Page 1

r

USER'S GUIDE

Combined Wind Senso

WMS301 and WMS302

M210375en-A

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.):+358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pa ge s at http://www.vaisala.com/

© Vaisala 2002

No part of this manual may be reproduced in any form or by any

means, electronic or mechanical (including photocopying), nor may its

contents be communicate d to a third party without prior written

permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations f or Vaisala towards the customer or end user. All legally

binding commitme nts and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

___________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION.......................................................3

About This Manual..................................................3

Contents of This Manual.......................................3

Version Information...............................................4

Feedback..............................................................4

Safety.......................................................................4

General Safety Considerations.............................4

Product Related Safety Precautions.....................5

ESD Protection.....................................................5

Regulatory Compliances........................................6

Warranty..................................................................6

CHAPTER 2

PRODUCT OVERVIEW.............................................................7

Introduction to WMS Series Wind Sensors..........7

Product Nomenclature ...........................................9

CHAPTER 3

INSTALLATION ......................................................................11

Selecting Location................................................11

Connector..............................................................12

Installation Procedure..........................................14

Initial Check........................................................14

Mounting.............................................................16

Mounting Sensor to the Wind Sensor Mast....16

Mounting to a Pole Mast with WMS30KIT......17

Aligning the Sensor.............................................19

CHAPTER 4

MAINTENANCE......................................................................21

Periodic Maintenance...........................................21

Testing Proper Operation ...................................21

Replacing Consumables.....................................21

Parts List for Consumables.................................24

VAISALA___________________________________________________________1

Page 4

User's Guide ________________________________________________________

CHAPTER 5

TROUBLESHOOTING............................................................25

Common Problems .............................................. 25

Technical Support................................................25

Return Instructions.............................................. 26

CHAPTER 6

TECHNICAL DATA.................................................................27

Specifications....................................................... 27

Dimensions........................................................... 29

MTBF .....................................................................29

MTTR .....................................................................29

List of Figures

Figure 1 WMS Series Combined Wind Sensor.......................8

Figure 2 Recommended Mast Location in Open Area..........11

Figure 3 Recommended Mast Length on the Top of

a Building ...............................................................12

Figure 4 WMS301 Connector............................................... 13

Figure 5 WMS302 Connector............................................... 13

Figure 6 WMS301 Principal Circuit Diagram........................ 14

Figure 7 WMS302 Principal Circuit Diagram........................ 15

Figure 8 WMS302 Factory Alignment (Models with the

Alignment Sleeve)..................................................15

Figure 9 Mounting of the Combined Wind Sensor................ 16

Figure 10 WMS301/WMS302 Installation with WMS30KIT.... 18

Figure 11 Aligning the Combined Wind Sensor......................19

Figure 12 WMS Assembly...................................................... 23

Figure 13 Dimensions (in mm) of the Combined Wind

Sensor....................................................................29

List of Tables

Table 1 Manual Revisions.....................................................4

Table 2 WMS Series Wind Sensor Nomenclature................. 9

Table 3 Available Spare Parts............................................. 24

Table 4 Some Common Problems and their Remedies......25

Table 5 Anemometer Specifications....................................27

Table 6 Vane Specifications................................................28

Table 7 Common Specifications..........................................28

2 ______________________________________________________ M210375en-A

Page 5

Chapter 1 ___________________________________________General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the product.

About This Manual

This manual provides information for installing,

maintaining, and troubleshooting WMS301 and WMS302

Combined W ind Sensor.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides gen eral notes

for the product.

- Chapter 2, Product Overview, introduces the W M S301

and WMS302 Com bined Wind Sensor features.

- Chapter 3, Ins tallation, provides you with inform ation

that is inte nded to help you install the wind sensor.

- Chapter 4, Maintenance, provides informatio n that is

needed in basic maintenance of t he product.

- Chapter 5, Tro ubleshooting, describes common problems,

their probable ca uses and remedies, and contact

information.

VAISALA___________________________________________________________3

Page 6

User's Guide ________________________________________________________

- Chapter 6, Technical Data, provides the technical data of

WMS301 and WMS302 Combined Wind Sensor.

Version Information

Table 1 Manual Revisions

Manual Code Description

M010030en-C WMS301 & WMS302 Combined Wind

Sensors Quick Reference Guide

M210375en-A First version of the WMS301 and

WMS302 Combined Wind Sensor User's

Guide. Replaces the above mentioned

Quick Reference Guide.

Safety

Feedback

Vaisala Customer Documentation Team welcom es your

comments and suggestions on the quality and usefulness of

this publicati on. If you find errors or have other suggestions

for improvement, please indicate the chapter, section, and

page number. Y ou can send comments to us by e-mail:

manuals@vaisala.com

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

4 ______________________________________________________ M210375en-A

Warning alerts you to a serious hazard. If you do not read

and follow instructions very carefully at this point, there is

a risk of injury or even death.

Page 7

Chapter 1 ___________________________________________General Information

CAUTION

NOTE

WARNING

Caution warns you of a potential hazard. If you do not read

and follow instructions carefully at this point, the product

could be dama ged or important data could be los t.

Note highlights important information on using the product.

Product Related Safety Precautions

The device delivered to you has been tested for safety and

approved as shipped from the factory. Note the following

precautions:

Ground the product, and verify outdoor installation

grounding periodically to minimize shock hazard.

CAUTION

Do not modify the unit. Improper modificatio n can damage

the product o r lead to malfunction.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent

damage to electronic circuits. Vaisala products are

adequately protected agains t ESD for their intended use.

However, it is possible to dam a ge the produ ct by deliver i ng

electrostatic discharges when touching, removing, or

inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages

yourself:

VAISALA___________________________________________________________5

Page 8

User's Guide ________________________________________________________

- Handle ESD sensitive components on a properly

grounded and protected ESD w orkbench. When this is

not possible, ground yourse lf to the equipment chassis

before touching the boards. Ground yourself with a wrist

strap and a resistive connection cord. When neither of the

above is possible, touch a cond uctive part of the

equipment chassi s with y our other ha nd befo re to uc hin g

the boards.

- Always hold the boards by the edges and avoid touching

the component contacts.

Regulatory Compliances

The WMS301 and WMS302 sensors comply with the

following performance and environmental test standards:

Warranty

- Mechanical vibration test per 1EC-68-2-6 Fc

- RF field emissi on test per EN 55022 Class B

- Conducted immunity tests

- Electrostatic discharge EN61000-4-2

- RF field immunity EN6100-4-3

- Fast transient burst EN61000-4-4

For certain prod ucts Vaisala n ormally gives a l imited oneyear warranty. Please obser ve that any such warranty may

not be valid in case of damage due to normal wear and tear,

exceptional operating conditions, negligent handling or

installation, or unauthorized modifications. Please see the

applicable supply contract or Conditions of Sale for details

of the warranty for each product.

6 ______________________________________________________ M210375en-A

Page 9

Chapter 2 ____________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the WMS301 and WMS302

Combined Wind Sensor features.

Introduction to WMS Series Wind Sensors

WMS series wind sensors are compact sized instruments

with the wind sp eed and direction sensors integrated into

one unit. The sensor electronics is located inside a

watertight compartment providing full protection against

water, dust, pollutants, and electromagnetic interference.

The cup wheel shape, dimensions, and material have bee n

carefully designed to achieve maximum measurement

quality. The co nical cups have been tested to give linear

response between wind speed and angular velocity of the

cup wheel. The polyamide plastic reinforced with carbon

fiber guarantees a rigid structure even at the highest wind

speeds.

The anemometer ball bearing assembly is composed of a

wheel shaft, a pair of low friction ball bearings, a nd a shaft

fixed magnet. A reed relay with e lectronics located in the

body of the sensor converts the cup wheel rotation to pulses.

Therefore, when properly supplied the sensor can be read

practically with any data logger, either by counting the

number of pulses within a fixed time period or measuring

the time between successive trans ients. In the latter method

VAISALA___________________________________________________________7

Page 10

User's Guide ________________________________________________________

averaging of transient interval s should be used, since two

pulses with non-symmetric positioning are generated during

one revolution.

The balanced wind vane is integ rated in the housing,

underneath the cup wheel. The circular tail is located far

enough from the body and the cup wheel to avoid

turbulence due to these structures. The vane assembly is

made of PA reinforced with glass fiber providing durable

and lightweight structure with fast response and low inertia.

The angular position of the vane is detected using an axial

symmetric rotating potentiometer. The potentiometer

features low starting and running torque, linear arc-toresistance transfer ratio, and long operation life.

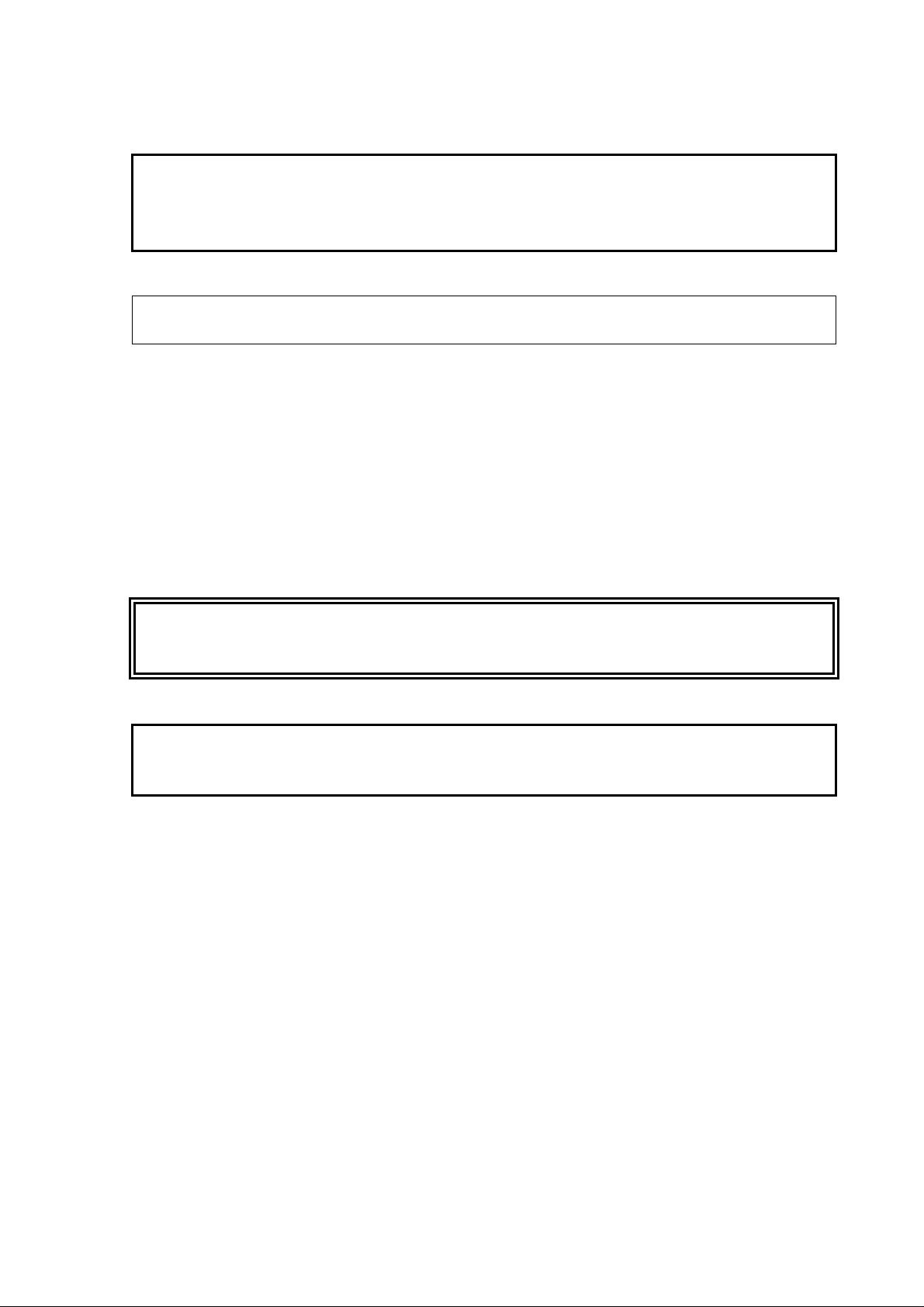

0212-220

Figure 1 WMS Series Combined Wind Sensor

The following numbers refer to Figure 1 above:

1 = The cup wheel assembly

2 = The vane assembly

3 = The sensor compartment

WMS301 is equipped with a one-wip e r type potentiometer

with an open gap of only 5 degrees. With constant voltage

applied to the potentiometer, the output voltage is directly

proportional to the azimuth angle.

8 ______________________________________________________ M210375en-A

Page 11

Chapter 2 ____________________________________________ Product Overview

WMS302 has a two-wiper type potentiometer to overc ome

the wind direction discontinuity. However, a more complex

voltage-to-direction conversion process is needed.

Product Nomenclature

Table 2 WMS Series Wind Sens or Nomenclature

Code Common Name

Basic

Options WMS30KIT Installation Accessories to be used

WMS301 Combined Wind Sensor with one

wiper potentiometer

WMS302 Combined Wind Sensor with two

wiper potentiometers

with pole masts

VAISALA___________________________________________________________9

Page 12

User's Guide ________________________________________________________

This page intentionally left blank.

10 _____________________________________________________ M210375en-A

Page 13

Chapter 3 __________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended

to help you install the wind sensor.

Selecting Location

Allow sufficient clearance for the wind sensor. Install the

wind sensor away from buildings or any other objects that

might affect the airf low.

0212-221

Figure 2 Recommended Mast Location in Open Area

VAISALA__________________________________________________________11

Page 14

User's Guide ________________________________________________________

In general, any object of height (h) will not rem a rkably

disturb the wind measurement at a minimum distance of

10 × h. There should be at least 150 m open area to all

directions from the mast. Refer to Figure 2 on page 11.

Connector

0212-222

Figure 3 Recommended Mast Length on the Top of a

Building

The recommended minimum length (h in Figure 3 above)

for the mast that is installed on the top of a building is 1.5

times the height of the building (H). When the diagonal (W)

is less than the height (H) the minimum length of the mast is

1.5 × W.

The WMS301 connector is shown in Figure 4 on page 13.

The WMS302 connector is shown in Figure 5 on page 13.

Type M12 female connector, for example, made by

Lumberg, Phoenix, or Binder is suitable for connecting the

cable to the sensor.

12 _____________________________________________________ M210375en-A

Page 15

Chapter 3 __________________________________________________ Installation

0212-223

Figure 4 WMS301 Connector

The following numbers refer to Figure 4 above.

1 = +Vref, voltage input

2 = DIR, signal output, wind direction

3 = GND, ground

4 = GND, ground

5 = SPD, signal output, wind speed

0212-223

Figure 5 WMS302 Connector

The following numbers refer to Figure 5 above.

1 = +Vref, voltage input

2 = DIR1, signal output, wind direction

3 = GND, ground

4 = DIR2, signal output, wind direction

5 = SPD, signal output, wind speed

VAISALA__________________________________________________________13

Page 16

User's Guide ________________________________________________________

A pull up resistor, for example, 10 kΩ, is needed at SPD

output to supply the anemometer electronics. It is

recommended to use a Schmitt-trigger input with the SPD

signal.

Installation Procedure

Initial Check

After you have unpacked the sensor, check for any signs of

shipping damage. Also test that the vane a nd cup wheel

rotate without friction.

Before installation, use an ohmmeter to check the proper

operation of speed (SPD ) and direction (DIR1 and DIR2)

outputs while rotating the cup wheel and vane slowly. For

measuring the direc tio n, note that 10 kΩ/360º and

10 kΩ/180° potentiometers are used with WMS301 and

WMS302 respectively. For the principal circuit diagrams,

refer to Figure 6 below and Figure 7 on page 15.

0212-224

Figure 6 WMS301 Principal Circuit Diagram

14 _____________________________________________________ M210375en-A

Page 17

Chapter 3 __________________________________________________ Installation

0212-225

Figure 7 WMS302 Principal Circuit Diagram

The WMS302 sensor is aligned at the factory according to

Figure 8 below. This factory alignment applies to all models

with the alignment sleeve. The alignment sleeve is secured

with a small size Allen bolt to the sensor body.

0212-226

Figure 8 WMS302 Factory Alignment (Models with

the Alignment Sleeve)

VAISALA__________________________________________________________15

Page 18

User's Guide ________________________________________________________

Mounting

Mounting Sensor to the Wind Sensor Mast

After a proper location for wind measurement has been

selected, you can mount the sen sor to the wind sensor mast.

The diameter of the wi nd sensor mast is 30 mm. To mount

the sensor, do the followi ng:

1. Fit the cable (number 2 in Figure 9 below) through the

mounting piece (3) and connect the cable to the sensor.

0212-227

Figure 9 Mounting of the Combined Wind

Sensor

2. Place the mounting piece (3) on t he top of the ma st and

align the tap (5) to north.

3. Align the n otch (4) to the ta p (5) and attach the sensor

to the mounting piece with the plastic collar (1).

16 _____________________________________________________ M210375en-A

Page 19

Chapter 3 __________________________________________________ Installation

4. Secure the mounting piece (3) to the mast by tightening

the mounting screw (6).

5. Route the sensor cable down along the mast and

always attach the cable to the mast with cable ties.

6. Mount the wind sensor mast firmly to a solid base, for

example, to a pole mast.

7. Connect the signa l cable to a data logge r or display

device.

Mounting to a Pole Mast with WMS30KIT

You can mount the wind sens or with a mast on the top of a

pole mast using WMS30KIT. When the mast is high, use a

combined wind sensor with a 10 m cable. You can mount

the wind senso r mast to a metallic or wooden mast.

WARNING

Do not install the wind sensor above the top of the

lightning protection rod.

To mount the wind sensor mast to a metallic mast, do the

following (the numbers refer to Figure 10 on page 18):

1. Install the plastic protective plate (5) between the mast

(6) and the mounting piece.

2. Attach the mounting piece to the mast (6) using the

large clamps.

3. Attach the wind sensor mast with the wind sensor (1)

to the mast (6) using the smaller clamps.

4. Secure the cable with the fixed cable tie ( 3) to the wind

sensor mast.

5. Route the sensor cable down along the mast and

always attach the cable to the mast with cable ties.

6. Connect the signa l cable to a data logge r or display

device.

VAISALA__________________________________________________________17

Page 20

User's Guide ________________________________________________________

1

2

6

5

3

4

2

3

0103-010

Figure 10 WMS301/WMS302 Installation with

WMS30KIT

The following numbers refer to Figure 10 above:

1 = WMS301 or WMS302

2 = Wood screws

3 = Cable tie

4 = Wooden mast

5 = Plastic protective plate

6=Pole mast

18 _____________________________________________________ M210375en-A

Page 21

Chapter 3 __________________________________________________ Installation

To mount the wind sensor mast to a wooden mast, do the

following (the numbers refer to Figure 10 on page 18):

1. Attach the mounting piece with the wood screws (2) to

the wooden mast (4) through the wind sensor mast.

2. Secure the cable with the fixed cable tie ( 3) to the wind

sensor mast.

3. Route the sensor cable down along the mast and

always attach the cable to the mast with cable ties.

4. Connect the signa l cable to a data logge r or display

device.

Aligning the Sensor

If you need to align the combined wind sensor, use the data

logger or display device to monitor the instant wind

direction. To align the combined wind sensor, do the

following (numbers refer to Figure 11 below):

1. Place the m ounting piece (2) on the top of the wind

sensor mast and attach the sensor to the mounting piece

(4) with the plastic collar (3).

0201-034

Figure 11 Aligning the Combined Wind Sensor

VAISALA__________________________________________________________19

Page 22

User's Guide ________________________________________________________

2. Choose a known wind direction reference point on the

horizon with the help of a compass.

3. Point the nose (1) of the vane at the reference point.

4. Hold the vane in position and slowly rotate the

mounting piece (4) until wind direction shows proper

value.

5. Secure the mounting piece (4) to the mast by tightening

the mounting screw.

20 _____________________________________________________ M210375en-A

Page 23

Chapter 4 ________________________________________________ Maintenance

CHAPTER 4

MAINTENANCE

This chapter provides information that is needed in basic

maintenance of the produc t.

Periodic Maintenance

Testing Proper Operation

It is recommended to check the ball bearings of the

anemometer and the vane every year. If the cup wheel or the

vane is not rotating smoothly or it creates detectable noise,

the bearings must be replaced.

Replacing Consumables

Only a trained technician should replace the bear ings.

If your sensor includes the alignment sleeve and the f actory

alignment ha s not been altered, you can simply remove and

remount the sensor to its plac e with the plast i c collar

without realigning.

VAISALA__________________________________________________________21

Page 24

User's Guide ________________________________________________________

To replace the ball bearings, do the following (the numbers

refer to Figure 12 on page 23):

Anemometer bearings:

1. Loosen the hubnut (14) with fingers or a 10 mm tool

and remove the cup w heel (13).

2. Remove the ball bearing assembly (12) by unscrewing

it counterclockwise (with a 10 mm tool).

3. Insert a new bearing assembly (12). Tighten gently.

4. Fasten the cup w heel to the sen sor. Tighten gently.

Vane bearings:

1. Proceed as described in steps 1 and 2 above.

2. Open the loc k screw (11) of the ta il assembly (10) and

remove the screw.

3. Remove the Seeger-ring (9) (with narrow point pliers).

4. Remove the bearing assembly (8).

5. Replace the bearings inside the housing with new ones.

6. Assemble the sensor in the reverse work order.

Note that part number 6 in Figure 12 on page 23 consists of

two parts. The lower portion has a notch that is aligned at

the factory in relation to the output of the potentiometer to

point north when the sensor is mounted.

The following numbers refer to Figure 12 on page 23:

1=Casing

2a = Reed switch PCB

2b = Potentiometer PCB

3 = Retainer

4=Sleeve

5 = O-ring

6= Base part

7 = Mast adapter sleeve

8 = Bearing assembly

9 = Seeger ring

22 _____________________________________________________ M210375en-A

Page 25

Chapter 4 ________________________________________________ Maintenance

10 = Tail assembly

11 = Lock screw

12 = Bearing assembly

13 = Cup wheel

14 = Hubnut

0009-022

Figure 12 WMS Assembly

VAISALA__________________________________________________________23

Page 26

User's Guide ________________________________________________________

Parts List for Consumables

Table 3 Available Spare Parts

Spare Part Order Code

Cup wheel assembly WA45233

Anemometer bearing assembly WA45232

Vane assembly WA35234

Set of bearings 25160WA

24 _____________________________________________________ M210375en-A

Page 27

Chapter 5 ______________________________________________Troubleshooting

CHAPTER 5

TROUBLESHOOTING

This chapter describes common problems, their probable

causes and remedies, and contact information.

Common Problems

Table 4 Some Common Problems and their

Remedies

Problem Probable Cause Remedy

The data is not

received from the

sensor.

The sensor is mechanically

damaged.

The sensor is not powered

properly.

Check the cables and

connectors.

Check that the supply voltage

is 3 to 15 VDC

Technical Support

For technical questions, contact the Vaisala technical

support:

E-mail helpdesk@vaisala.com

Telephone +358 9 8949 2789

Fax +358 9 8949 2790

VAISALA__________________________________________________________25

Page 28

User's Guide ________________________________________________________

Return Instructions

If the product needs repair, please follow the instructions

below to speed up the process and avoid extra costs.

1. Read the warranty information.

2. Write a Problem Report with the name and contact

information of a technically competent person who can

provide further information on the problem.

3. On the Problem Report, please explain:

- What failed (what w orked / did no t work)?

- Where did it fail (location and enviro nment)?

- When did it fail (da te, immediately / after a while /

periodically / randomly)?

- How many failed (only one defect / other same or

similar defects / several failures in one unit)?

- What was connected to the product and to which

connectors?

- Input power source type, voltage and l ist of other

items (lighting, heaters, motors etc.) that were

connected to the same power output.

- What was done when the failure was noticed?

4. Include a detailed return address with your preferred

shipping method on the Problem Report.

5. Pack the faulty product using an ESD protection bag of

good quality with proper cushioning material in a

strong box of adequate size. Plea se include the

Problem Report in t he same box.

6. Send the box to:

Vaisala Oyj

SSD Service

Vanha Nurmij ärventie 21

FIN-01670 Vant aa

Finland

26 _____________________________________________________ M210375en-A

Page 29

Chapter 6 _______________________________________________Technical Data

CHAPTER 6

TECHNICAL DATA

This chapter provides the tec h nic al data of WMS301 an d

WMS302 Com bined Wind Sensor.

Specifications

Table 5 Anemom e ter Specifications

Property Description/Value

Sensor / Transducer type Dual Reed switch

Measuring range 0.5 ... 60 m/s

Starting threshold < 0.4 m/s

Distance constant 2 m

Transducer output 1 Hz ~ 0.7 m/s

Accuracy

(≤ 10 m/s)

(> 10 m/s)

Transfer function, where

U = wind speed [m/s]

F = output frequency [Hz]

± 0.3 m/s

error < 2 %

U = - 0.24 + F × 0.699

VAISALA__________________________________________________________27

Page 30

User's Guide ________________________________________________________

Table 6 Vane Specifications

Property Description/Value

Sensor / Transducer type Potentiomet er

Measuring range

WMS302

WMS301

Starting threshold < 1.0 m/s

Damping ratio 0.3

Overshoot ratio 0.4

Delay distance 0.6 m

Accuracy

0 ... 360°

0 ... 355°

Better than ± 3°

Table 7 Common Specifications

Property Description/Value

Supply voltage 3 ... 15 VDC

Electrical connections 5-pin male with 12 mm

threads

Body material AlMgSi, gray anodized

Cup material PA, reinforced with carbon

fiber; black

Vane material PA, reinforced with glass fiber,

white

Operating temperature - 40 ... + 55 °C (-40 ... +131°F)

Storage temperature - 60 ... + 65 °C (-76 ... +149°F)

Dimensions 265 (h) × 360 (w) mm

(10.4 (h) × 14.2 (w) in)

Weight 360 g (12.7 oz)

28 _____________________________________________________ M210375en-A

Page 31

Chapter 6 _______________________________________________Technical Data

Dimensions

MTBF

MTTR

0212-228

Figure 13 Dimensions (in mm) of the Combined Wind

Sensor

The calculated mean time between failure is 4. 4 × 105 h for

permanent installations. The value equals to 2.27 when

expressed in a fail ure frequency during 10

Mean time to repair is 0.2 h.

6

hours of use.

VAISALA__________________________________________________________29

Page 32

*M210375

EN

*

www.vaisala.com

Loading...

Loading...