Page 1

Operating Instruction

VEGAFLEX 51V and 52V

Level and Pressure

Page 2

Safety information / Note Ex-area

Safety information

The described module must only be installed

and operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGAFLEX 51V and 52V

Note Ex-area

Please note the attached approval documents

(yellow binder) and especially the included

safety data sheet.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex-area ............................................................................... 2

1 Product description

1.1 Function ................................................................................ 4

1.2 Application features ............................................................. 5

1.3 Types and versions............................................................. 7

1.4 Type code ............................................................................ 8

1.5 Technical data ...................................................................... 9

1.6 Approvals .......................................................................... 12

1.7 Dimensions ........................................................................ 12

2 Mounting

2.1 Installation instructions ...................................................... 14

3 Electrical connection

3.1 Connection and connection cable .................................... 18

3.2 Connection of the sensor .................................................. 20

3.3 Connection of the indicating instrument VEGADIS 50 .... 21

4 Set-up

4.1 Adjustment structure ......................................................... 22

4.2 Adjustment with adjustment module MINICOM ............... 23

4.3 Adjustment with PC ........................................................... 28

4.4 Adjustment with signal conditioning instrument .............. 31

5 Diagnosis

5.1 Simulation ........................................................................... 32

5.2 Error removal ..................................................................... 32

VEGAFLEX 51V and 52V 3

Page 4

1 Product description

1.1 Function

High frequency microwave impulses are

guided along a steel rope. When reaching

the product surface, the microwave impulses

are reflected. The running time of the impulses is processed by the integral electronics and provided as level.

The sensors measure levels of all kind of

solids. Density, conductivity and dielectric

constant of the medium do not influence the

measurement. Also varying solid characteristics do not influence the measured value.

Lime, cement, cereals, plastic granules, flour,

gravel - in solids VEGAFLEX microwave

sensors are the ideal solution for arduous

applications. The level is also reliably detected in products with varying humidity or

fluctuating dielectric constant. High, narrow

vessels in which non-contact measuring

principles often do not deliver optimum measuring results, VEGAFLEX can be used without problems.

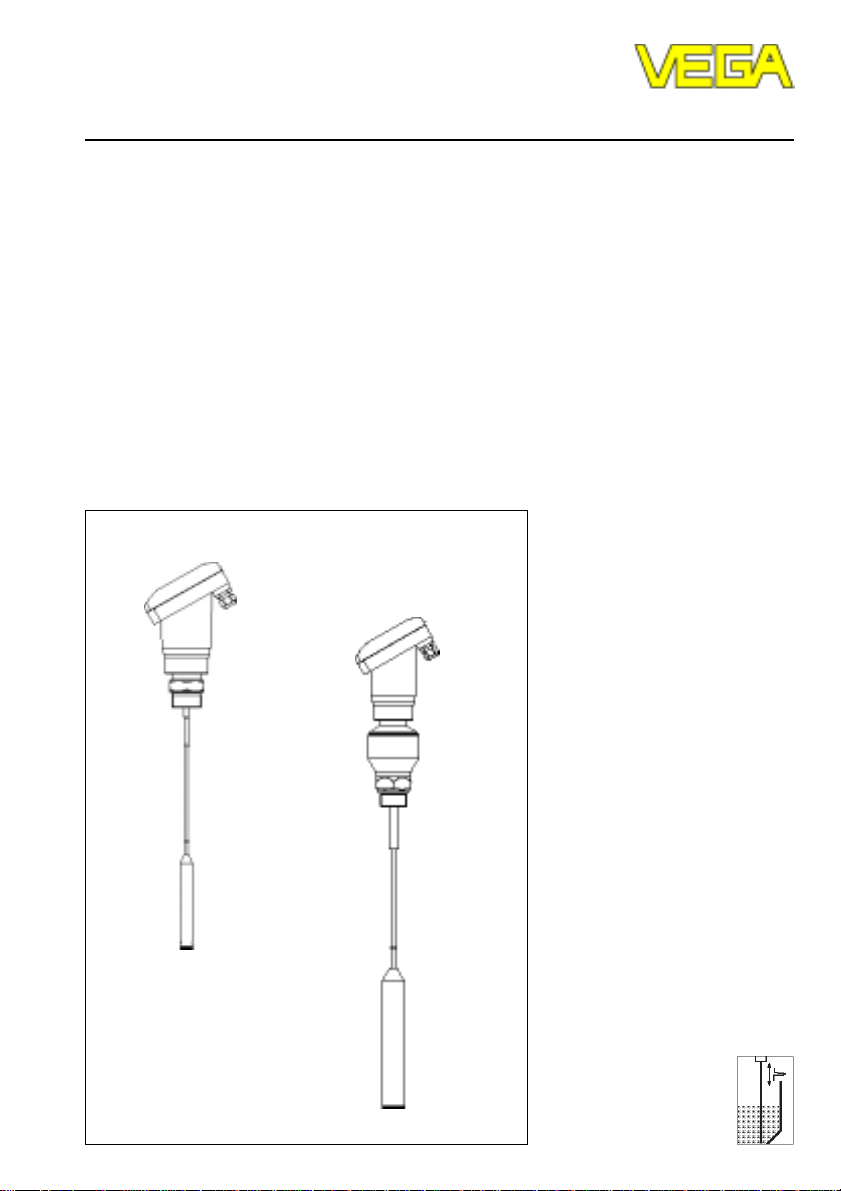

VEGAFLEX 51 and 52 mainly differ in the

thickness of the measuring cable.

VEGAFLEX 51 has a cable with 4 mm diameter and is available up to a length of 10 m.

The cable of VEGAFLEX 52 has a diameter of

8 mm and can have a length of up to 20 m.

With the thicker cable it is also suitable for

solids with higher extraction forces.

Product description / Function

• Measuring range up to 20␣ m with small

min. distance

• Up to 15 sensors can be connected via

one two-wire cable

• Two-wire sensor, supply and digital

measuring signal via one two-wire cable

• Independent on application conditions

such as:

- dust and noise generation

- humidity changes

- varying products

- build-up

• Adjustment without vessel filling or emptying

• Individual wiring, with 15 sensors on one

two-wire line (digital output signal)

• Unaffected by vessel material, e.g. metal,

concrete, plastic etc.

4 VEGAFLEX 51V and 52V

Page 5

Product description / Application features

1.2 Application features

Application features

• Level measurement in solids

• Measurement also in vacuum

• All slightly conductive and all substances

with a dielectric constant εr > 1,7 can be

measured

• Measuring ranges

VEGAFLEX 51 0 … 10 m

VEGAFLEX 52 0 ... 20 m

Two-wire technology

• Supply, signal transmission and output

signal on one two-wire cable

• digital output signal

• low wiring costs due to the use of bus

systems or two-wire technology

Rugged

• High resistance materials: PA, 1.4401

Exact and reliable

• Resolution 1 mm

• Unaffected by noise, vapours, dusts, gas

compositions and layering

• Unaffected by varying density

• Measurements under pressure up to

16 bar and medium temperatures up to

120°C

Communicative

• Integral measured value indication

• Indication either separated from the sensor

• Adjustment from the DCS-level

• Connection to all bus systems:

Interbus S, Modbus, Siemens 3964R,

Profibus DP, Profibus FMS, ASCII

Adjustment with adjustment module

MINICOM

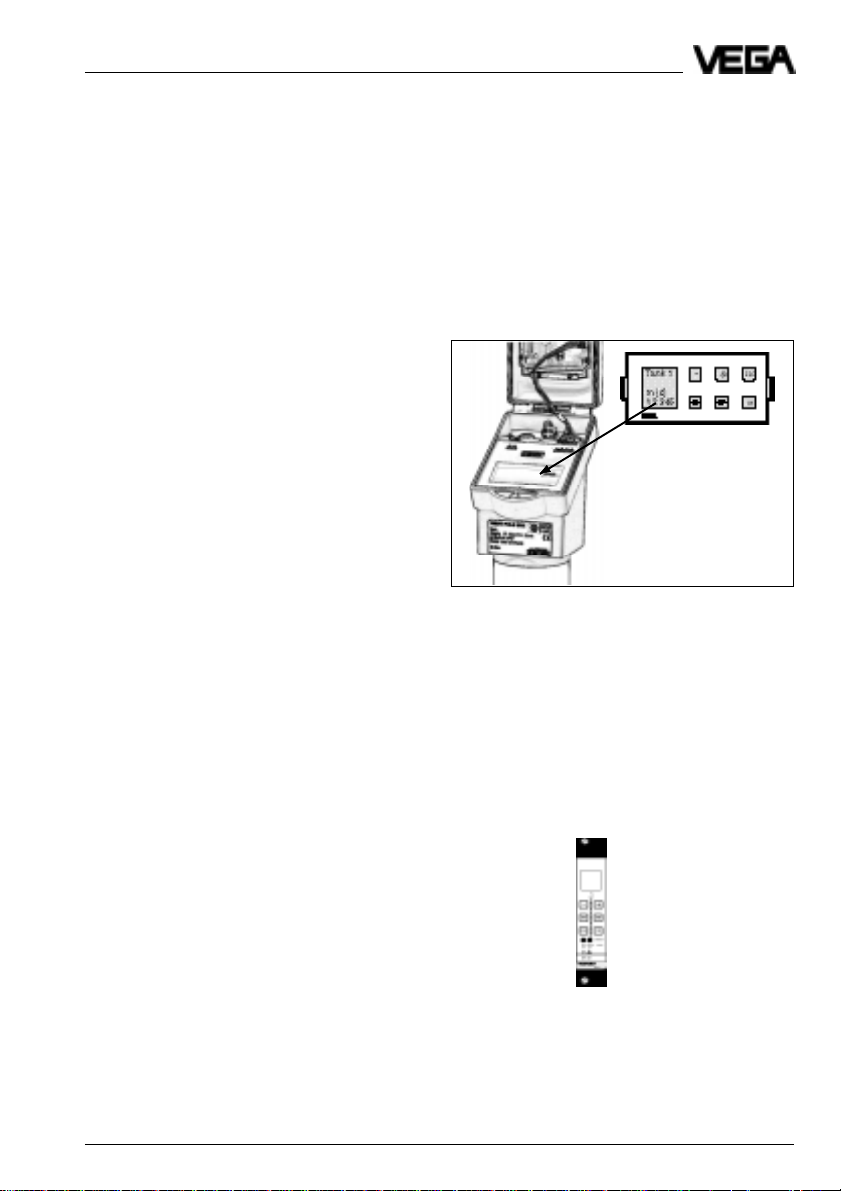

With the 6-key-adjustment module MINICOM

(3,2␣ cm␣ x␣ 6,7␣ cm) you can carry out the adjustment in clear text dialogue.

The adjustment module can be plugged into

VEGAFLEX or into the external indicating

instrument VEGADIS 50.

VEGAFLEX can therefore also be adjusted

from the external indicating instrument

VEGADIS 50.

Pluggable adjustment module MINICOM

Adjustment with VEGA signal conditioning instruments

VEGAFLEX-series 50V sensors can be also

operated with a VEGAMET signal conditioning instrument.

The display leads you in clear text. With the

6-key adjustment field the parameter adjustment can be carried out.

Approvals

Dust-Ex - Zone 10

VEGAFLEX 51V and 52V 5

Page 6

Adjustment with PC

The set-up and adjustment of the

VEGAFLEX-sensors can be made via PC

with the adjustment program VVO (VEGA

Visual Operating) under Windows®.

The software leads you quickly through the

adjustment and parameter adjustment by

means of pictures, graphics and process

visualisations.

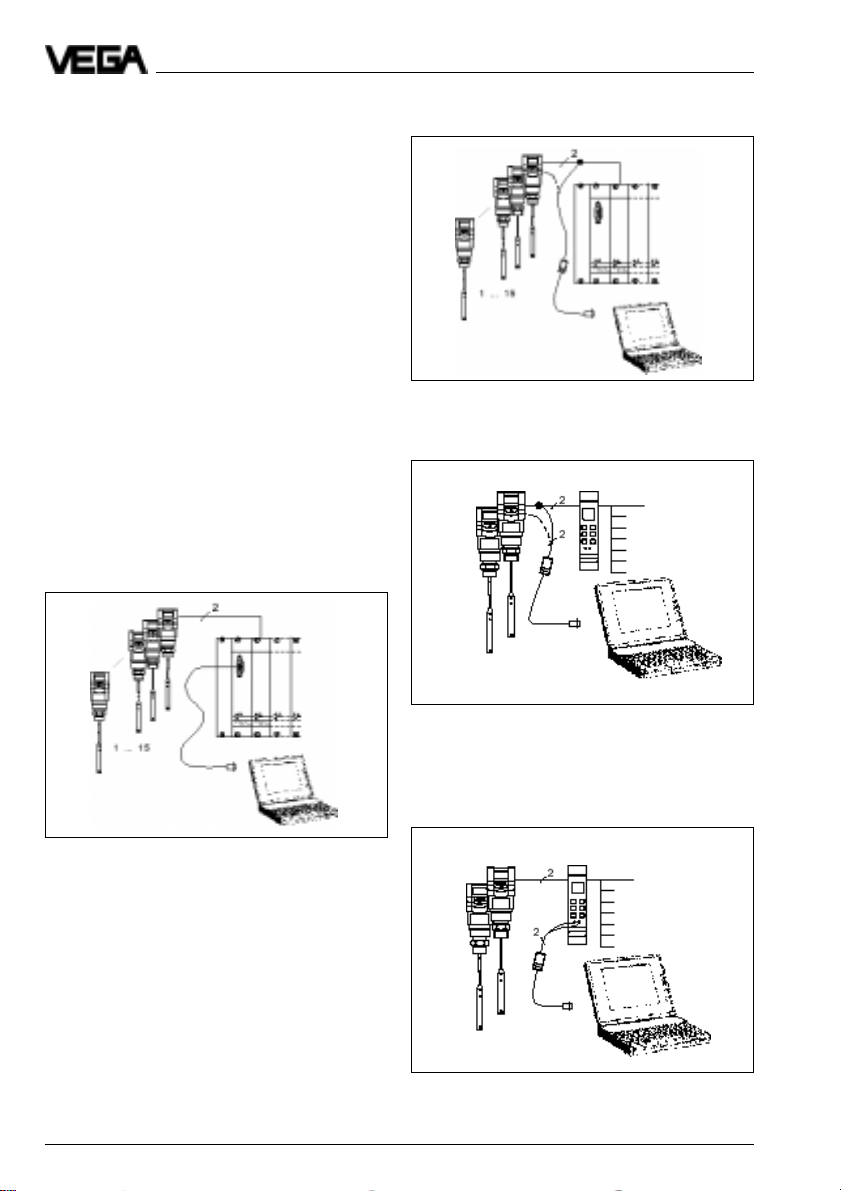

The PC can be connected to any individual

position of the system or the signal line. It is

therefore connected with the two-wire PCinterface converter VEGACONNECT 2 to the

sensor or to the signal line.

The adjustment and parameter adjustment

data can be saved with the adjustment software on the PC. If necessary the adjustments

can also be transferred to other sensors.

On the following figures you see the different

connection possibilities.

Product description / Application features

Adjustment with the PC on the digital signal

and supply line to the processing system or

on the sensor

Adjustment with the PC on the digital signal

and supply line between sensor and

VEGAMET signal conditioning instrument

Adjustment with the PC and the standard

cable RS 232 on the processing system

Adjustment with the PC on the signal conditioning instrument

6 VEGAFLEX 51V and 52V

Page 7

Product description / Types and versions

1.3 T ypes and versions

VEGAFLEX series 50 V

Generally all VEGAFLEX series 50 V sensors

can be adjusted with the pluggable adjustment module MINICOM or with a VEGAMET

signal conditioning instrument.

The sensor can be adjusted with the software

VEGA Visual Operating (VVO) also via PC.

VEGADIS 50

1

Configuration

A measuring system with a VEGAFLEX is

possible in different ways.

See the following figures.

The external indicating instrument VEGADIS

50 can be mounted up to 25 m separated

from the sensor.

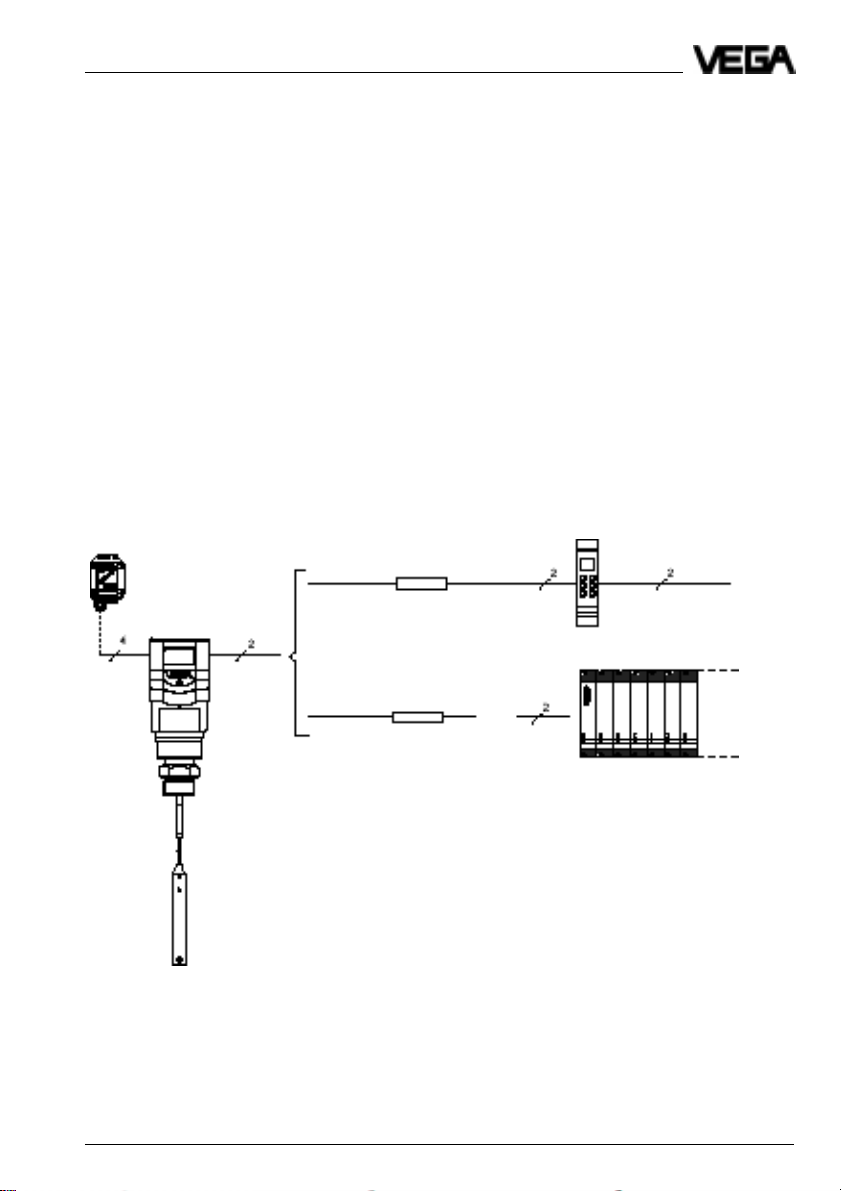

Two-wire technology

1 Connection to a VEGAMET 514V, 515V,

614V signal conditioning instrument

2 Connection to a VEGALOG 571

4 … 20 mA

VEGAFLEX

e.g. VEGAMET 514V

2

4 … 20 mA

passive

VEGALOG

VEGAFLEX 51V and 52V 7

Page 8

1.4 Type code

The second figure of the type designation,

e.g. VEGAFLEX 5[1]… distinguishes the

instruments according to the stability of the

cable.

The figure e.g. VEGAFLEX 51[V] characterizes the output signal:

K stands for an analogue 4␣ …␣ 20␣ mA output

signal (compact instrument)

V stands for a digital output signal (VBUS).

VEGAFLEX XX X EXS.X X

B - 20…72 V DC, 20...250 V AC / 4...20 mA-output, HART

D - Two-wire loop-powered / 4...20 mA-output, HART

E - Supply via signal conditioning instrument / V-BUS-output

Dust-Ex approved

V - Digital output signal (two-wire technology)

K - Analogue 0 … 20 mA output signal (two-wire or

four-wire technology)

Type 51: Instrument series with 4 mm-cable

Type 52: Instrument series with 8 mm-cable

Product description / Type code

®

®

Meas. principle (FLEX for guided microwave)

8 VEGAFLEX 51V and 52V

Page 9

Product description / Technical data

1.5 T echnical data

Power supply

Supply voltage from signal conditioning instrument VEGAMET

Current consumption max. 22,5 mA

Power consumption max. 80 mW, 0,45 VA

Measuring range

VEGAFLEX 51 0,3 … 10 m

VEGAFLEX 52 0,3 ... 20 m

Output signal

Digital measuring signal (VBUS)

Adjustment

- signal conditioning instruments VEGAMET 514V, 515V, 614V

- PC and adjustment software VEGA Visual Operating

- adjustment module MINICOM

Accuracy (under reference conditions acc. to IEC 770 - relating to the max. meas. range)

Linearity error < 0,1 %

Temperature drift 0,015 %/10 K

Resolution 1 mm

or from the processing system VEGALOG 571

(max. 36 v DC)

fuse 0,5 A (slow-blow)

Characteristics

Min. span between full and empty adjustment

- digital output signal 10 mm

Ambient conditions

Vessel pressure -1 … 16 bar

Ambient temperature on the housing -40°C … +60°C

Process temperature -40°C … +120°C

Storage and transport temperature -40°C … +80°C

Protection IP 66/IP 67 (meets both protections)

Protection class

- two-wire sensor II

Overvoltage category III

Max. tensile load cable → 4 mm 5 KN

Ex-technical data

Dust-Ex Zone 10

The permissible operating data of the VEGAFLEX-sensors for dust-Ex-areas are stated in

the certificate.

VEGAFLEX 51V and 52V 9

cable → 8 mm 20 KN

Page 10

Product description / Technical data

Materials

Housing PBT (Valox) or

Aluminium (powder coated)

Cable 1.4401 (stst; 316) or

galvanized steel - PA-coated

Process connections

VEGAFLEX 51, 52 G 11/2 A, 11/2“ NPT

steel chromated or of 1.4301 (stst)

Connection lines

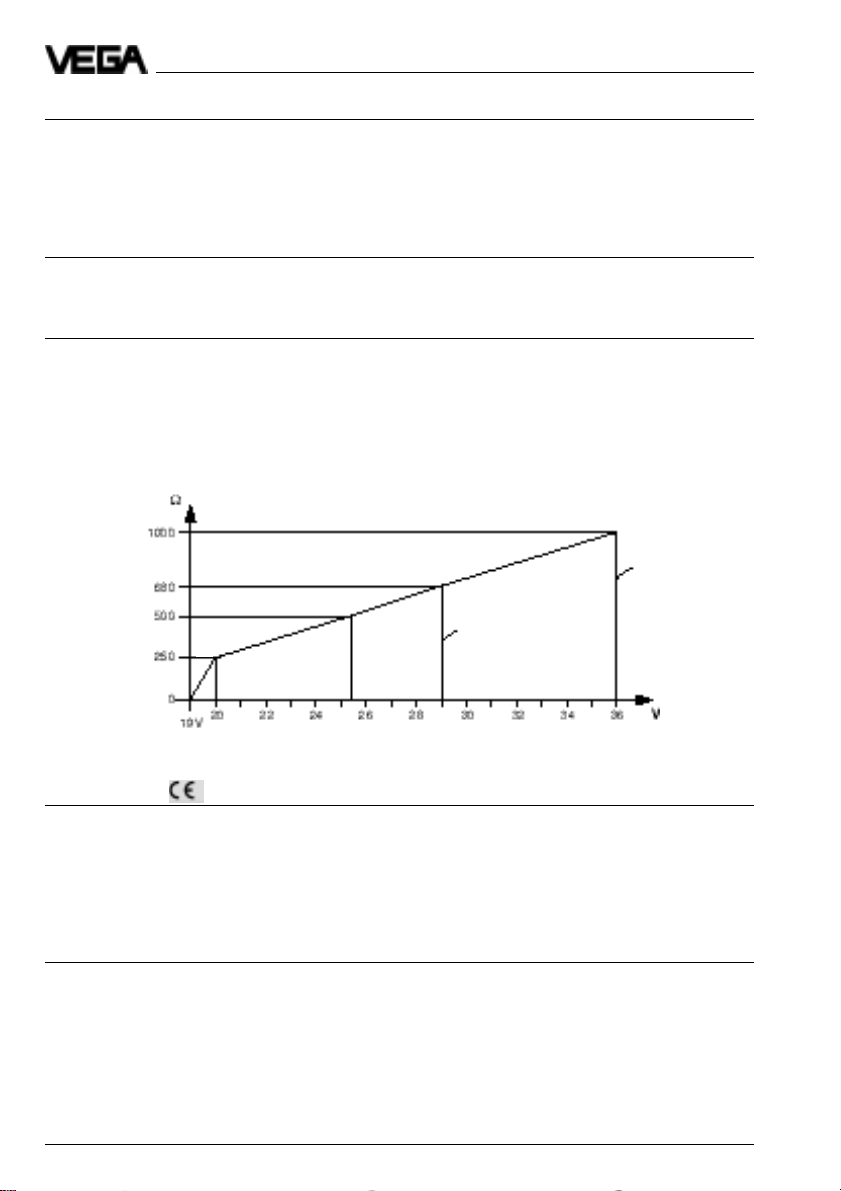

- supply and signal via one two-wire cable,

the line resistance depends on the supply voltage (see diagram).

Cross-section area of conductor generally 2,5 mm

Earth connection max. 4 mm

2

2

Cable entry 2 x M20 x 1,5 (cable diameter 5 … 9 mm)

Voltage limit

Ex-sensor

Voltage limit

not-Ex-sensor

Supply voltage

CE-conformity

VEGAFLEX sensors meet the protective regulations of EMVG (89/336/EWG) and NSR

(73/23/EWG).

The conformity has been judged acc. to the following standards:

EMVG Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

Display indication

Display scalable analogue and digital measured

value indication (option).

An external measured value indication, supplied by the sensor, can be mounted up to

25 m separated from the sensor.

10 VEGAFLEX 51V and 52V

Page 11

Product description / Technical data

Signal output VEGAFLEX 51V, 52V

Signal output digital output signal in two-wire technology

(VBUS)

Two-wire technology:

The digital output signal (measuring signal) is modulated to the power supply and further

processed in the signal conditioning instrument or in the processing system.

VEGAFLEX 51V and 52V 11

Page 12

Product description / Approvals

1.6 Approvals

VEGAFLEX sensors are approved for dustEx-Zone 10.

Note the attached approval documents when

using a sensor in Ex-area.

1.7 Dimensions

VEGAFLEX 51

Plastic housing Aluminium housing Aluminium housing (ExD)

Cable - steel

with gravity

weight

12 VEGAFLEX 51V and 52V

Cable - plastic

coated with

gravity weight

Cable - steel

with cable

loop

Cable - plastic

coated with

cable loop

Page 13

Product description / Dimensions

VEGAFLEX 52

Plastic housing Aluminium housing Aluminium housing (ExD)

Cable - steel

with gravity

weight

Cable - plastic

coated with

gravity weight

Cable - steel

with cable

loop

Cable - plastic

coated with

cable loop

Adjustment module MINICOM Cable loops

Adjustment module for plugging into series

50 sensors or into the external indicating

instrument VEGADIS 50

Cable - steel

VEGAFLEX 51V and 52V 13

Cable plastic

coated

Page 14

2 Mounting

2.1 Installation instructions

Lateral load

Note that the measuring cable is not subjected to strong lateral forces. Mount

VEGAFLEX to a position in the vessel where

no interfering influences such as e.g. of stirrers, filling openings etc. can occur (see fig.

2.1).

Fig. 2.1 Lateral load

Mounting / Installation instructions

Shortening of the measuring cable

The cable can be shortened afterwards.

Loosen the three pins on the gravity weight

(hexagon) and remove the pins. Pull the

cable out of the gravity weight.

To avoid splicing of the steel cable during

cutting, you have to tin the cable around the

cutting position with a copper bit or strongly

tighten the cable with a wire. Shorten the

cable with a metal cutting saw or a cutting-off

wheel by the requested length.

In case of isolated cables with gravity weight,

the isolation should be removed on a certain

length (see fig. 2.2).

VEGAFLEX 51 45 mm

VEGAFLEX 52 60 mm

In case of cable loops the cable should remain isolated.

Extraction forces

In case of strong extraction forces, e.g. during quick emptying or settling of solids, high

tensile loads can be caused.

When such an installation position is necessary, the cable should not be strained but

only equipped with a gravity weight as the

cable can more easily follow the product

movements. Note that the cable does not

touch the vessel wall.

Pressure

In case of gauge or low pressure in the vessel, the mounting boss should be sealed on

the thread. Use the attached seal ring. Check

if the seal ring is resistant against the medium.

14 VEGAFLEX 51V and 52V

Fig. 2.2 Shortening of the measuring cable

Page 15

Mounting / Installation instructions

Cable entries

When mounting outside, on cooled vessels or

in humid areas where cleaning is made e.g.

with steam or high pressure, the seal of the

cable entry is very important.

Use cable with a round cross-section area of

conductor and tighten the cable entry. The

cable entry is suitable for cable diameters of

5␣ mm to 9␣ mm.

Humidity from outside

To avoid humidity ingress, the connection line

to the housing should be looped directly

behind the cable entry to the bottom so that

rain and condensation water can drain off.

This is mainly valid for mounting outside, in

areas where humidity is expected (e.g. by

cleaning processes) or on cooled or heated

vessels (see fig. 2.3).

Fig. 2.3 Humidity

VEGAFLEX 51V and 52V 15

Page 16

Mounting / Installation instructions

Material cone

Note when installing VEGAFLEX into the vessel that material cones can be caused with

solids which can change the measured

value. We recommend to choose an installation place where the cable detects an average value of the material cone.

Dependent on the position of the filling and

emptying opening in the vessels, VEGAFLEX

should be installed appropriately. For compensation of measuring errors caused by the

material cone, you should install the cable at

a distance of d/6 from the vessel wall or vessel

installation. In any case keep a min. distance

of 300 mm.

3

1 Emptying

2 Filling opening

3 VEGAFLEX

16 VEGAFLEX 51V and 52V

1

2

Page 17

Mounting / Installation instructions

Straining

Generally the measuring result is only slightly

influenced when the gravity weight is in contact with the vessel wall.

Dependent on the kind of solid, the installation or the kind of filling, the cable can "float"

(fig. 2.4) despite of the gravity weight. The

solid can push the cable to the vessel wall or

to the top and wrong measured values are

caused.

In this case fasten the cable. When straining

the cable avoid strong cable forces. In our

pricelist you will find a spring as accessory

avoiding overloading of the cable.

Build-up

Generally build-up on the cable causes

changes of the measured value. If strong

build-up on the cable has to be expected, it

is recommended to use an isolated cable.

The higher surface quality avoids build-up.

Abrasion

In very abrasive products, e.g. the measurement of grit, use a measuring cable without

isolation.

Socket

If possible avoid long sockets.

Fig. 2.4 Cable electrode in solids

VEGAFLEX 51V and 52V 17

Page 18

Electrical connection / Connection and connection cable

3 Electrical connection

3.1 Connection and connection cable

Safety information

Ensure that the instrument is in currentless

condition. Always switch off the power supply before you carry out terminal work on the

radar sensors. Protect yourself and the instrument, especially when you use sensors

which do not work with low voltage.

Skilled staff

Instruments which are not operated with a

protective low voltage must only be connected by skilled staff.

Connection

For connection a standard two or four-wire

cable (sensors with separate supply) with

max. 2,5 mm2 can be used. Very often "Electromagnetic pollution" by electronic actuators,

energy lines and emitting systems is so

considerable that the two or four-wire cable

should be screened.

We recommend to use screened cable. This

screening prevents against future interferences (figure 3.1 a).

It is favourable to earth the screens on both

ends. However it must be noted that no earth

compensation currents flow via the sensor

cable screens (figure 3.1 b). Earth compensation currents can be avoided by connecting the cable screen in case of earthing on

both sides on one earthing side (e.g. in the

switching cabinet) via a capacitor (e.g.

0,1␣ µF; 250␣ V AC) to earth potential. Use a

very low impedance earth connection (foundation, plate or mains earth).

In dust-Ex-applications the screen should be

on one end.

Ex-protection

If an instrument is used in dust-Ex areas, the

appropriate regulations as well as the dustEx-certificate of VEGAFLEX for systems in

dust-Ex-areas should be noted.

Connection cable

Note that the connection cables must be specified for the expected operating conditions in

your systems. The cable must have an outer

diameter of 5␣ …␣ 9␣ mm (1/5 to 1/3␣ inch). Otherwise the seal effect of the cable entry will not be

ensured.

Cables for intrinsically safe circuits must be

marked blue and must not be used for other

circuits.

Earth conductor terminal

On VEGAFLEX sensors the earth conductor

terminal is galvanically connected with the

metal thread.

18 VEGAFLEX 51V and 52V

Page 19

Electrical connection / Screening

Earthing on one sensor side

Processing

Earthing on both ends (on the signal conditioning instrument via the potential

separating capacitor)

Fig. 3.1 a

≥ 0,1 µF

250 V AC

Processing

In dust-Ex-applications the screening should

only be made on one side. Due to the potential

difference earthing on both sides is not al-

Fig. 3.1 b

lowed.

VEGAFLEX 51V and 52V 19

Page 20

3.2 Connection of the sensor

• Loosen the closing screw on the upper

side of the sensor.

• Open the sensor cover.

• Remove the compression nut of the Pg

and shift the nut a little bit over the connection cable.

• Remove the rubber seal out of the Pg and

shift the seal over the connection cable.

• Remove the cover of the connection cable

over a length of approx. 10 cm.

• Loop the cable through the Pg into the

sensor.

Electrical connection / Connection of the sensor

• Connect the cable.

Push the white buckets of the spring

terminals with a small screwdriver and

insert the copper core of the connection

line into the terminal opening.

Check the position of the cables in the

terminal by slightly pulling.

• Fasten the compression nut on the Pg.

VBUS

To the indicating instrument in the

sensor cover or to the external indicating instrument VEGADIS 50

Two-wire sensor

M20 x 1,5

(diameter of the

connection cable

5…9␣ mm)

20 VEGAFLEX 51V and 52V

Page 21

Set-up / Connection of the indicating instrument VEGADIS 50

3.3 Connection of the indicating instrument VEGADIS 50

Loosen the 4 screws of the housing cover on

VEGADIS 50.

You can facilitate the connection procedure

by fastening the housing cover during connection on the housing by means of the

screws (figure).

Adjustment module

VEGADIS 50

Screws

VBUS

to VEGADIS 50

(use screened cable. See

fig. 3.1 a or fig. 3. 1 b)

T wo-wire sensor

M20x1,5

VEGAFLEX 51V and 52V 21

Page 22

4 Set-up

4.1 Adjustment structure

Series 50 sensors can be adjusted

- with PC (adjustment program VVO)

- with detachable adjustment module

MINICOM

- with a signal conditioning instrument

VEGAMET (V)

The sensors can only be adjusted with one of

the possibilities at the same time.

Independent whether you set-up a measuring system (unit of sensor and signal conditioning instrument VEGAMET or sensor and

processing system VEGALOG) with the

adjustment software VVO, with the signal

conditioning instrument or with the adjustment

module MINICOM, the adjustment procedure

is always the same:

- first of all configure a measuring system

in the menu "

- carry out the parameter adjustment of the

sensors in the menu "

Adjustment module MINICOM

With the adjustment module MINICOM you

adjust directly in the sensor or in the external

indicating instrument VEGADIS 50. The adjustment module MINICOM enables with the

6-key adjustment field with text display the

adjustment of the sensor in the same function

volume as with the adjustment program VVO.

Configuration

Instrument data

“ and then

“.

Set-up / Adjustment structure

Adjustment program VVO

With the adjustment program VVO (VEGA

Visual Operating System) on the PC you

adjust the sensors very comfortably. The PC

communicates via the interface adapter

VEGACONNECT␣ 2 with the sensor. The signal and supply line is therefore superimposed by a digital adjustment signal.

The PC can be connected to any position on

the cable or directly to the sensor.

Signal conditioning instrument

VEGAMET (V)

The signal conditioning instrument VEGAMET

enables with the 6-key adjustment field with

text display the parameter adjustment in the

same function volume as with the adjustment

program VVO on the PC.

22 VEGAFLEX 51V and 52V

Page 23

Set-up / Adjustment module MINICOM

4.2 Adjustment with adjustment module MINICOM

As with the PC, the sensor can also be adjusted with the small detachable adjustment

module MINICOM. The adjustment module is

therefore inserted into the sensor or the

external indicating instrument (optionally).

For the adjustment with adjustment module

also all adjustment options are available as

on the PC with adjustment program VVO.

All adjustment steps can be carried out with

the 6 keys of the adjustment module. A small

display gives you beside the measured

value a short information on the menu point or

the figure of a menu adjustment.

Adjustment elements

The adjustment module MINICOM is menu

orientated. The clear text indications on the

display lead through the menu. The functions

of the keys are described in the following.

OK-key (4)

With the OK-key adjustments can be confirmed.

When the symbol ▼ or is displayed, you can

move with the OK-key to the next lower menu

stage.

With the symbol there is no branch below

the menu point but only another menu point of

the appropriate function.

ESC-key (3)

With the Escape-key (ESC) you can dependent on the menu point interrupt an adjustment or a function or change to the next

higher menu stage.

E.g. to reach the top menu stage, push the

ESC-key several times.

+ and - key (2)

With the keys + and - you can modify the

values of the parameters or choose out of

several possibilities.

After pushing the first time, the value to be

adjusted flashes. The value will be modified

by further pushing the key.

Arrow keys (5)

With the keys > and < you can move within

the menu stage from one menu point to the

other.

Digital indication (1)

On the digital indication the actual measured

value is displayed during operation.

When you adjust the instrument, the clear text

indication displays the appropriate function.

▼

Branch out of which you can change to a

lower menu.

▼

This symbol informs you about a follow-

▼

ing safety enquiry.

▼

▼

▼

▼

2

1

5

VEGAFLEX 51V and 52V 23

3

4

Page 24

Set-up / Adjustment module MINICOM

Adjustment steps

On the following pages you see the menu

plan of the adjustment module MINICOM.

Set-up the sensor in the following sequence.

The numbers correspond to the sequence of

a set-up. The numbers are stated near the

appropriate menu points in the menu plan on

the following pages.

1. Adjustment

2. Conditioning

3.Outputs

4. Operating range

5. Meas. conditions

6. Indication of the useful and noise level

1. Adjustment

Under the menu point "

form the sensor with which span it should

work.

Max.

Adjustment

100 % (distance to the medium

0,300 m) correspond to

1200 l, e.g. 20 mA

“ you in-

Span

Adjustment without medium

• Enter with the "+“ and "–“ key the distance to the medium your sensor has at

0 % filling (example: 5,850 m)

If you do not know the distance, you have

to sound.

• Enter the distance to the medium which

your sensor has at 100 % filling.

Key Display

Sensor

m(d)

4.700

Para-

OK

OK

OK

OK

meter

adjustment

Adjustment

without

medium

Adjustment

in

(Min-adjustment)

m(d)

0.0 %

at

m (d)

XX.XXX

1)

1)

In case of two values which can be modified

you can move with the "OK“-key to the second value.

Min.

0 % (distance to the medium

5,850 m) correspond to

456 l, e.g. 4 mA)

Adjustment with medium

Fill the vessel e.g. to 10 %, enter in the menu

"

Min-adjustment

“ with the "+“ and "–“ keys

10 % and confirm with the "OK“-key. Then fill

the vessel e.g. to 80 % or 100 %, enter in the

menu "

You can carry out the adjustment without or

with medium. Generally you will carry out the

keys 80 % or 100 % and confirm with the

"OK“-key.

adjustment without medium as you can adjust

without vessel filling.

24 VEGAFLEX 51V and 52V

Max-adjustment

“ with the "+“ and "–“

with

medium

Max.

Min.

adjust

adjust

at %

at %

XXX.X

XXX.X

Page 25

Set-up / Adjustment module MINICOM

2. Conditioning

Under the menu point "

choose the distance at 0 % and at 100 %

filling. Then you enter the parameter and the

appropriate unit as well as the decimal point.

• Enter in the menu window "

sponds

“ the value of the 0 %-filling. This

will be e.g. "80“ for 80 l.

• Confirm with "OK“.

• With the arrow key you change to the

100␣ % menu. Enter here the value of your

parameter corresponding to a 100 %filling. E.g. "1200“ for 1200 l.

• Confirm with "OK“.

• Choose if necessary a decimal point.

Note that max. 4 digits can be shown.

• In the menu "

parameter (mass, volume, distance…).

• In the menu "

cal unit (kg, l, ft3, gal, m3 …).

• With the ESC-key you change to the

superimposed menu stage. With the

arrow key you choose the next menu

point.

• In the menu

between three standard linearisation

curves.

Preadjusted is a linear dependence between percentage value of the product

distance and the percentage value of the

filling volume.

You can choose between linear, spherical

tank and cylindrical tank. The adjustment

of a user programmable curve is only

possible with the PC and the adjustment

program VVO.

• In the menu point

can adjust a delay for the signal output.

Conditioning

0 % corre-

prop. to

“ you choose the

Unit

“ you choose the physi-

"Lin. curve“

you can choose

"Integration time“

“ you

you

3. Outputs

Under the menu "

display and determine which parameter

should be provided by the sensor display.

Outputs

“ you can scale the

4. Operating range

Without special adjustment, the operating

range corresponds to the measuring range.

The measuring range was already adjusted

with the Min/Max-adjustment. It is generally

suitable to choose a slightly bigger operating

range (approx. 5 %) than the measuring

range (span).

Example:

Set Min/Max-adjustment: 0,300 … 5,850 m;

operating range to approx. 0,250 … real

cable length.

When you shorten the cable, you have to

define the cable length again.

5. Meas. conditions

With these functions you can enter the ambient conditions in the vessel.

(see menu plan)

6. Useful and noise level

In the menu

tion on the signal quality of the product echo.

The higher the "

the measurement.

Ampl.: Means amplitude of the product echo

S-N: Means Signal-Noise (useful level

The higher the S-N-value (useful level minus

noise level), the better the reliability:

> 50 dB Measurement very good

40 … 50 dB Measurement good

20 … 40 dB Measurement satisfactory

15 … 20 dB Measurement sufficient

< 15 dB Measurement bad

"Info“

you get important informa-

S-N

“-value, the more reliable

in dB (useful level)

minus noise level)

VEGAFLEX 51V and 52V 25

Page 26

Set-up / Menu plan of the adjustment module MINICOM

Menu plan of the adjustment module MINICOM

Sensor

m(d)

4.700

Parameter

adjustment

Sensor

optimize

Sensor

Tag

Sensor

Meas.

environ

ment

Operating

range

Begin

m (d)

0.50

FLEX51

When switching on, the sensor type and the

V

software version are displayed for a few seconds.

0.50

4.

Cable

length

m (d)

6.00

Meas.

condit

ions

Condition

Solid

5.

fast

change

No

agitated

sur

face

No

Low DK

value

No

Empty

vessel

pro

file

Create

new

Meas.

dist.

m (d)

X.XX

Create

new

Now!

OK ?

Learning !

Update

Meas.

dist.

m (d)

X.XX

Update

now!

OK ?

Learning !

Delete

Delete

Now!

OK ?

Deleting !

Adjustment

Adjustment

in

m(d)

1.

0%

at

m (d)

XX.XXX

100 %

at

m (d)

XX.XXX

Note:

Set-up the sensor in the sequence of the

numbers.

Signal

conditioning

Scaling

0 %

corresponds

XXXX

2.

Lin.

curve

Linear

100 %

corresponds

XXXX

Integr

ation

time

Decimalpoint

888.8

0 s

prop.

Unit

to

Mass

kg

26 VEGAFLEX 51V and 52V

Page 27

Set-up / Menu plan of the adjustment module MINICOM

Add’l

functions

With these keys you move in

the menu field to the left, the

right, top and bottom.

ESC

OK

Reset

to default

Reset

Now !

OK ?

Reset

runs!

Outputs

Sensor

displ.

act.

dist.

m (d)

4.700

Ampl.:

XX dB

S-N:

XX

dB

Info

Reset

to de

fault

Reset

Now !

OK ?

Reset

runs !

Language

English

Meas.

unit

m (d)

6.

Sensor

Tag

Sensor

Sensor

type

FLEX51

V

Serial

number

1094

0213

Softw.

Vers.

1.00

Softw.

date

15.09.

1997

dist.

m (d)

4.700

XX dB

S-N:

XX

dB

Ampl.:

act.

3.

Bolt print figures are sensor or

measured value information and

cannot be modified in this position.

The menu points in white letters

stand for figures which can be

modified with the or key and

saved with the key.

OK

prop.

to

Distance

act.

dist.

m

X,XX

fast

change

Yes

VEGAFLEX 51V and 52V 27

Page 28

4.3 Adjustment with PC

Connection

The PC with the adjustment program VVO

(VEGA Visual Operating from version 2.50)

can be connected

- to the sensor or

- to the signal line.

PC on the sensor

For connection of the PC to the sensor you

require the interface adapter VEGACONNECT 2. Insert VEGACONNECT 2 into the

provided CONNECT-sockets in the sensor.

PC on the signal line

Connect the two-wire line of VEGACONNECT

2 to the signal or supply line of the sensor.

When the resistors of the systems (DCS,

current source etc.) connected to the signal/

supply line are less than 250 Ω, a resistor of

250 … 350 Ω should be looped into the signal/supply line during adjustment.

The digital signals modulated to the signal

line would be extremely damped via the low

system resistors (i.e. short-circuited) so that

the communication with the PC would be

interfered.

Set-up / Adjustment with PC

When you have connected the PC with the

operating software VVO to your measuring

system,

• switch on the power supply of the connected sensor.

In the first 10 … 15 seconds the sensor takes a

current of approx. 22 mA (self check) and

takes then a level proportional or distance

proportional current.

• Start the adjustment software VVO

(VEGA Visual Operating) on your PC.

• In the entrance window you choose with

the arrow keys or the mouse the point

Planning

You should only choose

you are entitled to modify instrument

parameters. Otherwise choose

or

In the window

asked for the name and the password.

• For set-up (

VEGA and under password also: VEGA.

It does not matter if you use capital or

small letters.

VVO determines automatically the type of the

connected sensor and shows shortly with

which sensor a connection exists.

and click to OK.

Maintenance

planning

Planning,

.

User identification

) enter under name:

when

Operator

you are

When you get no sensor connection, check

the following:

- The supply voltage should be at least

20 V.

- When connecting VEGACONNECT 2

directly to the sensor line, the load resistor should be 250 … 350 Ohm.

- You have to use a VEGACONNECT 2.

VEGACONNECT 2

28 VEGAFLEX 51V and 52V

Older versions of VEGACONNECT are

not compatible.

Further information on the adjustment with PC

and the adjustment software VVO is stated in

the operating instruction of the adjustment

software VEGA Visual Operating (VVO).

Page 29

Set-up / Adjustment with PC

Special functions

When a VEGAFLEX-sensor is determined,

you can choose with the adjustment software

VVO some special functions of VEGAFLEX.

Under the menu point Instrument data/Parameter adjustment you can choose the sensor optimisation.

Here you find all special functions of

VEGAFLEX:

- meas. environment

- echo curve

Measuring environment

Measuring conditions

Choose in this menu if you want to measure in

solids or liquids.

When you want to measure a product the

DK-value of which is below 2, you can increase the sensitivity of the sensor.

Echo curve

The echo curve shows all reflections of the

guided microwave signal.

This means not only the product signal is

shown but also false signals caused, e.g. by

vessel installations.

Generally the sensor determines the biggest

amplitude as useful echo.

You see a black arrow above the highest

amplitude. When you click to "Display info“, a

small window is displayed, listing the detailed

values of the selected echo.

Operating range

With this command you can limit the operating range of the sensor or enter the cable

length again after shortening the cable.

Carry out the adjustment before modifying

the operating range as a later adjustment can

overwrite the values of the operating range.

The right part of the graphics shows the

operating range, the left part the adjustment.

When e.g. you cannot fill your vessel completely, you can limit the operating range.

VEGAFLEX 51V and 52V 29

Zoom / Unzoom

After activation of these two functions, you

can either zoom or unzoom the curve with the

left mouse key.

When you activate "Zoom“, you can choose

the requested part of the figure by pushing

the left mouse key and drawing a frame.

Page 30

The following curves can be displayed:

Raw value curve (red)

The red curve means the absolute signal

which the receiver of VEGAFLEX detects.

Beside the useful echo this curve also contains false signals.

The highest amplitude is detected as useful

echo. Check by sounding if the value of the

useful echo corresponds to the actual distance to the level.

When both values do not correspond, you

have to gate out the dominant false echoes

with the function "Empty vessel profile“.

Set-up / Adjustment with PC

Start

When clicking to "Start“, the echo curve will

be updated continuously. With "Stop“ you can

terminate the update.

Vessel profile (blue)

This curve shows in normal condition the

actual empty vessel profile.

For gating out of false echoes you can modify

the blue curve of the vessel profile with the

function "Empty vessel profile".

Reference line (green)

All amplitudes of the red curve which are

below the green reference line, are suppressed (ringing, noise, false echoes etc.).

All amplitudes above this line are possible

echoes which are processed by the software.

Logarithmic raw value curve (black)

The curve shows the difference between raw

value curve (red) and reference line (green).

For this curve the scale on the right page

(dB) is valid.

Documentation

When clicking to the button "Documentation“

the actual echo curve will be saved.

Echo data

When clicking to the button "Echo data“, a

window is displayed where all echoes detected by the sensor with DB-information and

a probability processing are listed.

Empty vessel profile

With the functions in this window you can

gate out false echoes.

The blue empty vessel profile curve in the

echo curve window shows the actual empty

vessel profile.

Determine the level by sounding. When the

sensor has determined instead of the

sounded level a false echo as most probable

echo, you can gate the echo out. Choose the

function "Create new“. Enter the measured

distance to the medium. All false echoes, in

the range to the adjusted distance, are automatically gated out. Note that then also the

blue curve of the empty vessel profile

changes.

.

With "Update“ you can extend the empty

vessel profile when new false echoes occur

with reducing level.

When you want to delete the existing empty

vessel profile, click to "Cancel“.

30 VEGAFLEX 51V and 52V

Page 31

Set-up / Adjustment with signal conditioning instrument

4.4 Adjustment with signal conditioning instrument

VEGAMET (V)

VEGAFLEX 51V and 52V sensors can be

adjusted with the following signal conditioning instruments:

- VEGAMET 514V

- VEGAMET 515V

- VEGAMET 614V

For adjustment the digital signal conditioning

instruments VEGAMET (V) are provided with

a 6-key adjustment field with display. The

parameter adjustment can be therefore carried out in clear text dialogue.

The adjustment structure corresponds to the

adjustment on the adjustment module MINICOM.

The complete menu plan of the signal conditioning instrument is included in the appropriate operating instruction of the signal

conditioning instrument used.

VEGALOG 571

VEGAFLEX sensors can be also adjusted

with the processing system:

- VEGALOG 571

VEGALOG 571 processing system can only

be adjusted with the PC in conjunction with

the processing software VVO (VEGA Visual

Operating).

The adjustment of VEGALOG is described in

the operating instruction of the adjustment

software VVO.

VEGAFLEX 51V and 52V 31

Page 32

5 Diagnosis

5.1 Simulation

For simulation of a certain filling, you can

enquire the function "Simulation" on the adjustment module MINICOM, in the software

program VVO or in the signal conditioning

instrument VEGAMET (V).

You simulate a certain measured value. Note

that connected instruments such as e.g. a

DCS react according to their adjustments

and probably activate alarm signals or system functions.

5.2 Error removal

Error Error removal

E 013 Sensor does not find - Message is displayed during feeding

level echo phase.

- When the message remains, the DK-value

of the medium can be too low.

Check the useful and noise level.

See 4.2 Adjustment with adjustment module

MINICOM / 6. Useful and noise level.

When the message still remains, carry out

a new adjustment.

Diagnosis

E 017 Adjustment span too small Carry out a new adjustment.

E 036 Software-Update incorrect Return the instrument for repair.

E 040 Hardware failure / Check all connection lines.

electronics defect Contact our service department.

32 VEGAFLEX 51V and 52V

Note that the difference between min. and

max.-adjustment is at least 10 mm.

Page 33

Notes

VEGAFLEX 51V and 52V 33

Page 34

Notes

34 VEGAFLEX 51V and 52V

Page 35

Notes

VEGAFLEX 51V and 52V 35

Page 36

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

The statements on types, application, use and operating conditions of

the sensors and processing systems correspond to the actual knowledge at the date of printing.

Technical data subject to alteration.

2.23 227 / March ’99

Loading...

Loading...