Page 1

VEGAMET 407 AF

VEGAMET 407 AFT

TIB • Technical Information • Operating Instructions

Signal conditioning

instrument

For continuous level

measurement

- for connection of a

capacitive electrode

- or a pressure sensor

VEGA Grieshaber KG

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach

Phone 0 78 36/50-0

407 AF

100

0

50

%

tj

0

VEGAMET

!

Page 2

Application

The VEGAMET 407 AF or 407 AFT is a signal conditioning instrument and is used for level propor-

tional indication (continuous level measurement).

The VEGAMET 407 AF or 407 AFT consists of:

- plastic housing with plug-in socket (series400)

- electronics

- relay output with floating spdt (fail safe)

- front plate with:

- mains control lamp

- indicating instrument

- signal lamp

- potentiometer for full adjustment

- potentiometer for empty adjustment

- potentiometer for integration time

A measuring system consists of:

- signal conditioning instrument VEGAMET 407 AF

or 407 AFT

- capacitive electrode with oscillator or pressure

sensor with oscillator

Additional indicating instruments and auxiliary level

switches can be connected to the current and

voltage output.

Level measurement with capacitive electrodes

a) non-conductive products

Electrode and container wall form a capacitor.

The level changes the dielectric of the capacitor

and therefore its capacitance.

b) conductive products

The fully insulated electrode and product form a

capacitor. The level changes the size of the

capacitor and therefore its capacitance.

In both cases a level proportional measuring current is generated in the oscillator from the capacitance change.

Fault monitoring

The integral fault monitoring detects

- short-circuit or line break of the connection line

to the transducer

- current value of the connection line < 2,5 mA or

> 23,5 mA (e.g. as well as failures of the electronics in the transducer)

If one of the above mentioned failures is detected,

the failure LED lights and the output relay de-energizes, i.e. terminal 16 and 17 are connected

through relays (see electrical connection).

In addition more the output current increases to

approx. 23 mA and the voltage outputs take a

value< 5 V or < 10 V.

Current output

VEGAMET 407 AF

The current output of VEGAMET 407 AF is nonfloating with reference to the sensor input and

voltage output, however is floating with reference to

the mains connection.

VEGAMET 407 AFT

The current output of VEGAMET 407 AFT is floating.

Level measurement with pressure sensors

The diaphragm of the pressure sensor converts the

hydrostatic pressure of the product linear into a

movement. This movement changes the size of a

capacitor.

The respective oscillator generates a level proportional current out of this capacitance change.

The VEGAMET 407 AF or 407 AFT evaluates the

measuring current several times (see page 5).

Integration time

In case of fluctuating product surface it is useful to

smooth the outputs (indication, output 1 - 3), by

adjusting an integration time 0 … 20 sec.

Important note

The period of the integration time orientates on the

filling and emptying time of the vessel, i.e. integration time ≤ filling / emptying time.

Configuration

Function

Page 3

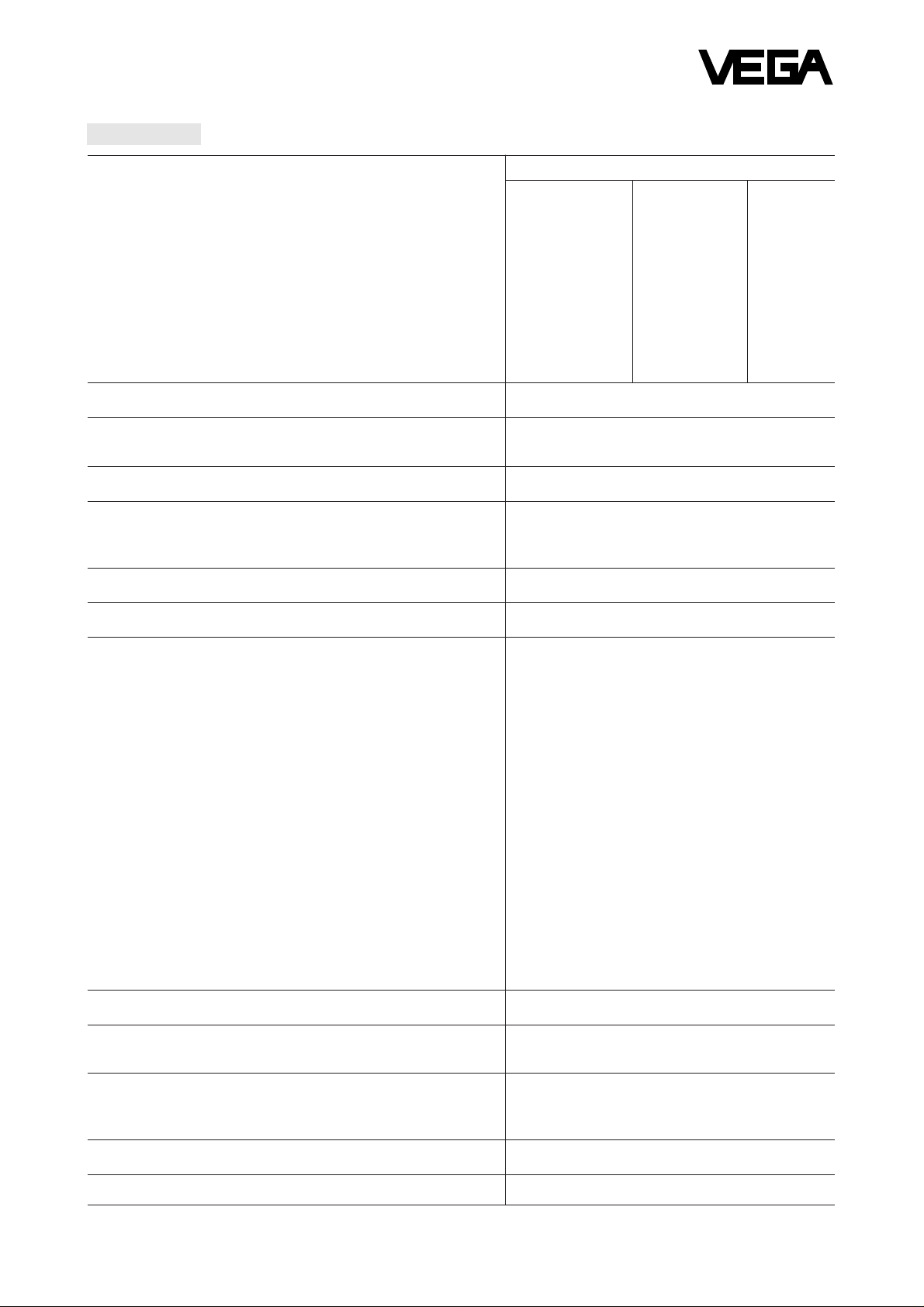

Technical data

Power supply Value Tolerance Frequency

standard AC 220 V +15 % -10 % 50 / 60 Hz

AC 230 V +10 % -15 %

options AC 110 V 50 / 60 Hz

130 V +15 %

240 V -10 %

260 V

AC 24 V +15 % 50 / 60 Hz

42 V -10 %

48 V

DC 9 … 16 V

16 … 60 V

Power consumption at UN: approx. 7 VA

Voltage for the transducer on

terminals 1 and 2 (terminal 3 and 4 bridged) approx. 22 V

Resistance per conductor to the transducer max. 50 Ohm

Voltage for the transducer on

terminals 1 and 2 (terminal 3 and 4 open)

(only for electrodes with oscillator type 117) approx. 15 V

Resistance per conductor to the transducer max. 50 Ohm

Indication analog indication 0 … 100 %

Output 1 type current output

range 0 … 20 mA or 4 … 20 mA

load max. 750 Ohm

floating VEGAMET 407 AFT

Output 2 type current output

range 0 … 5 V, max. 2 mA

for connection of

max. 10 auxiliary limit switches VEGASEL

Output 3 type voltage output

range 0 … 10 V, max. 2 mA

Output 4 type relay output

function fail safe

contact 1 spdt

relay data:

contact material AgCdO and Au plated

min. turn-on voltage 10 mV

switching current 10

µA

max. turn-on voltage AC 250 V, DC 60 V

switching current AC 2 A, DC 1 A

breaking capacity 125 VA, 60 W

Integration time 0 … 20 sec.

Permissible ambient temperature on the housing -20°C … +50°C / -4 … 122°F

Storage and transport temperature -20°C … +70°C / -4 … 158°F

Housing type plastic ABS light grey

protection IP 40

dimensions B = 53 mm, T = 143 mm, H = 127 mm

Terminal board: for cross section area of conductors max. 1 x 1,5 mm

2

Weight: with plug-in socket approx. 710 g

Page 4

Mounting instructions

Dimensional drawing

14

13

N

L1

VEGAMET

VEGAMET

15

14

13

15

The mounting assembly is provided as

standard feature with

- respective terminals

- interconnection pins

- distance sleeves for mounting

several instruments in a row

- coded key

Spacers slide onto the interconnecting

pins and ensure that adjacent instruments have a minimum gap of 5 mm

between each other.

For mounting on standard rail

(TS 35 mm) an adapter is enclosed.

The two screws located on the front of

the instrument are used to fasten the

instrument to the mounting assembly.

In case of single mounting remove the

interconnection pins and connect the

supply voltage directly. The coded key

avoids that instruments of series 400

are exchanged.

Remove all interconnection pins on the

first plug-in socket.

Attention:

The pins on terminals 13, 14 and 15 carry the supply

voltage.

127

110

58

4

143

22,6

8,7

15,8

2

Dimensions in mm Holes ø 4,5

or thread M4

transparent cover Plug-in socket

Plug-in socket

Distance sleeves

Coded key

Interconnecting pins

for supply voltage

Page 5

Electrical connection

The electrical connections should be made on the

mounting assembly in accordance with the diagram

located on the back of the instrument.

Standard two-wire cable can be used as measuring

line, electrode and signal conditioning instrument.

If electromagnetic interferences have to be

expected, screened cable must be used.

As factory preset, the terminals 3 and 4 are bridged

(supply voltage for oscillator: 22 V DC)

Attention:

In conjunction with oscillator type 117 the bridge

must be removed!

(Therefore supply voltage for oscillator: 12 V DC)

Protective measures:

If there is a danger of voltage spikes overvoltage

arresters are recommended.

Note TIB "Overvoltage arresters" for connection.

18

17

16

15

14

13

N

L1

9

2

1

+

-

-

+

-

+

5

7

+

1

4 … 20 mA

8

6

0 … 20 mA

2

1

2

1

3

4

Output 1 2 3

Indicated Current Voltage Voltage

value output output output

0 % 0 / 4 mA 0 V 0 V

100 % + 20 mA - 5 V - 5 V

Relay output

(fail safe)

Mains connection

Voltage output 0 … 10 V

Voltage output 0 … 5 V

Current output 0/4 … 20 mA

Wiring bridge

Measuring line

Electrode with

oscillator

Pressure sensor

with oscillator

Page 6

- Feed supply voltage.

The voltage must comply

with the figure stated on the wiring diagram.

- Adjust changeover switch on the back of the

instrument or on the front plate to the desired

current output range 0 … 20 mA or 4 … 20 mA

- turn potentiometer for integration time complete-

ly anti-clockwise

- potentiometer for full adjustment must be turned

clockwise by 22 turns

- Carry out adjustment as follows

Adjustment

The full or empty adjustment is carried out by a

spindle potentiometer. Overwinding is avoided by

the slide clutch. In practice three different methods

are possible for empty / full adjustment:

a) Level in the vessel can be filled to the

required min. level (= 0 %) and max. level

(= 100 %)

Empty adjustment

- Reduce product to required min. level.

- Adjust with potentiometer for empty adjustment

the indication of the instrument to 0 %.

Full adjustment

- Increase product to required max. level.

- Adjust with potentiometer for full adjustment the

indication of the instrument to 100 %.

Integration time

- Adjust potentiometer for integration time to

required value (see page 2).

b) Level in the vessel can be filled to the

required min. level (= 0 %), but only to a max.

level < 100 %

Empty adjustment

- Reduce product to required min. level.

- Adjust with potentiometer for empty adjustment

the indication of the instrument to 0 %.

Full adjustment

- Increase product to max. possible level and

dipcheck (e.g. 80 %)

- Adjust with the potentiometer for full adjustment

the indication of the instrument to the checked

value.

Integration time

- Adjust potentiometer for integration time to

required value (see page 2).

c) Level in the vessel can only be reduced to a

min. level > 0 % and to a max. level ≤ 100 %

Empty adjustment

- Reduce product to min. possible level and

dipcheck (e.g. 20 %)

- Adjust with the potentiometer for empty adjustment the indication of the instrument to the

checked value.

Full adjustment

- Increase level to max. possible level and

dipcheck (e.g. 60 %)

- Calculate indication value to be adjusted:

max. level minus min. level = indicating value to

be adjusted.

in the example: 60 % - 20 % = 40 %

- Set with the potentiometer for full adjustment the

indication of the instrument to the calculated

value (in the example 40 %).

- Set with the potentiometer for empty adjustment

the indication of the instrument to the actual

level (max. level in the example 60 %).

Integration time

- Adjust with potentiometer for integration time to

required value.

407 AF

100

0

50

%

tj

0

VEGAMET

Start-up

Fixing screw

Fixing screw

Mains control lamp

Indication instrument

Signal lamp

Potentiometer

for full adjustment

Potentiometer

for empty adjustment

Potentiometer

for integration time

Page 7

Example

100 %

0 %

90 %

10 %

-

+

L1

N

18

17

16

15

14

13

PE

0 … 20 mA

(+) N

(-) L1

4 … 20 mA

9

8

7

6

5

4

3

2

1

+

+

+

-

+

2

1

2

1

K2

18

17

16

15

14

13

PE

N

L1

12

11

10

8

7

L1

K2

N

Automatic emptying of a vessel

At a level of 90 % the pump is switched on and at

10 % level switched off.

Filling

Electrode

Pump Pressure sensor

Signal condition-

ing instrument

VEGAMET

Indicating

instrument

Auxiliary limit switch

VEGASEL

Signal lamp

Mains connection

Wiring bridge

VEGAMET 407 AF (T) VEGASEL 444

empty

channel

1 "A"

Input

signal

0 … 5 V

channel

1 "B"

Electrode

Pressure sensor

Indicating

instrument

0/4 … 20 mA

Page 8

VEGA Grieshaber KG

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach

Phone 0 78 36/50-0

Mounting instructions

Channel 1: A/B-switch in position A

one-point position 90 %

Channel 2: A/B-switch in position B

one-point position10 %

K2

K2

N

K2

11

10

11

12

16

17

L1

B

A

Control

pump

empty

Loading...

Loading...