Page 1

USER'S GUIDE

Vaisala Serial Wind Transmitter

WAC155

M210822EN-A

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2007

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Contents of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .7

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . .8

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Product Related Safety Precautions . . . . . . . . . . . . . . . . . . .8

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Introduction to Vaisala Serial Wind Transmitter WAC155 11

CHAPTER 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Optional Heating Power . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Mounting WAC155 to the Top of a Pole Mast . . . . . . . . . .28

Mounting Wind Sensors to WAC155 . . . . . . . . . . . . . . . . .29

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

CHAPTER 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . .31

NMEA Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Polling Data using a Query . . . . . . . . . . . . . . . . . . . . . . . .33

Service Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

List of Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .35

VAISALA________________________________________________________________________ 1

Page 4

________________________________________________________________________________

OPEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CLOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

SETDEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SETSPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SETDIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SETMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

SETMEA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SETCOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

SETHEA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

GETHEA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

SETALR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

SERVICE TIMEOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

GETSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

HELP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

INIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

ERRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

CHAPTER 5

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Visual Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Parts List for Consumables . . . . . . . . . . . . . . . . . . . . . . . .49

CHAPTER 6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Problem Situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Return Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Vaisala Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

CHAPTER 7

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Dimensions in mm (inches) . . . . . . . . . . . . . . . . . . . . . . . . .57

2 _______________________________________________________________________________

Page 5

________________________________________________________________________________

List of Figures

Figure 1 Vaisala Serial Wind Transmitter WAC155 . . . . . . . . . . . . . . . .12

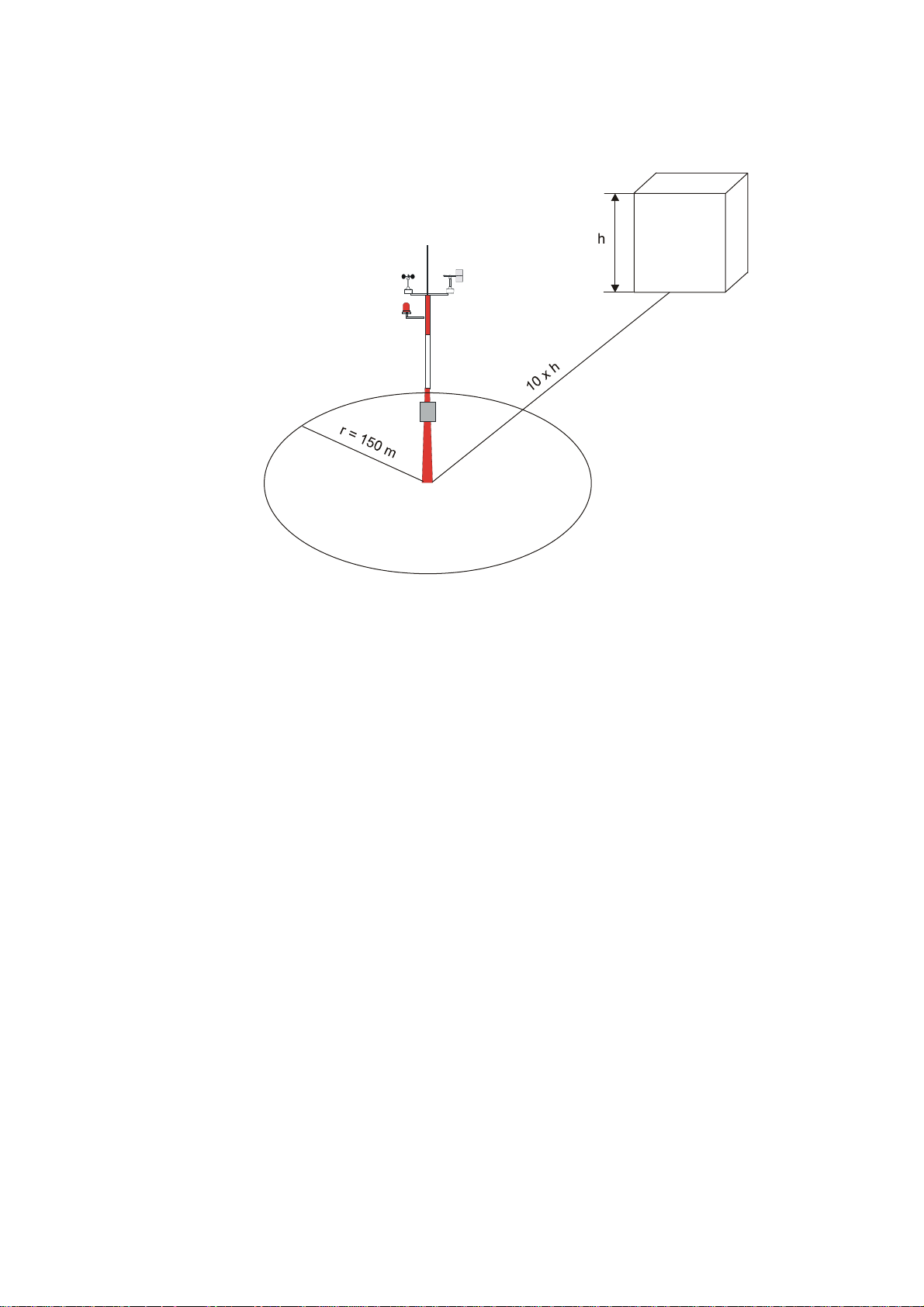

Figure 2 Recommended Mast Location in Open Area. . . . . . . . . . . . . .14

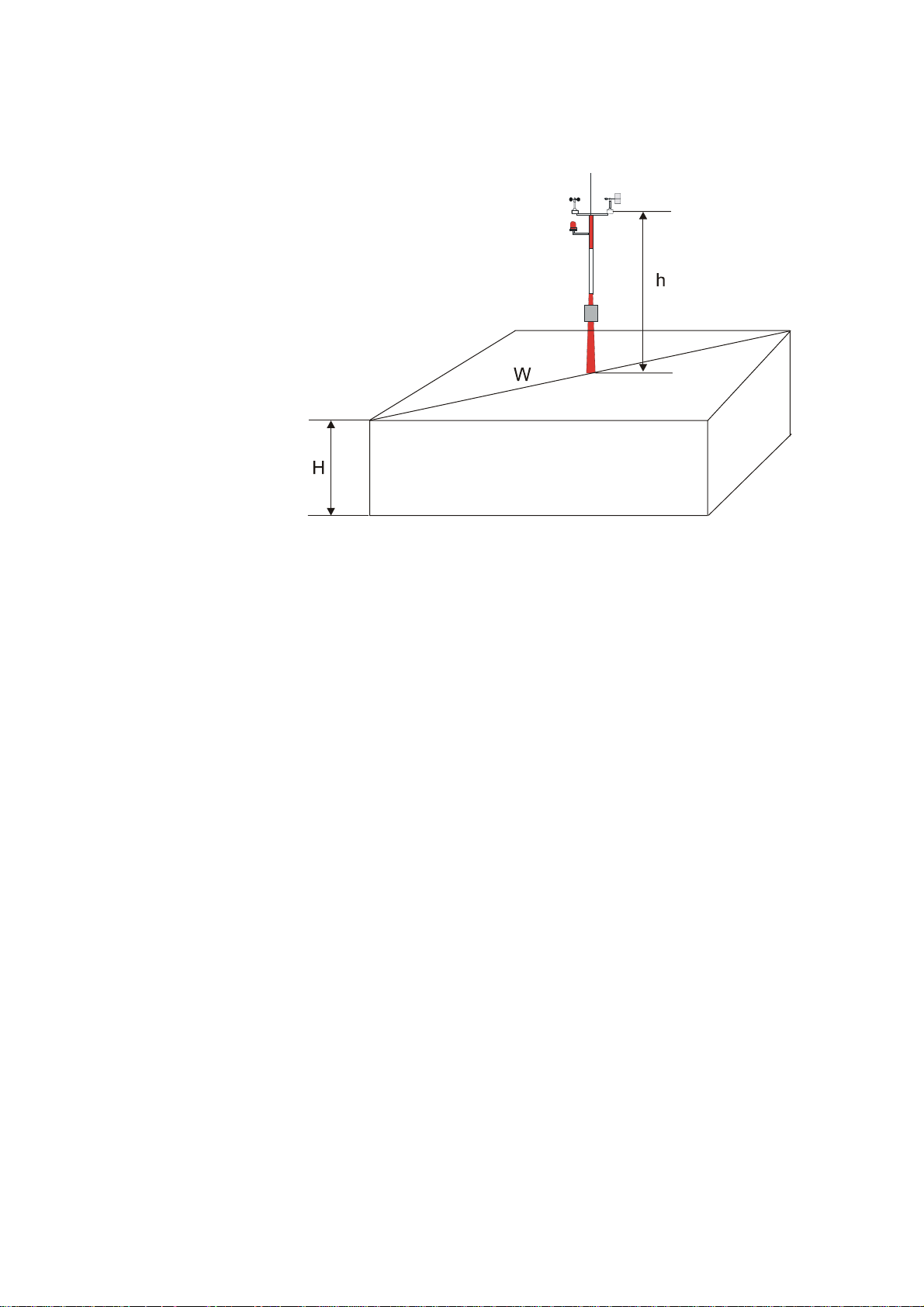

Figure 3 Recommended Mast Length on Top of a Building. . . . . . . . . .15

Figure 4 RS-485 Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 5 WAC155 Component Board. . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 6 Cable Shield Bent over the Plastic Sleeve and O-ring. . . . . . .17

Figure 7 I/O Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 8 Wiring of the Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 9 Typical System with 12 VDC Power Supply. . . . . . . . . . . . . . .21

Figure 10 Heating Power Connection with 40 V Power Supply . . . . . . . .22

Figure 11 Heating Power Connection with 20 V Power Supply . . . . . . . .23

Figure 12 Heating Power Connection for Anemometer Only. . . . . . . . . .23

Figure 13 Heating Power Connection for Wind Vane Only . . . . . . . . . . .24

Figure 14 Basic Wiring with WAA151 and WAV151 Sensors . . . . . . . . .25

Figure 15 Wiring with WHP151 Mains Power Supply . . . . . . . . . . . . . . .26

Figure 16 Wiring with WHP25 Mains Power Supply and the WA252

Series Wind Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 17 Mounting WAC155 to the Top of a Pole Mast . . . . . . . . . . . . .28

Figure 18 Installation of the Wind Sensors WAA151 and WAV151

to WAC155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 19 WAC155 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

VAISALA________________________________________________________________________ 3

Page 6

________________________________________________________________________________

4 _______________________________________________________________________________

Page 7

________________________________________________________________________________

List of Tables

Table 1 Anemometer Connector (X1) Pinout . . . . . . . . . . . . . . . . . . . . . .18

Table 2 Power/Control Connector (X2) Pinout . . . . . . . . . . . . . . . . . . . . .19

Table 3 Wind Direction Sensor Connector (X3) Pinout. . . . . . . . . . . . . . .19

Table 4 WAC155 Default Serial Communication Settings . . . . . . . . . . . .32

Table 5 Checksum table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 6 List of Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 7 Meaning of the Command Line Elements . . . . . . . . . . . . . . . . . .36

Table 8 Available Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 9 Problem Situations and Corrective Actions . . . . . . . . . . . . . . . . .51

Table 10 Self-diagnostics Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Table 11 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Table 12 Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 13 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 14 Dimensions and Mechanics. . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

VAISALA________________________________________________________________________ 5

Page 8

________________________________________________________________________________

6 _______________________________________________________________________________

Page 9

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the product.

About This Manual

This manual provides information for installing and maintaining the

Vaisala Serial Wind Transmitter WAC155.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information: This chapter provides general

notes for the manual and the product.

- Chapter 2, Product Overview: This chapter introduces the features

of the Vaisala Serial Wind Transmitter WAC155.

- Chapter 3, Installation: This chapter provides you with information

that is intended to help you install this product.

- Chapter 4, Operation: This chapter contains information that is

needed to operate the Vaisala Serial Wind Transmitter WAC155.

- Chapter 5, Maintenance: This chapter provides information that is

needed in basic maintenance of the Vaisala Serial Wind

Transmitter WAC155.

VAISALA________________________________________________________________________ 7

Page 10

User's Guide ______________________________________________________________________

- Chapter 6, Troubleshooting: This chapter describes common

problems, their probable causes and remedies, and contact

information.

- Chapter 7, Technical Data: This chapter provides technical data of

the Vaisala Serial Wind Transmitter WAC155.

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

WARNING

CAUTION

NOTE

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com

.

Product Related Safety Precautions

The Vaisala Serial Wind Transmitter WAC155 delivered to you has

been tested for safety and approved as shipped from the factory. Note

the following precautions:

8 ____________________________________________________________________M210822EN-A

Page 11

Chapter 1 ________________________________________________________ General Information

WARNING

CAUTION

Ground the product, and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself with a wrist strap and a resistive connection cord to the

equipment chassis before touching the boards. When neither of the

above is possible, at least touch a conductive part of the equipment

chassis with your other hand before touching the boards.

Recycling

- Always hold the boards by the edges and avoid touching the

component contacts.

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

Warranty

Vaisala hereby represents and wa rrants all Prod ucts

manufactured by Vaisala and sold hereunder to be free

from defects in workmanship or material during a

period of twelve (12) months from the date of delivery

save for products for which a special warranty is given.

If any Product proves however to be defective in

workmanship or material within the period herein

provided Vaisala undertakes to the exclusion of any

other remedy to repair or at its own option replace the

defective Product or part thereof free of charge and

otherwise on the same conditions as for the original

Product or part without extension to original warranty

time. Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to products

sold by it. In case the repair or service works should

appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the

service was performed Vaisala shall at its free option

either repair or have repaired or replace the product in

question. The working hours used by employees of

Vaisala for such repair or replacement shall be free of

charge to the client. This service warranty shall be

valid for a period of six (6) months from the date the

service measures were completed.

This warranty does not however apply when the defect

has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to service

the Product or otherwise follow Vaisala's service

instructions including any repairs or installation or

assembly or service made by unauthorized personnel

not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as

any adding to it without Vaisala's prior authorization;

e) other factors depending on the Customer or a third

party.

Notwithstanding the aforesaid Vaisala's liabi lit y under

this clause shall not apply to any defects arising out of

materials, designs or instructions provided by the

Customer.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala within

thirty (30) days after the defect or fault became known

or occurred, and

b) The allegedly defective Product or part shall, should

Vaisala so require, be sent to the works of Vaisala or to

such other place as Vaisala may indicate in writing,

freight and insurance prepaid and properly packed and

labelled, unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express or

implied, whether under law, statute or otherwise,

including without limitation any implied warranties of

merchantability or fitness for a particular purpose and

all other obligations and liabilities of Vaisala or its

representatives with respect to any defect or deficiency

applicable to or resulting directly or indirectly from the

Products supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and waived.

Vaisala's liability shall under no circumstances exceed

the invoice price of any Product for which a warranty

claim is made, nor shall Vaisala in any circumstances

be liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

10 ___________________________________________________________________M210822EN-A

Page 13

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features of the Vaisala Serial Wind

Transmitter WAC155.

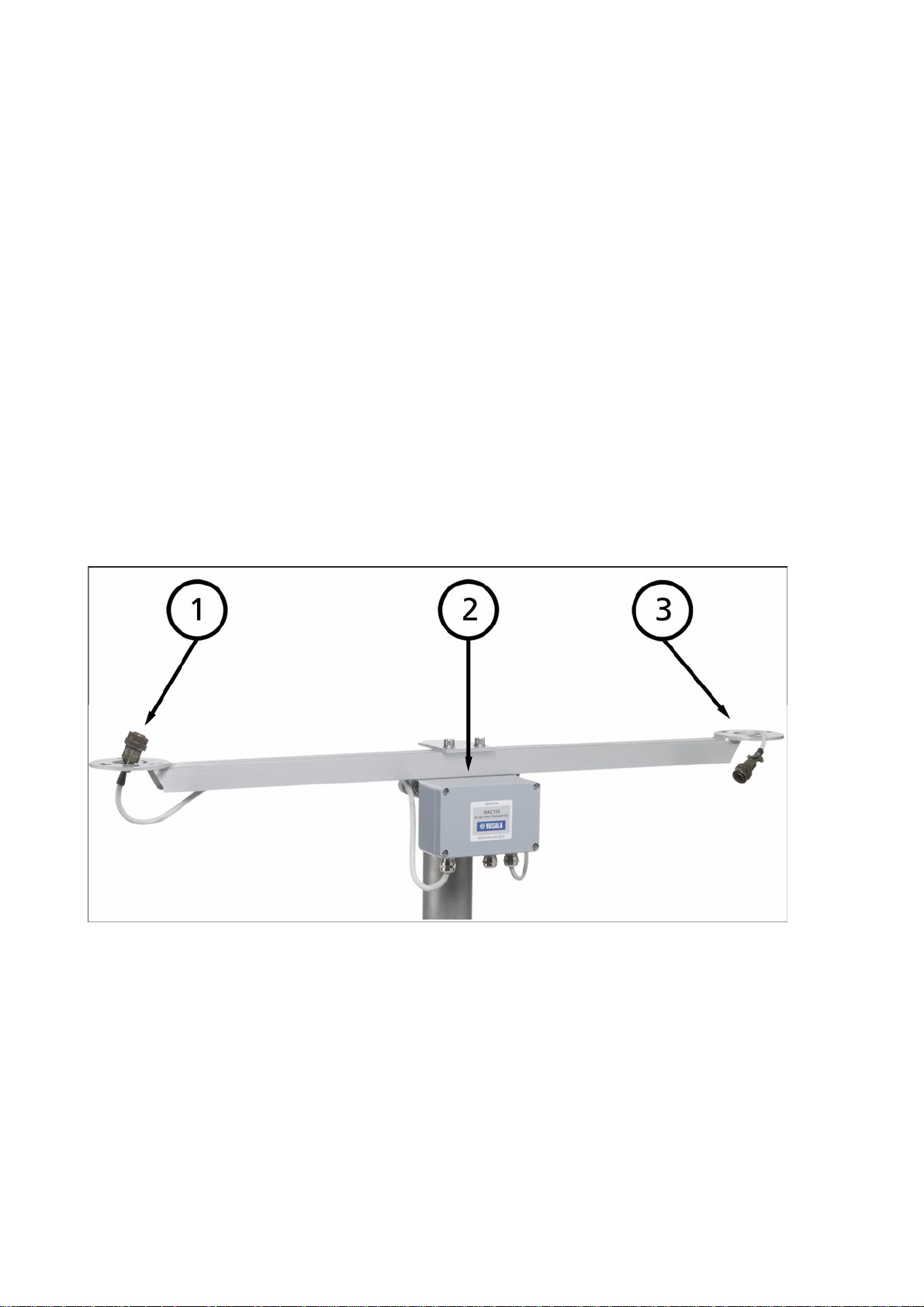

Introduction to Vaisala Serial Wind Transmitter WAC155

The Vaisala Serial Wind Transmitter WAC155 converts the digital data

supplied by the Vaisala 151 and 252 Series wind sensors for use in the

RS-485 bus. The WAC155 transmitter consists of a component board in

a junction box and a cross arm for mounting the wind sensors; see

Figure 1 on page 12.

The WAC155 unit is installed underneath the cross arm, and it

communicates with the controlling system via a twisted pair RS-485

cable. The electrical connections to the sensors are 6-bit parallel graycode for the direction measurement and up to 750Hz digital pulse for the

wind speed measurement (anemometer).

The power to the sensors is supplied through the WAC155 transmitter.

The transmitter accepts 9 ... 15.5 VDC as input power. The WAC155

transmitter also provides the sensors with a throughput for optional

heating power. The unit automatically connects the heating power in

temperatures below +3 °C (default setting).

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

The main features of the WAC155 are as follows:

- Communication with NMEA 0183 compliant protocol over

RS-485 electrical interface (half-duplex)

- Capable of measuring the wind parameters at a configurable

interval using the instant method according to the WMO standard

- Fail-safe RS-485 operation with configurable baud rate and

turnaround delay

- Configurable RS-485 bus termination and ID setting

- Service connection via the RS-485 interface for configuration and

maintenance

- Adjustable heating control of the sensors

- Automatic detection of sensor failure conditions

0710-010

Figure 1 Vaisala Serial Wind Transmitter WAC155

The following numbers refer to Figure 1 on page 12.

1 = Flange for mounting a Vaisala anemometer

2 = Junction box, containing the component board

3 = Flange for mounting a Vaisala wind vane

12 ___________________________________________________________________M210822EN-A

Page 15

Chapter 3 _______________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install this product.

Selecting Location

Finding a suitable site for the product is important for getting

representative ambient measurements. The site should represent the

general area of interest.

Allow sufficient clearance for the wind sensors. Wind sensors should

not be located next to a building or any other object that might affect the

flow of air.

CAUTION

Installations on top of high buildings or masts and in sites on open

grounds are vulnerable to lightning strikes. A nearby lightning strike

may induce a high-voltage surge not tolerable by the internal surge

suppressors of the instrument.

Additional protection is needed in regions with frequent, severe

thunderstorms, especially when long line cables (> 30m) are used.

Vaisala recommends using a surge protector such as the WSP150 in all

sites where there is an elevated risk of lightning strike.

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

0204-040

Figure 2 Recommended Mast Location in Open Area

In general, any object of height (h) will not remarkably disturb wind

measurement at a minimum distance of 10 h. There should be at least

150 m open area in all directions from the mast. Refer to Figure 2 on

page 14.

14 ___________________________________________________________________M210822EN-A

Page 17

Chapter 3 _______________________________________________________________ Installation

0204-041

Figure 3 Recommended Mast Length on Top of a Building

The recommended minimum length (marked with the letter h in Figure

3 on page 15) for the mast that is installed on top of a building is

1.5 times the height of the building (H). When the diagonal (W) is less

than the height (H), the minimum length of the mast is 1.5 W.

Installation Procedure

For installation, follow the procedure below and refer to corresponding

sections for details.

1. Remove the four screws holding the cover of the WAC155

transmitter. Remove the cover.

2. Select the RS-485 termination according to the instructions in

section Jumper Settings on page 16.

3. Enter the power and signal cables through the cable glands(s).

For better protection against RF interference, ground the cable

shield as shown in Figure 6 on page 17.

4. Connect the wires to the X2 removable screw terminal block

according to Figure 8 on page 20 and Figure 9 on page 21.

Tighten the output cable gland(s).

5. Carefully reattach the enclosure cover with the four screws.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

6. Attach the unit on the top of a pole mast with the mounting clamp

as shown in Figure 17 on page 28.

7. Mount the sensors onto the cross arm. Refer to Figure 18 on page

29 and the sensors' manuals.

8. Align the cross arm as instructed in section Alignment on page 29

before erecting the mast.

Jumper Settings

RS-485 serial bus termination can be selected with the on-board jumper.

Termination is on when pins 1 and 2 are shorted, and termination is off

when pins 2 and 3 are shorted or when the jumper plug is fully

disconnected. Termination is implemented by a 120 resistor on the

component board.

In a simple point-to-point configuration where only one WAC155

transmitter is used the jumper is always in ON position. In a multidrop

configuration where several WAC155 transmitters share the single

RS-485 communication line, the termination jumper is in ON position

only at the physically farthest transmitter (i.e. at the end of the

communication line), and in OFF position at the other transmitters.

0701-017

Figure 4 RS-485 Termination

16 ___________________________________________________________________M210822EN-A

Page 19

Chapter 3 _______________________________________________________________ Installation

0702-001

Figure 5 WAC155 Component Board

Connections

The following numbers refer to Figure 5 on page 17.

1 = RS-485 termination jumper

2 = Status indicator LED

The WAC155 transmitter provides the line cable entry through a gland

for a cable with a diameter from 7 to 10 mm. For better protection

against RF interference, bend the cable shield as illustrated in Figure 6

on page 17.

0206-046

Figure 6 Cable Shield Bent over the Plastic Sleeve and O-ring

The WAC155 transmitter has three I/O connectors as shown in

Figure 7 on page 18. For the location of the connectors and the routing

of the cables through the cable glands, refer to Figure 8 on page 20.

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

0702-008

Figure 7 I/O Connectors

The following numbers refer to Figure 7 on page 18.

X1 = Plug-in connector with screw terminals (5 pcs) for the

anemometer cable. Maximum wire cross section area is 1.5

mm2.

X2 = Plug-in connector with screw terminals (8 pcs) for the power

and signal cable. Maximum wire cross section area is 1.5

mm2.

X3 = Plug-in connector with screw terminals (11 pcs) for the wind

vane cable. Maximum wire cross section area is 1.5 mm2.

I/O connector X1-X3 pinouts are shown in following tables.

Table 1 Anemometer Connector (X1) Pinout

Pin # Signal Description

1 F Pulse input from sensor

2 F+ Supply voltage output to sensor

3 GND Sensor ground

4 HT1 Heating supply-1 from connector X2

5 HTC Heating common for heater serial connection

18 ___________________________________________________________________M210822EN-A

Page 21

Chapter 3 _______________________________________________________________ Installation

Table 2 Power/Control Connector (X2) Pinout

Pin # Signal Description

1 HT1+ Heating supply-1 input

2 HT2- Heating supply-2 input

3 Vin+ Supply voltage input

4 Vin+ Supply voltage input

5Vin-Ground

6Vin-Ground

7 RS-485 A(-) RS-485 inverting I/O

8 RS-485 B(+) RS-485 noninverting I/O

Table 3 Wind Direction Sensor Connector (X3) Pinout

Pin # Signal Description

1 HTC Heating common for heater serial connection

2 HT2 Heating supply-2 from connector X2

3 GND Sensor ground

4 D+ Supply voltage output to sensor

5 G5 Gray code input from sensor, bit-5

6 G4 Gray code input from sensor, bit-4

7 G3 Gray code input from sensor, bit-3

8 G2 Gray code input from sensor, bit-2

9 G1 Gray code input from sensor, bit-1

10 G0 Gray code input from sensor, bit-0

11 n.c. Not connected

Sensor Wiring

The transmitter connects to the wind sensors with the cross-arm's

standard cables through two cable glands. Through these cables the

WAC155 transmitter both feeds the sensor power and receives the wind

data. Plug-in type screw terminal connectors are provided both for the

sensor cables and the output line cable.

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

0702-007

Figure 8 Wiring of the Sensors

The following numbers refer to Figure 8 on page 20.

1 = Anemometer cable

2 = Glands for power and signal cables

3 = Wind vane cable

Signal Output

The WAC155 transmitter provides a half-duplex RS-485 serial bus

connection. Wind data is provided in standard NMEA messages. In

addition, a service connection is available for configuration and status

information. The service connection is available through the same

RS-485 interface. When the service connection is in use, data

transmission and query are disabled.

Several transmitters can be connected to the same RS-485 bus. If only

a single transmitter is connected, the transmitter can be configured in

auto-transmit mode, i.e. the device transmits data messages at

configured intervals. If there are several transmitters in the same bus,

auto-transmission may not be enabled, and data must be polled using a

query.

20 ___________________________________________________________________M210822EN-A

Page 23

Chapter 3 _______________________________________________________________ Installation

Each device in the same bus has a unique configurable ID, containing

1..5 characters. Alphabetical characters a-z and A-Z (case-sensitive) are

accepted, as well as numbers 0-9.

Typically, only a 4-wire shielded cable is required for the line between

the WAC155 transmitter and the receiving end. Two of the four wires

provide the operating power for the system. A twisted pair can be used

for the power wires to reduce interference. The other two wires are for

the RS-485 serial bus connection from the WAC155 transmitter.

The maximum length of an unisolated RS-485 line is 1200m (4000ft).

The cable used should be at least a twisted pair AWG 24 cable. The

achievable line length is affected by electrical noise and the number of

transmitters on the bus.

0702-002

Figure 9 Typical System with 12 VDC Power Supply

Powering

The WAC155 transmitter accepts 9 ... 15.5 VDC as input power.

The power line is protected against incorrect polarity. Transient

protection is accomplished with VDRs, series inductors and resistors,

and transient zener diodes on both the power line and each I/O line.

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

Optional Heating Power

The WAC155 transmitter also provides the sensors with a throughput

for heating power, which can be connected if sensor heating is required.

The heating power is galvanically isolated from the operating power.

The heating power connection requires an extra pair of wires. Since the

heating elements in the shafts of the WAA151 and WAV151 sensors

typically consume some 500 mA each, the heating power is most

conveniently supplied from a local power source. Unit can

automatically connect heating power in temperatures below +3 °C

(default setting).

There are two ways to connect the heating power, depending on the

heating power supply available. The default way is to connect a 40 VAC

or VDC power supply in series; see Figure 10 on page 22. When a 40 V

power supply is used, 500 mA is required. The 40 V power supply can

only be used when both sensors are connected.

NOTE

If you connect DC heating power, observe the correct polarity of the

X2 connector pins 1 and 2 (HT1+ and HT2-).

0702-014

Figure 10 Heating Power Connection with 40 V Power Supply

If a 20 VAC or VDC power supply is used, the heating power should be

connected in parallel. The power supply must provide 500 mA for each

connected WAV151 and WAA151 sensor; 1 A is required when both

22 ___________________________________________________________________M210822EN-A

Page 25

Chapter 3 _______________________________________________________________ Installation

sensors are connected. The parallel connection is illustrated in Figure 11

on page 23.

0702-019

Figure 11 Heating Power Connection with 20 V Power Supply

When a 20 V power supply is used, the heating power can also be

connected to a single sensor. Refer to Figure 12 on page 23 and Figure

13 on page 24.

0702-020

Figure 12 Heating Power Connection for Anemometer Only

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

0702-021

Figure 13 Heating Power Connection for Wind Vane Only

NOTE

Wiring Examples

Figure 14 on page 25 illustrates the basic wiring when the WAA151 and

WAV151 wind sensors are connected to the WAC155 transmitter.

Heating power is not connected in the figure.

Figure 15 on page 26 illustrates wiring with the WHP151 Mains Power

Supply, with heating power connected. Note that the WHP151 has

jumpers for configuring the power output. Connect pins 2-3 of the X5

jumper to set the correct voltage, and remove the X4 jumper to provide

continuous heating power. If you connect the heating in series to both

sensors as shown in the figure, set the heating power to 38 Vrms 0.5 A

by connecting pins 2-3 of the X8 jumper.

Figure 16 on page 27 illustrates the wiring with the WHP25 Mains

Power Supply and the WA252 series wind sensors. The WAC155

operating power is supplied from the WAA252 (+12Vout, F -> X2/3).

Thus no external operating voltage shall be applied to the connector X2.

The expansion connector required for the high current wiring in Figure

16 on page 27 is included in the WAA252 accessories

24 ___________________________________________________________________M210822EN-A

Page 27

Chapter 3 _______________________________________________________________ Installation

0702-005

Figure 14 Basic Wiring with WAA151 and WAV151 Sensors

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

0702-022

Figure 15 Wiring with WHP151 Mains Power Supply

26 ___________________________________________________________________M210822EN-A

Page 29

Chapter 3 _______________________________________________________________ Installation

0702-006

Figure 16 Wiring with WHP25 Mains Power Supply and the

WA252 Series Wind Sensors

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

Mounting

Mounting WAC155 to the Top of a Pole Mast

Figure 17 on page 28 illustrates mounting of the WAC155 transmitter

to the top of a Ø 60 mm pole mast using the standard mounting clamp.

The arrow on the cover of the junction box must point to north.

NOTE

0206-059

Figure 17 Mounting WAC155 to the Top of a Pole Mast

A long cable between different units (sensors, transmitters, power

supplies, and displays) can cause a lethal surge voltage if a lightning

strikes in the vicinity. Always ground the mast equipment case close

to the mast with a short low-resistance cable.

28 ___________________________________________________________________M210822EN-A

Page 31

Chapter 3 _______________________________________________________________ Installation

Mounting Wind Sensors to WAC155

0110-005

Figure 18 Installation of the Wind Sensors WAA151 and

WAV151 to WAC155

The following numbers refer to Figure 18 on page 29.

1 = WAA151 Cup assembly

2 = WAV151 Tail assembly

3 = Cross arm

4 = WAC155

5 = Connector

6 = Mounting flange

7 = South

8=North

Alignment

After mounting the WAC155 transmitter to the mast, check that the

WAV151 end of the cross arm is pointing to north with the required

accuracy, see Figure 17 on page 28. To ensure a correct assembly after

aligning the WAC155, you can mount the sensors on it only in one way.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

Verification

Monitor the status indicator LED when powering up the WAC155

transmitter. The LED will flash green if the self-diagnostics are

completed without errors, and red if there is an error condition.

An error condition may be caused by an erroneous installation,

configuration, or a combination of both. For example, enabling sensor

heating without connecting the heating power will cause an error state.

You may be able to diagnose the problem using the service connection.

Howerver, if the problem is with the operating power, the service

connection may not be available even if the LED is flashing.

If the signal cable from the WAC155 transmitter is connected to a data

collection system and the system is powered up, check that the wind

readings react correctly. For testing the anemometer, rotate the cups

manually. For testing the wind vane, hold the vane in a few fixed angles

and verify the data.

30 ___________________________________________________________________M210822EN-A

Page 33

Chapter 4 ________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate the Vaisala

Serial Wind Transmitter WAC155.

User Interface

The WAC155 does not provide a direct user interface, except for a

status indicator LED on the component board. The LED will flash green

when the operational status is OK, and red when there is an error

condition. The LED is activated for five minutes after the transmitter is

powered up. The LED is also activated when the service connection is

open.

The red LED does not indicate the type of the error. Service personnel

must connect to the service connection to resolve the problem.

Data and service connections are provided over the RS-485 interface.

These connections are described in the next section.

Communication Interfaces

The WAC155 transmitter communicates over a half-duplex RS-485

interface. The WAC155 can be configured to send wind data messages

at regular intervals (auto-transmit mode), and it can provide the data as

a response to an MWV query. The data is provided in standard NMEA

wind speed and angle messages. In addition, a service interface is

available for configuration and status information.

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

More than one transmitter can be connected to a single RS-485 bus.

In the case of single transmitter, the auto-transmit mode can be used (the

device transmits data messages with configured interval). If there are

several transmitters in the same bus, auto-transmission may not be

enabled, and data can be only polled by query.

Each device in the same bus has a unique configurable ID, containing

1..5 characters. Alphabetical characters a-z and A-Z (case-sensitive) are

accepted, as well as numbers 0-9.

Table 4 WAC155 Default Serial Communication Settings

Property Description / Value

Baud rate 9600

Data bits 8

Parity none

Stop bit s 1

NMEA Message Format

The NMEA specification defines wind speed and angle message MWV

as follows:

$WIMWV,<a.a>,<R>,<s.s>,<U>,<S>*<CS><cr><lf>

where

$WIMWV = Fixed text at the start of the message

<a.a> = Wind angle, 0..359 degrees

<R> = Reference: R=relative, T=theoretical

<s.s> = Wind speed

<U> = Units: K=km/h, M = m/s, N=knots

<S> = Status: A=valid, V=invalid

* = Asterisk, indicating that the next field is the checksum

<CS> = Two character checksum for the message

The comma "," is used as a separator between the fields. Here are some

examples of MWV messages output by the WAC155:

32 ___________________________________________________________________M210822EN-A

Page 35

Chapter 4 ________________________________________________________________ Operation

$WIMWV,39,R,1.3,M,A*06

$WIMWV,39,R,0.5,M,A*01

$WIMWV,61,R,1.0,M,A*08

$WIMWV,59,R,1.2,M,A*01

$WIMWV,53,R,1.5,M,A*0c

$WIMWV,46,R,1.2,M,A*0f

$WIMWV,70,R,1.1,M,A*09

Polling Data using a Query

Polling for the MWV messages can be done using the following

command:

$WIP<ID>Q,*<CS><cr><lf>

where

$WIP= Fixed text at the start of the query

<ID>= Transmitter device ID

Q = Marks the message as a query

* = Asterisk, indicating that the next field is the checksum

<CS>= Two character checksum for the device ID

The data in the response follows the MWV message format, but the

header is slightly different:

$P<ID>MWV,<a.a>,<R>,<s.s>,<U>,<S>*<CS><cr><lf>

where

$P = Fixed text at the start of the response

<ID> = Transmitter device ID

MWV = Marks the message as a wind speed and angle message

After receiving a query that uses its device ID, the transmitter will reply

with an MWV message containing the wind data. However, if you have

not defined any messages of the type mwvmessage using the SETMES

command, the transmitter will not respond.

Example polling command for transmitter with device ID "A":

$WIPAQ,*72

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Example response:

$PAMWV,50,R,0.0,M,A*04

Table 5 on page 34 provides checksums and polling strings for some

typical device IDs.

Table 5 Checksum table

ID Character <id> Checksum <CS> Polling String

A 72 $WIPAQ,*72<cr><lf>

B 71 $WIPBQ,*71<cr><lf>

C70$WIPCQ,*70<cr><lf>

D77$WIPDQ,*77<cr><lf>

E 76 $WIPEQ,*76<cr><lf>

F 75 $WIPFQ,*75<cr><lf>

G 74 $WIPGQ,*74<cr><lf>

H 7B $WIPHQ,*7B<cr><lf>

I 7A $WIPIQ,*7A<cr><lf>

J79$WIPJQ,*79<cr><lf>

K 78 $WIPKQ,*78<cr><lf>

L 7F $WIPLQ,*7F<cr><lf>

M 7E $WIPMQ,*7E<cr><lf>

N 7D $WIPNQ,*7D<cr><lf>

O 7C $WIPOQ,*7C<cr><lf>

Service Connection

The service connection allows you to configure the device and gather

status information. The same physical RS-485 interface connection is

used for both the data transmission and the service connection. When

the service connection is opened (using the OPEN command), the data

transmission and query are disabled as long as the service connection

remains open.

When you change any parameters using the service connection,

remember that a reset (or a power-up) is required to take the new

parameters into use.

The commands are not case-sensitive; formats 'COMMAND',

'command', 'Command' and all other combinations of upper and lower

case letters are accepted. However, the device ID is case-sensitive.

Commands are entered on a single line, terminated by a line feed <lf>

or carriage-return <cr> characters. If the terminal provides both

characters as the line end marker, the second EOL character is silently

34 ___________________________________________________________________M210822EN-A

Page 37

Chapter 4 ________________________________________________________________ Operation

discarded. Commands may include parameters and values which are

separated by a space ' '. Only one parameter can be set with a single

command; multiple parameters require multiple commands.

You can repeat the previous command by typing CTRL+P. The

previous command will be brought to the console, but it will not be

automatically executed. You can delete characters with the backspace

key [<=]. Arrow keys are not available for data editing, and tabulator

completion is not supported.

A list of the supported commands is provided in section List of Serial

Commands on page 35.

List of Serial Commands

The following table provides a list of the serial commands that are

available in the service connection.

Table 6 List of Serial Commands

Command Description

OPEN Open the service connection

CLOSE Close the service connection

HELP Display the command list

SETDEV Set the ID of the transmitter

SETMEA Configure measurement parameters

SETSPD Configure wind speed computation time period

SETDIR Configure wind direction computation time period

SETMES Specify data transmission mode

SETCOM Configure communication ports

SETALR Configure sensor stuck supervision functionality

SETHEA Configure wind sensor heating control

GETHEA Display the current heating status

SERVICE TIMEOUT Configure timeout for service connection

GETSET Display the current settings of the device

ERRS Display the current error status

INIE Reset the transmitter to factory default settings

RESET R eset the transmitter to new settings

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

The sections below contain a description of each command. The

meaning of the command line elements is presented in the table below.

Table 7 Meaning of the Command Line Elements

Element Meaning Text Style Used

SAMPLE Specifies the name of

the command or utility.

{variable} Indicates a set of

choices from which the

user must choose one,

several or all.

[option] Indicates optional items. lower case enclosed in

<value> Specifies the value for

the option

. , : ; Punctuation marks are

considered as part of

the command and

should be included as

they are.

<cr> Stands for pressing

ENTER (on your

computer keyboard)

UPPER CASE BOLD

lower case enclosed in

{braces}

[brackets]

lower case enclosed in

<angle brackets>

lower case

lower case

OPEN

The OPEN command establishes service communication with the

transmitter. Transmitter configuration commands are effective only

when the service connection is open.

OPEN [id]<cr>

where

id = Case-sensitive device ID that specifies the transmitter

where the service connection is opened. Must be specified

if a device ID has been set for the transmitter, or if there are

multiple transmitters on the same RS-485 bus.

If there is only one transmitter on the RS-485 bus, and no device ID has

been set for the transmitter using the SETDEV command, you can open

the service connection without specifying the ID. The device ID can be

1..5 characters (a-z, A-Z, 0-9).

36 ___________________________________________________________________M210822EN-A

Page 39

Chapter 4 ________________________________________________________________ Operation

If there are multiple transmitters on the same bus, you should always

open the service connection so that you specify the device ID. Do not

install multiple transmitters on the same bus without assinging a

different device ID for each transmitter.

NOTE

If you do not know the device ID of a transmitter, you can open the

service connection by using the dollar sign "$" as the device ID:

OPEN $

Only use this command when you have a single transmitter on the bus.

The service connection will remain open until it is closed by the

CLOSE command, or until the defined service timeout expires (i.e., no

commands have been given within the defined timeout period). The

timeout period is configured using the SERVICETIMEOUT

command. Once the service connection is closed, the transmitter will

return into the operation state it had prior to opening the connection,

either auto-transmitting or polling mode.

Example:

>open

Vaisala Serial Wind Transmitter WAC155

SW version 2.0.7

Service connection opened

>

CLOSE

The CLOSE command closes all current service connections. It is not

necessary to define the device ID. Note that new parameters are not

automatically taken into use when the service connection is closed; you

must reset or power cycle the transmitter to do that.

CLOSE<cr>

Example:

>close

Service connection closed

>

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

SETDEV

The SETDEV command sets the device ID of the transmitter. In a

multi-transmitter network, the device ID of each transmitter must be

unique.

SETDEV id <value><cr>

where

value = Specifies the new device ID for the transmitter. The

ID may contain up to 5 characters, including A-Z, az, and 0-9. The ID is case-sensitive.

Example:

>setdev id A1

ID=A1

>

SETSPD

The SETSPD command configures the wind speed computation time

period.

SETSPD average <value><cr>

where

value = Wind speed computation time period in seconds. Range

0.25 ... 5.00 in 0.25 second increments (default 3.00)

Example:

>setspd average 3.00

AVERAGE=3.00

>

SETDIR

The SETDIR command configures the wind direction computation

time period.

38 ___________________________________________________________________M210822EN-A

Page 41

Chapter 4 ________________________________________________________________ Operation

SETDIR average <value>

where

value = W ind direction computation time period in seconds. Range

0.25 ... 5.00 in 0.25 second increments (default 3.00)

Example:

>setdir average 3.00

AVERAGE=3.00

>

SETMES

The SETMES command specifies the data transmission mode. The

transmitter can support four (4) different messages at a time. Each

message has its own settings for the message type and transmit inter val.

Three message types are supported:

- NONE (no message)

- MWV (standard wind speed and direction message)

- MWVQUERY (Vaisala extension to MWV message)

SETMES {messagenumber} [type] [interval] <value><cr>

where

messagenumber = The number of the message to configure. Range 0

... 3

type = Configures the message type. Possible values:

NONE

MWV

MWVQUER Y

interval = Configures the transmit interval. Zero value

disables data auto-transmission. Possible values: 0

... 600.00 in 0.25 second increments

value = The value for the option.

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

Example:

>setmes 1 type mwvquery

0 TYPE=NONE INTERVAL=0.00

1 TYPE=MWVQUERY INTERVAL=1.00

2 TYPE=NONE INTERVAL=0.00

3 TYPE=NONE INTERVAL=0.00

>

SETMEA

The SETMEA command configures measurement parameters. The

configurable parameters include anemometer transfer function

parameters gain and offset.

SETMEA [allowedspdchange] [maxinvalidspdcount] [gaincorr]

[offset] [powersave] <value><cr>

where

allowedspdchange = Maximum allowed difference between two

adjacent samples in the sensor data, range

0.1 ... 25.0 (default 10.0)

maxinvalidspdcount= Maximum number of adjacent discarded

samples in the sensor data. Sensor data sanity

check functionality is enabled if this value is

not zero. Range 0 ... 15 (default 2)

gaincorr = Anemometer transfer function gain parameter.

Range 0.0 … 10.0 (default 0.09853)

offset = Anemometer transfer function offset

parameter. Range -10.0 … 10.0 (default

0.4054)

powersave = Defines whether sensor power is pulsed or

provided continuously. Pulsing saves power,

since the sensors are only powered when they

are being read.

0 = continuous power

1 = pulsed power (default)

value = Defines the value for the option.

40 ___________________________________________________________________M210822EN-A

Page 43

Chapter 4 ________________________________________________________________ Operation

Example:

>setmea offset 0.318

GAIN = 0.09853

OFFSET = 0.31800

POWERSAVE = 1

ALLOWEDSPDCHANGE = 10.0

MAXINVALIDSPDCOUNT = 2

>

SETCOM

The SETCOM command configures the co mmunication ports. Default

communication port settings are 9600-n-8-1.

SETCOM [portnumber] [baudrate] [databits] [stopbits] [parity]

[txddelay] <value><cr>

where

portnumber= The number of the COM port to configure, 0 or 1. If

omitted, the configuration will apply to the current port

in use.

baudrate = The baud rate of the port. Possible values: 300 600 1200

2400 4800 9600 19200

databits = The number of data bits, 7 or 8

stopbits = The number of stop bits, 1 or 2

parity = The parity to be used. Possible values: ODD EVEN

NONE

txddelay = The RS-485 half-duplex transmission turn-around delay

in milliseconds, range 0 .. 200

value = The value for the option.

Example:

>setcom baudrate 9600

BAUDRATE = 9600

DATABITS = 8

PARITY = NONE

STOPBITS = 1

TXDDELAY = 30

>

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

SETHEA

The SETHEA command configures the wind sensor heating control.

Sensor heating is provided to prevent frost in sensor bearings. Heaters

are powered by an external power supply, which is not the same as the

sensor system power supply. Heating is not enabled by default. If

necessary, heating can also be forced.

SETHEA [active] [tos] [thys] <value><cr>

where

active = Enables the wind sensor heating functionality. Possible

values: 0 = disabled (default) 1 = enabled 2 = forced

tos = Control limit for heating in degrees Celcius, range -

55…+125 (default 4)

thys = Thermal hysteresis in degrees Celcius, range -55…+125

(default 1)

value = The value for the option

If heating is enabled, it is turned on when temperature drops below

TOS-THYS. Heating is turned off when temperature rises above

TOS+THYS. With the default values of TOS=4 and THYS=1, heating

is enabled at +3 °C, and disabled at +5 °C.

Typical commands:

SETHEA ACTIVE 1 (enable sensor heating)

SETHEA TOS 3 (set heating control limit to 3 degrees Celcius)

Example:

>sethea active 1

ACTIVE = 1

TOS = 4.00

THYS = 1.00

>

GETHEA

The GETHEA command displays the current heating status and

temperature.

42 ___________________________________________________________________M210822EN-A

Page 45

Chapter 4 ________________________________________________________________ Operation

GETHEA<cr>

Example:

>gethea

Heating OFF

Temperature 14.25

>

SETALR

The WAC155 can monitor the wind sensor movement to detect if the

sensors appear to be stuck in place. The SETALR command is used to

configure this functionality.

If the functionality is enabled and timeouts are not zero, sensors are

cross-checked for changes, i.e. if the reading of the other sensor

changes, but the other one does not for certain period of time, the sensor

is considered stuck.

SETALR [active] [dir] [spd] [calm] [dirlimit] [spdlimit] <value><cr>

where

active = Enables the wind sensor stuck supervision functionality. 0

or 1 (default 0)

dir = Timeout for wind direction change, range 0 ... 256 (default

60)

spd = Timeout for wind speed change, range 0 ... 256 (default 60)

calm = The calm timeout. Defines how long both sensors may be

unchanged until both sensors are considered being stuck.

Range 0 ... 65535 (default 1440)

dirlimit = Threshold limit for wind direction change. If the wind

direction change is below the threshold, it is considered

unchanged from the wind sensor stuck functionality point

of view. Range 0 ... 180 (default 3)

spdlimit = Threshold limit for wind speed change. If the wind speed

change is below the threshold, it is considered unchanged

from the wind sensor stuck functionality point of view.

Range 0.0 ... 10.0 (default 0.0)

value = The value for the option

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Typical commands:

SETALR ACTIVE 1 (activate the alarm functionality)

SETALR DIR 60 (alarm if wind vane stuck for 60 seconds)

SETALR SPD 60 (alarm if anemometer stuck for 60 seconds)

SETALR CALM 1440 (alarm if both sensors stuck for 1440 minutes)

Example:

>setalr active 1

ACTIVE= 1

DIR= 60

SPD= 60

CALM= 1440

DIRLIMIT= 3

SPDLIMIT= 0.0

>

SERVICE TIMEOUT

The SERVICE TIMEOUT command configures the timeout period of

the auto-close function of the service connection. If no data is input

within the configured time interval, the connection will close itself and

the device returns it normal operational state.

Zero value disables the auto-close function, which means that the

service connection will never close unless explicitly closed using the

CLOSE command.

SERVICE TIMEOUT <value><cr>

where

value = The value of the service timeout, range 0 ... 30 min (default

5 min).

Example:

>service timeout 5

TIMEOUT=5

>

44 ___________________________________________________________________M210822EN-A

Page 47

Chapter 4 ________________________________________________________________ Operation

GETSET

The GETSET command will return the current configuration of the

current unit.

GETSET <cr>

Example:

>getset

SETDEV

ID=A1

SETSPD

AVERAGE=3.00

SETDIR

AVERAGE=3.00

…

HELP

The HELP command displays a list of the supported commands.

HELP<cr>

Example:

>help

CLOSE Close service connection

SETDEV Set device ID

SETSPD Speed computation average length

SETDIR Direction computation average length

...

INIE

The INIE command resets the transmitter to factory defaults. Note that

the current configuration settings will be lost. Before using the INIE

command, it may be a good idea to view the current settings using the

GETSET command , and record the output.

After using this command, you have to use the RESET command to

take the factory defaults into use, and re-open the service connection

with the OPEN command.

INIE <cr>

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

Example:

>inie

FACTORY DEFAULTS

>

RESET

The RESET command resets the transmitter, and takes any new

configuration settings into use. After using this command, you have to

re-open the service connection with the OPEN command.

RESET <cr>

Example:

>RESET

Wait 5 seconds delay...

ERRS

When issued alone without the [mask] option, the ERRS command

returns the current error status of the transmitter. Possible errors, their

codes, and the corresponding hexadecimal values are described inTable

10 on page 52.

You can use the [mask] option to define the set of errors that causes

NMEA messages to be marked as invalid. The error mask is a

hexadecimal number formed by combining the hexadecimal values of

the desired errors. By default the mask is 0010 which means that only if

both wind sensors are missing or broken, the NMEA data is invalid.

For example, if you want the mask to include errors 10 and 11 (0400 and

0800 in hex) , the desired mask value is 0C00:

0400 + 0800 = 0C00

46 ___________________________________________________________________M210822EN-A

Page 49

Chapter 4 ________________________________________________________________ Operation

ERRS [mask] <value><cr>

where

mask = Implements an error mask.

value = The value for the error mask in hexadecimal format

(default 0010).

Example:

>errs

Active errors:

ERROR 5: Heating control broken or heating power missing

ERRS = 0020

MASK = 0010

>

VAISALA_______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

48 ___________________________________________________________________M210822EN-A

Page 51

Chapter 5 ______________________________________________________________ Maintenance

CHAPTER 5

MAINTENANCE

This chapter provides information that is needed in basic maintenance

of the Vaisala Serial Wind Transmitter WAC155.

Periodic Maintenance

Visual Checking

Check every 1 to 2 years that the component board is not corroded.

Replacing Consumables

When replacing the component board, read carefully the section

ESD Protection on page 9.

Parts List for Consumables

Table 8 Available Spare Parts

Spare Part Order Code

Component Board for WAC155 WAC155CB

Sensor Cable for Anemometer (0.8m) ZZ45036

Sensor Cable for Wind Vane (0.8m) ZZ45037

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

50 ___________________________________________________________________M210822EN-A

Page 53

Chapter 6 ___________________________________________________________ Troubleshooting

CHAPTER 6

TROUBLESHOOTING

This chapter describes common problems, their probable causes and

remedies, and contact information.

Problem Situations

Table 9 Problem Situations and Corrective Actions

Problem Possible cause Action

Data is not received by the data

collecting system

Shaft heating of the sensors is

not working.

Improper or loose connections. Check wiring and tighten the

screw terminals.

Incorrect messaging settings. Check and correct using the

service connection.

Power failure. Check that the power supply is

online.

Heating power is not connected

properly.

Heating is not enabled in the

transmitter settings.

Power failure of the heating

power supply.

Check wiring and tighten the

screw terminals.

Check and correct using the

service connection.

Check that the power supply is

online.

VAISALA_______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

Error Messages

The table below describes the error codes defined in the WAC155. If

you use the ERRS command to specify an error mask, use the

hexadecimal values that are provided in the table. For help in using the

service connection to read the errors and configure the WAC155, refer

to section List of Serial Commands on page 35.

Table 10 Self-diagnostics Error Codes

Error # H ex

equivalent

0 0001 Input voltage too low Input voltage below accepted limit,

1 0002 Input voltage too high Over-voltage condition

2 0004 Wind speed sensor missing or

3 0008 Wind direction sensor missing or

4 0010 Both sensors missing or broken Wind speed and direction sensors

5 0020 Heating control malfunction or

6 0040 Erroneous reading from temperature

7 0080 Internal error in non-volatile memory

8 0100 Internal error This error code is reserved for future

9 0200 Temperature sensor not calibrated.

10 0400 Wind direction sensor stuck The wind vane has not turned for a

11 0800 Wind speed sensor stuck Anemometer has not turned for the

12 1000 Both wind sensors stuck Both wind sensors have not turned

Message Description

sensor behaviour not defined

Self-diagnostics does not detect the

broken

broken

heating power missing

sensor

access

Heating control malfunctioning.

proper voltage drop caused by an

operational sensor

Self-diagnostics does not detect the

proper voltage drop caused by

operational sensor

are both missing or broken

Heating power control mechanism

malfunctioning or heating power is

not connected

Internal temperature sensor gives

erroneous readings

Storing or reading parameters from

the internal non-volatile memory

failed

use

Production time calibration not

performed, temperature readings are

erroneous

certain period, but the anemometer

has

configured period of time, but the

wind vane has

for a long time

52 ___________________________________________________________________M210822EN-A

Page 55

Chapter 6 ___________________________________________________________ Troubleshooting

Technical Support

For technical questions, contact the Vaisala technical support:

E-mail helpdesk@vaisala.com

Fax +358 9 8949 2790

Return Instructions

If the product needs repair, please follow the instructions below to

speed up the process and to avoid extra costs to you.

1. Read the section Warranty on page 10.

2. Contact a Vaisala Service Center or a local Vaisala representative.

The latest contact information and instructions are available from

www.vaisala.com. Addresses of the Service Centers are provided

in section Vaisala Service Centers on page 54.

Please have the following information on hand:

- serial number of the unit

- date and place of purchase or last calibration

- description of the fault

- circumstances in which the fault occurs/occurred

- name and contact information of a technically competent

person who can provide further information on the problem

3. Pack the faulty product in a strong box of adequate size, with

proper cushioning material to avoid damage.

4. Include the information specified in step 2 in the box with the

faulty product. Also include a detailed return address.

5. Ship the box to the address specified by your Vaisala contact.

VAISALA_______________________________________________________________________ 53

Page 56

User's Guide ______________________________________________________________________

Vaisala Service Centers

Vaisala Service Centers perform calibrations and adjustments as well as

repair and spare part services. See contact information below.

Vaisala Service Centers also offer accredited calibrations, maintenance

contracts, and a calibration reminder program. Do not hesitate to

contact them to get further information.

./24(!-%2)#!.3%26)#%#%.4%2

6AISALA)NC$'ILL3TREET7OBURN-!53!

0HONE&AX

%MAILUSCUSTOMERSUPPORT VAISALACOM

%52/0%!.3%26)#%#%.4%2

6AISALA)NSTRUMENTS3ERVICE6ANHA.URMIJÊRVENTIE&).6ANTAA&).,!.$

0HONE&AX

%MAILINSTRUMENTSSERVICE VAISALACOM

4/+9/3%26)#%#%.4%2

6AISALA+++AGURAZAKA#HOME3HINJUKU+U4OKYO*!0!.

0HONE&AX

%MAILAFTERSALESASIA VAISALACOM

"%)*).'3%26)#%#%.4%2

6AISALA#HINA,TD&LOOR%!3"UILDING.O8IAO9UN2OAD$ONGSANHUAN"EILU

#HAOYANG$ISTRICT"EIJING02#().!

0HONE&AX

%MAILCHINASERVICE VAISALACOM

ZZZYDLVDODFRP

54 ___________________________________________________________________M210822EN-A

Page 57

Chapter 7 ____________________________________________________________ Technical Data

CHAPTER 7

TECHNICAL DATA

This chapter provides technical data of the Vaisala Serial Wind

Transmitter WAC155.

Specifications

Table 11 Performance

Property Description/Va lue

Equipment type Digital-to-RS-485 serial bus converter for

Full scale:

for direction

for speed

Resolution:

for direction

for speed

Updating interval:

for direction

for speed

Pulse-mode power feed:

to the vane

to the anemometer

Vaisala wind sensors

0 ... 360°

0 ... 75 m/s

5.625° (1.4° achieved by calculation)

0.1 m/s

3 s (default)

3 s (default)

500 µs / 4 Hz Nominal

50 µs / 2400 Hz Nominal

VAISALA_______________________________________________________________________ 55

Page 58

User's Guide ______________________________________________________________________

Table 12 Inputs and Outputs

Property Description/Value

Signal input:

wind direction

wind speed

Input operating power 9 ... 15.5 VDC, 8 mA typical incl. sensors

Maximum operating power 50 mA (when power-save mode is disabled)

Input heating power 16 ... 24 VAC or VDC

Typical heating power 500 mA per sensor

Output signals RS-485 serial bus

Signal cable 4 wires minimum: VIN+, VIN-, RS-485 A(-),

6-bit parallel GRAY code

Pulse frequency 0 ... 750 Hz

(when power-save mode is enabled)

32 ... 48 VAC or VDC can be used when

heating power is connected in series to both

sensors

RS-485 B(+)

Table 13 Operating Conditions

Property Description/Value

Temperature range:

operating

storage

Humidity 0 ... 100 %RH

-55 ... +55 °C

-60 ... +70 °C

Table 14 Dimensions and Mechanics

Property Description/Value

Dimensions:

printed circuit board

jucntion box

Cross arm length 800 mm

Ingress protection IP65

Mounting To a Ø 60 mm pole mast

Weight 1.5 kg

Material:

cross arm

junction box

115 × 58 mm

125 (w) × 80 (h) × 57 (d) mm

AI anodized

AI painted gray

2

56 ___________________________________________________________________M210822EN-A

Page 59

Chapter 7 ____________________________________________________________ Technical Data

Dimensions in mm (inches)

0702-009

Figure 19 WAC155 Dimensions

VAISALA_______________________________________________________________________ 57

Page 60

www.vaisala.com

*M210822EN*

Loading...

Loading...