Page 1

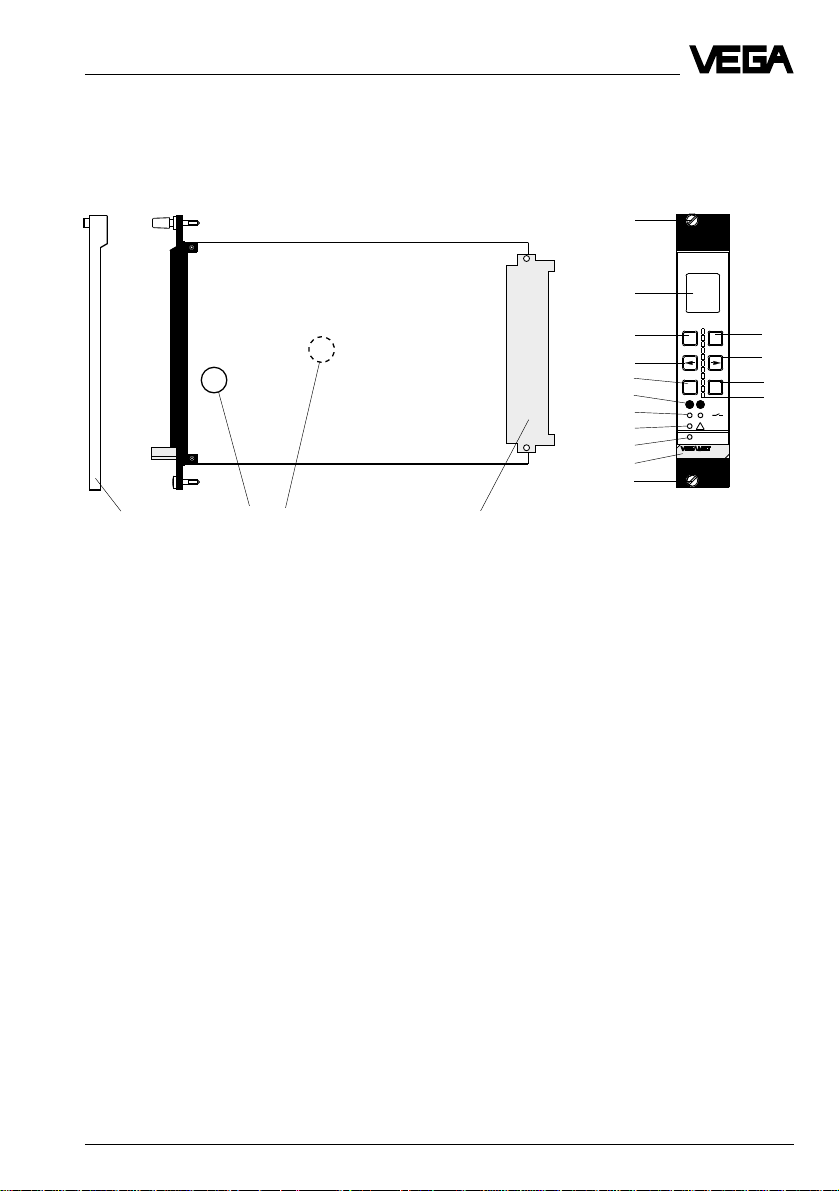

Operating Instruction

VEGAMET 514… D

Level and Pressure

-

ESC

%

100

+

OK

CONNECT

2

1

on

514 D

out

in

Page 2

Contents

Safety information ....................................................................................... 2

1 Product description

1.1 Function and configuration ................................................................ 4

1.2 Types and versions ............................................................................ 5

1.3 Applications ....................................................................................... 6

1.4 Technical data .................................................................................... 7

1.5 Dimensions ....................................................................................... 10

1.6 Ex-technical data ............................................................................. 11

1.7 Approvals ......................................................................................... 11

2 Mounting

2.1 Mounting versions ............................................................................ 12

2.2 Instrument address .......................................................................... 13

3 Electrical connection......................................................................... 14

Contents

Safety information

The described module must only be inser ted and

operated as described in this operating instruction.

Please note that other action can cause damage for

which VEGA does not take responsibility.

2 VEGAMET 514… D

Page 3

Contents

4 Set-up

4.1 Indicating and operating elements ................................................. 15

4.2 Adjustment system ........................................................................... 16

4.3 Menu list ........................................................................................... 17

4.4 Adjustment via PC ............................................................................ 18

4.5 Set-up sequence .............................................................................. 18

4.6 Set-up, configuration ....................................................................... 19

4.6.1 Configuration inputs............................................................ 19

4.6.2 Configuration meas. point .................................................. 21

4.6.3 Configuration output ........................................................... 23

4.7 Set-up, parameter adjustment ......................................................... 26

4.7.1 Parameter adjustment MST1, adjustment .......................... 26

4.7.2 Flow measurement .............................................................. 28

4.7.3 Parameter adjustment MST1 and MST2, processing ........ 33

4.7.4 Parameter adjustment MST1 and MST2, outputs .............. 35

4.7.5 Parameter adjustment MST1 and MST2, simulation .......... 42

4.7.6 Parameter adjustment MST1 and MST2, special functions43

4.8 Set-up, additional functions ............................................................. 43

4.8.1 Password ............................................................................. 43

4.8.2 Linearization curve 1 … 3 ................................................... 43

4.8.3 Info ....................................................................................... 44

4.8.4 Language ............................................................................ 44

4.8.5 VEGAMET Reset ................................................................. 45

4.8.6 Service................................................................................. 45

5 Diagnosis

5.1 Detailled menu list ............................................................................ 46

5.2 Maintenance ..................................................................................... 48

5.3 Repair ............................................................................................... 48

5.4 Fault signal ....................................................................................... 48

5.5 Error codes ....................................................................................... 49

VEGAMET 514… D 3

Page 4

1 Product description

Product description

1.1 Function and configuration

VEGAMET 514 D and 514 DV signal conditioning

instruments are designed for flow measurement.

Function

Flow measurement in flumes

Flumes or their throat cause a reflux of the measured

product. The flow can be determined out of the

appropriate levels.

Sensors detect levels and deliver analog or digital

measured data to connected VEGAMET.

In the signal conditioning instruments the parameter

"flow" is generated out of the measured data.

The output result is provided as current, volt and

relay output as well as digital signal output

(DISBUS).

The current and relay outputs are sometimes

provided with a flow specific preconfiguration.

Sketch

AB

Function components

Parameter for

- meas. point 1 (MST1)

- meas. point 2 (MST2)

Application

- Sensor

- Kind

- Option

- Sensor position A … D

FB

1

2

EB

1

AB

AB

Display

AB

EB

mA

V

PC

DIS

4

Configuration

The signal conditioning instruments are

microcomputer controlled and consist of software

components.

Mechanically the signal conditioning instruments are

designed in 19"-technology (width 5 TE = 24,5 mm).

Output components

Current outputs 0 … 20 mA

Voltage outputs 0 … 10 V

Relay outputs 1 … 2

Display

Digital signal output

- PC/DCS-output

- DISBUS-output

Input components

Correction signal input

- input 4

- channel no. K1

Sensor input

- input 1

- channel no. S1 or

- series no of sensor 1

4 VEGAMET 514… D

Page 5

Product description

Examplary application

- flow measurement in a flume

- with offset correction (by additional sensor)

A

no. 1 S1

no. 4 K1

Inputs

- input 1 and 4

- channel no. S1 and K1

D

Sensor

- offset correction signal in pos. D

- sensor 1 in pos. A

Meas. points Parameter

- MST1 = A - level

- MST2 = A - flow

1.2 Types and versions

According to the application and the appropriate

sensor the type and version of the signal

conditioning instrument can be determined.

VEGAMET for sensors with analog measured data

transmission

- hydrostatic pressure transmitter

VEGAMET Number of Number of outpouts

514 D… 1 1 3 3 2 1 1

… Ex = Signal conditioning instrument for meas. systems

inputs

Sensor Correct. mA V DIS

signal

in hazardous areas, certificate to CENELEC

VEGAMET for sensors with digital measured data

transmission (VBUS)

- hydrostatic pressure transmitter

- ultrasonic sensor

- radar sensor

VEGAMET Number of Number of outputs

514 DV 1 1 3 3 2 1 1

inputs

Sensor Correct. mA V DIS

signal

VEGAMET 514… D 5

Page 6

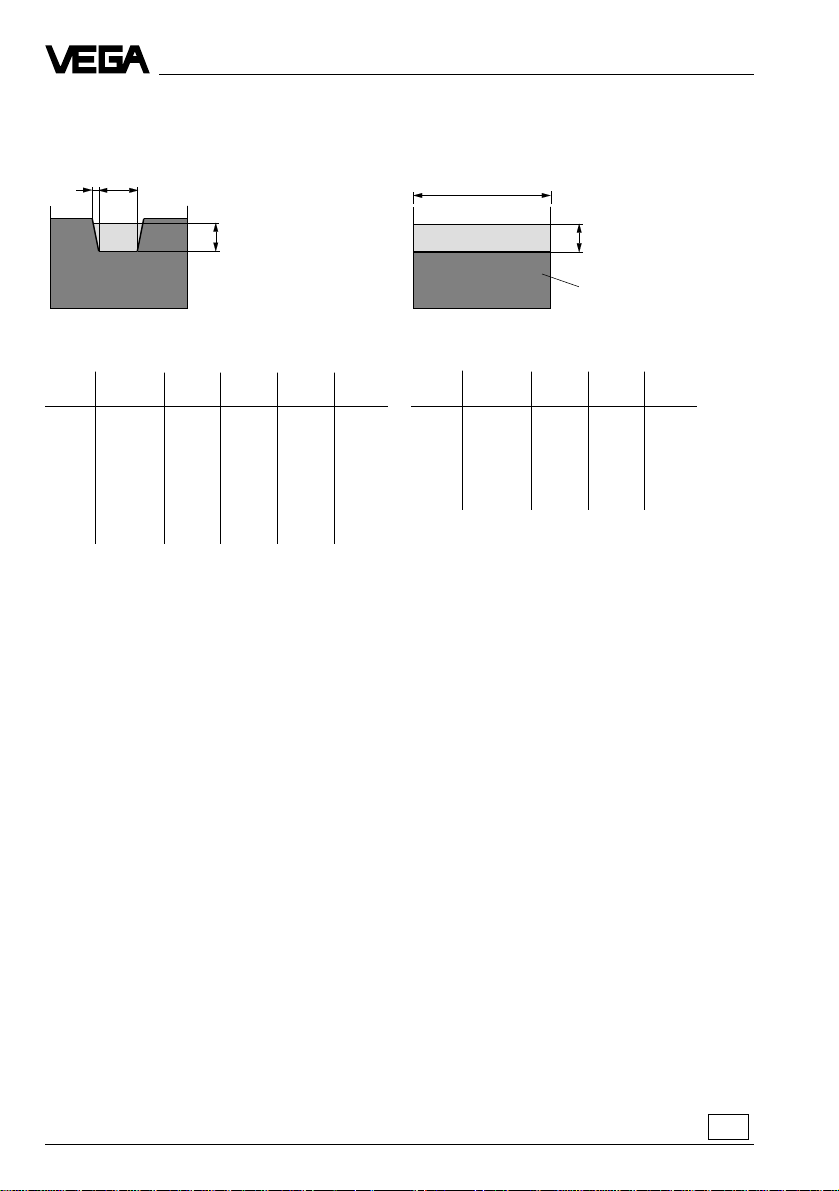

1.3 Applications

Product description

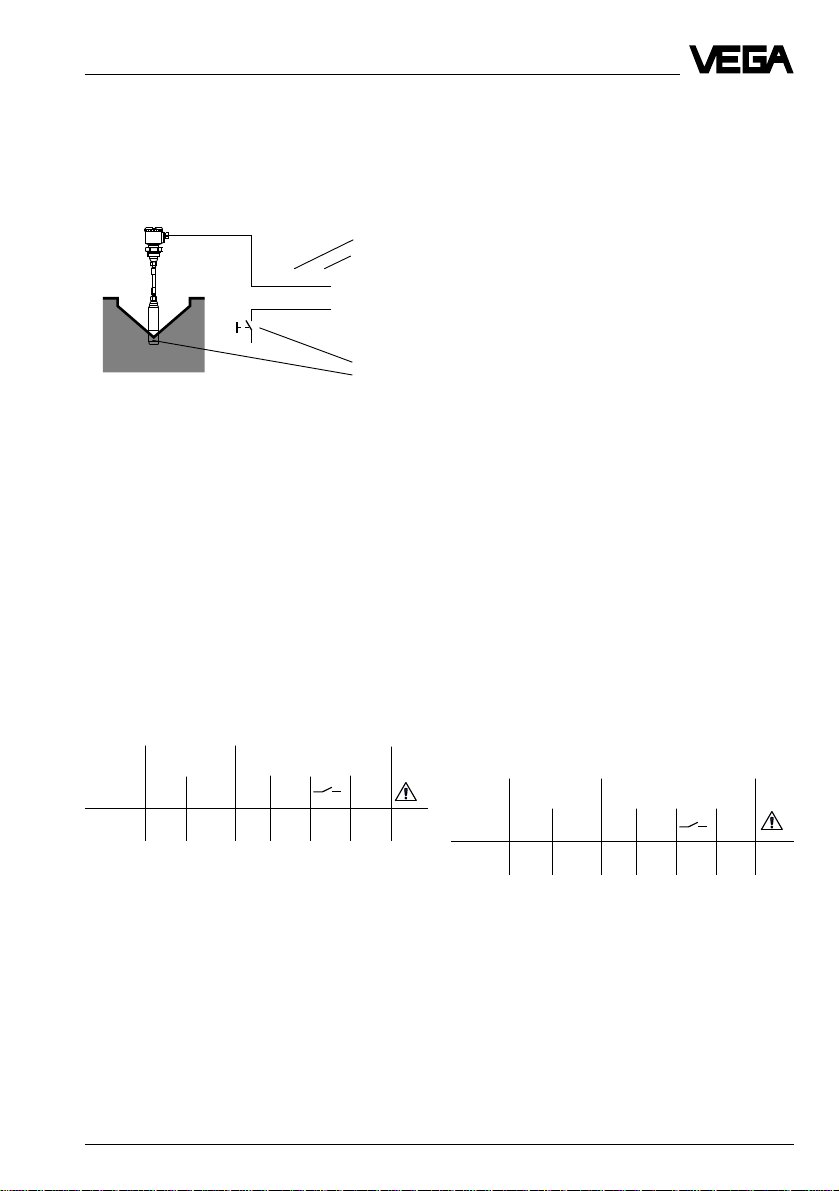

Flow measurement

Standard

Application: Flow

Sensor: Hydrostatic pressure transmitter

Kind: Level

Option: Offset correction (only with hydr. pressure transmitter)

Parameter: MST1 level

Option

A key connected to the correction input corrects the output results when

being set to zero.

Offset correction

- in empty flume

- preferably manually with key

- parallel shifting of the

adjustment characteristics

- effects MST1 and MST2

Ultrasonic sensors

Radar sensors

MST2 flow

actual measured value in

%

A

D

Fig. 1.13 Correction in the point

100 %

0

0

corrected measured value e.g. 0 % (m

h)

A

Fig. 1.2 Flow measurement

AA

incorrect course of measured

values

measured value too low

measured value too high

100 %

3

/

6 VEGAMET 514… D

Page 7

Product description

1.4 Technical data

Power supply

Operating voltage U

Power consumption

- VEGAMET 514 D appr. 7 VA or appr. 5 W

- VEGAMET 514 VD appr. 17 VA or appr. 12 W

Fuse 630 mA slow-blow

Measuring data input VEGAMET 514 D

Number 1 input

Kind of input active two-wire input, analog

Range 4 … 20 mA

Voltage at 4 mA appr. 18 V DC, at 20 mA appr. 15 V DC

Current limitation at appr. 26 mA, shortcircuit proof

Detection-line interruption < 2 mA

Detection-line shortcircuit > 23 mA

Min. adjustment delta 2 % of the adjusted sensor values

Connection line 2-wire (standard line)

Resistance per conductor max. 35 Ω

Resolution 1 µA

Linearity error 0,025 % at 4 … 20 mA

Temperature error 0,04 %/10 K at 4 … 20 mA

Measuring data input VEGAMET 514 VD

Number 1 input

Data transmission digital (VBUS)

Sensor hydrostatic pressure transmitters,

Voltage appr. 25 V DC

Power limitation at appr. 7 W, shortcircuit proof

Connection line 2-wire (screened)

Line length max. 1000 m

Resistance per conductor max. 200 Ω for hydrostatic pressure transmitters

Correction signal input

Number 1 input

Function switching signal to trigger and offset correction

Voltage 5 V (from instrument)

Current 5 mA

External line resistor ≤ 150 Ω

= 24 V AC (20 … 53 V), 50/60 Hz

nenn

= 24 V DC (20 … 72 V)

hydrostatic pressure transmitters

ultrasonic or radar sensor

max. 20 Ω for ultrasonic or radar sensors

>>

VEGAMET 514… D 7

Page 8

Product description

Current output

Number 3 outputs

Function current output 2 and 3 can be configured and

Output values

- level / flow proportional

Load max. 500 Ω

Range 0/4 … 20 mA

Resolution 0,05 % of range

Linearity error 0,05 % of range

Temperature error 0,05 %/10 k of range

- pulse output

Load min. 600 Ω

Voltage pulse 12 V DC at 20 mA

Pulse length 200 ms

Voltage output

Number 3 outputs

Function analog output of the output results

Range 0/2 … 10 V

Current max. 1 mA

Resolution 0,05 % of range

Linearity error 0,05 % of range

Temperature error 0,06 %/10 k of range

Relay outputs

Number 2 switching relays

Function can be configured and parameter adjusted as:

Contact 1 floating spdt

Turn-on voltage min. 10 mV DC

Switching current min. 10 µA

Breaking capacity max. 500 VA, 54 W

Min. switching hysteresis (Low/High-Delta) 0,5 %

parameter adjusted as:

- level proportional

- flow proportional

- flow pulses

- sampling pulse

1 fail dafe relay

- switching relay for level or flow

- pulse relay-flow quantity

- pulse relay-sampling

AgNiO and hard gold plated

max. 250 V AC/DC

max. 3 A AC, 1 A DC

DISBUS-output

Function digital transmission of output results and

Connection line 2-wire

Line length max. 1000 m

system information to VEGADIS 174 or

VEGACOM 557

>>

8 VEGAMET 514… D

Page 9

Product description

Indicating element

Clear text indication LC-display

Analog indication 11 segments 0 % … 100 %

LED in front plate green on: operating voltage on

Operating elements

Front plate 6 keys for configuration and parameter adjustment

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

Electrical connection

Multipoint connector component acc. to DIN 41 612, series F, 36-pole (three row) d, b, z

Carrier BGT 596 (Ex) connection to the respective module

Housing type 505 connection to screw terminals (max. 2,5 mm

Electrical protective measures

Protection

- unassembled IP 00

- mounted into carrier BGT 596

- mounted into housing

- terminal housing IP 20

- housing general IP 30

Protection II (in housing type 505 or type 506)

Overvoltage category II

Electrical separating measures

Reliable separation acc. to VDE 0106,

part 1 between power supply, fail safe and level relay,

- limit voltage 250 V

- isolation resistance 2,3 kV

- 4 line, 6 figures each

- background lightning

acc. to MST-enquiry

- %-value of level

- %-value of flow

red: fault signal

yellow (per relay): relay switching condition

(partly equipped)

front side completely equipped: IP 40

upper and lower side: IP 20

wiring side: IP 00

meas. data inputs and correction inputs

2

)

Galvanic separation between relay outputs

- limit voltage 250 V

- isolation resistance 1,4 kV

Potential separation between DISBUS, transistor outputs and correction

inputs

- limit voltage 50 V

- isolation resistance 0,5 kV

Common reference potential at voltage/current outputs, correction inputs

>>

VEGAMET 514… D 9

Page 10

Product description

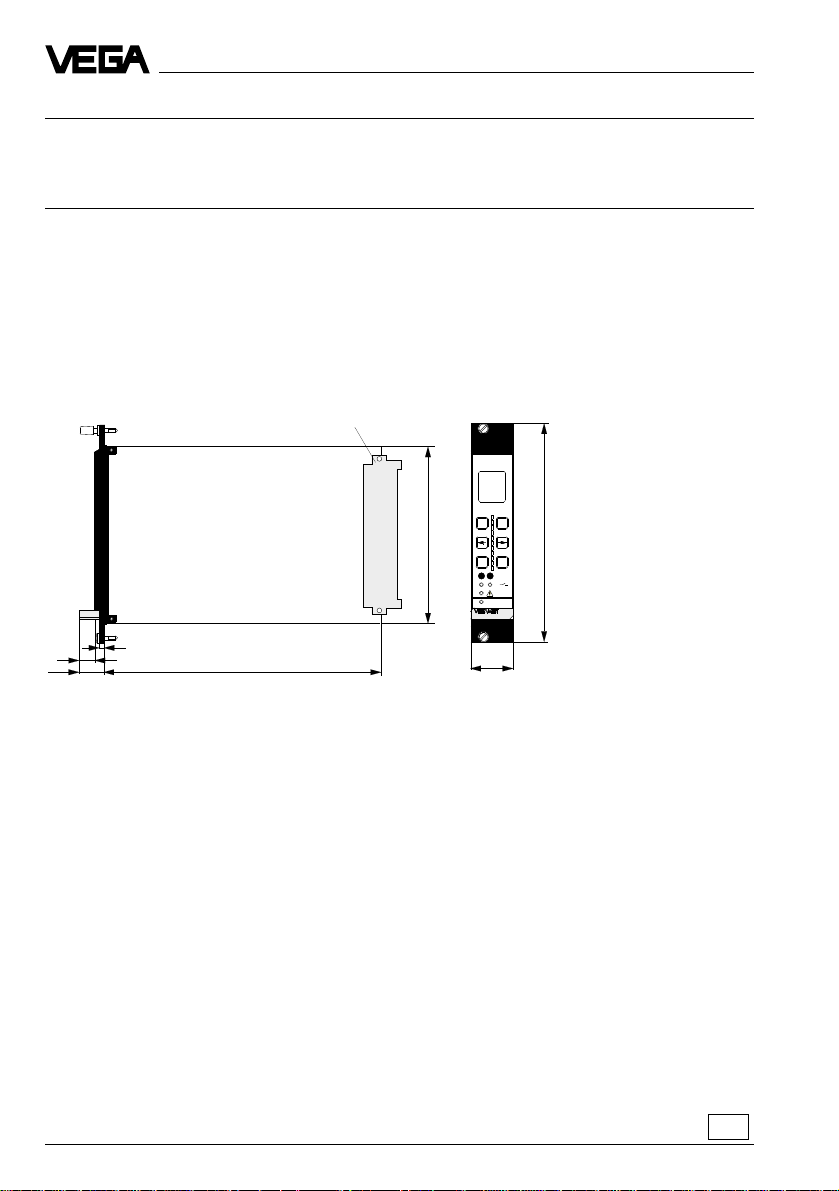

Mechanical data

Series module instrument for carrier BGT 596

or housing type 505 or type 506

Dimensions unassembled W = 25, 4 mm (5 TE), H = 128,4 mm, D = 162 mm

CE-approval, conformity judgement

VEGAMET signal conditioning instruments meets the protective regulations of EMVG (89/336/EWG) and

NSR (73/23/EWG). The conformity has been judged by means of a typical configuration acc. to the

following standards:

EMVG Emission EN 50 081 - 2: 1993

Immission EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

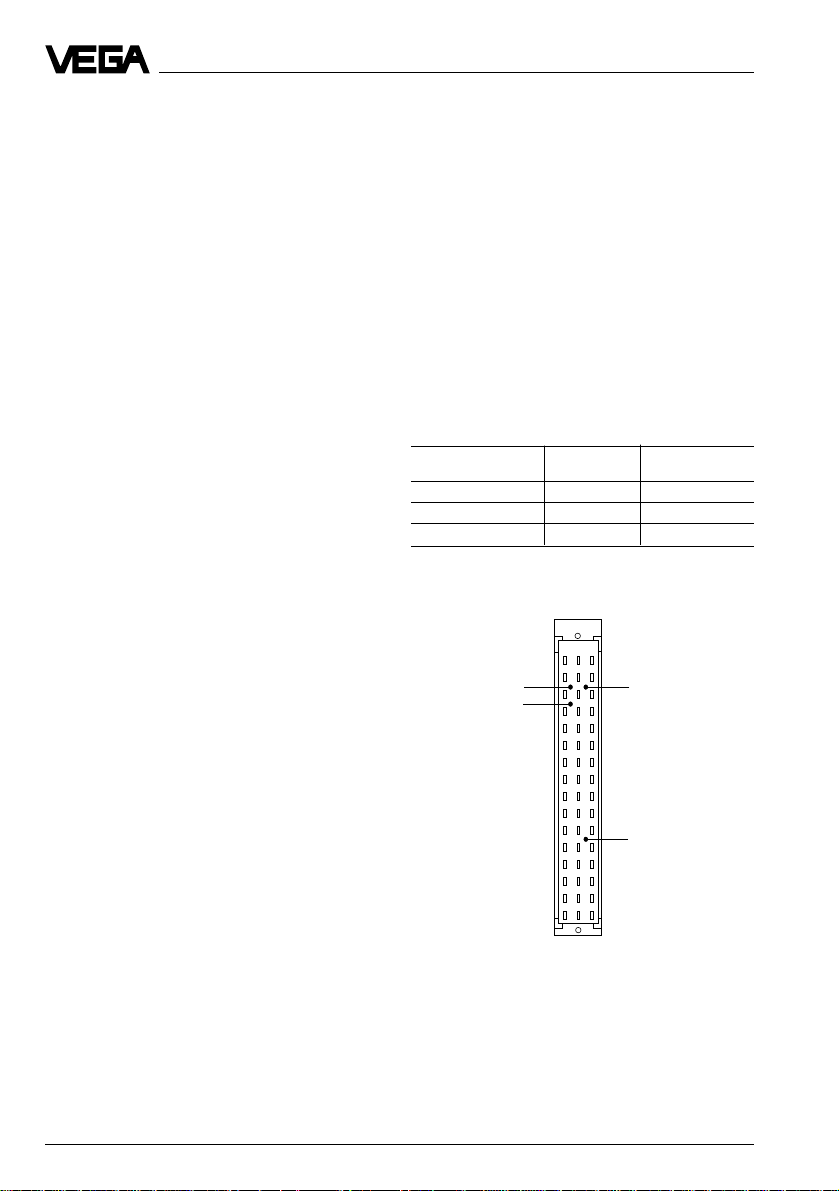

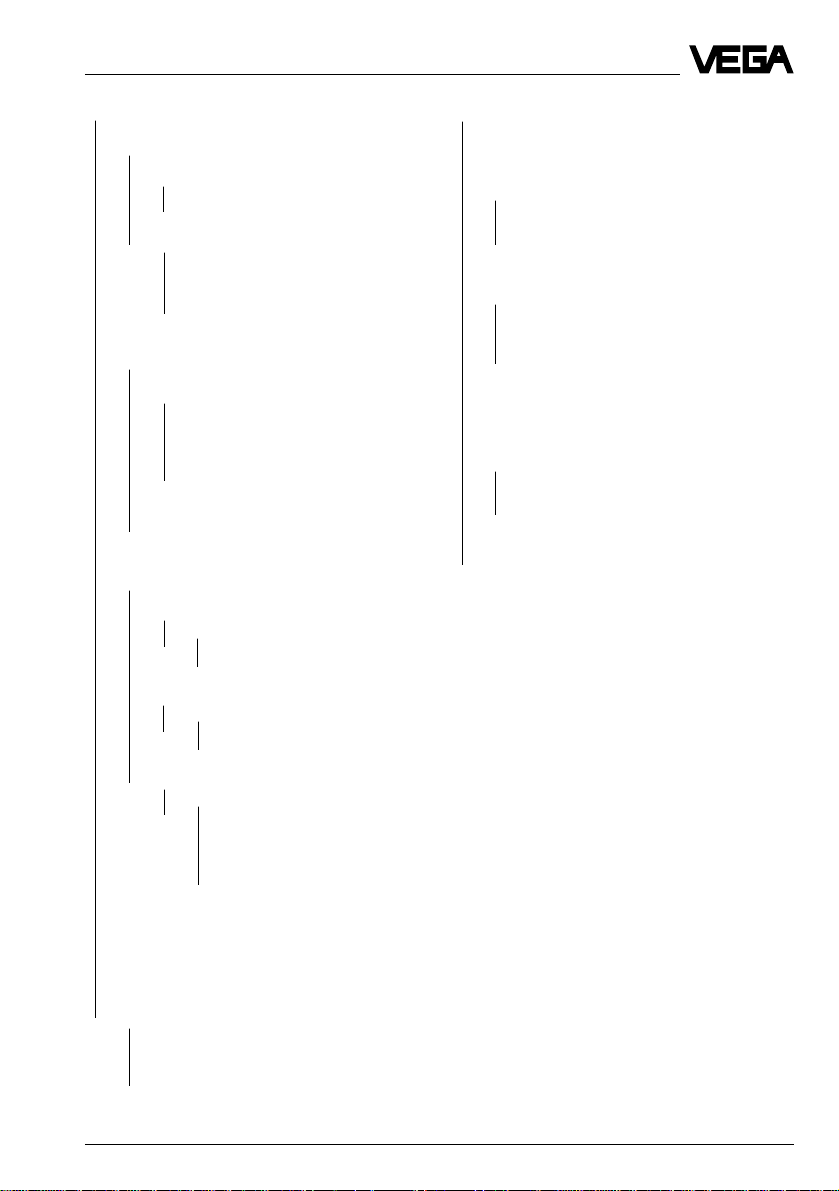

1.5 Dimensions

14,5

Circuit board 100 x 160 x 1,5

European size Multiple plug

9

3

162

5 TE

%

100

+

-

100

ESC

Ser.No.12345678

12

128,4

OK

CONNECT

on

514 D

25

>>

10 VEGAMET 514… D

Page 11

Product description

1.6 Ex-technical data

Power supply

Operating voltage U

Limit voltage U

corresponds to the not-Ex-version

nenn

= 250 V AC or 125 V DC

nenn

Measuring data input (intrinsically safe circuit)

Classification [EEx ia] IIC, [EEx ia] IIB, [EEx ib] IIC or [EEx ib] IIB

Max. values

- Voltage U

- Current I

- Power P

Characteristics linear

Effective inner inductance L

Effective inner capacitance C

i

i

= 20 V

O

= 128 mA

O

= 640 mW

O

unimportant

unimportant

EEx ia IIC EEx ia IIB EEx ib IIC EEx ib IIB

Max. permissible outer inductance LO (mH) 0,5 1 1,5 2 2 9

Max. permissible out capacitance CO (nF) 97 78 68 486 200 1000

The intrinsically safe circuits are reliably separated from the not-intrinsically safe circuits up to a peak

value of the nominal voltage of 375 V.

The max. voltage on the not-intrinsically safe circuits must not exceed 250 V

in case of failure.

eff

1.7 Approvals

VEGAMET are available with the following approvals:

- Explosions protection: appropriate operating instrument with intrinsically safe(s)

- Overfill protection to WHG and VbF applied

Observe with these applications the appropriate legal documents (test certificates, type approvals and

conformity certificates). These are supplied with the respective instrument.

WHG-approval

Signal conditioning instrument as part of an overfill protection to WHG or VbF (applied).

Ex-approval

For hazardous areas, certificate to CENELEC defined in the conformity certificate PTB-no. Ex-95.D.2161 X.

VEGAMET 514… D 11

Page 12

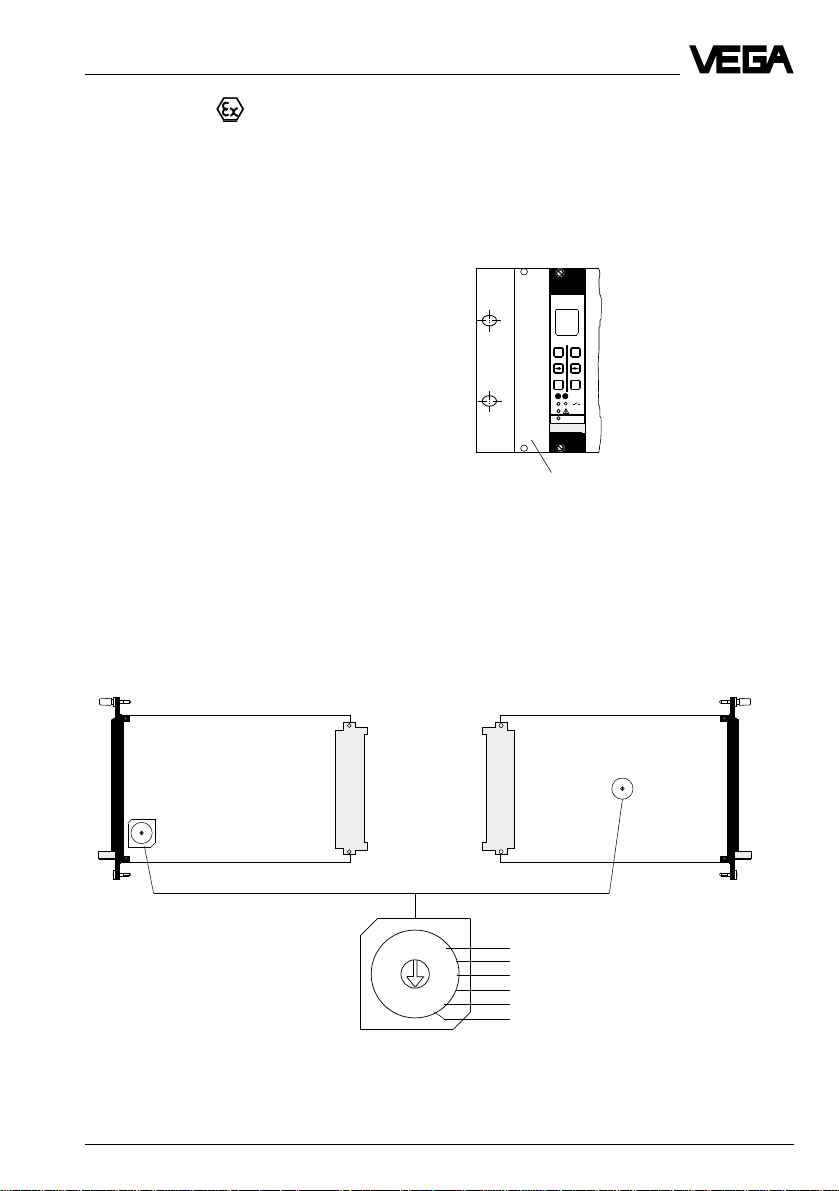

2 Mounting

Mounting

2.1 Mounting versions

VEGAMET 514 D … 514 VD signal conditioning

instruments can be either mounted with a module in

a carrier BGT 596 or BGT 596 Ex.M or in a single

housing type 505 or type 506.

Module

Multipoint connector DIN 41 612, series F, 33-pole

(d, b, z) with coded pins and mounting material for

mounting in carrier BGT 596 or BGT 596 Ex.M.

Module Ex

Multipoint connector DIN 41 612, series F, 33-pole

(d, b, z) with coded pins, Ex-separating chamber

and mounting material for mounting in carrier

BGT 596 Ex.M.

Single housing

Plastic housing type 505 or type 506 for single

mounting of signal conditioning instruments with a

width of 5 TE (25,4 mm).

Mounting carrier

Mount the respective module (standard or Exversion) in the carrier. Wire the connections of the

multipoint connector according to the wiring plan on

page 14.

The multipoint connector is available as follows:

- Wire-Wrap standard connection 1,0 x 1,0 mm

- plug connection 2,8 x 0,8 mm

- Termi-Point Standard connection 1,6 x 0,8 mm

- soldering connection

- screw terminals 2 x 0,5 mm

For further information concerning mounting see

operating instruction of the carrier.

Mounting single housing

You can either screw the housing socket directly to

the mounting plate or plug on a carrier rail

(TS 35 x 7,5 acc. to EN 50 022 or TS 32 acc. toEN

50 035). Connect the terminals according to the

wiring plans on the following pages. For further

information to the mounting see operating instruction

of the housing.

2

Coding

To avoid interchanging of the various signal

conditioning instruments, the multipoint connector of

the carrier or the housing is provided with pins and

the multiple plug of the signal conditioning

instrument with holes (mechanical coding).

An Ex-coding with fixed coded pin ensures that notEx and Ex-instruments are not interchanged.

An instrument coding ensures that the various signal

conditioning instruments are not interchanged. The

respective coded pins are attached to each module

or housing. Provide the multipoint connector with

these coded pins acc. to the following schedule and

figure.

Instrument Ex-

coding coding

VEGAMET 514 D a5 / c5

VEGAMET 514 D Ex a5 / c5 c23

VEGAMET 514 VD a7 / c5

Fig. 2.1 Coding schedule

Instrument coding Function coding

514 D

514 VD

z b d

a c

o 1 o

o 3 o

a5

a7

o 5 o

o 7 o

o 9 o

o11o

o13o

o15o

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

c5

c23

VEGAMET

Ex-coding

Transparent cover

To protect the housing against unauthorized

operation, the front plate of VEGAMET can be

provided with a lockable transparent cover.

12 VEGAMET 514… D

Fig. 2.2 Module coding, VEGAMET

Page 13

Mounting

Ex-version

Note!

Signal conditioning instruments must be generally

mounted outside hazardous areas or special Exprotective measures must be taken.

Ex-separating chamber

Mounting in carriers

If you mount your VEGAMET with Ex-approval in a

carrier, you have to use a VEGA-Ex-module. Keep a

distance of at least 10 mm (2 TE) to modules of other

manufacturers. If you want to mount the VEGAMET in

the extreme left position in the carrier, you have to

mount a blind cover of at least 20 mm (4 TE) in front

of the module of the instrument.

To ensure sufficient "air and creeping distances", an

Ex-separating chamber must be mounted to the

connections of VEGAMET. Lead the wires through the

Ex-separating chamber and connect them. Fasten

the Ex-separating chamber with the lower screw.

Observe the operating instrumention of carrier

BGT 596 Ex.M.

Protection for Ex-applications

In Ex-applications a protection of IP 20 must be kept.

Cover the spaces or not used modules from the front

by appropriate blind covers.

%

100

+

-

OK

ESC

CONNECT

on

VEGAMET

515 N

Blind cover

2.2 Instrument address

Adjust the instrument address on the appropriate switch on the circuit board. Address range 1 ...15. Observe

that no address is used twice. Factory setting = instrument address 0.

514 VD

Switch

8

9

7

A

6

5

4

33

2

F

1

0

corresp.

B

C

D

E

514 D Ex

Switch on bottom, visible through

an appropriate opening

10

11

12

13

14

15

Under the menu point "Instrument address" ´the

adjustment carried out on the switch can be

indicated.

VEGAMET 514… D 13

Page 14

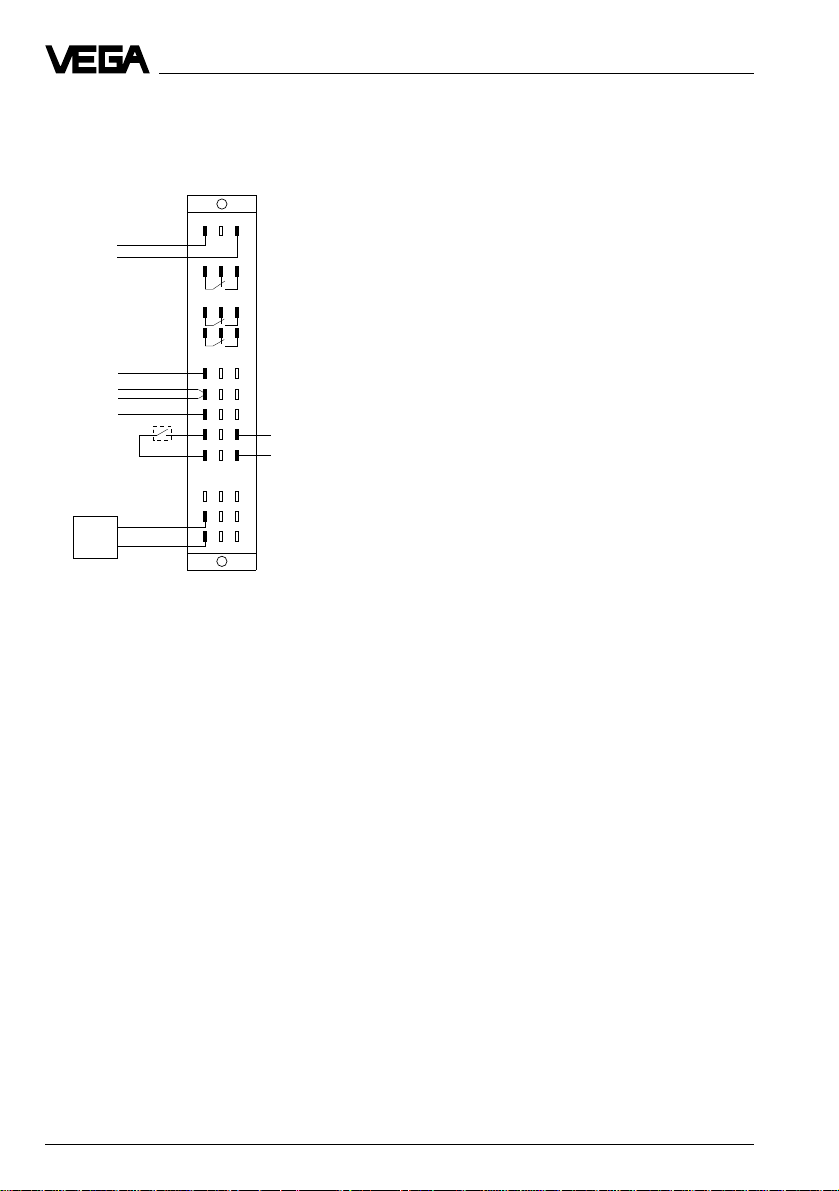

3 Electrical connection

VEGAMET 514 D, 514 D Ex

VEGAMET 514 VD

d b z

+-

Supply

voltage

L (+)

N (-)

Current outputs 1 … 3

Voltage output 1 … 3

Correction

signal input 4

+

-

Sensor

2

6

10

12

1 2 3

+

16

-

18

+

20

+

22

--

24

28

+

30

-

32

+

Fail safe relay

Relay output 1

Relay output 2

DISBUS-output

Electrical connection

Ex-version

For connection of Ex-certified instruments observe

the instructions in the attached legal documents as

well as in the valid mounting instructions. Note that

the Ex-separating chamber is mounted on the

multipoint connector.Always lead the wires through

the Ex-separating chamber. Observe the operating

instruction of the carrier BGT 596 Ex.M and the Exinstructions.

14 VEGAMET 514… D

Page 15

Set-up

4 Set-up

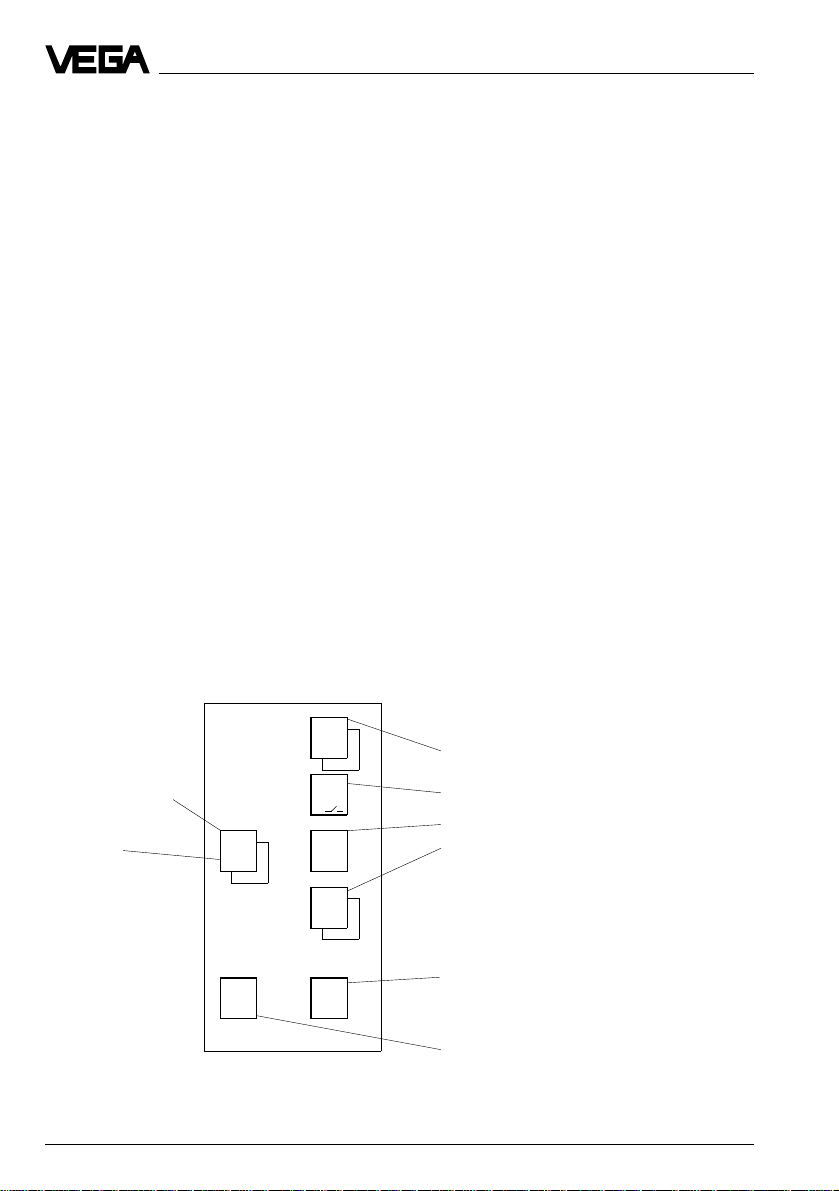

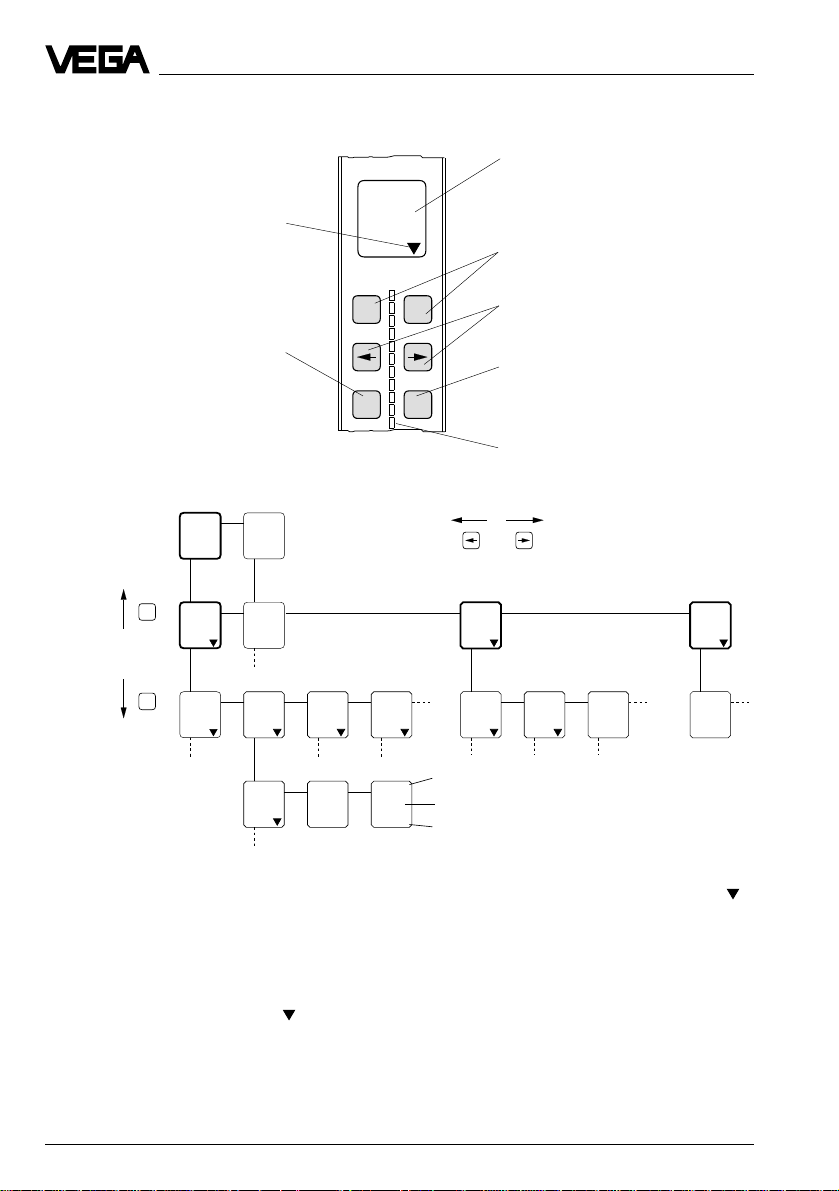

4.1 Indicating and operating elements

Signal conditioning instrument

with adjustment module

1

2

%

3

5

7

10

11

12

13

14

1

100

-

ESC

CONNECT

2

1

!

on

514

Ser.No.12345678

+

OK

4

6

8

9

16

18

1 Lockable fixing screw

2 Display (4 lines with 6 figures each,

illuminated)

3 … 8 See following page

9 Analog indication 11-digit

10 Connection for VEGACONNECT

connection cable

11 LED relay output 1 and 2

12 LED fault signal

[17]

15

13 LED supply voltage

14 Ledge

15 Multiple plug with wiring plan

16 Position of the switch for adjustment

of the instrument address [17] on

VEGAMET 514 D Ex

18 Transparent cover

Fig. 4.1

VEGAMET 514… D 15

Page 16

4.2 Adjustment system

Set-up

Indicating and adjustment module

Branch, i.e. jump to the lower menu

[OK]

Acc. to the menu point delete the

adjustment or change to the

upper menu

Menu tree

Indication of

measured values

Main

ESC

menu

Sub

OK

menu

MST1

36.9

Param.

MST1

Adjustment

MST2

%

Param.

MST2

cessing

%

Indication of

- measured value

- menu points

- parameters

- values

Acc. to the parameter, change value or

%

100

+

-

ESC

OK

OutputPro-

lation

select from list

Select menu point

Acc. to the menu point store the

adjusted value or change to the lower

menu

Analog indication

Configuration

InputsSimu-

Meas.

point

Outputs

add.

functions

Password

off

Scaling

Lin.

curve

The adjustment is menu oriented and is made via six

keys in conjunction with clear text indication. The

jump from indication of measured values to the main

menu is made with [OK]. Use [→] or [←] to change

within the main menu from one menu point to the

other.

A branch is indicated by the symbol

and ensures

with [OK] a jump to the lower menu. In each menu

are thematically combined parameters (possibly in

further sub menus).

Integration

time

Menu point

Parameter

10

value

Parameters are indicated by the missing symbol

The value of the parameters can be modified or

selected out of a list by [+] or [–]. The modified value

can be stored with [OK]. Push [ESC] to interrupt an

adjustment (without storing the modfication).

Certain parameters can be only indicated, however

their value cannot be modified.

Reset to the upper menu is made with [ESC].

60 minutes after a key is pushed for the last time, an

automatic reset to the indication of measured values.

16 VEGAMET 514… D

.

Page 17

Set-up

4.3 Menu list

Values must be adjusted or modified to determine

the meas. points. This determination is made

separately for each meas. point by the following

parameter adjustments.

Parameter adjustment MST1

–– Adjustment

–– with level

–– without level

–– Processing

–– Scaling (level)

–– Lin. curves

–– Integration time

–– Outputs

–– Current outputs

–– Volt outputs

–– Relay outputs

–– MET-indication

–– PC- / PLC-outputs

–– DIS-outputs

–– Simulation

–– Special functions

Adjustments and coordinations must be provided to

determine the instrument functions. This

determination is made by the following

configurations.

Configuration

–– Configuration

Inputs, Sensor connections, mark

–– Input 1

–– Input 4

–– Configuration meas. points

–– Application

–– Sensor

–– Kind

–– Options

–– Sensor coordination

–– Instrument address

–– Configuration outputs

–– Current outputs

–– Volt outputs

–– Relay outputs

–– PC- / PLC-output

–– VEGADIS-output

Parameter adjustment MST2

–– Adjustment

–– with flow

–– without flow

–– Processing

–– Scaling (flow)

–– Lin. curves

–– Integration time

–– Outputs

–– Current outputs

–– Volt outputs

–– Relay outputs

–– Display

–– PC / PLC

–– DISBUS-output

–– Simulation

–– Special functions

VEGAMET 514… D 17

Under the section "Additional functions" all superset

instrument functions, i.e. their adjustment and

coordination possibilities are composed.

Additional functions

–– Password

–– Edit lin. curves

–– Info

–– Input info

–– VEGAMET-Info

–– Program info

–– Meas. point info

–– Language

–– Reset VEGAMET

–– Reset configuration

–– Reset sensor characteristic values

–– Reset lin. curves

–– Service

Page 18

4.4 Adjustment via PC

Signal conditioning instrument with operating module

Set-up

%

100

-

ESC

2

1

!

on

Ser.No.12345678

CONNECT

515

+

OK

- directly via the keys of the adjustment module

(see following descriptions)

- or with a PC, provided with VVO-Software (VEGA

Visual Operating), and a VEGACONNECT

connection cable

VEGACONNECT

connection cable

PC with VVO-Software

Set-up

4.5 Set-up sequence

Configuration

- adjust instrument address

- configure inputs

- prepare meas. points

- coordinate outputs

Parameter adjustment

If you want to detect the level and the flow as

parameter, it is recommended, to carry out the

adjustment for MST1 and MST2 at the same time i.e.

immediately one after the other.

- Parameter adjustment MST1

- carry out adjustment

- determine the processing

- define outputs

- Parameter adjustment MST2

as described above

18 VEGAMET 514… D

Additional functions

- edit linearization curves

- change language (if necessary)

- activate password (if necessary)

Page 19

Set-up, configuration

4.6 Set-up, configuration

4.6.1 Configuration inputs

The inputs of the signal conditioning instruments are

configured according to the ordered instrument

version. Therefore no activities from your side are

necessary. However should there be a modification

necessary, you will find some explanations and

connection examples in the following.

The signal conditioning instruments are either

connected directly to the sensors or they receive

measured data from other sensors via the DISBUSconnection.

Connection example 1

VEGAMET 514 D

- Sensors connected directly to VEGAMET

Marking:

The sensor must be marked via its sensor

characteristics values (only hydrostatic pressure

transmitters).

A

Sensor

characteristics values

D

S1

K1

Connection example 2

VEGAMET 514 VD

- Sensors connected directly to VEGAMET

Marking:

The sensor must be marked with its series

number.

A

Sensor

series

number

Pos. A – input 1, series number 8888.8888

Pos. D – input 4, channel K1

D

K1

Pos. A – input 1, channel S1

Pos. D – input 4, channel K1

>>

VEGAMET 514… D 19

Page 20

Set-up, configuration

Connection example 1

Configuration, inputs

–– Input 1 Sensor with analog transmission of measured data

–– Input of this MET

–– Channel no. S1

–– Sensor characteristics values The menu point "Sensor characteristics values" is

–– Min. meas. range 0.00 Meas. range and sensor values are stated in the

–– Max. meas. range 1.00 test certificate of the hydrostatic pressure

–– Min. sensor value 4.000 transmitter.

–– Max. sensor value 20.000

–– Input 4 Correction signal (key)

–– Input of this MET

–– Channel no. K1

Connection example 2

Configuration, inputs

–– Input 1 Sensor with digital transmission of measured data

–– Input of this MET

–– Sensor adaption can be necessary for ultrasonic / radar sensors (see

–– Input 4 Correction signal (key)

–– Input of this MET

–– Channel no. K1

only visible with hydrostatic pressure transmitters.

BA of the appropriate sensor)

20 VEGAMET 514… D

Page 21

Set-up, configuration

A

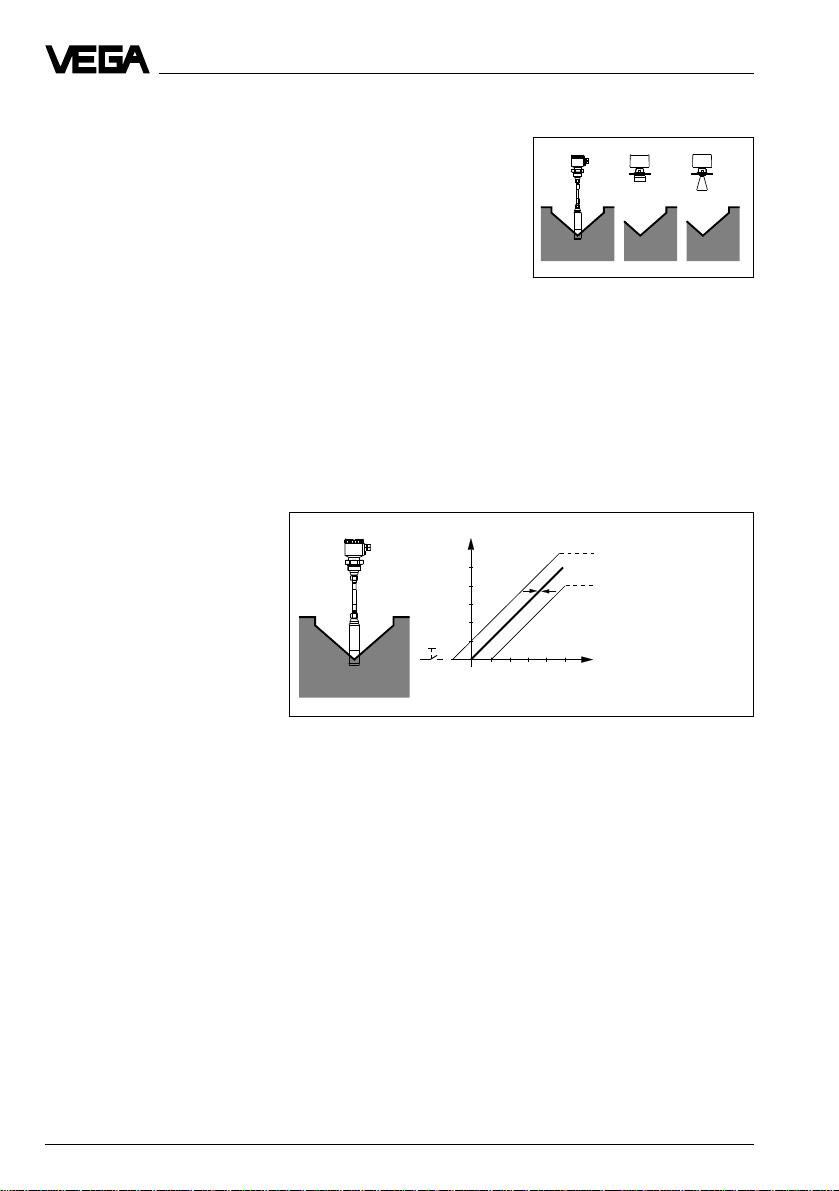

4.6.2 Configuration meas. point

VEGAMET 514 D and 514 VD signal conditioning instruments in their basic configuration are designed for

combi application, i.e.

- MST1, level

- MST2, flow measurement

Supplementary the following modifications of the configuration can be carried out.

Configuration meas. point

–– Combi application If a general modification of the basic configuration

–– Application flow should be necessary, a "Reset to combi application"

–– Sensor Hydrostatic should be carried out, see respective menu point on

–– Kind Standard page 44. A new basic configuration can be then

programmed acc. to the product description 1.3

(see page 6).

–– Options no

offset corr.

(for MST1 and MST2)

–– Sensor coordination

–– Position A Input 1

–– Position D Input 4

Input 1

Channel no.

S1

Input 4

Channel no.

K1

–– MST1 level

–– MST name MST Providing of a special MST

name MST name e.g. name

level

MST1

–– Fault signal on on means that a failure of MST1 is transmitted

off to the failure processing off means no

transmission

–– Tare see page 21

–– Monitoring see page 21

–– MST2 flow

–– MST name MST Providing of a special MST

name MST name, e.g. name

flow

MST2

–– Fault signal as above, however MST2

–– Monitoring see page 21

VEGAMET 514… D 21

Page 22

Tare

By means of the tare function an additional

measured value exists from the actual value

beginning at 0%. The tare function can be triggered

via a key connected to correction signal input 4.

Each current, voltage or relay output as well as the

display can be afterwards coordinated to the tared

measured value in the menu point "relating to". With

the allocation or allocations the tared measured

value is activated.

–– MST1

–– Tare

Measured values in %

100 %

Key

40

Set-up, configuration

tared course

0

0 40 100 %

actual measured values

tared measured values

actual course

–– Input not defined

Input 4 Determination of the correction signal input (key)

Monitoring

For the activation of the monitoring the following prerequirements must be met:

- Determine in the menu range "Configuration

meas. point" input 4

- Connect the key switch (opener) to input 4 (see

page 13).

Meas.value

50 %

High 7 %

Low –5 %

>57 %

<45%

- Select in the menu range "Parameter adjustment

relay outputs" the monitoring mode for the

concerned relay (see page 37 and 40).

Relay energized

Relay deenergized

Relay deenergized

The selected relay is energized.

By pushing the key switch (opener opens) the respectively actual measured value is frozen and derived from

this, in case the value is decreased (low) or exceeded (high) the relay energizes.

After a reset and pushing the key switch again the actual measured value is frozen again etc.

–– MST1

–– Monitoring

–– Input not defined

Input 4 with input 4 determination of the correction signal

input (key switch)

–– MST2 as described above

22 VEGAMET 514… D

Page 23

Set-up, configuration

4.6.3 Configuration output

Dependent on the basic configuration the outputs are automatically coordinated to the measuring points

MST1 and MST2. This coordination can be modified separately for each output.

In a list either the measuring point numbers MST1 and MST2 or the previously adjusted measuring point

names are provided as choice. In addition each output can be switched off (--), i.e. the switched off output

does not access to any measuring point.

Configuration, outputs

–– Configuration current outputs

–– Current 1 to MST1 ––– 0 … 20 mA level proportional

MST2

--

–– Current 2 to MST2 ––– 0 … 20 mA flow proportional

-MST1

–– Kind 2 Standard ––

Pulses

–– Current 3 to MST2 ––– Flow pulses

-MST1

–– Kind 3 Standard

Pulsed––

–– Configuration volt outputs

–– Volt 1 to MST1 ––– 0 … 10 V level proportional

MST2

--

–– Volt 2 to MST2 ––– 0 … 10 V flow proportional

-MST1

–– Volt 3 to -- ––– not coordinated to a MST

MST1

MST2

Coordination acc. to basic configuration:

>>

VEGAMET 514… D 23

Page 24

Configuration, outputs

–– Configuration relay outputs

–– Operating relay

–– Relay 1 to MST1 acc. to basic configuration coordinated to level

–– Relay 1 kind Standard

Set-up, configuration

Hold function

Parameter

High

Low

Taster

Relay outp.

t

d b z

Reset of alarm

funct.

Parameter

High

Low

Taster

Relay outp.

t

d b z

The relay modes "Hold function" and "Reset of alarm

functions" are configured as described above and

activated with one external signal each (correction

signal input).

–– Input not defined

Input 4 Determination of the correction signal input

(key, see above)

–– Relay 2 to MST2 acc. to basic configuration coordinated to flow

–– Relay 2 kind Standard

Pulses see Parameter adjustment page 41

–– Fail safe relay kind Standard The fail safe relay can be operated like the

Hold funct. operating relay, i.e. as described above.

Reset of

alarm funct.

–– Input not defined

Input 4 as scribed above

>>

24 VEGAMET 514… D

Page 25

Set-up, configuration

Configuration, outputs

–– Configuration PC/PLC Dependent on the basic configuration outputs

–– PC-/PLC-measured values

–– PLC 1 to MST1

–– PLC 2 to MST2 This coordination can be modified separately

–– PLC 3 to -- for each output. In a list either the measuring

–– PLC 4 to -- point numbers MST1 and MST2 or the

–– PLC 5 to -- previously adjusted measuring point names

–– PLC 6 to -- are available as a choice.

–– PLC 7 to --

are automatically coordinated to measuring points

MST1 and MST2.

Example acc. to configuration measuring point

MST

name

level

MST

name

flow

–– PC/PLC relay status off In addition each output can be switched off

–– PC/PLC Inp. status off

–– Configuration VEGADIS

–– PC-/PLC-measured values

–– DIS 1 to MST1 Configuration as abobe

–– DIS 2 to MST2

–– DIS 3 to -–– DIS 4 to -–– DIS 5 to -–– DIS 6 to -–– DIS 7 to --

Parameter adjustment of outputs see page 41

on (– –), i.e. the switched off output does not access to

any measuring point.

on

VEGAMET 514… D 25

Page 26

Set-up, parameter adjustment

4.7 Set-up, parameter adjustment

The menu described in the following is available for parameter adjustment. This menu has the same function

for VEGAMET 514… for each measuring point number, i.e. parameter adjustment MST1 and MST2.

4.7.1 Parameter adjustment MST1, adjustment

The menu range "Parameter adjustment MST1, adjustment" adapts automatically to the measuring point

configuration, i.e. acc. to the "Application" and "Sensor" different menu points are displayed.

Adjustment

- Application Flow measurement

- Sensor Hydrostatic pressure transmitters

Parameter adjustment MST1, adjustment

e.g. rectangular weir

= 0,60 m

h

max.

100 % ^ 0,06 m (h)

0 % ^ 0,00 m (h)

–– with measured product With this adjustment procedure %-values each must

be adjusted for min. and max. which correspond to

the actually measured levels/flow etc.

–– Min. adjustment at 0.0 % Range 0 … 80 %

–– Max. adjustment at 100.0 % Range 20 … 100 %

a ∆ of 20 % must be observed between min. and

max.

Please observe that for all these applications with hydrostatic pressure transmitters and

adjustment without level/flow first of all a position correction must be carried out.

–– without measured product For this adjustment procedure two future levels/flows

must be adjusted which correspond to 0% and

100%.

–– Adjustment in m (h) etc. modify unit if necessary

–– Position correction The menu points "Position correction" etc. are

released when connecting hydrostatic pressure

transmitters.

–– Sensor unpressurized? OK? With the position correction the measured data of

the unpressurized sensor (flume empty) are

detected

–– Position correction now? OK? as correction size and is considered for all following

measurements

–– 0 % at 0.00 m (h) the unit is displayed acc. to the menu point

"Adjustment in"

–– 100 % at 0.60 m (h) 0.00 and 0,60 correponds e.g. to an adjustment in m

Parameter adjustment MST2, adjustment as described above.

If you want to detect the level and the flow as parameter, it is recommended to carry out the adjustment for

MST1 and MST2 at the same time, i.e. immediately one of the other.

>>

26 VEGAMET 514… D

Page 27

Set-up, parameter adjustment

Adjustment

- Application Flow measurement

- Sensor ultrasonic sensors

e.g. rectangular weir

h

= 0,60 m

max.

radar sensors

100 %

^ 0,80 m (d)

^ 1,40 m (d)

0 %

Parameter adjustment MST1, adjustment

–– with measured product With this adjustment procedure %-values have to be

adjusted each for min. and max. which correspond

to the actual measured distances between sensor

and level/flow.

–– Min. adjustment at 0.0 % Range 0 … 80 %

–– Max. adjustment at 100.0 % Range 20 … 100 %

a ∆ of 20 % must be observed between min. and

max.

–– without measured product For this adjustment procedure two future distances

(sensor … level/flow) must be adjusted which

correspond to 0 % and 100 %.

–– Adjustment in m (d) etc. if necessary modify unit, the unit is displayed

acc. to the menu point "Adjustment in"

–– 0 % at 0.80 m(d) 0.80 and 1.40

–– 100 % at 1.40 m(d) corresponds e.g. to adjustment distances in m

Parameter adjustment MST2, adjustment as described above

If you want to detect the level and the flow as parameter, it is recommended to carry out the adjustment for

MST1 and MST2 at the same time, i.e. immediately one of the other.

VEGAMET 514… D 27

Page 28

Set-up, parameter adjustment

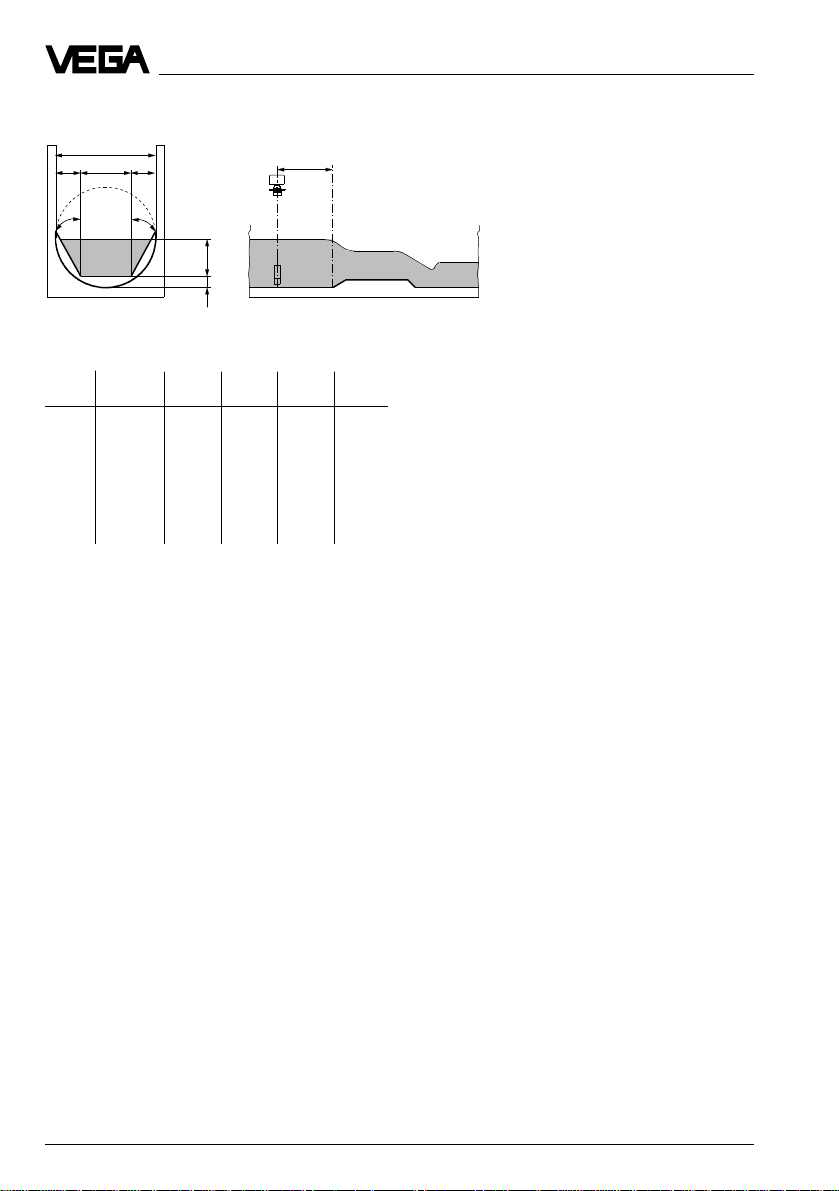

4.7.2 Flow measurement

General information

In the following section elementary information to dimensions in front of flumes, walls and sensor installation

positions is given.

Flume with meas. section (e.g. Khafagi-Venturi flume)

Top view

3 - 4 x h

max

Sensor

90°

Sensor

≥ min. distance

of the sensor

h

max

Inlet side

Lateral view

Outlet side

Fth meas. wall (e.g. rectangular weir)

k ≈ 3 cm

Sensor

90°

Sensor

≥ min. distance

of the sensor

h

max

≥ 2 x h

max

3 - 4 x h

90°

Upstream water Downstream water

max

45°

k ≈ 3 cm

≥ 5 cm

Note

General

is the max. damming or overflow height acc. to the meas. section or meas. wall.

-h

max

- All other dimensions are nearly derived from h

(see above drawings)

max

Sensor mounting position

- Mount sensor on the inlet /upstream water side.

- Observe distance 3 - 4 x h

- Mount the ultrasonic and radar sensors centred to the flume and vertically to the flow medium.

from sensor to the throat or meas. wall.

max

- Consider with ultrasonic sensors the min. distance to hmax.

Meas. wall

- Dimension dependent on h

- Thickness on the meas. wall (horizontal part) k ≈ 3 mm.

.

max

- Swelling of the meas. wall with a transition of 45° (see above drawing).

- Distance from the opening of the meas. wall to downstream water ≤ 5 cm.

>>

28 VEGAMET 514… D

Page 29

Set-up, parameter adjustment

Max. flow, Q

In the term Q

1000) the following flume specific factors are

max

(menu point 100 % corresponds to

max

considered relating to the adjustment at 100 %

- geometry of the flume

- material of the flume

- flow speed of the flow medium.

The respectively valid values for Q

determined by the manufacturer of the flume.

If the value for Q

this value can taken as a proximity out of the

of an existing flume is not known

max

are normally

max

following schedule or can be calculated.

In addition it is recommended to determine and

observe the frame conditions defined in the literature

to the flow measurement (surface structure of the

flume, flow speed etc.).

Some of the usual flumes are stated in the following

in form of schedules and calculation examples.

Explanations

Q

= maximum flow in m3/h

max

Q

= minimum flow in m3/h

min

h

= maximum damming or overflow height in mm

max

or m

h

= minimum damming or overflow height in mm

min

or m

B = flume or overflow width in mm or m

K = flume or overflow specific factor

k = thickness of the meas. wall in mm

D = tube diameter in inch

Calculation information

- Liter/sec x 3,6 = m

1

3

-m

/h x ––– = liter/sec

3,6

- Example 10 liter/sec

3

/h

^ 36 m3/h

Khafagi-Venturi flume

With rectangular cross section and even canal

bottom

B

h

max

Values for Q

BK Q

in mm (Factor) in m3/h in mm in m3/h in mm

max

maxhmax

Q

minhmin

45 605 80 260 4,8 40

120 838 124 280 9,3 50

160 1106 210 330 16,2 60

200 1383 363 410 25,6 70

240 1654 532 470 37,4 80

320 2178 864 540 58,8 90

640 4280 3776 920 383 200

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

B = 0,16 m

K = 1106 (derived from B)

h = 0,25 m

Q

max

1,5

=K x h

= 1106 x 0,25

1,5

= 138,2 m3/h

>>

VEGAMET 514… D 29

Page 30

Set-up, parameter adjustment

Trapezoidal weir (Cipolletti)

With sharp overflow edge

1

/4 h

Values for Q

BK Q

in mm (Factor) in m3/h in mm in m3/h in mm

B

max

h

max

max

Q

maxhmax

h

min

min

300 2011 116,8 150 29,5 60

450 3014 354,4 240 44,3 60

600 4011 760,4 330 58,9 60

800 5353 1457 420 78,7 60

1000 6688 2581 530 93,3 60

1500 10043 6523 750 147,6 60

2000 13381 14397 1050 196,7 60

3000 20082 36893 1500 295,1 60

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

B = 0,6 m

K = 4011 (derived from B)

h = 0,27 m

Q

max

1,5

=K x h

= 4011 x 0,27

1,5

= 562,73 m3/h

Rectangular overflow without contraction

With sharp overflow edge without throat

B

h

max

K = 6593

Values for Q

BQ

in mm in m3/h in mm in m3/h in mm

max

h

Q

max

max

h

min

min

200 54,81 120 19,4 60

400 310 240 38,7 60

600 650 300 58,1 60

800 1592 450 77,5 60

1000 3064 600 96,9 60

1500 6423 750 145,3 60

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

B = 1,5 m

K = 6593

h = 0,3 m

= B x K x h

Q

max

= 1,5 x 6593 x 0,3

1,5

1,5

= 1625 m3/h

>>

30 VEGAMET 514… D

Page 31

Set-up, parameter adjustment

Rectangular overflow without contraction

With sharp overflow edge and throat

B

h

max

K = 6290

Values for Q

BQ

in mm in m3/h in mm in m3/h in mm

max

h

Q

max

max

h

min

min

200 52,3 120 18,5 60

300 109,6 150 27,7 60

400 295,8 240 37,0 60

500 441,2 270 46,2 60

600 620 300 55,5 60

800 1519 450 73,9 60

1000 2923 600 92,4 60

1500 6128 750 138,7 60

2000 13535 1050 184,9 60

3000 34666 1500 277,3 60

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

B = 0,4 m

K = 6290

h = 0,13 m

= B x K x h

Q

max

= 0,4 x 6290 x 0,13

1,5

1,5

= 117,9 m3/h

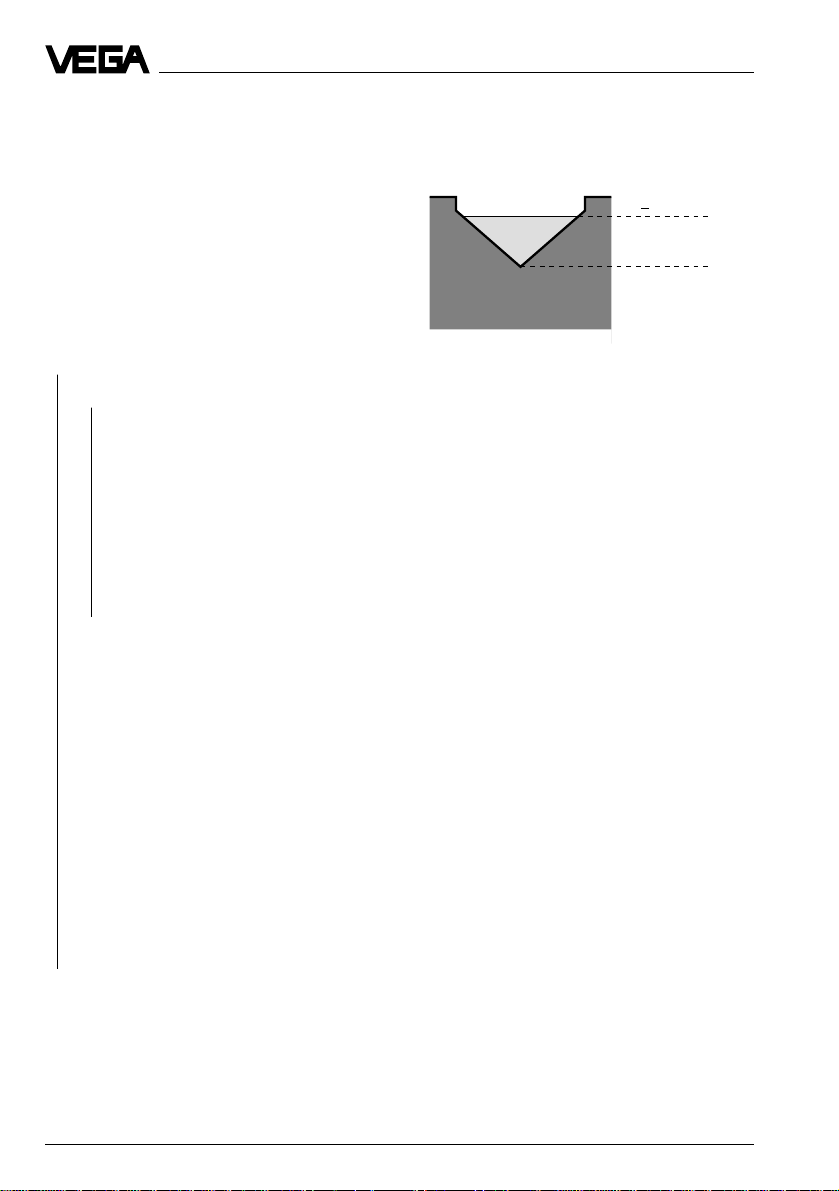

Rectangular flume (V-Notch)

With sharp overflow edge

α

h

max

Values for Q

α KQ

in ° (Factor) in m

max

maxhmax

3

/h in mm in m3/h in mm

Q

minhmin

90 4966 1385,0 600 4,4 60

60 2869 800,0 600 2,5 60

45 2056 573,3 600 1,8 60

30 1334 372,0 600 1,2 60

22,5 989 275,8 600 0,87 60

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

α = 45°

K = 2056 (derived from α)

h = 0,33 m

max

= 2056 x 0,33

2,5

2,5

=K x h

Q

= 128,6 m3/h

>>

VEGAMET 514… D 31

Page 32

Palmer-Bowlus-Flume

Set-up, parameter adjustment

D

D

D

/

4

30°

Values for Q

DK Q

in Zoll (Factor) in m3/h in mm in m3/h in mm

D

/

/

2

4

30°

h

max

D

/

6

max

maxhmax

D

/

2

Q

h

min

min

6" 1952 37,82 120 2,9 30

8" 2338 68,60 150 7,3 45

10" 2712 148,8 210 12,3 55

12" 3046 214,3 240 18,9 65

15" 3519 374,8 300 32,1 80

18" 3943 501,4 330 54,4 100

24" 4745 1074,0 450 114,5 135

30" 5488 2122,0 600 192,3 165

Note:

The data of above schedule relate to Palmer-BowlusFlumes of Messrs. Plasti-Fab.

Calculation of Q

max

The following formula can be used for calculation of

the actual flow of liquid levels < h

max…hmin

.

Presumed values for a calculation example

D = 12"

K = 3046 (derived from D 12")

h = 0,2 m

max

= 3046 x 0,2

1,86

1,86

=K x h

Q

= 152,63 m3/h

32 VEGAMET 514… D

Page 33

Set-up, parameter adjustment

4.7.3 Parameter adjustment MST1 and MST2, processing

Parameter adjustment MST1, processing (level)

–– Scaling

–– 0 % corresponds to 0.0 both values can be additionally influenced

–– 100 % corresponds to 100.0 with the determination of the decimal point

–– Decimal point 888.8

–– relating to Percent etc. choice out of list (scaled)

–– Unit % etc. choice adapted to above determination

.8888

–– Linearization curve linear

After a scaling or linearization the requested output must be coordinated to the scaled or linearized

value in the menu range "Parameter adjustment outputs", see menu points "relating to" and "Unit".

–– Integration time 0 s Range 0 … 600 sec.

Lin.curve 1 enquiry of three curves to be edited

Lin.curve 2 Editing see page 42

Lin.curve 3

>>

VEGAMET 514… D 33

Page 34

Set-up, parameter adjustment

Parameter adjustment MST2, processing (flow)

With the scaling of MST2 the conditions for the signal

conditioning instrument is provided to calculate the

Example relating to a rectangular flume (see page

31):

- Max. flow 1385 m

- Min. flow 4,4 m

3

/h

3

/h

flow volume/time. The respective values for min. and

max. flow are generally stated by the flume

manufacturers or can be calculated as proximity

100 %

values (see page 29 … 32).

In case of calculation the value of min. flow is

unimportant.

Parameter adjustment MST2, processing (flow)

–– Scaling

–– 0 % corresponds to 0 Range 0 … (4) … 9999 (Min. flow)

–– 100 % corresponds to 1000 Range 0 … (1385) … 9999 (Max. flow)

This value (1385) is automatically transferred to the

menu point "Pulse parameter volume", see page 36

and 41.

–– Decimal point 888.8

.8888

–– relating to flow

–– Unit L/s etc. choice adapted to flow measurement

–– Linearization curve linear Given curves for flumes and

Root funct. series

Venturi

Palmer-Bowlus

Quadrant

V-Notch

Trapezoidal weir

Rectangular overflow

Lin.curve 1 Enquiry of three curves to be edited

Lin.curve 2 Editing see page 43

Lin.curve 3

^ 1385 m3/h

4,4 m

3

/h

After a scaling or linearization the requested output must be coordinated to the scaled or linearized

value in the menu range "Parameter adjustment outputs", see menu points "relating to" and "Unit".

–– Integration time 0 s Range 0 … 600 sec.

34 VEGAMET 514… D

Page 35

Set-up, parameter adjustment

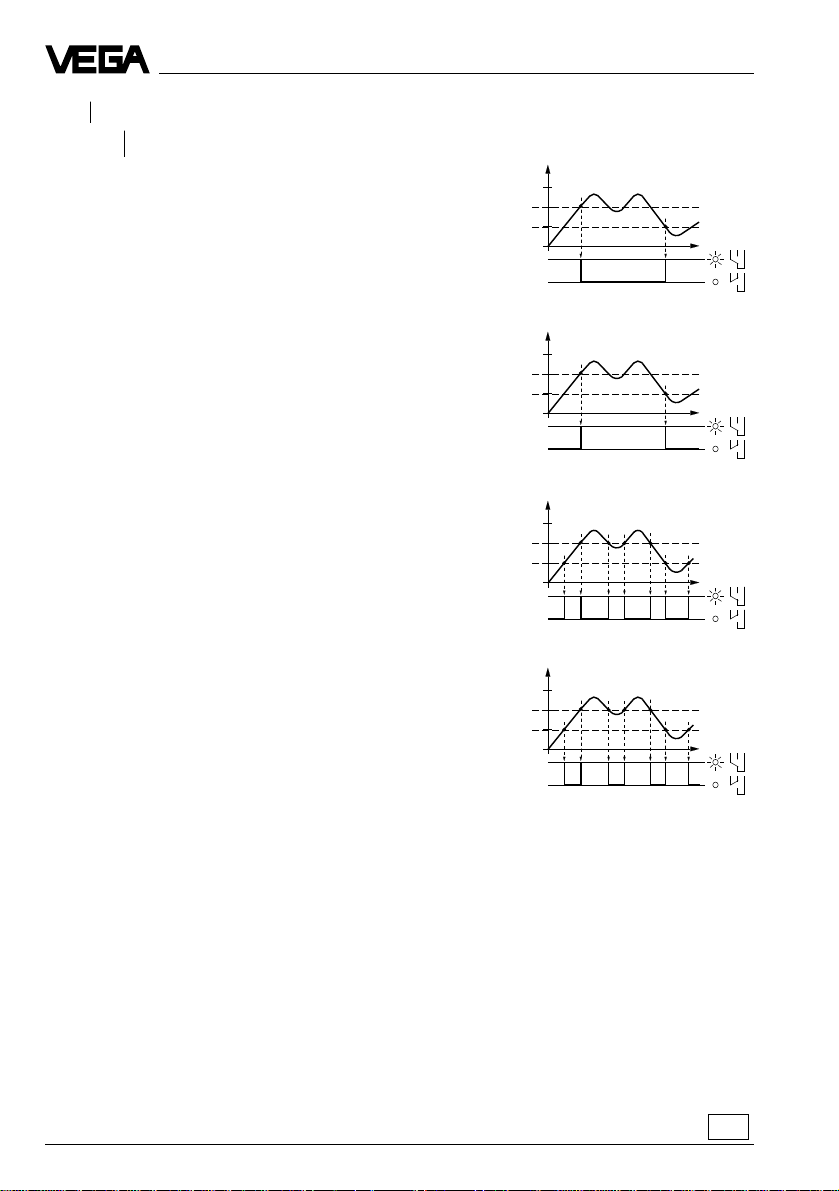

4.7.4 Parameter adjustment MST1 and MST2, outputs

Parameter adjustment MST1 and MST2, outputs

–– Current outputs

–– Current output 1 acc. to basic configuration coordinated to MST1, i.e. 0 … 20 mA

relating to level

–– relating to Percent etc. choice acc. to list

–– Unit % etc. choice adapted to above determination

–– Current output 4/20 mA

0/20 mA

20/4 mA

20/0 mA

-free- activated the menu points "Current at 0% and 100%"

–– Current at 0 % 4 mA adjustable range 0.0 … 20.0 mA

–– Current at 100 % 20 mA adjustable range 0.0 … 20.0 mA

reaction of the current output in case of failure

–– at failure 0 mA 0 mA

22 mA 22 mA

-- actual current value is kept

0 % current value relating to 0 %

100 % current value relating to 100 %

–– Current output 2 acc. to basic configuration coordinated to MST2, i.e. 0 … 20 mA

relating to flow, otherwise like current output 1. The output can be also

configured for pulses, see menu range of current output 3

–– Current output 3 acc. to basic configuration coordianted as pulse output MST2

–– Kind Pulse output

Parameter,

flow

t

20 mA

0 mA

Sampling

output

Parameter,

flow

t

20 mA

0 mA

>>

VEGAMET 514… D 35

Page 36

Parameter adjustment MST1 and MST2, outputs

Current output 3 (continuation)

–– Pulse parameter

–– Volume 1000 Range 0 … 9999

–– Quantity x factor 1 Multiplication factor x1, x10, x100, x1000

–– Creeping quantity

suppression 0 % Range 0 % … 100 %

–– Sampling h 1 Range 1 … 100 h (hours)

This menu point is only displayed in mode "Sampling

output".

–– Volt outputs

Set-up, parameter adjustment

–– Volt output 1 acc. to basic configuration coordinated to MST1, i.e. 0 … 10 V relating

–– relating to Percent etc. choice acc. to list

–– Current output 2/10 V

–– Volt at 0 % 2 V adjustable range 0.0 … 10.0 V

–– Volt at 100 % 10 V adjustable range 0.0 … 10.0 V

–– at failure 0 V 0 V

–– Volt output 2 as volt output 1, however acc. to basic configuration

–– Volt output 3 as basic configuration coordinated to no MST (– –).

to level

0/10 V

10/2 V

10/0 V

-free- activates the menu points "Current at 0% and 100%"

Reaction of the volt output in case of failure

11 V 11 V

-- Actual value is kept

0 % Volt value relating to 0 %

100 % Volt value relating to 100 %

coordinated to MST2, i.e. 0 … 10 V relating to flow.

Volt output 2 can be configured to level like volt output 1.

36 VEGAMET 514… D

Page 37

Set-up, parameter adjustment

Parameter adjustment MST1, outputs

–– Relay outputs

–– Relay output 1 acc. to basic configuration coordinated to MST1, i.e. level

–– relating to Percent etc. choice acc. to list

–– Unit % etc. choice adapted to above determination

–– Kind Overfill protection

–– Low 0.0 % In these menu points the switch points can be

–– High 100.0 % determined for above relay modes (except

–– at failure off - Relay de-energizes

–– additional functions

–– Switching delay

–– t on 0 s Switch on delay

–– t off 0 s Switch off delay

–– Relay output 2 see page 41

Prot. against dry running of pumps

Switching window Off

Switching window Off see additionally page 38 … 40

Tendency rising

Tendency falling

Monitoring

"Tendency rising" and "Tendency falling").

Range and unit acc. to selection in menu point

"relating to" and "Unit", see above

Reaction of the relay output in case of failure

-- - Actual switching condition is kept

>>

VEGAMET 514… D 37

Page 38

–– Relay output 1 (continuation 1)

–– Kind Over fill protection

The relay of relay output 1 de-energizes

at switch point "High" (reliable switching

condition)

Set-up, parameter adjustment

Parameter

High

Low

Relay outp.

d b z

t

Protection against dry running of pumps

The relay of relay output 1 de-energizes

at switch point "Low" (reliable switch

point)

Switching window On

The relay of relay output 1 is energized

within the switching window

Switching window Off

The relay of relay output 1 is deenergized within the switching window

Parameter

High

Low

Relay outp.

Parameter

High

Low

Relay outp.

Parameter

High

Low

Relay outp.

d b z

t

d b z

t

d b z

t

>>

38 VEGAMET 514… D

Page 39

Set-up, parameter adjustment

Tendency determination

The level change within the scanning time (ta) is determined and after all scannings (n) an average value is

generated out of the sum of the level changes.

If this average value exceeds a previously defined %-value, the tendency determination responds, i.e. an

energized relay de-energizes.

With the enquiry of "Tendency rising" or "Tendency falling" the menu points "Deviation in %" and "Deviation per

time" are released.

–– Relay output 1 (continuation 2)

–– Kind Tendency rising

%

t ges.

ta

The relay of relay output 1 de-energizes,

when the increasing average value of

"t ges." exceeds the previously defined

%-value

Tendency falling

same function however with falling

2

1

Relay outp.

ta = Scanning time

n = Number of scannings

%

t ges.

34

ta

n = 4

t

d b z

average value

t

2

1

Relay outp.

ta = Scanning time

n = Number of scannings

34

n = 4

d b z

–– Deviation in % 2 The level change exceeds the adjusted %-value, the

tendency determination responds.

0 … 110 %

Example 2 % (modification) per t ges.

–– Deviation per time

–– Scanning time in s60 Adjustment range 0 … 999 s

Example 60 s corresponds to 1 minute

–– Number of

scannings 4 Adjustment range 0 … 99 scannings

Example: t ges = ta • n = 60 • 4 = 240 s = 4 min, i.e.

after every 4 mins the average value of the deviation

is formed and the result is compared with the given

deviation in %, here in the example = 2%

>>

VEGAMET 514… D 39

Page 40

Set-up, parameter adjustment

Monitoring

The following requirements must be met for activation of the monitoring:

- Determine input 4 in the menu range "Configuration meas. point".

- Connect a key word (opener) to input 4 (see page 14).

- Select for the concerned relay the mode monitoring in the menu range "Parameter adjustment relay outputs"

(see page 37).

The selected relay is engergized. By pushing the key switch (opener opens) the respective actual measured

value is first of all frozen and derived thereof the relay de-energizes if the value is decreased (low) or

exceeded (high).

See additional diagram "Configuration meas. points" page 21.

–– Relay output 1 (continuation 3)

–– Kind Monitoring With the enquiry "Monitoring" the menu point

"Monitoring on" is released.

%

–– Monitoring on High

The relay of relay output 1 de-energizes when

the %-value stated under High is exceeded.

Low

The relay of relay output 1 de-energizes when

the %-value stated under Low is decreased.

High and

Low

The relay of relay output 1 de-energizes when

the %-value stated under High and Low is

exceeded or decreased.

High

frozen

meas.value

Key

switch

Relay outp.

%

frozen

meas.value

Low

Key

switch

Relay outp.

%

High

frozen

meas.value

Low

Key

switch

Relay outp.

t

d b z

t

d b z

t

d b z

–– Low -5 % Range and unit acc. to the selection in the menu

–– High 7 % points "relating to" and "Unit", see page 34.

–5 % and 7 % are exemplary values, relating to

above diagrams.

>>

40 VEGAMET 514… D

Page 41

Set-up, parameter adjustment

Parameter adjustment MST2, outputs

–– Relay outputs

–– Relay output 2 acc. to basic configuration coordinated to MST2, i.e. flow

Relay

output

Parameter,

flow

–– Kind Pulse output

d b z

t

Relay

output

Parameter,

flow

Sampling

output

–– Pulse parameter

–– Volume 0 Range 0 … 9999

–– Quantity x factor 1 Multiplication factor x1, x10, x100, x1000

–– Creeping quantity

suppression 0 % Range 0 % … 100 %

–– Sampling h 1 Range 1 … 100 h (hours)

This menu point is only displayed in the mode

"Sampling output".

d b z

t

VEGAMET 514… D 41

Page 42

Parameter adjustment MST1 and MST2, outputs

–– MET-indication

Set-up, parameter adjustment

–– relating to Percent

–– Unit %

–– PC/PLC-outputs

–– PC/PLC output 1

–– relating to Percent

–– Unit %

–– PC/PLC output 2 … 7 as described above

–– DIS-outputs

–– DIS-output 1

–– relating to Percent

–– Unit %

–– DIS-output 2 … 7 as described above

scaled etc. choice acc. to MST-enquiry

scaled etc. choice adapted to above determination

scaled etc. choice acc. to MST-enquiry

scaled etc. choice adapted to above determination

scaled etc. choice acc. to MST-enquiry

scaled etc. choice adapted to above determination

4.7.5 Parameter adjustment MST1 and MST2, simulation

Note

The whole indication flashes with activated simulation. The measured data delivered from the sensors are not

transmitted for processing, therefore this menu point should be quit as soon as possible. Reset to the

indication of measured values automatically after 60 minutes.

Parameter adjustment MST1, simulation

–– Simulation now! OK?

–– Simulation with [+] or [–]

42 VEGAMET 514… D

Page 43

Set-up, parameter adjustment

4.7.6 Parameter adjustment MST1 and MST2, special functions

Parameter adjustment MST1 and MST2, special functions

–– Reset meas. point (e.g. level or flow) Reset of all parameter values of the meas. point

–– Reset OK? MST1 or MST2 with this reset to factory

–– Reset now! OK? setting.

–– Failure mode Standard no fault signal

–– Manual corrections

–– Offset correction Only visible with hydrostat. pressure transmitters.

–– Offset correction OK?

–– Correction now! OK?

<–10% Fault signal with decreasing and/or exceeding

<110% of the adjusted measuring range

>110%

<-10a.>110%

<-110a.>110%

Carry out correction only with unpressurized sensor.

4.8 Set-up, additional functions

4.8.1 Password

Additional functions

–– Password off each menu point can be enquired and modified

on the password can be enquire menu point with [+]

and [–].

With the adjustment of password the whole menu is

released again.

Password for

VEGAMET 514 D … and 514 VD = -0514-

4.8.2 Linearization curve 1 … 3

A linearization curve is generated by a certain

number of index markers and their value pairs. A

value pair consists of a value for level percent (X %)

and a value for volume percent ( Lin %). Up to max.

32 index markers can be added.

A linearization curve can be terminated after any

individual number of index markers. The signal

conditioning instrument terminates automatically the

linearization curve with the values X = 100 % and

Y = 100 %.

The input of a linearization curve is made in the

menu point "Add index marker".

>>

VEGAMET 514… D 43

Page 44

Additional functions

–– Edit linearization curve

–– Linearization curve 1

–– Lin. curve 1

Set-up, additional functions

–– Edit lin.curve 1 Number of index markers 1 … 32 with [→] or [←]

–– Y … V % Edit the Y-value with [+] or [–], take over

–– Add index marker The new value pair is added automatically with [OK]

–– X …… at the correct position of the linearization curve.

Y …… The already available index markers are sorted

–– Delete index markers Enquiry of the value pairs with [→] or [←]

–– X ……

Y … delete? With [OK] the value pair and the appropriate index

–– Delete marker is deleted out of the linearization curve.

now? The remaining index markers and their value pairs

X…

%

…

Y… V%

…

X%

12,0

YV%

5,0

…

X……

Y……

…

lösch-

en

with [OK].

again.

move up

–– Lin. curve 2 as described above

–– Lin. curve 3

4.8.3 Info

All following menu points have display function.

Additional functions

–– Info

–– Input Info - for input configuration

–– VEGAMET Info - for VEGAMET configuration

–– Program Info - to program

–– Meas. point Info - to the individual meas. points

detailled information

4.8.4 Language

Additional functions

–– Language

– Deutsch

–– English Preadjustment and acc. to request

–– Francais modification, without data loss

–– Italiano

–– Espanol

44 VEGAMET 514… D

Page 45

Set-up, additional functions

4.8.5 VEGAMET Reset

Additional functions

–– VEGAMET Reset

–– Reset configuration

–– to default With reset to default the whole configuration

–– Reset OK? and the whole parameter adjustment

–– Reset now! OK? (if necessary all MST) are reset to factory setting

–– to combi application The combi application available at the moment

–– delete all MST? is deleted and in their position a preconfiguration

–– etc. to the new combi application to be adjusted is

–– Reset sensor values

–– Reset Input 1 The sensor data of the sensor connected to input 1

–– Reset OK? are deleted

–– Reset now! OK?

–– Reset linearization curves

–– Reset lin. curve 1 With this reset you delete the index markers

–– Reset OK? of linearization curve 1

–– Reset now! OK?

The basic configuration however remains,

e.g. pressurized level measurement.

generated, see page 6.

–– Reset lin. curve 2 as above, however linearization curve 2

–– Reset lin. curve 3 as above, however linearization curve 3

–– Reset all curves as above, however all linearization curves

4.8.6 Service

Additional functions

–– Service

–– Current output 1...3 the actual currents and voltages are

–– Volt output 1...3 indicated

VEGAMET 514… D 45

Page 46

5 Diagnosis

Diagnosis

5.1 Detailled menu list

Configuration

–– Configuration, inputs

–– Input 1 (analog)

–– Input of

–– Channel no.

–– Sensor characteristic values

or

–– Input 1 (VBUS)

–– Input von

–– Series no.

–– Sensor adaption

–– Input 4

–– Input of

–– Channel no.

–– Configuration meas. points

–– Application

–– Sensor

–– Kind

–– Options

–– Sensor coordination

–– MST1

–– MST-name, MST1

–– Fault signal

–– Tare

–– Monitoring

–– MST2, as MST1 (without tare)

–– Instrument address

(deleted up from Software-Version 6.0)

–– Configuration outputs

–– Configuration current outputs

–– Current 1 to (coordination)

–– Current 2 to (coordination)

–– Current 2 Standard (Kind)

–– Current 3 to (coordination)

–– Current 3 Standard (Kind)

–– Configuration volt outputs

–– Volt 1 to (coordination)

–– Volt 2 to (coordination)

–– Volt 3 to (coordination)

–– Configuration relay outputs

–– Operating relay

–– Rel. 1 to (coordination)

–– Rel. 1 Standard (Kind)

–– Rel. 2 to (coordination)

–– Rel. 2 Standard (Kind)

–– Fail safe relay

–– Relay Standard

–– Configuration PC / PLC-outputs

–– PC / PLC-output

–– PLC 1 to (coordination)

bis

–– PLC 7 to (coordination)

–– PC / PLC-relay status

–– PC / PLC-input status

–– Configuration VEGADIS

–– DIS 1 to (coordination)

bis

–– DIS 7 to (coordination)

46 VEGAMET 514… D

Page 47

Diagnosis

Parameter adjustment

–– Adjustment

–– with level / flow

–– Min. adjustment

–– Max. adjustment

–– without level / flow

–– Adjustment in

–– Position correction

–– 0 % at

–– 100 % at

–– Processing

–– Scaling (flow)

–– 0 % corresp. (Min.-flow)

–– 100 % corresp. (Max.-flow)

–– Decimal

–– relating to

–– Unit

–– Lin. curves

–– Integration time

–– Outputs

–– Current outputs

–– Current output 1

–– relating to

–– Unit

–– Volt outputs

–– Volt output 1

–– relating to

–– Unit

–– Relay outputs

–– Relay output 1

–– relating to

–– Unit

–– Kind

–– Low

–– High

Additional functions

–– Password

–– Edit lin. curves

–– Lin. curve 1

–– Lin. curve 2

–– Lin. curve 3

–– Info

–– Input info

–– VEGAMET-Info

–– Program info

–– Meas. point info

–– Language

–– Reset VEGAMET

–– Reset configuration

–– Reset sensor values

–– Reset lin. curves

–– Service

–– MET-indication

–– PC / PLC-outputs

–– DIS-outputs

–– Simulation

–– Special functions

–– Reset meas. point

–– Failure mode

–– Manual corrections

VEGAMET 514… D 47

Page 48

Diagnosis

5.2 Maintenance

The instrument is maintenance free.

5.3 Repair

Due to safety and guarantee reasons repair work

beside the wiring must only be made by VEGA-staff.

In case of a defect please return the respective

instrument with a short description of the error to our

repair department.

5.4 Fault signal

The signal conditioning instrument and the

connected sensor are permanently monitored during

operation. During the parameter adjustments to

adjusted values are checked on plausibility. In both

cases fault signals can be caused by irregularities.

In case of failure an error code is indicared on the

display (only in the range indication of measured

values), the fail safe relay de-energizes, the failure

LED lights and the outputs react acc. to their control

condition.

The error codes are listed in section 5.5 on the

following pages.

The diagnosis info is transferred by means of a

current text indication.

Configuration

You can determine separately for each meas. point, if

a fault signal should be transferred or not. See menu

range "Configuration meas. point" menu point "Fault

signal", see page 21.

Parameter adjustment

In the menu point "Failure mode" can be determined

separately for each measuring point how a

decreasing of the measuring range should trigger a

fault signal.

48 VEGAMET 514… D

Page 49

Diagnosis

5.5 Error codes

Error code Meaning

E004 This operation is not supported by the instrument (different software version). You tried to

E007 Sensor type not suitable.

E008 VBUS-sensor not found. The sensor cannot be found.

E010 The serial numbers of the connected VBUS-sensor has not been coordinated.

E013 VBUS-sensor signals failure. The VBUS-sensor signals failure; the communication with the

E014 Suspected shortcircuit

activate a function with a newer software version of VEGA Visual Operating in an instrument

with older software version. However the instrument cannot support this operation.

Please update the software of your instrument.

A VBUS-sensor with the serial number stated by you was found, however the sensor does

not correspond.

Please check the adjusted serial number or change the configuration.

Reasons:

- sensor is not connected

- no sensor connected with this serial number

- line break (VBUS)

- shortcircuit (VBUS)

- the sensor is defect

- interfered communication (VBUS)

probably

- interference in the VBUS-transmitter/receiver part of VEGAMET

Please check the serial number, the connection line, the sensor and if necessary the

VEGAMET.

sensor however is okay.

Reasons:

- failure on the VBUS-sensor

Please check the VBUS-sensor.

Reasons:

- shortcircuit

- sensor is defect

Please check the connection line and if necessary the sensor.

E015 Suspected line break

E016 Empty/full adjustment exchanged. The values for the empty adjustment are higher than the

E017 Adjustment span too small. The adjustment values are too close togther or are identical.

E021 Span of the sensor characterstic values too small or values exchanged. The sensor

VEGAMET 514… D 49

Reasons:

- no sensor connected

- line break

- sensor is defect

Please check the connection line and if necessary the sensor.

values for the full adjustment. Please carry out adjustment again.

Please carry out adjustment again.

characteristic values are too close together or are identical or the min. sensor characteristic

value is higher than the max. sensor characteristic value. Please check the sensor

charactersistic values.

Page 50

Diagnosis

Error code Meaning

E029 Measured valuated. The measured value is generated by simulation and does not reflect the

real condition.

E031 Same DISBUS-address. At least another instrument with the same DISBUS-address is

E032 Instrument address 0. Instrument address 0 is adjusted on VEGAMET. With this address

E034 Instrument error. A considerable error was detected on the instrument (possibly defect

E035 Instrument error. A considerable error was detected on the instrument (possibly check sum

E050 Remote VEGAMET not found. The VEGAMET from which a measured value is expected,

E051 Failure during the transmission of measured values via DISBUS. It is not possible to receive

E052 Input number not yet coordinated.

connected to this instrument. Please check the DISBUS-address.

VEGAMET does not participate in the DISBUS-communication, even the DISBUS is wired. If

necessary modify the instrument address.

EEPROM). Please disconnect voltage and then connect again (cold start). If the error does

not extinguish, please contact your VEGA-agency.

error in EEPROM). Please disconnect voltage and then connect again (cold start). If the

error does not extinguish, please contact your VEGA-agency.

cannot be found.

Reasons:

- the remote VEGAMET is not connected

- no VEGAMET with this instrument address connected

- line break (DISBUS)

- shortcircuit (DISBUS)

- the remote VEGAMET is defect

- interfered communication (DISBUS)

probably

- interference in the DISBUS-transmitter/receiver part of VEGAMET

Please check the instrument address on both VEGAMET, the connection line, the remote

VEGAMET and if necessary this VEGAMET.

a valid measured value via DISBUS from the remote VEGAMET; the communication to the

remote VEGAMET however is okay.

Reasons: