Page 1

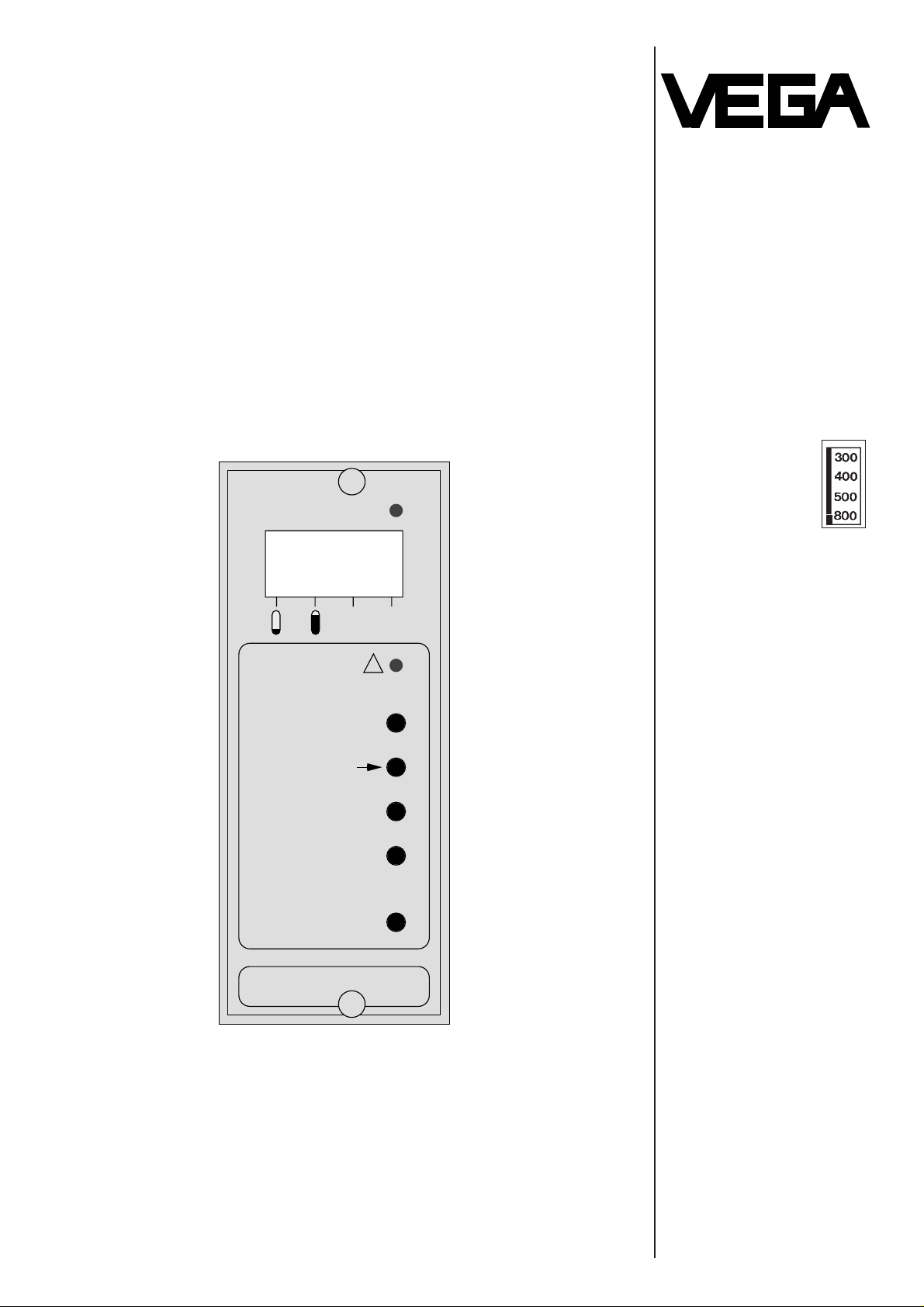

VEGAMET 407 Z

TIB • Technical Information • Operating Instructions

Signal conditioning

instrument for

continuous level

measurement

Signal conditioning instrument with plastic housing

of series 400

Supply for

- one pressure sensor

or

- one capacitive

measuring electrode

Conditioning of analog

transmitted measuring

data

VEGA Grieshaber KG

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach

Phone 0 78 36/50-0

MOD

+

-

STO

!

t

SIM

VEGAMET

407 Z

50.0

%

Page 2

Contents

Contents of the instruction manual

The described module must only be inserted and

operated as described in this TIB. Please note that

other action can cause damage or destruction for

which VEGA does not take responsibility.

The measuring systems certified as overfill

protection acc. to WHG and as overfill protection

acc. to the regulation for combustible liquids (VbF)

are listed on page 6 and 7.

Security information

Introduction Contents of the instruction manual .....................................................2

Security information ............................................................................2

Product description .............................................................................3

Technical Information Configuration of a signal conditioning instrument ...............................3

Configuration of a measuring system .................................................3

Technical data ....................................................................................4

Galvanical separation .........................................................................5

Dimensional drawing ..........................................................................5

Approvals ............................................................................................6

Mounting instructions ..........................................................................8

Electrical connection ...........................................................................8

Operating surface Indication and operating elements ......................................................9

Operation...........................................................................................10

Set-up ...............................................................................................10

Parameter adjustment Empty / full adjustment ..................................................................11

Integration time .................................................................................12

Simulation .........................................................................................12

Password ..........................................................................................13

Alarm information Alarm signal ......................................................................................13

Fault diagnosis .................................................................................14

The

Technical Information / Operating instruc-

tions is called TIB. It contains all necessary infor-

mation for correct:

- installation

- connection

- set-up

- parameter adjustment

of the signal conditioning instrument

VEGAMET 407 Z.

If you feel that any points in this data sheet are not

adequately covered our technical sales or service

departments will be pleased to assist.

Additional copies of this data sheet are freely

available and are automatically supplied with

quotations and purchases product.

Page 3

Introduction

Product description

The signal conditioning instrument VEGAMET

407 Z is used for manifold applications for

continuous level measurement.

VEGAMET 407 Z is integrated in a series 400

plastic housing.

A sensor (pressure transmitter or capacitive measuring electrode) can be connected via a two-core

line to the signal conditioning instrument. This line

is responsible for the power supply from the signal

conditioning instrument to the sensor. The measuring currents are transmitted analog from the sensor

to the signal conditioning instrument and evaluated.

The signal conditioning instrument can be

calibrated and adapted to the measurement by the

user via parameter adjustment.

These adjustments are made without additional

facilities and tools via a 5-button keyboard

integrated on the front panel.

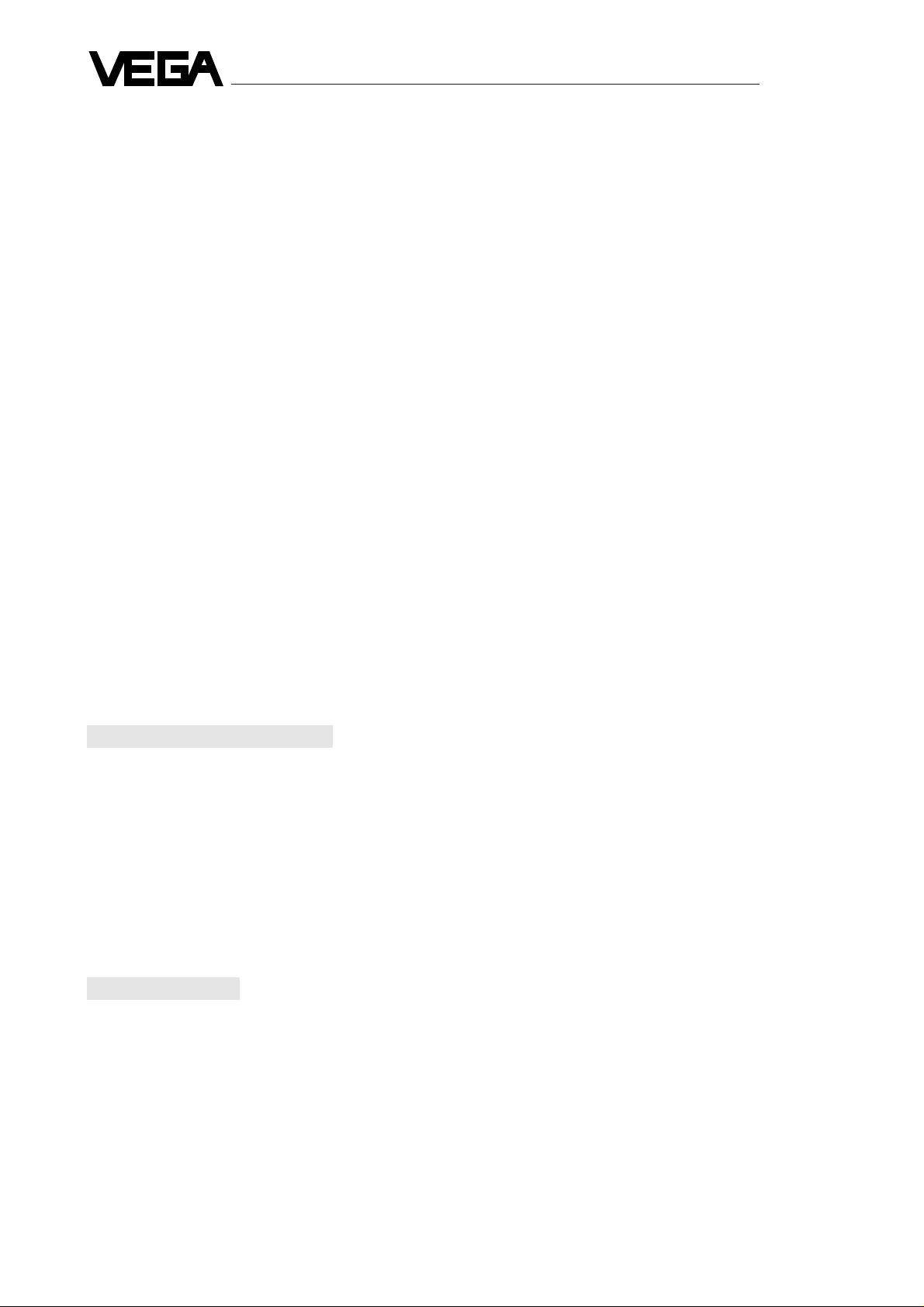

Configuration of a signal conditioning instrument

MOD

+

-

STO

!

t

SIM

VEGAMET

407 Z

or

4-digit LC-display

current output 0/4 … 20 mA

voltage output 0 … 5 V

voltage output 0 … 10 V

Fail safe relay

Alarm LED

capacitive measuring

electrode

pressure transmitter

Input Signal conditioning instrument Outputs:

50.0

%

Capacitive measuring

electrode with oscillator

or

Pressure transmitter

with oscillator

Optional auxiliary instruments e.g.: - Overvoltage arresters

- Indicating meters VEGADIS 171 (connection 0 … 20 mA)

- Auxiliary level switch VEGASEL ……

- Safety barrier type 145

Configuration of a measuring system

Signal conditioning instrument

VEGAMET 407 Z mounted into

plastic housing of series 400

Page 4

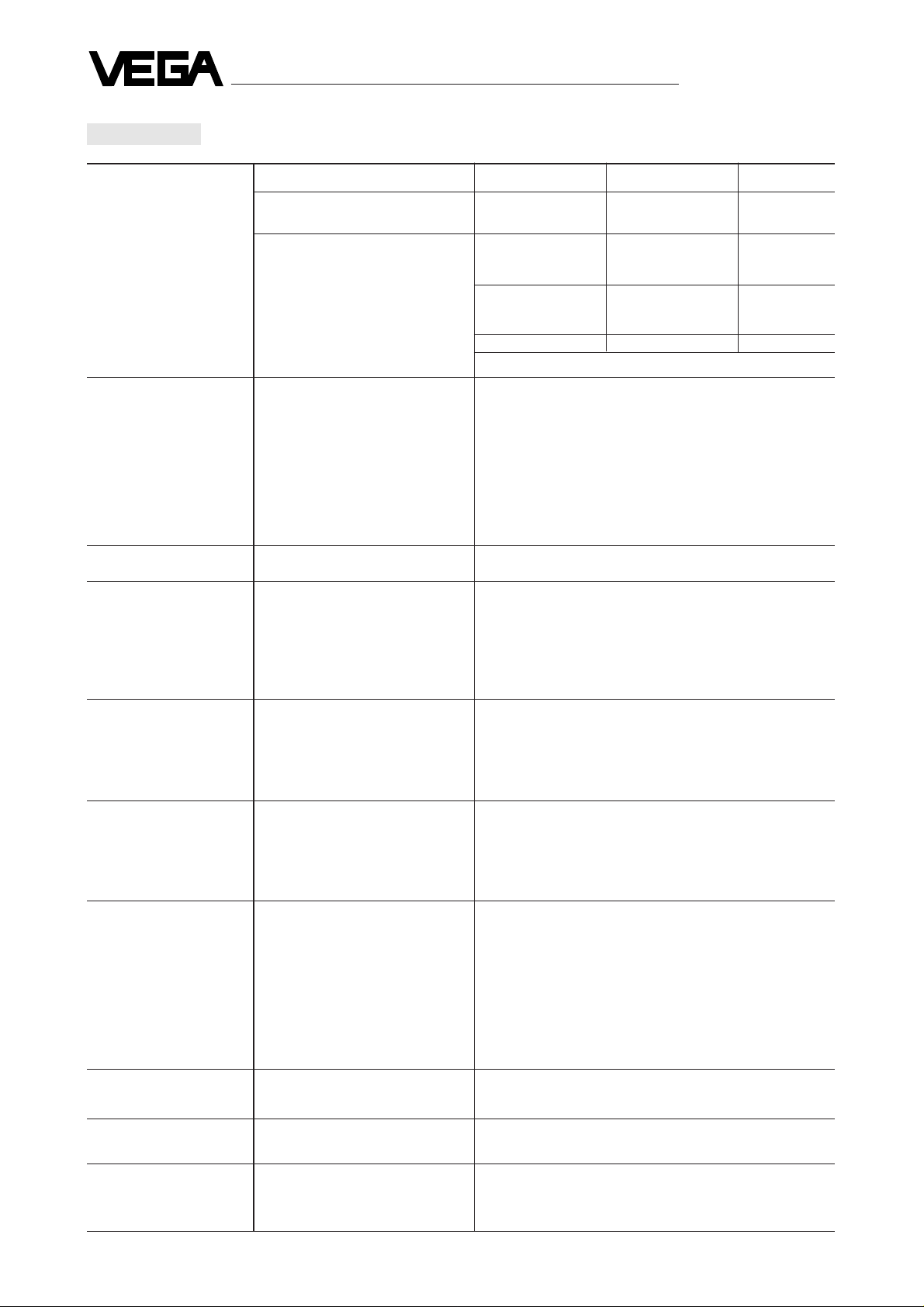

Technical Information

Technical data

Power supply Operating voltage value tolerance frequency

Standard 230 V AC +10 % –15 % 50 / 60 Hz

Options 110 V AC

130 V AC +15 % –10 % 50 / 60 Hz

240 V AC

24 V AC

42 V AC +15 % –10 % 50 / 60 Hz

48 V AC

16 … 60 V DC

Power consumption approx. 6 VA or 4 W

Measuring data Supply voltage for capacitive

measuring electrode or

pressure transmitter 24 V (max. 26 V) short-circuit proof, galvanically isolated

Data transmission analog

Connection cable 2-core, unscreened (standard line)

Resistance per conductor max. 200 Ω

Valid measured values 2 … 22 mA

Fault signal at < 2 mA; > 22 mA

Min. measuring distance 300 µA

Indication LC-display 4-digit

Current output Range 0 … 20 mA or 4 … 20 mA

Load max. 750

Ω

Galvanical separation to power supply unit and input

Resolution 0,05 % of range

Linearity error 0,05 % of range

Temperature error 0,06 % / 10 K of sensor

Voltage output 1 Range 0 … 10 V, max. 1 mA

Galvanical separation to power supply unit and to input

Resolution 0,05 % of range

Linearity error 0,1 % of range

Temperature error 0,06 % / 10 K of sensor

Voltage output 2 Range 0 … 5 V, max. 1 mA

Galvanical separation to power supply unit and to input

Resolution 0,05 % of range

Linearity error 0,1 % of range

Temperature error 0,06 % / 10 K of sensor

Fail safe relay Relay data:

1 spdt floating

Contact material Ag CdO and Au plated

min. turn-on voltage 10 mV

switching circuit 10 µA

AC DC

max. turn-on voltage U = 250 V U = 60 V

switching circuit I = 2 A I = 1 A

max. breaking capacity S = 125 VA P = 54 W

Operating Permissible operating temperat. –20°C … +60°C

conditions Storage and transport temperat. –20°C … +70°C

Electrical Protection IP 40

protective measures Protection class II

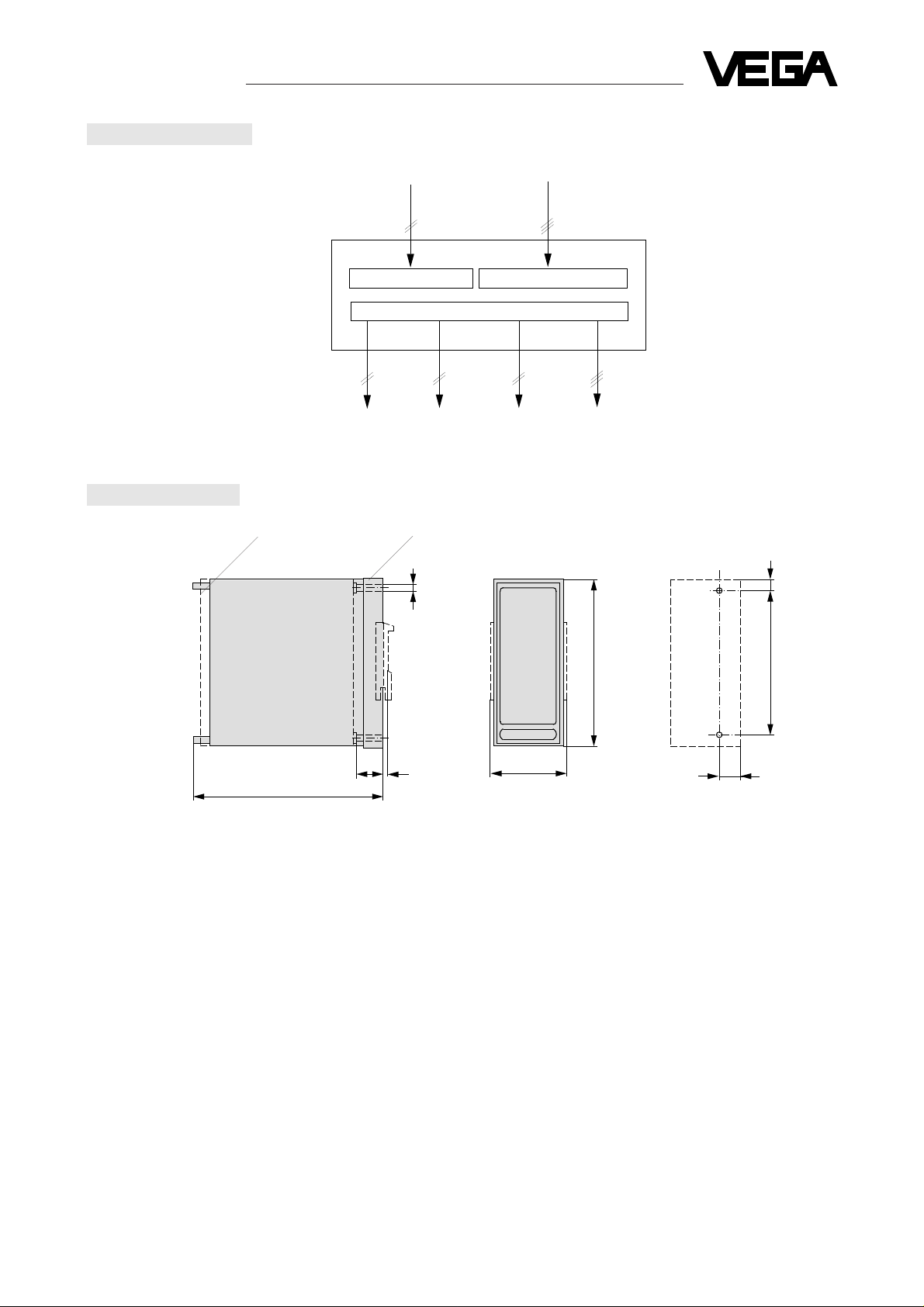

Mechanical Series Panel mounting, housing plastic ABS light grey

data Dimensions W = 53 mm, H = 127 mm, D = 143 mm

Weight approx. 700 g

Page 5

Technical Information

127

110

58

4,8

143

22,6

8,7

15,8

2

(dimensions in mm)

Dimensional drawing

Galvanical separation

Transparent cover Plug-in socket

Holes ø 4,5

or thread M4

Block diagram

Input Mains

Current output Voltage outputs Fail safe relay

Measuring data input Power supply

Microcomputer control and outputs

Page 6

Technical Information

Approvals

(for following measuring systems)

Approval as overfill protection acc. to

WHG

Pressure transmitters, approved for the following

measuring systems

Type .............................................................................D33, D34, D35, for type A, F, G, N, K

D36, Type G, N, F, S063

D37, Type G, N, S052

D38, Type G, N

Oscillator ................................................................... E27, E27 B

Signal conditioning instrument .................................. VEGAMET 407 Z

Auxiliary level switch .................................................. VEGASEL 444, 441 B, 441 C

defined in test certificate no. ..................................... PA-VI 810.76

Capacitive measuring electrodes, approved for the

following measuring systems

Type .............................................................................12.02, 12.12, 12.42 Ex, 12.72 Ex

22.02, 22.12

23.02, 23.12, 23.42 Ex, 23.72 Ex

25.02, 25.03, 25.12, 25.13

25.02 Ex, 25.03 Ex, 25.12 Ex, 25.13 Ex

26.02, 26.03, 26.12, 26.13

27.01, 27.11, 27.41 Ex, 27.71 Ex

32.04, 32.05, 32.14, 32.15

32.44 Ex, 32.45 Ex, 32.74 Ex, 32.75 Ex

42.04, 42.05, 42.14, 42.15

52.04, 52.05, 52.14, 52.15

Oscillator ................................................................... 117 A, 117/4 A, 117/4 A Ex

Signal conditioning instrument ................................... VEGAMET 407 Z

Auxiliary level switch ................................................. VEGASEL 444, 441 B, 441 C

defined in test certificate no. ...................................... PA-VI 870.15

If measuring systems acc. to the below approval

are installed, the legal documents have to be

observed.

Measuring systems for the use in hazardous areas

must only be operated in conjunction with pressure

transmitters or capacitive measuring electrodes in

Ex-version and safety barrier type 145.

see

- Conformity certificate

PTB-no. Ex-85.B.2038

- diagram page 7.

Page 7

Technical Information

Approvals

(continued)

Approval as overfill protection acc. to the regulation

for combustible liquids

VbF

Capacitive measuring electrodes, approved for the

following measuring systems

Type..............................................................................12.02, 12.03, 12.12, 12.13

23.02, 23.03, 23.12, 23.13

27.00, 27.01, 27.10, 27.11

32.04, 32.05, 32.06, 32.07

42.04, 42.05, 42.06, 42.07

32.14, 32.15, 32.16, 32.17

42.14, 42.15, 42.16, 42.17

12.42 Ex, 12.43 Ex, 12.72 Ex, 12.73 Ex

23.42 Ex, 23.43 Ex, 23.72 Ex, 23.73 Ex

27.40 Ex, 27.41 Ex, 27.70 Ex, 27.71 Ex

32.44 Ex, 32.45 Ex, 32.46 Ex, 32.47 Ex

32.74 Ex, 32.75 Ex, 32.76 Ex, 32.77 Ex

25.02 Ex, 25.03 Ex

25.12 Ex, 25.13 Ex

Oscillator ................................................................... 117/4 A Ex

Signal conditioning instrument .................................. VEGAMET 407 Z

Auxiliary level switch ................................................. VEGASEL 444, 441 B, 441 C

defined in test certificate no. ...................................... PTB-no. III B/S 2032 F

and type approval....................................................... 01/PTB-no. III B/S 2032 F

Transducer

(capacitive measuring electrode or

pressure transmitter)

If the sensor is installed in hazardous areas, the

special conditions of the conformity certificate must

be observed.

Signal conditoning instrument

The signal conditioning instrument VEGAMET

407 Z must be generally installed outside

hazardous areas (or special protective measures

must be taken.

Measuring systems for the use in hazardous areas

must only be operated in conjunction with pressure

transmitters or capacitive measuring electrodes in

Ex-version and safety barrier type 145. See

conformity certificate PTB-no. Ex-85.B.2038.

MOD

+

-

STO

!

t

SIM

VEGAMET

407 Z

Ex-area not Ex-area

Zone 0 Zone 1

Safety barrier

type 145

VEGAMET 407 Z

50.0 %

Page 8

Technical Information

18

17

16

15

14

13

N

L1

9

2

1

+

–

–

+

–

+

5

7

+

1

Sensor 1

1

2 3

4 … 20 mA

8

6

18

17

16

15

13

9

2

5

7

1

8

6

14

Sensor 1

1

2 3

0 … 20 mA

-

+

Electrical connection

Installation regulations:

- The wiring between VEGAMET 407 Z and sensor

(capacitive measuring electrode or pressure

transmitter) can be made with standard cable.

- In case of strong electromagnetic interferences,

screened cable must be used.

The screening must be earthed at one sensor

end.

Signal conditioning instrument

back view (type plate)

Plug-in socket with

terminals

VEGAMET 407 Z

Selection of the

current output

Alarm signals

Fault-monitoring relay

Supply voltage

(see data plate)

Voltage otuput 0 … 10 V

Voltage otuput 0 … 5 V

Current output 0/4 … 20 mA

capacitive

measuring

electrode

pressure

transmitter

Mounting instructions

14

13

VEGAMET

VEGAMET

15

14

13

15

N

L1

The plug-in base is provided with

- field terminals

- interconnection pins

- spacers for installation in series

- key coded

For installation in series the interconnection

pins are the power supply connections and

the distance sleeves ensure that adjacent

instruments have a minimum gap of 5 mm

between each other.

Remove the interconnection pins on the first

plug-in socket.

Warning: Beware of high voltage on

power supply terminals.

Plug-in base

Spacers

Key code

Interconnecting

pins for supply

voltage

In case of single mounting remove the interconnection pins and spacers, connect the supply voltage

directly.

The key coded base prevents other series 400

instruments being inserted.

Use adapter no. 040 002 for mounting on standard

rail.

Page 9

Operating surface

0407

Indication and operating elements

Measurements

Mode range

0.0

%

100.0

% Level 0 … 100 %

-10 % … 110 %

0 … 200 sec.

Adjustment in %

or in mA

Alarm signal

Empty adjustment

Full adjustment

Integration time

Simulation

Password

(Password)

MOD

+

-

STO

!

VEGAMET

407 Z

t

SIM

E1

E9

0 - -

0

Fault-monitoring LED-indication

Selection of the mode

Cursor position

Value (increase)

Value (decrease)

Storing programmed data

-8.8.8.8

PARAMETER FIELD

Measurements

MODEFIELD

%

Page 10

Operating surface

Operation

Set-up

- mounting socket

- connect capacitive measuring electrode or

pressure transmitter with the mounting socket

terminal 1 and 2, see page 8

- adjust the current output, see page 8

- check the connection and type plate

push VEGAMET 407 Z onto mounting socket and

fasten

- switch on power supply

LED (green) voltage supply lights

LED (red) fault signal lights

fault monitoring relay remains de-energized

software stage is indicated

- after approx. 2 sec.

fault-monitoring LED extinguishes

fault-monitoring relay is energized

a meaningless figure is displayed

- program empty and full adjustment, see

page 11

- if necessary, program

integration time, see page 12

password, see page 13

(procedure)

MOD

MOD

+

-

MOD

STO

SIM

0.0 %

000.0

001.6

z.B.

% %

The VEGAMET 407 Z has 3 modes which can be

obtained by scrolling the MOD-button:

Mode: 1. Measurement

2. Mode range

3. Parameter adjustment

Note that if no pushbutton is operated, after a

period of 60 minutes the display resets to level

measurement.

1. Measurement

2. Mode range

3. Parameter

adjustment

Measurement:

Level: %

Enquiry of the mode

numbers in the MODEFIELD. The parameters

of the enquired modes

can be indicated or

modified in mode 3.

Programming of the

parameters in the

PARAMETER FIELD.

The parameter of the

respectively selected

mode can be modified

and stored with the STObutton. If no change

should be realized, push

the MOD-button. In both

cases reset to mode 1.

Cursor position

Cursor position

Value (increase)

Value (decrease)

Storage

Page 11

Parameter adjustment

Empty, full adjustment in %

The measurement range for level 0 % and 100 % is

defined via the adjustment procedure.

When the vessel is partly filled or emptied the programming is as described on the right, however

with previously determined %-values.

The min. measuring range must correspond to a

current

∆ of > 300 µA.

Example

Full

• fill vessel

adjustment • select mode in MODEFIELD

• program level 100 % in

PARAMETER FIELD

• then store with STO

Empty • empty vessel

adjustment • select mode in MODEFIELD

• program level 0 % in

PARAMETER FIELD

• then store with STO

The empty and full adjustments may be performed

in any order.

%

100

0 %

Vessel full

Vessel empty

50

Empty, full adjustment in mA

The measuring current values are coordinated to

the levels 0 % and 100 % with the adjustment.

The measuring currents are experience values or

can be taken from the attached test certificate.

The procedure is used:

- for adjustment without rate of product level

change

- for correction of previous adjustments (alarm E3

or E4)

- for adjustment without connection of a capacitive

electrode or a pressure transmitter (alarm E2)

Example

Full • select mode in MODEFIELD

adjustment • push button + and button MOD

simultaneously (data input for mA)

• program 18,75 mA in

PARAMETER FIELD

• then store with STO

Empty • select mode in MODEFIELD

adjustment • push button + and button MOD

simultaneously (data input for mA)

• program 5,28 mA in

PARAMETER FIELD

• then store with STO

The empty and full adjustments may be performed

in any order.

%

100

0

mA

18,75

5,28

Level 100 %

^ measuring current

18,75 mA

Level 0 % ^

measuring current

5,28 mA

50

Page 12

Effects within the measuring range outside the measuring range

-10 % … 0 %...............100 % … 110 % < -10 % or >110 %

0/4 mA...............20 mA 22 mA

0 V..................10 V 11 V

0 V....................5 V 5,5 V

Example to end simulation ...................................... • push MOD–button again

Effects - Cancel the simulated output values

- Transmits the true output values

Parameter adjustment

Integration time

Application

- Where the product surface is agitated the system

outputs may be stabilized by adjusting the integration time.

Important notes:

The integration time depends on the filling and

emptying period of the vessel, i.e. integration time

≤ filling / emptying time. Mis-adjustment of the

integration time may degrade output sensitivity.

Definitions

- range = 0 … 199 sec.

- (0 … 199 secs. corresponds to the definition in

sec.)

At 200 sec. effects a time period, the actual value

is approx. 45 minutes.

- settings > 200 sec. are automatically limited to

the max. value 200 sec.

Example

- integration time of e.g. 15 sec.

• select mode t in MODEFIELD

• program 15 sec. in PARAMETER FIELD

• then store with STO

Example..............to activate the simulation ……… • select mode SIM in MODEFIELD

• activate the simulation with button MOD

• increase or reduce the output with button + or

button –

t

Simulation mode

In the simulation mode it is possible to test the

measuring system over the whole measuring range

independent of the process.

Button + increases and

button – reduces

all output values.

The longer the simulation button + and – are

pressed the greater the rate of change.

Integration time is ignored during the simulation

sequence.

t

fault-monitoring-LED lights

fault-monitoring relay de-energizes

Page 13

Parameter adjustment

Password

All parameters can be interrogated as previously

described and their data indicated on the display.

Data input can be inhibited by programming the

password.

Alarm signals

Indication Reason Result

Measuring results < - 10 % Input below minimum limit (flashing) without fail safe

> 110 % Input above maximum limit (flashing)

Error code E1 Connection cables reversed on with fail safe

short-circuit

E2 Line break

E3 Incomplete or incorrect adjustm. proced.

E4 (together with flashing mode segments)

E8.1 … Fault during Current output = 22 mA

E8.4 data transfer (acc. to STO) Voltage output

= 11 V or 5,5 V

E9 Fault in the EEPROM-memory

Activate password .................................................... • select mode - - - - in MODEFIELD

• program figure 1 in PARAMETER FIELD

• then store with button STO

Adjust password ....................................................... • select the mode required for parameter adjust-

ment in the MODEFIELD, in the example mode t

• select data input, the keyword 0 - - 0 is displayed

in the PARAMETER FIELD

• program

0407 as password

• then store with button STO

• the parameter adjustment of e.g. mode

t can be

made

(fail safe)

Page 14

Alarm information

E1 E2

1

2

+

-

VEGAMET 407 Z

V

mA

4 … 20

12 … 24

2

1

2

1

Sensors Measuring line

Capacitive Pressure

measuring transmitter

electrode

Fault diagnosis related to E1 or E2

Signal conditioning

instrument

Short-circuit

current > 22 mA

Check all connections

and measuring lines

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Shortcircuit

removed

?

Short-

circuit

removed

?

Short-

circuit

removed

?

Sensor defect

Short-circuit in the

connection cable

Separate sensor from

connection cable

Separate signal conditionining

instrument from connection cable

Line break

current < 2 mA

Check supply voltage

and measuring line

Signal conditioning

instrument defect

approx.

24 V

?

Alarm

E1 dis-

played?

Alarm

E1 is

displayed

?

Auswertgerät defekt

Fault or break on the

sensor (capacitive

measuring electrode or

pressure transmitter)

Cable break

Short-circuit the signal conditioning

instrument terminals

Remove short-circuit of the terminals on the

signal conditioning instrument, then short-

circuit terminal 1 and 2 on the sensor

Signal conditioning

instrument defect

E1 extinguishes

Signal conditioning

instrument defect

Page 15

Help for fault diagnosis The measuring current stored during empty and full

adjustment can be displayed in the mode range by

pushing the plus-button.

Application with …………………… - inaccurate measurements or

- alarm E3 or E4

Example: Measuring current of the previous

adjustment related to 0 % • select mode in MODEFIELD

• push plus-button, the adjustment current related

to 0 %, is displayed in PARAMETER FIELD

• reset by pushing the MOD-button twice

Measuring current of the previous

adjustment related to 100 % • select mode in MODEFIELD

• push plus-button, the adjustment current related

to 100 %, is displayed in PARAMETER FIELD

• reset by pushing the MOD-button twice

Alarm information

E3

E4

= Adjustment had been carried with no or with too

small level change.

= The modes or %-values had been exchanged

during adjustment

or

Fault diagnosis related to E3

Fault diagnosis related to E4

Alarm

removed

?

Repeat the adjustment

(e.g. empty adjustment)

Repeat the 2nd part of the

adjustment (e.g. full

adjustment)

or carry out

adjustment in mA

see page 11

E3 or E4 and mode

segment extinguish

E3 or E4 and

mode segment extinguish

Note

- %-value and

- mode

Note:

min. measuring

distance; %value and mode

Page 16

VEGA Grieshaber KG

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach

Phone 0 78 36/50-0

Technical data subject to alterations

2.12 245 / März '94

Alarm information

E8.1

Fault diagnosis related to E 8.1

The empty adjustment data has not been transferred

Repeat empty adjustment,

see page 11

Alarm E 8.1 extinguishes

O.K.

?

Auswertgerät defekt

E8.2

The full adjustment data has not been transferred

Repeat full adjustment,

see page 11

Alarm E 8.2 extinguishes

O.K.

?

Auswertgerät defekt

E8.3

The integration time data has not been transferred

Repeat programming of integration

time, see page 12

Alarm E 8.3 extinguishes

O.K.

?

Auswertgerät defekt

E8.4

The password data has not been transferred

Repeat activation or adjustment of

password, see page 13

Alarm E 8.4 extinguishes

O.K.

?

Auswertgerät defekt

E9

Try a new set-up, see page 10

Alarm E 9 extinguishes

O.K.

?

Auswertgerät defekt

Fault (data loss) in the EEPROM-memory

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Signal conditioning

instrument defect

Signal conditioning

instrument defect

Signal conditioning

instrument defect

Signal conditioning

instrument defect

Signal conditioning

instrument defect

Loading...

Loading...