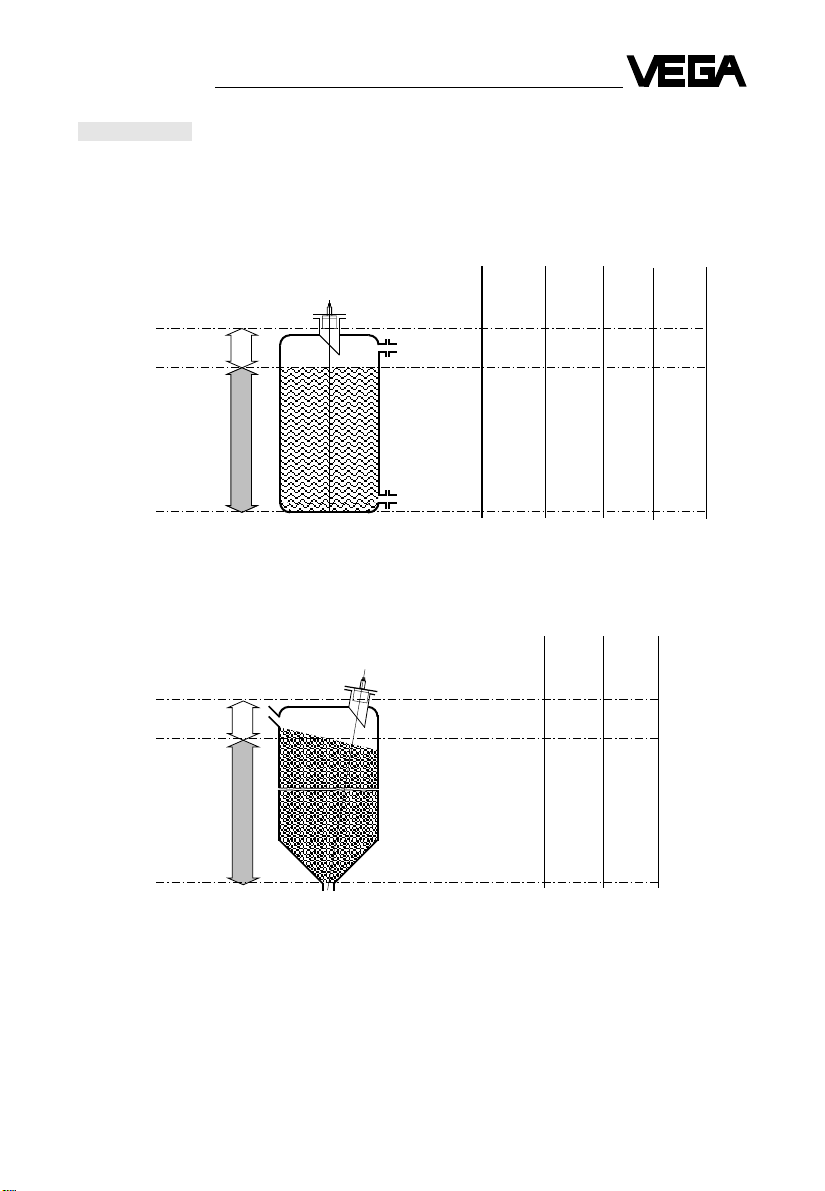

Measuring range

The measuring ranges described below are max.

values and can change dependent on process

conditions.

The location of the sensors should be carefully

selected and it should be noted that no struts,

edges or material inflow impede the measurement

(see installation recommendations page 10

and 11).

for liquids

VEGASON 71 - 2 72 - 2 73 - 2 74 - 2 75 - 2

Reference pane

Min.

distance 0,3 m 0,5 m 0,8 m 0,8 m 1,0 m

Measuring

range

5 m 5 m 10 m 20 m 30 m

for solids

VEGASON 73 - 2 74 - 2 75 - 2

Reference pane

Min.

distance particle size≥ 5 mm 0,8 m 0,8 m 1,0 m

particle size≤ 5 mm 1,0 m 1,1 m 1,2 m

Measuring

range

10 m 20 m 30 m

Page 10

Technical Information

10 71 - 2 … 75 - 2

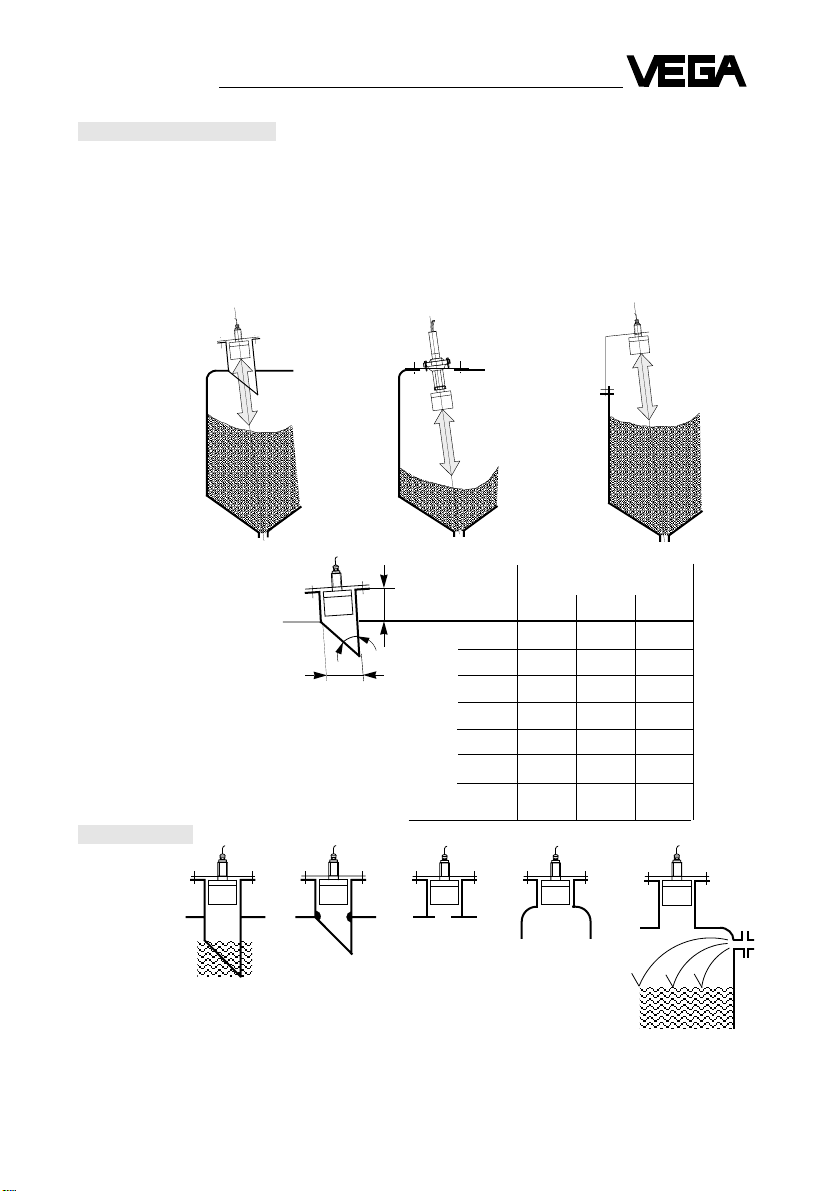

Installation example for liquid tanks

- Select sensor type and installation in relation to

max. level to be measured.

- Protect the inner side of the socket piece for

corrosion or use non-corrosive material.

- In case of round tank ceilings, the sensor should

be installed on a socket piece not located in the

centre or on an opening (on half radius).

In closed vessels:

Tube or direct mounting. If socket

piece length > 100 mm or for

VEGASON 72 / 73 or > 150 mm for

VEGASON 74 / 75 are required

(max. level). Note the dimensions

in the following table.

in open vessels: Mounting via

Mounting by means access hatch:

of bracketry Simple direct mounting

Max. socket piece length L at:

(dimensions in mm)

VEGASON 71 - 2 72 - 2 73 - 2 74 - 2 75 - 2

at socket 100 300 400 400 ––– –––

piece ø

150 300 500 400 300 300

200 ––– ––– 500 400 400

250 ––– ––– 600 500 500

300 ––– ––– ––– 600 600

350 ––– ––– ––– 700 700

Min. distance 300 500 800 800 1000

L

ø

45°

Socket piece length

Page 11

Technical Information

71 - 2 … 75 - 2 11

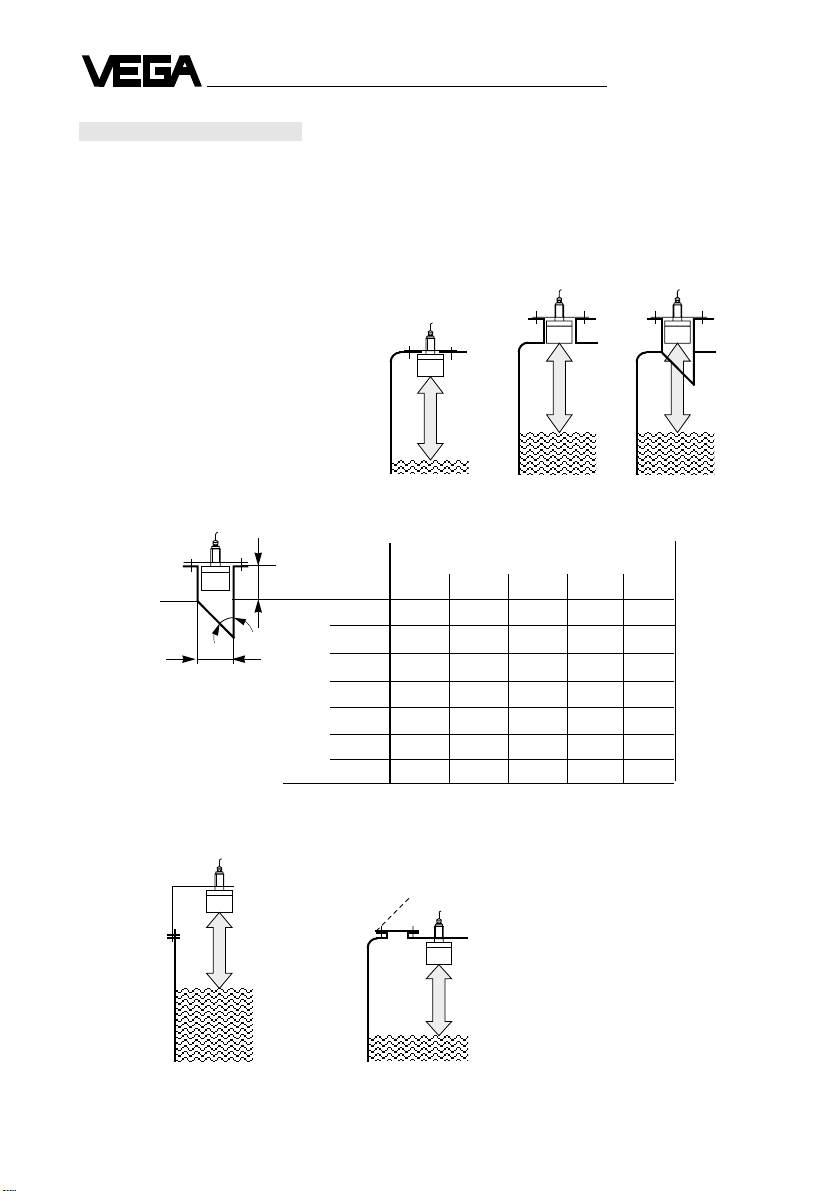

Installation examples for solids

- Select sensor type and installation in relation to

max. level to be measured.

- Protect the inner side of the socket piece from

corrosion or use non-corrosive material.

- Always direct the sensor (sound pulse) to the

centre of the silo.

- Install sensor as far as possible from the filling

entry.

- When using round ceilings, mount the sensor

half way between silo middle and edge.

Installation with cylindrical

socket piece

Installation with flanged

gimbal

Installation in open silos via

bracketry

socket piece length L at:

(dimensions in mm)

VEGASON 73 - 2 74 - 2 75 - 2

at socket 100 400 ––– –––

piece ø

150 400 300 300

200 500 400 400

250 600 500 500

300 ––– 600 600

350 ––– 700 700

Min. distance 800 … 800 … 1000 …

1000 1100 1200

Installation errors

(at tanks or silos)

L

45°

ø

The socket piece

should not be

covered by the

product.

The socket piece

should not have

weldment joints.

Access too small. Socket pieces in

the centre of

round tank ceilings

are not recommended for the

sensor installation.

The beam should

not cross the

material inflow.

Page 12

2

1

3

4

5

91011

12

13 14

21 22

23

15 16

17

18

19

20

24

+ - + -

6

7

8

Fail safe relay output

Supply voltage

Service socket

1

2

Service

switch

1…………2 …………… 3………...4

Relay output

1………2

Current output

respective max.

line length = 300 m

Sensor 1 Sensor 2

Channel 1

Channel 2

Technical Information

12 71 - 2 … 75 - 2

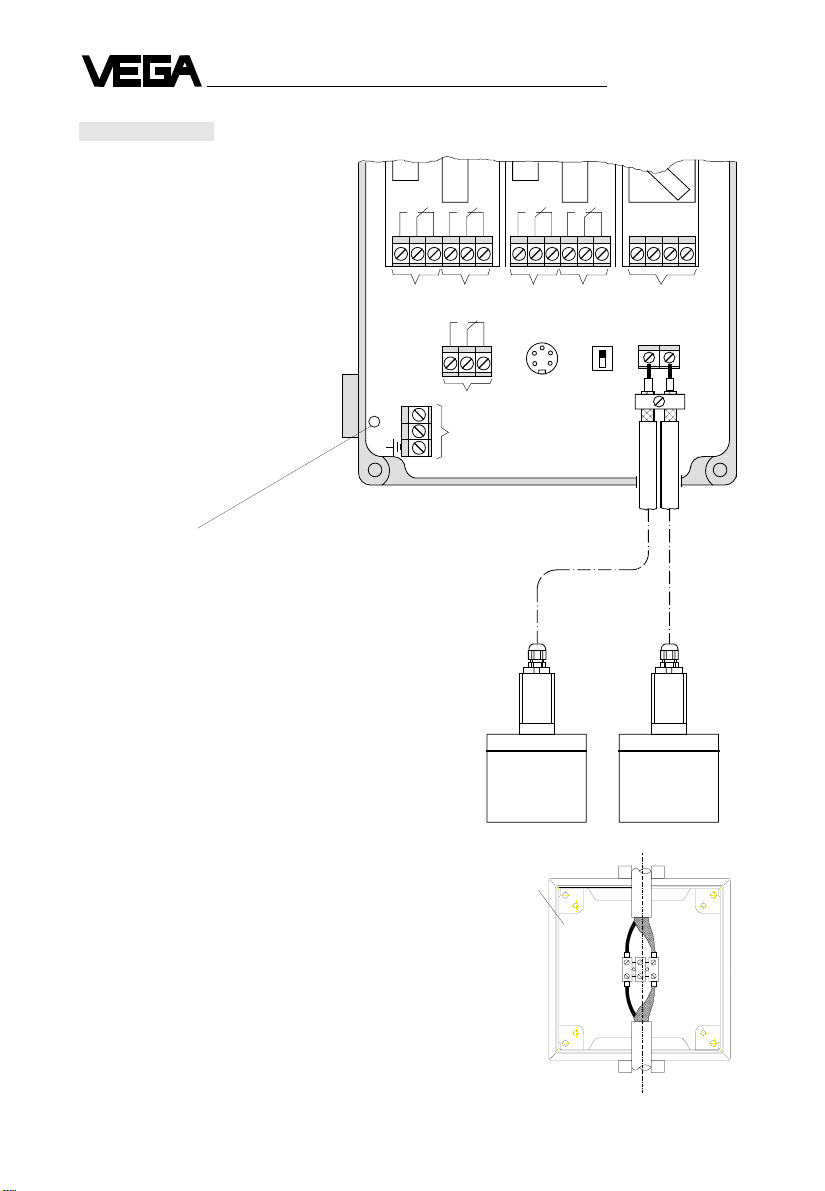

Electrical connection

Note:

During operation the transducer is pulsed with high

voltages. It is therefore recommended that first all

electrical connections are provided and then the

power supply for the instrument switched on.

Attention!

Fuse

Type TR5

Manufacturer e.g. Messrs. Wickmann

Current values see technical data page 6

The connection line to the respective sensors can

be extended afterwards as shown.

If must be observed that the max. line length of

300 m is not exceeded.

Standard

waterproof

dividing box

Page 13

Operating surface

71 - 2 … 75 - 2 13

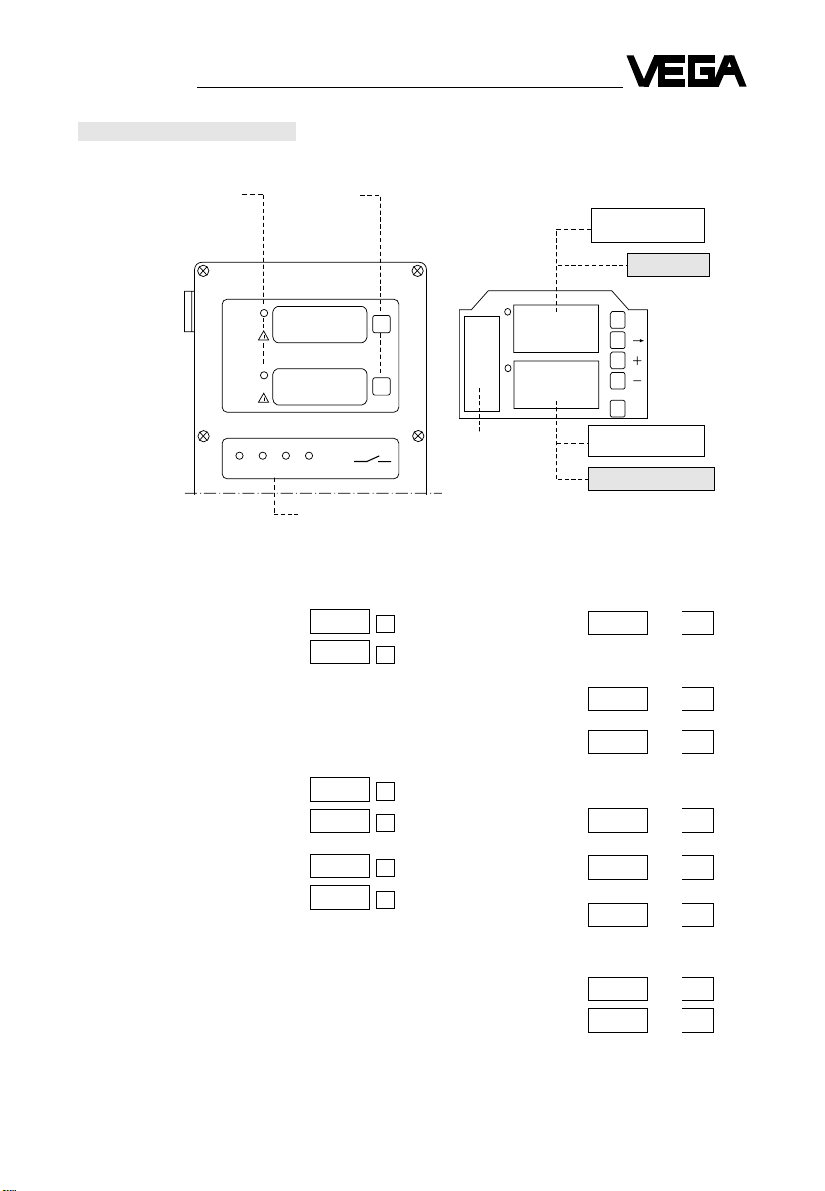

Indication and operating elements

Outer view Inner view

Indication of measured values

5.00 m

e.g. level 1 … 9 m

5.00 m

Demonstration form after

programming of - multiplier

- allocation of decimal point

- decimal point e.g.

50.0 %

level 0 … 100 %

5.00 %

2000 hl

level 0 … 4000 hl

2000 hl

Mode range

general reset 0 - 00 … 99

sensor optimization 1 1 - 01 … 27

sensor optimization 2 2 - 01 … 27

linearization curve 4 4.H.01 … 32

linearization curve 5 5.H.01 … 32

linearization curve 6 6.H.01 … 32

fault signals

channel 1 E2.01 … .04

channel 2 E2.01 … .04

4

1

1 2 3

2

1

MOD

STO

2

MODEFIELD

Indication of

measured values 1

PARAMETER FIELD

Indication of

measured values 2

8888

8888

8888

8888

LED-indication of

relay outputs 1…4

Operating

scheme

LED-indication

fault signal

channel 1 and 2

Units indicator

visible in slot

behind window

Selection of

mode

Cursor position

Figures raise

Figures lower

Storage

Page 14

Operating surface

14 71 - 2 … 75 - 2

The VEGASON 71 - 2 … 75 - 2 has 3 modes which

can be accessed (scrolling) via the MOD-button:

Mode: 1. indication of measured values

2. mode range

3. parameter input

If no push button is used for a 60 minutes period,

the VEGASON 71 - 2 … 75 - 2 times out and

reverts to the input value display.

Operating

In mode 99 the main stage 0 can be left and stage

1 and 4 … 6 can be selected. The reset to main

stage 0 is done in the respective mode 99.

During a parameter adjustment the last mode

number used is activated again after each STOcommand and entry to the mode range.

Indication of measured

values:

level in m

level in %

and acc. to the demonstration form e.g.

quantity in hl.

For selection of the mode

numbers see

MODEFIELD. The parameters of the selected

mode numbers can be

checked or modified in

mode 3.

Programming of parameters see PARAMETER

FIELD. The parameters of

the selected mode can be

modified and stored with

STO-button. With STO

reset to mode 1.

MOD

MOD

+

-

MOD

STO

+

-

Cursor position

Figures raise

Figures lower

Cursor position

Figures raise

Figures lower

5.00

5.00

0 00000

16.93

0 99

0 - 00

– – – –

0

1. Indication

of

measured

values

2. Mode range

3. Parameter

adjustment

Page 15

Start-up

71 - 2 … 75 - 2 15

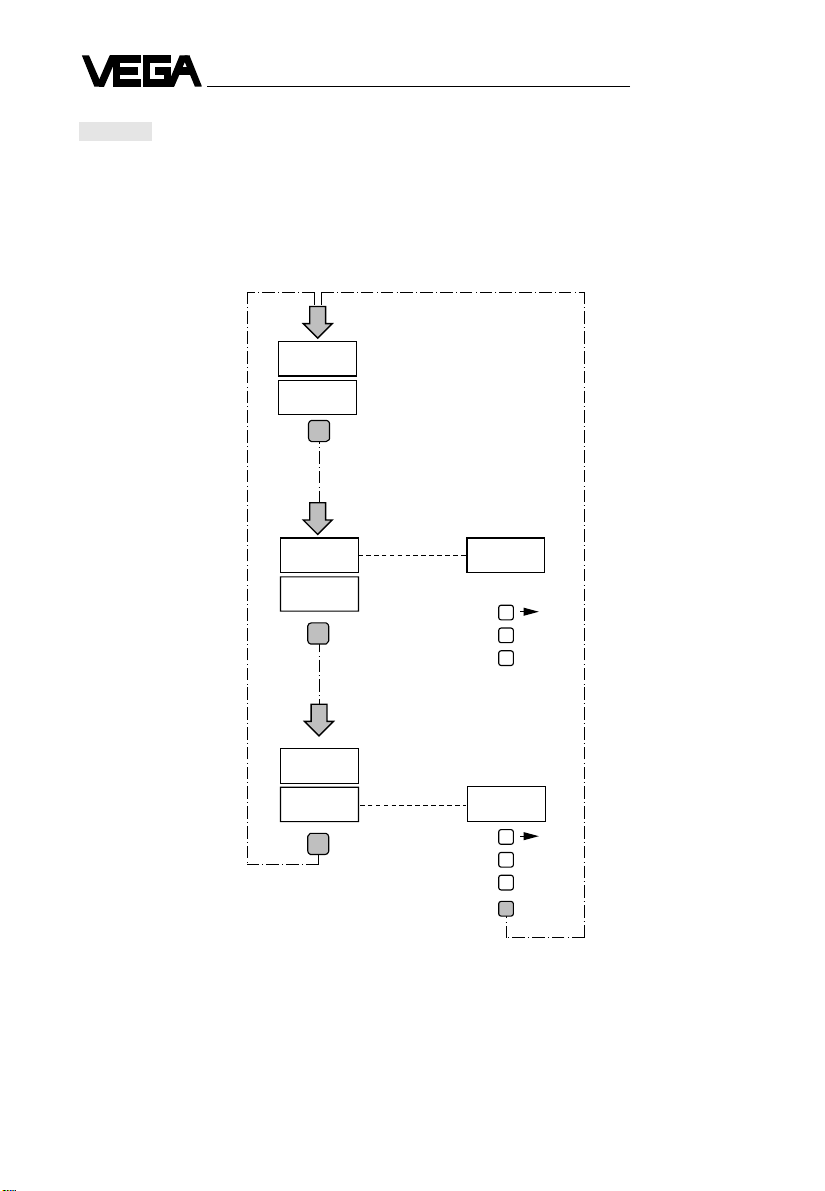

Flow diagram for start-up

Connect sensors with central electronics

and supply with operating voltage.

The software version is indicated and the

fault signal reacts.

The measuring system is now ready and

starts for each separate channel with the

commissioning preliminary indication: 0.00 m.

Commissioning, i.e.:

1. Echo limitation from top to bottom.

2. Echo limitation from bottom to top.

3. Formation of a measuring window within

which an evaluation of the echo is carried

out.

After approx. 1 … 3 minutes the measuring

system is ready. The fault signal extinguishes. The sensors 1 and 2 adapted to

the vessel feature and operate with the

parameters of the VEGA-adjustments.

Level measurement 1

Level measurement 2

Sensor 2 determines in vessel 2 the actual

distance of 9,50 m

Sensor 1 determines in vessel 1 the actual

distance of 9,20 m

Optimizations are necessary for sensor 1

and / or sensor 2

NO

YES

?

!

!

1

2

5 6

4

14.94

!

!

1

2

5 6

4

9.20

9.50

0.00

0.00

m

m

m

m

Page 16

Start-up

16 71 - 2 … 75 - 2

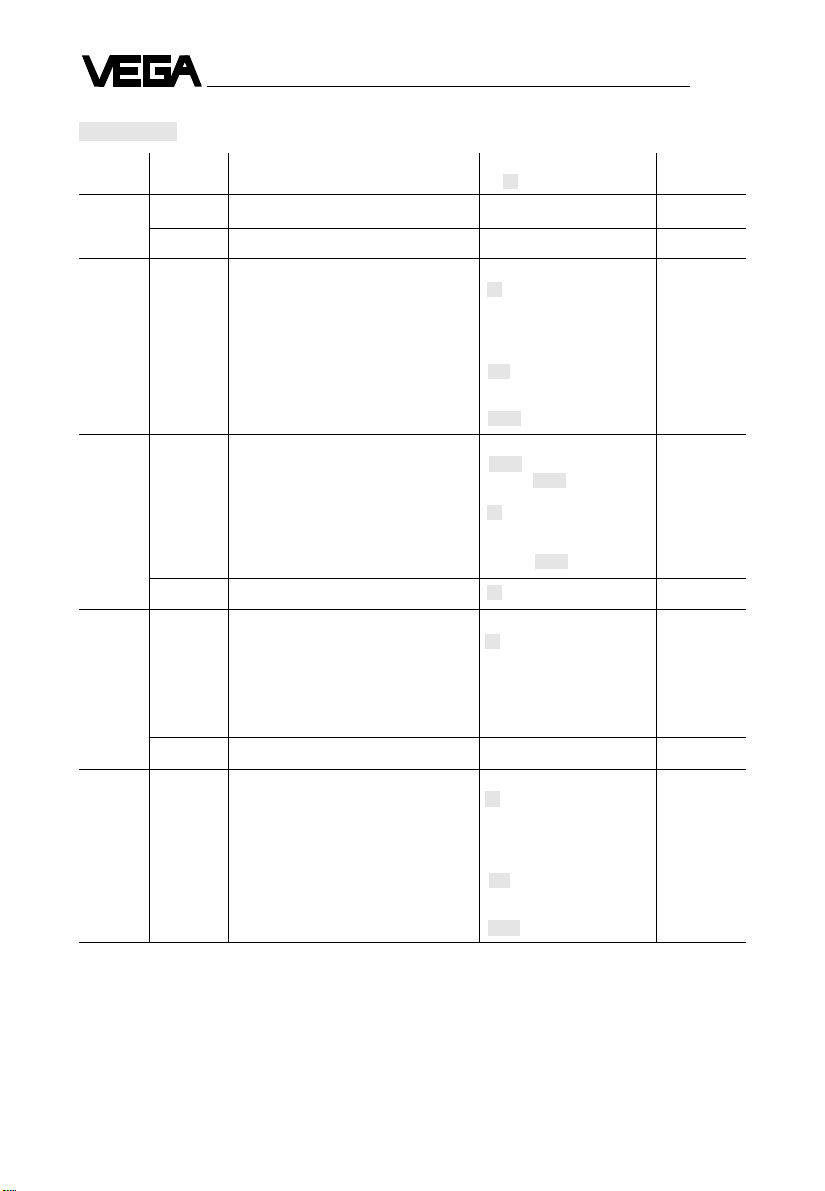

Mode listing 0

Function Mode-no. Mode description Parameter Page

( = factory preset)

0 - 00 Software version ........................................ e.g. 16.93

0 - 01

… 09 not used ..................................................... – – – –

Adjustment 0 - 10 Selection of adjustment procedure

channel 1

- in m without level change ....................... 1

- per cent correction .................................. 2

- in % with level change ........................... 3

0 - 11

Empty adjustment

- distance in m........................................... sensor specific p. 20

- level in % ................................................ 0.0 … 80.0

0 - 12

Full adjustment

- distance in m........................................... sensor specific

- level in % ................................................ 100.0 … 20.0

Display Multiplier

function 0 - 13 - related to 0 % ......................................... 0000 … 9999

0 - 14 - related to 100 % ..................................... 0000 … 1000 … 9999

0 - 15 Measuring unit

- level percentage in m ............................. 1 p. 29

- level percentage in % ............................. 2

- volume percentage (scaled) ................... 3

0 - 16 Decimal point............................................ 0.000 … 000.0 … 0000

0 - 17 Integration time ........................................ 0 … 900

Lineari- 0 - 18 Linearization curves

zation - linear ...................................................... 1

- cylindrical tank ........................................ 2

- not used ................................................. 3 p. 24

- individually programmable curve 4 ......... 4

- individually programmable curve 5 ......... 5

- individually programmable curve 6 ......... 6

0 - 19 not used ..................................................... – – – –

Adjustment 0 - 20 Selection of adjustment procedure

channel 2 - in m without level change ....................... 1

- per cent correction ................................. 2

- in % with level change ........................... 3

0 - 21 Empty adjustment

- distance in m........................................... sensor specific p. 20

- level in % ................................................ 0.0 … 80.0

0 - 22 Full adjustment

- distance in m........................................... sensor specific

- level in % ................................................ 100.0 … 20.0

general parameters

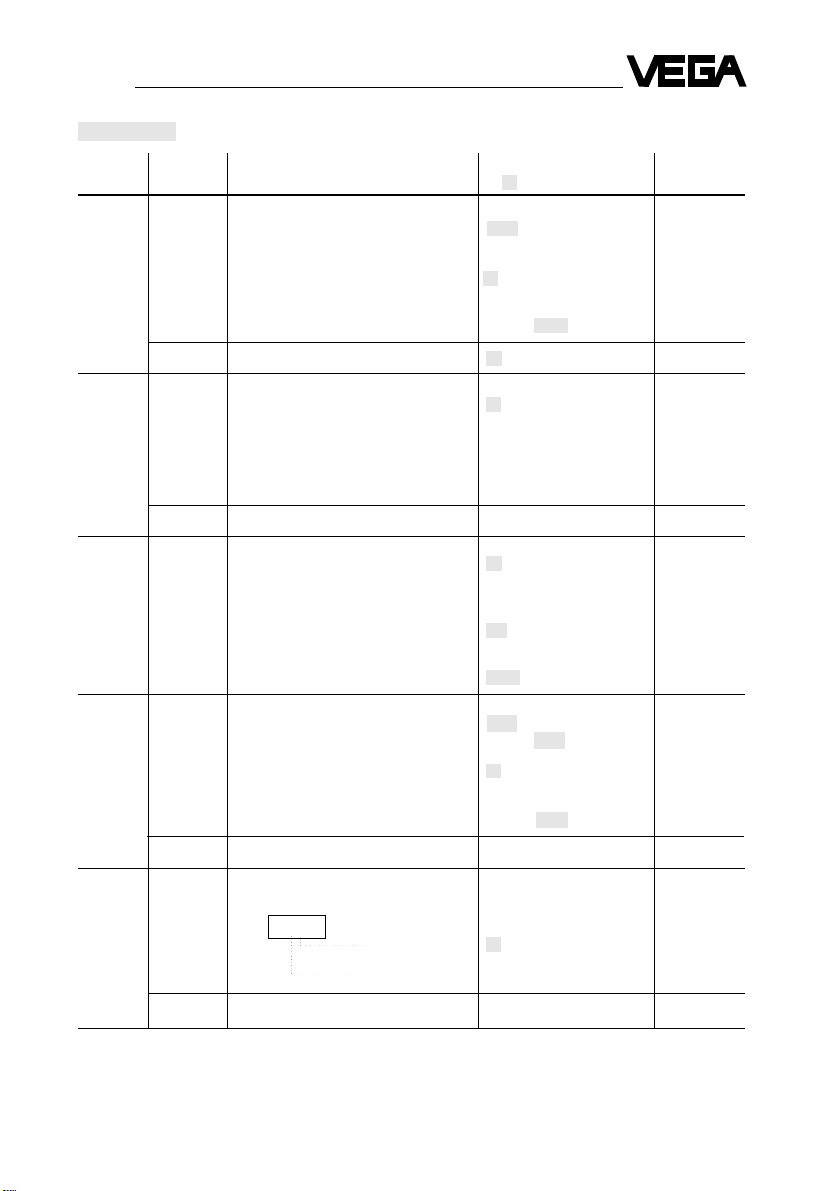

Page 17

Start-up

71 - 2 … 75 - 2 17

Mode listing 0 general parameters

Display Multiplier

function 0 - 23 - related for 0 % ........................................ 0000 … 9999

0 - 24

- related for 100 % .................................... 0000 … 1000 … 9999

0 - 25

Measuring unit

- level percentage in m ............................. 1 p. 29

- level percentage in % .............................

2

- volume percentage (scaled) ................... 3

0 - 26 Decimal point ........................................... 0.000 … 000.0 … 0000

0 - 27 Integration time ........................................ 0 … 900

Lineari- 0 - 28 Linearization curves

zation - linear ...................................................... 1

- cylindrical tank ........................................ 2

- not used ................................................. 3 p. 24

- individually programmable curve 4 .........

4

- individually programmable curve 5 ......... 5

- individually programmable curve 6 ......... 6

0 - 29 not used ..................................................... – – – –

Adjustment 0 - 30 Selection of adjustment procedure

differential - in m without level change ....................... 1

measure- - percent correction .................................. 2

ment 0 - 31 Adjustment min. difference

- in m ......................................................... sensor specific p. 22

- percent correction .................................. 0.0 … 80.0

0 - 32 Adjustment max. difference

- in m ......................................................... sensor specific

- percent correction .................................. 100.0 … 20.0

Display Multiplier

function 0 - 33 - related to 0 % ......................................... 0000 … 9999

0 - 34 - related to 100 % ..................................... 0000 … 1000 … 9999

0 - 35 Measuring unit

- level percentage in m ............................. 1 p. 29

- level percentage in % ............................. 2

- volume percentage (scaled) ................... 3

0 - 36 Decimal point ........................................... 0.000 … 000.0 … 0000

0 - 37 … 39 not used ..................................................... ––––

Display 0 - 40 Display coordination

1 1 0 = inactive p. 22

Display 2 1 = level indication

(channel specific)

Display 1

2 = differential indication

0 - 41 u. 42 not used ..................................................... – – – –

Function Mode-no. Mode description Parameter Page

( = factory preset)

(continuation)

Page 18

Start-up

18 71 - 2 … 75 - 2

Mode listing 0 general parameters

Function Mode-no. Mode description Parameter Page

( = factory preset)

(continuation)

Relay 0 - 43 Coordination

output 1 - channel 1 ................................................ in m = 1 in % = 2

- channel 2 ................................................ 34

- difference ............................................... 56p. 31

0 - 44 Mode

- two-point level switch ............................. 1

- pump function switch .............................. 2

- tendency determination raising .............. 3

- tendency determination lowering ........... 4

0 - 45 Switching 1 (on) ............................. sensor specific

0 - 46 command 2 (off) ............................. sensor specific

0 - 47 Indication of running period ....................... indication in 10 h-units

Relay 0 - 48 Coordination

output 2 - channel 1 ................................................ in m = 1 in % = 2

- channel 2 ................................................ 34

- difference ............................................... 56p. 31

0 - 49 Mode

- two-point level switch ............................. 1

- pump function switch .............................. 2

- tendency determination raising .............. 3

- tendency determination lowering ........... 4

0 - 50 Switching 1 (on) ............................. sensor specific

0 - 51 command 2 (off) ............................. sensor specific

0 - 52 Indication of running period........................ indication in 10 h-units

Relay 0 - 53 Coordination

output 3 - channel 1 ................................................ in m = 1 in % = 2

- channel 2 ................................................ 34

- difference ............................................... 56p. 31

0 - 54 Mode

- two-point level switch.............................. 1

- pump function switch .............................. 2

- tendency determination raising .............. 3

- tendency determination lowering ........... 4

0 - 55 Switching 1 (on) ............................. sensor specific

0 - 56 command 2 (off) ............................. sensor specific

0 - 57 Indication of running period ....................... indication in 10 h-units

Relay 0 - 58 Coordination

output 4 - channel 1 ................................................ in m = 1 in % = 2

- channel 2 ................................................ 34

- difference ............................................... 56p. 31

0 - 59 Mode

- two-point level switch ............................. 1

- pump function switch .............................. 2

- tendency determination raising .............. 3

- tendency determination lowering ........... 4

0 - 60 Switching 1 (on) ............................. sensor specific

0 - 61 command 2 (off) ............................. sensor specific

0 - 62 Indication of running period ....................... indication in 10 h-units

0 - 63 Interval time for pump function .................. 0000 … 9999 p. 34

Page 19

Start-up

71 - 2 … 75 - 2 19

Mode listing 0 general parameters

Function Mode-no. Mode description Parameter Page

( = factory preset)

(continuation)

Current 0 - 64 Coordination - channel 1 ..................... 1

output 1 - channel 2 ..................... 2

- difference ..................... 3 p. 37

0 - 65 Charac- - end ............................... 20.00 … 00.00

0 - 66

teristics - start .............................. 00.00 … 04.00 … 20.00

0 - 67

not used ..................................................... – – – –

Current 0 - 68 Coordination - channel 1 ..................... 1

output 2 - channel 2 ..................... 2

- difference...................... 3 p. 37

0 - 69 Charac- - end................................ 20.00 … 00.00

0 - 70

teristics - start .............................. 00.00 … 04.00 … 20.00

0 - 71 … 92 not used ..................................................... – – – –

0 - 93 Fault signal processing

store actual current

1 1 1 switching relay p. 38

difference unchanged = 1

channel 2 current 0 mA

channel 1 switching relay

de-energizes = 2

current goes to 0 %

switching relay

de-energizes = 3

current goes to 100 %

switching relay

de-energizes = 4

0 - 94 Simulation - channel 1

0 - 95 - channel 2 sensor specific in m p. 39

0 - 96 - difference

0 - 97 Basic - switched off .................. 0 p. 40

adjustment - switched on .................. 1

0 - 98 Keyword - switched off ................... 0 p. 40

- switched on .................. 1

0 - 99 Change - general parameter ................ 0

- sensor optimization 1 ........... 1

- sensor optimization 2 ........... 2 p. 41

- linearization curve 4 ............. 4

- linearization curve 5 ............. 5

- linearization curve 6 ............. 6

Page 20

Adjustment at level measurement

20 71 - 2 … 75 - 2

Level measurement

Two separate level measurements can be obtained

with the VEGASON 71 - 2 … 75 - 2 (measuring

system).

The adjustment is carried out for

- level measurement 1 = measuring channel 1

in mode range no. 10 … 12

- level measurement 2 = measuring channel 2

in mode range no. 20 … 22

The adjustment procedures are carried out separately for each sensor.

The display coordination is programmable and

supplied as factory preset in mode 40 as follows:

0 – 4 0

1 1

level 2 (display 2)

level 1 (display 1)

Selection of adjustment procedure

The type of empty adjustment (mode 11) and full

adjustment (mode 12) is determined with the parameter adjustment of this mode.

The type of adjustment depends on the local

conditions.

Mode description

Mode 10 = 1 means adjustment in m without product level change, i.e.

- with this adjustment procedure the distances in m determined from the vessel drawings

are programmed relating to the levels 0 % and 100 %

- level is not important

Mode 10 = 3 means adjustment in % without product level change, i.e.

- with this adjustment procedure the levels are programmed in % and the respective

measured distance (sensor … level) is calculated automatically

- product level change is needed.

Programming example

Change of mode 10 = 3 of mode 10 = 1 .................. • select mode 0 - 10 in MODEFIELD

• program figure1 in PARAMETER FIELD

• then store with STO-button

Same procedure for channel 2, however mode 0 - 20.

Demonstration

Mode 10 = 1 Mode 10 = 3

Min. distance

^ 100 %

partly filling

= e.g. 75 %

partly emptying

= e.g. 25 %

Max. distance

^0 %

MODE 0 - 10

Page 21

Adjustment at level measurement

71 - 2 … 75 - 2 21

Empty / full adjustment in m without product level change

Programming pre-requirement

Mode 10 = 1

Mode 40 = 11

With this adjustment procedure two distances

(sensor … product surface) are defined in m

relating to the levels of 0 % and 100 %.

MODE 0 - 11 and 0 - 12

Programming example with VEGASON 73 - 2 (individual programming sequence of the empty /

full adjustment)

• select mode 0 - 12 in MODEFIELD

• program 01.00 m in PARAMETER FIELD

• then store with STO-button

• select mode 0 - 11 in MODEFIELD

• program 09.00 m in PARAMETER FIELD

• then store with STO-button

Empty / full adjustment in % with product level change

Programming pre-requirement

Mode 10 = 3

Mode 40 = 11

MODE 0 - 11 and 0 - 12

Programming example with VEGASON 73 - 2 (individual programming sequence of the empty /

full adjustment)

• select mode 0 - 12 in MODEFIELD

• program 075.0 % in PARAMETER FIELD

• then store with STO-button

• select mode 0 - 11 in MODEFIELD

• program 025.0 % in PARAMETER FIELD

• then store with STO-button

With this adjustment procedure two levels are

defined in % relating to two different, actually

measured distances (sensor … product surface).

The difference should be as large as possible. The

central electronics determines the adjusted range

(e.g. 25 … 75 %) from the total range (0 … 100 %).

Same procedure for channel 2, however

mode 0 - 21 and 0 - 22.

1

distance

9

100

m0%

0

25

50

75

5

7

3

1 m distance

^ 100 %

9 m distance

^0 %

19100

0

25

50

75

5

7

3

measured

distance

^ 75 %

measured

distance

^ 25 %

m0%

level

distance level

Page 22

Adjustment at differential measurement

22 71 - 2 … 75 - 2

Differential measurement

A differential measurement can be obtained with

the measuring system VEGASON 71 - 2 … 75 - 2.

The difference is formed out of the values of channel 2 minus channel 1. If possible, mount the

sensors at the same height.

The adjustment is made for both measuring channels together in mode range no. 30 … 32.

It is possible to adjust channels 1 and 2 separately

as described under level measurement.

The display coordination is defined as follows in

mode 0 - 40:

0 - 4 0

1 1

0 = display 2 switched off

1 = display 2 indicates level

of channel 2

2 = display 2 indicates difference

0 = display 1 switched off

1 = display 1 indicates level

of channel 1

2 = display 1 indicates difference

The pre-adjustment 1 for mode 0 - 30 should not be

changed.

Mode description

Mode 0 - 30 = 1 mean adjustment in m without product level change, i.e.

- with this adjustment procedure various differences (levels, gauges etc.) are

programmed relating to the values 0 % and 100 %

- already available levels or water gauges are unimportant

Selection of adjustment procedure MODE 0 - 30

MODE 0 - 40

Programming example

for - differential level on display 1

- level 2 (downstream water) on display 2 ....... • select mode 0 - 40 in MODEFIELD

• program figure 21 in PARAMETER FIELD

• then store with STO-button

Page 23

Adjustment at differential measurement

71 - 2 … 75 - 2 23

Differential adjustment in m without differential measurement

Programming as pre-requirement

Mode 30 = 1

Mode 40 = 21 or 12, display coordination

With this adjustment procedure two differences

in m are defined, relating to the values of 0 % and

100 %.

MODE 0 - 31 and 0 - 32

Programming example 1

with VEGASON 71 - 2 mounted at the same height

for weir control.

(Individual programming sequence of the min. /

max. difference)

• select mode 0 - 31 in MODEFIELD

• program 00.00 m in PARAMETER FIELD

• then store with STO-button

• select mode 0 - 32 in MODEFIELD

• program 01.00 m in PARAMETER FIELD

• then store with STO-button

The level difference can occur within the whole

range (in the example e.g. 0 … 5 m) and can be

detected.

Programming example 2 as above, however

sensors mounted at different height

program 0 m + 0,5 m = 0,5 m respective 0 %

in mode 31 = 00.50 m

program 1 m + 0,5 m = 1,5 m respective 100 %

in mode 32 = 01.50 m

Further adjustment of channel 1 and 2

Upstream adjustment Full adjustment mode 0 - 12 = 01.00 m program distance

(channel 1) Empty adjustment mode 0 - 11 = 05.00 m program distance

Downstream adjustment Full adjustment mode 0 - 22

(channel 2) example 1 = 01.00 m or

example 2 = 01.50 m program distance

Empty adjustment mode 0 - 21

example 1 = 05.00 m or

example 2 = 05.50 m program distance

m

0

%

distance level

5

0

channel 1

upstream

liquid

Max-difference 1 m

^ 100 %

Min-difference 0 m

^0 %

downstream

liquid

∆ = 1m

4

3

2

1

100

channel 2

+ 0,5

m

0

%

100

5

0

channel 1

distance level

upstream

liquid

min-difference

max-difference

downstream

liquid

4

3

2

1

channel 2

The value of the sensor in the plus range of

channel 2 must be added to the min. and max.

distance

Page 24

Linearization

24 71 - 2 … 75 - 2

Linearization

Adapting to vessel geometry (channel 1)

The most usual vessel geometries are adjusted as

fixed curves in mode 0 - 18.

Mode 0 - 18 = 1 Fixed curve (linear) level percentage

for cylindrical tank output

Mode 0 - 18 = 2 Fixed curve for volume percentage

cylindrical tank output

It is also possible to program three customer

specific curves by accessing linearization 4 … 6

and to activate them in mode 18.

Each linearization curve consists of max. 32 index

markers, each index marker of a H/L-pair.

Mode 0 - 18 = 4 linearization curve 4 volume percentage

5 5 output

66

Output condition for the level in litres see

page 26, related to channel 1

- adjustment related to 0 % and 100 %, is carried

out

- Mode 0 - 15 = 3 (1 level percentage)

- Mode 0 - 18 = 1

- total volume of the vessel is known (for the

following example 100 m

3

)

- part volume for gauging the capacitance in litres

is known (for the following example = 5 m

3

)

Same procedure for channel 2.

MODE 0 - 18

Selection of linearization curve 4 … 6

Each linearization curve 4 … 6 can be accessed in

mode 0 - 99 and the reset carried out.

MODE 0 - 99

Programming example Linearization 4 ............. • select mode 0 - 99 in MODEFIELD

• program figure 4 in PARAMETER FIELD

• then store with STO-button

• push MOD-button to select index markers

Reset in mode 99 with figure 0 in PARAMETER

FIELD.

Selection of linearization curve 4 … 6

Reset to general parameter adjustment

0 - 99

0 - 01

4

5

4H.01

5H.01

6H.01

32

4 - 99

6

0

Page 25

Linearization

71 - 2 … 75 - 2 25

Display

number of the linearization curve 4 … 6

indication for level percentage = H

indication for volume percentage = L

number of index marker 01 … 32

Display 1 4 . H . 0 1 MODEFIELD

Display 2 1 0 0 . 0 PARAMETER FIELD

Mode listing 4 Linearization curve 4 … 6

Function Mode-no. Mode description Parameter

( = factory preset)

Index 4.H.01 1. index - level percentage ........... 000.0 … 100.0

marker 4.L.01 marker - volume percentage ...... 000.0 … 100.0

•

•

•

4.H.32 32. index - level percentage ........... 000.0 … 100.0

4.L.32

marker - volume percentage ...... 000.0 … 100.0

4 - 33

… 98 not used ..................................................... – – – –

4 - 99 Change - general parameter ............. 0

- sensor optimization 1 .......... 1

- sensor optimization 2 .......... 2

- linearization curve 4 ............ 4

- linearization curve 5 ............ 5

- linearization curve 6 ............ 6

Linearization curve 4

Linearization curve 5 see above, however 5.H.01 … 5.H.32

5.L.01 … 5.L.32 5 - 99

Linearization curve 6 see above, however 6.H.01 … 6.H.32

6.L.01 … 6.L.32 6 - 99

Proceeding

4.H.011

11

4.HHHH.01 4.H.00001 4.H.011

11

scrolling with

button

→

100.0

4.LLLL.01 4.H.99991 4.H.099

99

by scrolling with

button plus or minus

Page 26

Linearization

26 71 - 2 … 75 - 2

Determination of the index markers

Gauging the level in litres

- mode 40: coordinate display 1 to level 1

- mode 99: select linearization curve 4

- fill or empty step by step with part volume

- note the respectively measured values for H %

(level percentage) of display 1 on the linearity

protocol

- the respective value for L % (volume percentage) should be calculated as follows

100 % x part volume1 (…32)

L % = ––––––––––––––––––––––––

vessel volume

e.g. volume percentage for 1 part volume:

100 % x 5 m

3

L % = –––––––––––– = 5 % (acc. to example)

100 m

3

- note the calculated values for L % in the linearity

protocol

- continue the procedure of "gauging the level in

litres" with the same part volume until H 100 %

and L 100 % as described above.

- Attention:

The linearization curves must ALWAYS be

finished with H 100 % and L 100 %. This finish

can be programmed after any number of index

markers.

Demonstration to the following programming example (see page 27)

Heights %

Volume

%

5

etc.

level perc. 02

level perc. 01

0

30

40

50

70

80

60

90

100

10 20 30 40 50 60 70 80 90

100

20

10

100.0

12.0

4.H.01

4.L.01

4.L.32

5.0 100.0

4H.32

index marker

01 … 32

index marker

01 … 32

Page 27

Linearization

71 - 2 … 75 - 2 27

Linearity protocol

Linearization curve

index level percentage volume perc.

marker no. H L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Date

Name

Linearization curve

index level percentage volume perc.

marker no. H L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Date

Name

Page 28

Linearization

28 71 - 2 … 75 - 2

Programming example:

Index marker 01........................................................ • index marker 01 4.H.01

select level percentage

MODEFIELD

Level percentage ...................................................... • acc. to linearity protocol program 12.0 % in

PARAMETER FIELD

• then store with STO-button

• index marker 01 4.L.01

select volume percentage

MODEFIELD

Volume percentage................................................... • acc. to linearity protocol program 5 % in

PARAMETER FIELD

• then store with STO-button

Index marker 02 ....................................................... • index marker 02 4.H.02

select and program the data as

described above etc.

After programming is finished .................................. i.e. transmission of all data noted in the linearity

protocol,

- reset factory settings

- mode 0 - 15 = 3 (volume percentage)

- activate linearization curve 4 in mode 0 - 18

(mode 0 - 18 = 4)

Same procedure for linearization curve 5 and 6.

Page 29

Measurement, Display function

71 - 2 … 75 - 2 29

Multiplier

for 0 % and 100 % (channel 1)

(channel 1)

(channel 1)

MODE 0 - 13 and 0 - 14

Values of 0000 … 9999 can be coordinated to

levels 0 % and 100 % after the adjustment procedure.

The central electronics calculates all intermediate

values out of this data.

Measuring units and pattern MODE 0 - 15

Programming possibilities:

Mode combination

Demonstration / vessel geometry Measuring unit Measuring unit Linearization

0 - 15 0 - 18

Percentage level m / % / scaled m 1

%2

1

scaled 3

(Mode 0 - 13,

0 - 14 and 0 - 16)

Percentage volume % / scaled % 2

2

scaled 3 and

(Mode 0 - 13, 4 … 6

0 - 14 and 0 - 16)

Decimal point MODE 0 - 16

Summary

The display can be adjusted to a specific application by combinations of these modes and adaption

of their parameters.

Mode 0 - 13 and 0 - 14

values of

0000 … 9999

2005 hl

Mode 0 - 16

position of decimal point

Mode 0 - 15

measuring unit (pattern)

The position of the decimal point can be determined

in mode 16.

In mode 0 - 15 the signal conditioning instrument

can be defined for the display either (proportional)

volume or level.

Measuring units can be selected and slotted into

the window.

Pattern for:

% m cm ft kg t gal hl m

3

l

Page 30

Measurement, Display function

30 71 - 2 … 75 - 2

Programming example

After multiplying

- the distance corresponds

to 9 … 1 m

- the level corresponds to

10 … 4000 hl

(10 hl = min. quantity)

Example display

10 hl … 4000 hl

Multiplier for 0 % ...................................................... • select mode 0 - 13 in MODEFIELD

• program the value 001.0 in PARAMETER FIELD

• then store with STO-button

The actual distance of 5.00 (m)

remains indicated on display 1.

Multiplier for 100 % .................................................. • select mode 0 - 14 in MODEFIELD

• program the value 400.0 in PARAMETER FIELD

• then store with STO-button

The actual distance of 5.00 (m)

remains indicated on display 1.

Measuring unit and pattern ...................................... • select mode 0 - 15 in MODEFIELD

• program the figure 3 in PARAMETER FIELD

• then store with STO-button

50 % of the previously programmed

multiplication factor (

^ 199.5) plus

the min. quantity (

^ 1,0) is indicated

on the display, i.e.

Position of decimal point .......................................... • select mode 0 - 16 in MODEFIELD

• shift with button

→ the position of the decimal

point 1 x to the right

• then store with STO-button

The desired range is displayed.

Insert pattern hl.

Follow the same procedure for channel 2, but use

modes 0 - 23 … 0 - 26 or for differential measurement, modes 0 - 33 … 0 - 36.

100 %

50

Mode 14

Mode 13

4000 hl

2005

100

Mode 15+16

1 m

5 m

9 m

NiveauDistanz

hl

5.00

2005

5.00

5.00

200.5

2005

Distance level

(linearized)

Page 31

Measurement, Relay output

71 - 2 … 75 - 2 31

Module for relay output 1 … 4

The pulse-echo measuring system can be equipped

with max. two relay modules.

Each module has two relay outputs.

Two-point level switch

Mode coordination / meaning module relay coordi- mode switching command

output nation 1 and 2

1 1 0 - 43 0 - 44 = 1 0 - 45 and 0 - 46

2 0 - 48 0 - 49 = 1 0 - 50 and 0 - 51

2 3 0 - 53 0 - 54 = 1 0 - 55 and 0 - 56

4 0 - 58 0 - 59 = 1 0 - 60 and 0 - 61

Coordination

(Module 1, relay output 1)

MODE 0 - 43

For each relay output the coordination can be

programmed separately and relates to:

- measurement (channel 1, 2 and difference)

- measuring unit

- level / volume percentage

vessel geometry / measuring result measuring unit coordination linearization

(channel definition) 0 - 43 0 - 18, 0 - 28

level percentage channel 1 m = 1

% = 2 0 - 18 = 1

channel 2 m = 3

% = 4 0 - 28 = 1

difference m = 5

%= 6

volume percentage channel 1 % = 2 0 - 18 = 2

or 4 … 6

channel 2 % = 4 0 - 28 = 2

or 4 … 6

difference % = 6

Mode

(Module 1, relay output 1)

MODE 0 - 44

Mode 0 - 44 = 1

two-point level switch

switching command 2 via

switching command 1

correspond to function A

(overfill protection)

0

25

75

100

50

% m

distance acc.t o sensor type

mode combination

switching command 2,

mode 0-46

switching command 1,

mode 0-45

(off)

(on)

Page 32

Measurement, Relay output

32 71 - 2 … 75 - 2

Mode

(Module 1, relay output 1) continuation

Mode 0 - 44 = 1

two-point level switch

switching command 1 via

switching command 2

correspond to function B

(protection against dry

running of pumps)

Switching command 1 and 2

(Module 1, relay output 1)

MODE 0 - 45 and 0 - 46

Mode 0 - 43 defines the measurement units

coordinated to the relay output.

Mode 0-44 determines the function of the relay

output.

Mode 0-45 = switching command 1 corresponds

relay switched on (on)

Mode 0-46 = switching command 2 corresponds

relay switched off (off)

With the operating sequence of the switching

commands, the A- or B-function i.e. overfill protection or protection against dry running of pumps is

determined.

See page 31 and 32.

The min. ∆ for the switching commands is 10 cm or

0,5 %.

Programming example for relay output 1 ............... - coordination to channel 1 with units in %

- mode 1

- two-point level switch in function A

(see page 31)

Coordination (channel 1 in %) .................................. • select mode 0 - 43 in MODEFIELD

• program figure 2 in PARAMETER FIELD

• then store with STO-button

Mode (two-point level switch).................................... • select mode 0 - 44 in MODEFIELD

• program figure 1 in PARAMETER FIELD

• then store with STO-button

Switching command 1 (on) ...................................... • select mode 0 - 45 in MODEFIELD

• program 025.0 % in PARAMETER FIELD

• then store with STO-button

Switching command 2 (off) ....................................... • select mode 0 - 46 in MODEFIELD

• program 050.0 % in PARAMETER FIELD

• then store with STO-button

Same function and procedure

for module 1, relay output 2

and module 2, relay output 3 and 4, however

with respective modes, see page 31.

0

25

75

100

50

% m

distance acc. to sensor type

switching command 1,

Mode 0-45

switching command 2,

Mode 0-46

(off)

(on)

Page 33

Measurement, Relay output

71 - 2 … 75 - 2 33

Using the VEGASON-measuring system in pump

stations allows several pumps to be used independent of the level. Due to the different switching

commands there could be unequal pump running

times (and wear).

With programming the mode "pump function" the

switch on period of the respective relay outputs is

monitored via the central electronics. An automatic

change-over (priority determination) ensures

equality of pump running periods. See the following

example with three pumps.

Priority determination by:

- switching on the measuring system

- all relay outputs concerned in the pump function

switched off, i.e. with all pumps

- with time interval, the time interval is active if

within the time programmed in mode 63 all

pumps are

not stopped.

In this case first all relay outputs are switched

off, the actual priority will be determined and the

pumps will be switched on again in new

sequence after 10 secs.

Factory preset of mode 0 - 63 with 9999 minutes

^ approx. 1 week to the max interval time.

Note:

Before changing this time, it should be checked

if the (10 secs.) switch off of all pumps will create

a problem.

P3 on

% m

100

80

60

40

20

0

P2 on

P1 on

P3 off

P2 off

P1 off

P1 on

P2 on

P3 on

P1 off

P2 off

P3 off

P3

P2

P1

2h

4h

6h

6h

4h

2h

h

distance acc. to sensor type

running periods

= 8 h

= 8 h

= 8 h

Two-point level switch with pump function switch

Page 34

Measurement, Relay output

34 71 - 2 … 75 - 2

Note

- The relay output included in the pump function

must be coordinated to one channel.

- The switch points 1 (on) must be always above

the switching commands 2 (off) (function B).

- When adding or cancelling a relay output of the

pump function, first all relays and therefore all

pumps de-energize and are switched on again

after 10 secs. with new priority.

Before a manipulation of this type, the impact

should be checked.

Indication of the running period

(maintenance info)

The switching on period of the individual relay

outputs, i.e. the running period of the respective

pump is determined by a software operating hour

counter. This period can be indicated on the display

in the mode range under various mode numbers

(see table below).

The time unit corresponds to 10

1

h.

Programming example for relay output 1 … 3 ....... - mode2

- two-point level switch with pump function switch

in function B

- time interval 1,5 days

Coordination ............................................................. as described on page 31, but also for mode 0 - 48

and 0 - 53

Mode relay output 1 .......................... • select mode 0 - 44 in MODEFIELD

• program figure 2 in PARAMETER FIELD

• then store with STO-button

relay output 2 .......................... • as above, however mode 0 - 49

relay output 3 .......................... • as above, however mode 0 - 54

Switching command 1 and 2 for relay output 1 … 3 as described on page 32 (diagram), however for all

relay outputs with adapted % or m-values.

Time interval ............................................................. • select mode 0 - 63 in MODEFIELD

• program e.g. 2160 min. (1,5 days) in

PARAMETER FIELD

• then store with STO-button

Indication of running period for relay output 1 .......... • select e.g. mode 0 - 47 in MODEFIELD on

display 2 to switch on time of relay output 1 is

indicated, i.e. the running period of pump 1

(example indication 12

^ 120 hours).

Same procedure for all relay outputs, with

associated mode, numbers see above.

Mode coordination / meaning

module relay coordi- mode switching com- indication of time interval

output nation mand 1 and 2 running period

1 1 0 - 43 0 - 44 = 2 0 - 45 and 0 - 46 0 - 47

2 0 - 48 0 - 49 = 2 0 - 50 and 0 - 51 0 - 52

0 - 63

2 3 0 - 53 0 - 54 = 2 0 - 55 and 0 - 56 0 - 57

4 0 - 58 0 - 59 = 2 0 - 60 and 0 - 61 0 - 62

Two-point level switch with pump function switch

(continuation)

Page 35

Measurement, Relay output

71 - 2 … 75 - 2 35

By parameter adjustment it is possible to define for

each relay output the tendency determination mode

and to coordinate this relay output to a channel.

The information for tendency determination is

formed of the rate of level change per time unit

(cm / min) and can be taken for raising and lowering tendency.

The adjustment is made in cm / min. and detects a

range of 000.1 … 999.9 cm / min.

Programming example for tendency determination, e.g. 50 cm / min.

Coordination as described on page 31

Mode for relay output 1 ..................................... • select mode 0 - 44 in MODEFIELD

• program figure 3 in PARAMETER FIELD

• then store with STO-button

Tendency determination for relay output 1................ • select mode 0 - 45 in MODEFIELD

• program e.g. 050.0 (cm / min.) in PARAMETER

FIELD

• then store with STO-button

After above programming the relay output reacts as

follows:

with raising rate of level change ≤ 50 cm / min.

> 50 cm / min.

Same procedure for relay output 2 … 4, however

with respective modes, see above.

Mode coordination / meaning module relay coordi- mode tendency

output nation

1 1 0 - 43 0 - 44 = 3 or 4 0 - 45

2 0 - 48 0 - 49 = 3 or 4 0 - 50

2 3 0 - 53 0 - 54 = 3 or 4 0 - 55

4 0 - 58 0 - 59 = 3 or 4 0 - 60

Tendency determination

relating to increasing level

example relay output 1

Requirement:

- enquire mode 3 (parameter 3) in mode 0 - 44

- program the value of the required tendency

determination in mode 0 - 45

Procedure:

- relay is not operated

- if the level raises quicker than programmed in

mode 0 - 45, the relay energizes

- if the filling speed is the same or lower than the

given value, the relay de-energizes again

11

9

10

11

9

10

Tendency determination

Page 36

Measurement, Relay output

36 71 - 2 … 75 - 2

Programming example for tendency determination, e.g. 8 cm / Min.

Coordination as described on page 31

Mode for relay output 1 ..................................... • select mode 0 - 44 in MODEFIELD

• program figure 4 in PARAMETER FIELD

• then store with STO-button

Tendency determination for relay output 1................ • select mode 0 - 45 in MODEFIELD

• program e.g. 008.0 (cm / min.) in PARAMETER

FIELD

• then store with STO-button

After programming as above the relay output reacts

as follows:

with reducing rate of level change ≤ 8 cm / min.

> 8 cm / min.

Tendency determination (continuation)

relating to reducing level

example for relay output 1

Requirement:

- enquire mode 4 (parameter 4) in mode 0 - 44

- program the value of the required tendency

determination in mode 0 - 45

Procedure:

- relay is not operated

- if the level reduces quicker than programmed in

mode 0 - 45, the relay energizes

- if the filling speed is the same or lower than the

given value, the relay de-energizes again

Note

(for rising or falling tendency determination)

If in case of fluctuating product surfaces of small

values are given for the tendency determination, it

is useful to program additional integration time.

Uncontrolled and undesired operation of the relay

output is then suppressed.

Same procedure for relay output 2 … 4, using

associated modes, see page 35.

Example as guideline:

at tendency determination < 10 cm / min. recommended integration time: 10 … 30 sec.

With < 10 cm / Min. the response time of the

tendency determination can be several minutes.

11

9

10

11

9

10

Page 37

Measurement, Current output

71 - 2 … 75 - 2 37

The pulse-echo measuring system can be equipped

with a current module.

The module has two current outputs.

Coordination MODE 0 - 64

Each current output can be coordinated separately

to either channel (or difference).

Same procedure for current output 2, but with

respective modes, see above.

Mode coordination / meaning current coordination range of characteristics

output final value initial value

1 0 - 64 = 1 channel 1

2 channel 2 0 - 65 0 - 66

3 difference

2 0 - 68 = 1 channel 1

2 channel 2 0 - 69 0 - 70

3 difference

Programming example

Coordinate current output 1, channel 2 .................... • select mode 0 - 64 in MODEFIELD

• program figure 2 in PARAMETER FIELD

• then store with STO-button

Output characteristic MODE 0 - 65 and 0 - 66

The characteristic of the current output is fixed by

an initial and final point.

The factory preset defines a course of 4 … 20 mA

acc. to 0 … 100 %.

Within the total range of 0.00 … 20.00 mA each

current value can be programmed for a rising or

falling level.

The current-∆ between initial and final value must

be min. 1 mA.

• select mode 0 - 65 in MODEFIELD

• program 16.00 mA in PARAMETER FIELD

• then store with STO-button

• select mode 0 - 66 in MODEFIELD

• program 00.00 mA in PARAMETER FIELD

• then store with STO-button

%

100

0

mA

20

4

End of characteristic

100 %

^ 16 mA

Start of characteristic

0 %

^ 0 mA

Factory preset Programming example

Module for current output 1 and 2

Page 38

Supplementary programmings

38 71 - 2 … 75 - 2

Signal processing MODE 0 - 93

The parameter adjustment of mode 0 - 93 defines

the condition of

- the relay outputs and

- the current outputs in case of failure.

In the parameter field a figure is coordinated to

each channel (level measurement 1, 2 and difference). The parameter adjustment can differ for

each channel.

0 - 9 3

1 1 1

difference

level 2, channel 2

level 1, channel 1

Programming possibilities

Mode 0 - 93 relay output / LED current output

1 no change actual current is stored

2 operated current - 0 mA

3 relays / current acc. to 0 %

4 de-energized current acc. to 100 %

Programming example

Changeover of the signal processing

relating to channel 1 (input the figure 4) ................... • select mode 0 - 93 in MODEFIELD

• program figure 4 in PARAMETER FIELD

• then store with STO-button

Note:

When adjusting the signal processing note the table of

error codes on page 55.

Page 39

Supplementary programmings

71 - 2 … 75 - 2 39

Simulation MODE 0 - 94 … 0 - 96

These modes enable the outputs for each channel

to be simulated over the whole range of the

distance in m, to test the function of the connected

instrumentation.

The simulation influences the selected channel and

therefore the outputs coordinated to this channel,

i.e. the

- relay outputs

- current outputs and

- the indication (display 2).

Mode coordination / meaning mode function simulation range

no. 72 / 73 - 2 74 - 2 75 - 2

94 level 1 / channel 1 0 … 11 m

95 level 2 / channel 2 0 … 22 m

96 difference 0 … 33 m

Operation

The plus button increases, the

minus button reduces the

outputs.

The simulation operates first of

all 0,05 m steps and is

accelerated to 0,25 m steps

after approx. 10 secs.

Note

The active simulation is recognized by

- selection of mode 94, 95 or 96

- flashing indication of all figures, e.g. .....................................................15.25 m.

Note:

If the simulation is active the measured values from

the sensor are NOT transmitted.

Mode 0 - 94, 0 - 95 or 0 - 96 must therefore be

immediately quit after the simulation is carried out.

The timer reset (after 60 minutes) should only be

used if absolutely necessary.

After having finished the simulation all outputs are

up-dated with the valid measured value.

Simulation example, e.g. channel 1 ....................... • select mode 0 - 94 in MODEFIELD

• activate simulation with button MOD, the actual

measurement flashes in PARAMETER FIELD

• modify the outputs with button Plus or Minus

• After having finished the test procedures quit the

simulation with MOD or STO-button.

relay output

measured value

sensor

current output

Simulation:

indication (in m)

15.25

0 - 94 96

Page 40

Supplementary programmings

40 71 - 2 … 75 - 2

Basic adjustment MODE 0 - 97

After having finished the parameter adjustments of

one or several modes it may be necessary to reset

the parameters of these modes to factory preset

values.

Mode 0 - 97 offers this possibility. Previously

adjusted parameters are cancelled. Cancellation is

indicated with CAL on the display (approx. 5 secs.).

Programming example .......................................... • select mode 0 - 97 in MODEFIELD

• program figure 1 in PARAMETER FIELD

• then store with STO-button, CAL is displayed for

5 secs. in the PARAMETER FIELD

Keyword MODE 0 - 98

Description

Acc. to the factory preset the keyword is switched

off and therefore data input is adjustable.

All mentioned modes can be selected as described

before and their parameters indicated on the

display of the sensors and perhaps modified.

The activation of the keyword (mode 0 - 98 = 1)

ensures the protection of the parameters for unauthorized modifications.

Adjustment of the data input is possible only after

programming the keyword (over writing of the

indicated key symbol).

This programming can be carried out in each mode,

the whole mode range is then accessible (mode 98

will be 0).

The keyword is: 0070

Activate keyword ...................................................... • select mode 0 - 98 in MODEFIELD

• program figure 1 in PARAMETER FIELD

• then store with STO-button

Adjust keyword ......................................................... • select the mode requested for parameter

adjustment, here in the example mode 0 - 40 in

MODEFIELD

• select data input, the key symbol 0 – – n is

indicated in the PARAMETER FIELD

• program

0070 as keyword

• then store with STO-button

• the parameter adjustment of e.g. mode 0 - 40 can

be continued

Page 41

Sensor optimization

71 - 2 … 75 - 2 41

Selection of sensor optimization

In mode 0 - 99 the sensor optimization 1 and 2 and

also the reset to the general parameter adjustment

can be carried out.

Programming example sensor optimization 1 ....... • select mode 0 - 99 in MODEFIELD

• program e.g. figure 1 in PARAMETER FIELD

• then store with STO-button

• operate MOD-button to enquire the sensor

optimization

Reset in mode 99, however with figure 0 in the

PARAMETER FIELD.

Same procedure for sensor optimization 2 (however

figure 2).

Mode listing 1

Mode-no. Mode description Parameter Page

( = factory preset)

1 - 01

1 - 02

not used ..................................................... – – – –

1 - 03 sensor type ................................................. 71 - 2 … 75 - 2

1 - 04 not used ..................................................... – – – –

1 - 05 - indication, distance in m

1 - 06 - indication, gain in dB p. 44

Working range

1 - 07 - start of working range ............................ 0 m

1 - 08 - end of working range ............................ 6 / 12 / 24 / 36 m

Product type

1 - 09 - liquids / solids ........................................ VEGASON 71 and 72 1 / 0 p. 45

VEGASON 73 … 75 1 / 0

Liquid

1 - 10 - vessel top flat / dished .......................... 1 / 0 p. 45

Solids

1 - 10 - angle of repose ..................................... 0 … 50 degrees p. 46

1 - 11 - particle size............................................ 1 … 11 mm

Sensor optimization 1, channel 1

0 - 99

0 - 01

1

2

1 - 01

2 - 01

27

1 - 99

0

MODE 0 - 99

Sensor optimization

Reset

Page 42

Sensor optimization

42 71 - 2 … 75 - 2

Mode listing 1

Sensor optimization 1, channel 1 (continuation)

Multiple echo

1 - 12 - reduction ............................................... 0.00 … 1.25 V p. 47

1 - 13 - optimization ........................................... 0.00 … 1.25 V

False echo learn

1 - 14 - indication, gain

1 - 15 - learn distance ........................................ 0,3 m … 12 / 24 / 36 m 2 m p. 48

1 - 16 - delete learn cycle .................................. 0 / 1

1 - 17 - activate learn cycle ............................... 0 / 1

Profile interpolation

1 - 18 - switched off / switched on ..................... 0 / 1 p. 49

1 - 19 Rate of product level change ..................... 0.01 … 11 cm / s (4 cm / s) p. 50

Max. gain

1 - 20 - indication, gain

1 - 21 - limitation................................................. 0.03 … 4.95 V p. 51

1 - 22 - optimization ........................................... 0.03 … 4.95 V

Measuring window

1 - 23 - switched on / switched off ..................... 1 / 0 p. 52

Fault signals

1 - 24 - switched on / switched off ..................... 0 / 1 p. 52

1 - 25 Real distance ............................................. 0,3 m … 12 / 24 / 36 m 2 m p. 53

1 - 26 not used ..................................................... – – – –

Basic adjustment (factory preset)

1 - 27 - switched off / switched on ..................... 0 / 1 p. 53

1 - 51 … 75 Service activities ........................................ PASS

1 - 99 Change

- general parameter ................................. 0

- sensor optimization 1 ............................ 1

- sensor optimization 2 ............................ 2

- linearization curve 4 .............................. 4

- linearization curve 5 .............................. 5

- linearization curve 6 .............................. 6

sensor optimization 2, channel 2 as above, however 2 - 01 … 2 - 99

Mode-no. Mode description Parameter Page

( = factory preset)

Page 43

Sensor optimization

71 - 2 … 75 - 2 43

Information for sensor optimization 1

If optimization is required, always compare the local

conditions with the programmed parameters - if

necessary correct or adapt.

Basic test of

Mode-no. Information Selection / measures Page

1 - 09 product type liquids or solids p. 45

1 - 10 vessel geometry vessel top flat or dished p. 45

1 - 10 solid define particle size / p. 46

1 - 11 angle of repose

1 - 19 rate of level change define in cm / sec. p. 50

False echo tests

Mode-no. Mode description Page

False echo BEFORE useful echo (output too high)

1 - 07 start of working range define p. 44

1 - 14 …17 false echo learn (activate) p. 48

1 - 18 profile interpolation activate p. 49

False echo AFTER useful echo (output too low)

1 - 08 end of working range define p. 44

1 - 12 / 13 multiple false echo reduce p. 47

1 - 21 / 22 max. gain limited p. 51

Supplementary programmings

1 - 23 measuring window switched on or off p. 52

1 - 24 false echo determine p. 52

1 - 25 real distance program p. 53

1 - 27 basic adjustment define p. 53

Above information for sensor optimization, relate to

sensor 1, channel 1.

Sensor optimization for sensor 2, channel 2 as