Page 1

Analog Wind Transmitter

WAT12

USER'S GUIDE

M210309EN-A

June 2002

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.):+358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2002

No part of this manual may be reproduced in any form or by any

means, electronic or mechanical (including photocopying), nor may its

contents be communicated to a third party without prior written

permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

___________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION.......................................................5

About This Manual..................................................5

Contents of This Manual.......................................5

Version Information...............................................6

Related Manuals...................................................6

Safety .......................................................................6

General Safety Considerations.............................6

Product Related Safety Precautions.....................7

ESD Protection .....................................................7

Regulatory Compliances........................................8

Warranty ..................................................................8

CHAPTER 2

PRODUCT OVERVIEW.............................................................9

Introduction to WAT12 Analog Wind

Transmitter ..............................................................9

CHAPTER 3

INSTALLATION ......................................................................11

Selecting Location................................................11

Installation Procedure ..........................................13

Jumper Settings..................................................14

Connections........................................................16

Sensor Wiring.................................................18

Signal Output..................................................19

Powering ........................................................21

Optional Heating Power..................................22

Wiring Examples ............................................23

Mounting the Thermostat Switch ........................26

Mounting.............................................................27

Mounting WAT12 to the Top of a Pole Mast...27

Mounting Wind Sensors to WAT12 ................28

Alignment............................................................29

Verification..........................................................29

VAISALA___________________________________________________________1

Page 4

User's Guide ________________________________________________________

CHAPTER 4

MAINTENANCE...................................................................... 31

Periodic Maintenance .......................................... 31

Visual Checking ................................................. 31

Testing Proper Operation................................... 31

Replacing Consumables...................................... 33

Parts List for Consumables................................ 33

CHAPTER 5

TROUBLESHOOTING............................................................ 35

Common Problems .............................................. 35

Error Messages .................................................... 35

Getting Help.......................................................... 36

Return Instructions .............................................. 37

CHAPTER 6

TECHNICAL DATA................................................................. 39

Specifications....................................................... 39

List of Figures

Figure 1 WAT12 Analog Wind Transmitter ........................... 10

Figure 2 Recommended Mast Location in Open Area.......... 11

Figure 3 Recommended Mast Length on Top of

a Building ............................................................... 12

Figure 4 Location of the Jumpers......................................... 14

Figure 5 Jumpers for the Setting: 4 ... 20 mA, 0° ... 360°,

0 ... 51.2 m/s........................................................... 15

Figure 6 Jumpers for the Setting: 1 ... 5 mA, 0° ... 360°,

0 ... 76.8 m/s........................................................... 16

Figure 7 Jumpers for the Setting: 0 ... 10 mA, 0° ... 540°,

0 ... 51.2 m/s........................................................... 16

Figure 8 Cable Shield Bent over the Plastic Sleeve

and O-ring .............................................................. 17

Figure 9 I/O Connectors ....................................................... 17

Figure 10 Wiring of the Sensors............................................. 18

Figure 11 Typical System with 24 VDC Power Supply

and 5 mA Signal Currents ...................................... 19

Figure 12 Wiring for High Noise Environment ........................ 20

Figure 13 Long Distance Wiring ............................................. 20

Figure 14 Long Distance Wiring with Four Wires ................... 21

Figure 15 Default Heating Power Connection with both

Sensors .................................................................. 22

2 ______________________________________________________M210309EN-A

Page 5

___________________________________________________________________

Figure 16 Basic Wiring with WAA151 and WAV151

Sensors...................................................................23

Figure 17 Wiring with WHP151 Mains Power Supply .............24

Figure 18 Wiring with WHP25 Mains Power Supply

and the 252 Series Wind Sensors ..........................25

Figure 19 Mounting the Thermostat Switch inside

the WAT12 Junction Box ........................................26

Figure 20 Standard Connection for Thermostat Switch ..........27

Figure 21 Mounting WAT12 to the Top of a Pole Mast ...........27

Figure 22 Installation of the Wind Sensors WAA151 and

WAV151 to WAT12.................................................28

List of Tables

Table 1 Manual Revisions......................................................6

Table 2 Related Manuals.......................................................6

Table 3 Jumper Settings for the 1 to 5 mA Current Loop.....15

Table 4 I/O Connectors........................................................18

Table 5 Power Line Resistance with an 24 VDC Power

Supply.....................................................................21

Table 6 Jumper Selectable Reference Sources

for Testing...............................................................32

Table 7 Output Values for the Jumpers in the Test Mode....32

Table 8 Available Spare Parts .............................................33

Table 9 Some Common Problems and their Remedies.......35

Table 10 WAT12 Analog Wind Transmitter Specifications ....39

VAISALA___________________________________________________________3

Page 6

User's Guide ________________________________________________________

This page intentionally left blank.

4 ______________________________________________________M210309EN-A

Page 7

Chapter 1 ___________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

About This Manual

This manual provides information for installing and

maintaining WAT12 Analog Wind Transmitter.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides important

safety, revision history, and warranty information for the

product.

- Chapter 2, Product Overview, introduces WAT12 Analog

Wind Transmitter features.

- Chapter 3, Installation, provides you with information

that is intended to help you install this product.

- Chapter 4, Maintenance, provides information that is

needed in basic maintenance of WAT12 Analog Wind

Transmitter.

- Chapter 5, Troubleshooting, describes common problems,

their probable causes and remedies, and provides contact

information.

- Chapter 6, Technical Data, provides technical data of

WAT12 Analog Wind Transmitter.

VAISALA___________________________________________________________5

Page 8

User's Guide ________________________________________________________

Version Information

Table 1 Manual Revisions

Manual Code Description

T649en-1.1 WAT12 Analog Wind Transmitter -

Technical Reference.

M210309EN-A This manual, the first version of WAT12

Analog Wind Transmitter User's Guide.

Supersedes the above mentioned

Technical Reference.

Related Manuals

Table 2 Related Manuals

Safety

WARNING

Manual Code Manual Name

M210293en WAA151 Anemometer - User's Guide

M210294en WAV151 Wind Vane - User's Guide

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

Warning alerts you to a serious hazard. If you do not read

and follow instructions very carefully at this point, there is

a risk of injury or even death.

CAUTION

6 ______________________________________________________M210309EN-A

Caution warns you of a potential hazard. If you do not read

and follow instructions carefully at this point, the product

could be damaged or important data could be lost.

Page 9

Chapter 1 ___________________________________________ General Information

NOTE

WARNING

CAUTION

Note highlights important information on using the product.

Product Related Safety Precautions

WAT12 Analog Wind Transmitter delivered to you has

been tested for safety and approved as shipped from the

factory. Note the following precautions:

Ground the product, and verify the grounding of the

outdoor installation periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage

the product or lead to malfunction.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent

damage to electronic circuits. Vaisala products are

adequately protected against ESD for their intended use.

However, it is possible to damage the product by delivering

electrostatic discharges when touching, removing, or

inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages

yourself:

- Handle ESD sensitive components on a properly

grounded and protected ESD workbench. When this is

not possible, ground yourself to the equipment chassis

VAISALA___________________________________________________________7

Page 10

User's Guide ________________________________________________________

before touching the boards. Ground yourself with a wrist

strap and a resistive connection cord. When neither of the

above is possible, touch a conductive part of the

equipment chassis with your other hand before touching

the boards.

- Always hold the boards by the edges and avoid touching

the component contacts.

Regulatory Compliances

WAT12 Analog Wind Transmitter is a CE compliant

product.

Warranty

For certain products Vaisala normally gives a limited one

year warranty. Please observe that any such warranty may

not be valid in case of damage due to normal wear and tear,

exceptional operating conditions, negligent handling or

installation, or unauthorized modifications. Please see the

applicable supply contract or conditions of sale for details of

the warranty for each product.

8 ______________________________________________________M210309EN-A

Page 11

Chapter 2 ____________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces WAT12 Analog Wind Transmitter

features.

Introduction to WAT12 Analog Wind Transmitter

The WAT12 transmitter converts the digital data supplied

by the Vaisala 151 and 252 Series wind sensors, into two

industry standard analog current loops; one representing the

wind speed and the other the wind direction. The current

loops are suitable for connection to, for example, chart

recorders, analog or digital panel meters, analog inputs of

computers, or other instruments with an analog input

interface. The power to the sensors is also supplied through

the WAT12 transmitter. The transmitter accepts a wide

range of input power, from 12 to 28 VDC.

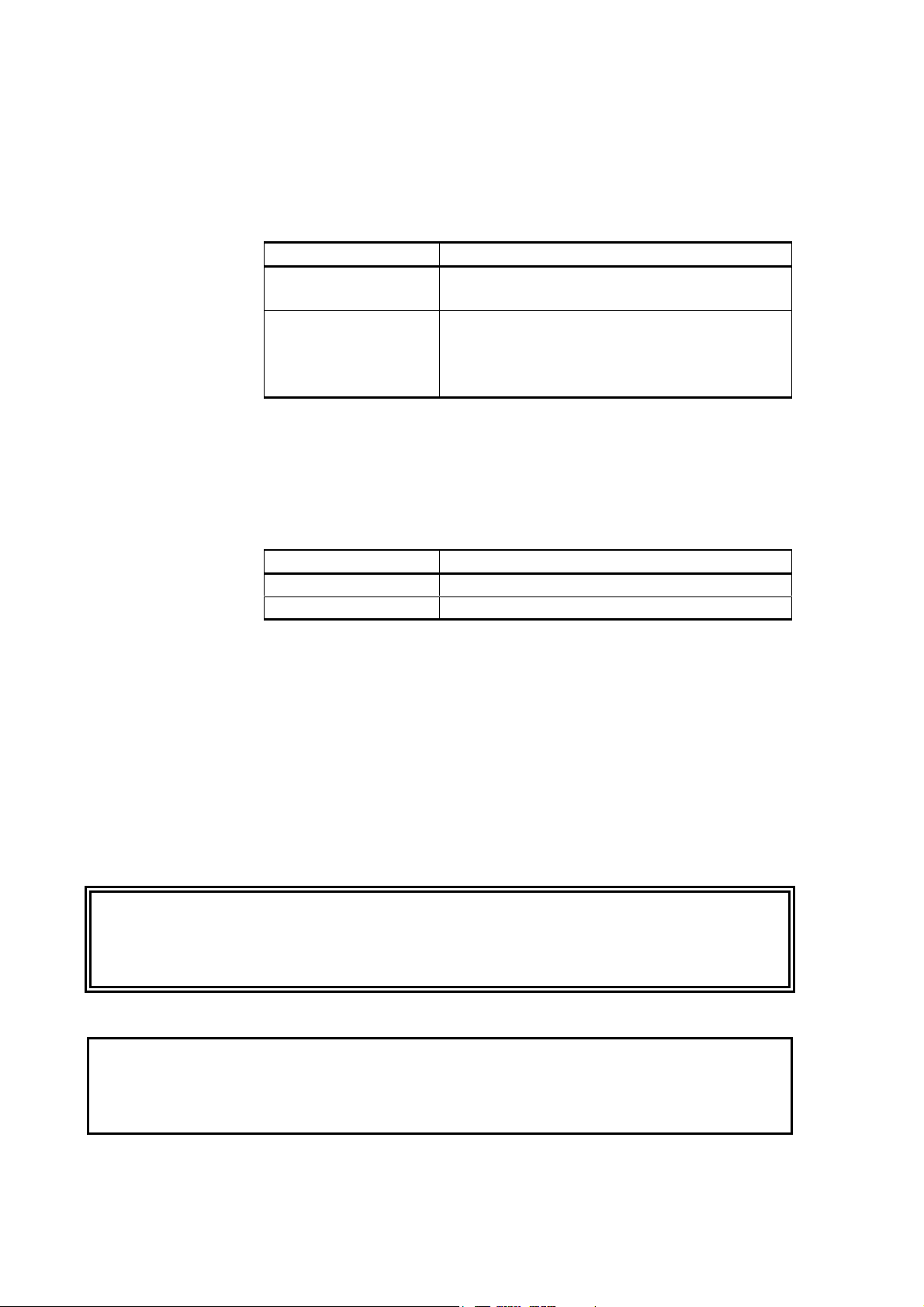

The WAT12 transmitter consists of a printed circuit board

unit in a junction box and a cross arm for mounting the wind

sensors, see Figure 1 on page 10. A 4-wire cable for the

wind speed and direction signals and power supply is

needed between the transmitter and the receiving end.

The loop current is user selectable. The loops are supplied

by high-side drivers with a return to the signal and power

ground; thus nearly any input type can be driven.

VAISALA___________________________________________________________9

Page 12

User's Guide ________________________________________________________

The WAT12 transmitter provides the sensors with a

throughput for optional heating power. A thermostat switch

is available as an option to automatically connect the

heating power in temperatures below +4 °C.

0206-041

Figure 1 WAT12 Analog Wind Transmitter

The following numbers refer to Figure 1 above:

1 = Flange for mounting a Vaisala anemometer

2 = Junction box, containing the circuit board

3 = Flange for mounting a Vaisala wind vane

10 _____________________________________________________M210309EN-A

Page 13

Chapter 3 __________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended

to help you install this product.

Selecting Location

Allow sufficient clearance for the wind sensors. Wind

sensors should not be located next to a building or any other

object that might affect the flow of air.

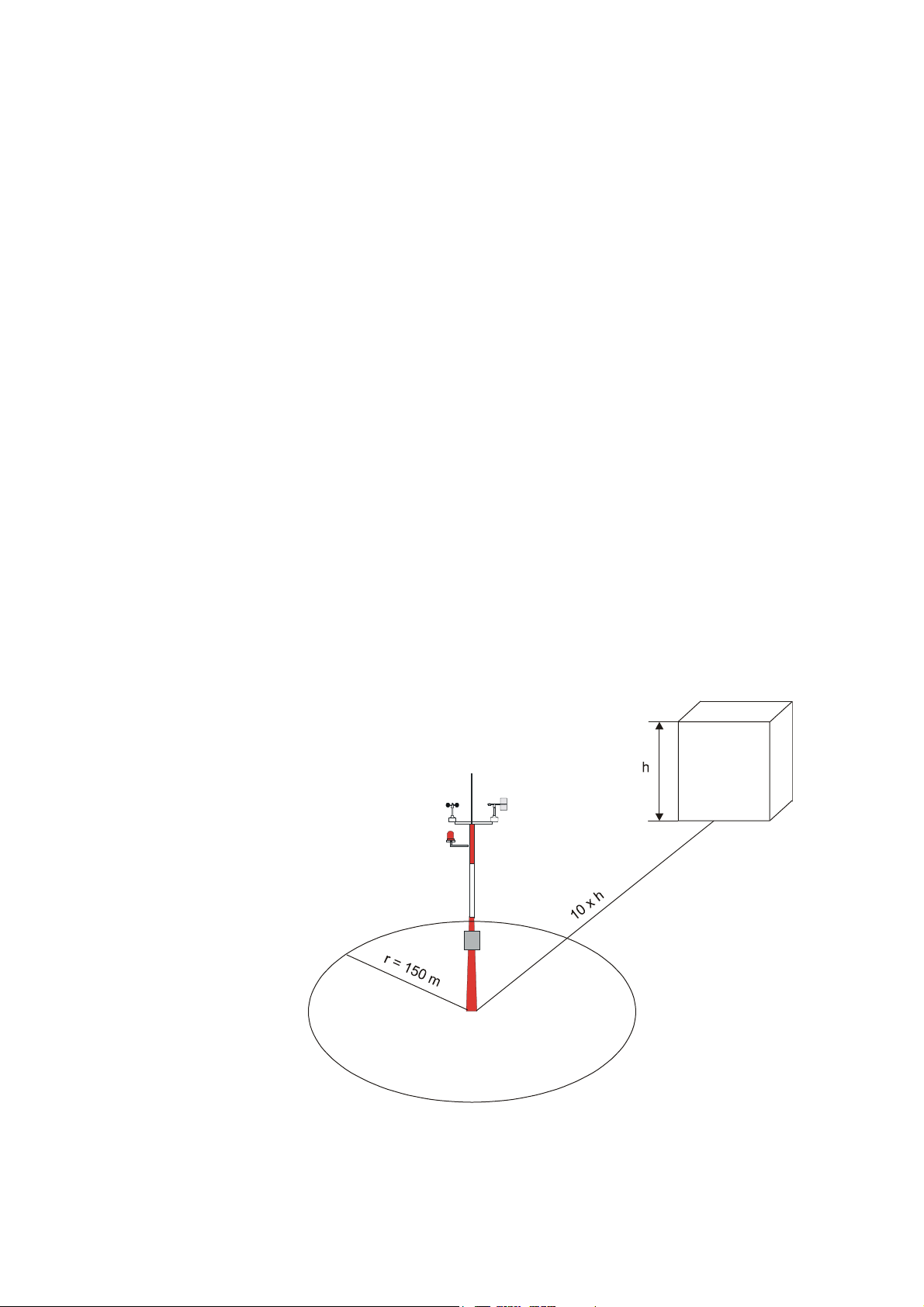

0204-040

Figure 2 Recommended Mast Location in Open Area

VAISALA__________________________________________________________11

Page 14

User's Guide ________________________________________________________

In general, any object of height (h) will not remarkably

disturb wind measurement at a minimum distance of 10 × h.

There should be at least 150 m open area in all directions

from the mast. Refer to Figure 2 on page 11.

0204-041

Figure 3 Recommended Mast Length on Top of a

Building

The recommended minimum length (marked with the letter

h in Figure 3 above) for the mast that is installed on top of a

building is 1.5 times the height of the building (H). When

the diagonal (W) is less than the height (H), the minimum

length of the mast is 1.5 × W.

12 _____________________________________________________M210309EN-A

Page 15

Chapter 3 __________________________________________________ Installation

Installation Procedure

For installation, follow the procedure below and refer to

corresponding sections for details.

1. Remove the four screws holding the cover of the

WAT12 transmitter. Remove the cover.

2. Select the current output span, as well as direction and

speed scaling according to the instructions in section

Jumper Settings on page 14. Some examples of

selecting scales and ranges are shown in Figure 5 on

page 15, Figure 6 on page 16, and Figure 7 on page 16.

3. Enter the power and signal cables through the cable

glands(s). For better protection against RF interference,

ground the cable shield as shown in Figure 8 on page

17.

4. Connect the wires to the X2 removable screw terminal

block according to Figure 11 on page 19, Figure 12 on

page 20, Figure 13 on page 20, or Figure 14 on page

21. Tighten the output cable gland(s).

5. Carefully reattach the enclosure cover with the four

screws.

6. Attach the unit on the top of a pole mast with the

mounting clamp as shown in Figure 21 on page 27.

7. Mount the sensors onto the cross arm. Refer to Figure

22 on page 28 and the sensors' manuals.

8. Align the cross arm as instructed in section Alignment

on page 29 before erecting the mast.

VAISALA__________________________________________________________13

Page 16

User's Guide ________________________________________________________

Jumper Settings

The loop current can be selected with the on-board jumper

plugs. Several output ranges, such as 0 to 20 mA, 4 to

20 mA, 0 to 10 mA, 2 to 10 mA, 0 to 5 mA, and 1 to 5 mA,

are available as user configurable options, each with

factory-adjusted zero and span levels. The voltage-mode

signals are easily obtained by connecting a suitable resistor

across the readout device's terminals. Signal full scale

options are also available. For instance, a directional scale

of 540° (0-360-180°), which is convenient for analog panel

meters or chart recorders, can be chosen to prevent the

needle or pen from oscillating across the scale with

northerly winds.

0206-042

Figure 4 Location of the Jumpers

The following numbers refer to Figure 4 above.

1 = X4: Test and operation

2 = X5: Output zero

3 = X7: Scaling together with X6

4 = X8: Output span

5 = X6: Scaling together with X7

14 _____________________________________________________M210309EN-A

Page 17

Chapter 3 __________________________________________________ Installation

For example, you can set the wind speed output from 1 to

5 mA which corresponds to speed values from 0 to 51.2 m/s

and to direction values from 0 to 540 degrees. This range

does not change the scaling of 360 degrees corresponding to

one full turn, rather it allows to calculate the average

direction during northerly winds. These settings are carried

out by the jumpers of the WAT12 transmitter as described

in Table 3 below.

Table 3 Jumper Settings for the 1 to 5 mA Current

Loop

Jumper Description

X4 J5 ON Normal operation

X5 J1 ON 1 / 2 / 4 mA for 51.2 m/s

X6 J1 ON

J3 ON

X7 J5 ON

X7 J6 ON 0 ... 51.2 m/s

X8 ALL OFF 1 ... 5 mA

0 ... 540°

Some examples for selecting scales and ranges are shown in

Figure 5 below, Figure 6 on page 16, and Figure 7 on page

16.

0206-043

Figure 5 Jumpers for the Setting: 4 ... 20 mA,

0° ... 360°, 0 ... 51.2 m/s

VAISALA__________________________________________________________15

Page 18

User's Guide ________________________________________________________

0206-044

Figure 6 Jumpers for the Setting: 1 ... 5 mA,

0° ... 360°, 0 ... 76.8 m/s

0206-045

Figure 7 Jumpers for the Setting: 0 ... 10 mA,

0° ... 540°, 0 ... 51.2 m/s

Connections

The WAT12 transmitter provides the line cable entry

through a gland for a cable with a diameter from 7 to

10 mm. For better protection against RF interference, bend

the cable shield as illustrated in Figure 8 on page 17.

16 _____________________________________________________M210309EN-A

Page 19

Chapter 3 __________________________________________________ Installation

0206-046

Figure 8 Cable Shield Bent over the Plastic Sleeve

and O-ring

The WAT12 transmitter has three I/O connectors as listed in

Table 4 on page 18. For the location of the connectors, refer

to Figure 9 below.

0206-047

Figure 9 I/O Connectors

The following numbers refer to Figure 9 above.

1 = X1: For the anemometer cable

2 = X2: For the power and signal cable

3 = X3: For the wind vane cable

VAISALA__________________________________________________________17

Page 20

User's Guide ________________________________________________________

Table 4 I/O Connectors

Connector Description

X1 Plug-in connector with screw terminals (5 pcs)

for the anemometer cable. Maximum wire cross

section area is 1.5 mm2.

X2 Plug-in connector with screw terminals (8 pcs)

for the power and signal cable. Maximum wire

cross section area is 1.5 mm2.

X3 Plug-in connector with screw terminals (11 pcs)

for the wind vane cable. Maximum wire cross

section area is 1.5 mm2.

Sensor Wiring

The transmitter connects to the wind sensors with the crossarm's standard cables through two cable glands. Through

these cables the WAT12 transmitter both feeds the sensor

power and receives the wind data. Plug-in type screw

terminal connectors are provided both for the sensor cables

and the output line cable.

0206-048

Figure 10 Wiring of the Sensors

18 _____________________________________________________M210309EN-A

Page 21

Chapter 3 __________________________________________________ Installation

The following numbers refer to Figure 10 on page 18.

1 = Anemometer cable

2 = Glands for power and signal cables

3 = Wind vane cable

Signal Output

The signal output provides two analog current loops,

direction and speed, with sourcing drivers with an o/p

driving voltage 10.5 V typically and an o/p resistance of

57 Ω. The loops return to the common ground for power

and signal. The signal and sensor power outputs are also

current limited.

Typically, only a 4-wire shielded cable is required for the

line between the WAT12 transmitter and the receiving end.

Two of the four wires provide the operating power for the

system. The other two are for the current source outputs

from the WAT12 transmitter; one delivering the speed

signal and the other the direction signal. The two readout

devices are wired each across the respective current source

terminal (+) and the negative terminal of the power supply

(-). Refer to Figure 11 below for a typical system with a

24 VDC power supply and the 5 mA signal currents.

0206-049

Figure 11 Typical System with 24 VDC Power Supply

and 5 mA Signal Currents

VAISALA__________________________________________________________19

Page 22

User's Guide ________________________________________________________

Figure 12 below illustrates wiring for high noise

environment. It is essential to ground the cable also at the

power supply.

0206-050

Figure 12 Wiring for High Noise Environment

Figure 13 below illustrates wiring for long distance with the

5 mA loop current. Note the maximum resistance values for

both the power and signal leads.

0206-051

Figure 13 Long Distance Wiring

Figure 14 on page 21 illustrates 4-wire wiring for long

distance with a 48 VDC power supply.

CAUTION

A source resistance, over 1000Ω, must be used for

dropping VIN to an acceptable level, because if VIN

exceeds 28 VDC, the transmitter may be damaged

permanently.

20 _____________________________________________________M210309EN-A

Page 23

Chapter 3 __________________________________________________ Installation

0206-052

Figure 14 Long Distance Wiring with Four Wires

Powering

The WAT12 transmitter accepts a wide range of input

power, from 12 to 28 VDC. When the 5 mA loop current is

selected, the total current consumption is less than 40 mA

including the sensors and the loop current. The low current

consumption enables to remotely supply the operating

power from a distance of several kilometers, even through

private or leased telephone lines.

The maximum power line resistance depends on the supply

voltage and the loop current selection. For an example with

an 24 VDC power supply, refer to and to Figure 11 on page

19.

Table 5 Power Line Resistance with an 24 VDC

Power Supply

Loop Current, mA

5 360

10 310

20 250

Power Line Resistance, ΩΩΩΩ

For other powering options, refer to Figure 12 on page 20,

Figure 13 on page 20, and Figure 14 above.

VAISALA__________________________________________________________21

Page 24

User's Guide ________________________________________________________

The power line is protected against the wrong polarity.

Transient protection is accomplished with VDRs, series

inductors and resistors, and transient zener diodes on both

the power line and each I/O line.

Optional Heating Power

The WAT12 transmitter also provides the sensors with a

throughput for optional heating power. The heating power

connection requires an extra pair of wires. Since the heating

elements, in the shafts of the WAA151 and WAV151

sensors, typically consume some 500 mA, the heating power

is most conveniently supplied from a local power source. A

thermostat switch is available for automatic connection of

the heating power in temperatures below +4 °C.

The optional heating power requirement is 20 VAC or

VDC, and 500 mA for both WAV151 and WAA151

sensors. The sensors can be connected in series, when a

40 V power supply providing 500 mA is required.

Alternatively, the sensors can be connected in parallel, when

a 20 V power supply providing 1 A is required. For the

default connection, refer to Figure 15 below.

0206-053

Figure 15 Default Heating Power Connection with

both Sensors

22 _____________________________________________________M210309EN-A

Page 25

Chapter 3 __________________________________________________ Installation

Wiring Examples

Refer to Figure 16 below for the basic wiring, when the

WAA151 and WAV151 wind sensors are connected to the

WAT12 transmitter.

NOTE

0206-054

Figure 16 Basic Wiring with WAA151 and WAV151

Sensors

Figure 17 on page 24 illustrates the wiring with WHP151

Mains Power Supply.

Figure 18 on page 25 illustrates the wiring with WHP25

Mains Power Supply and the 252 series wind sensors.

An expansion connector and discrete joining wires are

included in the WAA252 accessories.

VAISALA__________________________________________________________23

Page 26

User's Guide ________________________________________________________

0206-055

Figure 17 Wiring with WHP151 Mains Power Supply

24 _____________________________________________________M210309EN-A

Page 27

Chapter 3 __________________________________________________ Installation

0206-056

Figure 18 Wiring with WHP25 Mains Power Supply

and the 252 Series Wind Sensors

VAISALA__________________________________________________________25

Page 28

User's Guide ________________________________________________________

Mounting the Thermostat Switch

The thermostat switch connects at +4 °C (+3 °C) and

disconnects at +11 °C (+3 °C). For mounting, refer to

Figure 19 below. For standard wiring, refer to Figure 20 on

page 27.

CAUTION

0206-057

Figure 19 Mounting the Thermostat Switch inside the

WAT12 Junction Box

The following numbers refer to Figure 19 above.

1 = Thermostat switch

2 = Regulator

3=Wires

The thermostat switch (number 1 in Figure 19 above) must

not touch the regulator (2).

26 _____________________________________________________M210309EN-A

Page 29

Chapter 3 __________________________________________________ Installation

0206-058

Figure 20 Standard Connection for Thermostat Switch

Mounting

Mounting WAT12 to the Top of a Pole Mast

Figure 21 below illustrates mounting of the WAT12

transmitter to the top of a Ø 60 mm pole mast, with the

standard mounting clamp. The arrow on the cover of the

junction box must point to north.

0206-059

Figure 21 Mounting WAT12 to the Top of a Pole Mast

VAISALA__________________________________________________________27

Page 30

User's Guide ________________________________________________________

WARNING

A long cable between different units (sensors, transmitters,

power supplies, and displays) can cause a lethal surge

voltage, if a lightning strikes in the vicinity. Always

ground the mast equipment case close to the mast with a

short and low-resistance cable.

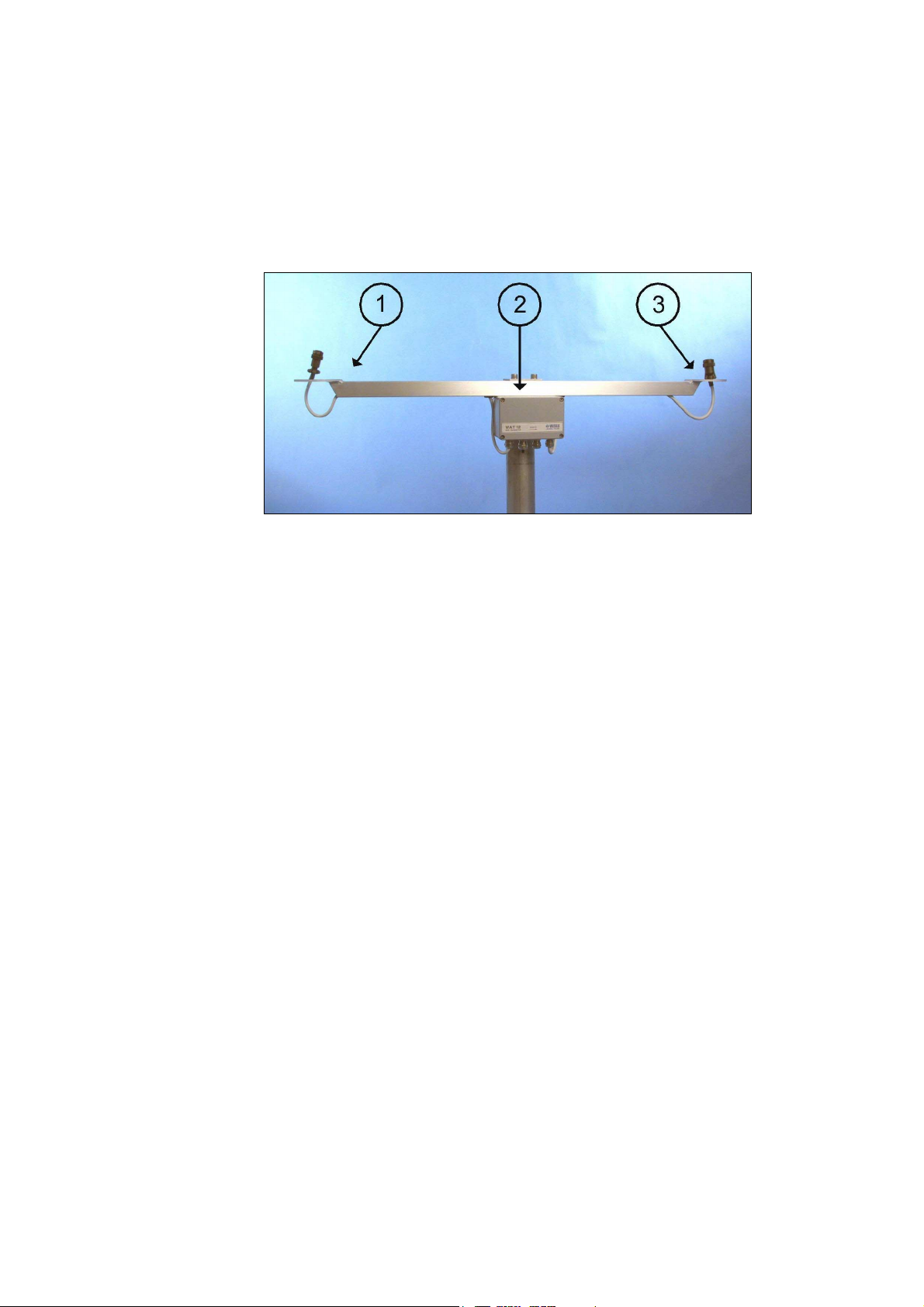

Mounting Wind Sensors to WAT12

0110-005

Figure 22 Installation of the Wind Sensors WAA151

and WAV151 to WAT12

The following numbers refer to Figure 22 above:

1 = WAA151 Cup assembly

2 = WAV151 Tail assembly

3 = Cross arm

4=WAT12

5 = Connector

6 = Mounting flange

7 = SOUTH

8 = NORTH

28 _____________________________________________________M210309EN-A

Page 31

Chapter 3 __________________________________________________ Installation

Alignment

After mounting the WAT12 transmitter to the mast, check

that the WAV151 end of the cross arm is pointing to north

with the required accuracy, see Figure 21 on page 27. For

ensuring correct assemblage after aligning the WAT12, you

can mount the sensors on it only in one way.

Verification

If the signal cable from the WAT12 transmitter is connected

to the data collection system and the system is powered up,

check that the wind readings react correctly. For testing the

anemometer, rotate the cups manually. For testing the wind

vane, hold the vane in a few fixed angles and verify data.

VAISALA__________________________________________________________29

Page 32

User's Guide ________________________________________________________

This page intentionally left blank.

30 _____________________________________________________M210309EN-A

Page 33

Chapter 4 ________________________________________________ Maintenance

CHAPTER 4

MAINTENANCE

This chapter provides information that is needed in basic

maintenance of WAT12 Analog Wind Transmitter.

Periodic Maintenance

Visual Checking

Check every 1 to 2 years that the printed circuit board is not

corrored.

Testing Proper Operation

For easy testing and adjustment, reference signals are

provided for the two output channels. For instance, by

inserting a jumper plug, an output can be forced to the full

scale or zero level. Hence a readout device can be easily

adjusted to comply with the transmitter output. Inside the

transmitter box there is an instruction label, showing all the

useful jumper combinations for output scale, measurement

range, and testing.

VAISALA__________________________________________________________31

Page 34

User's Guide ________________________________________________________

Table 6 Jumper Selectable Reference Sources for

Testing

Variable Reference Signal Alternatives

Direction 000° / 008° / 357°

Speed 0.0 m/s / 0.8 m/s / 51.2 m/s

Follow the procedure below to test the WAT12 transmitter

functionality with the reference signals:

1. Remove the four screws holding the cover of the

WAT12 transmitter. Remove the cover.

2. Remove the jumper J5 from the jumper block X4 to

enable the test stage.

3. Select one of the direction and speed alternatives with

jumpers J1, J2, J3, and J4, refer to Table 7 below. For

the location of the jumper block X4, see Figure 4 on

page 14.

CAUTION

Table 7 Output Values for the Jumpers in the

Test Mode

Jumper Output Value

J1 ON 51.2 m/s

J2 ON 0.8 m/s

J3 ON 357°

J4 ON 008°

All open 0 m/s and 000°

4. Verify the readings with the data collecting system at

the receiving end.

5. To end the test stage, reattach the jumper J5 to the

jumper block X4.

6. After a successful test, carefully reattach the enclosure

cover with the four screws.

Do not try to adjust the transmitter scaling from the sealed

potentiometers of the transmitter.

32 _____________________________________________________M210309EN-A

Page 35

Chapter 4 ________________________________________________ Maintenance

Replacing Consumables

When replacing the component board, read carefully section

ESD Protection on page 7.

When replacing the thermostat switch, refer to section

Mounting the Thermostat Switch on page 26.

Parts List for Consumables

Table 8 Available Spare Parts

Spare Part Order Code

Component Board for WAT12 16637WA

Thermostat switch 16923WA

VAISALA__________________________________________________________33

Page 36

User's Guide ________________________________________________________

This page intentionally left blank.

34 _____________________________________________________M210309EN-A

Page 37

Chapter 5 ______________________________________________ Troubleshooting

CHAPTER 5

TROUBLESHOOTING

This chapter describes common problems, their probable

causes and remedies, and provides contact information.

Common Problems

Table 9 Some Common Problems and their

Remedies

Problem Probable Cause Remedy

Data is not received

by the data

collecting system.

Shaft heating of the

sensors is not

working.

Error Messages

Improper or loose

connections

Improper or loose

connections

Heating is not

connected.

The thermostat

switch is failing.

Check wiring and

tighten the screw

terminals.

Check wiring and

tighten the screw

terminals.

Check the

connections.

Replace the

thermostat switch.

If the wind speed or direction sensor is removed (output

current is 0), the values in the messages are replaced by

slashes and the I/O error bit of status is set to 1.

VAISALA__________________________________________________________35

Page 38

User's Guide ________________________________________________________

Getting Help

For technical questions or for comments on the manuals,

contact the Vaisala technical support:

E-mail helpdesk@vaisala.com

Telephone +358 9 8949 2789

Fax +358 9 8949 2790

36 _____________________________________________________M210309EN-A

Page 39

Chapter 5 ______________________________________________ Troubleshooting

Return Instructions

If the product needs repair, please follow the instructions

below to speed up the process and avoid extra costs.

1. Read the warranty information.

2. Write a Problem Report with the name and contact

information of a technically competent person who can

provide further information on the problem.

3. On the Problem Report, please explain:

- What failed (what worked / did not work)?

- Where did it fail (location and environment)?

- When did it fail (date, immediately / after a while /

periodically / randomly)?

- How many failed (only one defect / other same or

similar defects / several failures in one unit)?

- What was connected to the product and to which

connectors?

- Input power source type, voltage and list of other

items (lighting, heaters, motors etc.) that were

connected to the same power output.

- What was done when the failure was noticed?

4. Include a detailed return address with your preferred

shipping method on the Problem Report.

5. Pack the faulty product using an ESD protection bag of

good quality with proper cushioning material in a

strong box of adequate size. Please include the

Problem Report in the same box.

6. Send the box to:

Vaisala Oyj

SSD Service

Vanha Nurmijärventie 21

FIN-01670 Vantaa

Finland

VAISALA__________________________________________________________37

Page 40

User's Guide ________________________________________________________

This page intentionally left blank.

38 _____________________________________________________M210309EN-A

Page 41

Chapter 6 _______________________________________________Technical Data

CHAPTER 6

TECHNICAL DATA

This chapter provides technical data of WAT12 Analog

Wind Transmitter.

Specifications

Table 10 WAT12 Analog Wind Transmitter

Property Description / Value

Equipment type Digital-to-analog current loop

Signal input:

wind direction

wind speed

Input operating power 12 ... 28 VDC, 30 mA

Output sensor power

on-board regulated to 10.7 VDC typically

Output signals Two analog current loops, one for

Loop current options,

jumper selectable and

common for both

channels

Specifications

converter for Vaisala wind sensors

6-bit parallel GRAY code

(optionally 7 bits)

Pulse frequency 0 ... 750 Hz

direction, one for speed.

High-side drivers; the loops return to

the common signal and power ground.

Loop driving voltage 10 V typically.

0 ... 5 mA

1 ... 5 mA

0 ... 10 mA

2 ... 10 mA

0 ... 20 mA

4 ... 20 mA

VAISALA__________________________________________________________39

Page 42

User's Guide ________________________________________________________

Property Description / Value

Signal cable 4 wires minimum

(VIN+, VIN-, DOP, SOP)

Max. loop resistance

(incl. cable and

receiver's input

1800 ohm for 5 mA loop

900 ohm for 10 mA loop

450 ohm for 20 mA loop

resistance)

Full scale options:

for direction

for speed

0 ... 360° / 0 ... 540°

0 ... 51.2 m/s / 0 ... 76.8 m/s

Resolution:

for direction

for speed

±2.8°

0.1 m/s

Updating interval:

for direction

for speed

8 times a second (with no averaging)

Once a second (averaged over

previous 1 s period)

Output accuracy Better than 1 % of full scale

Accuracy with loop

resistance:

RL= 100 Ω

RL= 20 ... 2000 Ω

±0.2 % of full scale at +25 °C

±0.8 % of full scale at full temp. range

Pulse-mode power

feed:

to the vane

Nominally 490 µs wide pulse,

applied every 125 ms

to the anemometer

Nominally 70 µs wide pulse,

applied every 0.49 ms .

Testing references:

for direction

for speed

000° / 008° / 357°

0.0 m/s / 0.8 m/s / 51.2 m/s

Dimensions:

printed circuit board

junction box

114 × 69 mm

125 (w) × 80 (h) × 57 (d) mm

2

Cross arm length 800 mm

Ingress protection IP65

Mounting To a Ø 60 mm pole mast

Weight 1.5 kg

Material:

cross arm

junction box

AI anodized

AI painted gray

Temperature range:

operating

storage

-55 ... +55 °C

-60 ... +70 °C

Humidity 0 ... 100 %RH

40 _____________________________________________________M210309EN-A

Loading...

Loading...