Page 1

Operating Instructions

VEGAMET 614V

Level and Pressure

CONNECT

12

on

614

%

100

+

-

OKESC

Ser.No.

12345678

out

in

Page 2

Contents

1 Product description

1.1 Function and configuration ................................................ 4

1.2 Approvals ........................................................................... 5

1.3 Features............................................................................. 5

1.4 Technical data .................................................................... 6

1.5 Dimensions......................................................................... 9

2 Mounting and installation instructions .............................. 10

3 Electrical connection

3.1 Connection instructions ................................................... 12

3.2 Wiring plan ........................................................................ 12

4 Adjustment

4.1 Indicating and adjustment elements ............................... 13

4.2 Adjustment system .......................................................... 14

4.3 Adj ustmen t via PC ........................................................... 15

4.4 Configuration and parameter adjustment ....................... 16

4.5 Comparison: "Reduced menu" – "Extended menu" ...... 17

Contents

5 Setup .......................................................................................... 18

6 Settings in the „Reduced menu“

6.1 Con figurati on of mea surement loop ............................... 19

6.2 Sensor optimization ......................................................... 20

6.3 Adj ust men t wi th med ium.................................................. 20

6.4 Adjustment without medium ............................................ 21

6.5 Scaling .............................................................................. 22

6.6 Inte gration ti me ................................................................ 23

6.7 Outputs............................................................................. 24

6.9 Password, language, reset, menu mode ....................... 25

6.8 Simulation ......................................................................... 25

2 VEGAMET 614V

Page 3

Contents

7 Settings in the „Extended menu“

7.1 Config uration o f measur ement loo p ............................... 26

7.2 Configu ration of t emperatur e measurem ent loop .......... 27

7.3 Configuration of inputs ..................................................... 28

7.4 Configu ration of ou tputs .................................................. 2 9

7.5 Adjustment........................................................................ 30

7.6 Conditioning...................................................................... 31

7.7 Paramet er adjustm ent of outp uts ................................... 32

7.8 Simulation ......................................................................... 37

7.9 Special function: Reset .................................................... 37

7.10 Password, language, menu mode .................................. 38

7.11 Special function: Manual correction ................................ 38

7.12 Li nearisa tion cur ves ........................................................ 39

7.13 Info .................................................................................... 42

7.14 Reset VEGAMET ............................................................. 43

8 Measured quantity and units ................................................ 44

9 Diagnosis

9.1 Maintenance..................................................................... 45

9.2 Simulation ......................................................................... 45

9.3 Fault signal........................................................................ 45

9.4 Repair............................................................................... 45

9.5 Error codes ...................................................................... 46

10 Menu schematics

10.1 Menu schematic "Reduced menu" ................................. 49

10.2 Menu schematic "Extended menu" ................................ 50

Safety informatio n ...................................................................... 56

Note Ex area .............................................................................. 56

VEGAMET 614V 3

Page 4

1 Product description

Product description

1.1 Function and configuration

VEGAMET 614 V is a signal conditioning

instrument for a number of different applications, e.g.:

- level measurement

- gauge measurement

- process pressure measurement

- additional temperature measurement (with

respective sensors)

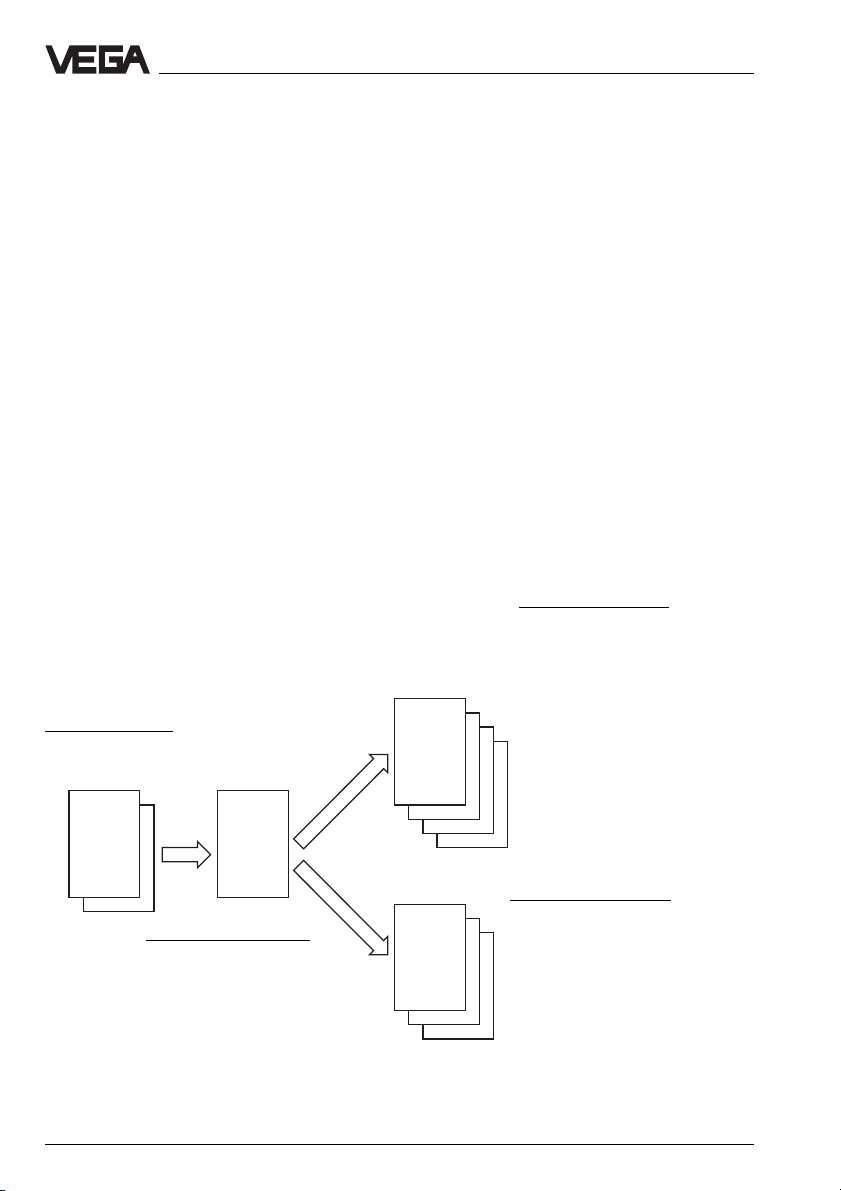

Software configuration

Input component

- continuous current

input

Function

The signal conditioning instruments power

the connected sensors and process their

analogue measuring data. The conditioning is

done by a special software consisting of

functional components (FB), input components (EB), output components (AB) as well

as DCS components (PB).

Configuration

The VEGAMET 614 V signal conditioning

instrument is a module unit with plug-in

socket. The front plate contains an adjustment module with LC display and keys.

Output components

- current output

- voltage output

- DISBUS outputs

- failure output

- MET display

- relay outputs

AB

EB FB

PC/DCS components

- PC/DCS outputs

Functional component

- measurement loop

TA G 1

4 VEGAMET 614V

PB

Page 5

Product description

1.2 Approvals

As an accessory, intrinsically safe instrument.

EC type approval certificate acc. to

CENELEC

II (1) G [EEx ia] II C

1.3 Features

- microcomputer-controlled signal conditioning instrument for continuous measurement

- adjustment module with LC display and 6

keys

- adjustable integration time

- two fixed and three user-programmable

linearisation curves

- fault monitoring

- fault signal and failure diagnosis via display

- temperature measurement loop (on pressure transmitters and ultrasonic sensors

delivering a temperature signal)

Input:

- 1 sensor input for digital transmission of

measured data (VBUS) (pressure transmitters, ultrasonic and radar sensors)

Outputs:

- 2 current outputs 0/4 … 20 mA

- 2 voltage outputs 0/2 … 10 V

- 2 relay outputs (spdt)

- 1 DISBUS output for digital wiring and for

connection of VEGADIS 174

- 1 fail safe relay

- adjustment also via PC with adjustment

software VVO; connection via the interface

adapter of the VEGACONNECT series

VEGAMET 614V 5

Page 6

Product description

1.4 Technical data

Power supply

Operating voltage / power consumption U

VA

Optional instrument version U

Power supply with Ex approved instrument

Operating voltage / power consumption U

Meas. data input

Number 1 input

Type of input active two-wire input, digital (VBUS) (sensor

Sensor pressure transmitters, ultrasonic sensors and

Voltage approx. 25 V DC

Power limitation at approx. 4.5 W, short-circuit proof

Min. adjustment delta 2 % of sensor range (hydrostatic)

Connection cable 2-wire standard cable (screening

max. cable length 1000 m

max. resistance per wire 15 Ω

= 90 … 250 V AC, 50/60 Hz / approx. 14

nom

= 90 … 250 V DC

= 20 … 72 V DC / 7 W

nom

= 20 … 53 V AC, 50/60 Hz, 14 VA

= 20 … 250 V AC, 50/60 Hz / 14 VA

nom

= 20 … 72 V DC / 5 W

powered by VEGAMET)

radar sensors

5 mm (ultrasonic, radar)

recommended)

Meas. data input with Ex approved instrument

Voltage approx. 15 V at 5 mA

approx. 13.5 V at 25 mA

Current limitation at 32 mA (short-circuit proof)

further data of the meas. data input the same as the instrument without Ex approval

Current output

Number 2 outputs

Function analogue output of the processing results

Range individually adjustable in the range of 0 … 20 mA

Load max. 500 Ω

Resolution 1 µA

Linearity error 0.05 % (relating to 20 mA)

Temperatur e error 0.05 %/10 K (relating to 20 mA)

Voltage output

Number 2 outputs

Function analogue output of the processing results

Range individually adjustable in the range of 0 … 10 V

Current max. 1 mA

Resolution 0.5 mV

Linearity error 0.05 % (relating to 10 V)

Temperature error 0.06 %/10 K (relating to 10 V)

6 VEGAMET 614V

Page 7

Product description

Relay outputs

Numbe r 2 operating relays, 1 fail safe relay

Contact floating spdt

Contact material AGSNO

Tur n-on voltage min. 10 mV DC

, hard gold plated

2

max. 250 V AC/DC

Switching current min. 10 µA

max. 3 A AC, 1 A DC

Turn-on voltage max. 750 VA

max. 18 W at U > 40 V DC

max. 40 W at U ≤ 40 V DC

Min. switching hysteresis

(Low/High delta) 0.5 %

DISBUS output

Function digital transmission for linking between signal

conditioning instruments and for connecting

digital indicating instruments

Connection cable 2-wire standard cable (screening

recommended)

max. cable length 1000 m

max. resistance per wire 15 Ω

Indicating elements

Clear text indication LC display

- 4-lines, 6 digits each

- background lighting

Analogue indication LED chain consisting of:

- 11 segments 0 % … 100 %

- indicates the actual value of the selected

measurement loop

LEDs in front plate green: operating voltage on

red: fault signal (LED lights with deenergised

relay)

yellow: relay switching condition (standard

adjustment: LED lights with energised relay)

Adjustment elements

Front plate 6 keys for configuration and parameter setting

Upper housing side rotary switch for adjustment of the instrument

address

on DISBUS (in mounted status covered by

plug-in socket)

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

Electrical connection

Screw terminal max. 1.5 mm

VEGAMET 614V 7

2

Page 8

Product description

Electrical protective measures

Instrument IP 30

Plug-in socket IP 20

Protection class II

Overvoltage category II

Electrical separating measures

Reliable separation acc. to

VDE 0106, part 1 between power supply, fail safe and level relay

and meas. data inputs

- reference voltage 250 V

- insulation resistance 2.3 kV

Galvanic separation between relay outputs

- reference voltage 250 V

- insulation resistance 1.4 kV

Potential separation between DISBUS and outputs

- reference voltage 50 V

- insulation resistance 0.5 kV

Common reference potential at voltage and current output

Mechanical data

Series module unit with plug-in socket, incl. transpa-

rent cover, sensor terminal cover, coded

pin, two connection jumpers

Mounting carrier rail mounting acc. to DIN 46 277, Bl. 3

Dimensions, unmounted W = 72 mm, H = 118.5 mm, D = 134 mm

Weight approx. 480 g

CE conformity

The VEGAMET 614V Ex signal conditioning instrument meets the protective regulations of

EMC (89/336/EWG) and NSR (73/23/EWG). Only for use in industrial areas. Conformity has

been judged acc. to the following standards:

EMC Emission EN 50 081 - 2: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

8 VEGAMET 614V

Page 9

Product description

Ex technical data

Power supply

Operating voltage U

Reference voltage U

Meas. data input (intrinsically safe circuit)

Classification

Max. values

- voltage U

- current I

- power P

Characteristics linear

Effective inner inductance L

Effective inner capacitance C

I

I

= 20 … 250 V AC

nom

= 20 … 72 V DC

= 253 V AC or 125 V DC

m

II (1) G [EEx ia] II C

= 18.2 V

o

= 270 mA

o

= 926 mW

o

negligible

negligible

EEx ia IIC

Max. permissible outer inductance L

O

0.28 mH

Max. permissible outer capacitance CO297 nF

The intrinsically safe circuits is reliably separated from the non-intrinsically safe circuits up

to a peak value of the nominal voltage of 375 V. The max. voltage on the non-intrinsically

safe circuits must not exceed 253 V

in case of failure.

eff

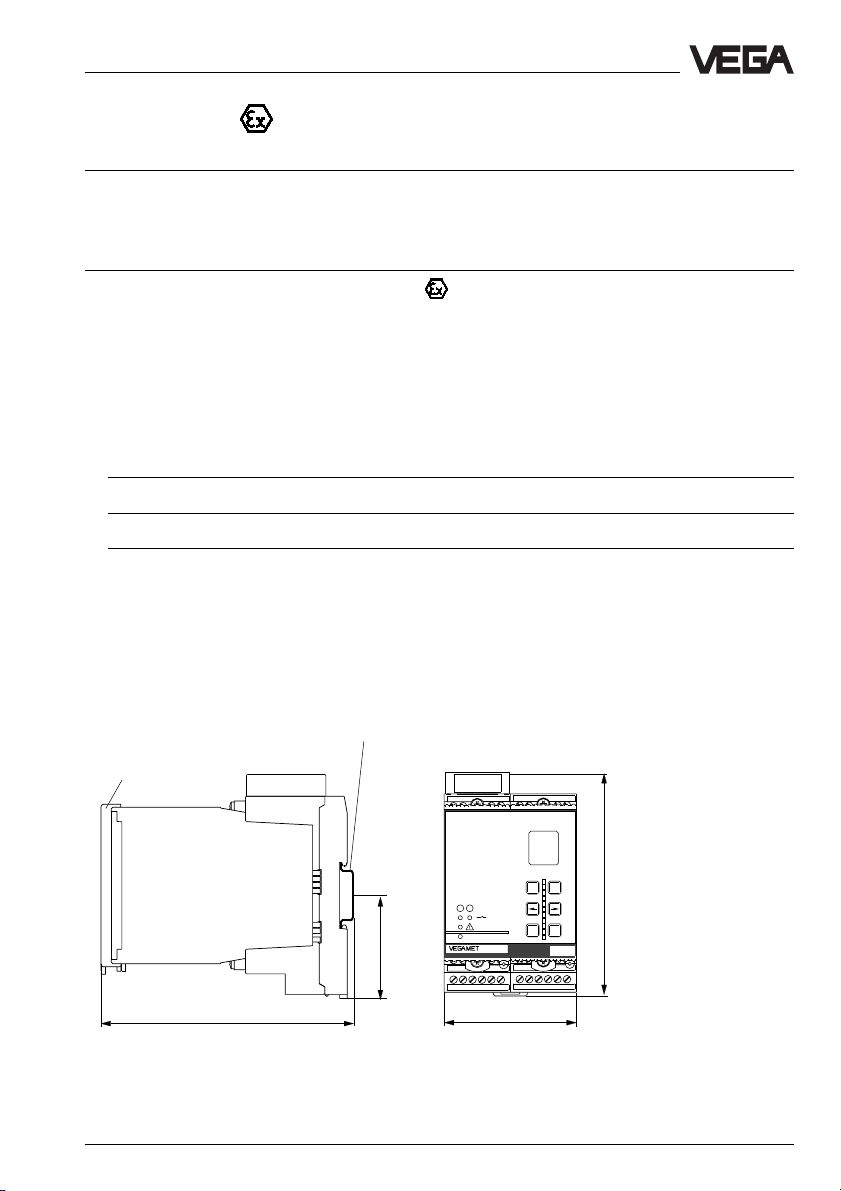

1.5 Dimensions

Carrier rail 35 x 7.5 or 35 x 15 acc.

to EN 50 022

Transparent cover

12

on

CONNECT

614

56 78

13 14 15 16

23 24 25 26 27 28

72

%

100

+

-

118,5

OKESC

Ser. No.

12345678

134

54,5

12 34

910 1112

17 18 20 21 22

VEGAMET 614V 9

Page 10

2 Mounting and installation instructions

Mounting

Each series 600 signal conditioning instrument consists of a plug-in socket for carrier

rail mounting DIN 46 277 and a module unit.

The supply voltage can be connected to

terminals 17 and 18.

For neighbouring series 600 signal conditioning instruments, it is possible to continue the

connection L1 and N directly via the supplied

jumpers. The same is valid for the connection

of VEGAMET voltage output 0 … 10 V (terminals 15 and 16) and for DISBUS output (terminals 9 and 10).

Note!

The jumpers must never be used with single

instruments or at the terminating end of an

instrument row. If this is not observed, there

is danger of coming in touch with the operating voltage or causing a short-circuit.

VEGAMET 614V Ex signal conditioning instrument is intrinsically safe and must not be

installed in hazardous areas.

Before setup, the Ex separating chamber

must be plugged into VEGAMET 614V Ex as

shown in the illustration.

Safe operation is ensured only if the operating instructions manual and the EC type

approval certificate are observed. VEGAMET

614V Ex must not be opened.

Separating

chambers

Ex coding

Direct supply for

voltage output 1

DISBUS and supply

voltage with jumpers

Coding

To avoid interchanging the various signal

conditioning instruments, the plug-in socket

is provided with pins and the signal conditioning instrument with corresponding gaps

(mechanical coding)

An Ex coding with inserted coding pins ensures that the non-Ex and Ex instruments are

not interchanged.

and Ex coding pin) must be inserted by the

user according to the below table.

Mounting and installation instructions

left right

A o

B o

C o

1 o

2 o

3 o

o

0…10 V

o

DISBUS

o

7 o

8 o

9 o

o

o

12 o

A o

VEGA

-

+

N

L1

VEGA

B o

C o

1 o

2 o

3 o

4 o

0…10 V

5 o

DISBUS

6 o

7 o

8 o

9 o

N

10 o

L1

11 o

12 o

On VEGAMET 614V Ex, the supplied

coding pins (instrument coding pin

-

+

Instrument Ex

coding coding

VEGAMET 614V right 2 ––

VEGAMET 614V Ex right 2 left A

left B

right B

left B

right B

10 VEGAMET 614V

Page 11

Mounting and installation instructions

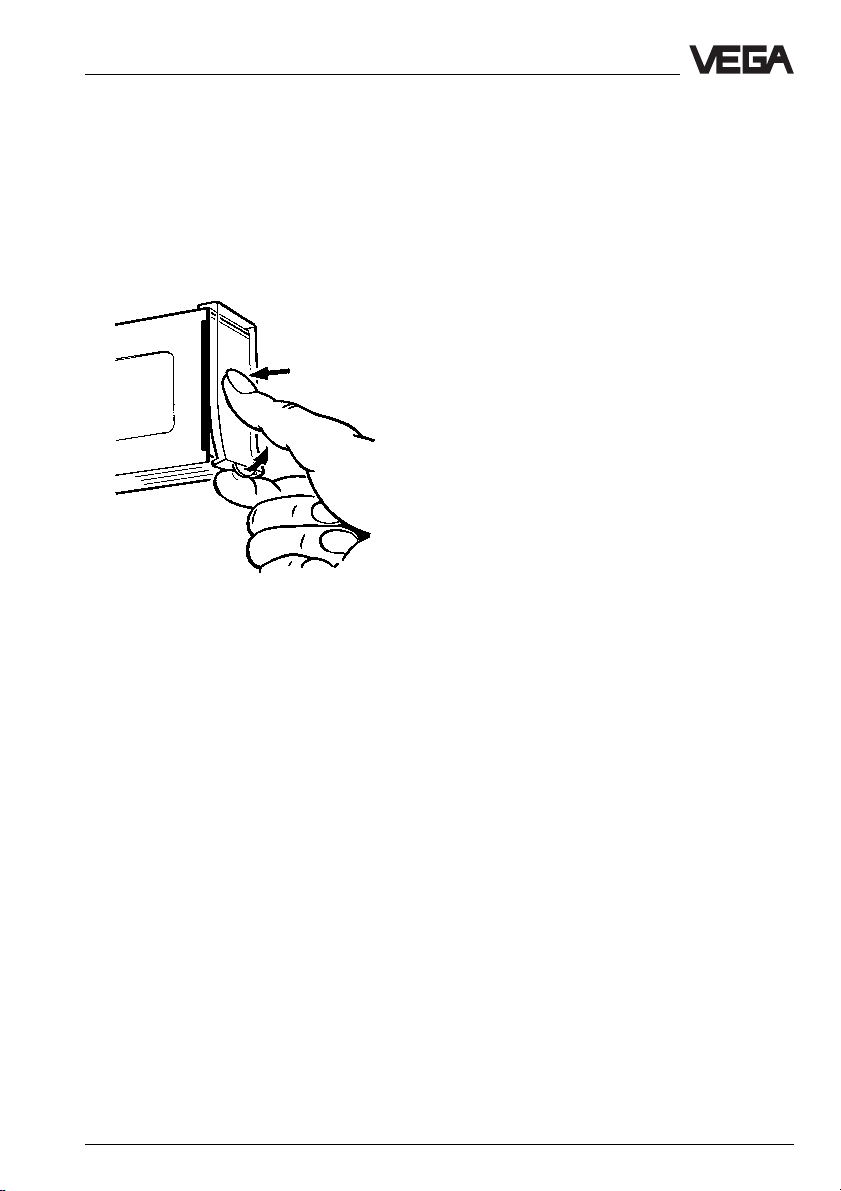

Transparent cover

To protect the instrument against unauthorized adjustment, the front plate of VEGAMET

can be equipped with two lockable transparent covers after setup. To remove the transparent cover, see illustration.

VEGAMET 614V 11

Page 12

3 Electrical connection

Electrical connection

3.1 Connection instructions

Note the following instructions for electrical

connection:

- The connection must be made acc. to the

local installation standards (e.g. in Germany acc. to the VDE-regulations).

- The wiring between VEGAMET 614 V and

sensor can be made with standard twowire cable.

- If strong electromagnetic interferences are

expected, we recommend the use of

screened cable. The screening must be

earthed on both ends.

- The line resistances stated in the technical

data must not be exceeded.

- If overvoltages are expected, we recommend a sensor electronics with integrated

overvoltage protection or the installation of

VEGA overvoltage arresters.

Connection instructions for Ex

approved applications

When wiring between VEGAMET 614V Ex

and an explosion protected sensor, the installation rules, in Germany acc. to VDE 165

and the EC type approval certificate must be

observed. The official documents are supplied with the respective instrument.

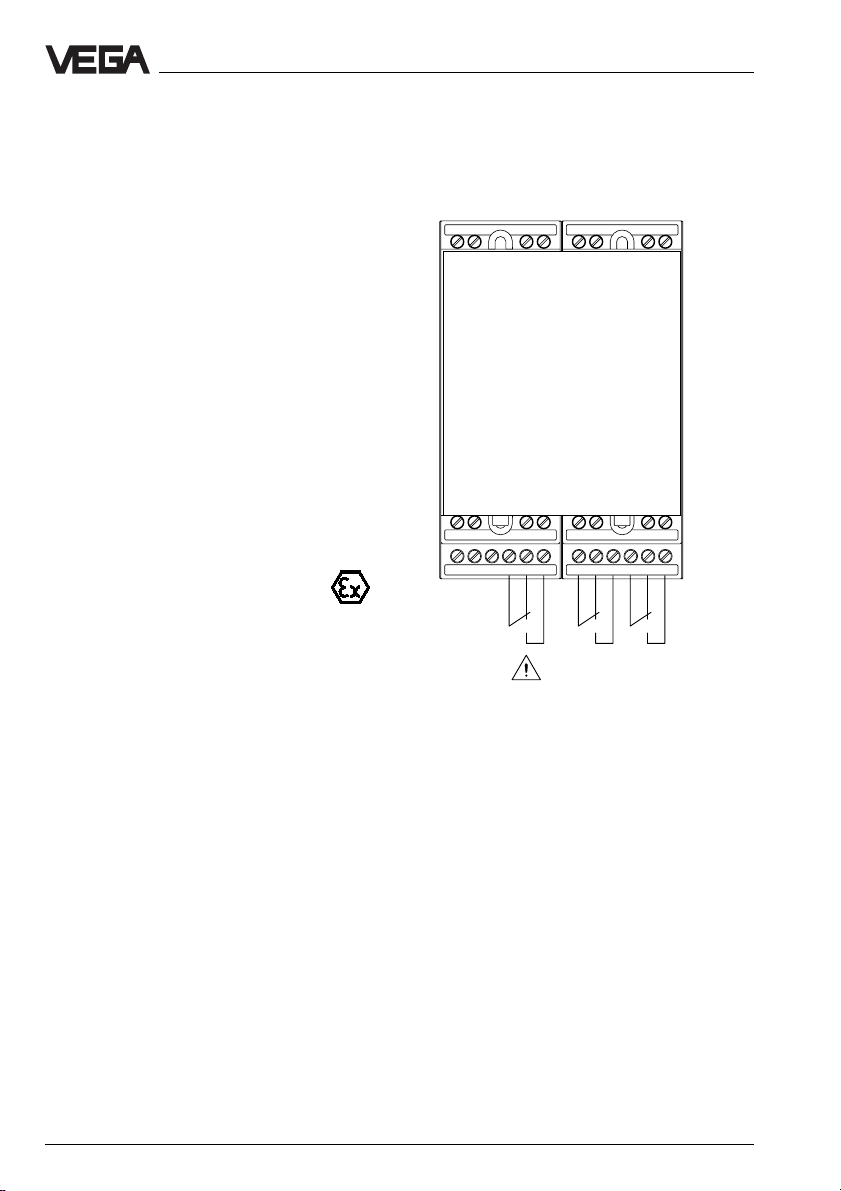

3.2 Wiring plan

Fail

safe

relay

Current

output 2

56 78

Voltage

output 2

13 14 15 16

23 24 25 26 27 28

Level

relay 1

Current

output 1

Voltage

output 1

Level

relay 2

VBUS

sensor

+- +- +-

12 34

DISBUS

output

+- +- +-

910 1112

17 18 19 20 21 22

+-

L1

N

Power supply

The connections „9, 10, 15, 16, 17 and 18“ can be

connected with the supplied jumpers to neighbouring

series 600 signal conditioning instruments.

Ex version

Before connecting Ex certified instruments,

please note the instructions in the attached

official documents as well as the valid installation regulations. Make sure that the Ex separating chamber is plugged in on the left

instrument side before setup (see illustration

Coding).

12 VEGAMET 614V

Page 13

Adjustment

4 Adjustment

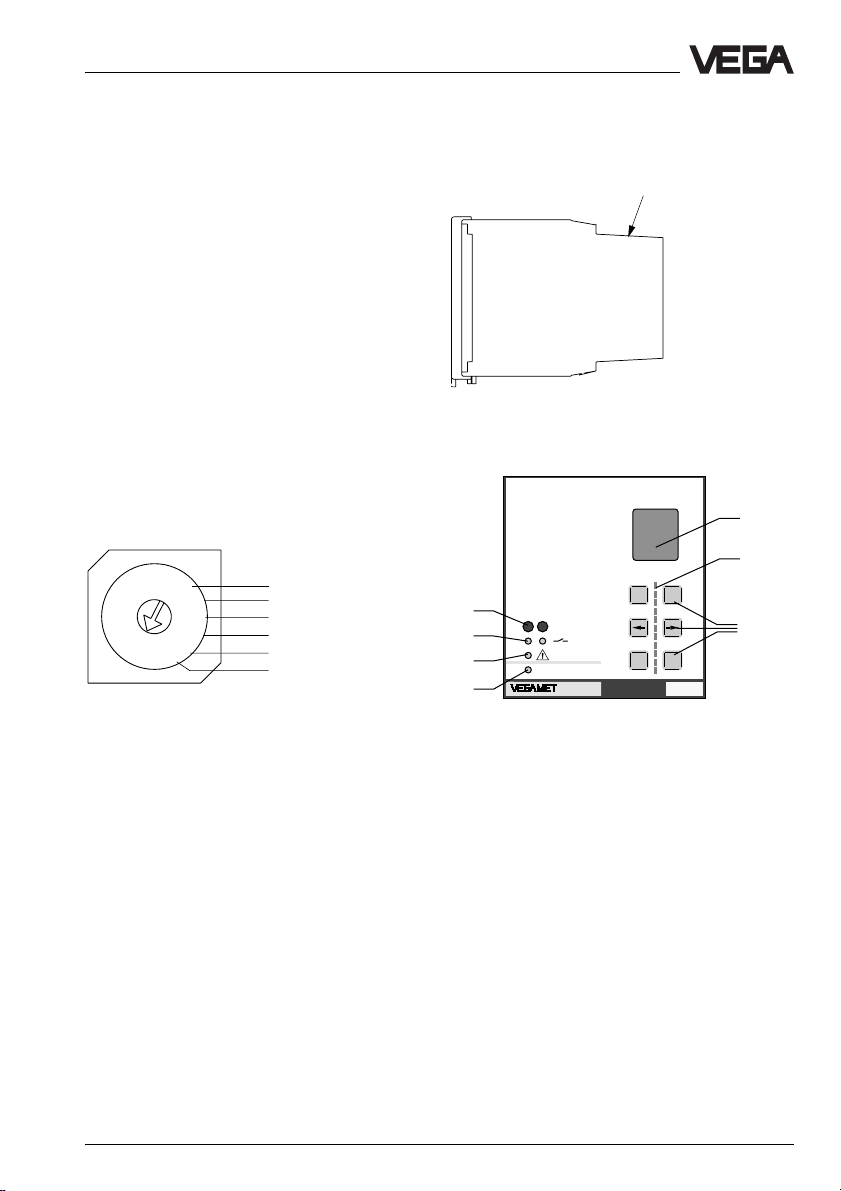

4.1 Indicating and adjustment elements

A rotary switch is located on the upper side

of the housing. It is used to set the instrument

address on DISBUS. This setting is necessary if several VEGAMET signal conditioning

instruments are linked via the DISBUS or if

you control a VEGADIS 174 indicating instrument via the DISBUS.

The adjustment range 1 … F corresponds to

the DISBUS addresses 1 … 15.

Factory setting: 1

Note:

If address 0 is set, the VEGAMET does not

participate in the DISBUS communication.

Rotary switch

8

9

7

A

6

5

4

33

2

B

C

D

E

F

1

0

The set instrument address on the DISBUS

can be indicated via the LC display.

Note

If several VEGAMET are linked via the

DISBUS, each address must be assigned

only once!

10

11

12

13

14

15

Position of the rotary switch

Rotary switch

Front plate

1

%

100

+

4

5

6

7

1 LCD (4 lines with 6 figures each, illuminated) for clear text

indication

2 LED chain (yellow) for quasianalogue indication of the

measured value

3 Keys for menu adjustment

4 Connection socket for VEGACONNECT

5 LED (yellow) lights if the relay is energised (standard

setting)

6 LED (red), lights if fail safe relay is deenergised

7 LED (green), lights if operating voltage is on

CONNECT

12

on

614

-

OKESC

Ser.No.

12345678

2

3

VEGAMET 614V 13

Page 14

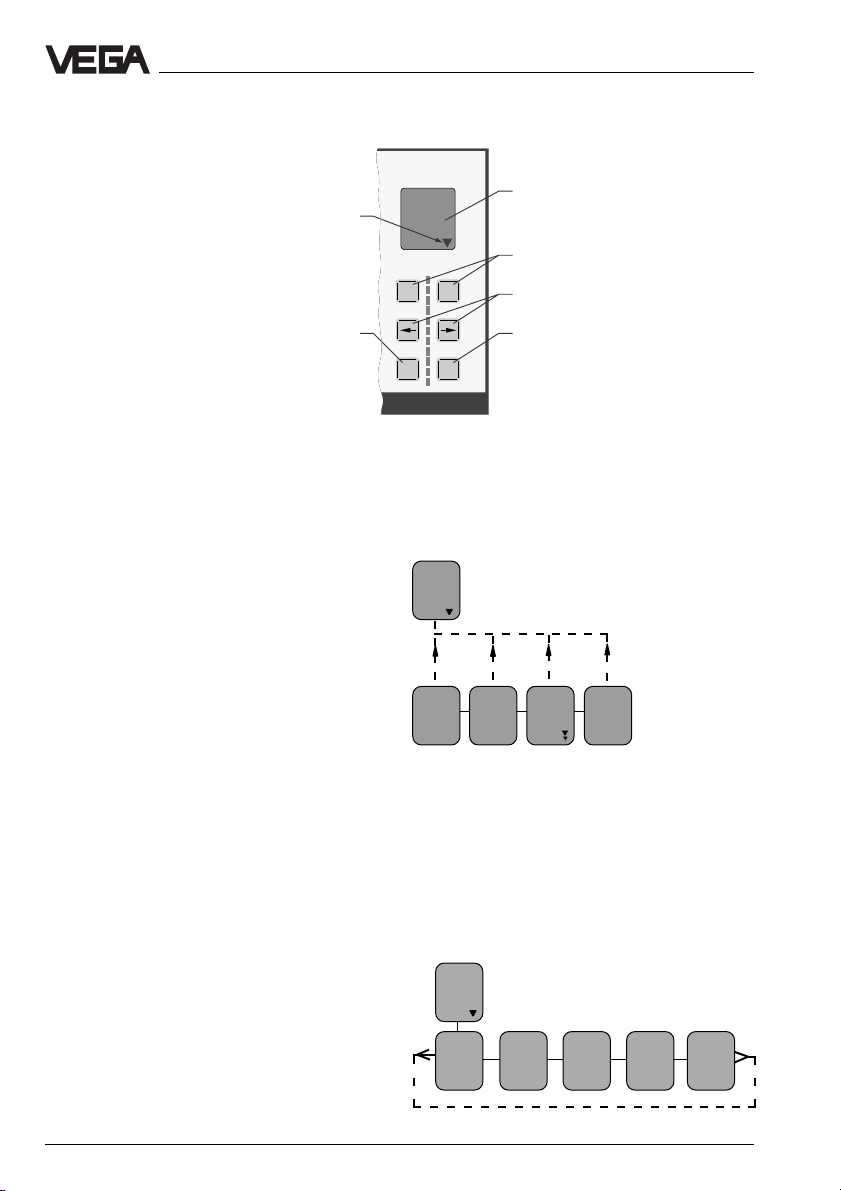

4.2 Adjustment system

Indicating and adjustment module

Branching point, i.e. jump to the

next lower menu with [OK]

Adjustment

Indication of

- measured value

- menu item

- parameter

%

100

+

-

Depending on the menu item, change value

or choose out of a list

Choose menu item

Depending on the menu item, interrupt

adjustment or change to the next higher

menu

"Reduced menu" – "Extended menu"

Two menu systems are available: the „reduced menu“ and the „extended menu“.

Note:

VEGAMET 614 V is preset to „reduced menu“

mode!

In the majority of applications, you can carry

out the necessary settings in this menu mode

(see also chapter 4.5 Comparison of the

menu modes).

Adjustment structure

The adjustment is made via 6 keys in conjunction with the text display. The jump from

the measured value display to the next lower

menu item is made with [OK]. Use [–>] or

[<–] to change within this menu level from

one menu item to the other. A branching point

is indicated by the symbol ▼ and enables

with [OK] a jump to the next lower menu item.

Parameters are indicated by the missing

symbol ▼. The value of the parameters can

be modified with [+] or [–] or chosen out of a

list. The modified value can be saved with

[OK]. To interrupt a setting (without saving

the modification), you have to push [ESC]. A

jump up to the next higher menu item is

Depending on the menu item, save the set

value or change to the lower menu

OKESC

made with [ESC]. 15 minutes after pushing a

key for the last time, an automatic reset to the

measured value display is triggered. A jump

up to the next higher menu level with [ESC] is

possible from each menu item , even if no

connection is shown in the menu schematics.

Add’l

function

ESCESC ESC ESC

Menu

Language

English

TAG 1

to default

mode

Reduced

Password

off

If you are in the utmost right menu item of a

menu row and push the [–>] key, you will

immediately reach the utmost left menu item

of this row. You also reach immediately the

right menu item from the left one, if you push

the [<–] key.

The connections (shown with a broken line)

are not shown in the menu schematics in

order to provide a clearer overview.

Volt

output 1

prop.

to

Percent

14 VEGAMET 614V

Unit

0,0%

Volt

output

0/10V

Failure

mode

0V

Volt

limitation

on

Page 15

Adjustment

Formatting examples of the menu

schematic

White letters indicate parameters

Language

which can be modified with the [+] or

Eng-

[–] key and saved with the [OK] key.

lish

Examples:

- In the menu item „Language“ you can

change from German to English.

Bolt print/italic inputs, e.g. the meas-

Param.

TAG-

urement loop name "TAG-No. 1" can

No. 1

show a different text if you have

▼

carried out a parameter adjustment

or configuration of the measurement loop. In

the menu schematics, you will see the factory

setting.

Light grey menu items are only dis-

Volt

at

played if necessary (depending on

0%

the adjustments in the other menu

0,000

items).

Changing the menu mode:

Move from the display of measured value

(TAG-No.1) to the menu item „Menu mode

reduced“. Now push [+] twice until „Menu

mode Extended“ appears, then push [OK].

You can now return to the measured value

indication by pushing [ESC] twice.

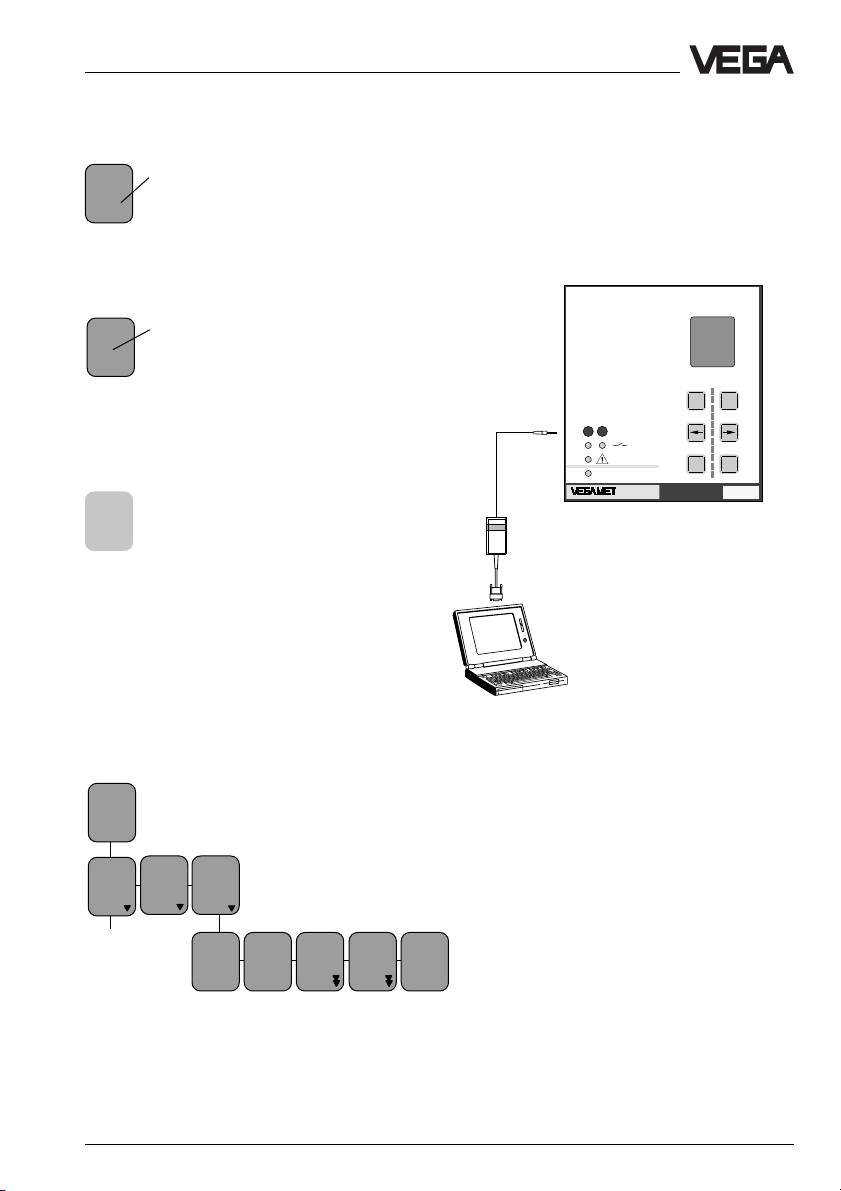

4.3 Adjustment via PC

Setup

- directly via the keys of the adjustment

module

- or with a PC, equipped with VVO software

(VEGA Visual Operating) and an interface

adapter VEGACONNECT.

%

100

+

-

CONNECT

12

on

614

VEGACONNECT

OKESC

Ser.No.

12345678

TAGNo. 1

%

xx,x

Add’l

Confi-

Param.

TAGNo. 1

guration

functions

Password

off

Language

English

TAG 1

to default

Reset

TAG 1

Menu

mode

Reduced

VEGAMET 614V 15

Page 16

Adjustment

4.4 Configuration and parameter adjustment

No matter whether you set up your

VEGAMET via the keys of the adjustment

module or via a PC with the software VVO,

the procedure is always the same.

Proceed in the following sequence:

- configuration (if not already configured with

a factory setting)

- parameter adjustment.

In this operating instructions manual, the

adjustment steps are described which are

directly carried out on the keys of VEGAMET.

The adjustment via the software VVO is described in a separate manual.

Configuration

Configuration means initially assigning or

setting functions. VEGAMET requires a

(mostly once) basic co-ordination that determines the applications and the assignments

of the inputs and outputs. Choices can be

made from existing functions and options.

This procedure is called configuration. The

signal conditioning instruments are delivered

with a configuration which only needs to be

changed in special cases.

The basic configuration includes the following

steps:

1 Configuration measurement loop

• Choose the kind of application (level,

gauge…)

• Choose sensor type (hydrostatic, ultra-

sonic…)

• Determine application (standard, level

difference…)

• Determine options (no option, correc-

tions…)

Note:

The measurement loop configuration can only

be modified, if a „Reset to single measurement“ has been carried out previously (under

„Additional functions“ in the extended menu).

If you only want to modify the sensor type,

you first have to carry out „Reset TAG 1“

(under „Additional functions“ in the reduced

menu).

2 Configuration of inputs

• Determine from where your VEGAMET

receives the input data (sensor, other

VEGAMET)

• Enter sensor characteristics values (meas.

range, current range)

3 Configuration of outputs

• All outputs (except fail safe relay) can been

assigned to one sensor or can be switched

off.

After basic configuration, VEGAMET goes

into operating mode and indicates the actual

measured value. The other configurations

should be carried out after the parameter

adjustment.

Parameter adjustment

Parameter adjustment means changing the

values. Signal conditioning instruments have

many parameters, the values of which can be

modified, such as for example, the integration

time of 0 … 600 s. The modification of these

values is called parameter adjustment. The

parameter adjustment does not influence the

configuration. Take note that parameter adjustment is only possible after a configuration

has been carried out (e.g. set values of the

current input after the current output has

been assigned).

16 VEGAMET 614V

Page 17

Adjustment

4.5 Comparison: "Reduced menu" – "Extended menu"

In the table the most important functions of VEGAMET 614 V are listed – each with a mark

indicating in which menu mode the functions are available.

Function Reduc. Ext.

Adjustment with medium x x

Adjustment without medium x x

Set integration time x x

Simulation xx

Switch over current output (4/20 mA, 0/20 mA, 20/4 mA, 20/0 mA) x x

Switch over voltage output (2/10 V, 0/10 V, 10/2 V, 10/0 V) x x

Switch over relay mode (overfill protection – dry run protection) x x

Scaling (display) x x

Change menu language x x

Activate/deactivate password x x

Change sensor type x x

Change measurement loop name x x

Reset measurement loop (Reset TAG) x x

Reset measurement loop to default (TAG to default) x x

Configuration and parameter adjustment of temperature measurement loop – x

Edit linearisation curves – x

Change mode (e.g. level – gauge) – x

Select different reference values for outputs – x

Define output behaviour (current/voltage output) in case of failure – x

Offset correction during adjustment – x

Adjust relay switching delay – x

Reset level –x

Assign inputs (from another VEGAMET) – x

Switch on/off current/Volt limitation – x

Individual setting of current/voltage output values betw. 0 … 20 mA/0 … 10 V – x

Manual offset correction – x

Manual real value correction – x

Info indication – x

Assign outputs to measurement loop (current, Volt, DCS, DIS,

relay outputs) – x

Select further relay modes (switching window, tendency determination) – x

menu menu

VEGAMET 614V 17

Page 18

5 Setup

• Set the VEGAMET instrument address on

the circuit board by means of the rotary

switch (only necessary, if several

VEGAMET are connected on the DISBUS).

• Install VEGAMET.

• Connect sensor and power supply.

• After switching on, the display indicates for

approx. 10 secs the instrument type and

the software version, e.g. „MET 614V

V1.12“.

• If a measurement loop has not yet been

configured, the display shows „Configuration“, the red failure LED also lights. In this

case, proceed as described under „6.1

Configuration of measurement loop“.

• If a measurement loop has been

configured, the display shows a value, e.g.

„TAG-No. 1 21.8 %“.You can now carry out

the settings as described in the chapter „6

Settings in the reduced menu“.

Setup

18 VEGAMET 614V

Page 19

Settings in the „Reduced menu“

6 Settings in the „Reduced menu“

6.1 Configuration of measurement loop

Choose sensor type

Meas.

TAG-

value

No. 1

%

indication

xx,x

Param.

TAGNo. 1

Configuration

Sensor

type

Hydrostatic

Pulse-Echo

Pulse-Radar

By default, VEGAMET 614V is configured for

connection to a hydrostatic pressure transmitter. If, for example, you use another sensor, you have to carr y out previously „Reset

TAG 1“ (in the menu item „Reset Now! OK?“

you confirm this with the [OK] key). Move to

the menu item „Sensor type Hydrostatic“,

there you choose with the [+] or [–] keys the

sensor type and confirm it with [OK].

Add’l

functions

Password

off

Language

English

TAG 1

to default

Reset

TAG 1

Delete

TAG

1?

Reset

OK ?

Reset

Now !

OK ?

Name measurement loop

TAGNo. 1

%

xx,x

Param.

TAGNo. 1

Configuration

Sensor

type

Hydrostatic

Sensor

optimize

TAGName

TAG No. 1

You can modify the measurement loop name

„TAG-No. 1“, if you want a more useful designation.

Two lines with six figures each are available.

To do this, move to the menu item „TAG name

…“.

Push [+] or [–] once. The first char-

TAGName

acter of the measurement loop name,

TAG -

in this example the letter T, flashes

No. 1

(editing mode). Continue pushing the

[+] or [–] key, by doing this you scroll

through the alphabet, through the row of

numbers and through a list of characters.

When you have reached the re-

TAGName

quested character, push [–>]. The

TAG -

next character is activated and be-

No. 1

gins flashing. Scroll again with [+]

and [–] to the requested character. With [–>]

you move to the next character.

If you have finished the last position

TAGName

of the name and you have "written"

Ves.4

the name of the measurement loop in

Hall3

this way, you have to push [OK] to

save the setting. If you quit the menu item

without saving, the name of the measurement

loop is again „TAG-No. 1“.

In the display of measured value and

Ves.4

Hall3

in all other menu items in which the

%

measurement loop name is shown,

27,8

you will now find the new designation.

VEGAMET 614V 19

Page 20

Settings in the „Reduced menu“

6.2 Sensor optimization

TAGNo. 1

%

xx,x

Param.

Configura-

TAG-

tion

No. 1

Sensor

Sensor

type

opti-

Hydro-

mize

static

For radar/ultrasonic sensors: see

MINICOM menu schematic in the

VEGASON/VEGAPULS operating

instruction manual in chapter „Adjust-

ment with VEGAMET or MINICOM“.

Like the measurement loop name, the sensor

name can also be modified if you want to give

it another designation. To do this, move to the

menu item „Sensor-Tag…“ (first menu item in

the sensor menu). The procedure is the

same as the modification of the measurement

loop name. The sensor name is saved in the

memory component of the sensor.

When you move to the menu item „Sensor

menu“, a new menu item opens which is

independent of VEGAMET. It is provided by

the connected sensor and has different adjustment options (e.g. installation geometry,

meas. environment…) depending on the

sensor type. The appropriate description is

stated in the operating instructions manual of

the sensor. These data, like the sensor name,

are also saved in the sensor. If at a later date

the sensor is connected to another signal

conditioning instrument, its adjustment data

remain.

Normally, the sensor will have been adapted

to customer-specific conditions so that modifications in the sensor menu will only be necessary if the sensor is used for a

measurement other than originally planned.

6.3 Adjustment with medium

You can either carry out the adjustment with

medium or without medium. Adjustment with

medium means that you carry out the adjustment taking the actual level into account. To

carry out an adjustment with medium, it is

necessary to know the percentage value of

the actual vessel filling.

TAGNo. 1

%

xx,x

Param.

TAGNo. 1

Adjustment

with

medium

Min-

Max-

adjust

adjust

at %

at %

100,0

0,0

In this procedure, the percentage values

which correspond to the actual min. and max.

fillings are entered. It doesn’t matter if you

enter first the min. value or the max. value. If

you know, for example, that your filling is

actually 80 %, you can enter in the menu

“max. adjustment” the value „80“. Later, when

your filling is, for example, 10 %, you enter in

the menu “min. adjustment” the value „10“.

The bigger the difference between the two

adjustment points, the more precise the

measurement over the whole measuring

curve. An adjustment at 0 % and 100 %

would be ideal. For practical reasons, it is not

always possible to completely empty or fill a

vessel. The distance between the two adjustment points, however, should be at least

10 % of the sensor range.

20 VEGAMET 614V

Page 21

Settings in the „Reduced menu“

Adjustment example

You know that your vessel is actually

Maxadjust

filled up to 80%. Move to the menu

at %

item „Max. adjust at % 100.0“. Push

100,0

the [–] key briefly, so that the figure

100.0 flashes (editing mode).

Continue pushing [–] until the figure

Maxadjust

80.0 appears on the display. Now

at %

push [OK] to save the adjustment.

80,0

Later, when your filling is, for exam-

Minadjust

ple, 10 %, you move to the menu item

at %

„Min. adjust at % 0.0“. Briefly push

0,0

[+], until the figure 0.0 flashes

(editing mode).

Continue pushing [+] until „10“ ap-

Minadjust

pears on the display. Now push [OK]

at %

to save the adjustment.

10,0

You can, of course, carry out the adjustment

with medium at 0 % and 100 % filling. Note:

The figures 0 % and 100 % must flash (editing mode), before they can be saved with the

[OK] key.

6.4 Adjustment without medium

Meas.

TAG-

value

No. 1

indication

%

xx,x

Param.

TAGNo. 1

Adjustment

with

without

medium

medium

Adjust-

0%

at

bar

0,000

100%

at

bar

1,000

ment

bar

m

For this adjustment procedure, you have to

enter two values (pressure or distance) corresponding to the levels 0 % and 100 %.

VEGAMET 614V 21

Page 22

Settings in the „Reduced menu“

Adjustment example

You know the data of the vessel, i.e. you

know that at 0 % filling, the distance from the

liquid to the sensor is 3.5 m and at 100 %

filling, 0.3 m.

Radar sensor

d1

0.3 m

at 100 %

d2

3.5 m at 0 %

In this menu item, you choose the

Adjustment

adjustment unit, e.g. m (d), if you use

a radar sensor [m (d) = distance in

m(d)

m]. Use the [+] and [–] key to

choose the unit and [OK] to save the selected unit.

0%

Enter in these two menu items the

at

distance values (d1 and d2). With the

m (d)

[+] and [–] keys you set the values,

3,50

with [OK] you save them.

100%

at

Note that in this example, a lower

m (d)

distance value exists at 100 % filling

0,30

than with 0 % filling!

6.5 Scaling

TAG-

Meas.

No. 1

value

%

indication

xx,x

Param.

TAGNo. 1

Sig-

Ad-

nal

just-

condi-

ment

tioning

Integr

Scal-

ation

ing

time s

0

0%

100%

corres-

corres-

ponds

ponds

1000

0

The adjustments under scaling determine

which number values and which unit will be

actually displayed on the measured value

indication (upper menu item). In the menu

items „0 % corresponds…“ and „100 % corresponds…“ you can enter with [+] or [–]

and [OK] values which should be displayed

at 0 % and at 100 % filling. In the menu item

„Decimal point…“ you determine the position

of the decimal point. In the next menu item

„prop. to…“ you can select from a list of parameters: percent, mass, volume, pressure

etc. After pushing [+] or [–] save with [OK].

According to this adjustment, the menu item

„Unit…“ provides a new choice, e.g. m, dm,

cm, mm, ft, yd and in, if you have selected

the parameter „Height“ (compare chapter „8

Measured quantity and units“).

Decimal

point

888,8

prop.

to

undefined

Unit

– –

22 VEGAMET 614V

Page 23

Settings in the „Reduced menu“

Scaling example

You have a raised tank and you want the

level to be indicated in meters with three

places after the decimal point.

100 %

h=4.5 m

h=1.5 m

2.341 m

0%

corresponds

1500

0 %

Enter the number 1500 (with keys

[+], [–] and [OK]) in this menu item.

This corresponds to the level at 0 %

(if you want to have a lower resolution

of the meas. value indication, you can also

enter 150 or 15).

Enter the number 4500 (with keys

100%

corres-

[+], [–] and [OK]) in this menu item.

ponds

This corresponds to the level at

4500

100 %.

6.6 Integration time

Meas.

TAG-

value

No. 1

%

indication

xx,x

Param.

TAGNo. 1

Sig-

Ad-

nal

just-

condi-

ment

tioning

Scaling

If the integration time is set to 0 s (factory

setting), each quick change of the product

surface (e.g. waves) will be immediately

detected and interpreted as level change. All

output values of VEGAMET will follow the

wave movements. To avoid this, the integration time can be increased (max.

600 s are possible with VEGAMET). The

higher the time setting, the slower the measured value display reacts.

Integr

ation

time s

0

Adjust the decimal point as shown

Decimal

(with keys [+], [–] and [OK]).

point

8,888

prop.

Choose the term „Height“ in this

to

menu item (with keys [+], [–] and

Height

[OK]).

Percent

Pressure

Mass

If you have chosen „Height“ in the

Unit

previous menu item, you get a choice

m

of several units (mm, dm, cm, m,

yard…). Choose m (with the keys

dm

cm

[+], [–] and [OK]).

….

TAG -

You can now see the scaled value in

No. 1

the measured value display.

m

2,341

VEGAMET 614V 23

Page 24

6.7 Outputs

Meas.

TAG -

value

No. 1

indication

%

xx,x

Param.

TAGNo. 1

Adjustment

Signal

conditioning

Outputs

Settings in the „Reduced menu“

Current

output 1

4/20mA

0/20mA

20/4mA

20/0mA

Current

output 2

4/20mA

0/20mA

20/4mA

20/0mA

Volt

output

1

0/10V

10/2V

10/0V

2/10V

Volt

output

2

0/10V

10/2V

10/0V

2/10V

The current output of VEGAMET is set to

4 … 20 mA. By pushing [+] or [–] and [OK]

you can set the output to the following values:

0/20 mA, 20/4 mA and 20/0 mA.

Beside the preadjustment (0/10 V), the following options are available for the voltage output: 10/2 V, 10/0 V and 2/10 V.

As a factory setting, the relay outputs are set

to mode „Overfill protection“ (mode A). By

pushing [+] or [–] and [OK] you can assign

the mode „Dry run protection“ (mode B)

separately for each relay output. In the next

menu items you can determine the upper and

lower switching points for the set mode.

The graphics on the right show the behaviour

of the relay outputs and LEDs depending on

the level.

Relay

Relay

output

output

2

1

High

Low

%

0,0

High

%

100,0

%

100,0

Mode

Overfill

protec

Dry run

protec

Mode

Overfill

protec

Dry run

protec

Low

%

0,0

Overfill protection

Parameter

High

Low

Relay output

t

The relay of relay output 1 deenergises at the

switching point „High“ (safe switching condition).

Dry run protection

Parameter

High

Low

Relay output

t

The relay of relay output 1 deenergises at the

switching point „Low“ (safe switching condition).

24 VEGAMET 614V

Page 25

Settings in the „Reduced menu“

6.8 Simulation

Meas.

TAG-

value

No. 1

%

indication

xx,x

Param.

TAGNo. 1

Adjustment

Signal

conditioning

Outputs

Simulation

Simulation

Now !

OK ?

Simulation

%

xx,x

To check outputs and connected instruments,

you can adjust any individual percentage

value with the keys [+] and [–] in this menu

item. Initial point is always the actual measured value. The indicated value flashes when

simulation is activated. 15 minutes after setting the simulated value, the simulation automatically terminates and resets to meas.

value indication.

6.9 Password, language, reset,

menu mode

Meas.

TAG-

value

No. 1

%

indication

xx,x

Configuration

Add’l

functions

Password

off

on

Language

English

German

French

etc.

TAG 1

to default

Reset

OK ?

Reset

TAG 1

Menu

mode

Reduced

Param.

TAGNo. 1

Password

You can also protect VEGAMET 614V against

unauthorised or incorrect adjustment. Activate in the menu „Password“ the option „on“

(with keys [+], [–] and [OK]). Now you can

only check the meas. value on the display.

You can still reach any menu item with the

arrow and OK keys, but as soon as you try

to modify an adjustment, you are asked for

the password. Enter the number „614“ (with

the keys [+], [–] and [OK]), to carry out the

adjustment. Entering the password once is

sufficient to open all protected menu items.

Language

In the menu item „Language“, you can

choose a language other than German, such

as English, French etc. as menu language

(with keys [+], [–] and [OK]).

Reset

In the menu item „TAG 1 to default“ you reset

all settings relating to measurement loop 1 to

default. If, for example, you have changed

the name of the measurement loop to „Silo 5“,

after the reset, the name is again „TAG-No.

1“. Also, all the adjustment values you have

entered for measurement loop 1 are now

reset to default. A measurement loop configuration carried out later on, however, remains.

Menu mode

The menu modes „Reduced“ and „Extended“

are available. With the keys [+], [–] and [OK]

you choose the required menu mode. The

menu schematics of the reduced menu and

the extended menu are shown later in this

operating instructions manual. The factory

Ex-

setting is „Reduced menu“.

tended

Reset

Now !

OK ?

VEGAMET 614V 25

Page 26

7 Settings in the „Extended menu“

7.1 Configuration of measurement loop

TAG -

TAG -

No. 1

No. 2

%

°C

xx,x

xx,x

Confi-

Param.

Param.

TAGNo. 1

TAGNo. 2

guration

Config

inputs

Config

meas.

loop

TAG 1

Level

TAG 2

Temperature

Settings in the „Extended menu“

Application

Level

Gauge

Pressure

TAGname

TAG No. 2

Sensor

type

Hydrostatic

Pulse-Echo

Pulse-Radar

Failure

mode

on

off

Mode

Standard

The measurement loop configuration is usually provided as factory setting. Should a

fundamental modification of the measurement

loop configuration be necessary, a „Reset to

single measurement“ must be carried out first

(in the menu range „Additional functions“,

„Reset VEGAMET“). Only then can you

modify the adjustments in the menu items

Application, Sensor type, Mode and Option.

You should, therefore, work through the individual menu items in the given sequence. The

selection or adjustment options always depend on the adjustment in the previous menu

item. If, for example, in the menu item Application "Level" has been set, only a sensor

type that is suitable for level detection can be

selected in the menu "Sensor type".

As soon as you have carried out and confirmed an adjustment in the menu item „Option“, the following message appears on the

display: „TAG being created!“.

Option

no

options

Sensor

coordination

Position A

Input

no.1

TAGname

TAG No. 1

Failure

mode

on

off

In the menu item „TAG-Name“ you can assign

any name to the measurement loop (see

chapter „6.1 Configuration of measurement

loop in the Reduced menu“). If you chose

„Failure mode off“, the fail safe relay and the

failure indication on the front plate become

nonoperatable. In the following illustrations

further application modes are shown. In addition, you will see there which adjustments you

have to carry out in the menu items „Sensor

type“, „Mode“ and „Option“.

26 VEGAMET 614V

Page 27

Settings in the „Extended menu“

Level measurement

Application: Level

Sensor: Hydrostatic pressure transmitters

Ultrasonic sensors

Radar sensors

Differential pressure transmitters

Mode: Standard

Option: none

Parameter: TAG1 level

Gauge measurement

Application: Gauge

Sensor: Hydrostatic pressure transmitters

Ultrasonic sensors

Radar sensors

Mode: Standard

Option: none

Parameter: TAG1gauge

Distance measurement

Application: Distance

Sensor: Ultrasonic sensors

Radar sensors

Mode: Standard

Option: none

Parameter: TAG1 process pressure

Pos. A Pos. A

Pos. A

Level measurement

Pos. A Pos. A Pos. A

Gauge measurement

Pos. A Pos. A

Distance measurement

7.2 Configuration of temperature measurement loop

With pressure transmitters and ultrasonic

sensors, it is possible to create an additional

measurement loop for temperature measurement. One requirement is that a sensor be

used which delivers a temperature signal.

After having selected a suitable sensor type

for configuration of measurement loop 1,

VEGAMET 614V creates automatically measurement loop 2. In the highest menu level

(measured value indication), the temperature

is displayed. Parameter adjustment of the

temperature measurement loop is like adjustment of measurement loop 1.

VEGAMET 614V 27

Page 28

7.3 Configuration of inputs

TAG No. 1

%

xx,x

Param.

TAGNo. 2

Configuration

Param.

TAGNo. 1

Settings in the „Extended menu“

Config

inputs

Input no. 1: VBUS input (measured value)

Input no. 2: VBUS input (measured temperature value)

Input

Input

no. 1

no. 2

like input 1

MET02

MET03

MET04

….

Serial

no.

xxxx

xxxx

Input

undefined

Input 1

Input 2

Input 3

Sensor

characteristics

Min.

meas.

range

0,00

Input

from

local

Met

Input local MET:

Here you can call another VEGAMET (e.g.

Met 05) and thereby specify that the input

signal should not be taken from a directly

connected sensor, but from a VEGAMET

connected via DISBUS (e.g. VEGAMET

614V). The called VEGAMET number corresponds to the DISBUS address of the instrument (see chapter 4.1).

Sensor

optimisation

Max.

meas.

range

5,00

For radar/ultrasonic sensors: see

MINICOM menu schematic in the

VEGASON/VEGAPULS operating instruc-

tion manual under chapter „Adjustment

with VEGAMET or MINICOM“.

If another VEGAMET has been selected, the

menu item „Input undefined" appears in

which you can set the input number of the

other VEGAMET (see illustration).

The sensor characteristics values are delivered by the connected sensor and cannot be

modified here. The sensor menu is delivered

by the connected sensor and enables configuration of the sensor from VEGAMET.

DISBUS

Ein-

gang

Ein-

gang1

%

100

+

-

OKESC

614

Ser.No.

12345678

CONNECT

12

on

TAGNo. 1

%

35,9

%

100

+

-

CONNECT

OKESC

MET 05

input 1

Ser.No.

12345678

614

12

on

„local MET“

28 VEGAMET 614V

Page 29

Settings in the „Extended menu“

7.4 Configuration of outputs

TAG No. 1

%

xx,x

Param.

TAGNo. 1

Param.

TAGNo. 2

Configuration

Config

inputs

Config

meas.

loop

Config

outputs

Config

current

output

Current

1 to

TAG No. 1

TAG 2

----

Config

Volt

output

Volt1

to

TAG No. 1

TAG 2

----

Current

2 to

TAG No. 2

TAG 1

----

PC/DCS output and DIS output:

The PC/DCS signal as well as the DIS signal

are transmitted via the DISBUS. The PC/DCS

output delivers output signals from

VEGAMET to the interface converter

VEGACOM 557. This interface converter

transfers the signals from VEGAMET via

different standard protocols to connected

systems (DCS/DCS). In the menu items „DCS

1 to“ up to „DCS 7 to…“ the measurement

loop can be assigned or switched off. In the

menu items „PC/DCS relay status“ and „PC/

DCS input status“ it can be specified that the

relay mode is transmitted via the DISBUS. Up

to seven external indicating instruments

(VEGADIS 174) can be connected to

DISBUS. In the menu items „DIS 1 to…“ up to

„DIS 7 to–“ the measurement loop can be

coordinated or switched off.

Config

Config

PC/

DCSoutput

PC/

DCS

meas.

values

DCS 1

to

TAG No. 1

----

VEGADIS

DIS 1

to

TAG No. 1

----

PC/DCS

relay

status

off

DCS 7

to

----

DIS 7

to

----

PC/DCS

input

status

off

V olt2

to

TAG No. 2

TAG 1

----

Config

relay

output

Operating

relay

Rel. 1

to

TAG No. 1

TAG 2

----

Fail

safe

relay

Rely

Standard

Rel. 2

to

TAG No. 2

TAG 1

----

The current, volt and relay outputs with

number 1 (current 1, Volt 1 and Rel. 1) are

assigned as factory setting to measurement

loop „TAG-No. 1“. If a second measurement

loop exists, as is the case when a sensor

with temperature output is connected, then

the outputs with number 2 are assigned to

measurement loop TAG-No. 2. All outputs can

be assigned individually to the other measurement loop or switched off (----), i.e. the

switched off outputs do not access a measurement loop.

A hold function or a reset of alarm functions

can be assigned to each operating relay. In

this case, the menu item „Input“ appears.

Here, the relay can be assigned to „Input 4“

(correction input). For a description of the

relay functions, see the following pages.

VEGAMET 614V 29

Page 30

7.5 Adjustment

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG-

No. 2

No. 1

Adjustment

like T A G- No. 1

Settings in the „Extended menu“

with

medium

Minadjust

at %

0,0

Max adjust

at %

100,0

without

medium

Adjustment

bar

Offset

correction

Sensor

unpressur’d?

OK ?

Offset

corr.

Now !

OK ?

0%

at

bar

0,000

100%

at

bar

5,000

The adjustment with medium corresponds

to the procedure in the reduced menu (see

appropriate chapter).

- if the medium is changed later on (medium

with another density value) and no new

adjustment can be made

or

- if the MET indication and the DIS outputs

relate to height in meters

note the following:

In applications with hydrostatic pressure

transmitters, the adjusted density value (see

menu „Parameter“) must correspond to the

value of the medium.

For the adjustment without medium, two

anticipated values for level, pressure etc.

corresponding to 0 % and 100 % must be

entered.

The menu item „Offset correction“ is activated

when hydrostatic pressure transmitters are

connected. The offset correction should be

carried out after installation of the sensor, as

the sensor values can differ slightly due to

different installation positions or strong tightening during mounting.

With the offset correction, the meas. data of

the unpressurised sensor (vessel empty) are

detected as correction values and taken into

account in all subsequent measurements.

30 VEGAMET 614V

Page 31

Settings in the „Extended menu“

7.6 Conditioning

TAG No. 1

%

xx,x

Param.

Param.

TAG -

TAG-

No. 1

No. 2

like T A G- No. 1

Adjust-

Signal

ment

conditioning

Scaling

0%

corresponds

0

Integr

Lin.

ation

curve

time s

0

linear

cylindrical tank…

Deci-

100%

mal

corres-

point

ponds

888,8

1000

Density in

Kg/dm

1,000

prop.

to

undefined

3

Unit

– –

The menu items „Scaling“ and „Integration

time“ correspond to the menu items in the

„reduced menu“ (see appropriate chapter).

The menu item „Density…“ is displayed as

an option when under „Configuration measurement loop“ the appropriate sensor type

has been selected. The density value must,

before adjustment with medium, be so adjusted that it corresponds to the value of the

medium (water has a density of 1.0 kg/dm

3

The following linearisation curves are available:

- linear (factory setting)

- horiz. cylindrical tank

- spherical tank

- Lin-curve 1

- Lin-curve 2

- Lin-curve 3

Lin-curves 1 … 3 can be edited by the

user (see appropriate chapter).

Meas.

value

limitation

nega-

Failure

tive

mode

values

Stan

yes

dard

>110%

After scaling or linearisation, the required

output must be assigned to the scaled or

linearised value (menu item "prop. to..." and

"Unit...") in the menu range "Parameter adjustment outputs".

Under Meas. value limitation, you can exclude negative values.

Failure mode Standard

means that at a sensor current of 3.6 mA or

).

21 mA, the fail safe relay responds.

Failure mode >110%

also causes a fault signal if a meas. value of

more than 110 % or less than -10 % is

reached.

VEGAMET 614V 31

Page 32

7.7 Parameter adjustment of outputs

Current outputs/Volt outputs

TAG No. 1

%

xx,x

Param.

Param.

TAG -

TAG-

No. 1

No. 2

like T A G- No. 1

Out-

Signal

Adjustment

conditioning

puts

Settings in the „Extended menu“

Current

outputs

Current

output

1

prop.

to

Percent

Volume T ARE%

Current

output 2

Unit

0,0%

like current

output 1

Current

output

4/20mA

0/20mA

20/4mA

20/0mA

free

Volt

outputs

Volt

output

1

prop.

to

Percent

Volum e TAR E %

Current at

0%

4,000

0,0

..20,0

In the menu item „prop. to“, you can choose

between percent and volume. „Prop. to volume“ is then useful when under „Signal conditioning - Linearisation curves“, for example,

a spherical tank or an individually defined

linearisation curve is selected. The output

current or the output voltage is then proportional to the volume of the tank contents.

Unit:

Selection list dependent on the choice in the

previous menu item „prop. to“ (see chapter

„8 Measured quantity and units“).

Volt output/Current output:

If „free“ is chosen, the following (light grey)

menu items appear:

Volt

output 2

like Volt output 1

Unit

0,0%

Current

at

100%

20,000

0,0

..20,0

Volt

output

0/10V

10/2V

10/0V

2/10V

free

Failure

mode

0mA

22mA

- 0%

100%

Volt

at

0%

0,000

0,0

..10,0

Current

limitation

on

off

Volt

at

100%

10,000

0,0

..10,0

Failure

mode

0V

11V

- 0%

100%

- Volt at 0 %/100 %:

Individual voltage values between 0 V and

+10 V can be set.

- Current at 0 %/100 %:

Individual current values between 0 mA

and +20 mA can be set.

Failure mode:

The height of the output current/output voltage in case of failure is determined. If „--“ is

chosen, the actual value is maintained.

Volt limitation/Current limitation on:

Voltage/current remain within the values

which are given in the menu item “Voltage

output/current output”.

Volt

limitation

on

off

32 VEGAMET 614V

Page 33

Settings in the „Extended menu“

Relay outputs

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG-

No. 1

No. 2

like T A G- No. 1

Signal

conditioning

Outputs

Current

outputs

Volt

outputs

Relay

outputs

Relay

output

1

prop.

to

Percent

Volume

Height

Pressure

Adjustment

Relay

output

2

like relay output 1

Unit

Mode

Overfill

protec

0,0%

0,00 %

Tare %

Low

%

0,0

Dry run protec.

Switching window on

Switching window off

Tendency rising

Tendency falling

High

%

100,0

Deviation

s

1,0

Deviation

per

time

Cycle

time

s

1

Failure

mode

off

hold

Number

of

cycles

10

Add’l

functions

Switching

delay

t on

s

0

t off

s

0

In the menu item „prop. to“, you choose a

parameter that the relay will react to. You can

choose between percent and volume („prop.

to volume“ is useful when under „Conditioning

- Linearisation curves“, for example a spherical tank or a user-programmable lin. curve is

selected). In the next menu item you can

select the suitable Unit. In the menu item

„Mode“ the mode of the relay can be se-

With all other modes, the menu items „Low“

and „High“ appear. There you can determine

the switching points for the relay.

The menu item „Failure mode“ always ap-

pears. „Failure mode off“ causes the relay to

deenergise when a failure (e.g. sensor

shortcircuit) occurs. „Failure mode hold“

causes the actual relay status to be main-

tained when a failure occurs.

lected. The individual relay modes are described on the following pages.

Under „Add’l functions“ you can adjust a

switch on delay (t on) and a switch off delay

If mode „Tendency rising“ or „Tendency falling“ is selected, the menu items „Deviation“,

„Dev. per time“, „Cycle time“ and „Number of

(t off) of the relay of max. 600 s (with the relay

modes „Tendency rising“ or „Tendency fall-

ing“, no switching delay can be set).

cycles“ appear.

VEGAMET 614V 33

Page 34

Settings in the „Extended menu“

Relay mode: overfill protection

The relay deenergises at switching point

„High“ (safe condition).

Relay mode: dry run protection

The relay deenergises at switching point

„Low“ (safe condition).

Relay mode: switching window on

The relay of relay output 1 is energised within

the switching window.

Parameter

High

Low

t

Relay output

Parameter

High

Low

t

Relay output

Parameter

High

Low

t

Relay output

Relay mode: switching window off

The relay of relay output 1 is deenergised

within the switching window.

Parameter

High

Low

t

Relay output

34 VEGAMET 614V

Page 35

Settings in the „Extended menu“

Tendency determination

The level change within the cycle time (ta) is determined and after completion of all cycles (n)

an average value is generated from the sum of the level changes. If this average value exceeds a previously defined % value, the tendency determination responds, i.e. an energised

relay deenergises. If „Tendency rising“ or „Tendency falling“ are selected, the menu items

„Deviation in %“ and „Deviation per time“ are activated.

%

t ges.

t

a

–– Mode Tendency rising

The relay deenergises when the

rising average value of „t tot.“

exceeds the previously defined %

value.

Tendency falling

Relay output

ta = cycle time

n = number of cycles

%

4 n=4

321

t ges.

t

a

same dependence, however with

falling average value

4 n=4

321

Relay output

ta = cycle time

n = number of cycles

–– Deviation in % 2 If the level change exceeds the % value set

here, the tendency determination responds.

0 … 110 %

Example 2 % (change) per t tot.

–– Deviation per time

t

t

–– Cycle time

in s 60 Adjustment range 0 … 999 s

Example 60 s correspond to 1 minute

–– Number of

cycles 4 Adjustment range 0 … 99 cycles

Example: t tot = ta • n = 60 • 4 = 240 s = 4 min,

i.e. after every 4 min., the average value of the

deviation is generated and the result is compared with the given deviation in %, here in the

example = 2 %

VEGAMET 614V 35

Page 36

MET indication/PC/DCS outputs/DIS outputs

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG-

No. 1

No. 2

like T A G- No. 1

Signal

conditioning

Outputs

Adjustment

Settings in the „Extended menu“

Current

outputs

Volt

outputs

Relay

outputs

MET

display

prop.

to

Percent

scaled

Height

…

MET indication/Unit:

In the menu item „prop. to“, you choose the

parameter to which the VEGAMET display

reacts (if you have carried out a scaling under the menu item „Signal conditioning“,

„prop. to scaled“ will have been automatically

set, i.e. the display will indicate the scaled

value). „Prop. to volume“ is then useful if you

have selected, for example, a spherical tank

or a user-programmable lin. curve under

„Signal conditioning - Linearisation curves“.

The indicated values of the VEGAMET display then react proportionally to the volume of

the tank contents.

DCS

output 1

prop.

to

Percent

scaled

Height

…

DIS

outputs

DIS

output

1

prop.

to

Percent

scaled

Height

…

Unit

0,0%

Unit

0,0%

DIS

output 7

like DIS output 1

DCS

output

7

like DCS output 1

Unit

0,0%

PC/

DCS

outputs

PC/DCS outputs and DIS outputs:

Are adjusted according to the same procedure as the MET indication.

36 VEGAMET 614V

Page 37

Settings in the „Extended menu“

7.8 Simulation 7.9 Special function: Reset

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG -

No. 2

No. 1

like TAG-No. 1

Out-

Adjustment

Signal

conditioning

puts

Simulation

Simulation

Now!

OK?

Simulation

%

XX,X

To check the outputs and connected instruments, you can adjust in this menu item any

individual percentage value with the keys [+]

and [–]. The starting point is always the actual measured value. The indicated value

flashes when the simulation is activated. 15

minutes after setting the simulated value, the

simulation is automatically terminated and the

display reset to measured value indication.

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG-

No. 2

No. 1

like T A G- No. 1

Out-

Simu-

Adjustment

Signal

conditioning

puts

lation

Special

functions

Reset

Level

Reset

OK ?

Reset

Now!

OK ?

With this reset, all parameter values of the

measurement loop TAG-No. 1 are reset to

factory settings (empty and full adjustment,

relay outputs, current output, volt output and

scaling of the meas. value indication are

reset).

VEGAMET 614V 37

Page 38

7.10 Password, language, menu mode

See chapter „6 Settings in the reduced menu“.

TAG No. 1

%

Settings in the „Extended menu“

Param.

TAGNo. 1

Param.

TAGNo. 2

Configuration

Add’l

functions

Password

off

lin.

curve

InfoEdit

Language

English

7.11 Special function: Manual correction

TAG Nr. 1

%

xx,x

Param.

TAGNr. 1

Adjustment

Param.

TAGNo. 2

like T A G- No. 1

Signal

conditioning

Outputs

Simulation

Special

functions

Reset

Level

Manual

corr.

Offset

correction

Manual offset correction

(only with hydrostatic pressure transmitters)

This correction can be carried out to compensate changes of the sensor values due to

ageing. In order to do this, the sensor must

be in an unpressurized condition (empty

vessel).

Manual real value correction

In the menu item „Correction % 0.0“ you can

enter a percentage value which corresponds

to the actual level.

Real

value

corr.

Reset

VEGAMET

Service

Menu

mode

Extended

Reduced

Offset

correc tion

OK?

Correction

now!

Real

value

corr.

OK?

Correction

%

0,0

Correction

now!

OK ?

38 VEGAMET 614V

Page 39

Settings in the „Extended menu“

7.12 Linearisation curves

TAG No. 1

%

xx,x

Param.

TAGNo. 1

Param.

TAGNo. 2

Configuration

Add’l

functions

Pass

word

off

Edit

lin.

curve

Lin.

curve1

Lin.

curve2

Lin.

curve3

Add

lin.

point

x %

0,0

y V%

0,0

like LIN-curve 1

Edit

lin.

curve 1

x 0 %

y 0 V%

0,0

Linearisation curve 1 … 3

A linearisation curve is generated by a certain number of index markers and their value

pairs. A value pair consists of a value for

level percent (X %) and a value for volume

percent (Y V %). Up to max. 32 index markers can be added. A linearisation curve can

be terminated after any individual number of

index markers. The signal conditioning instrument terminates the linearisation curve automatically with the values X = 100 % and Y

= 100 %.

The data for the value pairs can be determined by incremental filling or can be taken

from a table of values provided by the vessel

manufacturer.

An example of incremental filling

Initial situation:

- you have already carried out the 0 % and

100 % adjustment

- the total volume of the vessel is known to

you, for example 300 m

- the gauging volume in this example was

set at 15 m

3

3

Delete

lin.

point

x 1 %

0,0

100,0

y 1

V%100,0

Index marker number

(0…32)

x 2 %

100,0

y 2

V% 100,0

x 32 %

100,0

y 32V%

100,0

x 0,0

y 0,0

delete

Delete

Now?

1st index marker

- fill the vessel with the liquid quantity of the

gauging volume of 15 m

3

- the value for level percent is indicated on

VEGAMET, transfer this value into the linearity protocol, column X %

- the value for volume percent must be calculated acc. to the following formula

100 % x gauging volume

Y 1 V = ––––––––––––––––––––––––

total volume

100 % x 15 m

= ––––––––––––––– = 5 %

300 m

3

3

Transfer this value also into the linearity

protocol, column Y V %.

2nd index marker, etc.

See also the following illustration.

x 100,0

y 100,0

delete

Delete

Now?

VEGAMET 614V 39

Page 40

Illustration of a linearisation curve

Settings in the „Extended menu“

X (in %)

100

80

60

40

20

Add

lin.

point

x %

0,0

y V%

0,0

With [OK] the new value pair

is automatically placed at the

correct position in the

linearisation curve. The already present index markers

are re-sorted.

0

X1 %

12,0

Y1 V %

5,0

Edit

lin.

curve 1

x 0 %

0,0

y 0 V%

0,0

x 1 %

100,0

y 1

V%100,0

x 2 %

100,0

y 2

V% 100,0

Select the index markers

1 … 32 with [–>] or [<–], edit

the Y value with [+] or [–],

accept with [OK].

40 60 80 100

Delete

lin.

point

x 0,0

y 0,0

delete

Delete

now?

X32 %

100,0

Y32V %

100,0

x100,0

y100,0

delete

Delete

now?

To delete the index markers,

select the value pairs with [–

>] or [<–]. With [OK] the

value pair and the corresponding index marker are

deleted from the lin. curve.

The remaining index markers

move up.

V (in %)20

40 VEGAMET 614V

Page 41

Settings in the „Extended menu“

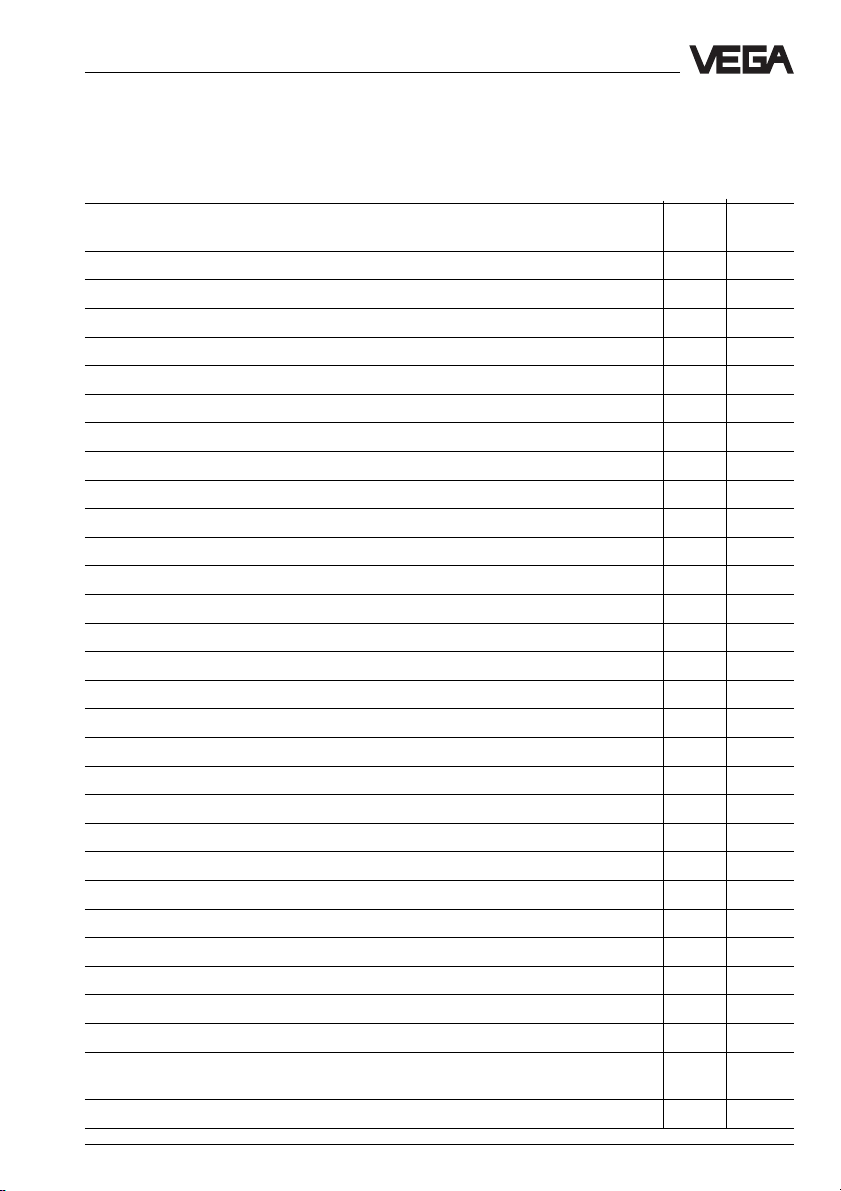

Linearity protocol

A linearisation curve is entered in the menu item "Add. lin. point“.

Linearisation curve 1

Index Value pair

marker no. X % Y V %

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

29

30

31

32

Linearisation curve 2

Index Value pair

marker no. X % Y V %

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

29

30

31

32

Linearisation curve 3

Index Value pair

marker no. X % Y V %

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

29

30

31

32

Note

Date

Name

VEGAMET 614V 41

Page 42

7.13 Info

TAG No. 1

%

xx,x

Param.

Param.

TAG-

TAG-

No. 1

No. 2

Configuration

Add’l

functions

Password

off

Edit

lin.

curve

Info

Input

info

VEGAMET

info

Type

MET614

Program