Page 1

Operating Instructions

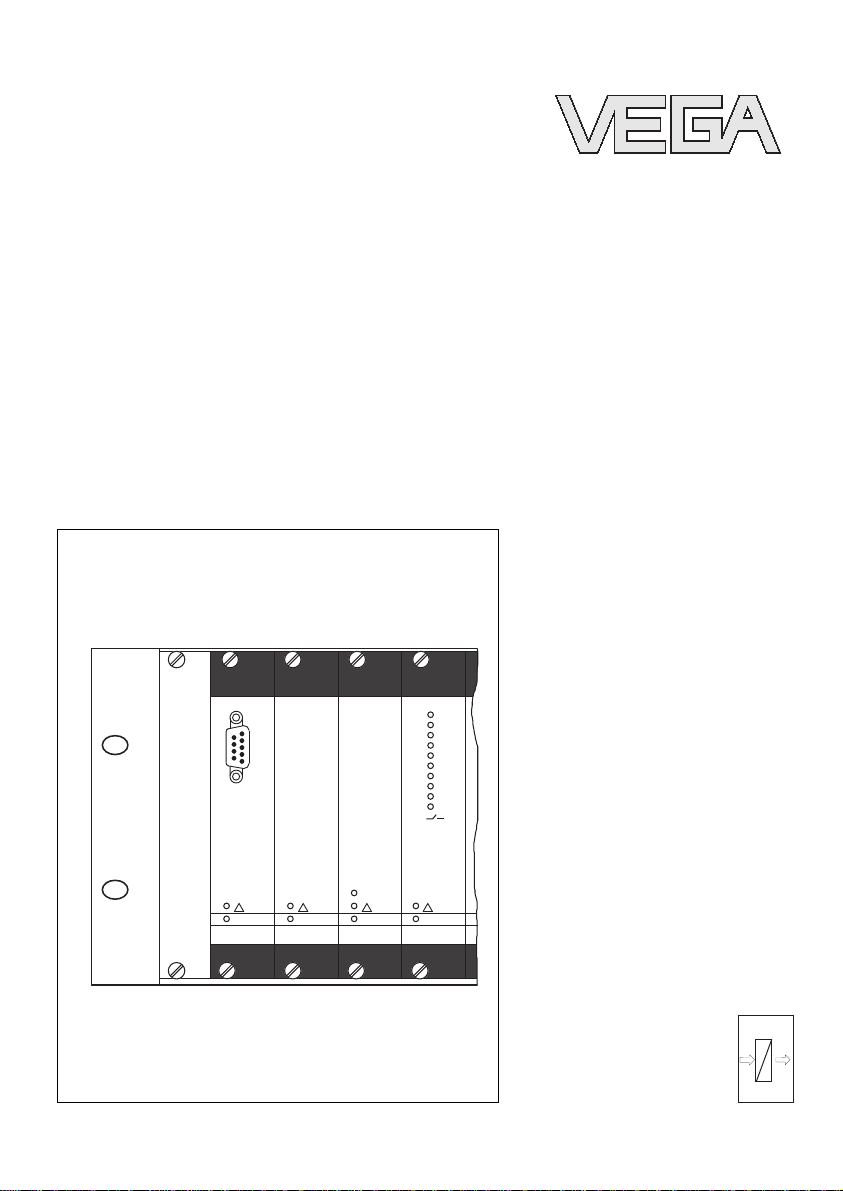

VEGALOG 571

CPU and carrier

on on

on

PC

on

VEGALOGVEGALOG

1

2

3

4

5

6

7

8

9

10

571 CPU

VEGALOGVEGALOG

571 EA

VEGALOGVEGALOG

571 EP

VEGALOGVEGALOG

571 AR

!

!

!

!

BA

inin

outout

Page 2

Contents

1 About this document

1.1 Function .............................

4

1.2 Target group ..........................

4

1.3 Symbolism used .......................

4

2 For your safety

2.1 Authorised personnel....................

5

2.2 Appropriate use........................

5

2.3 Warning about misuse ...................

5

2.4 CE conformity .........................

5

2.5 Environmental instructions ................

6

3 Product description

3.1 Configuration..........................

7

3.2 Principle of operation ....................

7

3.3 Operation ............................

8

3.4 Storage and transport ...................

8

4 Mounting

4.1 General instructions.....................

10

4.2 Carrier ..............................

10

4.3 Mount female multipoint connectors .........

11

4.4 Coding ..............................

11

5 Connecting to power supply

5.1 General connection instructions ............

14

5.2 Additional instructions for Ex applications .....

15

5.3 Wiring plan ...........................

16

6 Set up

6.1 Indicating and adjustment elements .........

19

6.2 Module card types......................

19

6.3 Setup requirements .....................

22

6.4 Start PACTware™ .....................

23

6.5 Creating a project ......................

24

6.6 Example projects.......................

25

6.7 Parameter adjustment ...................

26

7 Maintenance and fault rectification

7.1 Maintenance ..........................

30

7.2 Fault rectification .......................

30

7.3 Instrument repair .......................

31

2 VEGALOG 571 - CPU and carrier

Contents

31947-EN-060606

Page 3

8 Dismounting

8.1 Dismounting procedure ..................

32

8.2 Disposal .............................

32

9 Supplement

9.1 Technical data.........................

33

9.2 Dimensions ...........................

35

VEGALOG 571 - CPU and carrier 3

Contents

31947-EN-060606

Page 4

1 About this document

1.1 Function

This operating instructions manual has all the information you

need for quick setup and safe operation. Please read this

manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained,

qualified personnel. The contents of this manual should be

made available to these personnel and put into practice by

them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or

malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or

serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons

and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

4 VEGALOG 571 - CPU and carrier

About this document

31947-EN-060606

Page 5

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual

must be carried out only by trained specialist personnel

authorised by the operator. For safety and warranty reasons,

any internal work on the instruments must be carried out only

by personnel authorised by the manufacturer.

2.2 Appropriate use

VEGALOG 571 is a modular processing system for a wide

range of applications, e.g. for level, process pressure and

differential pressure measurement.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to

system components through incorrect mounting or adjustment.

2.4 General safety instructions

VEGALOG 571 CPU is a high-tech instrument requiring the

strict observance of standard regulations and guidelines. The

user must take note of the safety instructions in this operating

instructions manual, the country-specific installation standards

(e.g. the VDE regulations in Germany) as well as all prevailing

safety regulations and accident prevention rules.

2.5 CE conformity

The VEGALOG 571 CPU(Ex) module card is in CE conformity

with EMVG (89/336/EWG) and LVD (73/23/EWG).

Conformity has been judged according to the following

standards:

l EMC:

- Emission EN 50081-2

- Susceptibility EN 50082-1

l LVD: EN 61010

VEGALOG 571 - CPU and carrier 5

For your safety

31947-EN-060606

Page 6

2.6 Environmental instructions

Protection of the environment is one of our most important

duties. That is why we have introduced an environment

management system with the goal of continuously improving

company environmental protection. The environment management system is certified according to DIN EN ISO 14001.

Please help us fulfil this obligation by observing the environmental instructions in this manual:

l Chapter "Storage and transport"

l Chapter "Disposal"

6 VEGALOG 571 - CPU and carrier

For your safety

31947-EN-060606

Page 7

3 Product description

3.1 Configuration

The scope of delivery encompasses:

l 19" module card VEGALOG 571 CPU

l 19" carrier with integrated bus board

l Female multipoint connectors with card guide, screws and

coded pins (optional)

l Documentation

- this operating instructions manual

- Ex-specific "Safety instructions" (with Ex versions)

- if necessary, further certificates

A VEGALOG 571 processing system consists of a CPU, one

or several peripheral cards as well as a power supply unit

which are inserted into the 19" carrier BGT LOG 571. CPU and

peripheral card are designed as module cards in European

size (DIN 41494) with 5 TE width (25.4 mm). The supply

voltage of the cards with 24 VDCis provided e.g. via a power

supply unit VEGASTAB 593. The carrier with a width of 84 TE

and a height of 3 HE corresponds to the 19" standard format,

however, has an integrated LOGBUS board for communication

among the cards.

The maximum configuration of a VEGALOG consists of two

carriers mounted above one another with one CPU, 31

peripheral cards and one power supply unit. With this

configuration, up to 255 measurement loops can be set up.

3.2 Principle of operation

VEGALOG 571 is a modular processing system for a wide

range of applications, e.g. for level, process pressure and

differential pressure measurement.

To suit the application and the individual requirements,

VEGALOG 571 is put together using several module cards. A

CPU card and different input/output cards are available which

are inserted into a 19" carrier.

To suit these applications, VEGALOG 571 powers the

connected sensors and processes their analogue/digital

measuring signals or switching commands. The peripheral

cards take over the power supply as well as the processing of

the measuring signals. The processing is carried out in the

CPU through a special software consisting of function

Scope of delivery

Area of application

Physical principle

VEGALOG 571 - CPU and carrier 7

Product description

31947-EN-060606

Page 8

components (FB), input components (EB) and output components (AB). The input components receive the measuring

signals, the output components make them available via the

hardware outputs of the peripheral cards or the CPU. The

communication among the individual cards is carried out via an

own bus system (LOGBUS).

On the input side, 0/4 … 20 mA current outputs or Profibus PA

inputs are available. On the output side, there are relay or

current outputs. In addition, digital output cards for Ethernet,

Profibus, Modbus, Interbus and RS232/ASCII are available.

Voltage is supplied by a 19" power supply unit type

VEGASTAB. Detailled information on the voltage supply is

available in the "Technical data" in the "Supplement".

3.3 Operation

The operation of VEGALOG 571 is carried out via a PC which

can be connected via the RS232 interface of the CPU. Asan

alternative, connection via Ethernet and VEGACOM 558 is

possible.

The adjustment software PACTware™ with the corresponding

DTMs is installed under Windows™ and ensures easy

configuration of measuring systems as well as parameter

adjustment of connected VEGA sensors. For this purpose,

PACTware™ provides a clear adjustment interface with menu

structure, window technology and graphic support. In addition,

online help is available which describes the available functions

and parameter adjustment options. For earlier VEGALOG

systems with CPU software 1.xx, the previous software VVO

(VEGA Visual Operating) must be used for operation.

3.4 Storage and transport

Your instrument was protected by packaging during transport.

Its capacity to handle normal loads during transport is assured

by a test according to DIN EN 24180.

The packaging of standard instruments consists of environ-

ment-friendly, recyclable cardboard. For special versions, PE

foam or PE foil is also used. Dispose of the packaging material

via specialised recycling companies.

l Storage and transport temperature see "Supplement -

Technical data - Ambient conditions"

Power supply

Packaging

Storage and transport tem-

perature

8 VEGALOG 571 - CPU and carrier

Product description

31947-EN-060606

Page 9

l Relative humidity 20 … 85 %

VEGALOG 571 - CPU and carrier 9

Product description

31947-EN-060606

Page 10

4 Mounting

4.1 General instructions

The module cards of VEGALOG 571 can only be mounted into

the 19" carrier BGT LOG 571. It is provided with a special bus

board for data transmission between CPU and the individual

peripheral cards (LOGBUS). The carrier is designed for

mounting into a switching cabinet or 19" housing.

The plug position for the individual cards is individually

selectable, the system saves the card positions when switching on.

Note:

The plug positions must not be changed after the parameter

adjustment because measurement loops that have already

been set up would otherwise have to be reconfigured.

4.2 Carrier

By means of the plug connectors on the bus board, a fixed

pattern is created for the use of the modules. This ensures that

each module card is plugged into the multipoint connector and

also into its LOGBUS socket.

l Number of subunits (TE)

- 84 TE, thereof one 4 TE blind cover on module 1

l Width of the module cards

- 5 TE for CPU and peripheral cards

- 10 TE for VEGASTAB 593

l Number of module cards in the BGT LOG 571

- max. 16 pcs.(e.g. 1x VEGASTAB 693, 1x CPU and

13x peripheral cards)

A VEGALOG 571 in the maximum configuration consists of

two completely equipped carriers which are connected to each

other via a pluggable bus cable (see "Chapter Electrical

connection"). Because the bus cable may not be lengthened,

the two carriers must be mounted directly above one another.

Note:

In the following cases, it is recommended to mount a 19"

ventilator to avoid a temperature increase in VEGALOG.

l If more than one carrier is placed above the other

l If air cannot circulate in the area of the carrier

10 VEGALOG 571 - CPU and carrier

Mounting

31947-EN-060606

Page 11

l With increased ambient temperatures

4.3 Mount female multipoint connectors

The carrier BGT LOG 571 is supplied completely assembled.

To mount the individual module cards, modules must be

provided in the requested positions. A module consists of:

l a female multipoint connector according to DIN 41612,

series F, 48-pole

l two fixing screws

l two coded pins

l two guide rails

The female multipoint connector is available with the following

connections:

l Wire-Wrap standard connection 1.0x1.0 mm

l Plug connection 2 .8x0.8 mm

l Termi-Point standard connection 1.6x0.8 mm

l Soldering connection

l Screw terminals 0.5 mm²

If the VEGALOG 571 is supplied completely with carrier and

peripheral cards, the modules are completely mounted and

voltage supply for the individual cards is already looped. In

case of part or supplementary orders, the female multipoint

connectors must be mounted in the requested position by

means of the attached screws. Also the card guides must be

plugged in the corresponding positions. To complete the

setup, connect the 24 V supply voltage, the terminal assignment is stated in chapter "Connecting to power supply".

Tip:

Determine the position of the individual cards now and plug in

the coded pins as described in chapter "Coding".

4.4 Coding

A mechanical coding system avoids later interchanging of the

various module cards in the carrier.

The coding system consists of:

l two coded pins in the female multipoint connector

l two holes in the male multipoint connector of the respective

component

The coded pins are attached to the module.

VEGALOG 571 - CPU and carrier 11

Mounting

31947-EN-060606

Page 12

Equip the female multipoint connector with the two coded pins

according to the "Coding chart" and "Position of the coded

pins". The function coding points out that these are module

cards of VEGALOG. The instrument coding is used to

differentiate between the individual module cards.

The male multipoint connectors of the individual module cards

point to the holes suiting the pin positions.

Instrument coding Function coding

CPU card a1 c3

EP card a3 c3 and c23 with Ex

AA card a5 c3

AR card a7 c3

AT card a9 c3

EA card a11 c3

VEGACOM 557 a27 c3, c11

VEGACOM 558 a29 c11

VEGASTAB 593 -- --

o 9 o

z b d

o 1 o

a c

a1

a3

a5

a7

o 3 o

o 5 o

o 7 o

o11o

o13o

o15o

c3

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

a9

a11

a13

c11

c23

a23

a25

a27

3

1

2

Fig. 1: Positioning of the coded pins on the male multipoint connector

1 Instrument coding

2 Function coding

3 Ex coding

12 VEGALOG 571 - CPU and carrier

Mounting

31947-EN-060606

Page 13

1

Fig. 2: Detail coded pin mounting

1 Coded pin

VEGALOG 571 - CPU and carrier 13

Mounting

31947-EN-060606

Page 14

5 Connecting to power supply

5.1 General connection instructions

Always observe the following safety instructions:

l Connect only in the complete absence of line voltage

l If overvoltage surges are expected, overvoltage arresters

should be installed

In hazardous areas you should take note of the appropriate

regulations, conformity and type approval certificates of the

sensors and power supply units.

The VEGALOG cards must be powered with extra low voltage

(24 VDC) to keep protection class II. Detailled infromation to

voltage supply is available in the "Technical data" in the

"Supplement". When using a VEGASTAB 593, a reliable

separation from the mains circuits is ensured according to DIN

VDE 0106, part 101.

If voltage supply is not taken over by VEGASTAB, the supply

cable must be looped via the supplied NF filter (type: Schaffner

FN660-10/06). The supply cable after the filter must be wired

with a considerable distance to the signal cables to avoid

couplings.

Note:

Sum the power consumptions of the individual cards and

sensor and select a power supply unit with sufficient power

reserve.

Power supply is connected with standard cable acc. to the

national installation standards.

To connect 4 … 20 mA instruments, standard two-wire cable

without screen can be used. If electromagnetic interference is

expected which is above the test values of EN 61326 for

industrial areas, screened cable should be used.

When connecting Profibus PA sensors, screened cable

according to Profibus specification must be used.

Please make sure that your installation is carried out according

to the Profibus specification. In particular, make sure that the

termination of the bus is done with appropriate terminating

resistors.

Note safety instructions

Take note of safety

instructions for Ex

applications

Select power supply

Selecting the connection ca-

ble

14 VEGALOG 571 - CPU and carrier

Connecting to power supply

31947-EN-060606

Page 15

Connect the cable screen on both ends to ground potential. In

the sensor, the screen must be connected directly to the

internal ground terminal. The ground terminal outside on the

sensor housing must be connected to the potential equalisation (low impedance).

If potential equalisation currents are expected, the screen

connection on the side of VEGALOG 571 CPU must be made

via a ceramic capacitor (e.g. 1 nF, 1500 V). The low frequency

potential equalisation currents are thus suppressed, but the

protective effect against high frequency interference signals

remains.

Take note of the corresponding installation regulations for Ex

applications. In particular, make sure that no potential equalisation currents flow over the cable screen. In case of

grounding on both sides this can be achieved by the use of a

capacitor or a separate potential equalisation.

The total capacitance of the cable and of all capacitors must

not exceed 10 nF in Ex applications.

5.2 Additional instructions for Ex applications

Applications in the area according to the CENELEC Ex

protective reguations and ElexV (Germany) zone 0 require the

use of approved sensors.

For these applications, not the respective legal documents

(test certificates, test notes and conformity certificates). These

belong to the scope of delivery of the respecitive instrument.

These sensors must only be powered via an intrinsically safe

circuit. With the EA card, the sensors must be connected via a

safety barrier. The EP card is available in Ex version, no

separate separating facility necessary.

Also note the legal documents of these instruments.

To mount, note the following:

l VEGALOG 571 as well as the used separting facilities

must be only used outside the Ex area.

l A separating wall must be provided between the con-

nection parts of intrinsically safe and non-intrinsically safe

circuits so that there is a min. distance of 50 mm

l Only one sensor must be connected to each safety barrier

Cable screening and grounding

Select connection

cable for Ex applications

Mounting instructions

VEGALOG 571 - CPU and carrier 15

Connecting to power supply

31947-EN-060606

Page 16

5.3 Wiring plan

3

1

2

Fig. 3: Connection with NF filter

1 Supply cables

2 NF filter

3 Signal cables

2

1

L (+)

N (-)

2

6

12

20

24

22

10

16

18

30

28

32

dbz

14

26

8

4

Fig. 4: Terminal assignment VEGALOG 571 CPU

1 Supply voltage

2 The contacts (d/b/z 4 to d/b/z 32) are free

BGT/NF filter

CPU card

16 VEGALOG 571 - CPU and carrier

Connecting to power supply

31947-EN-060606

Page 17

Coupling of the carriers

If the number of the available modules of a carrier (BGT) is not

sufficient, the VEGALOG 571 can be also completed with a

second BGT.

The carriers are place above another and connected via the

supplied ribbon cable. On the rear of the bus board there is an

appropriate plug connection.

For the configuration with two carriers you have to set the

following two switch positions according to below description.

l Hook switch for the termination resistor

l Slide switch

Hook switch - closed

Slide switch - position M

l BGT 1

- Hook switch - closed

- Slide switch - position M

l BGT 2

- Hook switch - open

- Slide switch - position S

Switch position, one BGT

Switch position, two BGT

VEGALOG 571 - CPU and carrier 17

Connecting to power supply

31947-EN-060606

Page 18

M

S

M

S

5

4

3

2

1

Fig. 5: Coupling of two carriers

1 Hook switch

2 Slide switch

3 BGT 1 (modules 1 … 16)

4 Bus cable

5 BGT 2 (modules 17 … 32)

18 VEGALOG 571 - CPU and carrier

Connecting to power supply

31947-EN-060606

Page 19

6 Set up

6.1 Indicating and adjustment elements

1

2

3

on

PC

VEGALOGVEGALOG

571 CPU

!

Fig. 6: Indicating and adjustment elements VEGALOG 571 CPU

1 RS232 interface

2 LED for fault signal

3 LED for operating voltage

l LED fault signal [1]

- flashes in case of communication problems on the

LOGBUS

- lights during initialisation and during the self-test

- lights permanently during a hardware error

l LED operating voltage [2]

- lights when voltage supply is on

The module cards of the VEGALOG system have no own

adjustment elements. All adjustment measures are carried out

through the PC via the adjustment software PACTware™.

6.2 Module card types

The modular system of VEGALOG 571 consists of different,

special module card types:

l CPU card

Description of the status

LEDs

VEGALOG 571 - CPU and carrier 19

Set up

31947-EN-060606

Page 20

l Input cards

l Output cards

l Communication cards for standard bus systems

l Power supply cards for supply of the individual module

cards

The processor card is the centre of VEGALOG. It has the

following functions:

l Communication handling among the individual cards

l Creating and administrating of individual measurement

loops

l Calculating tasks such as adjustment, scaling, linearisa-

tion, differential generation etc.

l Coupling to the PC via RS232 interface

The CPU is further used for detection of levels or for monitoring

the switching on and switching off times.

The CPU read cyclically measured values from the peripheral

cards (e.g. with 30 measurement loop in the 300 ms cycle).

These are compared with the programmed data, standardised

and processed. The programmed data (configuration data,

adjustment parameters etc.) are available in the EEPROM

where they remain even in case of voltage loss. In the memory

of the CPU, a process picture is created which is outputted to

the peripheral cards via LOGBUS.

For backup, the programmed data can be read out any time via

the RS232 interface and can then be saved on the PC.

EA card

Up to ten 0/4 … 20 mA instruments can be connected to the

EA card (Eingang Analog, i.e. input analogue), e.g.:

l Capacitive probes

l Hydrostatic pressure transmitters

l Vibrating level switches

l Conductive probes

l Process and differential pressure transmitters

l Switching contacts (level signaller)

The inputs can be connected actively (sensor is powered by

the EA card) or passively (sensor delivers current).

Within an EA card, mixed connection of active/passive inputs

is permitted.

CPU card

Input cards

20 VEGALOG 571 - CPU and carrier

Set up

31947-EN-060606

Page 21

EP card

The EP card (Eingang Profibus PA, i.e. input PROFIBUS PA)

is used as input card for Profibus PA sensors of VEGA or other

manufacturers. Up to max. 15 Profibus PA sensors (max. 10

with Ex version) can be connected.

The EP (Ex) card recognises VEGA sensors on their serial

number and assigns automatically a bus address. For instruments of other manufacturers, the Profibus address must be

assigned separately for each instrument.

The power supply of the sensors, the transmission of the

sensor measuring signals as well as the parameter adjustmetn

commands are carried out via the same bus cable.

AA card

The AA card (Ausgang Analog, i.e. output analogue) provides

the processing results via up to ten analogue currents in the

range of 0 … 20 mA. The scaling as well as the definition as

rising or falling characteristics is carried out via the PC with

PACTware™.

Indicating instruments, recorders, controllers or PLC systems

are connected to these outputs.

AR card

The AR card (Ausgang Relais, i.e. output relay) provides ten

relay outputs with floating contacts. Connected are, for

example:

l Acoustic or optical signalling systems

l Magnet valves

l Contactors for pump control, etc.

The AR card is used to output switching, single or sum fault

messages. The switching status of each relay is indicated via a

two-colour LED in the front plate. This LED lights depending on

the parameter adjustmetn of the relay (limit contact yellow or

fail safe relay red). Each fail safe relay can be individually

assigned to one or several measurement loops. The definition

of the relay function, the switching points as well as the LED

colour is carried out via the PC with PACTware™.

AT card

The AT card (Ausgang Transistor, i.e. output transistor)

provides ten floating outputs via NPN trransistors. Binary input

cards of PLC systems are connected.

The application possibilities and the signalling of the switching

condition correspond to those of the AR card.

Output cards

VEGALOG 571 - CPU and carrier 21

Set up

31947-EN-060606

Page 22

VEGACOM 558

The communication card VEGACOM 558 is an interface

converter for Ethernet connection via TCP/IP. Hence the

parameter adjustment of VEGALOG as well as reading out of

measured values from any network PC is possible. It can be

used as webserver and provides the measured values as

HTML pages to all network participants. E-mails can be sent

also with the actual measured values or event messages.

VEGACOM 558 can be also used for connection to Visual

VEGA. Here all measured values and trend curves can be

enquired via Ethernet and displayed on any PC.

VEGACOM 557

The VEGACOM 557 communication card is an interface

converter (Gateway) for conversion of VEGA-specific data

formats into standard protocols. It is used for connection of the

VEGALOG system to a PLC or a PLC system. The

communication card is available for the following protocols:

l Siemens S5 (3964R procedure)

l Modbus (RTU and ASCII)

l Interbus S

l Profibus FMS

l Profibus DP

l VEGA-ASCII

The communication card can also be used to provide data of

VEGALOG via RS232 to the visualisation software Visual

VEGA. For this case, the communication card is also available

without interface function.

Adapter print

With the adapter card VEGACOM 557 AP, data of standard

protocols (Profibus, Interbus etc.) which are normally only

available on the rear of the carrier, are led to the front plate.

VEGASTAB 593

The 19" power supply unit powers all cards of VEGALOG with

24 VDC. The sensors are also powered via the active inputs of

the input cards. The versions VEGASTAB 593-60 (24 V, 45 W)

and VEGASTAB 593 (24 V, 120 W) are available.

6.3 Setup requirements

The adjustment software PACTware™ with the corresponding

DTMs is installed under Windows™ installiert and enables

easy configuration of measuring systems as well as parameter

adjustment of connected VEGA sensors. For this purpose,

Communication cards

Power supply card

22 VEGALOG 571 - CPU and carrier

Set up

31947-EN-060606

Page 23

PACTware™ offers a clear adjustment surface with menu

structure, window technology and graphic support as well as

an online help. For older VEGALOG systeme with CPU

software 1.xx the previous software VVO (VEGA Visual

Operating) must be used.

All currently available VEGA DTMs are provided in a DTM

Collection with the current PACTware™version on CD. This

CD is available from an authorised VEGA agency for a token

fee. The basic version of this DTM Collection incl.

PACTware™ is also available as a free-of-charge download

from the Internet. The professional version also includes

saving and printing of project documentation. A DTM licence

for the respective instrument family can be purchased via the

responsible VEGA agency.

Tip:

You find further information in the operating instructions

manual "DTD-Collection/PACTware™" as well as in the online

help.

Connect the PC via an RS232 cable (interlink modem) to the

PC interface of the CPU card in the front. If your VEGALOG

has also a VEGACOM 557/558 you can connect the PC also to

its RS232 interface. As an alternative the connection via

Ethernet and VEGACOM 558 is also possible. This has the

advantage that the adjustment can be carried out on any PC

within the network.

6.4 Start PACTware™

Start PACTware™ via the Windows start menu. For the first

log in, select the user "Administrator" and enter the password

"manager". Please enter uppercase/lowercase letters correctly. This password can be modified under the PACTware™menu item "Extras - User management". Here, you can

assign a password for the users with limited rights.

Information:

To ensure that all instrument functions are supported, you

should always use the latest DTM Collection. Furthermore all

not described functions are included in older firmware

versions. For many instruments, the latest instrument software

can be downloaded from our homepage. The transmission of

the instrument software is carried out via PACTware™ and an

individual interface. A description of the update sequence is

also available in the Internet.

VEGALOG 571 - CPU and carrier 23

Set up

31947-EN-060606

Page 24

6.5 Creating a project

Starting point for the adjustment of all types of field devices is

the partial or complete mapping of the instrument network in a

PACTware™project. For this purpose, PACTware™ provides

an area, the instrument catalogue, in which all installed DTMs

are displayed. Typically the DTMs have the same name as the

instruments that are adjusted by them. In addition,

PACTware™ provides a second area, the project window, in

which the instrument network is mapped.

The easiest and quickest way to generate an instrument

network in the project window of PACTware™ is via the VEGA

projectassistantt. It is available as manufacturer-specific

extension module in all VEGA DTM Installation package and

extends hence automatically the functions of PACTware™3.0.

The automatic generation of projects by means of the VEGA

projectassistantt, however, is only possible for instrument

networks in which only VEGA instruments are used.

You open the VEGA project assistant from the PACTware™

menu board under "Project - VEGA project assistant". The

window "VEGA project assistant" opens and you just have to

select the requested interface for automatic generation of the

project. Further information on the VEGA project assistant is

available in the corresponding online help. The online help can

be opened directly in the window "VEGA projekt assistant".

Fig. 7: Project assistant

To create a project in the project window, paste in the DTMs

from the instrument catalogue - one DTM for each actually

used instrument. The entry HOST-PC is the starting point for

pasting in the DTMs. The requested DTM can be brought over

Generate a project automatically

Generate a project manually

24 VEGALOG 571 - CPU and carrier

Set up

31947-EN-060606

Page 25

from the instrument catalogue to the project window with a

double click or Drag and Drop. If the project window or the

instrument catalogue are not visible, they can be activated in

the menu bar under " View ".

6.6 Example projects

Project creation VEGALOG and Profibus PA sensor

The following example shows a typical VEGALOG project with

EP card and Profibus sensors. We recommend using the

"VEGA project assistant", this considerably facilitates the

project creation and errors during the address assignment of

the VEGALOG module cards and the sensors are avoided. All

existing cards are found automatically and are added to the

project. Also all connected Profibus sensors are automatically

taken over into the project.

In case the planning is nevertheless carried out manually, e.g.

when creating an offline project, the following DTMs must be

added to the project tree:

1 First of all a driver must be selected by which the

communication via the PC can be carried out. Select the

"VEGA Ethernet" DTM from the instrument catalogue. With

this driver, the connection to VEGACOM 558 in the

VEGALOG 571 processing system is established.

When the "VEGA Ethernet" DTM in the project tree is

selected, you can later adjust the IP address for the

VEGACOM 558 module card in the PACTware™ menu

under "Device data - Add'l functions - Change DTM

addresses". The implementation of this setting is only

possible if a suitable DTM (e.g. VEGACOM 558) has

already been added to the project tree.

2 Finally the DTM "VEGALOG 571" must be added. This

DTM represents the VEGALOG 571 processing system. In

this DTM, measurement loops are created and processed

later on.

When the "VEGALOG 571" DTM in the project tree is

selected, you can later adjust the card addresses for the

VEGALOG module cards in the PACTware™ menu under

"Device data - Add'l functions - Change DTM addresses".

The implementation of this setting is only possible if a

corresponding DTM (e.g. VEGACOM 558) has already

been added to the project tree.

Connection via VEGACOM 558/Ethernet

VEGALOG 571 - CPU and carrier 25

Set up

31947-EN-060606

Page 26

3 Then the DTMs for the individual VEGALOG module cards

must be added to the project tree. These are in this

example: VEGALOG CPU, VEGACOM 558, VEGALOG

571EP.

4 The two DTM types "VEGALOG 571 EP" and "VEGALOG

571 EV" are VEGALOG module cards for connection of

digitally communicating VEGA sensors. This means,

corresponding sensor DTM can be added to these cards.

Select the suitable sensor DTM from the device catalogue

and transfer it to the project window.

If the sensor is already connected, it is possible to search

for it with PACTware™. In this case, the VEGALOG 571

DTM must be in online mode (right mouse key "Connect"). Then the automatic search function can be

started via the right mouse key - "Add'l functions -

Instrument search".

Fig. 8: Project VEGALOG 571 with Profibus PA sensors

6.7 Parameter adjustment

After the project was created, the parameter adjustment of the

instrument can be started. This is done via double click to the

requested DTM in the project window or via the right mouse

key by selecting "Parameter".

In the following procedure, adifference is made between

offline and online mode.

26 VEGALOG 571 - CPU and carrier

Set up

31947-EN-060606

Page 27

Offline mode

The project can be prepared, created and stored in offline

mode without instruments being connected. Later these data

can be transferred in online mode to the instruments now being

ready for operation. Keep in mind that saving of these data on

the hard drive is only possible in the Professional version with

costs.

Online mode

In online mode, the instruments on which the parameter

adjustment is to be carried out must be connected and ready

for operation. By selecting the appropriate DTM with the right

mouse key and the command "Connect", the online mode is

set up for operation. After double clicking, connection is

initiated which simultaneously checks the communication, the

sensor type and additional parameters. If necessary, all

parameters will be transferred automatically. Via the DTM

menu item "Device data - Read data from device", all

parameters of the sensor can be loaded anytime. All settings

which are carried out now must be transferred afterwards to

the instrument. This can be done via the DTM menu item

"Device data - Write data to device".

Fig. 9: DTM connection to VEGALOG 571

The most important thing is to creare the requested

measurement loops. For this purpose, a comfortable assistant

is available which is asking for the necessary settings. Select

the DTM menu item "Measurement loops" and push the button

"Create new measurement loop". The following applications

are available:

l Level measurement

l Process pressure measurement

Create measurement loops

VEGALOG 571 - CPU and carrier 27

Set up

31947-EN-060606

Page 28

l Connection 0/4 … 20 mA instrument

l Arithmetik

l Temperature measurement

l Universal

Depending on the selected application, a suitable sensor or

the measuring principle and probable options will be enquired.

The designation of the measurement loop with an individual

name is made at the end of the assistant setup.

Fig. 10: Creating/modifying measurement loop

After creating the measurement loop you can carry out the

adjustment, select a linearization or assign and configure relay/

current outputs.

When using the EP card, the project includes also all

connected PA sensors. Via the same cable connection you

have also access to these sensors to show e.g. the echo curve

or carry out a false echo memory. With analogue 4 … 20 mA

instruments, however, this direct access is not possible. In this

case, each sensor must be connected individually, e.g. via a

VEGACONNECT.

Sensor parameter adjustment

Set up

28 VEGALOG 571 - CPU and carrier

31947-EN-060606

Page 29

Fig. 11: DTM view, VEGAPULS 61 PA

Information:

Detailed expalantions to the parameter adjustmetn and project

creation are available in the onling help of PACTware™ and

the DTMs. Also consult the operating instructions manual of

the corresponding instrument for setup and correct parameter

adjustment.

Set up

VEGALOG 571 - CPU and carrier 29

31947-EN-060606

Page 30

7 Maintenance and fault rectification

7.1 Maintenance

When used as directed in normal operation, the module card

VEGALOG 571 CPU is completely maintenance-free.

7.2 Fault rectification

VEGALOG 571 CPU offers maximum reliability. Nevertheless

faults can occur during operation. These may be caused by the

following, e.g.:

l Measured value of the sensor not correct

l Voltage supply

l Interference on the cables

The first measures to be taken are checking the input/outout

signal as well as processing failure messages. The diagnostic

information are updated cyclically in a 5 sec. pattern.

PACTware™ with the suitable DTM offers comprehensive

diagnostics options. The integrated online help offers you

additional information. In many cases, these causes can be

thus determined and faults can be rectified.

If these measures are not successful, you can call the VEGA

service hotline in urgent cases under the phone no.

+49 1805 858550.

The hotline is available to you 7 days a week round-the-clock.

Since we offer this service world-wide, the support is only

available in the English language. The service is free of

charge, only the standard telephone costs will be charged.

The operating condition of the CPU and peripheral cards is

displayed via the status LEDs in the front plate.

l LED failure message (red)

- flashes in case of communication problems on the

LOGBUS

- lights during initialisation and during the self-test

- lights permanently during a hardware error

l LED operating voltage (green)

- lights when voltage supply is on

Causes of malfunction

Fault rectification

24 hour service hotline

Fault messages via LED status indication

Maintenance and fault rectification

30 VEGALOG 571 - CPU and carrier

31947-EN-060606

Page 31

7.3 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our homepage

www.vega.com under: "Downloads - Forms and Certificates -

Repair form".

By doing this you help us carry out the repair quickly and

without having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and possibly also a safety data

sheet to the instrument

l Please request the address for the return shipment from

the VEGA agency serving you.

Maintenance and fault rectification

VEGALOG 571 - CPU and carrier 31

31947-EN-060606

Page 32

8 Dismounting

8.1 Dismounting procedure

Warning:

Before dismounting, be aware of dangerous process conditions such as e.g. pressure in the vessel, high temperatures,

corrosive or toxic products etc.

Take note of chapters "Mounting" and "Connecting to power

supply" and carry out the listed steps in reverse order.

8.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials

and have designed the electronic modules to be easily

separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/

EG and the respective national laws (in Germany, e.g.

ElektroG). Pass the instrument directly on to a specialised

recycling company and do not use the municipal collecting

points. These may be used only for privately used products

according to the WEEE directive.

Correct disposal avoids negative effects to persons and

environment and ensures recycling of useful raw materials.

Materials: see "Technical data"

If you cannot dispose of the instrument properly, please

contact us about disposal methods or return.

Dismounting

32 VEGALOG 571 - CPU and carrier

31947-EN-060606

Page 33

9 Supplement

9.1 Technical data

General data carrier BGT

Series 19" carrier for mounting in switching cabinet or

housing

Dimensions W = 482.6 mm (19 in), H = 132.5 mm (5.22 in),

D = 254 mm (10 in)

Weight approx. 1650 g (3.53 lbs)

Material Alumininium anodized

General data

Series 19" module card for BGT LOG 571

Dimensions W = 25.4 mm (1 in), H = 128.4 mm (5.06 in), D

= 166 mm (6.54 in)

Weight approx. 400 g (0.882 lbs)

Voltage supply

Supply voltage U

nom

= 24 VDC(18 … 36 V)

Power consumption

- CPU card max. 6 W

- EA card max. 11 W

- EP card max. 8 W

- AA card max. 9 W

- AD card max. 10 W

- AR card max. 6 W

- AT card max. 6 W

- VEGACOM 557 max. 6 W

- VEGACOM 558 max. 4 W

Fuse protection Pigtail fuse 1 A slow-blow

Electrical connection

Module card Multipoint connector according to DIN 41612,

series F, 48-pole (d, b, z) with coding hole

Module in the carrier BGT LOG 571 Suitable female multipoint connector according

to DIN 41612 with connection via standard

connection technologies

Supplement

VEGALOG 571 - CPU and carrier 33

31947-EN-060606

Page 34

RS232 interface

Quantity 1x on front plate

Data transmission 9600 baud, 8 data bits, 1 stop bit, no parity

Plug connection 9-pole D-SUB plug

Displays

LED displays

- Status indication operating voltage 1x LED green

- Status indication fault signal 1x LED red

Ambient conditions

Ambient temperature -20 … +60 °C (-4 … +140 °F)

Storage and transport temperature -20 … +80 °C (-4 … +176 °F)

Electrical protective measures

Protection mounted in BGT LOG 571

- front side completely equipped or

covers

IP 40

- Upper and lower side IP 20

- Wiring side IP 00

Protection class I (in carrier BGT LOG 571)

Overvoltage category II

Electrical separating measures

Reliable separation according to VDE 0106 part 1 between voltage supply, LOGBUS

connection and RS232 interface

- Reference voltage 250 V

- Insulation resistance 2.3 kV

Supplement

34 VEGALOG 571 - CPU and carrier

31947-EN-060606

Page 35

9.2 Dimensions

185mm (7 9/32")

3mm (

1

/8")

132,5mm (5

7

/

32

")

10,5mm (13/32")

465mm (18

5

/16")

19" = 482,6mm

84 TE = 426,72mm (16

3

/4")

258mm (10

5

/32")

7,5mm (

19

/

64

")

57mm

(2

1

/

4

")

1

2

3

Fig. 12: Dimensions 19" carrier BGT LOG 571

1 Carrier 1

2 Carrier 2

319" ventilator (optional)

100mm (3

15

/16")

162mm (6 3/8")

5,5mm (

7

/32")

9mm (

23

/64")

128,4mm (5

1

/16")

25,4mm

(1")

5 TE

on

PC

VEGALOGVEGALOG

571 CPU

!

Fig. 13: Dimensions VEGALOG 571 CPU

Supplement

VEGALOG 571 - CPU and carrier 35

31947-EN-060606

Page 36

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application,

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2006

Technical data subject to alterations 31947-EN-060606

Loading...

Loading...