Page 1

Operating Instructions

VEGACAP

Level and Pressure

Page 2

Safety information

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as prevailing safety regulations and accident

prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGACAP

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Types and versions ............................................................. 6

1.3 Technical data ....................................................................... 7

1.4 Dimensions ......................................................................... 10

1.5 Product temperature and operating pressure ............... 14

1.6 Approvals ........................................................................... 16

2 Mounting

2.1 Mounting instructions ......................................................... 17

3 Electrical connection

3.1 Connection instructions ..................................................... 21

3.2 Connection plan ................................................................. 21

4 Setup

4.1 Adjustment elements ......................................................... 24

4.2 Switching point adjustment ............................................... 25

4.3 Functions chart ................................................................... 29

5 Diagnostics

5.1 Simulation ............................................................................ 30

5.2 Maintenance ....................................................................... 30

5.3 Repair .................................................................................. 30

5.4 Exchange of electronics .................................................... 31

5.5 Shortening of the electrodes ............................................. 31

5.6 Failure rectification ............................................................. 33

VEGACAP 3

Page 4

1 Product description

Product description

1.1 Function and configuration

The compact capacitive level switches VEGACAP detect the level of virtually any medium regardless of whether in liquid, powder,

paste or granule form. This applies also to

adhesive products.

Depending on the chosen adjustment,

VEGACAP can detect if the medium exceeds

or fails to reach a defined level.

Sensor, processing electronics and power

supply form one unit in VEGACAP. The

modular construction ensures adaption to

virtually any application. Beside rod, cable,

high temperature and plate electrodes, there

are also three electronics versions available

(non-contact switch, relay or transistor output

NPN/PNP).

VEGACAP 27, 35 and 98 combine all these

positive features with the advantage that an

adjustment with medium is no longer necessary. This is made possible by the oscillator

CAP E31 R and the patented mechanical

configuration of the electrode.

Application

The area of application for VEGACAP is

mainly in the detection of max. and min. levels

in vessels. A switching command can be

triggered either when the electrode is immersed or exposed. VEGACAP can be

mounted laterally, from the top or from the

bottom.

Measuring principle

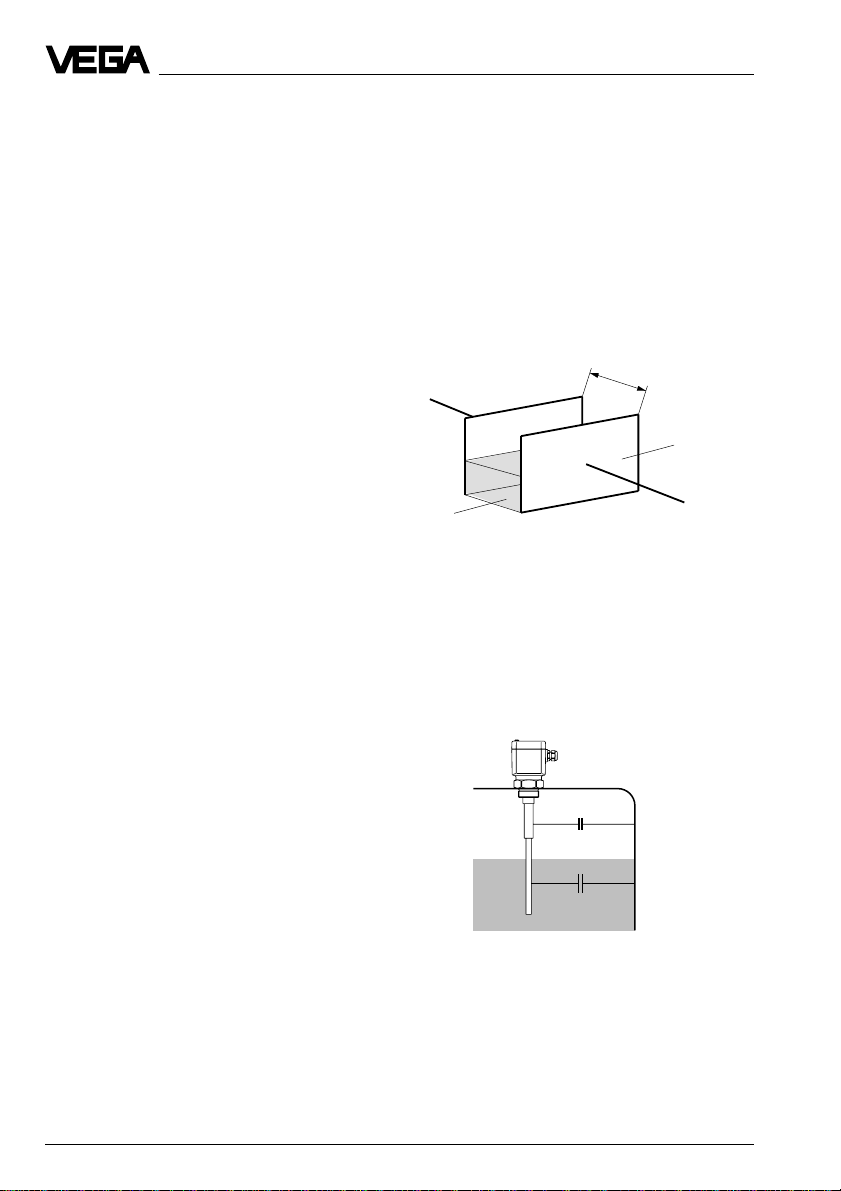

Electrode, medium and vessel wall form an

electrical capacitor.

The capacitance of the capacitor is generally

influenced by three factors:

- distance of the electrode plates (a)

- size of the electrode plates (b)

- type of dielectric between the electrodes

(c)

a

b

c

The electrode and the vessel wall are the

capacitor plates. The medium is the dielectric. Due to the higher dielectric constant (DKvalue) of the medium compared with air, the

capacitance of the capacitor increases as the

electrode is gradually immersed.

Partly insulated

The electrode is insulated over a defined

length. The measurement is made only in the

uninsulated zone.

Fully insulated

The electrode is insulated along the entire

The capacitance change is converted by the

oscillator into a switching command.

length; on cable electrodes also the gravity

weight can be fully insulated.

4 VEGACAP

Page 5

Product description

Buildup resistant

(VEGACAP 26, 27, 35 and 98)

The special mechanical construction compensates conductive buildup. Leakage currents caused by build-up are drained off via

the screen segment.

Even strong condensation or buildup do not

influence the switching condition of VEGACAP.

The compensation of buildup is supported

by the patented processing technology

(phase selective admittance processing) in

the oscillator CAP E31 R.

VEGACAP 35 can be shortened locally to the

requested length. Planning and stocking is

thereby facilitated.

Adjustment-free

(VEGACAP 27, 35 and 98)

Set-up is very easy because the switching

point must no longer be adjusted.

Adjustment-free means that changing mediums with different dielectric constant figures

(er), e.g. water and oil or conductive and nonconductive mediums, do not influence the

adjustments on VEGACAP and the switching

accuracy.

With horizontally installed electrodes, the

installation position is also the position of the

switching point.

Note

Check for correct functioning of the sensor.

When filling for the first time, make sure that

VEGACAP responds and switches correctly

so that in case of failure, the filling or emptying process can be manually stopped.

With vertical installation, the switching point is

only determined by the length of the electrode.

All products with a dielectric constant ³ 1.5

can be detected. With a DK value < 2 a fresh

adjustment must be carried out on VEGACAP

27 and 98.

VEGACAP 5

Page 6

Product description

1.2 Types and versions

Type survey

VEGACAP 111)21 26 27 311)33 34 35 42 52 53 60 61 821)84 92 97 98

Series

Rod electrode • • • • • • •

Cable electrode • • ••••• •

Plate electrode ••

Pipe clamp electr. •

Version

Partly insulated • • • • • • • •

Fully insulated • • • • • • • • •

Thread

NPT 11/2" • • • • • • •••••

G 11/2 A • • • • • • ••••••• •

Electrode

material

Steel • • • • • • ••••••• •

StSt • • • • • • • • • • •

Insulating

material

PTFE • • • • • • • • • •

PP • • • •

PE/PA 12 • • •

PFA • • •

PE •

Ceramic • •

Temperature

adapter

Steel • • • • • • •

StSt • • • • • • •

PA •• •• •• • •

Others

Test switch • • • • • • ••••• • • • •

Adhesive prod. • • • • •

Adjustment-free • • •

High temp. version • •

1)

VEGACAP 11 R ExS, 31 R ExS and 82 R ExS with integrated oscillator E30 R ExS are approved for StEx

applications.

6 VEGACAP

Page 7

Product description

1.3 Technical data

General

Housing

Housing material plastic PBT (Polyester)

Protection class plastic IP 66 (StEx IP 65)

Cable entry 1 x Pg 13.5

Terminals for max. 1.5 mm2 wire cross-section

Thread

Material

- VEGACAP all except VEGACAP 97, 98 steel (St 37), 1.4571 (stst), Aluminium

- VEGACAP 97, 98 PP

Thread G 11/2 A or NPT 11/2“

Rod electrode (VEGACAP 11, 21, 26, 27, 60, 97, 98)

Rod material

- VEGACAP 11, 21, 26, 27, 60 steel (St 37) or 1.4571 (StSt)

- VEGACAP 97, 98 PP (insulation)

Length

- VEGACAP 11, 21, 26, 27 max. 4 m

- VEGACAP 97, 98 max. 1.5 m

VEGACAP 27, 35, 98 also Aluminium

Aluminium IP 66/67

(with oscillator R = 2 x Pg 13.5)

also flange or hygienic versions

Cable electrode (VEGACAP 31, 33, 34, 35, 42, 52, 53, 61)

Cable material

- VEGACAP 31, 33, 42, 61 steel (St 37) or 1.4571 (stst)

- VEGACAP 34, 35, 52, 53 steel (St 37)

Length max. 25 m (VEGACAP 35 max. 20 m)

Weight

Basic weight

- VEGACAP 11, 21, 26, 27 approx. 1.2 kg

- 31, 33, 34, 35, 42, 52, 53, 60, 61 approx. 3.3 kg

- VEGACAP 82, 84, 92 approx. 2.1 kg

- VEGACAP 97, 98 approx. 0.6 kg

Rod weight approx. 1.4 kg/m

Cable weight

- all except VEGACAP 42 approx. 0.3 kg/m

- VEGACAP 42 approx. 0.1 kg/m

Ambient conditions

Ambient temperature on the housing -40°C … +70°C

- StEx version -20°C … +60°C

Storage and transport temperature -40°C … +80°C

Medium temperature and operating see "1.5 Medium temperature and operating

pressure pressure“

Dielectric constant er medium ³ 1.5

VEGACAP 7

Page 8

Product description

Function

Modes A/B mode

Integration time approx. 0.5 sec

Signal lamp LED for indication of the switching mode

Test switch (option) switching point simulation

CE conformity

VEGACAP compact level switches meet the protective regulations of EMC (89/336/EWG)

and NSR (73/23/EWG). The conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 1: 1992

NSR EN 61 010 - 1: 1993

CE conformity (VEGACAP 27, 35, 98)

VEGACAP 27, 35 and 98 compact level switches meet the protective regulations of EMC

(89/336/EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the following

standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

A - max. detection or overfill protection

B - min. detection or dry run protection

(not VEGACAP 27, 35, 98)

Oscillators

General (CAP E30 R, C, T)

Frequency 400 kHz

Capacitance range

- range 1 0 … 20 pF sensitive

- range 2 0 … 85 pF …

- range 3 0 … 450 pF insensitive

Switching hysteresis approx. 2 % relating to the adjusted

Terminals max. 1.5 mm2 wire cross-section

capacitance value

C - Non-contact switch (CAP E30 C)

Supply voltage 20 … 250 V AC, 50/60 Hz

Output non-contact switch

Domestic current requirement < 5 mA (via the load circuit)

Load current min. 10 mA, max. 400 mA (4 A for 40 ms)

Protection class I

Overvoltage category III

8 VEGACAP

20 … 250 V DC

for reliable switching off of contactors with very

low holding current, the domestic current is

briefly lowered below 1 mA.

at a load current of more than 300 mA the

max. permissible ambient temperature is 60°C.

Page 9

Product description

R - Relay output (CAP E30 R)

Supply voltage 20 … 250 V AC, 50/60 Hz

20 … 72 V DC

Power consumption 1 … 9 VA, max. 1.5 W

Output relay output (SPDT)

Relay data

- potential separation min. 500 V DC

- contact floating spdt

- contact material AgNi, Au plated

- turn-on voltage min. 10 mV

max. 250 V AC, 250 V DC

- switching current min. 10 µA

max. 3 A AC, 1 A DC

- breaking capacity max. 500 VA, 54 W

Protection class I

Overvoltage category III

T - Transistor output (CAP E30 T)

Supply voltage 10 … 55 V DC

Power consumption max. 0.5 W

Output floating transistor output

NPN/PNP, individually selectable through differ

ent terminal assignments

Load current max. 400 mA (the output is overload resistant

and permanently shortcircuit proof))

Blocking current max. 10 µA

Voltage loss max. 1 V (if output conductive)

Protection class II

Overvoltage category III

R - Relay output (CAP E31 R)

Supply voltage 20 … 250 V AC, 50/60 Hz

20 … 72 V DC

Power consumption 1 … 9 VA, max. 1.5 W

Output relay output (DPDT)

Relay data

- potential separation min. 500 V DC

- contact 2 floating spdt

- contact material AgNi, Au plated

- turn-on voltage min. 10 mV

max. 250 V AC, 250 V DC

- switching current min. 10 µA

max. 5 A AC, 1 A DC

- breaking capacity max. 750 VA, 54 W

Protection class I

Overvoltage category III

Note:

The oscillator is independent of the electrode and can be replaced locally. Set the changeover

switch of the new oscillator to the same position and repeat the switching point adjustment

(CAP E30 R, C, T). For CAP E31 R a fresh adjustment is also necessary.

VEGACAP 9

Page 10

Product description

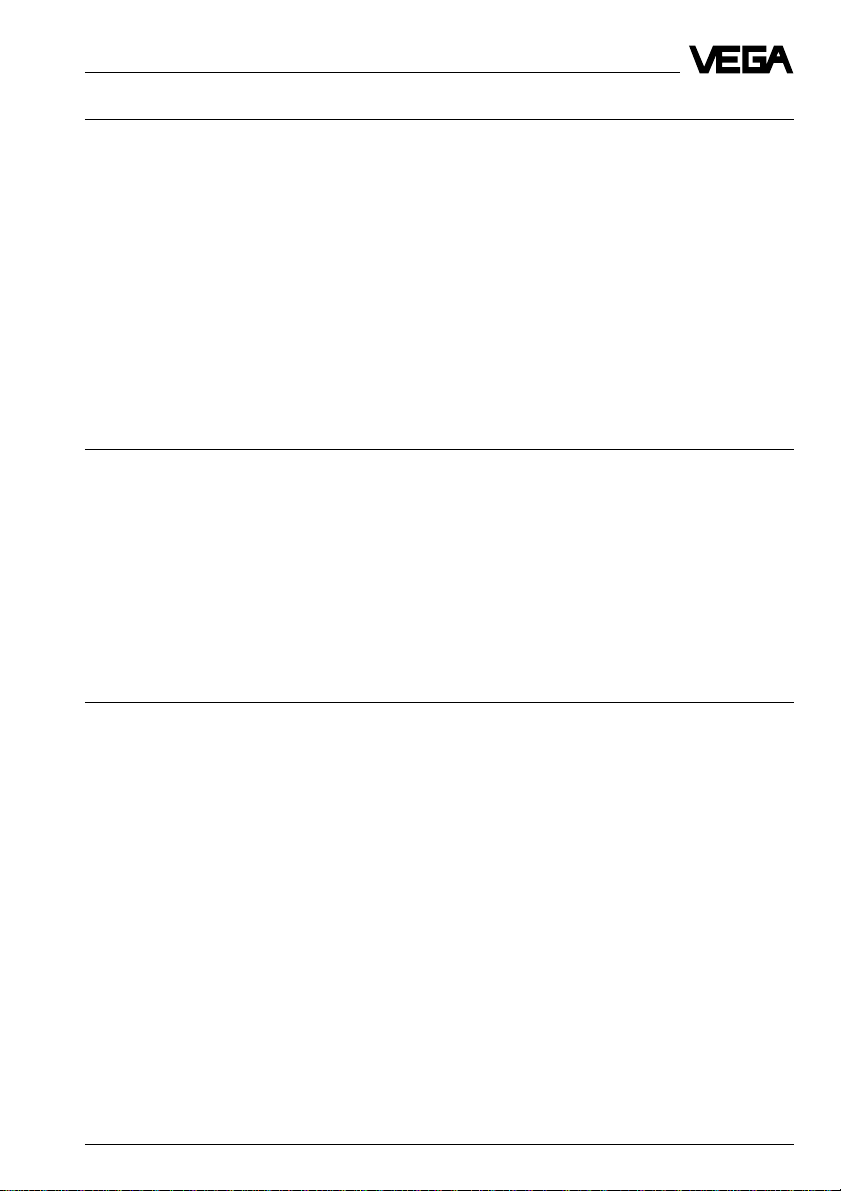

Survey

VEGACAP 11 21 26 27 31 33 34 35 42 52 53 60 61 82 84 92 97 98 11 31 82

Non-contact

switch

CAP E30 C ••• ••• •••••••••

Floating

relay output

CAP E30 R,

E30 R ExS ••• ••• ••••••••• • • •

Floating

relay output

CAP E31 R •• •

Floating

transistor

output

CAP E30 T ••• ••• •••••••••

StEx StEx StEx

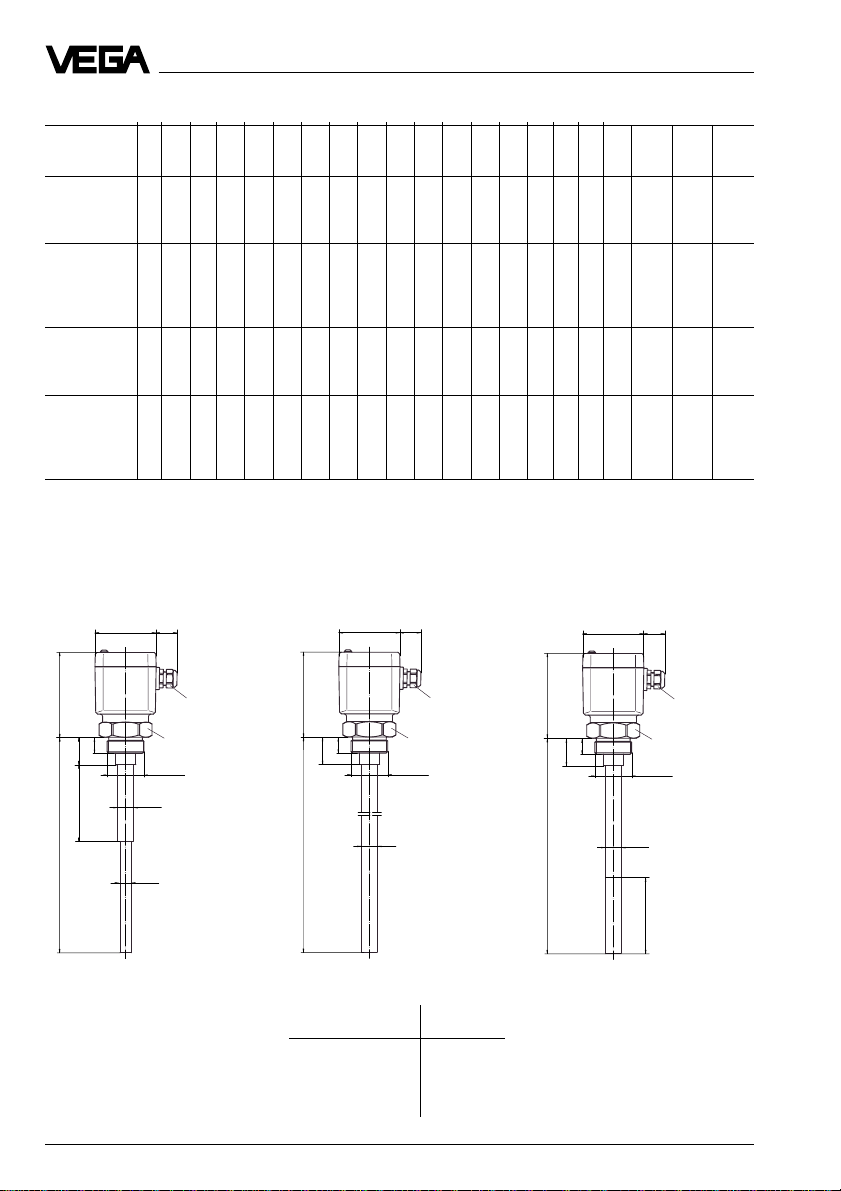

1.4 Dimensions

VEGACAP 11 (partly insulated)

80 x 110

~30

111

20

35

L1

L (max. 4000 mm)

Isolation length L1:

(VEGACAP 11 and VEGACAP 31)

PP: 100 mm

PTFE: 50 mm

StEx: max. 100 mm

Pg 13,5

SW 60

G 1½ A

Ø 20

Ø 15

VEGACAP 21 (fully insulated)

80 x 110A~30

111

20

35

L (max. 4000 mm)

Isolation A

PE 2.0 mm 20 mm

PTFE 2.0 mm 20 mm

PTFE 3.2 mm 16 mm

PFA 2.0 mm 20 mm

Pg 13,5

SW 60

G 1½ A

Outer-ø

VEGACAP 26 (fully insulated, for adhesive products)

LA = active length (standard

100 mm)

80 x 110 ~30

111

20

35

L (min.300, max. 4000 mm)

SW 60

G 1½ A

Ø 20

LA

Pg 13,5

10 VEGACAP

Page 11

Product description

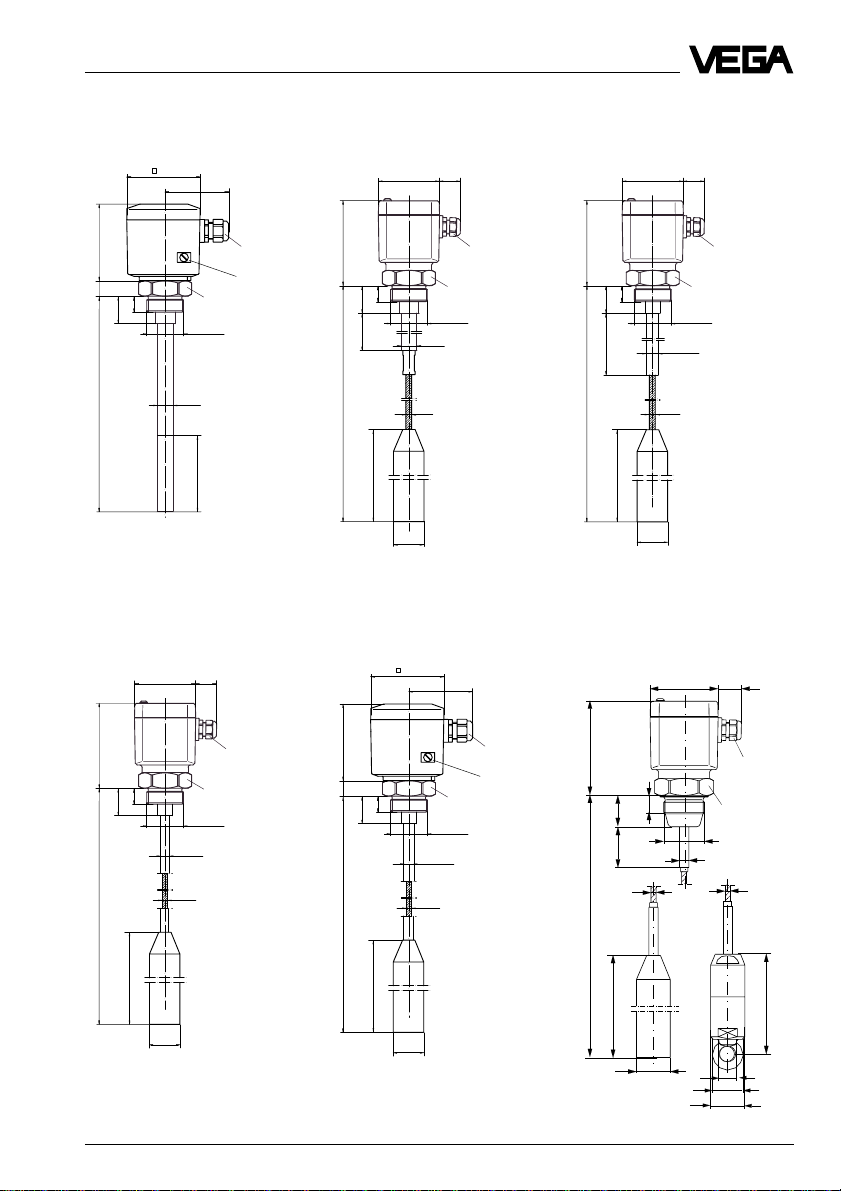

VEGACAP 27 (fully insulated, for adhesive products, adjustment-free)

85

~76

90

20

20

35

L

Ø 20

M20x1,5

PA connection

SW 60

G 1½ A

LA

VEGACAP 34 (partly insulated)

80 x 110 ~30

VEGACAP 31 (partly insulated)

80 x 110 ~30

111

20

35

L1

L (max. 25.000 mm)

200

Ø 40

Pg 13,5

SW 60

G 1½ A

Ø 20

Ø 8

VEGACAP 35 (partly insulated, for adhesive products, adjustment-free)

85

~76

VEGACAP 33 (partly insulated)

80 x 110 ~30

111

20

35

L1

L (max. 25.000 mm)

200

Ø 40

Pg 13,5

SW 60

G 1½ A

Ø 15,5

Ø 8

VEGACAP 42 (fully insulated)

~30

80 x 110

111

20

35

L (max. 25.000 mm)

200

Ø 40

G 1½ A

Ø 11

Ø 6

SW 60

Pg 13,5

90

20

20

35

Ø 13,5

L

Ø 6

200

Ø 40

SW 60

G 1½ A

M20x1,5

PA

connection

111

20

35

100

∅3

L

200

∅40

Gravity weight

∅5

SW 60

PG 13.5

∅3

120

∅20

36

∅40

Fixing weight

VEGACAP 11

Page 12

Product description

VEGACAP 52 (fully insulated)

111

L

200

∅40

Gravity weight

∅8

20

35

80 x 110

Fixing weight

~30

Pg 13.5

SW 60

∅16

VEGACAP 84

80 x 110

~30

∅8

VEGACAP 53 (fully insulated)

111

20

35

∅6

L

125

∅20

36

∅40

200

∅40

Gravity weight

VEGACAP 97 (fully insulated, for adhesive products)

80 x 110

80 x 110

Fixing weight

~30

∅11

~30

Pg 13.5

SW 60

∅6

VEGACAP 82/

VEGACAP 92

(partly / fully insulated)

91

18,5

60

125

∅20

36

∅40

VEGACAP 98 (fully insulated, for adhesive products, adjustment-free)

80 x 110 ~30

Pg 13,5

6

Ø 90

Ø 125/4xØ18

Ø 165

85

~ 76

91

Pg 13.5

SW 60

65

D

111

L

LA = active length (90 mm)

SW 60

G 1½ A

ø33

LA

Pg13,5

9020

21

28

L (200 mm

standard)

LA = active length (90 mm)

G 1½ A

ø 33

LA

M20x1,5

PA

connection

SW 60

12 VEGACAP

Page 13

Product description

Temperature adapter

St / StSt

SW 60

20090

SW 60

Temperature adapter PA

for temperatures

up to 150°C, from

100°C only

Ø 60

7020

unpressurized

VEGACAP 60 (partly insulated, high-temperature

electrode)

L

111

200180

L1 Stützrohr (300)

80 x 110

~30

Pg 13,5

SW 60

23

G 1½ A

Ø 38

VEGACAP 61 (partly insulated, high-temperature

electrode)

L

111

200

180

L1 Stützrohr (300)

100

80 x 110

~30

Pg 13,5

SW 60

23

G 1½ A

Ø 38

Ø 8

Screening tube

SW 60

of St or 1.4571 with

closing cone of PP or

PTFE

L

Ø 38

Closing cone

10

Ø 15

VEGACAP 13

200

Ø 40

Page 14

Product description

1.5 Product temperature and operating pressure

The numbers in the tables relate to the numbers of the opposite illustrations. The pressure stated are valid for thread connections

G 11/2 A, NPT 11/2“ and R 11/2. Boltings DN 50

acc. to DIN 11 851 only up to max. 25 bar.

When using flange versions, give attention to

their respective nominal pressures. All electrodes are also suitable for vacuum (–1 bar).

Mechanical connection, 1.4571 (StSt)

Isolation

VEGACAP

11 - 1 3 - -

21 1-3-3

2)

21

26 - - 3 - 3

2)

26

27 - - 3 - 3

31 - 1 3 - -

33 - - 3 - -

34 unpressurized - - - 1 -

35 - - - 1 -

42 - - 2 - -

52 - - 3 - -

53 - - - 1 -

PE

PP

PTFE

PE/PA 12

PFA

--2--

--2--

bar

40

16

0

-30

bar

63

-50

-50

0

bar

63

25

0

bar

40

16

0

-10

60 80

60 80

˚C

˚C

VEGACAP 21, 35, 53:

PE and PE/PA 12

up to 16 bar

VEGACAP 34:

unpressurized

VEGACAP 42:

up to 16 bar

°C

100

100

Temperature

1)

adapter

VEGACAP 21, 35, 53:

PE and PE/PA 12

up to 16 bar

VEGACAP 34:

unpressurized

1

2

3

200

˚C

4

Mechanical connection, steel (St 37)

Isolation

VEGACAP

PE

PP

PTFE

PE/PA 12

PFA

11 - 4 6 - -

21 4-6-6

2)

21

--5--

26 - - 6 - 6

2)

26

--5--

27 - - 6 - 6

31 - 4 6 - -

33 - - 6 - -

34 unpressurized - - - 4 -

35 - - - 4 -

42 - - 5 - -

52 - - 6 - -

53 - - - 4 -

1)

2)

14 VEGACAP

bar

63

VEGACAP 42:

up to 16 bar

0

-10

bar

63

25

0

-10

100

˚C

100

Temperature

adapter

1)

Temperature adapter of PA up to 150°C, from

100°C unpressurized

Flange plated

5

6

200

˚C

Page 15

Product description

Mechanical connection, Aluminium

(VEGACAP 97, 98: PP)

Isolation

VEGACAP

11 - 7 8 - -

21 7-8-8

26 - - 8 - 8

27 - - 8 - 8

31 - 7 8 - -

33 - - 8 - -

34 unpressurized - - - 7 -

35 - - - 7 -

42 - - 8 - -

52 - - 8 - -

53 - - - 7 -

82 unpressurized - - 9 - -

84 unpressurized

92 - - 9 - -

97 - 7 - - -

98 - 7 - - -

PE

PP

PTFE

PE/PA 12

PFA

bar

16

0

-30

60 80

VEGACAP 34, 97, 98

unpressurized

˚C

7

8

bar

16

0

-30

VEGACAP 82, 82 R ExS: unpressurized

VEGACAP 92: up to 6 bar

bar

6

-20

0

100

˚C

100 150

˚C

Temperature

adapter

9

1)

0

StSt: up to -50°C

Steel: up to -10°C

100

200

with separate

housing

10

300

400

°C

High-temperature electrode

Isolation

VEGACAP

60 11

Ceramic

bar

10

-10

-50

61 11

Instruments with StEx approval

Mechanical connection, steel (St 37) or

1.4571 (StSt)

Isolation

VEGACAP

PP

PTFE

bar

40

0

-20

1)

Temperature adapter of PA up to 150°C, from

80

˚C

60

100°C unpressurized

11

11 R ExS 10 9

31 R ExS 10 9

82 R ExS unpressurized - 9

VEGACAP 15

Page 16

Mounting

1.6 Approvals

StEx (Zone 10)

Level detection

Instrument Oscillator Level switch Certificate

Capacitive VEGACAP E30 R ExS Signal conditioning in- BVS no. 95.Y.8001

11 R ExS.- strument not required,

31 R ExS.- compact instrument

82 R ExS.-

16 VEGACAP

Page 17

Mounting

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

2 Mounting

2.1 Mounting instructions

Plate electrode

Install the plate electrode (VEGACAP 82, 92)

General

Generally, the instrument can be mounted in

any desired orientation. The instrument must

simply be mounted such that the electrode is

such that the electrode is flush to the vessel

wall. The wall thickness of the vessel should

not exceed 20 mm. Chamfer the inner edge

of the hole so that build-up can be avoided.

at the height of the requested switching point.

Various mediums and measurement specifications require different types of installation.

Shortening of the electrode

Hence, some instructions should be noted.

Rod electrodes

Fully insulated electrodes have fixed dimen-

Length of the electrode

Note at the time of ordering electrodes for

vertical installation, that the electrode must be

sions and thus must not be modified in their

dimensions. Any modification will destroy the

instrument.

immersed to the requested level according to

the electrical properties of the medium.

All partly insulated electrodes can be short-

ened, see 5.5 Shortening of the electrode.

Note that the switching point of vertically

installed, adjustment-free electrodes (VEGACAP 27, 35, 98) can vary in the range of

the active part.

The measuring probes are compensated to

the respective electrode length with the fac-

tory setting. If the electrode is to be short-

ened by more than 30 %, you should

recompensate the electrode. Call our service

department.

Lateral load

Make sure that the electrode is not subjected

to strong lateral forces. Mount VEGACAP at a

position in the vessel where no interferences

such as from e.g. stirrers, filling openings

etc. can occur (see fig. 2.1).

1

0

Fig. 2.1

VEGACAP 17

1

0

Cable electrodes

The cable electrodes VEGACAP 31, 33, 34

and 35 can be shortened afterwards (see fig.

2.2). See 5.5 Shortening of the electrode.

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

Fig. 2.2

Page 18

Mounting

Extracting forces

In case of strong extracting forces e.g. due

to material inflow, high tensile loads can be

caused.

In this case use for short meas. distances a

rod electrode, as generally a rod is more

stable. If due to the length or the installation

position a cable electrode should be necessary, the electrode should not be fixed but

just provided with a gravity weight, as the

cable can more easily follow the product

movements. Make sure that the electrode

cable does not touch the vessel wall.

Fasten the gravity weight of VEGACAP 35

with a plastic cable.

Pressure

In case of excess or low pressure in the

vessel, the mounting boss must be sealed on

the housing. Use the attached seal ring.

Check whether the seal ring is resistant

against the medium.

Isolating measures such as e.g., the covering of the thread with Teflon tape, can interrupt the necessary electrical connection in

metal vessels. In such case earth the electrode with an additional cable connection to

the vessel.

Aluminium vessel

In case of Aluminium vessels, an electrode

with steel thread should be used. The combination Aluminium on Aluminium should be

avoided, as the thread "seizes“ and cannot

be removed after some time without damage.

Horizontal mounting

The electrode can be mounted horizontally to

achieve an exact switching point for level

detection. We recommend mounting the

electrode approx. 20° inclined to the bottom

so that build-up is avoided (see fig. 2.4).

a.

Fig. 2.4

b.

20˚

Sheet

0

1

Moisture

When mounting outside, on cooled vessels or

in humid areas where the cleaning is done,

e.g. with steam or high pressure, the sealing

of the cable entry is very important. Use

cable with sufficient conductor cross-section

and tighten the cable entry very securely. For

cables with insufficient conductor crosssection, an appropriate reduction insert must

be used to ensure tightness.

Two different seal rings are attached to the

instrument to also enable reliable sealing of

cables with smaller diameter in the cable

entry. Use the smallest possible seal ring.

Turn the cable entries of the instrument downwards to avoid moisture ingress. For this

purpose the housing can be rotated by

approx. 330°. For vertically installed electrodes loop the connection line to the instrument housing downwards so that rain and

condensation water can drain off (see fig.

2.5).

18 VEGACAP

Page 19

Mounting

Fig. 2.5

Metal vessels

Make sure that the mechanical connection of

the instrument to the vessel is electrically

conductive, in order to ensure sufficient

grounding.

Use conductive seals such as e.g. copper,

lead etc. Isolating measures such as covering the thread with Teflon tape can interrupt

the necessary electrical connection. In this

case use the earth terminal on the housing to

connect the instrument to the vessel wall.

Non-conductive vessels

In non-conductive vessels, e.g. plastic tanks,

the second pole of the capacitor must be

provided separately, e.g. by a concentric

tube or earth rod.

Under ideal ground conditions (e.g. short

electrodes) the earth plates or concentric

tube can be omitted.

If the filling medium has not been grounded

separately (VEGACAP 27 and 35) and the

electrode is covered with a conductive. adhe-

sive medium (up to the mounting boss), the

full signal is triggered only when the medium

touches the threaded mounting boss and

gets grounded. With vertically installed sen-

sors therefore, a provision for grounding the

filling medium should be made.

Filling opening

Install the electrode such that it does not

protrude directly into a strong filling stream.

Should such a mounting location be neces-

sary, mount a suitable sheet metal cover

above or in front of the electrode e.g. L 80 x 8

DIN 1028, etc. (see fig. 2.4 a).

In abrasive solids, mounting acc. to fig. 2.4 b

has proven to be a good solution. A material

cornice forms on the concave protective

sheet, thus preventing unnecessary wear of

the sheet.

Mounting boss

Install the rod electrode (VEGACAP 11, 21,

26, 97) such that the electrode protrudes into

the vessel. When installed in a tube or a

socket, build-up can be caused which can

influence the measurement. This is particu-

larly true for viscous or adhesive products

(see fig. 2.6).

In case of longer sockets, use an electrode

for adhesive products (VEGACAP 26, 27, 35,

97, 98) or a screening tube.

When using a standard electrode, a suitable

earth plate is necessary. For this purpose

provide the largest possible earth plate, e.g.

wire braiding laminated into the vessel wall or

a metal foil glued to the vessel. Connect the

max. 80 mm

0

1

earth plates with the earth terminal on the

instrument housing (or on the hexagon).

Fig. 2.6

VEGACAP 19

Page 20

;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;

;;

;;;;;

;;;;;;;;;;;

Mounting

Material cone

Note when installing the electrodes in the

vessel that material cones can form in solids,

thus changing the switching point. We recommend selecting a mounting location where

the electrode detects an average value of the

material cone.

The measuring probe must be installed at a

location which takes the filling and emptying

apertures of the vessel into account. To compensate meas. errors caused by the material

cone, you should install the electrode at a

distance of approx. d/10 from the vessel wall.

You should keep a min. distance of approx.

20 cm (see fig. 2.7 and 2.8).

Filling

Emptying

Fig. 2.7 Material cone, filling and emptying centered

Filling Emptying

3

10

d

d

1

2

1 Emptying

2 Filling opening

3 Capacitive

electrode

Fig. 2.8 Material cone, filling centered, emptying

lateral

20 VEGACAP

Page 21

Electrical connection

3 Electrical connection

3.1 Connection instructions

Danger

Switch off the power supply before starting

connection work.

The electrical connection must be carried out

in accordance with the integrated oscillator

version. Connect mains voltage acc. to the

following connection plans.

Note

Give attention when replacing the housing

cover that the inspection glass is above the

control lamp (LED).

Note

If strong electromagnetic interference is expected, we recommend the use of screened

cable. The screening of the cable should only

be earthed only on the sensor end (electrode).

As a rule, connect VEGACAP with vessel

ground (PA). To do this, use the ground terminal on the housing (VEGACAP 27, 35 and

98) or the thread on the hexagon surfaces of

the mounting boss (screw

M4 x 5). On VEGACAP 97 terminal 3 must be

connected. This connection is used to draw

the ground potential as well as to drain off

electrostatic discharge.

1

2

3

1 Housing cover

2 Oscillator, e.g. CAP E30

3 Housing

3.2 Connection plan

Non-contact switch (CAP E30 C)

123

AC L1 N Earth

DC + –

or

DC – +

Voltage supply: 20 … 250 V AC,

50/60 Hz; 20 … 250 V DC (for further infor-

mation see technical data)

VEGACAP 21

Page 22

Electrical connection

For direct control of relays, contactors, magnetic valves, signallers, horns etc. It must not

be operated without connected load (connected in series) as the oscillator would be

destroyed if directly connected to mains. Not

suitable for connection to low voltage PLCinputs. The domestic current is briefly lowered below 1 mA when switching off the load,

so that contactors, the holding current of

which is lower than the permanently flowing

domestic current of the electronics, nevertheless can be switched off reliably.

Floating transistor output (CAP E30 T)

-

2

1

3 4+5

Voltage supply: 10 … 55 V DC

(for further information see the following

switching examples as well as the technical

data)

Switching examples

+- +

-

- +- +

2

1

3 4 5

+

NPN action PNP action

-

+

2

1

3 4 5

+

-

+

The transistor switches a second voltage

source with the same reference potential to

the binary input of a PLC or to an electrical

load. Through different connection of the

consumer (load), PNP or NPN action can be

preset.

+- +

1

2

-

3 4 5

2

1

3 4 5

2

1

3 4 5 123 4 5

-

--

+

+

NPN action PNP action

+

-

+

The transistor switches a second, galvanically separated voltage source to the binary

+

NPN action PNP action

-

+

-

input of a PLC or to an electrical load.

Through different connection of the consumer

(load), PNP or NPN action can be preset.

The transistor switches the supply voltage of

the oscillator to the binary input of a PLC or to

an electrical load. Through different connection of the consumer (load), PNP or NPN

action can be preset.

22 VEGACAP

Page 23

Electrical connection

Control of alternating current loads

- +

2

1

3 4 5

~

+

-

~

The transistor switches a galvanically separated alternating voltage 10 … 42 V AC to a

load.

- +

123 4 5

~

~

Floating relay output (CAP E30 R)

Relay output

Power supply

Voltage supply: 20 … 250 V AC,

50/60 Hz; 20 … 72 V DC (for further informa-

tion see technical data)

Is used to switch external voltage sources to

relays, contactors, magnet valves, signallers,

horns etc.

Floating relay output (CAP E31 R)

+

-

L1

N

123456

78

Relay output

Relay output

Power supply

The transistor switches an alternating voltage

10 … 42 V AC, which is also supply voltage,

to a load.

Voltage supply: 20 … 250 V AC,

50/60 Hz; 20 … 72 V DC (for further informa-

tion see technical data)

Note

The transistor outputs of several VEGACAP

can be switched in series or in parallel to

connect the signals logically. The wiring must

be done so that terminal 2 has a higher volt-

In conjunction with oscillator CAP E31 R, the

measuring probes VEGACAP 27, 35 and 98

are adjustment-free and suitable for adhesive

products.

age than terminal 3.

With double relay (DPDT), i.e. both relays

carry out the same switching function, e.g.

simultaneous control of a horn and a magnet

valve.

VEGACAP 23

Page 24

4 Setup

Setup

4.1 Adjustment elements

Oscillator CAP E30

1

1

6

1 - Type plate (oscillator)

2 - Control lamp (LED)

3 - Terminals

4 - A/B-switch

5 - Potentiometer

6 - Changeover switch

Fig. 4.1

The switching mode of the electronics can be

checked with closed housing (2) (only plastic

housing) see "4.3 Functions chart“. To adjust

VEGACAP, loosen the four screws on the

instrument top with a screwdriver and remove the housing cover.

2

3

5

4

With the potentiometer (5) and the changeover switch (6) you can modify the switching

point of the electrode or adapt the sensitivity

of the electrode to the electrical properties of

the medium and the conditions in the vessel.

This is necessary so that the level switch can

reliably detect e.g. products with very low or

very high dielectric constant (DK = dielectric

constant).

On the oscillator CAP E31 R, this adjustment

is not necessary.

Capacitance range

(oscillators CAP E30 C, R, T)

- range 1 0 … 20 pF sensitive

- range 2 0 … 85 PF …

- range 3 0 … 450 pF insensitive

Examples of DK values:

Air = 1, Oil = 2, Acetone = 20, Water = 81 etc.

Turn the potentiometer anticlockwise to increase the sensitivity of the electrode.

Note

When positioning the housing cover, make

sure that the inspection glass is above the

control lamp (LED).

The following adjustments are possible on

oscillator CAP E30:

- A/B-mode

- switching point adjustment

- range selection.

With the A/B-switch (4) you can change the

switching mode of the non-contact switch

(C), the relay (R) or the transistors (T). You

can thus adjust the requested mode acc. to

"4.3 Functions chart“.

A - Max. detection or overfill protection,

B - min. detection or detection against dry

running of pumps.

24 VEGACAP

Page 25

Setup

4.2 Switching point adjustment

With the A/B-switch (4) you can choose the

mode of VEGACAP - whether the level switch

should be used as max. detection A (overfill

protection) or min. detection B (protection

against dry running of pumps). As a rule, the

switching point adjustment is only possible in

assembled condition. The numbers in

parantheses relate to figure "4.1 Adjustment

elements“.

Horizontally mounted electrodes,

electrodes for adhesive products, plate

electrodes, angled electrodes

(with oscillator CAP E30…, fig.

(VEGACAP 11, 21, 26, 60, 61, 82, 84, 92, 97)

Mode A /

• Make sure that the test switch (outside on

the housing - option) is set to position 0.

• Set the A/B-switch (4) to mode A

• Set the changeover switch (6) to position 1.

• Make sure that the electrode is uncovered.

• Turn the potentiometer (5) to 0; the control

lamp (2) lights

• Turn the potentiometer (5) very slowly

clockwise until the control lamp extinguishes

switching point. If the lamp does not extinguish

the next higher stage and repeat the adjustment with the potentiometer until the

control lamp extinguishes

• Note the position of the potentiometer (5).

In some cases the lowest range (range 1 =

highest sensitivity) is not sufficient to adjust

the full switching point. This would require

another filling procedure.

For this reason, we recommend adjusting

and noting the empty switching point in all

three ranges.

[mode B]

[extinguishes]

[lights]

, to determine the empty

[light]

, set the changeover switch to

4.1

.

[lights]

)

[B]

.

.

- Set the changeover switch (6) to the next

higher position and repeat the adjustment. Note the value for the next higher

range.

Empty Full

adjustment adjustment

Range 1

Range 2

Range 3

- Set the changeover switch (6) to the

lowest range where the control lamp

extinguishes

• Fill the vessel until the electrode is completely covered.

• Turn the potentiometer (5) very slowly

clockwise until the control lamp extinguishes

potentiometer (5). We recommend documenting the value of the empty and full

switching point as well as the range.

• If the lamp does not extinguish

the changeover switch (6) to the next

higher stage and repeat the adjustment

with the potentiometer until the control lamp

extinguishes

• Set the potentiometer (5) to the average

value of the two noted values.

The measuring system is now ready for

operation.

• If you cannot find the full switching point in

one of the ranges, we recommend setting

the changeover switch (6) to the lowest

range in which you have found the empty

switching point. Set the potentiometer (5) to

the average value between empty switching point and 10.

[lights]

.

[lights]

. Note the position of the

[lights]

.

[light]

, set

VEGACAP 25

Page 26

Setup

Vertically mounted electrodes

(with oscillator CAP E30…, fig. 4.1

(VEGACAP 11, 21, 31, 33, 34, 42, 52, 53, 60,

61)

Mode A

(Max. detection)

• Make sure that the test switch (outside on

the housing - option) is set to position 0.

• Set the A/B-switch (4) to mode A.

• Set the changeover switch (6) to position 1.

• Fill the vessel to the requested level.

• Turn the potentiometer (5) to 10; the control

lamp (2) extinguishes.

• Turn the potentiometer (5) very slowly

anticlockwise until the control lamp (2)

lights. If the control lamp does not light, set

the changeover switch (6) to the next

higher stage and repeat the adjustment

with the potentiometer until the control lamp

lights. The measuring system is ready for

operation.

Mode B

(Min. detection)

• Make sure that the test switch (outside on

the housing - option) is set to position 0.

• Set the A/B-switch (4) to mode B.

• Set the changeover switch (6) to position 1.

• Lower the product down to the requested

min. level.

• Turn the potentiometer (5) to 0; the control

lamp (2) extinguishes.

• Turn the potentiometer very slowly clockwise until the control lamp (2) lights. If the

control lamp does not light, set the

changeover switch (6) to the next higher

stage and repeat the adjustment with the

potentiometer until the control lamp lights.

The measuring system is ready for operation.

)

Adjustment-free electrodes for adhesive products

(with oscillator CAP E31 R, fig. 4.2)

3

6

2

1

4

5

1 - Type plate (oscillator)

2 - Control lamp (LED)

3 - Terminals

4 - A/B-switch

5 - Potentiometer

6 - Strap

Fig. 4.2

In general, the measuring probes VEGACAP

27, 35 and 98 (up to max. 3 m) in conjunction

with oscillator CAP E31 R no longer require

adjustment (see exceptions on the following

pages). The vessel must not be filled for the

adjustment.

With the A/B-switch (4) you can choose the

mode of VEGACAP, whether the level switch

should be used as max. detection A (overfill

protection) or as min. detection B (protection

against dry running of pumps).

These measuring probes have an active

length and a screening segment. Due to this

screening segment, the standing capacitance caused by the vessel after the installation of the electrode is almost completely

compensated.

26 VEGACAP

Page 27

Setup

The oscillator is factory-adjusted to the basic

capacitance of the electrode. The relay output switches when the active part of the electrode is covered. Varying dielectric constants

of products, such as e.g. in mixing vessels

have no effect on the switching accuracy

within the active length. The selection of the

electrode length is thus very important since

the length determines the switching point

which cannot be shifted on the electrode

(exception: the electrode of VEGACAP 35

can be shortened).

The electrodes can be fabricated with different high-resistance insulating materials and

are thus suitable for corrosive products (see

also "1.2 Types and versions“).

The electrodes VEGACAP 27, 35 and 98 are

also unaffected by buildup.

Exceptions

In rare cases, e.g. in pipelines or when the

electrode is mounted very close to the vessel

wall or where high standing capacitances

exceed the preadjustment of VEGACAP, it

can happen that the electrode signals overfilling (covered) even if the electrode is uncovered. The oscillator of VEGACAP must be

readjusted.

In the following cases, a new adjustment is

necessary:

- in case of electrodes with a length of more

than 3 m

- in case of cramped installation conditions

with high standing capacitance (pipes

etc.),

- in products with a very low dielectric constant

- after shortening of the cable electrode

VEGACAP 35 by more than 0.5 m,

- after exchange of the oscillator.

New adjustment

• Make sure that the electrode is uncovered.

• Push through the adhesive cover, as on

figure 4.3, with a screwdriver.

• Turn the potentiometer first anticlockwise

until the control lamp signals the condition

„covered“ (max. 20 turns).

- mode A (overfill protection) control lamp lights

- mode B (dry run protection) control lamp extinguishes

If this condition has already been reached,

continue with the following item.

• Turn the potentiometer very slowly (due to

the integration time) clockwise until the

control lamp signals the condition „uncovered“:

- mode A (overfill protection) control lamp extinguishes

- mode B (dry run protection) control lamp lights

• Then turn the potentiometer clockwise acc.

to the following table. The instrument is

ready for operation

Sensitivity

Standard very

sensitive

VEGACAP DK ³ 2 DK ³ 1.5

27, 98 2.0 turns 1 turn

VEGACAP DK ³ 1.5

35 2.5 turns

Fig. 4.3

VEGACAP 27

Page 28

Note

For the measurement of products with very

low dielectric constant, the number of turns

can be reduced to 1. Note, however, that this

adjustment is too sensitive for conductive,

adhesive products.

Note

Make sure when positioning the housing

cover that the inspection glass is above the

control lamp (LED).

Setup

28 VEGACAP

Page 29

Setup

5

(8)

3

(6)4(7)

4.3 Functions chart

The following chart gives a survey on the switching conditions dependent on the adjusted

mode and level.

Level Switching condition Control

CAP E30 C CAP E30 R CAP E31 R CAP E30 T lamp

Mode A Transistor

6

4

(7)5(8)

21

3

(9)

(6)4(7)

Switch Relay Relay

closed energized energized

6

4

(9)

(7)5(8)

21

Relay Relay

Switch open deenergized deenergized

Mode B Transistor

4

21

(7)5(8)

3

6

(6)4(7)

(9)

Switch Relay Relay

closed energized energized

4

(7)5(8)

21

Relay Relay

(6)4(7)

(9)

3

6

Switch open deenergized deenergized

Failure of the individual Transistor

supply blocks

voltage

4

(7)5(8)

21

Relay Relay

3

6

(6)4(7)

(9)

Switch open deenergized deenergized

5

(8)

5

(8)

5

(8)

(8)

conductive

Transistor

blocks

conductive

Transistor

blocks

5

VEGACAP

VEGACAP 29

Page 30

5 Diagnostics

Diagnostics

5.1 Simulation

Test switch (option with E30 R, C, T)

As an option, a test switch can be integrated

in the housing to simulate a switching condition.

By turning on the test switch, an additional

capacitance is provided. Through this, the

function of the oscillator and the connected

instruments can be tested.

The numbers in parantheses relate to the

illustration "Adjustment elements“.

Note

When the changeover switch (6) is set to

position 3, it is possible that the additional

capacitance is not sufficient to carry out a

test.

The test switch can only be used for simulation of a max. level (overfill protection).

Test

• Make sure that the A/B-switch (4) is set to

position A. In normal operation, the test

switch is set to position 0.

• Set the test switch to position 1. Turning the

test switch to position 1 increases the capacitance of the uncovered electrode,

causing the oscillator to respond and trigger an alarm signal; the control lamp (2)

lights and the connected instruments are

activated.

Note

It is absolutely necessary to set the test

switch to its initial position (position 0) after

the test.

5.2 Maintenance

The instrument is maintenance free.

5.3 Repair

Repair work usually involves opening the

instrument to diagnose and correct defects.

For safety and warranty reasons, any internal

work on the instrument, apart from installation

and wiring, must be carried out only by

VEGA personnel.

In case of a defect, please return the respective instrument with a short description of the

error to our repair department.

1

0

Fig. 5.1

30 VEGACAP

Page 31

Diagnostics

5.4 Exchange of electronics

• Loosen the four screws with a screwdriver

and open the housing cover.

• Loosen the two screws and remove the old

electronics.

• Insert the new oscillator.

• Carry out an adjustment. The instruction is

given under "4.2 Switching point adjustment“.

5.5 Shortening of the electrodes

Shortening of the electrode

Rod electrodes

Fully insulated electrodes have fixed dimensions and must therefore not be modified in

their dimensions. Any modification will destroy the instrument.

All partly insulated electrodes can be shortened. The measuring probes are compensated to the appropriate electrode length with

the factory setting. If the probe is shortened

by more than 30 %, it should be recompensated. Call our service department.

Cable electrodes

The cable electrodes VEGACAP 31, 33, 34

and 35 can be shortened afterwards.

• Shorten the electrode cable with a metal

cutting saw or a cutting-off wheel. Insulated

cable must not be tinned since it cannot

come unravelled.

• Insert the cable into the hole of the gravity

weight (insulated cables: with the insulation) and clamp the cable with the two set

screws. With insulated electrode cable, the

tips of the two set screws must penetrate

the cable insulation to ensure contact of the

gravity weight with the metal cable.

• Carry out an adjustment. The instructions

can be found under "4.1 Adjustment“.

If the cable is shortened considerably, it may

not be possible to carry out an adjustment

with the measuring probe. In this case, the

measuring probe must be recompensated.

Note the serial number of the measuring

probe and call one of our technicians.

Instructions for shortening VEGACAP 31,

33 and 34

• Loosen the two set screws on the gravity

weight (hexagon socket) and remove

them.

• Pull the cable out of the gravity weight.

• To avoid fraying the steel cable during

cutting, you must tin the cable approx.

5 cm around the cutting position with a

soldering iron or blowtorch, or tightly bind

the cable together with a wire.

VEGACAP 31

Page 32

Instructions for shortening VEGACAP 35

VEGACAP 35 can be shortened by any

amount. Recompensation is not necessary

(see fig. 5.2)

If the measuring probes are shortened by

more than 0.5 m, an empty adjustment must

be carried out. The instructions can be found

under „4.2 Switching point adjustments/New

adjustment“.

• Loosen the outer set screw (8).

• Unscrew the lower part of the weight (7).

• Shift the upper part of the weight (1), the

four O-rings (2) and the isolating socket

(3) on the cable upward above the planned

cutting point.

• Remove the isolating sleeve (6) from the

terminal bush (4).

• Loosen the two set screws (5) on the terminal bush (4) and pull out the cable.

• Shorten the electrode cable with a metal

cutting saw or a cutting-off wheel to the

requested length.

• Shorten the cable insulation by 60 mm with

a sharp knife.

• Push the terminal bush (4) onto the cable

(with the chamfered side first) with a rotating movement.

Make sure that the cable is flush with the

lower side of the terminal bush (4).

• Fasten the cable with the two set screws

(5).

Make sure that the screen of the electrode

cable has no contact to the inner steel

cable.

• Push the isolating sleeve (6) onto the terminal bush (4).

• Slide the upper part of weight (1) back

against the lower part of weight (7) and

screw the two parts together.

• Secure the upper part of weight (1) with

the outer set screw (8).

• Carry out an adjustment. The instructions

can be found under "4.2 Switching point

adjustment“.

1 Upper part of weight

2 O-rings

3 Isolating socket

4 Terminal bush

5 Set screws

6 Isolating bushing

7 Lower part of weight

8 Set screw

Fig. 5.2

Diagnostics

1

8

2

3

4

5

6

7

32 VEGACAP

Page 33

Diagnostics

5.6 Failure rectification

Failure Measure, failure rectification

No function or Make sure with Ex-systems that the Ex-protection is not influenced by

defective switching the meas. instruments.

function Check the following possible causes of failure:

- shortcircuit

- sensor not correctly connected

- sensor line interrupted

- supply voltage too low

Push the A/B-switch on the oscillator. The relay output of VEGACAP

switches and the control lamp (LED) changes condition. If the relay

output does not switch, the sensor, or rather the oscillator, is defective.

Reed

contact

C

K

Screen

3

4

7

1

6

C

C

M

1MΩ

T

CAP E30 R

CT - Test capacitor

CM - Meas. capacitor

CK - Compensation capacitor

VEGACAP 33

Page 34

Diagnostics

C

PH

7

3

1 MΩ

4

1M

6

C

M

CAP E31 R

CM - Meas. capacitor

CPH- Phase shifting capacitor

Check the internal connections:

• Remove the housing cover.

• Loosen the three screws with a screwdriver and remove the oscillator

from the housing.

• Measure with an ohmmeter (range MW) the resistance values be-

tween the following contacts:

Contact 4 to middle pin (1)

The resistance must be 1 MW.

If the resistance is less, it means there is moisture in the housing or a

failure of the electrode insulation. A possible reason could be a

noninsulated electrode which is used in conductive (moist) product.

If the resistance is higher or if the connection is interrupted, the reason

is usually a bonding failure in the adapter plate or a resistor defective

due to strong electrostatic discharge.

In both cases, the measuring probe must be repaired by VEGA.

34 VEGACAP

Page 35

Diagnostics

Contact 4 to vessel

The electrical connection between contact 4 and the metal vessel (not

mounting boss or electrode flange) should be as good as possible.

Measure with an ohmmeter (range very low) the resistance value between contact 4 and the vessel.

• Shortcircuit (0 … 3 W), optimum connection

• Resistance > 3 W

- corrosion on the mounting boss or flange

- possibly the mounting boss was covered with Teflon tape or

something similar

Check the connection to the vessel. If there is no connection, you can

connect a line from the external grounding terminal to the vessel.

Make sure that coated flanges are always connected via the earth

terminal to the vessel.

Contact 7 to middle pin (1)

The resistance must be infinite (>10 MW).

If the resistance is less, moisture has entered, or the compensation

capacitor or the phase shifting capacitor (CAP E31R) are defective.

Contact 3 to 4

On electrodes without screen the resistance is infinite (>10 MW). On

VEGACAP 26, 27, 35 and 98 the resistance must be 1 MW. In case of

lower values, the electrode insulation is defective or moisture entered

the instrument housing.

In case of higher values, a bonding failure in the adapter plate or a

defective resistor is likely the cause.

If you cannot detect a failure in the measuring probe, exchange the

oscillator with one of the same type (if available) or return the probe for

repair to VEGA.

If the failure does not disappear after inserting the new oscillator, you

have to carry out a new adjustment (because of production tolerances

of the oscillators).

Note:

Make sure when positioning the housing cover that the inspection glass

is above the control lamp (LED).

VEGACAP 35

Page 36

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alterations

2.17 610 / September 2000

Loading...

Loading...