Page 1

Operating Instructions

PROF I

BUS

PROCESS FIELD BUS

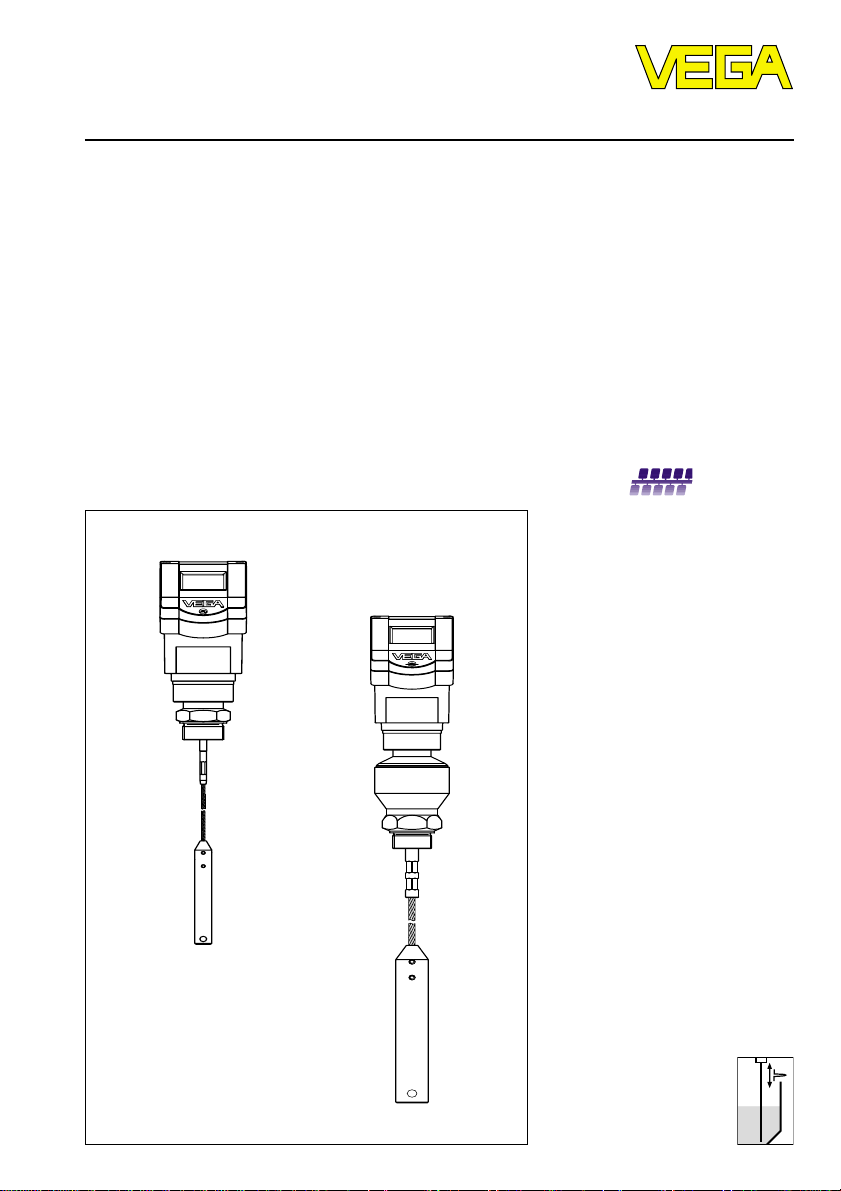

VEGAFLEX 51P and 52P (Profibus PA)

Level and Pressure

Page 2

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGAFLEX 51P and 52P

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 5

1.3 Adjustment media ................................................................ 5

1.4 Profibus output signal .......................................................... 6

1.5 Type code ........................................................................... 10

1.6 Bus configuration ............................................................... 11

1.7 Technical data ..................................................................... 14

1.8 Approvals ........................................................................... 17

1.9 Data format of the output signal ........................................ 17

1.10 Dimensions ......................................................................... 18

2 Mounting

2.1 Installation instructions ...................................................... 20

3 Electrical connection

3.1 Connection – Connection cable – Screening ................... 23

3.2 Sensor address ................................................................. 27

3.3 Connection of the sensor .................................................. 29

3.4 Connection of the external indicating instrument ............ 30

4 Setup

4.1 Adjustment media .............................................................. 31

4.2 Adjustment with the adjustment module MINICOM ........ 32

4.3 Adjustment with the PC ...................................................... 38

5 Diagnostics

5.1 Simulation ............................................................................ 43

5.2 Function diagram ............................................................... 43

5.3 Error rectification ................................................................ 48

5.4 PA parameters .................................................................... 49

VEGAFLEX 51P and 52P 3

Page 4

1 Product description

Product description

1.1 Function

High frequency microwave impulses are

guided along a steel rope. When reaching

the product surface, the microwave impulses

are reflected. The running time of the impulses is processed by the integrated electronics and outputted as level.

The sensors measure the levels of all kinds of

solids. Density, conductivity, dust generation

and dielectric constant of the product do not

influence the measurement. Also, the changing features of a solid do not influence the

measured value.

Lime, cement, cereals, plastic granules, flour,

gravel - VEGAFLEX microwave sensors

solve difficult application problems in solids.

The level is also detected reliably in products

with varying moisture content or fluctuating

dielectric constant. High, narrow vessels or

steep material cones in which non-contact

measuring principles did not deliver optimum

measuring results, can be measured without

problem with VEGAFLEX.

VEGAFLEX 51 and 52 differ mainly in the

thickness of the measuring cable.

VEGAFLEX 51 has a cable with 4 mm diameter and is available up to a length of

10 m.

• Measuring range up to 20 m with low min.

distance.

• Up to 32 sensors (Ex area: 8 sensors) can

be connected via one two-wire cable.

• Two-wire sensor, supply and digital measuring signal via one two-wire cable.

• Unaffected by application conditions such

as:

- dust and noise generation

- humidity changes

- varying products

- buildup

• Adjustment without vessel filling or emptying.

• Unaffected by vessel material, e.g. metal,

concrete, plastic etc.

• Measuring cable or gravity weight must not

be insulated from the vessel.

The cable of VEGAFLEX 52 has a diameter of

8 mm and can have a length of up to 20 m.

Due to the stronger cable it is suitable for

solids subjected to higher extracting forces.

4 VEGAFLEX 51P and 52P

Page 5

Product description

1.2 Application features

Applications

• Level measurement in solids.

• Measurement also in vacuum.

• All slightly conductive substances and all

products with a dielectric constant er > 1.7

can be measured.

• Measuring ranges

VEGAFLEX 51 0 … 10 m

VEGAFLEX 52 0 ... 20 m

Rugged

• High-resistance materials: PA, 1.4401.

Precise and reliable

• Resolution 1 mm.

• Unaffected by noise, steam, dust, gas

compositions and inert gas stratifications.

• Unaffected by varying density.

• Measurements under pressure up to

16 bar and at product temperatures up to

120°C.

Communicative

• Integrated measured value display.

• Optional display and adjustment module

separate from the sensor.

• Adjustment from the PLC level.

Approvals

• StEx Zone 10

• Ex Zone 0

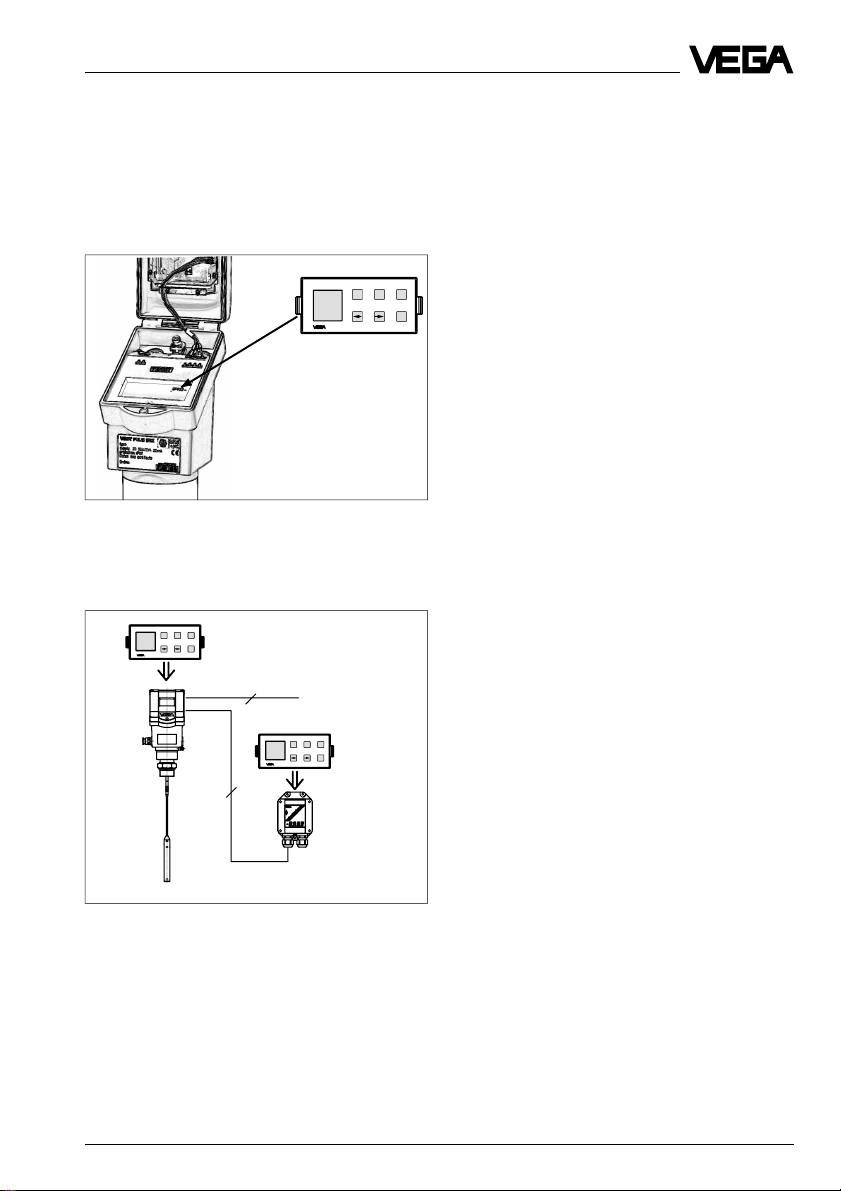

1.3 Adjustment media

Adjustment with the adjustment module

MINICOM

With the 6-key adjustment module MINICOM

(3.2 cm x 6.7 cm) the adjustment can be

carried out in clear text dialogue. The adjustment module can be plugged into the VEGAFLEX or into the external indicating

instrument VEGADIS 50. It also possible to

adjust VEGAFLEX from the external indicating instrument VEGADIS 50.

Tank 1

m (d)

12.345

Pluggable adjustment module MINICOM

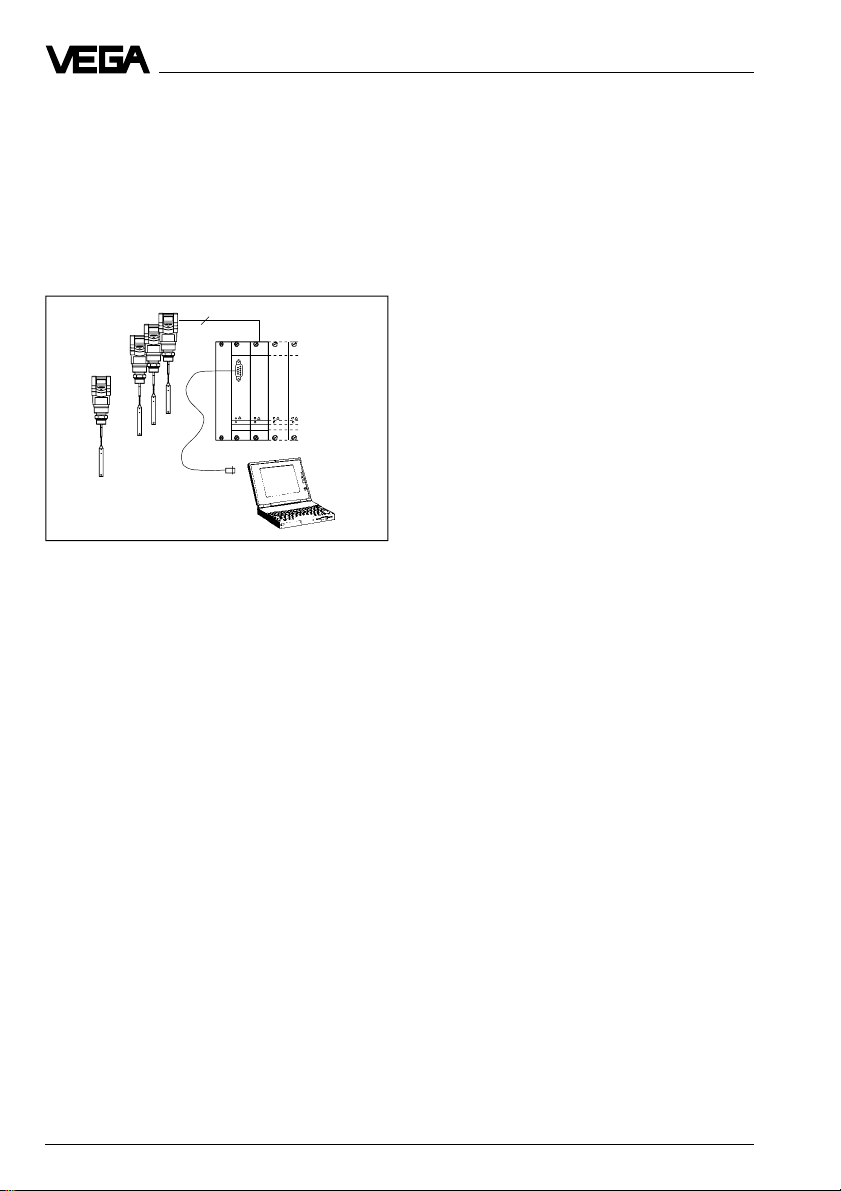

Adjustment with PC

The setup and adjustment of the VEGAFLEX

sensors can be done on the PC with the

adjustment program VVO (VEGA Visual Operating) under Windows®.

The software leads quickly through adjustment and parameter setting by means of

pictures, graphics and process

visualisations.

ESC

+

-

OK

The adjustment program VVO from VEGA

makes the full range of functions of VEGA

sensors accessible and, if necessary, can

update the entire sensor software. For this

reason, the adjustment program must be

installed on a PC which is equipped with a

Profibus Master Class 2 interface card

(Softing) (see figure under "1.4 Profibus

output signal").

VEGAFLEX 51P and 52P 5

Page 6

Product description

The PC with the Profibus interface card can

be connected directly at any location to the

DP bus by means of the standard RS 485Profibus cable.

The adjustment and parameter data can be

saved with the adjustment software on the

PC. On request, the adjustment can be also

transferred to other sensors.

2

......

VEGALOG

VEGALOG

571 CPU

571 EA

1 ... 15

1 … 32

Adjustment with the PC and the standard cable

RS 232 on the VEGALOG processing system

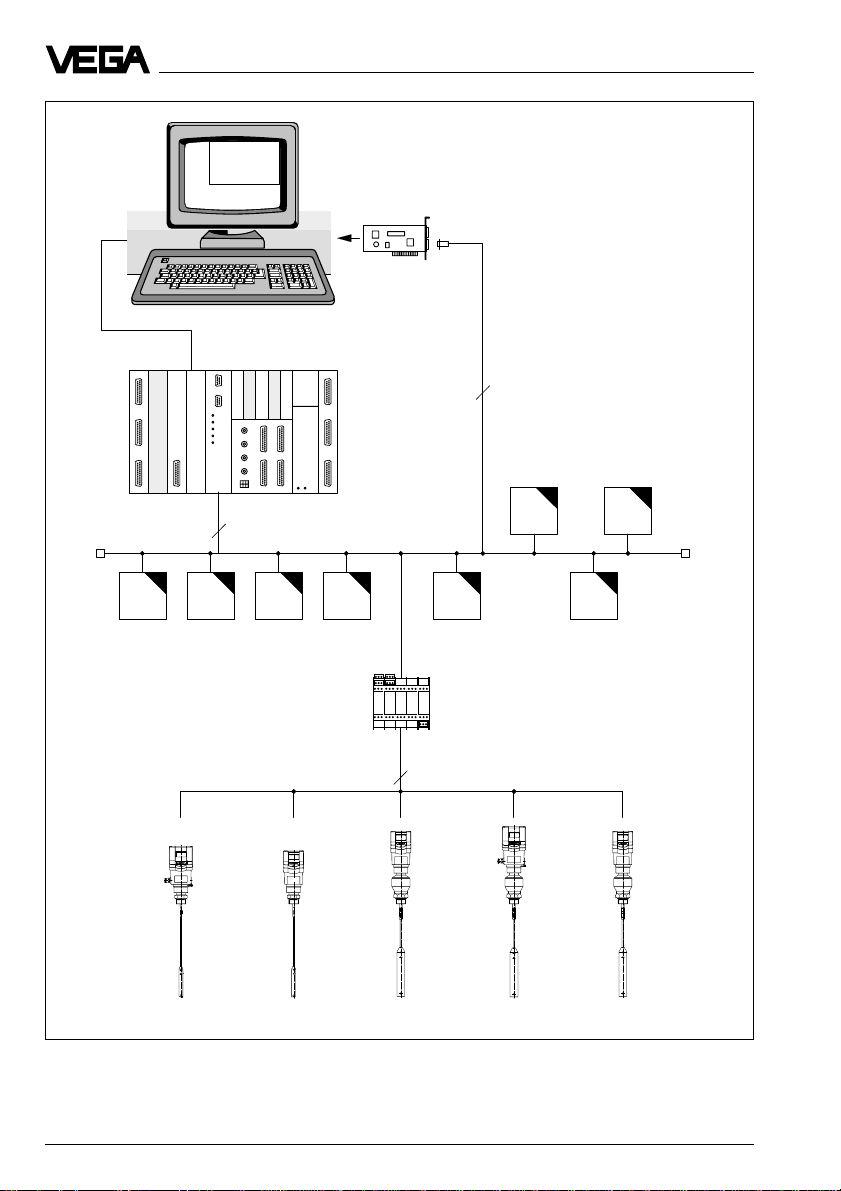

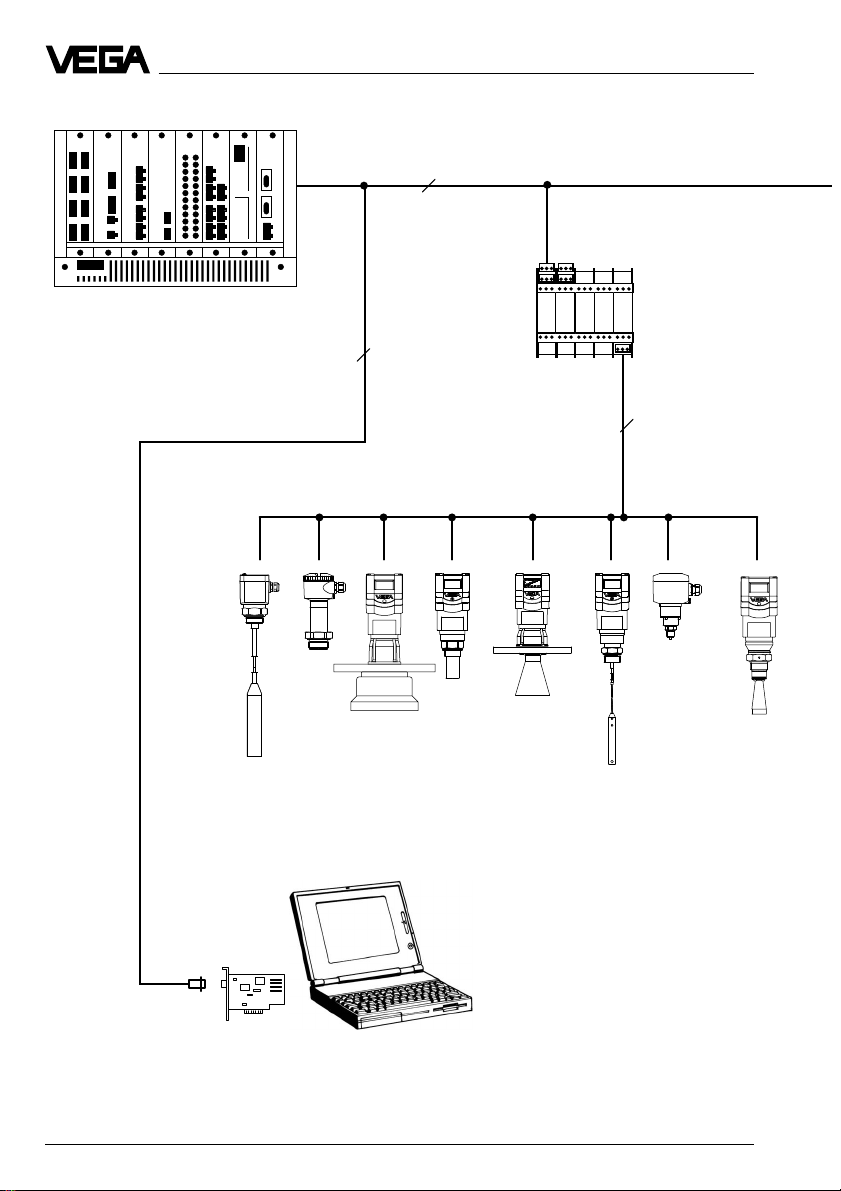

1.4 Profibus output signal

As a process automation bus, Profibus PA

enables power supply over the bus. Up to 32

sensors can be operated on a shielded twowire cable that carries both power supply

and measuring signal. In Ex areas, up to ten

sensors can be connected from the PA level

to one two-wire cable (EEx ia).

Bus structure

The DP and PA bus consists of up to 126

master and slave participants. Data are always exchanged from point to point, with the

data traffic being exclusively controlled and

checked by master devices. Communication

is carried out according to the Token-Passing

procedure. This means that the master holding the token can contact the slaves, give

instructions, enquire data and cause the

slaves to receive and transmit data. After the

work is done or after a predetermined time

interval, the token is passed on by the master to the next master.

Master-Class 1

is the actual automation system, i.e. the process control computer or the PLC that enquires and processes all measured values.

Master-Class 2

One or several Master-Class 2 can operate in

a Profibus network. As a rule, Master-Class 2

devices are engineering, adjustment or visualisation stations. The VEGA adjustment software VVO (VEGA Visual Operating) operates

as Master-Class 2 participant on the DP bus

and can work on an engineering PC, on an

adjustment PC or on the process control

computer and can access any VEGA sensor

on the PA level.

6 VEGAFLEX 51P and 52P

Page 7

Product description

Profibus adjustment structure

In the Profibus environment, there are different adjustment concepts and adjustment

tools which often differ considerably from

manufacturer to manufacturer. From the user’s point of view, a manufacturer-independent adjustment program which could be

operated directly on the Profibus DP, but also

at a central point (e.g. the engineering station

or the process control), would be ideal.

In the past, only the program "SIMATIC PDM",

based on the HART® adjustment structure,

could fulfil this wish. However, this program

also has the limitations common to HART®. As

with HART®, the availability of an instrumentspecific database for a comprehensive adjustment with PDM (Process Device Managing) is a requirement. Otherwise, only the

basic instrument functions such as adjustment will be available. In the PDM environment, this instrument-specific database is

called EDD (Electronic Device Description),

in complete analogy to the HART® environment which, except for the VEGA-HART

instruments, also requires a DD (Device

Description) for each sensor.

®

VEGAFLEX 51P and 52P 7

Page 8

Product description

Adr. 21

SPS

Adr. 22

VVO

3

PA-

Adr. 23

Master-Class 1

Adr. 1

DP-Bus

Adr. 24

DP interface card as MasterClass 2 (e.g. Softing)

Adr. 10

3

Adr. 57

Segment coupler

Adr. 25 … 56

2

(max. 32 participants)

Adr. 58

Adr. 60

Adr. 59

Adjustment of the VEGAFLEX sensors from the process control via a Profibus interface card in the process

control computer or in an additional PC. The adjustment software VEGA Visual Operating (VVO) accesses via

the interface (interface card) the sensors bidirectionally.

8 VEGAFLEX 51P and 52P

Page 9

Product description

Adjustment with adjustment module

MINICOM

With the small (3.2 cm x 6.7 cm) 6-key adjustment module with display in the sensor,

the sensor-relevant adjustments can be carried out directly on the sensor.

Tank 1

m (d)

12.345

Detachable adjustment module MINICOM

The adjustment module can be plugged into

the sensor or into the optional, external indicating instrument.

ESC

+

-

Tank 1

m (d)

12.345

OK

2

PA-Bus

ESC

+

-

OK

Adjustment with the SIMA TIC PDM adjustment program

For adjustment of all essential functions of the

VEGA sensor with the adjustment station

SIMATIC PDM from Siemens, a so-called

EDD is required. Without this EDD, only the

basic functions such as min./max. adjustment

or the integration time can be adjusted with

the PDM adjustment program. Further important adjustment functions, such as input of

measuring environment data or false echo

storage, are not available without EDD. After

integration of the EDD files in the Simatic PDM

adjustment software, all important adjustment

functions are accessible. If it is not at hand,

the obligatory GSD (instrument master file)

as well as the EDD (Electronic Device Description) necessary for PDM can be

downloaded from the VEGA-Homepage

(http://www.vega.com).

ESC

+

-

Tank 1

m (d)

12.345

OK

4

max. 25 m

Adjustment with detachable adjustment module. The

adjustment module can be plugged into the sensor or

the external indicating instrument VEGADIS 50.

The sensor can be adjusted with the adjustment module MINICOM and basic functions

can be set. Beside the measuring conditions

and the simulation mode, the Profibus address can also be adjusted and a false echo

storage can be carried out, see "4.2 Adjustment with MINICOM".

VEGAFLEX 51P and 52P 9

Page 10

1.5 Type code

The second figure of the type name, e.g.

VEGAFLEX 5[1]… distinguishes the instruments acc. to the stability of the cable.

The letter, e.g. VEGAFLEX 51[P] indicates

the output signal:

K stands for an analogue 4 … 20 mA output

signal (compact instrument)

V stands for a digital output signal (VBUS).

P stands for a digital output signal with Profibus PA

VEGAFLEX XX P EXS.X G

G - Connection to segment coupler Profibus PA

Dust Ex approved

P - Digital output signal for connection to

Profibus PA

Type 51: Instrument series with 4 mm cable

Type 52: Instrument series with 8 mm cable

Measuring technology (FLEX for guided microwave)

Product description

10 VEGAFLEX 51P and 52P

Page 11

Product description

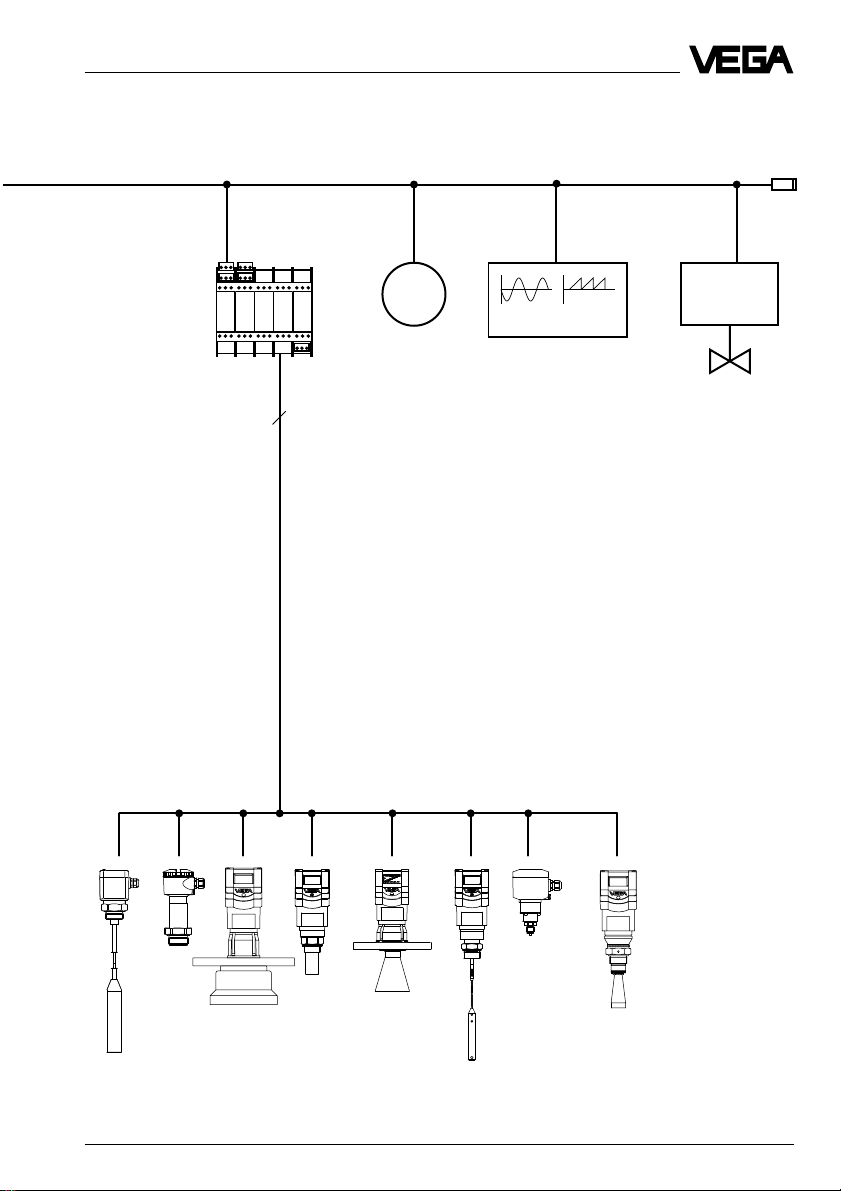

1.6 Bus configuration

The type of sensor you use depends on the

process requirements and mounting conditions, as well as on the requirements of your

control, regulative, or process control system.

VEGAFLEX 51P and 52P Profibus sensors

are sensors for use in Profibus PA environment. Profile 3 has been implemented in the

sensors. A measuring system consists of

one or several sensors, one or several segment couplers and one DP master computer,

such as e.g. a S7 PLC with Profibus interface

or a process control system with Profibus

DP-Master-Slot. The processing unit, e.g. the

PLC, evaluates the level-proportional, digital

measuring signals in a number of evaluation

routines and puts them to use process-specifically.

On the following two pages you will find a

schematic of the bus configuration.

The automation system as Master-Class 1

takes over the complete bus control. It reads

out all signals cyclically and, if necessary,

gives instructions to the participants (e.g.

sensors). In addition, further master systems

(e.g. visualisation systems or adjustment

tools) can be connected to the DP bus.

These systems operate as so-called MasterClass 2 participants. Like the Master-Class 1

system, they can read out signals, give instructions and operate in acyclical mode.

A DP bus does not allow power supply via

signal cable, whereas the PA bus does. Both,

DP and PA, require at least one screened

two-wire cable. The DP bus can additionally

have up to 8 cores (screened), some of

which can be supply cables.

Each participant on the bus must have an

address. The addressing covers both bus

levels. A Profibus DP system can have max.

126 participants, including all participants on

the PA level. In practice, each Master-Class 1

computer gets address 1 and the MasterClass 2 computers address 10 … 20. As a

rule, the slaves or participants get the addresses 21 … 126. On the Profibus PA level,

max. 32 sensors are possible on one PA

segment coupler.

Ex environment

In Ex environment, intrinsically safe (EEx ia)

PA sensors are used with Ex segment couplers. Generally, the number of PA sensors

on a segment coupler (Ex or non Ex) depends on the current requirement of the

sensors and on the current supplied by the

segment coupler. Segment couplers for

EEx ia environment provide 90 … 110 mA.

The number of sensors results from the sum

of:

- the basic current intake of all sensors

- plus 9 mA communication signal

- plus the leakage currents of all sensors

- plus a recommended current reserve

(approx. 10 mA)

The min. basic current has been set at 10 mA

according to the Profibus specification.

VEGA Profibus sensors constantly consume

a basic current of 10 mA and operate without

leakage current requirement, so that in Ex

environment, up to ten VEGA sensors can be

operated on one segment coupler.

VEGAFLEX 51P and 52P 11

Page 12

Address 1

Product description

2…8

Segment

coupler

PLC/DCS

Address

21...52

3

2

Profibus PA

21 22 52

1 … 32 sensors

(Ex: 1 … 10)

Master-Class 2

interface card

12 VEGAFLEX 51P and 52P

Address 10

Page 13

Product description

Profibus DP

Segment

coupler

Address

53...84

M

Address

85

3~M

Address

86

2

Profibus PA

53 54 84

Address

87

1 … 32 sensors

VEGAFLEX 51P and 52P 13

Page 14

Technical data

1.7 Technical data

Power supply

Supply voltage 9 … 32 V DC)

(output voltage UO of the segment dependent on the segment coupler used

coupler) see PA specification, e.g.

- non Ex e.g. 22 V DC (nominal voltage of the segment

- Ex 13.5 V DC nominal voltage of the segment

Current consumption constant 10 mA (no leakage current output)

Cable load dependent on the segment coupler, see

Measuring range

VEGAFLEX 51 0.3 … 10 m

VEGAFLEX 52 0.3 … 20 m

Output signal

digital (Profibus) two-wire technology:

Integration time 0 … 999 seconds (adjustable)

coupler) max. 32 sensors on one two-wire

cable

coupler max. 10 sensors on one two-wire

cable (typical 8 sensors)

technical data of the segment couplers and

Profibus specification

the digital output signal (meas. signal is

modulated onto the power supply and is further

processed in the PLC or in the process control

Adjustment

- adjustment software VEGA Visual Operating on Master-Class 2 PC

- adjustment module MINICOM in the sensor or in the external indicating instrument

(optional)

- process adjustment interface PACTwareTM (VVO as subprogram)

- SIMATIC PDM in conjunction with Electronic Device Description (EDD)

Accuracy

1)

(under reference conditions acc. to IEC 770 - relating to the max. measuring range)

Linearity error < 0.1 %

Temperature drift 0.015 %/10 K

Characteristics linear

Deviation in characteristics including

linearity, reproducibility and

hysteresis (determined acc. to the

limit point method) better than 0.05 %

Average temperature coefficient of the

zero signal 0.06 %/10 K

Resolution general max. 1 mm

Resolution of the output signal 0.005 % or 1 mm

1)

Similar to DIN 16 086, reference conditions according to IEC 770, e.g.

temperature 15°C … 35°C; moisture 45 % … 75 %; pressure 860 mbar … 1060 mbar

3)

The adjustment time (also actuating time, response time or adjustment period) is the time the sensor

requires to output the correct level (with max. 10% deviation) after a quick level change.

14 VEGAFLEX 51P and 52P

Page 15

Technical data

Characteristics

Min. span between full and empty adjustment

- digital output signal 10 mm

Adjustment time

2)

> 1 s (depending on the parameter setting)

Measuring range begin 300 mm below the seal surface

Measuring range end upper edge of the gravity weight or

the cable loop

Ambient conditions

Vessel pressure -1 … 16 bar

Ambient temperature on the housing -40°C … +60°C

Process temperature -40°C … +120°C

Storage and transport temperature -60°C … +80°C

Protection IP 66/IP 67 (meets both protections)

Protection class

- two-wire sensor II

Overvoltage category III

Max. tensile load

- cable ø 4 mm 5 KN

- cable ø 8 mm 20 KN

Ex technical data

StEx Zone 10

Ex Zone 0

The permissible operating data of VEGAFLEX sensors for StEx areas are stated in the

certificate.

Process connections

VEGAFLEX 51 and 52 G 11/2 A, 11/2" NPT

chromized steel or 1.4301 (stainless steel)

Connection cables

Two-wire sensors power supply and signal via one

Wire cross-section generally 2.5 mm

two-wire cable

Ground connection max. 4 mm

2

2

Cable entry 2 x M20 x 1.5 (cable entry 5 … 9 mm)

Materials

Housing PBT (Valox) or Aluminium (powder-coated)

Cable 1.4401 (stainless steel, 316) or

galvanized steel/PA coated

VEGAFLEX 51P and 52P 15

Page 16

Product description

CE conformity

VEGAFLEX sensors meet the protective regulations of EMC (89/336/EWG) and NSR (73/

23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

Display indication

Display scalable analogue and digital

display of measured values (option)

An external measured value display powered by the sensor can be mounted at a distance

of up to 25 m from the sensors.

Signal output

Signal output digital output signal in two-wire technology

(Profibus)

Two-wire technology:

The digital Profibus output signal (measuring signal) is superimposed on the power supply

and further processed in the signal conditioning instrument or in the processing system.

16 VEGAFLEX 51P and 52P

Page 17

Product description

1.8 Approvals

VEGAFLEX sensors are approved for StEx Zone 10.

Please note the attached approval documents if you want to use a sensor in Ex environment.

1.9 Data format of the output signal

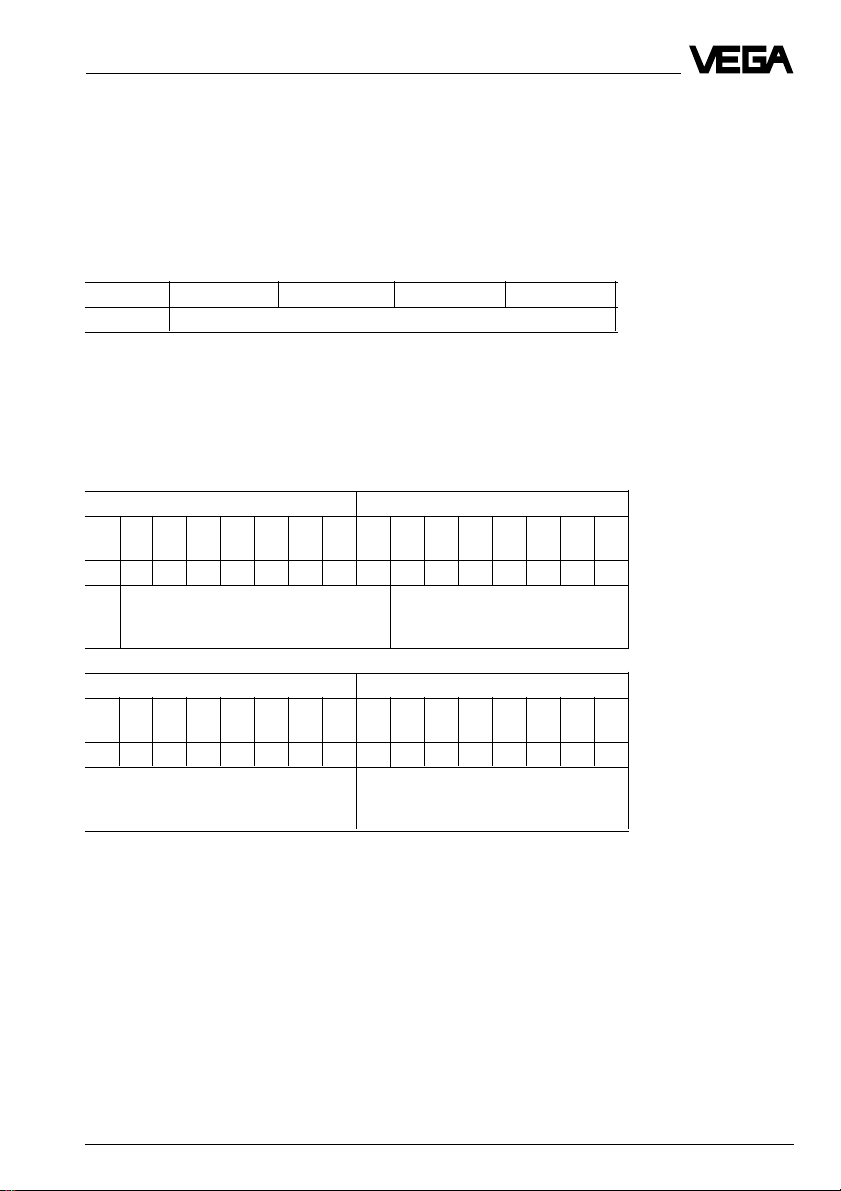

Byte4 Byte3 Byte2 Byte1 Byte0

Status Meas. value (IEEE-754 format, see below)

Status byte:

The status byte corresponds to the profile 3.0 "Profibus PA Profile for Process Control Devices" coded. The status "Meas. value OK" is coded as 80 (hex) (Bit7 = 1, Bit 6 … 0 = 0).

Measured value:

The meas. value is transferred as 32 Bit floating point number in the IEEE-754 format.

Byte n Byte n+1

Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit

7654321076543210

VZ 27262524232221202-12-22-32-42-52-62

Sign

Exponent Mantissa

-7

Byte n+2 Byte n+3

Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit Bit

7654321076543210

2-82-92

-102-112-122-132-142-152-162-172-182-192-202-212-222-23

Mantissa Mantissa

Formula: Meas. value = (-1)VZ • 2

Examples: 41 70 00 00 (hex) = 0100 0001 0111 0000 0000 0000 0000 0000 (bin)

Meas. value = (-1)0 • 2

(Exponent - 127)

(130 - 127)

• (1 + 2-1 + 2-2 + 2-3)

• (1 + Mantissa)

= 1 • 23 • (1 + 0.5 + 0.25 + 0.125)

= 1 • 8 • 1.875

= 15.0

VEGAFLEX 51P and 52P 17

Page 18

1.10 Dimensions

VEGAFLEX 51

Plastic housing Aluminium housing

201

10˚

101

215

185

Product description

25 116

322

182

165

Cable ø 4 mm uncoated 125 mm

Cable ø 4 mm coated 250 mm

SW 55

G 1½ A

244

90

25

70

ø 4

L

155

ø 8

8

ø 20

370

205

EXD connection housing

268

SW 55

G 1½ A

L

ø 8

Adjustment module MINICOM Cable loops

Tank 1

m (d)

12.345

-

ESC

+

OK

32,5

25

70

ø 4

155

8

ø 20

67,5

74

Adjustment module to be plugged into the

series 50 sensors or into the external indicating instrument VEGADIS 50

Cable - steel

18 VEGAFLEX 51P and 52P

Cable - plastic

coated

Page 19

Product description

VEGAFLEX 52

Plastic housing Aluminium housing

201

215

185

10˚

322

182

165

345

L

SW 64

G 1½ A

101

370

90

25

80

ø 8

205

EXD

connection

housing

25 116

368

SW 64

G 1½ A

L

25

80

ø 8

250

Cable ø 8 mm uncoated 200 mm

Cable ø 8 mm coated 400 mm

ø 12

ø 40

15

ø 12

15

ø 40

VEGAFLEX 51P and 52P 19

250

Page 20

2 Mounting

Mounting

2.1 Installation instructions

Lateral load

Make sure that the measuring cable is not

subjected to strong lateral forces. Mount

VEGAFLEX to a position in the vessel where

no interfering influences from e.g. stirrers,

filling openings etc., can occur.

Lateral load

Extraction forces

In case of strong extraction forces, e.g. during quick emptying or settling of solids, high

tensile loads can occur.

When such an installation position is necessary, the cable should not be anchored but

only equipped with a gravity weight, so that

the cable can more easily follow the product

movements.

Shortening the measuring cable

The cable can be shortened later as required. Loosen the three set screws on the

gravity weight (hexagon) and remove them.

Pull the cable out of the gravity weight.

To avoid fraying the steel cable during cutting, you have to tin the cable around the

cutting position with a soldering iron or torch,

or wrap the cable tightly with wire or insulating tape. Shorten the cable with a metal cutting saw or a cutting wheel to the desired

length.

In case of insulated cables with gravity

weight, a certain length of insulation should

be removed (VEGAFLEX 51: 45 mm; VEGAFLEX 52: 60 mm). In cable loops, the

insulation must remain on the cable.

After shortening, reinsert the cable (see "4.2

Adjustment with adjustment module MINICOM").

L

Make sure that the vessel top can support

the max. tensile load.

Pressure

In case of gauge or low pressure in the vessel, the mounting boss should be sealed on

the thread. Use the attached seal ring. Check

if the seal ring is resistant against the contained medium.

20 VEGAFLEX 51P and 52P

Shortening the measuring cable

Page 21

Mounting

Cable entries

When mounting outdoors, on cooled vessels

or in humid areas where cleaning is done e.g.

with steam or high pressure, the seal of the

cable entry is very important.

Use cable with a round conducting crosssection and tighten the cable entry. The cable

entry is suitable for cable diameters of 5 mm

to 9 mm.

Moisture from outside

To avoid moisture ingress, the electrical connection cable should be looped downward

behind the cable entry so that rain and condensation water can drain off.

This is mainly valid for mounting outdoors, in

areas where humidity is expected (e.g. by

cleaning processes) or on cooled or heated

vessels.

If this happens, anchor the cable. When

straining the cable, avoid high cable tension.

In our price list, you will find a spring (as

accessory) which prevents overloading of

the cable.

Please note that in solids, strained cables

must be able to resist strong forces. In case

of strong extracting forces, the cable should

not be anchored. Please note the paragraph

"Extracting forces".

Cable electrode in solids

Buildup

Generally, buildup on the cable will cause

only slight changes of the measured value. If

strong buildup on the cable is expected, the

use of insulated cable is recommended. The

higher surface quality prevents buildup.

Abrasion

In very abrasive products, e.g. in loose

Moisture

Anchoring

In general, the measuring result will be noticeably influenced if the gravity weight

comes into contact with the vessel wall. Depending on the kind of solid, the installation or

the kind of filling, the cable can "float" in spite

of the gravity weight. The solid can push the

chippings, use a measuring cable without

insulation.

Socket

Sockets cause strong interfering reflections.

Therefore avoid socket mounting. If this is not

possible, choose the flattest socket possible

and use a socket with a diameter of at least

600 mm.

cable to the vessel wall or to the top, causing

incorrect measured values.

VEGAFLEX 51P and 52P 21

Page 22

Mounting

Material cone

When selecting a mounting location for

VEGAFLEX in the vessel, please remember

that material cones can form in solids, causing inaccurate measuring results. We recommend selecting a mounting location where the

cable detects an average value of the material cone.

d

6

d

d

6

VEGAFLEX should be installed at a spot that

takes the filling and emptying apertures of

the vessel into consideration. To compensate

measuring errors caused by the material

cone, you should install the cable at a distance of d/6 from the vessel wall or vessel

installation. In any case keep, a min. distance

of 300 mm.

d

3

10

d

d

1 Emptying

2 Filling opening

3 VEGAFLEX

22 VEGAFLEX 51P and 52P

1

2

Page 23

Electrical connection

3 Electrical connection

3.1 Connection – Connection cable

– Screening

Safety information – Qualified personnel

Instruments which are not operated with

protective low voltage or DC voltage must be

connected only by qualified personnel. This

also applies to the configuration of measuring

systems planned for Ex environment.

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work on the sensors. Protect

yourself and the instruments.

Connection cables and bus configuration

Very often "Electromagnetic pollution" by

electronic actuators, energy lines and emitting systems is so considerable that the twowire cable should be screened.

We recommend the use of screened cable.

This screening also guards against future

sources of interference. The screening

should be applied only to one sensor end

(fig. 3.1 a).

It is better if the screens are earthed on both

ends. However, it must be certain that no

earth compensation currents flow via the

sensor cable screens (fig. 3.1 b). Earth compensation currents can be avoided by connecting the cable screen (in case of earthing

on both sides) on one earthed side (e.g. in

the switching cabinet) via a capacitor (e.g.

0.1 µF; 250 V AC) to earth potential. Use a

very low impedance earth connection (foundation, plate or mains earth). In dust-Ex applications the screen should be on one end.

Potential losses can be caused by earthing

on both ends.

Note the Profibus specification. The connection cables must be specified for the expected operating temperatures in the plant

and must have an outer diameter of

6 … 12 mm, to ensure the seal effect of the

cable entry on the sensor.

For power supply and bus communication, a

two-wire cable acc. to the Profibus specification (up to max. 2.5 mm2 cross-section area

of conductor) is used. The electrical connection on the sensor is made by spring-loaded

terminals.

In a laboratory setup, a Profibus system will

also work with standard, unshielded two-wire

cable. In practice however, an automation

network and bus system can only be protected reliably against electromagnetic interference with screened cable. Acc. to the

Profibus specification (IEC 1158-2),

screened and twisted cables are prescribed.

All participants are connected in one line

(serially). At the beginning and end of the

bus segment, the bus is terminated by an

active bus termination. On the DP bus level,

most participants already have a bus termination implemented. With more than 32 participants on the DP level, a so-called repeater

must be used to open and combine another

DP level with a max. of 32 additional participants. On the PA bus branch of the segment

coupler, the PA radar sensors work also with

max. 32 participants (Ex max. 10 participants).

A PA sensor can work only in conjunction with

a Profibus DP system, to which a Profibus PA

subsystem is connected. A PA Profibus participant must consume min. 10 mA supply

current.

VEGAFLEX 51P and 52P 23

Page 24

Electrical connection

Earthing on one sensor end

Processing

Earthing on both ends (on the processing unit via potential separating capacitor)

Fig. 3.1 a

³ 0.1 µF

250 V AC

Processing

In dust-Ex applications the screening should

only be made on one side. Due to potential

difference earthing on both sides is not al-

Fig. 3.1 b

lowed.

24 VEGAFLEX 51P and 52P

Page 25

Electrical connection

Connection cable and cable length

Connection cables must correspond to the

Profibus specification and the FISCO model.

The sensor cable must be in conformity with

the values of the reference cable acc. to

IEC 1158-2:

0.8 mm2; R

Z

= 80 … 120 W; damping = 3 dB/km;

31.25kHz

C

asymmetric

The max. cable length first of all depends on

the transmission speed:

up to 32 kbit/s: 1900 m Profibus PA

up to

94 kbit/s: 1200 m Profibus DP

up to

188 kbit/s: 1000 m Profibus DP

up to

500 kbit/s: 500 m Profibus DP

up to

1500 kbit/s: 200 m Profibus DP

up to

12000 kbit/s: 100 m Profibus DP

The distributed resistance of the cable, in

conjunction with the output voltage of the

segment coupler and the current requirement

(VEGAFLEX 10 mA) or the voltage requirement (VEGAFLEX 9 V) of the sensors, determines the max. length of the cable.

In a practical application of a PA bus branch,

the max. length of the cable is also determined (beside the required supply voltage

and max. current consumption of all participants on the PA bus branch) by the bus

structure and the type of segment coupler

used.

= 44 W/km;

DCmax.

= 2 nF/km.

Ground terminal

The electronics housings of the sensors have

a protective insulation. The ground terminal in

the electronics is galvanically connected with

the metallic process connection. For sensors

with a plastic thread as process fitting, the

sensor grounding must be made by a

ground connection to the outer ground terminal.

Screening

According to the Profibus specification

screening should be applied to both ends. To

avoid potential equalisation currents, a potential equalisation system must be available

in addition to the screening.

According to specification, we recommend

the use of twisted and screened two-wire

cable, e.g.: SINEC 6XV1 830-5AH10 (Siemens), SINEC L26XV1 830-35H10 (Siemens),

3079A (Belden).

Alternatively, when grounding at both ends in

non-Ex areas, the cable shielding can be

connected on one ground side (in the switching cabinet) via a capacitor (e.g. 0.1 µF;

250 V) to the ground potential. Make sure

that the ground connection has the lowest

possible resistance (foundation, plate or

mains earth).

The cable length results from the sum of all

cable sections and the length of all stubs.

Profibus P A in Ex environment

The length of the individual stubs must not

exceed the following lengths:

1 … 12 stubs 120 m (Ex: 30 m)

13 … 18 stubs 60 m (Ex: 30 m)

19 … 24 stubs 30 m (Ex: 30 m)

When used in Ex area, a PA bus with all connected instruments must be carried out in

intrinsically safe protection class "i". Four-wire

instruments requiring separate supply must

at least have an intrinsically safe PA connec-

More than 24 stubs are not permitted,

whereby each branch longer than 1.2 m is

tion. VEGA sensors for PA-Ex environment

are generally "ia” two-wire instruments.

counted as a stub. The total length of the

cable must not exceed 1900 m (in Ex version

1000 m).

VEGAFLEX 51P and 52P 25

Page 26

Electrical connection

In the so-called Fieldbus Intrinsically Safe

Concept (FISCO), the general conditions for

an Ex safe bus configuration have been laid

down. Therein the participants and the bus

cables with their electrical data have been

determined, so that the linking of these components always meets the Ex requirements.

A more time-consuming Ex calculation is

therefore not necessary. You can build your

Ex bus according to the IEC standard 1158-

2.

The Ex segment coupler delivers a controlled

power supply to the PA bus. All other components (field instruments and bus terminators)

are only consumers. A field instrument must

consume at least 10 mA. Ideally, an individual

sensor should not consume more than

10 mA, so that the number of instruments can

be as large as possible.

VEGA PA sensors, whether Ex or non Ex,

consume a constant current of 10 mA. According to the Profibus specification, this is

the minimum participant current. With VEGA

sensors it is therefore possible to connect 10

sensors (also in Ex environment) even with a

limited energy supply from the Ex segment

couplers.

Watch out for potential losses

Due to potential losses, earthing on both

sides without a potential equalisation system

is not allowed in Ex applications. If an instrument is used in hazardous areas, the required regulations, conformity and type

approval certificates for systems in Ex areas

must be noted (e.g. DIN 0165). Please also

note the approval documents with the safety

data sheet attached to the Ex sensors.

Ex protection

If an instrument is used in hazardous areas,

the required regulations as well as the dustEx certificates of VEGAFLEX for systems in

dust-Ex areas must be noted.

Electrical data of the cables

R

DC

No. of A in Z

cores mm

2

31.25kHz

C in Damping Screen

nF/km

SINEC 6XV1 44 W/km 2 0.75 100 W < 90 < 3 dB/km Cu braiding

830-5AH10 +/- 20 W 39 kHz

(Siemens)

SINEC L26XV1 44 W/km 2 0.75 100 W < 90 < 3 dB/km Cu braiding

830-35H10 +/- 20 W 39 kHz

(Siemens)

3079A 105 W/km 2 0.32 150 W 29.5 < 3 dB/km Foil

(Belden) 39 kHz

26 VEGAFLEX 51P and 52P

Page 27

Electrical connection

1

2

4

8

16

32

64

128

8765 4

3

2

1

3.2 Sensor address

In a Profibus system composed of Profibus

DP and Profibus PA subsystem, each participant must have a unique address. Each

participant, whether master or slave, is

accessed by means of its own address in

the bus system. The address of a participant, whether on DP or PA level, should be

assigned before connecting to the bus, because an address can be used only once. If

an address is used twice, interference in the

bus will be caused.

The address of a VEGAFLEX sensor can be

set in three ways:

- with the adjustment software VVO (soft-

ware addressing),

- with the DIP switch block in the sensor

(hardware addressing) or

- with the adjustment module MINICOM.

VEGA Profibus sensors are dispatched with

the address set at 126 (all DIP switches to

"ON").

Remember, in a Profibus system there are

max. 126 participants possible. When the

DIP switch is set to address 126 (or higher),

the address can be adjusted with the adjustment software VVO, the adjustment module

MINICOM or another configuration tool (e.g.

PDM). However, there can be only one sensor on the bus with address 126 (delivery

status) during address assignment via software. For that reason, hardware addressing

(DIP switch) before connection to the bus is

recommended.

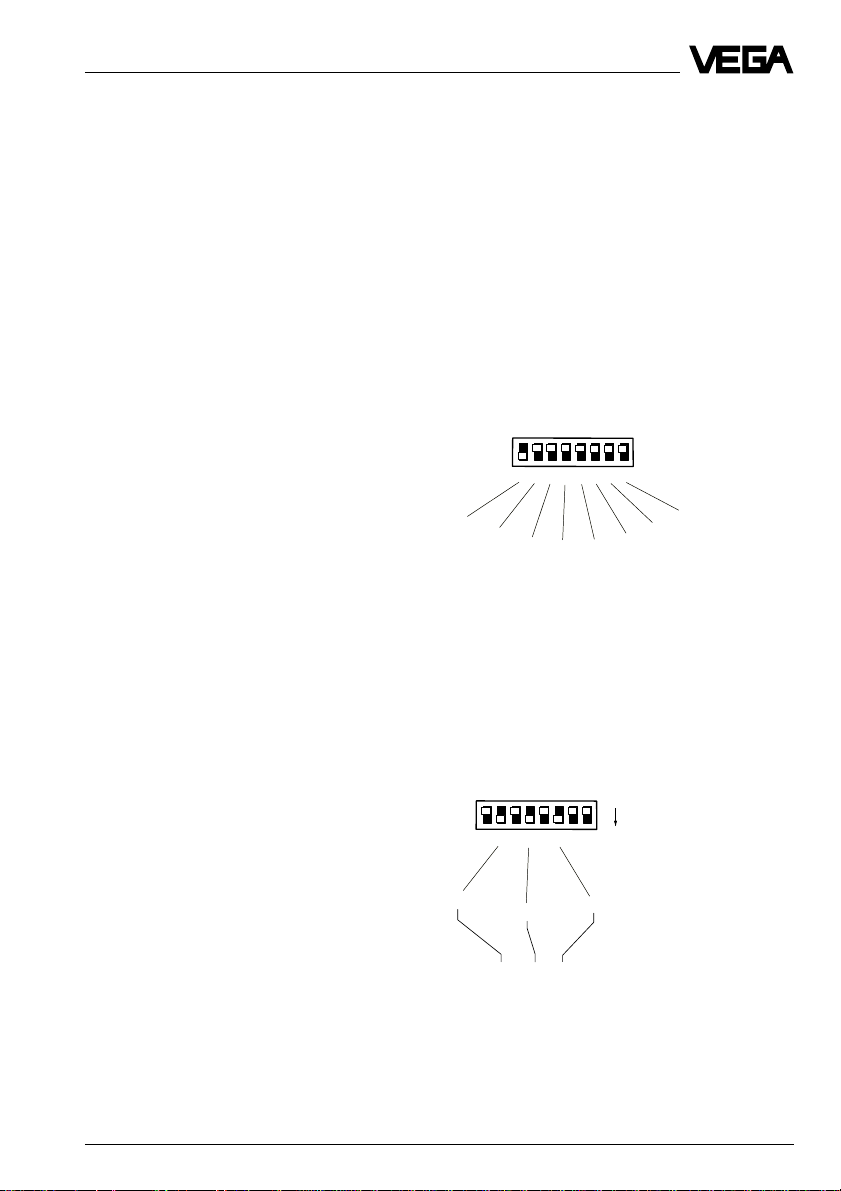

Hardware addressing

The DIP switches generate an address

number in the binary system. This means

that, from right to left (ascending), any switch

represents a number twice as high as the

previous switch on the right. The corresponding number in the decimal system

results from the sum of all switches set to

"ON". In the illustration, you see the decimal

number that corresponds to each individual

DIP switch.

DIP switch 8 corresponds to the number 128,

switch 1 corresponds to the number 1 and

switch 3 corresponds to the decimal number

4.

Example 1

The switches 3, 5 and 7 are set to "ON". The

address is then:

DIP switch 3 to "ON" means 4

DIP switch 5 to "ON" means 16

DIP switch 7 to "ON" means 64

4 + 16 + 64 = Address 84

ON

1

2

8765 4

3

64

VEGAFLEX 51P and 52P 27

16

64 + 16 + 4 = 84

4

Page 28

Electrical connection

Example 2

You want to set address 27.

16 + 8 + 2 + 1 = 27

You must set the DIP switches

5 = 16

4 = 8

2 = 2

1 = 1

to "ON".

Example 3

You want to set address 99

64 + 32 + 2 + 1 = 99

You must set the DIP switches

7 = 64

6 = 32

2 = 2

1 = 1

to "ON".

Software addressing

The DIP switches must be set to an address

of 126 … 255, i.e.

- either all DIP switches are set to "ON",

corresponding to address 255 (delivery

status)

OFF

1

2

64

3

ON

8765 4

32

16

1

2

3

1

2

4

8

8765 4

Addr.

- or only DIP switch 8 is set to "ON", corresponding to address 128.

128

Of course, software addressing is also possible if the switches 7 … 2 are set to "ON"

(address 126).

The adjustment of the address with software

VVO is described in the operating instructions of the adjustment software VVO.

It is also possible to set the address with the

adjustment module MINICOM. Please check

the menu schematic of MINICOM.

28 VEGAFLEX 51P and 52P

Page 29

Electrical connection

3.3 Connection of the sensor

• Loosen the closing screw on the upper

side of the sensor.

• Open the sensor cover.

• Remove the compression nut from the

cable entry and slide the nut a small distance over the connection cable.

• Remove the rubber seal from the cable

entry and slide it over the connection cable.

• Strip off the insulation of the connection

cable over a length of approx. 10 cm.

Version with Aluminium housing

Power supply and Profibus signal

+

To the indicating instrument in the

sensor lid or to the external

indicating instrument VEGADIS 50

–

M20x1.5 (diameter of the

connection cable

6…9 mm)

• Insert the cable through the cable entry

into the sensor.

• Connect the cables.

Push back the white tabs of the spring

terminals with a small screwdriver and

insert the copper core of the connection

line into the terminal opening.

Check the hold of the cables in the terminal

by slightly pulling on them.

• Screw the compression nut back on to the

cable entry and fasten it tightly.

Version with plastic housing

Power supply and

Profibus signal

M20x1.5 (diameter of the

connection cable

6…9 mm)

+

To the indicating instrument in the sensor lid or to

the external indicating

–

instrument

Spring-loaded terminals

(max. 2.5 mm2 wire

cross-section)

1

2

3

87654

1

2

3

8 765 4

+1 2- 5678

Addr.

Bus

Display

ON

ESC

-

+

OK

Opening tabs

Pluggable

adjustment

module

MINICOM

+1 2- 5678

Addr.

Bus

Tank 1

m (d)

12.345

Display

ON

ESC

+

-

OK

VEGAFLEX 51P and 52P 29

Page 30

3.4 Connection of the external indicating instrument

Loosen the four screws of the housing lid on

VEGADIS 50.

The connection procedure can be facilitated

by fixing the housing cover during connection work with one or two screws on the right

of the housing.

Adjustment

module

OUTPUT

(to the sensor)

3

2

1

4

5

8

6

7

VEGADIS 50

+

-

Tank 1

m (d)

12.345

Electrical connection

ESC

OK

Voltage supply and

digital meas. signal

-

+

8 7654

+1 2- 5678

Addr.

Bus

Tank 1

m (d)

12.345

DISPLAY

(in the lid of the

indicating

instrument)

1

2

3

Display

ON

ESC

+

-

OK

Screws

30 VEGAFLEX 51P and 52P

Page 31

Setup

4 Setup

4.1 Adjustment media

All VEGA Profibus sensors operate in profile

3 and can be adjusted with:

- the adjustment program VVO on a PC with

Profibus card

- the adjustment program PACTwareTM, under

which VVO runs as a subprogram

- the Siemens software PDM in conjunction

with an EDD (Electronic-Device-Description)

- the adjustment module MINICOM in the

sensor.

Adjustment with VVO on the PC

The adjustment program VVO enables userfriendly adjustment of VEGA Profibus PA

sensors. All functions and options of sensor

adjustment are accessible. The program

runs under Windows® on a PC with a Profibus-Master-Class 2 interface card on Profibus DP level as Master-Class 2 tool. The

VVO program accesses the VEGA PA sensors via the DP bus, the segment coupler

and the PA bus.

The adjustment program VVO from VEGA

makes full range of functions of VEGA sensors available and can update the entire

sensor software if necessary. For this reason,

the adjustment program must be installed on

a PC which is equipped with a ProfibusMaster-Class 2 interface card (Softing) (see

figure on the next page).

The adjustment and parameter data can be

saved with the adjustment software on the

PC and protected by passwords. On request, the adjustment can be also transferred to other sensors.

In practice, the adjustment program VVO is

often installed as a tool on an engineering

station or an adjustment station. VVO then

accesses over the bus each VEGA sensor

via the Profibus interface card (e.g. from

Softing) as Master-Class 2, from the DP level,

through the segment coupler on the PA level

right down to the individual sensor

Device description (DD)

Beside the instrument master file (GSD), by

which a sensor is logged on the Profibus

system, the majority of all Profibus sensors

requires for adjustment, beside the specific

adjustment software, also a so-called EDD

(Electronic Device Description) for each

sensor, to access and adjust the sensor from

the bus levels. This is not the case with VVO.

The adjustment software VVO can communicate at any time with all VEGA sensors without requiring a special database. Of course,

all other VEGA sensors can be adjusted with

the adjustment software as well (4 … 20 mA

sensors or VBUS sensors). With VEGA sensors, it is not necessary to go looking for the

latest EDD. This is the essential requirement

of a manufacturer-independent adjustment

program anticipated by many users.

The PC with the Profibus interface card can

be connected directly at any location on the

DP bus by means of the standard RS 485Profibus cable.

VEGAFLEX 51P and 52P 31

Page 32

Setup

Adjustment with P ACT ware

TM 1)

The adjustment with PACTwareTM corresponds to VVO adjustment, in this case, VVO

runs as a subprogram of PACTwareTM. The

adjustment instructions can be found in the

documentation of PACTwareTM.

Adjustment with PDM

The sensors can be adjusted completely with

PDM. However, some user-friendly functions

and many special features, like e.g. display

of an echo curve, are not available. In addition to the PDM software, an EDD (upon

request available from VEGA) is required for

each sensor type. The adjustment instructions for PDM are described in the PDM

documentation.

Adjustment with the adjustment module

MINICOM

With the adjustment module MINICOM, you

adjust the individual sensor directly on the

sensor or in the external indicating instrument

VEGADIS 50. The adjustment module MINICOM enables (with the 6 key adjustment field

with text display) all essential functions of

parameter setting and adjustment.

4.2 Adjustment with the adjustment

module MINICOM

As with the PC, the sensor can also be adjusted with the small detachable adjustment

module MINICOM. The adjustment module is

inserted into the sensor or into the external

indicating instrument (optional).

ESC

+

Tank 1

-

m (d)

12.345

OK

2

4 ... 20 mA

ESC

+

Tank 1

-

m (d)

12.345

OK

4

The adjustment module also provides all the

adjustment options available on the PC with

adjustment program VVO. All adjustment

steps can be carried out with 6 keys of the

adjustment module. A small display gives

you, beside the measured value, a short

information on the menu item or the value of a

menu adjustment.

Not possible, however, are parts of the adjustment relating to the configuration and

signal processing (e.g. linearisation curve).

This is only possible with the PC.

32 VEGAFLEX 51P and 52P

Page 33

Setup

Adjustment elements

The adjustment module MINICOM is menu

orientated. The clear text indications on the

display lead through the menu. The functions

of the keys are described in the following.

2

1

Tank 1

-

m (d)

12.345

5

OK key (4)

With the OK key adjustments can be confirmed.

When the symbol ▼ or is displayed, you can

move with the OK key to the next lower menu

level.

With the symbol there is no branch below

▼

▼

the menu item but only another menu item of

respective function.

ESC key (3)

With the Escape key (ESC) you can, depending on the menu item, interrupt an adjustment or a function or change to the next

higher menu level.

3

ESC

+

OK

4

▼

▼

Arrow keys (5)

With the keys > and < you can move within

the menu level from one menu item to the

other.

Digital indication (1)

On the digital indication the actual measured

value is displayed during operation. When

you adjust the instrument, the clear text indication displays the appropriate function.

▼

Branching point from which you can

change to a lower menu.

▼

This symbol informs you about an ensu-

▼

ing safety enquiry.

E.g. to reach the top menu level, push the

ESC key several times.

+ and - key (2)

With the keys + and - you can modify the

values of the parameters or choose from

several possibilities.

After pushing the first time, the value to be

adjusted flashes. The value will be modified

by further pushing the key.

VEGAFLEX 51P and 52P 33

Page 34

Setup

Address

First choose a free bus address (see chapter 3.2 Sensor address").

Adjustment steps

On the following pages you see the menu

schematic of the adjustment module MINICOM.

Set up the sensor in the following sequence.

The numbers are stated near the appropriate

menu items in the menu schematic on the

following pages.

1. Adjustment

2. Conditioning

3. Outputs

4. Operating range

5. Meas. conditions

6. Indication of the useful and noise level

1. Adjustment

Under the menu item "

the sensor with which span it should work.

Max.

Min.

Adjustment

100 % (distance to the medium

0.300 m) corresponds to

1200 l

0 % (distance to the medium

5.850 m) corresponds to 456 l

" you inform

Span

Adjustment without medium

• Enter with the "+" and "–" key the distance

to the medium your sensor has at 0 %

filling (example: 5.850 m)

If you do not know the distance, you have

to do a sounding.

• Enter the distance to the medium which

your sensor has at 100 % filling.

Key Display

Sensor

m(d)

4.700

Para-

OK

OK

OK

OK

meter

adjustment

Adjustment

without

medium

Adjustment

in

(min. adjustment)

m(d)

0.0 %

at

m (d)

XX.XXX

1)

Adjustment with medium

Fill the vessel e.g. to 10 %, enter in the menu

"

Min. adjustment

" with the "+" and "–" keys 10

% and confirm with the "OK" key. Then fill the

vessel e.g. 80 % or 100 %, enter in the menu

"

Max. adjustment

" with the "+" and "–" keys 80

% or 100 % and confirm with the "OK" key.

with

medium

You can carry out the adjustment without

medium. Generally, you will carry out the

adjustment without medium, since you can

adjust without filling the vessel.

1)

In case of two values which can be modified, you

can move with the "OK" key to the second value.

34 VEGAFLEX 51P and 52P

Min.

adjust

at %

XXX.X

Max.

adjust

at %

XXX.X

Page 35

Setup

2. Conditioning

Under the menu item "

choose the distance at 0 % and at 100 %

filling. Then you enter the parameter and the

appropriate unit as well as the decimal point.

• Enter in the menu window "

sponds

" the value of the 0 % filling. This will

be e.g. "80" for 80 l.

• Confirm with "OK".

• With the arrow key you change to the

100 % menu. Enter here the value of your

parameter corresponding to a 100 % filling.

E.g. "1200" for 1200 l.

• Confirm with "OK".

• If necessary, choose a decimal point. Note

that max. 4 digits can be shown.

• In the menu "

rameter (mass, volume, distance…)

• In the menu "

unit (kg, l, ft3, gal, m3 …).

• With the ESC key you change to the next

higher menu level. With the arrow key you

choose the next menu item.

• In the menu

between three standard linearisation

curves.

Preadjusted is a linear dependence between percentage value of the product

distance and the percentage value of the

filling volume.

You can choose between linear, spherical

tank and cylindrical tank. The adjustment of

a user-programmable curve is only possible with the PC and the adjustment program VVO.

• In the menu item

adjust a delay for the signal output.

Conditioning

0 % corre-

prop. to

" you choose the pa-

Unit

" you choose the physical

"Lin. curve"

you can choose

"Integration time"

" you

you can

3. Outputs

4. Operating range

Without special adjustment, the operating

range corresponds to the measuring range.

The measuring range was already adjusted

with the min./max. adjustment. It is usually

better to choose a slightly bigger operating

range (approx. 5 %) than the measuring

range (span).

Example:

Set min./max. adjustment: 0.300 … 5.850 m;

operating range to approx. 0.250 … real

cable length.

If you shorten the cable, you have to redefine

the cable length.

5. Meas. conditions

With these functions you can enter the ambient conditions in the vessel.

(see menu schematic)

6. Useful level and noise level

In the menu

tion on the signal quality of the product echo.

The higher the "

the measurement.

Ampl.: means amplitude of the product echo

S-N: means Signal-Noise (useful level

The higher the S-N value (useful level minus

noise level), the higher the reliability:

> 50 dB Measurement very good

40 … 50 dB Measurement good

20 … 40 dB Measurement satisfactory

15 … 20 dB Measurement sufficient

< 15 dB Measurement bad

"Info"

you get important informa-

S-N

" value, the more reliable

in dB (useful echo)

minus noise level)

Under the menu "

display and determine which parameter the

sensor display should show.

VEGAFLEX 51P and 52P 35

Outputs

" you can scale the

Page 36

Menu schematic of the adjustment module MINICOM

Setup

Sensor

m(d)

4.700

Parameter

Sensor

optimise

Sensor

Tag

Sensor

Meas.

enviro

nment

Operating

range

Begin

m (d)

FLEX51

P

0.50

0.50

When switching on, the sensor type and the

software version are displayed for a few seconds.

Configuration

4.

Cable

length

m (d)

6.00

Meas.

condit

ions

Condit

ion

solid

Sensor

Tag

Sensor

5.

Foaming

prod.

No

Sensor

addr.

(••••/ • •••)

Low DK

product

No

126

Meas.

unit

m (d)

False

echo

memory

Update

Meas.

dist.

m (d)

X.XX

Echo

learn

Now !

OK ?

Learning!

Update

Meas.

dist.

m (d)

X.XX

Update

Now !

OK ?

Learning!

Delete

Delate

Now !

OK ?

Delating!

Adjustment

w.out

medium

Adjustment

in

m(d)

1.

0.0 %

at

m (d)

XX.XXX

100.0%

at

m (d)

XX.XXX

with

medium

Minadjust

at %

XXX.X

Maxadjust

at %

XXX.X

Note:

Set up the sensor in the sequence of the

numbers.

Signal

conditioning

Scaling

0 %

correspond

XXXX

2.

Lin.

curve

Linear

100 %

correspond

XXXX

Integr

ation

time

Decimalpoint

888.8

0 s

Prop.

Unit

to

Masse

kg

36 VEGAFLEX 51P and 52P

Page 37

Setup

With these keys you move in

the menu field to the left, the

right, top and bottom.

ESC

False

echo

memory

Reset

Now !

OK ?

Reset

ing!

Distance

m (d)

4.700

Ampl.:

XXdB

S-N:

XX

weitere

Funkt.

Info

False

echo

dB

memory

Reset

Now !

OK ?

Reset

ing!

Language

English

OK

6.

Ampl.:

Sensor

Tag

Sensor

Sensor

type

FLEX51

P

Serial

number

1094

0213

Softw.

vers.

1.00

Softw.

date

15.09.

1997

Sensor

addr.

(••••/ • •••)

126

Distance

m (d)

4.700

S-N:

XXdB

XX

dB

3.

Outputs

PAoutput

Prop.

to

Distance

Error

mode

last

value

Sensor

displ.

Prop.

to

Distance

VEGAFLEX 51P and 52P 37

Simulation

Simulation

Now!

Simulation

XXX.X

OK?

act.

dist.

%

m

X,XX

Fast

change

Yes

Bolt print figures are sensor or

measured value information and

cannot be modified in this position.

The menu items in white letters

stand for figures which can be

modified with the "+" or "–" key

and saved with the "OK" key.

Page 38

Setup

4.3 Adjustment with the PC

Before you can adjust the sensors with the

adjustment program VVO (VEGA Visual

Operating), they must be integrated into the

Profibus system. First of all address the

sensors and connect them to your PA segment. With the attached GSD file you integrate the sensors into your system.

To adjust VEGA sensors with the adjustment

software VVO, the PC or the adjustment

station on which VVO is installed must be

equipped with a Profibus DP interface card

(e.g. of Messrs. Softing). The PC or the adjustment station communicates then as Master-Class 2 participant on the DP bus with the

VEGA sensors on the PA bus segment.

To connect the PC to the DP bus, a standard

RS 485-DTE interface cable (Data Terminal

Equipment) is required. With the cable you

connect the DP interface card on the bus or

to the segment coupler.

PC BUS

Screen 1 1 Screen

– – 2 2 M24

RxD/TxD-P 3 3 RxD/TxD-P

– – 4 4 CNTR-P

GND 5 5 GND

– – 66VP

– – 7 7 P24

RxD/TxD-N 8 8 RxD/TxD-N

– – 9 9 CNTR-P

Profibus-DP DP bus (in brackets the

interface card PIN number of the P+F

segment couplers)

(40)

(55)

(41)

Segment

coupler

Profibus PA

cable

VVO

DP cable

Profibus DP

interface card

(Messrs. Softing)

Sensor Sensor Sensor Sensor

If the computer is connected to the Profibus

DP cable, you can start VVO.

• Switch on the power supply of the connected sensor.

• Start the adjustment software VVO (VEGA

Visual Operating) on your PC.

• In the entrance window you choose with

the arrow keys or the mouse the item

ning

and click to OK.

You should only choose

Planning

Plan-

if you are

authorised to modify instrument parameters. Otherwise choose

tenance

In the window

.

User identification

Operator

or

Main-

you are

asked for the name and the password.

• For setup (

planning

) enter under name:

VEGA and under password also: VEGA. It

does not matter if you use capital or small

letters.

VVO determines automatically the type of the

connected sensor and shows shortly with

which sensor a connection exists.

Further information on the adjustment with

PC and the adjustment software VVO is

stated in the operating instructions of the

adjustment software VEGA Visual Operating

(VVO).

38 VEGAFLEX 51P and 52P

Page 39

Setup

Configuration

The term "Configuration" means the basic

adjustments of the meas. system. You inform

the meas. system about the application (level

measurement, gauge, distance …), the

measurement loop name and the DCS output

address of the sensors. The configuration

corresponds to an electronic wiring and

labelling of your sensor or, in other words,

telling the system which sensor for what

application and where.

Parameter adjustment

After the configuration, you carry out the

parameter adjustment for each individual

sensor. This means adjusting the sensors to

the respective operating range and adjusting

to the actual application. You inform the sensor which product distance (which level) is

"empty" and which "full". This is called adjustment. Here you choose in which physical unit

(volume, mass) and unit of measurement (m3,

gal, liters …) the adjusted measured value

should be outputted. In the submenu "Sensor

optimisation" you inform the sensor electronics about the actual environment, such as

e.g. quick changes of the measured value,

foam generation, gas stratification, solid or

liquid.

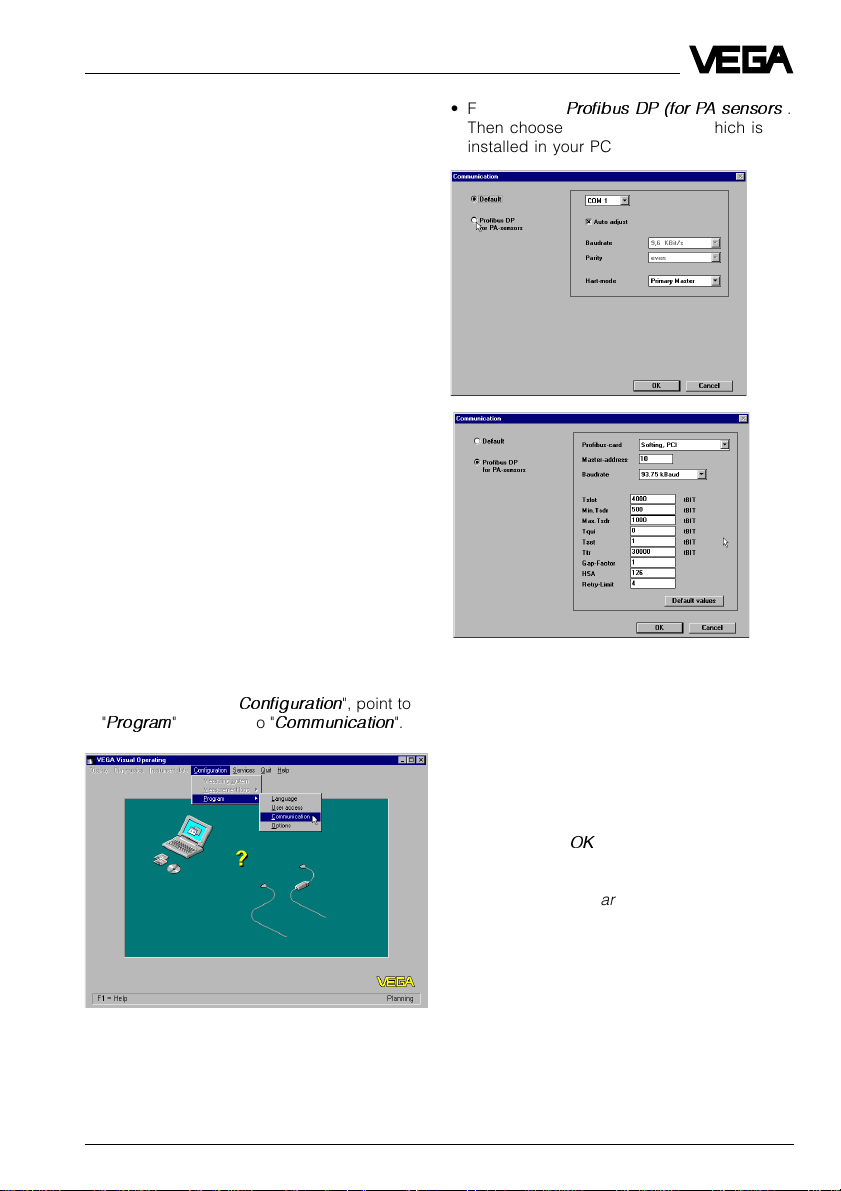

• To do this click to "

"

Program

" and click to "

Configuration

Communication

", point to

".

• First click to "

Profibus DP (for PA sensors

Then choose the Profibus card which is

installed in your PC.

The window for the bus communication adjustments opens. Ten is preadjusted as address for the Master-Class 2 interface card. If

participant number ten is free on your bus,

you can accept the setting. Typical values for

bus parameters have been preset. At this

point, you should adjust the communication

parameters that apply to your system.

).

• Now click to "OK".

The message "

dows® must be restarted

VEGAFLEX 51P and 52P 39

VVO will shut down and Win-

" appears.

Page 40

Note: As a rule, a Windows® restart is not

necessary.

• Now start VVO (restart).

Special functions

As soon as a VEGAFLEX sensor has been

identified, you can choose with the adjustment software VVO some special functions of

VEGAFLEX.

Under the menu item Instrument data/Parameter adjustment you can choose the sensor

optimisation.

Here you find all special functions of VEGAFLEX:

- meas. environment

- echo curve

Measuring environment

Setup

Operating range

With this command you can limit the operating range of the sensor or enter the cable

length again after shortening the cable. Carry

out the adjustment before modifying the operating range, since a later adjustment can

overwrite the values of the operating range.

The right side of the graphics shows the

operating range, the left side the adjustment.

If you, for example, do not want to fill your

vessel completely, you can limit the operating

range.

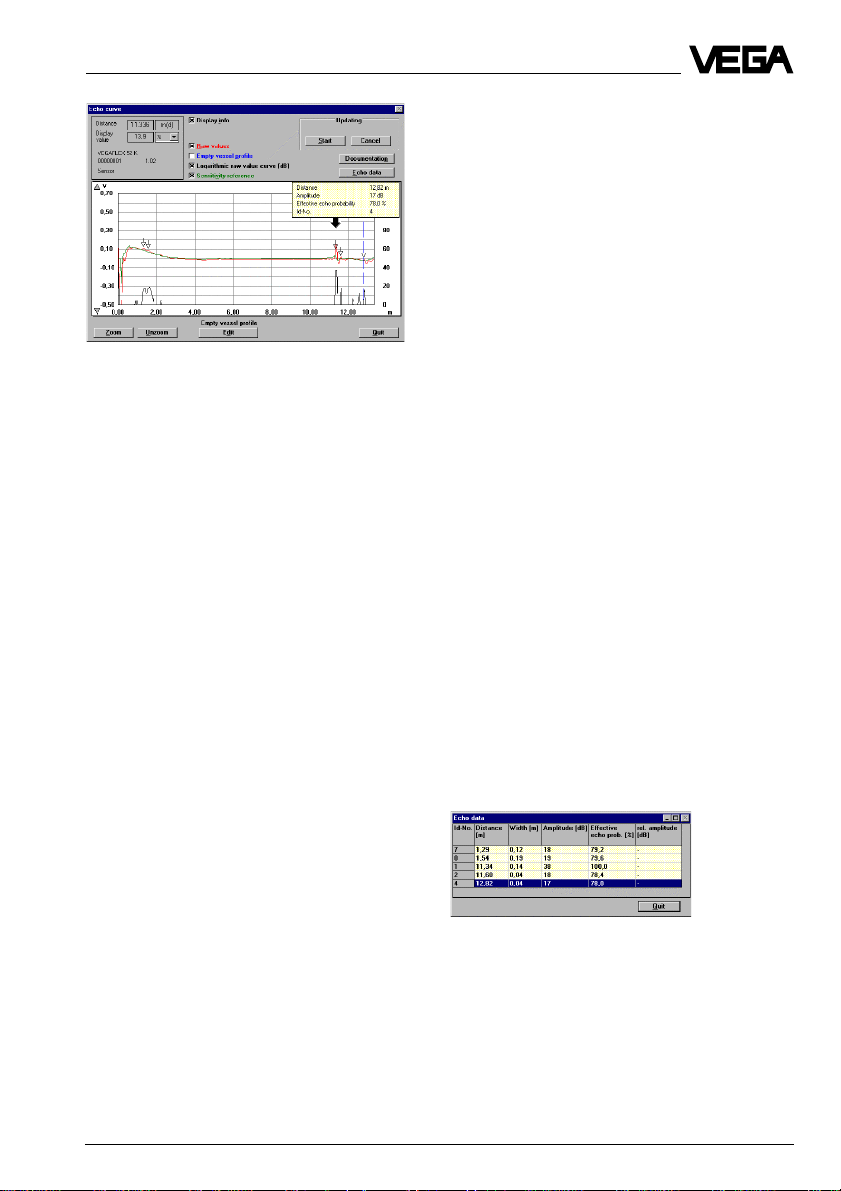

Echo curve

The echo curve shows all reflections of the

guided microwave signal. This means not

only the product signal is shown but also

false signals caused, e.g. by vessel installations.

Measuring conditions

Choose in this menu if you want to measure in

solids or liquids.

If you want to measure a product the DK

value of which is below 2, you can increase

the sensitivity of the sensor.

40 VEGAFLEX 51P and 52P

Generally, the sensor identifies the biggest

amplitude as the useful echo. You see a

black arrow above the highest amplitude.

When you click to "Display info", a small window is displayed, listing the detailed values

of the selected echo.

Page 41

Setup

Empty vessel profile (blue)

This curve shows in normal condition the

actual empty vessel profile.

To gate out of false echoes, you can modify

the blue curve of the vessel profile with the

function "Empty vessel profile".

Reference line (green)

All amplitudes of the red curve which are

below the green reference line are suppressed (ringing, noise, false echoes etc.).

Zoom/Unzoom

After activation of these two functions, you

can either zoom or unzoom the curve with the

left mouse key.

When you activate "Zoom", you can choose

the requested part of the figure by pushing

the left mouse key and drawing a frame.

The following curves can be displayed:

Raw value curve (red)

The red curve means the absolute signal

which the receiver of VEGAFLEX detects.

Beside the useful echo, this curve also contains false signals.

The highest amplitude is detected as useful

echo. Check by sounding to determine if the

value of the useful echo corresponds to the

actual distance to the level.

If the two values do not correspond, you

have to gate out the dominant false echoes

with the function "Empty vessel profile".

All amplitudes above this line are possible

echoes which are processed by the software.

Logarithmic raw value curve (black)

The curve shows the difference between raw

value curve (red) and reference line (green).

The scale on the right side (dB) applies to

this curve.

Documentation

If you click on the button "Documentation", the

actual echo curve will be saved.

Echo data

If you click on the button "Echo data", a window is displayed in which all echoes detected by the sensor are listed with dB

information and a probability evaluation.

VEGAFLEX 51P and 52P 41

Page 42

Start

If you click to "Start", the echo curve will be

updated continuously. With "Stop" you can

terminate the update.

Empty vessel profile

With the functions in this window you can

gate out false echoes. The blue empty vessel

profile curve in the echo curve window shows

the actual empty vessel profile.

Determine the level by sounding. If the sensor has identified a false echo as most probable echo instead of the actual filling level,

you can gate the echo out.

Choose the function "Create new". Enter the

measured distance to the medium. All false

echoes in the range up to the adjusted distance are automatically gated out.

With "Update" you can extend the empty

vessel profile if new false echoes occur as

the level falls. If you want to delete the existing empty vessel profile, click to "Cancel".

Setup

42 VEGAFLEX 51P and 52P

Page 43

Diagnostics

5 Diagnostics

5.1 Simulation

To simulate a certain filling, you can call up

the function "Simulation" on the adjustment

module MINICOM or in the software VVO

program.

You simulate a certain measured value and

thereby a certain sensor current. Please note

that connected instruments, such as e.g. a

PLC, react according to their adjustments

and will probably activate alarms or system

functions.

Simulation with VVO

If you start the simulation mode with the adjustment program VVO on the PC, the simulated level is outputted until you quit the

simulation mode.

Simulation with MINICOM

If you start the simulation mode on the adjustment module MINICOM, the sensor returns

to standard operating mode after one hour.

5.2 Function diagram

The following function diagram is used for

setup with the automation system, if there is

no adjustment software available. Make sure

that all VEGA sensors are profile 3 sensors.

In general, the setup of the sensors can be

carried out very conveniently with the VEGA

adjustment software VVO or with the adjustment module MINICOM in the sensor.

The function diagram is generally not necessary for setup and is used only to deepen

the knowledge of the interested user who is

able to read in the sensor measured values

into the processing system (also without

adjustment tool).

VEGAFLEX 51P and 52P 43

Page 44

Raw-Distance

(value, status)

[in m]

Sensor value (Float)

[sensor unit (m,ft ...)]

Sensor offset (Float)

[sensor unit (m,ft ...)]

Zero adjust

Zero offset

Function diagram and PA parameters

F Time (Float)

(sec)

(not available over

PA Parameter)

Filter

Cal point hi, cal point lo (Float)

[sensor unit (m,ft ...)]

Level hi, level lo (Float)

[level unit (%,m,ft ...)] (*1)

Cal type (Unsigned8)

Live adjustment (min-max) and

dry adjustment possible

Cal

Level hi

Level lo

Cal point hi Cal point lo

Simulate procent value (DS_50)

[level unit (%,m,ft...)] (*1)

(manuf. spec. parameter)

Simulation

off

on

Simulate value

Level (Float)

[level unit (%,m,ft...)] (*1)

Level offset (Float)

[level unit (%,m,ft...)] (*1)

Offset

Offset

44 VEGAFLEX 51P and 52P

Page 45

Function diagram and PA parameters

Simulation distance value (DS_50)

[sensor unit (m,ft ...)]

(manuf. spec. parameter)

Simulation

off

on

Simulate value

Secondary value 2 (DS_33)

[secondary value 2 unit, (m,ft ...)]

distance

Max min memory

max

min

Secondary value 1 (DS_33)

[secondary value 1 unit

(%,m,ft...)] (*1)

Max sensor value,

min sensor value (Float)

[sensor unit (m,ft ...)]

Lin type (Unsigned8),

Tab index (Unsigned8),

Tab X Y value (2 x Float)

[level unit (%,m,ft ...). (*1)

primary value unit (%,m,ft ...)]. (*1)

Tab min number (Unsigned8),

Tab max number (Unsigned8),

Tab op code (Unsigned8),

Tab status (Unsigned8),

Tab actual number (Unsigned8)

Linearization

level %

Transducer

Block

Primary value (DS_33)

[primary value unit (%,m,ft...)] (*1)

lin %

A

B

distance

C

VEGAFLEX 51P and 52P 45

Page 46

lin %

level %

distance

Display source select

(Unsigned8)

Source selector

scale

PV FTime (Float)

[sec]

Function diagram and PA parameters

Sensordisplay

VEGA

Hi hi limit, hi limit,

lo limit, lo lo limit,

alarm hys

(Float) [out scale unit]

Alarm checkFilter

Hi hi limit

Hi limit

Lo limit

Lo lo limit

Alarm hyst

Hi hi alarm, hi alarm,

lo alarm, lo lo alarm

(DS_39)

Alarm sum (DS_42)

lin %

A

B

C

level %

Channel (Unsigned16)

Channel

distance

Simulate Linearization value (DS_50)

[primary value unit (%,m,ft ...).(*1)

secondary value 1 unit, (%,m,ft ...).(*1)

secondary value 2 unit, (m,ft ...)

(dep. on channel)]

Simulation

off

on

Simulate value

46 VEGAFLEX 51P and 52P

Page 47

Function diagram and PA parameters

Fail safe value (Float)

[out scale unit]

Fail safe type (Unsigned8)

Target mode (Unsigned8)

Out (DS_33)

[out scale unit]

Fail safe

Fail safe value

Divice status

PV scale (2 x Float)

[primary value unit (%,m,ft ...).(*1)

secondary value 1 unit, (%,m,ft ...).(*1)

secondary value 2 unit, (m,ft ...)

(dep. on channel)]

PV Scale

1

0

EU 0% EU 100%

Mode

Auto

Man

Mode & Status calc.

Out scale (DS_36)

[out scale unit (included)]

Out Scale

EU 100%

EU 0%

Data value (DS_33)

[out scale unit]

Actual mode

(DS_37)

Function

Block

10

VEGAFLEX 51P and 52P 47

Page 48

5.3 Error rectification

Error Error rectification

Diagnostics

E 013 Sensor cannot find - Message is displayed during the warm-up

E 017 Adjustment span too small Carry out a new adjustment.

E 036 Software update incorrect Return the instrument for repair.

E 040 Hardware failure / Check all connection cables.