Page 1

_________________________________________________________________________CONTENTS

PTU200 Series

Transmitters

USER'S GUIDE

M210195EN-A

AUGUST 2001

VAISALA ___________________________________________________________________________I

Page 2

USER'S GUIDE_______________________________________________________________________

Table of contents

CHAPTER 1 GENERAL INFORMATION ............................................................ 1

Safety.............................................................................................. 1

Warranty......................................................................................... 2

CHAPTER 2 PRODUCT DESCRIPTION............................................................. 3

Pressure measurement ................................................................ 3

Humidity and temperature measurement ................................... 4

CHAPTER 3 GETTING STARTED ...................................................................... 5

Mounting ........................................................................................ 5

Electrical connections .................................................................. 5

Connecting the probe ................................................................... 7

CHAPTER 4 COMMISSIONING .......................................................................... 9

Display and keypad....................................................................... 9

Operating modes......................................................................... 11

SMODE Selecting the sending mode ...................................... 11

Software settings ........................................................................ 12

SERI Serial bus settings .......................................................... 12

ECHO Setting the serial bus echo on/off ................................. 12

FORM Defining the output format ............................................ 13

EFORM Defining the error output format................................. 14

DFORM Defining the display format ........................................ 15

PROMPT Setting the prompt outputting ON or OFF ............... 16

UNIT Setting the pressure and temperature units ................... 16

AVRG Setting the averaging time ............................................ 17

INTV Setting the output interval ............................................... 18

ADDR Setting the transmitter address (for POLL mode)......... 18

SCOM User specific SEND command..................................... 19

PSTAB Setting the pressure stability indicator ........................ 20

PDMAX Setting the pressure difference limit........................... 20

KEYLOCK Setting the keyboard lock on/off ............................ 21

Hardware settings ....................................................................... 21

CHAPTER 5 OPERATING ................................................................................. 25

RUN and STOP modes................................................................ 25

R Starting the continuous output.............................................. 26

S Stopping the output .............................................................. 26

SEND Outputting a single message only................................. 27

RESET Resetting the transmitter............................................. 27

POLL mode .................................................................................. 27

SEND Outputting one single message .................................... 28

OPEN Setting a transmitter from POLL mode to STOP mode 29

CLOSE Setting a transmitter from STOP mode to POLL mode29

SEND mode.................................................................................. 30

CHAPTER 6 CALIBRATION AND ADJUSTMENT........................................... 31

Pressure ....................................................................................... 31

CORR Listing linear and multipoint pressure corrections ........ 32

LC Linear pressure corrections ................................................ 33

II_____________________________________________________________________ M210195EN-A

Page 3

_________________________________________________________________________CONTENTS

LCI Entering linear pressure corrections ..................................34

MPC Multipoint pressure corrections........................................35

MPCI Entering multipoint pressure corrections ........................36

CALD Storing the date of calibration ........................................37

Humidity........................................................................................38

Humidity adjustment ................................................................. 38

Temperature .................................................................................39

Offset ........................................................................................39

Gain ..........................................................................................40

TXCI Entering corrections for HMP45D and PT100 temperature

measurement............................................................................40

V0XCI Entering corrections for HMP45A-P temperature

measurement............................................................................41

CHAPTER 7 SELF-TESTING AND PROBLEM HANDLING.............................43

Returning the serial communication parameters.....................43

Diagnostic commands ................................................................44

? Basic information on the transmitter settings .......................44

VERS Software version ............................................................ 45

SNUM Serial number ................................................................45

ERRS Error message output ................................................... 45

CHAPTER 8 TECHNICAL DATA .......................................................................47

Barometric pressure....................................................................47

Operating range........................................................................47

Accuracy class..........................................................................47

Humidity........................................................................................48

Temperature .................................................................................48

HMP45A-P & HMP45D.............................................................48

Pt100 sensor head.................................................................... 48

General..........................................................................................49

Mechanics.....................................................................................50

Transmitter body.......................................................................50

HMP45A-P and HMP45D .........................................................50

PT100 sensor head ..................................................................50

Weight.......................................................................................50

Dimensions ...............................................................................51

Transmitter body..................................................................51

HMP45A-P & HMP45D........................................................ 51

Pt100 sensor head ..............................................................52

Electromagnetic compatibility.................................................... 52

Accessories..................................................................................52

APPENDIX A OPTIONAL RS485/422 INTERFACE OF PTU200

TRANSMITTERS...........................................................................53

APPENDIX B ASHTECH PORT A/B 16 PIN CONNECTOR...............................56

APPENDIX C NMEA DATA FORMAT ................................................................. 58

GPS Commands...........................................................................59

Serial number ...........................................................................60

VAISALA __________________________________________________________________________III

Page 4

Page 5

CHAPTER 1_______________________________________________________ GENERAL INFORMATION

CHAPTER 1 GENERAL INFORMATION

Safety

Throughout the manual important instructions regarding the safety

considerations are focused as follows.

WARNING

CAUTION

NOTE

Warning denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to,

could result in injury to or death of personnel.

Caution denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to,

could result in damage to or destruction of part or all of the product.

Note highlights important information. It calls attention to an essential

procedure, practice, condition or the like.

VAISALA __________________________________________________________________________ 1

Page 6

USER'S GUIDE_______________________________________________________________________

Warranty

Vaisala hereby represents and warrants all Products manufactured by Vaisala and sold

hereunder to be free from defects in workmanship or material during a period of twelve (12)

months from the date of delivery save for products for which a special warranty is given. If any

Product proves however to be defective in workmanship or material within the period herein

provided Vaisala undertakes to the exclusion of any other remedy to repair or at its own option

replace the defective Product or part thereof free of charge and otherwise on the same

conditions as for the original Product or part without extension to original warranty time.

Defective parts replaced in accordance with this clause shall be placed at the disposal of

Vaisala.

Vaisala also warrants the quality of all repair and service works performed by its employees to

products sold by it. In case the repair or service works should appear inadequate or faulty and

should this cause malfunction or nonfunction of the product to which the service was

performed Vaisala shall at its free option either repair or have repaired or replace the product in

question. The working hours used by employees of Vaisala for such repair or replacement

shall be free of charge to the client. This service warranty shall be valid for a period of six (6)

months from the date the service measures were completed.

This warranty is however subject to following conditions:

a) A substantiated written claim as to any alleged defects shall have been received by

Vaisala within thirty (30) days after the defect or fault became known or occurred, and

b) the allegedly defective Product or part shall, should Vaisala so require, be sent to the

works of Vaisala or to such other place as Vaisala may indicate in writing, freight and

insurance prepaid and properly packed and labelled, unless Vaisala agrees to inspect and repair

the Product or replace it on site.

This warranty does not however apply when the defect has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of the Product or negligence or error in

storing, maintaining or in handling the Product or any equipment thereof;

c) wrong installation or assembly or failure to service the Product or otherwise follow

Vaisala's service instructions including any repairs or installation or assembly or service made

by unauthorized personnel not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as any adding to it without Vaisala's

prior authorization;

e) other factors depending on the Customer or a third party.

Notwithstanding the aforesaid Vaisala's liability under this clause shall not apply to any defects

arising out of materials, designs or instructions provided by the Customer.

This warranty is expressly in lieu of and excludes all other conditions, warranties and

liabilities, express or implied, whether under law, statute or otherwise, including without

limitation ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE and all other obligations and liabilities of Vaisala or its

representatives with respect to any defect or deficiency applicable to or resulting directly or

indirectly from the Products supplied hereunder, which obligations and liabilities are hereby

expressly cancelled and waived. Vaisala's liability shall under no circumstances exceed the

invoice price of any Product for which a warranty claim is made, nor shall Vaisala in any

circumstances be liable for lost profits or other consequential loss whether direct or indirect or

for special damages.

2 ____________________________________________________________________ M210195EN-A

Page 7

CHAPTER 2_______________________________________________________ PRODUCT DESCRIPTION

CHAPTER 2 PRODUCT DESCRIPTION

The PTU200 transmitter combines three measurement parameters:

pressure, temperature and humidity. The applications of the PTU200

range from calibration laboratory environmental condition monitoring

to laser interferometer active wavelength compensation and GPS

meteorological measurements.

The PTU200 transmitters are available with one or two pressure

transducers. Three different kinds of sensor heads can be used with

PTU200: HMP45A-P, HMP45D and Pt100.

The PTU200 transmitters use a RS232 or RS485 (optional) serial

interface and they are available also with a local display.

In outdoor applications, it is recommended to use the PTU200MIK

mounting kit with the PTU200 transmitters. In addition, a mounting

tripod is available to support the PTU200MIK in temporary field

installations.

Pressure measurement

The PTU200 series transmitters use a BAROCAP® silicon capacitive

absolute sensor developed by Vaisala for barometric pressure

measurement applications. The measurement principle of the PTU200

series digital transmitters is based on an advanced RC oscillator and

three reference capacitors against which the capacitive pressure sensor

and the capacitive temperature compensation sensor are continuously

measured. The microprocessor of the transmitter performs

compensation for pressure linearity and temperature dependence.

VAISALA __________________________________________________________________________ 3

Page 8

USER'S GUIDE_______________________________________________________________________

Humidity and temperature measurement

The HMP45A-P and HMP45D probes are designed for the

measurement of relative humidity and temperature. The humidity

measurement is based on a capacitive thin film polymer sensor,

HUMICAP180. The temperature measurement is based on resistive

platinum sensors. Both the humidity and the temperature sensors are

located at the tip of the probe and protected by a membrane filter.

The HMP45A-P probe has the HUMICAP180 polymer sensor and

the Pt 1000 resistive platinum sensor for RH and T measurements,

respectively. The 20 metres cable of the HMP45A-P is connected to a

board with a plug and thus the user can cut the cable to suitable length

and reconnect it easily. The HMP45A-P and the HMP45D have a

similar humidity output, but the temperature output is active in the

HMP45A-P (voltage output 0-1V) and passive in the HMP45D

(resistive output Pt 100). The HMP45D comes with a 3.5-meter

connection cable. The cable is soldered directly to the board inside the

transmitter.

When the humidity measurement is not required, the PTU200 can be

supplied with a small, high stability wire-type Pt100 temperature

sensor head.

4 ____________________________________________________________________ M210195EN-A

Page 9

CHAPTER 3___________________________________________________________ GETTING STARTED

CHAPTER 3 GETTING STARTED

Mounting

Choose a place, which represents the environment to be measured, and

is as clean as possible. Air should circulate freely around the probe; it

ensures that the sensor head and the ambient air are at the same

temperature.

NOTE

NOTE

For outdoor installation of the PTU200 transmitter, it is

recommended to use a PTU200MIK mounting kit. For further

information, please contact Vaisala or Vaisala distributor.

Please take into a consideration that the pressure fitting supplied with

the transmitter is not a static pressure head and that the transmitter

cannot be used successfully as such in turbulent or high speed static

wind conditions.

The barometric pressure measurement accuracy quoted for the

PTU200 series digital transmitters does not include any wind or air

conditioning system measurement errors.

Electrical connections

PTU200 series transmitters have as a standard a RS 232C and as an

option a RS485/422 serial interface. Connect the RS 232C serial

interface and a power supply according to the following pin

assignment.

5

1234

9

8

67

FIGURE 3-1 9-pin female sub D-connector

VAISALA __________________________________________________________________________ 5

Page 10

USER'S GUIDE_______________________________________________________________________

T

ABLE 3-1 Pin assignment for RS 232C/TTL serial output

PIN SIGNAL

1 TX with diode

2 TX/TXD/TXD inverted

3 RX/RXD/RXD inverted

4 external power on/off control

5 ground for the RS 232C

6

7 ground for supply voltage

8

9 supply voltage (10...30 VDC)

TABL E 3-2 Pin assignment for optional RS 232C/485/422

PIN SIGNAL

1 TX with diode

2 TX/TXD/TXD inverted

3 RX/RXD/RXD inverted

4 external power on/off control

5 ground for the RS 232C

6 RS 485/422 LO

7 ground for supply voltage and TTL level serial interface

8 RS 485/422 HI

9 supply voltage (10...30 VDC)

The factory settings of the PTU200 series transmitters are the

following:

TABL E 3-3 Serial interface factory settings

Baud rate 9600

Parity even

Data bits 7

Stop bits 1

Duplex full duplex

After having made the electrical connections, switch the power on,

and the transmitter responds indicating its type and the software

version.

PTU200 / 1.01

>

The transmitter is now ready to respond to any command available.

6 ____________________________________________________________________ M210195EN-A

Page 11

CHAPTER 3___________________________________________________________ GETTING STARTED

1

At power-up, the display will first show the transmitter type and the

software version. Then it switches to display the reading as defined

with the DFORM command (page 9).

Set the desired sending form according to software settings (described

starting from page 12) and select the sending mode for the transmitter

(see page 11).

Should there be any problems please check the jumper settings in

connector X15 and the settings in dip switch S1 inside the transmitter.

The settings should be as indicated in the figure below.

RX/RXD

RXD

TX

ON

S

TXD

TXD

X15

FIGURE 3-2 Basic RS 232C jumper and dip switch S1 settings

Connecting the probe

As the cable of HMP45A-P is connected via screw terminals the user

can shorten the cable to desired length and reconnect it easily. The

cable wires are connected as shown in FIGURE 3-3.

NOTE

It is not recommend to unsold and then re-sold the wires of HMP45D

and PT100 sensor head.

OFF

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

FIGURE 3-3 Wire colours of HMP45A-P.

VAISALA __________________________________________________________________________ 7

Page 12

USER'S GUIDE_______________________________________________________________________

FIGURE 3-4 Connecting the cable. Dimensions in mm (inches).

8 ____________________________________________________________________ M210195EN-A

Page 13

CHAPTER 4_____________________________________________________________COMMISSIONING

CHAPTER 4 COMMISSIONING

Display and keypad

The optional LCD display has an on/off selectable backlight for better

readability at any light conditions. The two rows of the display can be

defined to indicate different kind of information. The keypad of the

display cover can be used to inspect and change the parameters

available.

The format of the display is defined by using the serial command

DFORM (see page 15). There are two rows containing 16 characters

each; the user can define a maximum of 32 characters to be displayed,

16 characters on each row. The following fields in the display format

can be used:

pressure quantities (pressure, average, difference)

three-hour pressure trend and pressure tendency code

temperature quantity and relative humidity

units

error status and stability indicator

number and text fields

The following basic rules apply to the use of the keypad:

1. Use ENT key to acknowledge a new selection.

2. Use CL key to activate a parameter or unit to be changed or to

revert to the original display.

3. Use arrow keys to make a selection between functional

alternatives.

Only the display contrast can be adjusted if the KEYLOCK is ON.

The transmitter displays NO MODIFICATIONS ALLOWED message

for a few seconds before reverting to the original display. It is also

possible to inspect the settings of the transmitter although the

KEYLOCK has been turned ON.

VAISALA __________________________________________________________________________ 9

Page 14

USER'S GUIDE_______________________________________________________________________

Example of changing units:

1. Press ENT and the text UNIT starts blinking. Acknowledge it with

the ENT key (enter).

2. Press CL and the pressure unit in use starts blinking. Use arrow

keys to choose a desired unit and acknowledge it with enter.

3. The temperature unit in use starts blinking. Use arrow keys to

choose a desired unit and acknowledge it with enter. The

transmitter now returns to the original display.

Example of changing serial settings:

1. Press ENT and the text UNIT starts blinking. Choose SER by using

the arrow keys and acknowledge with enter.

2. Press CL and BAUD starts blinking. After pressing ENT, all the

available baud rates will be displayed. Use arrow keys to choose a

desired value and acknowledge it with enter. PARI starts blinking.

Press CL to exit or continue to change other serial parameters in

same way as the baud rate.

NOTE

Note that modifications made using the keyboard will affect the serial

interface settings, too.

FIGURE 4-1 Available functions and selections of the local display

10 ___________________________________________________________________ M210195EN-A

Page 15

CHAPTER 4_____________________________________________________________COMMISSIONING

Operating modes

Select the desired sending mode for the transmitter. This is done with

a command SMODE.

SMODE Selecting the sending mode

SMODE x <cr>

where:

x = STOP, RUN, SEND or POLL

The SMODE command is used to set or inspect the sending mode of

the transmitter. The PTU200 series transmitters have four sending

modes: STOP, RUN, SEND and POLL.

In STOP mode, after power-up the transmitter outputs its type and

software version and then waits for further commands.

In RUN mode, continuous outputting starts automatically from powerup.

In SEND mode, a single message is automatically output after powerup.

POLL mode allows the communication with multiple transmitters or

other digital instruments connected to one serial bus. The transmitter

does not echo in POLL mode.

Examples:

>smode <cr>

Serial mode : STOP

>smode run <cr>

Serial mode : RUN

>smode send <cr>

Serial mode : SEND

>smode poll <cr>

Serial mode : POLL

>smode stop <cr>

Serial mode : STOP

>reset<cr>

NOTE

Remember to give the RESET command to initialize the new sending

mode.

VAISALA _________________________________________________________________________ 11

Page 16

USER'S GUIDE_______________________________________________________________________

Software settings

SERI Serial bus settings

SERI b p d s x <cr>

where: (* = factory setting)

b = baud rate (300...9600*...38400)

p = parity (E = even*, O = odd, N =

none)

d = data bits (7* or 8)

s = stop bits (1* or 2)

x = duplex (F = full* or H = half)

<cr> = carriage return is generated by the

ENTER or RETURN key of the

host computer

The SERI command is used to set or inspect the serial bus settings of

the transmitter.

Examples:

>seri <cr>

9600 E71F

>seri 1200N81H<cr>

1200 N81H

>reset <cr>

PTU200 / 1.01

>

NOTE

Always give the RESET command after the SERI command to

activate the new serial bus settings.

ECHO Setting the serial bus echo on/off

ECHO x <cr>

where:

x=ONorOFF

The ECHO command can be used to set or inspect the echoing

condition of the transmitter. In OFF mode the transmitter does neither

output the '>' prompt character nor echo the given commands.

12 ___________________________________________________________________ M210195EN-A

Page 17

CHAPTER 4_____________________________________________________________COMMISSIONING

Examples:

>echo <cr>

Echo : ON

>

>echo off <cr>

Echo : OFF

FORM Defining the output format

FORM <cr>

The FORM command can be used to set or inspect the output format

of the transmitter. The maximum length of FORM is 80 characters.

The user can define the following fields into the output format:

amount of decimals give number of decimals before a

quantity. Giving 4.2 before the

pressure quantity outputs a reading

with the following form: 1013.12

pressure quantities P1, P2, P (average), PD

(difference)

pressure trend *) TRE (three-hour trend)

pressure tendency A (three-hour tendency)

temperature quantity of PT100

and HMP45D sensor heads *) T

temperature quantity

of HMP45A-P *) TH

relative humidity RH

units U, UU, UUU, UUUU, UUUUU

serial number of the transmitter SN

error status ERR (three characters)

stability indicator OK (uses three characters)

checksums CS2, CS4

CSX

number fields n.m where: n = 0 - 9, m = 0 - 9

text fields within “ “ characters

CR \ r or #r

LF \ n or #n

TAB \ t or #t

nnn ASCII code \ nnn or # nnn (cannot be 000)

*) The PTU200 transmitter cannot output + sign for pressure trend or

temperature reading; a space is output instead.

VAISALA _________________________________________________________________________ 13

Page 18

USER'S GUIDE_______________________________________________________________________

Example of setting the output format:

>form

P1""UUU""T""UU""RH""UUU\r\n

?4.1P""UUU"""Tend"""1.0A""3.1TUU""

3.0 RH UUU \r \n

>send

1007.9 hPa Tend 7 24.9'C 28%RH

>

Inspecting the output format:

>form

P1""UUU""T""UU""RH""UUU\r\n

?<esc>

Use ESC-key to abort without changing the settings.

EFORM Defining the error output format

EFORM <cr>

The EFORM command can be used to define a user specific error

output format for the serial line. In case of an error, the transmitter

outputs the defined format instead of *****.

Example of an EFORM definition:

>eform <cr>

? "ERROR" \r \n <cr>

>send

1007.8 hPa OK (correct operation)

>send <cr>

ERROR (incorrect operation)

>

Any previous EFORM definition may be removed with the following

command:

>eform * <cr>

>

14 ___________________________________________________________________ M210195EN-A

Page 19

CHAPTER 4_____________________________________________________________COMMISSIONING

DFORM Defining the display format

DFORM <cr>

The DFORM command is used to define the format for the optional

LCD display. There are two rows containing 16 characters each. The

user can define the following fields into the display format:

pressure quantities P1, P2, P (average), PD

(difference)

pressure trend *) TRE (three-hour trend)

pressure tendency A (three-hour tendency)

temperature quantity of PT100

and HMP45D sensor heads *) T

temperature quantity

of HMP45 TH

relative humidity RH

units U, UU, UUU, UUUU, UUUUU

serial number of the transmitter SN

error status ERR (three characters)

stability indicator OK (uses three characters)

number fields n.m where: n = 0 - 9, m = 0- 9

text fields within “ “ characters

*) The PTU200 transmitter cannot output + sign for pressure trend or

temperature reading; a space is output instead.

Any previous DFORM definition may be removed and the original

factory setting restored with the following command:

>dform * <cr>

>

Example of setting the display format to show pressure, stability

indicator, pressure trend and pressure tendency:

>dform <cr>

4.2P""UUUUU OK \r \n

?""4.2P""UUUOK"trend " 2.1 TRE""UUU""A

<cr>

>

The display will look similar to the following:

VAISALA _________________________________________________________________________ 15

Page 20

USER'S GUIDE_______________________________________________________________________

The PTU200 transmitter will show * instead of numeric values for

pressure trend and pressure tendency for three hours from power-up.

In case of error, the relevant error message will automatically appear

on the display. In this case, any other information defined using the

DFORM command will be replaced with an error message.

PROMPT Setting the prompt outputting ON or OFF

PROMPT x

where:

x = ON or OFF

>PROMPT<cr>

Prompt : ON

>PROMPT OFF<cr>

Prompt : OFF

send<cr>

1007.9 hPa Tend 7 24.9 'C 28 %RH

PROMPT ON<cr>

Prompt : ON

>

UNIT Setting the pressure and temperature units

UNIT x <cr>

where (* = factory setting)

x = hPa*, kPa, Pa, bar, mbar, inHg, mmHg, torr, mmH2O, psia, C*, F

This command is used to set and inspect the pressure and temperature

unit.

Example of changing the pressure and temperature units:

>unit <cr>

P unit : hPa

T unit : 'C

>unit C <cr>

>send

1018.33 hPa 24.19 'C 32.96 %RH

>unit torr <cr>

P unit : torr

T unit : 'C

>unit F <cr>

>send

763.84 torr 75.62 'F 32.89 %RH

>

16 ___________________________________________________________________ M210195EN-A

Page 21

CHAPTER 4_____________________________________________________________COMMISSIONING

AVRG Setting the averaging time

AVRG x <cr>

where:

x = 1 ... 600 (seconds)

The AVRG command is used to set and inspect the averaging time

during which the individual measurement samples are integrated to

get an averaged reading. The averaging time is the total averaging

time of the transmitter.

In case of two internal pressure transducers, the defined averaging

time is divided by three to get an averaging time for each pressure

transducer. The third transducer is the VMT for measuring RH/T.

Note that if the averaging time is defined to be long, the settling time

at power-up will be long, too.

The output reading is a running average pressure reading. The

measurement is updated in normal measurement mode approximately

every 1 to 4 seconds, depending on the AVRG setting.

A minimum of one-second averaging time is recommended per each

pressure transducer. These selections are used as the factory setting

averaging times.

Example of setting the averaging time to 60 seconds (WMO averaging

time for barometric pressure measurement):

>avrg <cr>

Averaging time: 1.0 ?<cr>

>

>avrg 60 <cr>

Averaging time: 60.0

>

VAISALA _________________________________________________________________________ 17

Page 22

USER'S GUIDE_______________________________________________________________________

INTV Setting the output interval

INTV x y <cr>

where:

x = output interval (0...255)

y = unit (s, min, h)

This command is used to set and inspect the output interval. The R

command is used to start the outputting.

Examples:

>intv <cr>

Output intrv. : 0 s

>

>intv 10 s <cr>

Output intrv. : 10 s

>r <cr>

NOTE

In case of the half duplex RS 485/422 serial communication, the user

is requested to set the interval time to one second or more. This

enables an interruption of outputting, if the R command is given by

mistake.

ADDR Setting the transmitter address (for POLL mode)

ADDR x <cr>

where:

x = the address (0 ... 99)

This command is used to set and inspect the address of the transmitter

for the POLL mode. The address feature is important when multiple

transmitters are connected to one RS232C interface or when a

transmitter is used on an RS485/422 serial interface.

Example of setting the address to 7:

>addr 7 <cr>

Address : 7

>

18 ___________________________________________________________________ M210195EN-A

Page 23

CHAPTER 4_____________________________________________________________COMMISSIONING

A new address replaces the previous one. Always set the address to 0

when no address is needed:

>addr 0 <cr>

Address : 0

>

NOTE

If the transmitter is not closed in the POLL mode, it will respond to

any SEND command despite of the address. The transmitter has to be

set to POLL mode and then closed with CLOSE command (see

Chapter POLL mode).

SCOM User specific SEND command

SCOM <cr>

This command is used to define a user specific SEND command for

one message output. The standard SEND command of the transmitter

will always function normally whatever the SCOM definition may be.

The new command must be defined within “ “ signs, then some end

characters also can be defined.

Note that the SCOM command is case sensitive. It is in fact

recommended to use the opposite case characters for SCOM definition

to avoid incocsistency with other commands. Note also that the

PTU200 does not react on <eot> at the end of a command.

Example of setting a P (note the upper case character in comparison to

the rest of the lower case characters) command for one message

output:

>scom <cr>

? "P" \ r <cr>

>P <cr>

1020.30 hPa

>

Example of defining a similar command without an end character:

>scom <cr>

"P" \r

? "P" <cr>

>P1020.30 hPa

>

Any previous SCOM definition may be removed with the following

command:

>scom * <cr>

>

VAISALA _________________________________________________________________________ 19

Page 24

USER'S GUIDE_______________________________________________________________________

PSTAB Setting the pressure stability indicator

PSTAB x <cr>

where:

x = pressure reading (in current unit)

The PSTAB command is used to define the pressure stability indicator

reflecting maximum allowed pressure difference between two

successive averaged measurements. The user has to also define the

FORM command to include the "OK" stability indicator field. The

factory setting for the stability indicator level is 0.5 hPa.

>pstab 0.5 <cr>

Stab. level : 0.50 hPa

>form

?4.2P""UUU""OK\r\n

>send <cr>

1020.30 hPa OK (accepted)

>send <cr>

1020.30 hPa (rejected)

>

PDMAX Setting the pressure difference limit

PDMAX x <cr>

where:

x = pressure reading

This command is used to define the maximum pressure difference

between the pressure readings from two pressure transducers (P1 and

P2). If the defined value is exceeded, the relevant digits in the ERR

field will change from 0 to 1. More than one ´1´ in the ERR field

indicates that the pressure reading output is not reliable.

For an acceptable measurement crucial conditions are:

- two transducers: P high - P low ≤ Pdmax

The factory setting for Pdmax is 1 hPa.

20 ___________________________________________________________________ M210195EN-A

Page 25

CHAPTER 4_____________________________________________________________COMMISSIONING

Example of setting the limit to 0.5 hPa:

>pdmax <cr>

Pd max : 1.000 ? 0.5 <cr>

>

Example of exceeding the Pdmax limit:

>form <cr>

4.2P""UUUU \r \n

?4.2P1""P2""P""UUU""ERR\r\n<cr>

>send <cr>

1020.30 1020.32 1020.31 hPa 00

>send <cr>

1020.30 1022.30 1021.30 hPa 11

>

Please use the ERRS command to analyze problems.

KEYLOCK Setting the keyboard lock on/off

KEYLOCK x <cr>

where:

x = ON or OFF

The KEYLOCK command is used to set or inspect the keypad lock

condition of the display cover keypad. The PTU200 transmitters with

display cover are supplied with the keypad locked (KEYLOCK OFF).

It is thus possible to inspect the settings but not to change them. With

the keypad locked the settings can be inspected but not changed.

Example:

>keylock on <cr>

Keylock : ON

>

If anyone tries to change the settings using the keypad with the

KEYLOCK ON, the transmitter will display NO MODIFICATIONS

ALLOWED

for a few seconds and then returns to the original display.

Hardware settings

Inside the transmitter, there is a connector X15 (see FIGURE 4-2) and a

dip switch S1 (see

hardware settings of the PTU200.

VAISALA _________________________________________________________________________ 21

FIGURE 4-3). These are used to make the main

Page 26

USER'S GUIDE_______________________________________________________________________

1

1

With the connector X15 the user can select the RS 232C (RX, TX) or

TTL levels for serial communication. With TTL levels, the user also

has phase alternatives available for both input (RXD, RXD inverted)

and output (TXD, TXD inverted).

RX/RXD

RXD

TX

TXD

TXD

X15

FIGURE 4-2 RS 232C/TTL level and phase selections

The half duplex two-wire RS485/422 serial interface of the PTU200

does not require any hardware settings to be made to the transmitter.

See page 53 for quick reference information on how to use the

RS485/422 interface of the PTU200 series digital transmitters.

Normally, the dip switch S1 settings are all OFF as in

ON

S

FIGURE 4-3

OFF

SW3

SW5

SW1

FIGURE 4-3 Basic dip switch S1 settings

SW2

SW4

SW6

SW7

SW8

An external power control can be used to switch the PTU200

transmitter ON/OFF. The control is activated with the switch SW2 in

position

ON as shown in FIGURE 4-4. The TTL signals are: 0VDC OFF

and 5VDC ON.

ON

S

OFF

SW3

SW5

SW1

SW2

SW4

SW6

SW7

SW8

FIGURE 4-4 External power control ON

22 ___________________________________________________________________ M210195EN-A

Page 27

CHAPTER 4_____________________________________________________________COMMISSIONING

T

ABLE 4-1 Summarized settings of the dip switch S1.

SW1 OFF not used

SW2 OFFONexternal power control OFF (TTL: 0 VDC)

external power control ON (TTL: 5 VDC

SW3 OFF not used

SW4 OFFONmemory write DISABLE

memory write ENABLE

SW5 OFF not used

SW6 OFF not used

SW7 OFF not used

SW8 OFFONfactory settings OFF / user settings ON

factory settings ON (9600, E, 7, 1, F)

VAISALA _________________________________________________________________________ 23

Page 28

Page 29

CHAPTER 5________________________________________________________________ OPERATING

CHAPTER 5 OPERATING

Only a few commands are needed to operate a PTU200 transmitter in

the RUN, STOP and POLL modes. In the SEND mode, no commands

are needed.

In the RUN or STOP modes, the commands R, S and SEND can be

used. The user may also use his own SEND command if he has

previously specified one using the SCOM command.

In the POLL mode, the transmitter responds to a SEND command

only if it includes the address. OPEN and CLOSE commands are also

available for temporary communication with one single transmitter.

In the SEND mode, no commands are needed. The transmitter will

automatically output one message at power-up, or when triggering the

transmitter on using pin 4.

RUN and STOP modes

TABL E 5-1 summarizes the commands that are used in the RUN and

STOP modes. In addition, the user may use his own SEND command

if he has previously specified one with the SCOM commissioning

command. The commands are not case sensitive except for the SCOM

command.

TABL E 5-1 Commands used in RUN and STOP modes

Function Command

starting output R

stopping output S

single message output SEND

resetting the transmitter RESET

VAISALA _________________________________________________________________________ 25

Page 30

USER'S GUIDE_______________________________________________________________________

R Starting the continuous output

R <cr>

This command is used to start continuous outputting in the STOP and

RUN modes and after setting the output interval (see page and 18).

Example (in STOP mode):

>reset <cr>

PTU200 / 1.01

>r <cr>

1013.25 hPa 22.9 %RH 22.4 'C

1013.25 hPa 22.9 %RH 22.4 'C

1013.25 hPa 22.) %RH 22.4 'C

...

Example of restarting the outputting (in RUN mode):

>SMODE<cr>

Serial mode : RUN

>RESET<cr>

1009.1 hPa 42.4 %RH 24.2 'C

1009.1 hPa 42.4 %RH 24.2 'C

...

S<cr> (text invisible)

>R<cr>

1009.2 hPa 42.5 %RH 24.2 'C

1009.1 hPa 42.5 %RH 24.2 'C

...

S Stopping the output

This command is used to stop the continuous outputting (activated

with power-up or reset in RUN mode or using the R command).

Example:

>r <cr>

1013.25 hPa 22.9 %RH 22.4 'C

1013.25 hPa 22.9 %RH 22.4 'C

1013.25 hPa 22.9 %RH 22.4 'C

s <cr> (text invisible)

>

S <cr>

26 ___________________________________________________________________ M210195EN-A

Page 31

CHAPTER 5________________________________________________________________ OPERATING

SEND Outputting a single message only

SEND <cr>

This command is used to output one message at a time in the STOP

and RUN modes.

>reset <cr>

PTU200 / 1.01

>send <cr>

1013.25 hPa 22.9 %RH 22.4 'C

>

The user may also use his own one-message command if he has

previously specified one using the SCOM command (see Chapter on

page 11).

RESET Resetting the transmitter

RESET <cr>

The RESET command is used to reset the transmitter. All software

settings remain in the memory after reset or any power failure. The

RESET command must always be given if the serial bus settings, DIP

switch settings or the operating mode of the transmitter have been

changed.

Example:

>reset <cr>

PTU200 / 1.01

>

POLL mode

TABL E 5-2 Commands used in RUN and STOP modes

Function Command

single message output SEND

opening a transmitter OPEN

closing a transmitter CLOSE

VAISALA _________________________________________________________________________ 27

Page 32

USER'S GUIDE_______________________________________________________________________

The POLL mode is used when several PTU200 series transmitters are

connected to one RS232C serial interface. It is also used when several

intelligent transmitters are connected to a half duplex RS 485/422

serial interface.

In the POLL mode, the transmitter must have a specific address so

that the host system is able to direct the outputting commands to the

particular transmitter. The addressable SEND command is used to ask

for a single message output from the transmitter.

The OPEN command can be used to open a single transmitter

temporarily to STOP mode. The CLOSE command will restore the

POLL mode.

SEND Outputting one single message

SEND a <cr>

where:

a = the address of the transmitter (0...99)

This command is used to output one message from the transmitter in

the POLL mode (see SMODE command).

Example:

>addr 7 <cr>

Address : 7

>smode poll <cr>

Serial mode : POLL

>close <cr>

line closed

send 7 <cr> (text invisible)

1013.25 hPa

28 ___________________________________________________________________ M210195EN-A

Page 33

CHAPTER 5________________________________________________________________ OPERATING

OPEN Setting a transmitter from POLL mode to STOP mode

CLOSE Setting a transmitter from STOP mode to POLL mode

OPEN a <cr> CLOSE <cr>

where:

a = the address of the transmitter (0...99)

These commands are used to set a transmitter temporarily to STOP

mode and back to POLL mode again. The OPEN command is useful

when several transmitters are connected to one serial bus and

communication with a single transmitter is needed. The CLOSE

command is a global command and requires no address.

The PTU200 series transmitters must always be closed after the POLL

mode selection. The RESET command and powering-up will close the

PTU200 series transmitters automatically.

>addr 7 <cr>

Address : 7 <cr>

>smode poll <cr>

Serial mode : POLL

>close <cr>

line closed

Example of opening and closing a transmitter with address 7:

open 7 <cr> (text invisible)

PTB 7 line opened for operator commands

>

Any commands (except for the ? command) can now be used for the

transmitter with address 7 without affecting other transmitters with

different addresses connected to the same serial interface. However, if

the RESET command is given or the transmitter is powered-up, the

transmitter will automatically return to the POLL mode.

Example of closing a transmitter:

>close <cr>

line closed

VAISALA _________________________________________________________________________ 29

Page 34

USER'S GUIDE_______________________________________________________________________

SEND mode

In the SEND mode, the transmitter will automatically output one

message at power-up or when triggering the transmitter on using pin 4

of the transmitter. The trigger signal must be a TTL level signal. TTL

HIGH (5 VDC) turns the transmitter ON and TTL LOW (0 VDC)

turns the transmitter OFF.

Examples of outputting with the prompt (ECHO ON) and without the

prompt (ECHO OFF):

>echo <cr>

Echo : ON

>smode send <cr>

Serial mode : SEND

>reset <cr>

1013.25 hPa

>

>echo off <cr>

Echo : OFF

reset <cr> (text invisible)

1013.25 hPa

Example of outputting a minimum amount of (six) characters by

excluding the <cr> and <lf> characters, the pressure unit and the

decimal point with the FORM command:

>form <cr>

4.2P""UUUU \r \n

? 6.0 P <cr>

>unit Pa

P unit : Pa

>smode send <cr>

Serial mode : SEND

>echo off <cr>

Echo : OFF

reset <cr> (text invisible)

101325

or

(power-up)

101325

30 ___________________________________________________________________ M210195EN-A

Page 35

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

CHAPTER 6 CALIBRATION AND

ADJUSTMENT

Pressure

The user can select a simple offset or a two-point offset and gain

adjustment and use the LCI command for adjustment of pressure

transducer. The MPCI command is used for the more sophisticated

multipoint correction capability at up to eight pressure levels.

NOTE

Check first what linear corrections the transmitter is currently using

before attempt to readjust the transducer. As the previous linear

corrections will disappear when new linear corrections are input, the

user has to take into account the previous linear corrections when

deciding about the new ones.

Entering new linear or multipoint corrections will always cancel the

previous corrections. It is advisable to write down the previous linear

and multipoint corrections so that they will not be lost by mistake.

Entering new linear or multipoint corrections or changing their status

will also automatically cancel the date of calibration of the

transmitter (see CALD command).

TABL E 6-1 Adjustment and calibration commands

Function Command

listing corrections CORR

linear corrections on/off LC ON/OFF

multipoint corrections on/off MPC ON/OFF

entering multipoint corrections MPCI

calibration date CALD

The linear and multipoint corrections are protected by switch SW4

(see figure 6.2). The switch SW4 is normally in write DISABLE

position (OFF) and the user must change it to write ENABLE position

VAISALA _________________________________________________________________________ 31

Page 36

USER'S GUIDE_______________________________________________________________________

1

(ON) to be able to enter new linear and multipoint corrections to the

transmitter.

ON

S

OFF

SW3

SW5

SW6

SW7

SW8

NOTE

SW1

FIGURE 6-1 Switch SW4 in write ENABLE position (ON)

SW2

SW4

Always remember to return the switch SW4 to write DISABLE

position (OFF).

CORR Listing linear and multipoint pressure corrections

CORR <cr>

The CORR command is used to indicate the status of linear and

multipoint pressure corrections. In case the status is ON, the

corrections and valid date of calibration are listed. The listing varies

according to the number of transducers in the transmitter. The

transmitter lists * in the second column if there exists only one

pressure transducer in the transmitter.

Example of the listing of a transmitter with one pressure transducer:

>corr

Linear adjustments ON

Reading Correction Reading Correction

500.010 0.120*******.**********.***

1100.320 0.150*******.**********.***

Multipoint adjustments ON

Reading Correction Reading Correction

499.660 -0.110*******.**********.***

599.110 -0.080*******.**********.***

698.580 -0.060*******.**********.***

800.950 -0.030*******.**********.***

900.400 0.010*******.**********.***

947.200 0.020*******.**********.***

999.840 0.050*******.**********.***

1099.090 0.070*******.**********.***

32 ___________________________________________________________________ M210195EN-A

Page 37

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

Transducer 2

CORRECTIONS:

TXD0,TXD1,TXD2 : -0.12000 1.00000 0.00000

V0XD0,V0XD1,V0XD2: 0.00000 1.00000 0.00000

V1XD0,V1XD1,V1XD2: 0.00000 1.00000 0.00000

Calibration date 1998-12-11

>

LC Linear pressure corrections

LC x <cr>

where:

x = ON or OFF

The LC command is used to activate or deactivate the linear offset or

offset/gain pressure corrections. Plain command LC outputs the linear

corrections in use.

NOTE

NOTE

The linear corrections are protected with switch SW4 (see FIGURE 6-1)

Turn the switch SW4 to write ENABLE position (ON) to be able to

turn the linear corrections on or off.

Changing the linear corrections on or off will automatically cancel the

date of calibration of the transmitter.

The listing varies according to the number of pressure transducers.

Example of linear adjustments performed on a transmitter with two

transducers:

>lc off <cr>

Linear adj. : OFF

>lc on <cr>

Linear adj. : ON

>lc <cr>

Reading Correction Reading Correction

1013.250 -0.100 800.000 0.050

1013.250 -0.100 1000.000 -0.020

>

Always remember to return the switch SW4 to write DISABLE

position (OFF).

VAISALA _________________________________________________________________________ 33

Page 38

USER'S GUIDE_______________________________________________________________________

LCI Entering linear pressure corrections

LCI n <cr>

where:

n = number of the pressure transducer (1 or 2)

The LCI command is used to enter new linear offset and offset/gain

pressure corrections to the transmitter. Note that the linear corrections

are given to each pressure transducer separately.

Entering new linear corrections is protected by switch SW4. Turn the

switch SW4 to write ENABLE position (ON) to be able to enter new

linear and multipoint corrections to the transmitter.

Deactivate the previous corrections by using the LC OFF. Precalibration of the transmitter then gives the required new corrections.

NOTE

The new linear corrections will always cancel the previous

corrections as well as the valid date of calibration of the transmitter

(see CALD command).

Activate the new linear corrections with the LC ON command. Use

ESC to abort without executing the command.

In the following, an example of performing an offset adjustment for

pressure transducer P1 and an offset and gain adjustment for pressure

transducer P2 is given.

>lc off <cr>

Linear adj. : OFF

>lci 1 <cr>

P1 1. reading ? 1013.25 <cr>

correction ? -0.1 <cr>

P1 2. reading ? <cr>

>lci 2 <cr>

P2 1. reading ? 800.00 <cr>

correction ? 0.05 <cr>

P2 2. reading ? 1000.00 <cr>

correction ? -0.02 <cr>

>lc on <cr>

Linear adj. : ON

Reading Correction Reading Correction

1013.250 -0.100 800.000 0.050

1013.250 -0.100 1000.000 -0.020

>

NOTE

Always remember to return the switch SW4 to write DISABLE

position (OFF).

34 ___________________________________________________________________ M210195EN-A

Page 39

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

MPC Multipoint pressure corrections

MPC x <cr>

where:

x = ON or OFF

The MPC command is used to activate or deactivate the multipoint

corrections. Plain command MPC outputs the corrections in use.

The multipoint corrections are protected with switch SW4 (see FIGURE

6-1). Turn the switch SW4 to write ENABLE position (ON) to be able

to turn the multipoint corrections on or off.

NOTE

Changing the multipoint corrections on or off will automatically

cancel the previous date of calibration of the transmitter (see CALD

command).

Example of multipoint adjustments performed on a transmitter with

one pressure transducer:

>mpc off <cr>

Multipoint adj: OFF

>mpc on <cr>

Multipoint adjustments ON

>mpc<cr>

Reading Correction Reading Correction

499.660 -0.110*******.**********.***

599.110 -0.080*******.**********.***

698.580 -0.060*******.**********.***

800.950 -0.030*******.**********.***

900.400 0.010*******.**********.***

947.200 0.020*******.**********.***

999.840 0.050*******.**********.***

1099.090 0.070*******.**********.***

Multipoint adj: ON

>

NOTE

Always remember to return the switch SW4 to write DISABLE

position (OFF).

VAISALA _________________________________________________________________________ 35

Page 40

USER'S GUIDE_______________________________________________________________________

MPCI Entering multipoint pressure corrections

MPCI n <cr>

where:

n = number of the pressure transducer (1 or 2)

The MPCI command is used to enter new multipoint corrections to the

transmitter. Note that the user must give the multipoint corrections to

each pressure transducer separately.

Turn the switch SW4 to write ENABLE position (ON) to be able to

enter new linear and multipoint corrections to the transmitter.

Deactivate the previous corrections first using the LC OFF and/or

MPC OFF commands. Precalibration of the transmitter then gives the

required corrections.

NOTE

When entering new multipoint corrections, always start at the lowpressure end and then go up the pressure range.

The new multipoint corrections will always cancel the previous

corrections as well as the valid date of calibration of the transmitter

(see CALD command).

Use ESC to abort without executing the command. The new

multipoint corrections are activated with the MPC ON command.

In the following, an example of performing a multipoint adjustment

for pressure transducer P1 is given.

>lc off <cr>

Linear adj. : OFF

>mpc off <cr>

Multipoint adj: OFF

>mpci 1 <cr>

P1 1. reading ? 499.72 <cr>

correction ? -0.07 <cr>

P1 2. reading ? 599.20 <cr>

correction ? -0.08 <cr>

P1 3. reading ? 698.71 <cr>

correction ? -0.01 <cr>

P1 4. reading ? 801.12 <cr>

correction ? -0.01 <cr>

P1 5. reading ? 900.61 <cr>

36 ___________________________________________________________________ M210195EN-A

Page 41

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

correction ? -0.03 <cr>

P1 6. reading ? 947.42 <cr>

correction ? -0.02 <cr>

P1 7. reading ? 1000.10 <cr>

correction ? -0.04 <cr>

P1 8. reading ? 1099.58 <cr>

correction ? -0.04 <cr>

>mpc on <cr>

Multipoint adj: ON

>

NOTE

Always remember to return the switch SW4 to write DISABLE

position (OFF).

CALD Storing the date of calibration

CALD yyyy-mm-dd <cr>

This command is used to store the date of calibration in the memory

of the transmitter.

Example:

>cald <cr>

Calibration date ????-??-??

>cald 1997-01-01 <cr>

Calibration date 1997-01-01

>

Changing the status (ON/OFF) of the linear or multipoint corrections

or entering new linear or multipoint corrections will automatically

cancel the date of calibration.

NOTE

VAISALA _________________________________________________________________________ 37

position (OFF).

Always remember to return the switch SW4 to write DISABLE

Page 42

USER'S GUIDE_______________________________________________________________________

Humidity

Calibration of the HMP45A-P/D probes should be performed at

regular intervals, depending on the conditions of use and desired

accuracy. The recommended calibration interval is one year.

The HMP45A-P/D probes are easy to maintain, calibrate and adjust.

The probe consists of a probe head and a handle with cable. All

calibration electronics are in the probe head, which can be

disconnected from the handle without disconnecting the wires. The

probe heads are interchangeable.

T

D

W

FIGURE 6-2 Adjustment trimmers and probe head connection/

Humidity adjustment

For a high-accuracy two-point adjustment, use a Vaisala HMK15 or

HMK13B calibrator and saturated salt solutions as described in the

respective manuals. If there is no local display, read the outputs via

the serial line.

Leave the calibrator and the probe head in the same space for at least

four hours so that their temperatures have time to equalize. Unscrew

the plastic grid of the probe.

The adjustment is done first for the dry end and then for the wet end

with trimmer potentiometers marked “D” (dry, <50 %RH) and “W”

(wet, >50 %RH). The potentiometers are located under a protective

plug; see FIGURE 6-2. Use a ceramic screwdriver with 2.5 mm blade for

adjusting the potentiometers. Note: if zero point is adjusted in

Nitrogen (N2), the minimum output signal of 0.008 V corresponds to a

relative humidity of 0.8 %RH.

pull the probe head

off the handle

disconnection

adjustment trimmers:

W = wet D = dry

(T for factory use only!)

TABL E 6-2 Greenspan’s calibration table

Temperature °C 15 20 25 30 35

LiCl %RH *) 11.3 11.3 11.3 11.3

NaCl %RH 75.6 75.5 75.3 75.1 74.9

K2SO

4

*) Do not use or store the LiCl solution in temperatures below +18°C as its humidity

equilibrium may change permanently

38 ___________________________________________________________________ M210195EN-A

%RH 97.9 97.6 97.3 97.0 96.7

Page 43

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

As the D (dry) and W (wet) adjustments may affect each other, check

again the humidity reading at the low end. If needed repeat the

procedure in low and high ends until the reading is correct.

Temperature

The temperature channels of PTU200 transmitters are very stable and

the probes have been calibrated and adjusted at the factory. Unless

there is a strong reason to believe that the adjustments have changed,

DO NOT perform a temperature adjustment. This is a very demanding

procedure and requires extremely accurate references. Furthermore, it

is important to allow enough time for the stabilization during

calibration. If for some reason, it is necessary to perform the

temperature adjustment, follow attentively the instructions given

below.

NOTE

NOTE

Offset

The temperature channel has to be calibrated if the probe head has

been changed.

The temperature adjustment can be done via the serial line using linear

offset and gain corrections. Entering any corrections is protected by

switch SW4. Turn it to write ENABLE position (ON) to be able to

enter new offset and gain corrections.

If there is need for an adjustment, check first whether there exist any

previously set corrections. Before entering new corrections, it is

recommended to set the offset to 0 and the gain to 1. Then measure

the temperature again at two reference points, and calculate the new

offset and gain corrections.

It is recommended to perform the one-point offset correction in

temperature, which is close to average measurement temperature. The

offset can be calculated by using equation 6-1.

TTOffset −= (6-1)

measref

where:

= T measured with an accurate reference thermometer

T

ref

T

= T measured with PTU200

meas

VAISALA _________________________________________________________________________ 39

Page 44

USER'S GUIDE_______________________________________________________________________

()(

)

Gain

Example: T

= 23.15°C

ref

T

meas

= 23.28°C

Offset = -0.13°C

The gain correction can be calculated with the equation 6-2. It is

reasonable to use the low (T1) and the high (T2) end of needed

temperature range.

−−−

TTTT

measrefmeasref

Gain

1

+=

1

1

1

2

−

TT

measmeas

2

2

(6-2)

where:

T

= measured with a reference thermometer at temperature T

T

T

T

ref1

ref2

meas1

meas2

= measured with a reference thermometer at temperature T

= measured with PTU200 at temperature T

= measured with PTU200 at temperature T

1

2

1

2

Example:

T

= -14.97°C and T

ref1

T

= +30.12°C and T

ref2

= -14.90°C

meas1

meas2

=+30.29°C

Gain = 0.99779

Offset = T

-Gain*T

ref2

meas2

= -0.10

T = 0.99779 * 30.29°C - 0.10 = 30.12°C

TXCI Entering corrections for HMP45D and PT100 temperature measurement

TXCI x

where:

x = 2 if there is one pressure transducer installed

3 if there is two pressure transducers installed

The TXCI command is used to enter new offset and offset/gain

corrections for temperature measurement of HMP45D and PT100.

40 ___________________________________________________________________ M210195EN-A

Page 45

CHAPTER 6_______________________________________________ CALIBRATION AND ADJUSTMENT

>txci

TXD0 : -1.199999971E-01 ? -0.10<cr> (offset)

TXD1 : 1.000000000E+00 ? 0.99779<cr> (gain)

TXD2 : 0.000000000E-01 ?<cr> (factory use only)

>

The factory setting TXD2 is passed by pressing enter. Use ESC to

abort without executing the command.

Reset the transmitter to activate the given corrections.

NOTE

Always remember to return the switch SW4 to write DISABLE

position (OFF).

V0XCI Entering corrections for HMP45A-P temperature measurement

V0XCI x

where: x = 2 if there is one pressure transducer installed

3 if there is two pressure transducers installed

The V0XCI command is used to enter new offset and offset/gain

corrections for temperature measurement of HMP45A-P.

Entering new corrections is protected by switch SW4. Turn it to write

ENABLE position (ON) to be able to enter new offset/gain

corrections.

The factory setting V0XD2 is passed by pressing enter. Use ESC to

abort without executing the command.

Reset the transmitter to activate the given corrections.

In the following, an example of performing an offset and gain

adjustment:

>V0XCI 2

V0XD0 : 0.000000000E-01 ? -0.10<cr>

V0XD1 : 1.000000000E+00 ? 0.99778<cr>

V0XD2 : 0.000000000E-01 ?<cr>

>

NOTE

Always remember to return the switch SW4 to write DISABLE

position (OFF).

VAISALA _________________________________________________________________________ 41

Page 46

Page 47

CHAPTER 7____________________________________________SELF-TESTING AND PROBLEM HANDLING

1

CHAPTER 7 SELF-TESTING AND

PROBLEM HANDLING

Returning the serial communication parameters

To restore factory software and hardware settings, set the dip switch

S1 on the CPU board as in FIGURE 7-1. Other switches except the SW8

must be OFF. In addition, the serial interface has to be set for basic RS

232C operation according to FIGURE 7-1. With these selections, one

single transmitter can be operated through the RS 232C serial

interface using factory serial bus settings as in TABLE 7-1. Returning

the SW8 to OFF will restore the original, application specific software

settings.

RX/RXD

RXD

ON

OFF

SW3

SW5

SW1

FIGURE 7-1 Factory settings for the dip switch S1 and Basic RS

SW2

SW4

SW7

SW6

SW8

S

TX

TXD

TXD

X15

232C settings

TABL E 7-1 Serial interface factory settings

Baud rate 9600

Parity even

Data bits 7

Stop bits 1

Duplex full duplex

VAISALA _________________________________________________________________________ 43

Page 48

USER'S GUIDE_______________________________________________________________________

Diagnostic commands

The PTU200 series digital transmitters respond to a set of diagnostic

commands, which are useful for analyzing the basic settings and

general operation of the transmitters. The diagnostic commands are

listed in

TABL E 7-2 Diagnostic commands

Function Command

basic information on settings ?

software version VERS

serial number SNUM

outputting error messages ERRS

? Basic information on the transmitter settings

? <cr>

The ? command lists the basic information of the transmitter.

>?

Software version PTU200 / 1.02

Serial number T5030004

Configuration 12

Linear adjustments ON

Multipoint adjustments ON

Calibration date 1999-03-12

Baud Parity Data Stop Dpx 9600 E 7 1 F

Echo ON

Sending mode STOP

Address 0

Output interval 3 s

Output format 4.1P""UUU""2.1RH""UUU#r#n

Error output format

SCOM format

Pressure unit hPa

Temperature unit 'C

Transducer 1:

TYPE: PMT

Transducer 2:

TYPE: VMT

Transducer 3:

TYPE: NONE

>

NOTE

Use this command only for one transmitter at a time. Any PTU200

series transmitter will always respond to ?-command whatever its

settings are, provided that the serial interface settings are correct.

44 ___________________________________________________________________ M210195EN-A

Page 49

CHAPTER 7____________________________________________SELF-TESTING AND PROBLEM HANDLING

VERS Software version

VERS <cr>

The VERS command is used to output the software version of the

transmitter.

>vers <cr>

PTU200 / 1.01

>

SNUM Serial number

SNUM <cr>

The SNUM command is used to output the serial number of the

transmitter.

>snum

CPU serial no : T2210005

TR1 serial no : 0

TR2 serial no : 0

TR3 serial no : 0

CTR1 serial no : 0

CTR2 serial no : 0

CTR3 serial no : 0

>

ERRS Error message output

ERRS <cr>

The ERRS command is used to print the error messages. The

command outputs an error code and an error description:

>errs <cr>

E00 Nothing special to report

>

Complete list of error codes:

E00 Nothing special to report

E10 CPU EEPROM ackn. error

E20 CPU EEPROM csum error

E11 TR1 Transducer not present

E21 TR1 EEPROM csum error

E31 TR1 serial number error

VAISALA _________________________________________________________________________ 45

Page 50

USER'S GUIDE_______________________________________________________________________

E41 TR1 f out of range

E51 TR1 y-value out of range

E61 TR1 pressure out of range

E71 TR1 P difference too large

E12 TR2 Transducer not present

E22 TR2 EEPROM csum error

E32 TR2 serial number error

E42 TR2 f out of range

E52 TR2 y-value out of range

E62 TR2 pressure out of range

E72 TR2 P difference too large

E13 TR3 Transducer not present

E23 TR3 EEPROM csum error

E33 TR3 serial number error

E43 TR3 f out of range

E53 TR3 y-value out of range

E63 TR3 pressure out of range

E73 TR3 P difference too large

46 ___________________________________________________________________ M210195EN-A

Page 51

CHAPTER 8_________________________________________________________ TECHNICAL DATA

CHAPTER 8 TECHNICAL DATA

Barometric pressure

Operating range

Pressure ranges 500 ... 1100 hPa, 50...1100 hPa

Accuracy class

Pressure range 500...1100 hPa 50...1100 hPa

class A class B

Linearity * ± 0.05 hPa ± 0.10 hPa

Hysteresis * ± 0.03 hPa ± 0.03 hPa

Repeatability * ± 0.03 hPa ± 0.03 hPa

Calibration uncertainty ** ± 0.07 hPa ± 0.15 hPa

Accuracy at +20 *C *** ± 0.10 hPa ± 0.20 hPa

Temperature dependence**** ± 0.1 hPa ± 0.1 hPa

Total accuracy including

one year drift ± 0.15 hPa ± 0.25 hPa

Long-term stability ± 0.1 hPa / year

Response time (100% response) class A class B

one sensor 2 seconds 1 second

* Defined as the ±2 standard deviation limits of end-point nonlinearity, hysteresis error or repeatability error.

** Defined as ±2 standard deviation limits of inaccuracy of the

working standard including traceability to NIST.

± 0.20 hPa

± 0.08 hPa

± 0.08 hPa

± 0.20 hPa

± 0.30 hPa

± 0.30 hPa

± 0.45 hPa

± 0.20 hPa/year

*** Defined as the root sum of the squares (RSS) of end-point nonlinearity, hysteresis error, repeatability error and calibration

uncertainty at room temperature.

**** Defined as ±2 standard deviation limits of temperature

dependence over the operating temperature range.

VAISALA _________________________________________________________________________ 47

Page 52

USER'S GUIDE_______________________________________________________________________

C

Humidity

Measurement range 0.8 ... 100 %RH

Accuracy at +20 °C (incl. non-linearity and hysteresis)

against factory references ±1 %RH (0...90 %RH)

±2 %RH (90...100 %RH)

field calibration against

references ±2 %RH (0...90 %RH)

±3 %RH (90...100 %RH)

Typical long-term stability < 1 %RH / year

Temperature dependence ±0.05 %RH/ °C

Response time (90%)at +20 °C 15 s with membrane filter

®

Humidity sensor HUMICAP

180

Temperature

HMP45A-P & HMP45D

Measurement range -36 ... +60 °C (HMP45A-P)

Accuracy at 20°C ±0.2 °C

Accuracy over the whole measurement range:

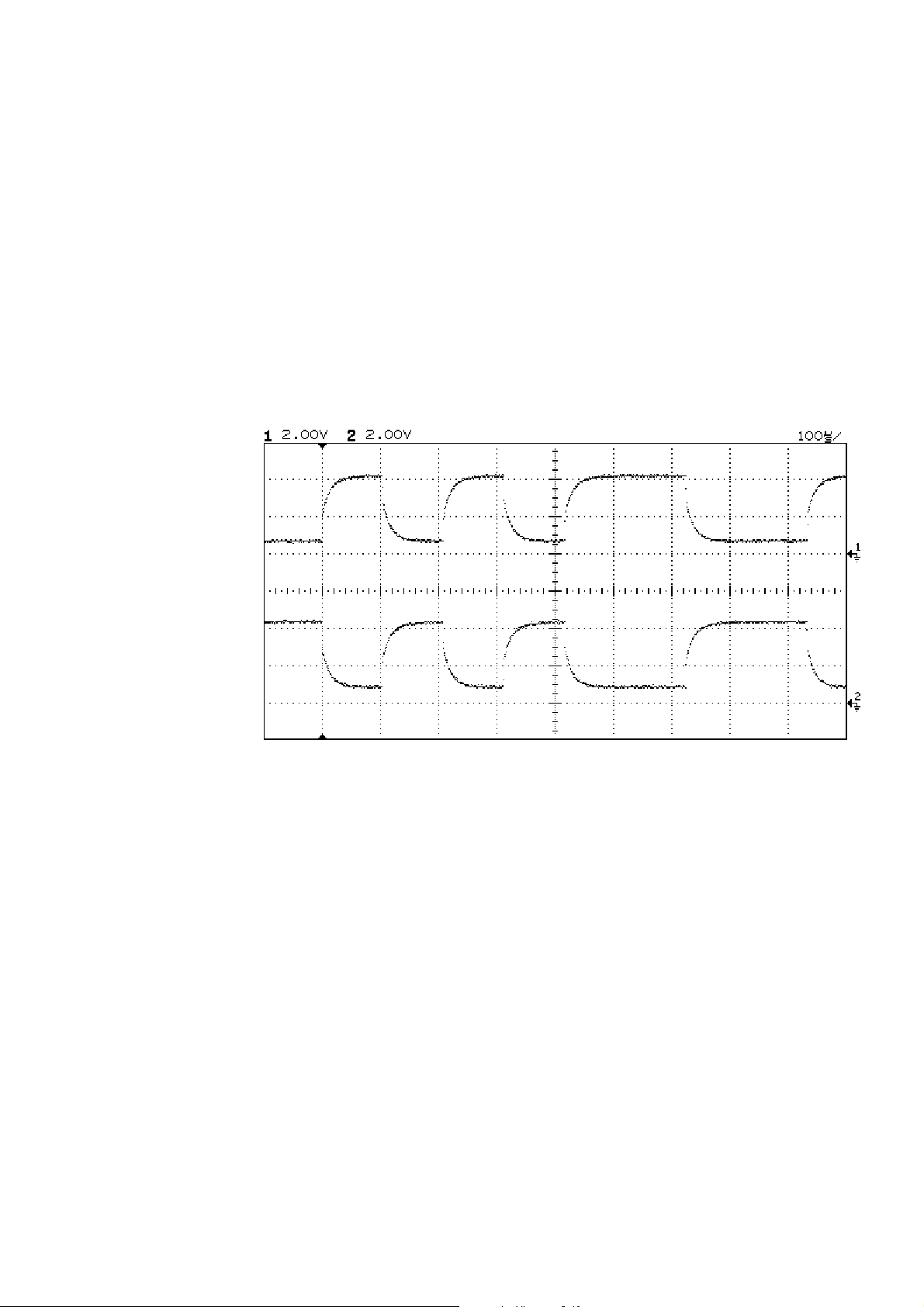

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

-40

-30

Temperature sensor

HMP45A-P Pt 1000 IEC 751 1/3 Class B

HMP45D Pt 100 IEC 751 1/3 Class B

Pt100 sensor head

-20

-10 0

-40 ... +60 °C (HMP45D)

10

20

30

40

50 60

°

Measurement range -40 ... +60 °C

Accuracy over

the whole measurement range ±0.2 °C

Temperature sensor Pt 100 IEC 751 1/4 Class B

48 ___________________________________________________________________ M210195EN-A

Page 53

CHAPTER 8_________________________________________________________ TECHNICAL DATA

General

(* factory settings)

Temperature range

operating -40 ... +60 ºC

with local display 0 ... +60 ºC

storage -40 ... +60 ºC

with local display -20 ... +60 ºC

Humidity range non-condensing

Supply voltage 10 ... 30 VDC, reverse polarity

protected

Supply voltage sensitivity negligible

Current consumption less than 30 mA

with local display less than 30 mA (without

backlight)

less than 50 mA (with backlight)

hardware shutdown mode less than 0.1 mA

Serial I/O full duplex RS 232C * or

bidirectional TTL level or

half duplex two-wire RS 485/422

code ASCII

parity even*, odd, none

data bits 7* or 8

stop bits 1* or 2

Baud rates 300, 600, 1200, 2400, 4800, 9600*

Electrical connections

excitation supply, GND, CTRL (for

shutdown)

serial communication TX, RX, GND, TXD, RXD, GND,

TXD inverted, RXD inverted,

GND, RS 485/422HI,

RS485/422LO

Units

pressure hPa*, kPa, Pa, mbar, bar, inHg,

mmHg, torr, mmH2O, psia

humidity %RH

temperature °C*, °F

Resolution 0.1 hPa*, 0.1 %RH, 0.01 °C