Page 1

USER'S GUIDE

Vaisala HUMICAP® Humidity and

Temperature Transmitter Series

HMT130

M211280EN-B

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FI-00421 Helsinki

Finland

Visit our Internet pages at www.vaisala.com.

© Vaisala 2013

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 7

About This Manual ................................................................... 7

Contents of This Manual ....................................................... 7

Version Information ............................................................... 8

Related Manuals ................................................................... 8

Documentation Conventions ................................................. 8

Safety ......................................................................................... 9

ESD Protection ......................................................................... 9

Recycling .................................................................................. 9

Regulatory Compliances ....................................................... 10

Patent Notice .......................................................................... 10

Trademarks ............................................................................. 10

License Agreement ................................................................ 10

Warranty .................................................................................. 10

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 11

Introduction to the HMT130 ................................................... 11

Accessories ......................................................................... 12

Fixed and Remote Probe Models........................................ 12

Optional Display .................................................................. 12

Interchangeable Probe ........................................................ 12

Constant Output Probe ....................................................... 13

Transmitter Components ..................................................... 14

CHAPTER 3

INSTALLATION ............................................................................................ 15

Opening the Transmitter Cover ............................................ 15

Mounting ................................................................................. 16

Wall Mounting...................................................................... 16

Installation with Rain Shield ................................................ 17

Installation with Radiation Shield ........................................ 18

Duct Installation Kit ............................................................. 19

Probe Assembly with Duct Installation Kit ..................... 20

Drilling Instructions for Duct Installation Kit ................... 20

Probe Mounting Flange ....................................................... 21

Probe Mounting Clamp ....................................................... 22

Connections ............................................................................ 23

RS-485 Bus Termination ..................................................... 25

CHAPTER 4

SERIAL LINE OPERATION ......................................................................... 27

Using the Service Port ........................................................... 27

VAISALA _________________________________________________________________________ 1

Page 4

User's Guide _______________________________________________________________________

Installing the Driver for the USB Cable ................................ 27

Terminal Application Settings .............................................. 28

List of Serial Commands ....................................................... 30

Device Information and Status .............................................. 31

Show Device Information..................................................... 31

Set/Show Available Quantities ............................................ 31

Set/Show Calibration Date .................................................. 32

Set/Show Calibration Information ........................................ 32

Show Analog Output Status ................................................ 33

Show System Information ................................................... 34

Show Firmware Version ...................................................... 34

Serial Line Output Commands .............................................. 34

Start Continuous Outputting ................................................ 34

Stop Continuous Outputting ................................................ 35

Set/Show Output Interval .................................................... 35

Output a Reading Once ....................................................... 35

Calibration Commands .......................................................... 36

Calibrate Humidity Measurement ........................................ 36

Restore Probe RH Factory Calibration ................................ 37

Calibrate Temperature Measurement ................................. 37

Restore Probe T Factory Calibration ................................... 38

Calibrate Analog Output ...................................................... 38

Configuring Serial Line Operation ........................................ 39

Set/Show Serial Line Settings ............................................. 39

Set/Show Terminal Echo ..................................................... 39

Set/Show Serial Interface Mode .......................................... 40

Configuring Measurement Parameters ................................ 40

Set/Show Environmental Parameters ................................. 40

Configuring Analog Output ................................................... 41

Set/Show Analog Output Mode ........................................... 41

Set/Show Analog Output Error Levels ................................. 42

Set/Show Analog Output Quantity and Scaling ................... 42

Test Analog Outputs ............................................................ 44

Configuring Relay Output ...................................................... 44

Set/Show Relay Quantity..................................................... 44

Set/Show Relay Operating Mode ........................................ 45

Show Relay Settings ........................................................... 45

Other Commands.................................................................... 46

Set/Show Displayed Quantities ........................................... 46

Set/Show Output Formatting ............................................... 47

Display Command List......................................................... 48

Display Active Errors ........................................................... 48

Save Changed Settings ....................................................... 48

Restore Saved Settings ....................................................... 49

Reset Transmitter ................................................................ 49

Restore Factory Settings ..................................................... 49

Set/Show Output Unit .......................................................... 50

Operating the User Port (RS-485) ......................................... 50

Networking Commands ....................................................... 50

SERI ............................................................................... 50

SERI2 ............................................................................. 50

ECHO ............................................................................. 51

SMODE .......................................................................... 51

SDELAY ......................................................................... 51

INTV ............................................................................... 52

2 ____________________________________________________________________ M211280EN-B

Page 5

_________________________________________________________________________________

ADDR ............................................................................. 52

SEND ............................................................................. 52

OPEN ............................................................................. 53

CLOSE ........................................................................... 53

CHAPTER 5

MAINTENANCE ........................................................................................... 55

Replacing the HUMICAP® Sensor ......................................... 55

Fixed and Remote Probe Models........................................ 55

Removing and Fastening the Probe ..................................... 56

Fixed Probe Model .............................................................. 56

Remote Probe Model .......................................................... 57

Calibration and Adjustment .................................................. 58

HMT130 Push-Button Calibration ....................................... 58

Humidity and Temperature Adjustment .............................. 59

Adjustment with HM70 ........................................................ 62

Field Checking and Adjustment Using a Calibrated

Reference Probe ............................................................ 63

One-Point Adjustment Using a Calibrator ...................... 63

Two-Point Adjustment Using a Calibrator ...................... 64

LiCl-NaCl Adjustment ..................................................... 65

Temperature Field Check and Adjustment by Using a

Calibrated Reference Probe .......................................... 66

Adjustment with HMI41 ....................................................... 67

Connections and Selecting the Calibrator Function ....... 68

Offset and Gain Adjustments ......................................... 69

HMI41 as a Reference Meter .................................... 70

HMI41 as a Terminal ................................................. 71

Troubleshooting ............................................................. 72

Analog Output Tests .............................................................. 73

CHAPTER 6

TROUBLESHOOTING ................................................................................. 75

Error Codes ............................................................................. 75

Solving Typical Problems...................................................... 76

Analog Output Error Notification .......................................... 77

Technical Support .................................................................. 77

CHAPTER 7

TECHNICAL DATA ...................................................................................... 79

Specifications ......................................................................... 79

Options and Accessories ...................................................... 81

Transmitter Dimensions ........................................................ 82

APPENDIX A

CALCULATION FORMULAS ...................................................................... 85

Dewpoint Temperature .......................................................... 85

Dew/frostpoint Temperature ................................................. 86

Mixing Ratio ............................................................................ 87

Absolute Humidity .................................................................. 87

Enthalpy .................................................................................. 87

VAISALA _________________________________________________________________________ 3

Page 6

User's Guide _______________________________________________________________________

Saturation Vapor Pressure .................................................... 88

Water Vapor Pressure ............................................................ 89

Accuracies of Calculated Variables ...................................... 89

Accuracy of Dewpoint Temperature °C ............................... 89

Accuracy of Mixing Ratio g/kg (Ambient Pressure 1013

mbar) ................................................................................... 89

Accuracy of Wet Bulb Temperature °C ............................... 90

Accuracy of Absolute Humidity g/m³ ................................... 90

INDEX ........................................................................................................... 91

4 ____________________________________________________________________ M211280EN-B

Page 7

_________________________________________________________________________________

List of Figures

Figure 1 HMT130 Components .............................................................. 14

Figure 2 Opening the Transmitter Cover ................................................ 15

Figure 3 HMT130 Wall Mounting ............................................................ 16

Figure 4 HMT130 Installation with Rain Shield ...................................... 17

Figure 5 Installation of the Probe with Radiation Shield ......................... 18

Figure 6 Probe Installation with the Duct Installation Kit ........................ 19

Figure 7 Assembly of the Probe with Duct Installation Kit ...................... 20

Figure 8 Drilling Instructions ................................................................... 20

Figure 9 Optional Probe Mounting Flange ............................................. 21

Figure 10 Optional Probe Mounting Clamp .............................................. 22

Figure 11 HMT130 Component Board ..................................................... 23

Figure 12 Power Supply and Voltage Outputs (A), and Serial

Communication and Relay (B) ................................................. 24

Figure 13 PuTTY Terminal Application..................................................... 29

Figure 14 Removing the Humidity Probe (Fixed Probe Model) ................ 56

Figure 15 Removing the Humidity Probe (Remote Probe Model) ............ 57

Figure 16 Adjustment Buttons .................................................................. 58

Figure 17 Location of the MI70 Probe and Cable Connector Ports ......... 62

Figure 18 Example of the MI70 Adjustment Menu ................................... 64

Figure 19 Example of the MI70 Adjustment Mode Graph Display ........... 64

Figure 20 Location of the HMI41 Calibration Connector .......................... 67

Figure 21 HMT130 Output Voltage Measurement ................................... 73

Figure 22 Dimensions of the Fixed Probe Model in mm (inches) ............ 82

Figure 23 Dimensions of the Remote Probe Model in mm (inches) ......... 83

List of Tables

Table 1 Manual Revisions ....................................................................... 8

Table 2 Related Manuals ........................................................................ 8

Table 3 Wiring Table ............................................................................. 25

Table 4 Default Serial Interface Setting ................................................ 28

Table 5 Serial Port Commands ............................................................. 30

Table 6 Common Problems During Adjustment and Their Remedies .. 72

Table 7 Error Codes and Texts ............................................................. 75

Table 8 Troubleshooting Table .............................................................. 76

Table 9 Relative Humidity Measurement Specifications ....................... 79

Table 10 Temperature Measurement Specifications .............................. 79

Table 11 Operating Environment Specifications ..................................... 80

Table 12 Inputs and Outputs ................................................................... 80

Table 13 Mechanical Specifications ........................................................ 81

Table 14 Options and Accessories.......................................................... 81

VAISALA _________________________________________________________________________ 5

Page 8

User's Guide _______________________________________________________________________

This page intentionally left blank.

6 ____________________________________________________________________ M211280EN-B

Page 9

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and HMT130.

About This Manual

This manual provides information for installing, operating, and

maintaining the Humidity and Temperature Transmitter HMT130.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the manual

and HMT130.

- Chapter 2, Product Overview, provides general information about the

Vaisala Humidity and Temperature Transmitter HMT130

- Chapter 3, Installation, provides information on the installation of

Vaisala Humidity and Temperature Transmitter HMT130

- Chapter 4, Serial Line Operation, contains information for operating

the RS-485 bus (user port) and the service port of the HMT130.

- Chapter 5, Maintenance, provides information that is needed in basic

maintenance of the product.

- Chapter 6, Troubleshooting, describes error messages and analog

output error behavior, introduces some common problems, their

probable causes and remedies and provides contact information for

Technical Support

- Chapter 7, Technical Data, provides the technical data of the product.

- Appendix A, Calculation Formulas, contains the formulas used for the

calculated output quantities.

- INDEX

VAISALA _________________________________________________________________________ 7

Page 10

User's Guide _______________________________________________________________________

Manual Code

Description

M211280EN-B

June 2013. This version. New probe options

updated.

M211280EN-A

November 2010. First version.

Manual Code

Manual Name

M210185EN

Humidity Calibrator HMK15 User's Guide

M210297EN

Hand-held Humidity and Temperature Meter

HM70 User's Guide

M210316EN

HMI41 Indicator and HMP41/45/46 Probes

Operating Manual

M211060EN

HMP60/110 Probe User's Guide

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this po

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights

Version Information

Table 1 Manual Revisions

added. Installation and operating instructions

Related Manuals

Table 2 Related Manuals

WARNING

CAUTION

NOTE

Documentation Conventions

Throughout the manual, important safety considerations are highlighted

as follows:

int, there is a risk of injury or even

important information on using the product.

8 ____________________________________________________________________ M211280EN-B

Page 11

Chapter 1 _________________________________________________________ General Information

Do not modify the unit.

or lead to malfunction.

Recycle all applicable material.

D

with regular household refuse.

Safety

The Humidity and Temperature Transmitter HMT130 delivered to you

has been tested for safety and approved as shipped from the factory. Note

the following precautions:

CAUTION

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the product

by delivering electrostatic discharges when touching, removing, or

inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground yourself

to the equipment chassis before touching the boards. Ground yourself

with a wrist strap and a resistive connection cord. When neither of the

above is possible, touch a conductive part of the equipment chassis

with your other hand before touching the boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

Improper modification can damage the product

Recycling

VAISALA _________________________________________________________________________ 9

ispose of the unit according to statutory regulations. Do not dispose of

Page 12

User's Guide _______________________________________________________________________

Regulatory Compliances

Vaisala HUMICAP® Humidity and Temperature Transmitter Series

HMT130 is in conformity with the provisions of the following EU

directives:

- EMC-Directive (2004/108/EC)

Conformity is shown by compliance with the following standards:

- EN 61326-1: Electrical equipment for measurement, control and

laboratory use – EMC requirements – for use in industrial locations.

- EN 55022 + Am1: Information technology equipment – Radio

disturbance characteristics – Limits and methods of measurement.

Patent Notice

The HMT130 is protected by the following patents and their

corresponding national rights:

Finnish patent 98861, French patent 6650303, German patent 69418174,

Japanese patent 3585973, UK patent 0665303, U.S. patent 5607564.

Trademarks

HUMICAP is a registered trademark of Vaisala Oyj.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is provided

by the applicable supply contract or Software License Agreement.

Warranty

Visit our Internet pages for standard warranty terms and conditions:

www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

10 ___________________________________________________________________ M211280EN-B

Page 13

Chapter 2 ___________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

Thank you for choosing the Vaisala HUMICAP® Humidity and

Temperature Transmitter Series HMT130. This chapter introduces you to

its features.

The Vaisala range of relative humidity measurement instruments covers

all the applications from ventilation to process control in demanding

conditions. For more information about other Vaisala relative humidity

instruments, please contact your Vaisala representative or visit

www.vaisala.com.

Introduction to the HMT130

The Vaisala HUMICAP® Humidity and Temperature Transmitter Series

HMT130 measures relative humidity and temperature and outputs the

measurements to voltage outputs and RS-485. Other quantities, such as

dewpoint (Td) can be calculated from the basic RH and T values

according to the device configuration. HMT130 is powered with a

10 ... 35 VDC or a 24 VAC supply (15 ... 35 VDC or 24 VAC required

when using 0 ... 10 V output). It outputs two analog voltage signals with

nominal 0 ... 10 V range. HMT130 has also an RS-485 digital interface

and a relay.

HMT130 transmitter's output quantities are configurable. Available

quantities for outputs are limited to two at the time. These two quantities

can be used freely at any outputs (display, service port and voltage

outputs).

Available quantities are RH, T, Td, Td/f, a, x, h, Tw, pws and pw.

The default output quantities are set at the factory during order time.

These factory preset quantity selections can be changed afterwards via

the service port if necessary.

The HMT130T and HMT130H models are single-parameter transmitters.

The only output quantity of HMT130T is temperature. The output of the

HMT130H can be configured to be any one of the humidity-related

quantities (RH, Td, Td/f, a, x, h, Tw, pws and pw).

VAISALA ________________________________________________________________________ 11

Page 14

User's Guide _______________________________________________________________________

Only probes that have a compatible digital output (VDIGI mode) can be

used with HMT130 transmitter.

the first letter in their order code. The order code is written on the probe.

Accessories

The following accessories are optionally available:

- Duct installation kit

- Rain shield with installation kit

- Rain/solar radiation shield installation kit (for pole installation)

- Probe mounting flange

- Probe mounting clamp

- Constant output probe (HMP110REF, gives constant RH and T

values)

Fixed and Remote Probe Models

The HMT130 is available either with a fixed probe directly attached to

the transmitter housing or a remote probe with different (3/5/10/20 m)

cable lengths. All extension cables can be easily cascaded in order to

obtain longer reach; see Options and Accessories on page 81.

NOTE

Optional Display

The HMT130 is also available with an optional graphical 128*64

resolution LCD display. The display shows the measurement results of

selected parameters in selected units (defined at the time of ordering).

The parameters are displayed simultaeously at two separate rows on the

display.

Interchangeable Probe

The HMP110 relative humidity probe used in the HMT130 transmitter is

fully interchangeable. You can easily remove the probe and replace it

with a new one without having to adjust the transmitter. You have the

following options when purchasing a new probe from Vaisala:

- Order a new probe and keep your current one.

- Order a new probe and return the old one to Vaisala (replacement

probe).

Compatible probes have the letter "V" as

12 ___________________________________________________________________ M211280EN-B

Page 15

Chapter 2 ___________________________________________________________ Product Overview

The transmitter goes to the error state for a short time when the probe is

changed. This is normal.

Constant Output Probe

The constant output probe HMP110REF is a testing accessory that can

be used to check transmitter's functions and measurement signal transfer

chain all the way to the control system. The constant output probe does

not measure humidity and temperature; instead, it outputs constant

humidity and temperature readings.

The values output by the constant output probe are specified when

ordering. These values are written on an additional label on the probe

body.

The procedure for using the constant output probe is simply to replace

the original probe for the duration of the testing:

1. Disconnect the normal probe from transmitter.

2. Connect the constant output probe to the transmitter.

3. Check that all used outputs (analog, display, serial line) show the

correct measurement values.

NOTE

4. After checking the outputs, disconnect the constant output probe

and reconnect the original probe.

VAISALA ________________________________________________________________________ 13

Page 16

User's Guide _______________________________________________________________________

The following numbers refer to Figure 1 above:

1 = Transmitter enclosure

2 = Cable bushing: cable gland, cable grommet, or conduit fitting.

3 = Probe cable

4 = HMP110 probe

5 = Plastic grid filter

Transmitter Components

Figure 1 below illustrates the main features of HMT130. On the left is a

remote probe model without display, and on the right is a fixed probe

model with the optional display. The numbers and arrows indicate the

main components of the transmitters.

1007-001

Figure 1 HMT130 Components

See section Options and Accessories on page 81 for accessory parts and

their numbers.

14 ___________________________________________________________________ M211280EN-B

Page 17

Chapter 3 ________________________________________________________________ Installation

CHAPTER 3

INSTALLATION

Opening the Transmitter Cover

1. If the transmitter is not mounted already, hold it against a flat

surface.

2. Push on the cover with your thumb, and pull the bottom part of the

cover towards yourself.

1301-019

Figure 2 Opening the Transmitter Cover

VAISALA ________________________________________________________________________ 15

Page 18

User's Guide _______________________________________________________________________

Select the size and type of the fastening screws according to the wall

material (wood, stone, etc.). Even though using all four screws is

strongly recommended, the HMT130 enclosure fastening holes

initially covered with a thin plastic membrane, so less than four screws

could be also be used without sacrificing the ingress protection (IP) class

of the enclosure. The diameter of the fastening screws is typically

between 3.5 and 4

Mounting

Wall Mounting

1. Remove the transmitter cover. See section Opening the Transmitter

Cover on page 15.

2. Make sure that the HMT130 Humidity and Temperature

Transmitter is correctly aligned and attach it directly to the wall

with up to four screws (not included in the package).

1011-160

Figure 3 HMT130 Wall Mounting

CAUTION

It is possible to damage the display when tightening the screws, as there

is not much room between the upper fastening holes and the exposed

display component. Be particularly careful when using a cordless drill.

NOTE

mm.

16 ___________________________________________________________________ M211280EN-B

are

Page 19

Chapter 3 ________________________________________________________________ Installation

Installation with Rain Shield

The installation kit with rain shield includes a metal mounting plate and

a rain shield for the transmitter. Vaisala order code: 215109.

1011-161

Figure 4 HMT130 Installation with Rain Shield

1. Fasten the metal mounting plate to the wall or pole with screws

(see Figure 4 above). Note the arrow on the mounting plate. Attach

the mounting plate with the arrow pointing upwards.

2. Drill holes for the screws in the HMT130 frame, and fasten

HMT130 Humidity and Temperature Transmitter to the metal

mounting plate with four (M4) screws.

3. Fasten the rain shield to the metal mounting plate with two (M6)

mounting screws.

VAISALA ________________________________________________________________________ 17

Page 20

User's Guide _______________________________________________________________________

The following numbers refer to Figure 5 above:

1 = DTR504

2 = Probe

3 = Plastic nut

4 = Installation support (part no. 227777)

6 = Probe

Installation with Radiation Shield

DTR504 with probe installation kit includes a rain/solar radiation shield

DTR504 and a plastic installation support for the humidity probe. Vaisala

order code: DTR504A. If you already have the DTR504 shield and need

only the installation support for the probe, it is available with Vaisala

order code 227777.

1. Fasten the probe (item 2 in Figure 5 below) to the installation

support with a cable tie (item 5).

2. Insert and attach the support to the radiation shield by tightening

the plastic nut (3).

3. Attach the entire radiation shield/probe assembly to a pole mast

(pole mast diameter: 30 ... 60 mm/1.2 ... 2.3") with a U-bolt and a

support arm.

1303-034

Figure 5 Installation of the Probe with Radiation Shield

18 ___________________________________________________________________ M211280EN-B

Page 21

Chapter 3 ________________________________________________________________ Installation

The following explanations refer to Figure 6 above:

1 = Tension screw

Distance L can be adjusted and locked in place with the tension screw.

24

L

1

Duct Installation Kit

The duct installation kit includes a plastic pipe with a flange (Vaisala

order code: 215619). To install the HMP110 probe with the duct

installation kit, drill a hole to the duct wall, assemble the probe to the

duct installation kit, slide the probe head through the hole, and attach the

flange to the duct wall with four screws. See section Probe Assembly

with Duct Installation Kit on page 20 for details.

0505-176

Figure 6 Probe Installation with the Duct Installation Kit

VAISALA ________________________________________________________________________ 19

Page 22

User's Guide _______________________________________________________________________

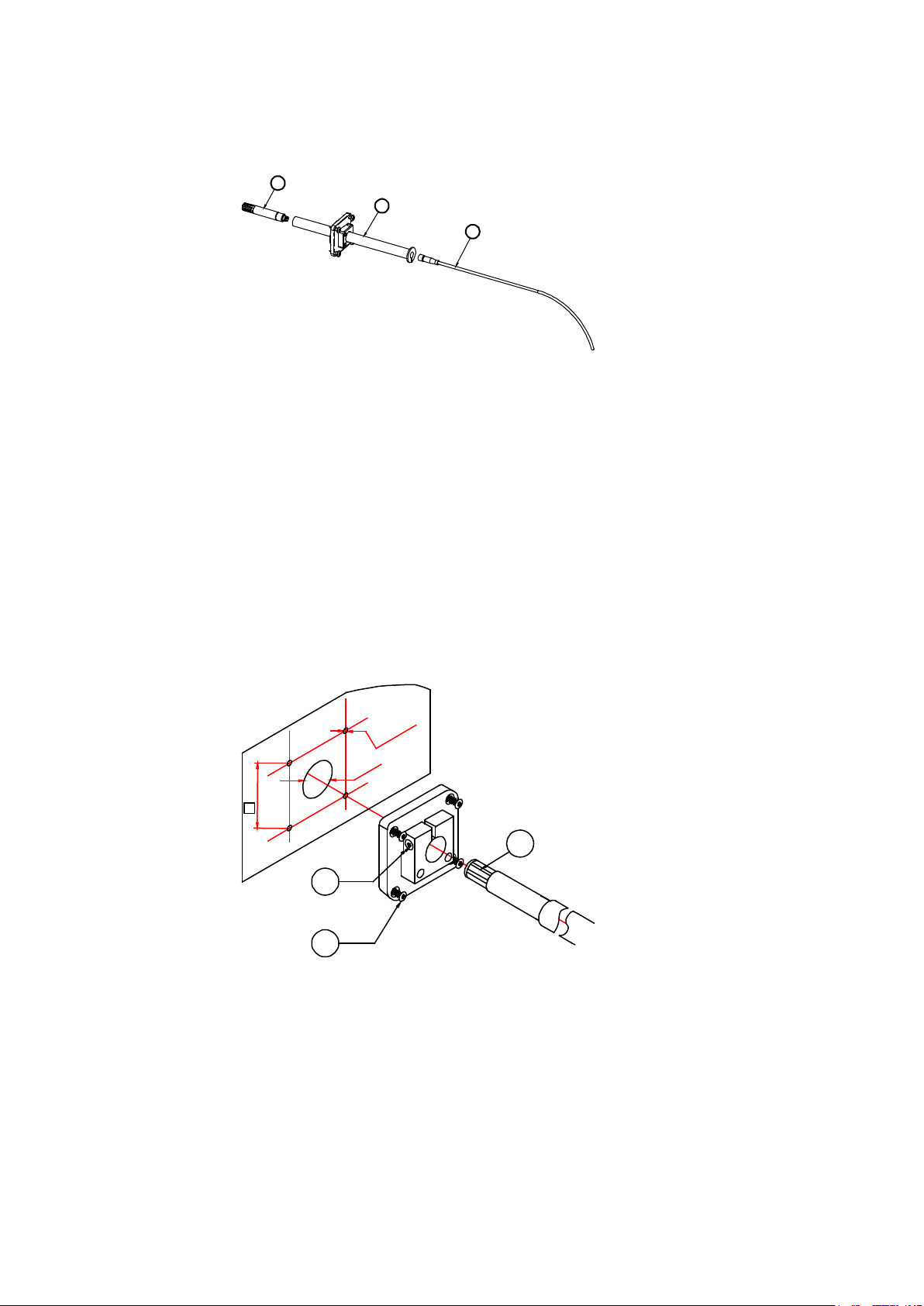

The following numbers refer to Figure 7 above:

1 = HMP110

2 = Duct installation kit

3 = Probe cable

The following numbers refer to Figure 8 above:

1 = Mounting screw

2 = Tension screw

3 = HMP110 assembled in duct installation kit plastic pipe

2

1

3

42

1

2

3

Ø24

Ø3.2

Probe Assembly with Duct Installation Kit

0505-177

Figure 7 Assembly of the Probe with Duct Installation Kit

1. Slide the probe cable through the duct installation kit plastic pipe.

2. Attach the probe cable to the HMP110 Humidity Probe.

3. Attach probe assembly to the duct.

Drilling Instructions for Duct Installation Kit

0505-178

Figure 8 Drilling Instructions

20 ___________________________________________________________________ M211280EN-B

Page 23

Chapter 3 ________________________________________________________________ Installation

The coaxial silicone plug that is delivered with the flange is not

for use with the probe cable of the HMT130.

Drill the holes for the duct installation kit as follows:

1. Use a 24-mm drill bit to drill a hole to the duct wall for the

humidity probe.

2. Drill holes for the duct installation kit mounting screws around the

hole in a square arrangement, 42 mm apart from each other. Use a

3.2-mm drill bit to drill the holes for the mounting screws (four

ST4.2×16-C-Z DIN 7981 screws).

Probe Mounting Flange

The probe mounting flange (Vaisala order code: 226061) is a general

purpose mounting flange for 12 mm diameter probes. It can be used to

hold the HMP110 probe in a through-wall installation.

NOTE

0911-109

suitable

Figure 9 Optional Probe Mounting Flange

VAISALA ________________________________________________________________________ 21

Page 24

User's Guide _______________________________________________________________________

Attaching the probe mounting clamp to a conductive wall material

should

supplies and uncontrolled earth current loops could cause measurement

errors or even damage to the HMT130 transmitter

Probe Mounting Clamp

The optional mounting clamp makes it easy to install the probe on the

wall of the measurement environment. The probe can be detached for

calibration simply by loosening the lower screw. You can order a single

clamp (Vaisala order code 225501) or a set of 10 clamps (226067).

Installing the entire probe in the measurement environment prevents heat

conduction to the sensor, and is the recommended installation method.

CAUTION

Figure 10 Optional Probe Mounting Clamp

be avoided, since the potential galvanic connection to the power

1001-138

22 ___________________________________________________________________ M211280EN-B

Page 25

Chapter 3 ________________________________________________________________ Installation

The following numbers refer to Figure 11 above:

1 = Optional LCD display

2 = Indicator LEDs

3 = Adjustment buttons

4 = RS-485 bus termination switch

5 = Service port

6 = Relay terminals

7 = RS-485 bus

8 = Analog outputs

9 = Power supply connectors

SE

R

V

I

C

E

P

O

RT

A

D

J

+

-

R

H

T

48

5

-

485+

G

N

D

REL

C

A

L

S

GND

CH1

C

H2

SHI

ELD

V

IN

–

V

I

N +

485

T

E

R

M

SE

R

V

I

C

E

P

O

R

T

A

D

J

+

-

R

H

T

48

5

-

485

+

GN

D

REL

C

A

L

SGND

CH1

CH

2

S

HIE

LD

VI

N –

V

IN

+

485

T

E

R

M

2

5

3

4

1

9

876

Connections

1011-162

Figure 11 HMT130 Component Board

VAISALA ________________________________________________________________________ 23

Page 26

User's Guide _______________________________________________________________________

1. Remove the transmitter cover. See section Opening the Transmitter

Cover on page 15.

2. Insert the signal wires through the selected cable gland/conduit

fitting in the bottom of the transmitter or alternatively through the

rubber grommet at the back side of the transmitter.

3. Connect the wires as indicated in Figure 12 below and in Table 3

on page 25. Suitable wire size is between 0.5 mm2 and 1.5 mm2.

4. Switch on the RS-485 bus termination switch if necessary. For

more information on the RS-485 bus termination switch see section

5. Close the cover by keeping it slightly tilted and first attaching it to

the fixing snaps at the top of the enclosure base and then pushing

the lower part of the cover firmly forward until it locks. The

transmitter is ready for use.

1303-038

Figure 12 Power Supply and Voltage Outputs (A), and

Serial Communication and Relay (B)

NOTE

15 ... 35 VDC or 24 VAC is needed when using the 0 ... 10 V output.

24 ___________________________________________________________________ M211280EN-B

Page 27

Chapter 3 ________________________________________________________________ Installation

Terminal

Description

1

SGND (signal ground)

2

CH1+ (signal +)

3

CH2+ (signal +)

4

Cable shield (optional)

5

Vin- (power supply - or VAC)

6

Vin+ (power supply + or VAC)

7

485-

8

485+

9

GND (ground)

10

Relay

11

Relay

Table 3 Wiring Table

Numbers 1 ... 6 in the first column of the wiring table refer to section (A)

and numbers 7 ... 11 to section (B) in Figure 12 on page 24.

There is an internal connection between numbers 1 and 5 on section (A)

and number 9 on section (B).

RS-485 Bus Termination

If you use RS-485 to connect just one HMT130 to a master computer,

enable the internal termination of HMT130 by switching switches 1 and

2 ON. Make sure that the master's end of the line is also terminated (by

using master's internal termination or with a separate terminator).

If you are connecting many transmitters to the same RS-485 bus, make

sure that switches 1 and 2 are OFF and terminate the bus with separate

terminators at both ends. This allows removing any transmitter without

blocking the bus operation.

VAISALA ________________________________________________________________________ 25

Page 28

User's Guide _______________________________________________________________________

This page intentionally left blank.

26 ___________________________________________________________________ M211280EN-B

Page 29

Chapter 4 ________________________________________________________ Serial Line Operation

The service port is intended for short

permanent installation, use the analog output or the RS

Connecting a PC to the service port may cause erroneous analog output

because of a possibl

and disconnect the PC after the service operation.

CHAPTER 4

SERIAL LINE OPERATION

This chapter contains information for operating the RS-485 bus

(user port) and the service port of the HMT130.

Using the Service Port

HMT130 motherboard has an 8-pin RJ-45 connector for service use.

Service port uses RS-232 signaling levels. Vaisala offers an optional

USB cable (Vaisala order code 219685) for connecting the transmitter to

your PC.

NOTE

-term use such as calibration. For

-485 serial line.

e ground loop. Use the service port for service only,

The cable can also provide operation power to the transmitter, so the

wires at the screw terminals need not to be connected in order to operate

the transmitter.

If you have not used the HMT130 USB cable before, install the driver

that came with the cable. Refer to section Installing the Driver for the

USB Cable below for detailed instructions.

Installing the Driver for the USB Cable

Before taking the USB service cable into use, you must install the

provided USB driver on your PC.

1. Check that the USB service cable is not connected. Disconnect the

cable if you have already connected it.

2. Insert the media that came with the cable, or download the latest

driver from www.vaisala.com.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

VAISALA ________________________________________________________________________ 27

Page 30

User's Guide _______________________________________________________________________

Property

Value

Baud rate

19200

Parity

None

Data bits

8

Stop bits

1

Flow control

None

4. After the driver has been installed, connect the USB service cable

to a USB port on your PC. Windows will detect the new device,

and use the driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu.

Windows will recognize each individual cable as a different device, and

reserve a new COM port. Remember to use the correct port in the

settings of your terminal program.

There is no reason to uninstall the driver for normal use. However, if you

wish to remove the driver files and all Vaisala USB cable devices, you

can do so by uninstalling the entry for Vaisala USB Instrument Driver

from the Programs and Features menu in the Windows Control Panel.

In Windows XP and earlier Windows versions the menu is called Add or

Remove Programs.

Terminal Application Settings

The default settings of the HMT130 serial interface are presented in

Table 4.

Table 4 Default Serial Interface Setting

The steps below describe how to connect to the HMT130 using the

PuTTY terminal application for Windows (available for download at

www.vaisala.com) and the USB serial interface cable:

1. Connect the USB cable between your PC and the service port of the

HMT130.

2. Start the PuTTY application.

3. Select the Serial settings category, and check that the correct COM

port is selected in the Serial line to connect to field.

Note: You can check which port the USB cable is using with the

Vaisala USB Instrument Finder program that has been installed

in the Windows Start menu.

4. Check that the other serial settings are correct for your connection,

and change if necessary. Flow control should be set to None unless

you have a reason to change it.

28 ___________________________________________________________________ M211280EN-B

Page 31

Chapter 4 ________________________________________________________ Serial Line Operation

5. Click the Open button to open the connection window and start

using the serial line.

Note: If PuTTY is unable to open the serial port you selected, it

will show you an error message instead. If this happens, restart

PuTTY and check the settings.

6. You may need to adjust the Local echo setting in the Terminal

category to see what you are typing on the serial line. To access the

configuration screen while a session is running, click the right

mouse button over the session window, and select Change

Settings... from the pop-up menu.

0807-004

Figure 13 PuTTY Terminal Application

VAISALA ________________________________________________________________________ 29

Page 32

User's Guide _______________________________________________________________________

Command

Description

?

Show transmitter information

??

Show transmitter information (POLL mode)

ACAL

Calibrate analog outputs

ADDR

Set/show device address

AERR

Set/show analog output error levels

AMODE

Set/show analog output mode

AOUT

Show analog output status

ASEL

Set/show analog output quantities and scaling

ATEST

Test analog outputs

CALCS

Set/show measured quantities

CDATE

Set/show calibration date

CLOSE

Start POLL mode

CRH

Calibrate probe RH

CRHCLR

Restore probe RH factory calibration

CT

Calibrate probe T

CTCLR

Restore probe T factory calibration

CTEXT

Set/show calibration info

DSEL

Set/show displayed quantities

ECHO

Set/show terminal echo mode

ENV

Set/show environmental parameters

ERRS

Display active errors

FORM

Set/show output formatting

FRESTORE

Restore all transmitter settings to factory defaults

HELP

List available commands

INTV

Set/show the continuous output interval

OPEN

Stop POLL mode

R

Start continuous outputting

RESET

Reset transmitter

RESTORE

Restores the latest saved settings

RMODE

Set/show relay operating mode

ROUT

Show all relay-related parameters

RSEL

Set/show relay quantity

S

Stop continuous outputting

SAVE

Save changed settings to FLASH memory

SDELAY

Set/show RS-485 turnaround time for User Port

SEND

Output the reading once

SERI

Set/show Port settings (Default: 19200 N 8 1)

SERI2

Set/show User Port settings (Default: 19200 N 8 1)

SMODE

Set the serial interface mode

SYSTEM

Show transmitter information and build date

UNIT

Set/show output unit

VERS

Show firmware version of the transmitter

List of Serial Commands

All commands can be issued either in uppercase or lowercase. The

notation <cr> refers to pressing the carriage return (ENTER) key on your

computer keyboard. Enter a <cr> to clear the command buffer before

starting to enter commands.

Whenever you change any of the parameters and want to store the

changes permanently, use the SAVE command.

Table 5 Serial Port Commands

30 ___________________________________________________________________ M211280EN-B

Page 33

Chapter 4 ________________________________________________________ Serial Line Operation

Where

q1, q2

=

Any two of the allowed quantity parameters, i.e. RH, T,

TD, TDF, A, X, H, TW, PWS, PW

Device Information and Status

Show Device Information

The ? command outputs a listing of device information.

?<cr>

Example:

>?

Device Name : HMT130

SW Name : HMT120/130

SW model : HMT130

SW version : 0.9.3.389

Serial number : "F2220101"

Address : 0

Unit : METRIC

Ch1 Status : ON

Ch2 Status : ON

Probe name : "HMP110"

Probe SW : "1.01.1"

Probe SW date : ""

Probe SN : "F0740011"

>

Set/Show Available Quantities

The CALCS command shows the abbreviations of the quantities

measured by HMT130. The command can also be used to select the

desired quantities for measurement. Only after the quantities have been

set with the CALCS command, can these quantities be selected for

different outputs (see commands DSEL, ASEL, and FORM). The

quantities in DSEL, ASEL, RSEL, and FORM must match with

CALCS.

CALCS [q1 q2]<cr>

Examples:

>calcs

RH Td

>

calcs td t

>

VAISALA ________________________________________________________________________ 31

Page 34

User's Guide _______________________________________________________________________

where

date

=

Calibration date in format yyyy-mm-dd

where

location

=

Freely defined text string typically indicating the

calibration location

NOTE

Single-parameter transmitters HMT130H and HMT130T have only one

quantity (T for HMT130T, and RH, TD, TDF, A, X, H, TW, PWS, PW

for HMT130H.)

Set/Show Calibration Date

Use the CDATE command to show or set the calibration date field.

(Calibration refers to the calibration of the HMT130's analog outputs.)

CDATE [date]<cr>

Examples:

>cdate

Calibrated : "NOT SET"

>

>cdate 2009-06-22

Calibrated : "2009-06-22"

>

Set/Show Calibration Information

Use the CTEXT command to show or set the calibration info field.

(Calibration refers to the calibration of the HMT130's analog outputs.)

CTEXT [location]<cr>

Examples:

>ctext

Calib. info: "VAISALA HELSINKI"

>

>ctext "Calibration lab 2"

Calib. info: "Calibration lab 2"

>

32 ___________________________________________________________________ M211280EN-B

Page 35

Chapter 4 ________________________________________________________ Serial Line Operation

Show Analog Output Status

The AOUT command shows the following information:

- Analog out mode is the output mode for the channel, for example

0 ... 10 V.

- Error level is the level that the analog output is set to in case of

transmitter error.

- Status indicates the current status of the channel. The statuses are

- ON: Normal measurement operation.

- OFF: No quantity selected for the channel using the ASEL

command. See section Set/Show Analog Output Quantity and

Scaling on page 42.

- ERROR: Transmitter error, channel set to error level.

- TEST: Analog channel being tested using the ATEST command.

See section Test Analog Outputs on page 44.

AOUT<cr>

Example:

>aout

*** ANALOG OUTPUT 1 ***

Ch1 Analog out mode : 0_10V

Ch1 Error level : 10.8

Ch1 Quantity : RH

Ch1 Status : ON

RH lo : 0

RH hi : 100

RH : 36.64 %

Ch1 Voltage : 3.66 V

*** ANALOG OUTPUT 2 ***

Ch2 Analog out mode : 0_10V

Ch2 Error level : 10.8

Ch2 Quantity : T

Ch2 Status : ON

T lo : -60

T hi : 100

T : 23.85 'C

Ch2 Voltage : 5.24 V

>

VAISALA ________________________________________________________________________ 33

Page 36

User's Guide _______________________________________________________________________

Show System Information

SYSTEM<cr>

Example:

>system

Device Name : HMT130

SW Name : HMT120/130

SW model : HMT130

SW version : 1.0.0.500

Serial number : A1234567

>

Show Firmware Version

VERS<cr>

Example:

>vers

HMT130 / 0.1.0.103

>

Serial Line Output Commands

Start Continuous Outputting

Use the R command to start the continuous outputting of measurement

values as an ASCII text string to the serial line. The output always

includes the readings of the currently selected analog output quantities.

R [X]<cr>

Example:

>r

RH= 25.10% T= 24.77'C

RH= 25.12% T= 24.96'C

…

Outputting the results continues in intervals issued with the command

INTV. You can stop the output by entering the S command.

Output data formatting can be defined with FORM command. With X

parameter the transmitter will output RH + T value in predefined format

regardless of what quantities are selected.

34 ___________________________________________________________________ M211280EN-B

Page 37

Chapter 4 ________________________________________________________ Serial Line Operation

where

n = Time interval in range 1 ... 255

xxx = Time unit = "S", "MIN", or "H"

Stop Continuous Outputting

Use the S command to stop the continuous measurement output:

S<cr>

Set/Show Output Interval

Use the INTV command to show or set the output interval of the serial

line measurement messages (applies when R command or RUN mode is

used). The shortest output interval is one second. This command has no

effect on the operation of the analog outputs.

INTV [n xxx]<cr>

Examples:

>intv

Value : 1

Unit : S

>

>intv 3 min

Value : 3

Unit : MIN

>

Output a Reading Once

Use the SEND command to output a single measurement reading from

the transmitter.

SEND [X]<cr>

Example:

>send

RH= 25.12 % T= 24.91 'C

>

VAISALA ________________________________________________________________________ 35

With X parameter the transmitter will output RH + T value in predefined

format regardless of what quantities are selected.

Page 38

User's Guide _______________________________________________________________________

Calibration Commands

Serial commands that are related to calibration are described below. For

the actual calibration procedures, see section Calibration and Adjustment

on page 58.

Calibrate Humidity Measurement

Use the CRH command to perform a one-point or two-point humidity

(RH) calibration.

CRH<cr>

When performing a one-point calibration, you need to place the probe in

a single humidity reference with RH < 50%. Run the command and enter

the exact RH of the reference after the measurement has stabilized. Exit

the command by pressing the ESC key before proceeding to the second

point (see example below). To update the value, press ENTER without

inputting a value.

For two-point calibration, the first point requires a RH < 35% humidity

reference, the second point must be RH > 50%.

Example 1: One-point calibration

>crh

RH: 11.29915720 Ref1 ? 11.3

Press ENTER to continue or ESC to exit

OK

>

Example 2: Two-point calibration

>crh

RH: 11.29915720 Ref1 ? 11.3

Press ENTER to continue or ESC to exit

RH: 75.04306440 Ref2 ? 75

OK

>

Example 3: No calibration, only updating the value

>crh

RH: 20.28000200 Ref1 ?

RH: 20.14000000 Ref1 ?

Calibration terminated with ESC

>

36 ___________________________________________________________________ M211280EN-B

Page 39

Chapter 4 ________________________________________________________ Serial Line Operation

Restore Probe RH Factory Calibration

Use the CRHCLR to restore the probe RH factory calibration.

CRHCLR<cr>

Example:

>crhclr

OK

>

Calibrate Temperature Measurement

Use the CT command to perform a one-point or two-point temperature

(T) calibration.

CT<cr>

When performing a one-point calibration, you need to place the probe in

a single temperature reference. Run the command and enter the exact

temperature of the reference after the measurement has stabilized. Exit

the command by pressing the ESC key before proceeding to the second

point. To update the value, press ENTER without inputting a value.

For two-point calibration, the second reference point must be at least

20 ºC warmer than the first. The measurement reading for the second

point will appear when this requirement is met.

Example 1: One-point calibration

>ct

T 21.9827 Ref1 ? 22

Press ENTER to continue or ESC to exit

OK

>

Example 2: Two-point calibration

>ct

T 22.0007 Ref1 ? 22

Press ENTER to continue or ESC to exit

T 44.9847 Ref2 ? 45

OK

>

Example 3: No calibration, only updating the value

>ct

T 22.0007 Ref1 ?

T 22.0145 Ref1 ?

Calibration terminated with ESC

>

VAISALA ________________________________________________________________________ 37

Page 40

User's Guide _______________________________________________________________________

Restore Probe T Factory Calibration

Use the CTCLR to restore the probe T factory calibration.

CTCLR<cr>

Example:

>ctclr

OK

>

Calibrate Analog Output

Use the ACAL command to calibrate the analog voltage outputs.

ACAL<cr>

After you give this command, the CH1 analog output of the transmitter

is set to the low limit (0V). Measure the output and enter the measured

value. After entering the low limit, you must measure and enter the high

limit also (for example 10V, depends on the output mode of the

channel). The same procedure is then repeated with CH2.

NOTE

Calculated coefficients are printed after the measured values are given.

Example:

>acal

Ch1 V1 (V) ? 0.11

Ch1 V2 (V) ? 10.21

1.92308600E+02 a0

2.58811860E+03 a1

OK

Ch2 V1 (V) ? 0.11

Ch2 V2 (V) ? 10.20

1.92024420E+02 a0

2.59068400E+03 a1

OK

Question mark is displayed after certain stabilization time has expired.

Values should be entered only after question mark is displayed. Values

entered before question mark will be discarded.

38 ___________________________________________________________________ M211280EN-B

Page 41

Chapter 4 ________________________________________________________ Serial Line Operation

where

b = baud rate (9600, 19200, 38400, 76800, 115200)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

Configuring Serial Line Operation

Set/Show Serial Line Settings

Use the SERI command to show or set the serial line settings for the

serial port that you are currently using (service port or user port).

Use the SAVE command after changing the settings to store them. The

new settings will be taken into use when the transmitter is reset or

powered up.

SERI [b p d s]<cr>

Examples:

>seri

Baud P D S : 19200 N 8 1

>

>seri 9600 e 7 1

Baud rate : 9600

Parity : E

Data bits : 7

Stop bits : 1

>save

Saving settings...done

>

Set/Show Terminal Echo

To show or set the terminal echo status, use the ECHO command.

ECHO [ON/OFF]<cr>

Examples:

>echo

COM1 Echo : OFF

>

>echo on

COM1 Echo : ON

VAISALA ________________________________________________________________________ 39

Page 42

User's Guide _______________________________________________________________________

where

x.xxxx

=

Absolute pressure in the measuring environment.

The default is 1.013. The pressure unit is bar.

Set/Show Serial Interface Mode

Use the SMODE command to show or set the serial interface mode. Note

that a separate SAVE command is not needed to store the new serial

interface mode setting.

SMODE [STOP/RUN]<cr>

In STOP mode: outputting only when command is issued, any command

can be used.

In RUN mode: outputting automatically, only command S can be used.

Example:

>smode stop

Output mode : STOP

>

Configuring Measurement Parameters

Set/Show Environmental Parameters

Use the ENV command to show or set the environmental compensation

values. In HMT130, the humidity measurement can be compensated for

ambient pressure. The value set using ENV command is a permanent

value which will survive a restart.

ENV [x.xxxx]<cr>

Example:

>env

Pressure (bar) : 1.013

>

>env 0.980

Pressure (bar) : 0.98

>save

Saving settings...done

>

NOTE

You can use the Vaisala Humidity Calculator to simulate the effect of

pressure change to dewpoint. The Humidity Calculator can be found at:

www.vaisala.com/humiditycalculator

40 ___________________________________________________________________ M211280EN-B

Page 43

Chapter 4 ________________________________________________________ Serial Line Operation

Where

CH1mode

CH2mode

=

0_5V (Output scale 0 … 5V)

0_10V (Output scale 0 … 10V)

X_YV (Output scale lowlimit … highlimit)

CH1lowlimit

CH2lowlimit

=

Low limit for output voltage

CH1highlimit

CH2highlimit

=

High limit for output voltage

Configuring Analog Output

Set/Show Analog Output Mode

Use the AMODE command to show or set the analog output mode.

AMODE [CH1mode CH2mode] [CH1lowlimit CH1highlimit]

[CH2lowlimit CH2highlimit]<cr>

Example (Channel 1 limits configured as 1 ... 6 volts and Channel 2 as

0 ... 5 volts):

>amode x_yv 0_5V 1 6

Ch1 Analog out mode : X_YV

Ch2 Analog out mode : 0_5V

Ch1 low limit : 1

Ch1 high limit : 6

>

Example (User prompted to accept currently used channel limits or enter

new limits):

>amode x_yv

Ch1 Analog out mode : X_YV

Ch2 Analog out mode : 0_10V ?

Ch1 low limit : 0 ?

Ch1 high limit : 10 ? 1

>

VAISALA ________________________________________________________________________ 41

Page 44

User's Guide _______________________________________________________________________

where

level1 level2

=

Error levels for analog output channel

where

q1 q2

=

Analog output channel quantities

lo1 lo2

=

Low limits of scaling

hi1 hi2

=

High limits of scaling

Where

q = Analog output channel quantity

lo = Low limit of scaling

hi = High limit of scaling

Set/Show Analog Output Error Levels

Use the AERR command to show or set the analog output error levels.

AERR [level1 level2]<cr>

Examples:

>aerr

Ch1 Error level : 0.0

Ch2 Error level : 0.0

>

>aerr 10.8 10.8

Ch1 Error level : 10.8

Ch2 Error level : 10.8

>

Set/Show Analog Output Quantity and Scaling

After you have defined the quantities with the CALCS command, use the

ASEL command to show or set the quantity output by the analog

channels, and the scaling that is used. If you do not enter scaling limits,

default values are used. Valid quantities are: RH, T, TD, TDF, A, X, H,

TW, PWS, PW and NONE. NONE parameter disables analog output and

output is forced to error level.

ASEL [q1 q2] [lo1 hi1 lo2 hi2]<cr>

Syntax for single-parameter transmitters:

ASEL [q] [lo hi]<cr>

42 ___________________________________________________________________ M211280EN-B

Page 45

Chapter 4 ________________________________________________________ Serial Line Operation

Examples:

>asel

Ch1 Quantity : RH

RH lo : 0

RH hi : 100

Ch2 Quantity : T

T lo : -60

T hi : 100

>

>asel rh td

Ch1 Quantity : RH

RH lo : 0

RH hi : 100

Ch2 Quantity : TD

Td lo : -40

Td hi : 60

>

>asel t td 0 60 -20 60

Ch1 Quantity : T

T lo : 0

T hi : 60

Ch2 Quantity : TD

Td lo : -20

Td hi : 60

>

>asel rh none

Ch1 Quantity : RH

RH lo : 0

RH hi : 100

Ch2 Quantity : NONE

>

>asel none none

Ch1 Quantity : NONE

Ch2 Quantity : NONE

>

VAISALA ________________________________________________________________________ 43

Page 46

User's Guide _______________________________________________________________________

where

val1 val2

=

Analog channel output value (V)

where

q = Quantity to define relay state.

Test Analog Outputs

Use the ATEST command to test the analog outputs. The ATEST

command will force the output to the given value, which can then be

measured with a calibrated multimeter.

ATEST command affects only the analog outputs and hence it does not

disable measurement functions. ATEST without parameters will exit the

test mode and let the measurement continue. It will also indicate the the

current analog output levels in normal measurement state.

ATEST [val1 val2]<cr>

Examples:

>atest

CH1: 2.360000

CH2: 3.765010

>

>atest 5.0 5.0

CH1: 5.000000

CH2: 5.000000

>

Configuring Relay Output

Set/Show Relay Quantity

After you have defined the quantities with the CALCS command, use the

RSEL command to show or set the relay quantity. Valid quantity

parameters are RH, T, TD, TDF, A, X, H, TW, PWS and PW.

RSEL [q]<cr>

Example:

>RSEL T

Relay quantity : T

44 ___________________________________________________________________ M211280EN-B

Page 47

Chapter 4 ________________________________________________________ Serial Line Operation

where

xxxx

=

OFF, LO_OPEN or HI_OPEN

lo = Low limit

hi = High limit

In OFF mode:

relay contacts are always open

In LO_OPEN

mode:

relay contacts are opened when the value is below

the set low limit and closed when value is above

the high limit.

In HI_OPEN

mode:

relay contacts are opened when the value is above

the set high limit and closed when value is below

the low limit.

Set/Show Relay Operating Mode

Use the RMODE command to set/show relay mode, low and high limits.

Relay modes are OFF, LO_OPEN and HI_OPEN. Low and high values

specify relay operation limits for the selected quantity.

RMODE [xxxx] [lo] [hi]<cr>

Example:

>RMODE LO_OPEN 10 20

Relay mode : LO_OPEN

Relay low : 10

Relay high : 20

Show Relay Settings

Use the ROUT command to show the current relay settings.

ROUT<cr>

Example:

>ROUT

*** RELAY OUTPUT ***

Relay quantity : RH

RH : 22.35 %

Relay mode : LO_OPEN

Relay low : 10

Relay high : 20

Relay status : CLOSED

VAISALA ________________________________________________________________________ 45

Page 48

User's Guide _______________________________________________________________________

where

q1 q2

=

Quantities to be shown on transmitter display

where

q = Quantity to be shown on transmitter display

Other Commands

Set/Show Displayed Quantities

After you have defined the quantities with the CALCS command, use the

DSEL command to show or set the displayed quantities. Number of

parameters determine the display mode (ie. one or two rows). If one

quantity is given, display will switch to one row mode. If two quantities

are given, two row mode is used. Valid quantities are: RH, T, TD, TDF,

A, X, H, TW, PWS and PW.

DSEL [q1 q2]<cr>

Syntax for single-parameter transmitters:

DSEL [q]<cr>

Examples:

>dsel

1. quantity : RH

2. quantity : T

>

>dsel rh t

1. quantity : RH

2. quantity : T

>

>dsel t

1. quantity : T

>

46 ___________________________________________________________________ M211280EN-B

Page 49

Chapter 4 ________________________________________________________ Serial Line Operation

where

format

=

A formatting string, which can consist of following fields:

“”

String constant

x.y

Value length modifier. x is numbers before dot

and y is numbers after dot.

Ux

Unit field length. U…U format is also supported.

Q

Quantity name (e.g. rh, t, td etc.)

#t or \t

Tabulator

#r or \r

Carriage return

#n or \n

Line feed (new line)

Set/Show Output Formatting

After you have defined the quantities with the CALCS command, use the

FORM command to set the output format for SEND and R commands.

FORM [format]<cr>

Note 1. Quantity must be after x.y and Ux modifiers.

Note 2. There must be a space between parameters, #r#n or \r\n is not supported.

Note 3. Max. string length is 80 characters.

Note 4. If Ux parameter is not used, unit is not displayed.

Examples:

>form "RH= " 3.2 U2 rh #r #n

>send

RH= 32.16 %

>

>form "t=" 4.1 U3 t \t "rh=" 3.2 U2 rh \r \n

>send

t= 22.5 'C rh= 29.12 %

>

>form "t=" 4.1 U3 t \t "rh=" rh \r \n

>send

t= 22.3 'C rh= 29.5 %

>

>form 3.2 UUU "RH=" rh \t "T=" t \r \n

>send

RH= 27.99 % T= 23.34 'C

>

>form 3.3 rh " " t \r \n

>send

26.740 23.660

>

>form "->" "RH=" 3.2 U2 rh " " "T=" 3.1 U3 t #r #n

>send

->RH= 27.79 % T= 23.4 'C

>

VAISALA ________________________________________________________________________ 47

Page 50

User's Guide _______________________________________________________________________

Display Command List

Use the HELP command to display a list of available commands.

HELP<cr>

Display Active Errors

Use the ERRS command to display the currently active error codes. For

troubleshooting active errors, see Table 7 on page 75.

ERRS<cr>

Example (no active errors):

>errs

No errors.

>

Save Changed Settings

NOTE

Use the SAVE command to save changed settings to the transmitter

FLASH memory. Most settings have to be saved or the changes are lost

at the next reset or power down.

The SMODE command saves the new serial mode immediately;

a separate SAVE command is not needed.

The probe calibration commands (CRH, CT, CRHCLR, CTCLR) store

the parameters into the probe's memory automatically without a separate

SAVE command.

SAVE<cr>

Example:

>save

Saving settings...done

>

48 ___________________________________________________________________ M211280EN-B

Page 51

Chapter 4 ________________________________________________________ Serial Line Operation

Restore Saved Settings

Use the RESTORE command to restore saved settings from transmitter

FLASH memory to RAM. All unsaved changes will be lost.

RESTORE<cr>

Example:

>restore

Restoring default settings...done

>

Reset Transmitter

Use the RESET command to reset the transmitter. Upon reset or powerup, the transmitter enters the serial mode that has been set with the

SMODE command.

After reset the configuration is loaded from FLASH memory. That

configuration can be altered with SAVE-command.

RESET<cr>

Example (transmitter set to serial mode STOP, will output transmitter

software version at reset):

>reset

HMT130 / 0.1.0.001

Type "help" for command list

>

Restore Factory Settings

Use the FRESTORE command to restore the factory settings to the

transmitter. All user settings, including the user-performed calibration

corrections, will be lost. The transmitter will revert back to the factory

calibrated settings. Note that this only returns the factory settings of the

transmitter and not of the interchangeable probe (see section Restore

Probe RH Factory Calibration on page 37 and section Restore Probe T

Factory Calibration on page 38).

FRESTORE<cr>

Example:

>frestore

Restoring factory defaults...done

>

VAISALA ________________________________________________________________________ 49

Page 52

User's Guide _______________________________________________________________________

where

b = bit rate (1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

Set/Show Output Unit

Use the UNIT command for output unit selection (metric or non-metric).

UNIT [METRIC/NON_METRIC]<cr>

Example:

>unit

Unit : METRIC

>

>unit non_metric

Unit : NON_METRIC

>

Operating the User Port (RS-485)

The RS-485 interface enables communication between RS-485 network

and HMT130 transmitter. The RS-485 interface is not isolated.

Networking Commands

Set the RS-485 interface by using the following commands. The other

serial line commands are presented in section List of Serial Commands

on page 30.

SERI

Use the SERI command to input RS-485 bus settings. This command

affects the serial port where the settings are given (service port or user

port).

SERI [b p d s]<cr>

SERI2

The SERI2 command is equivalent to the SERI command, but it affects

only the user port settings. The main purpose of the command is to

change the user port settings via the service port.

SERI2 [b p d s]<cr>

50 ___________________________________________________________________ M211280EN-B

Page 53

Chapter 4 ________________________________________________________ Serial Line Operation

where

x = ON/OFF (default = OFF)

where

xxxx

=

STOP, RUN or POLL

In STOP mode:

measurements output only by command SEND, all

commands can be used

In RUN mode: