Page 1

USER'S GUIDE

Vaisala HUMICAP® Humidity and

Temperature Probes

HMP45A/D

U274EN-1.2

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

HMP45A and HMP45D

U274en-1.2 Operating Manual

1. GENERAL

The HMP45A and HMP45D probes are designed for the measurement of

relative humidity and temperature. Humidity measurement is based on the

capacitive thin film polymer sensor HUMICAP180. Temperature

measurement is based on resistive platinum sensors (Pt 100 and Pt 1000).

Both the humidity and temperature sensors are located at the tip of the probe

and in standard version protected by a membrane filter. The HMP45A and

HMP45D have a similar humidity output, but the temperature output is active

in HMP45A (voltage output 0-1V) and passive in HMP45D (resistive output

Pt 100).

2. CONNECTIONS

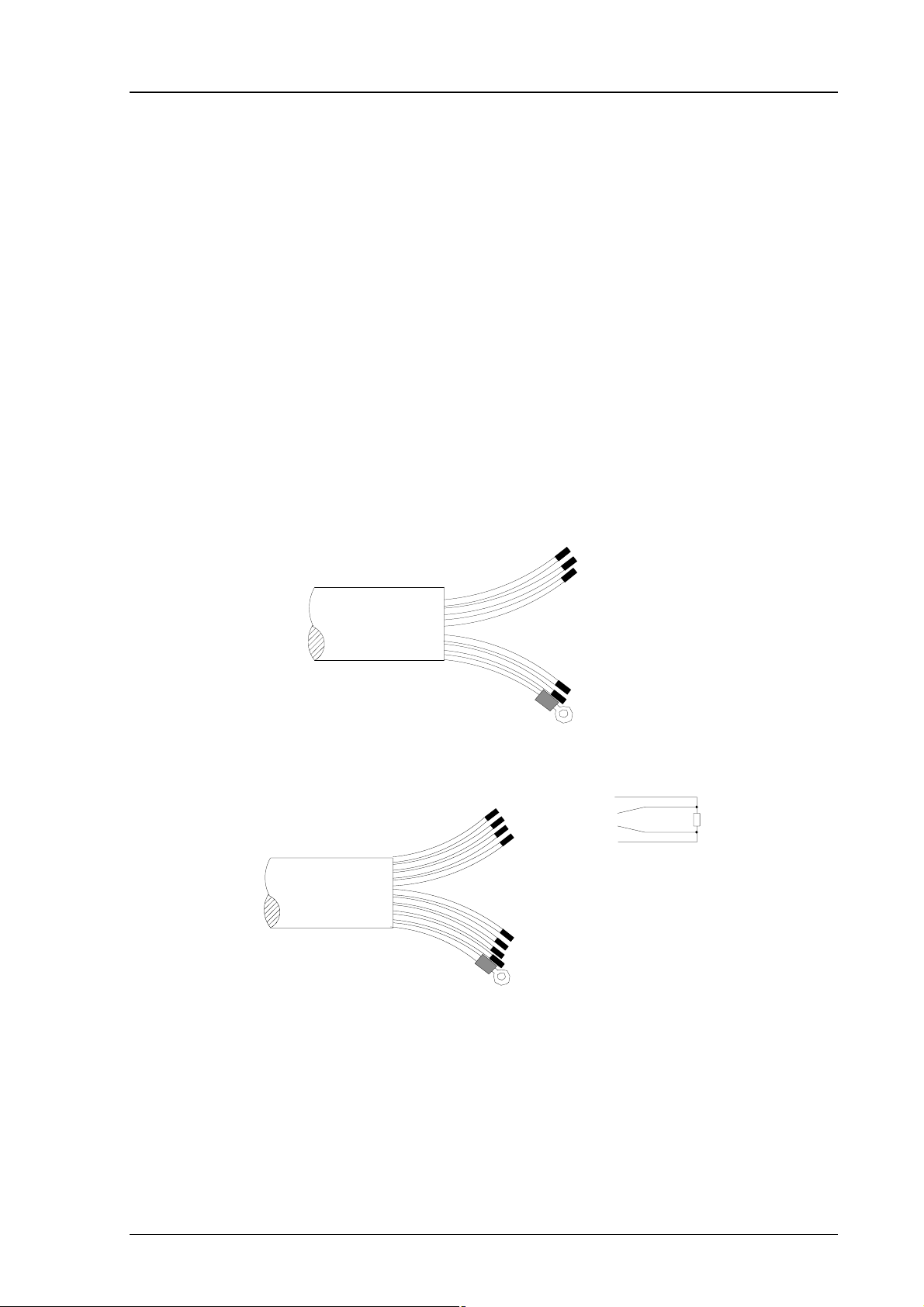

The cable wires are connected as shown in Figure 1.

HMP45D

HMP45A

YEL OUTPUT

0...1V=-40...+60 ˚C

BLU V+ 7...35VDC

BRN OUTPUT

0...1V=0... 100%RH

VIO GND

RED GND (SENSE)

GREY (SHIELD)

YEL

WHT

GRN

BLK

GREY (SHIELD)

Pt100

Pt100

Pt100

Pt100

BLU 7...35VDC

BRN OUTPUT 0...1V=0...100%RH

VIO GND

RED GND (SENSE)

Figure 1 Wire colours

Pt100

SIGNAL GROUND is used for output signal in a differential measurement. With

SIGNAL GROUND, the cable can be extended up to 100 metres without

disturbing the measurement accuracy. When outputs are not measured against

SIGNAL GROUND, connect GROUND and SIGNAL GROUND to the same point.

1

Page 4

HMP45A and HMP45D

Operating Manual U274en-1.2

3. CALIBRATION AND MAINTENANCE

Calibration and maintenance of the probes should be performed at regular

intervals, depending on the conditions of use and desired accuracy. The

recommended calibration interval is one year.

The HMP45A/D probes are easy to maintain and calibrate. The probe consists

of a probe head and a handle with cable. All calibration electronics are in the

probe head which can be disconnected from the handle without disconnecting

the wires (see Figure 2). The handles of all HMP45A and HMP45 probes are

fully interchangeable. If you wish to continue the measurement immediately,

you can insert a calibrated probe head in place of the disconnected one; this

way, the measurement is interrupted for less than a minute.

3.1 Reading the outputs during calibration

adjustment trimmers:

W = wet D = dry

(T = temperature; for

D

W

T

factory use only!)

pull the probe head

off the handle

NOTE:

remove the O-ring if you

connect the probe directly

to the HMI41 indicator

ENTERMODE HOLD ON/OFF

HMI41HMH45

Figure 2 Adjustment trimmers and probe head connection/disconnection

In calibration, the HMP45A/D output is normally read from the output cables.

The HMP45A probe head can also be checked with Vaisala’s HMI41 indicator

(see Figure 2); the probe head can be connected either to the HMH45 handle,

or directly to the HMI41 indicator. However, note that if you connect the

probe head directly to the HMI41, you must first remove the O-ring. Measured

humidity and temperature appear on the HMI41 display.

A simple field check can also be performed when there seems to be something

wrong with the measurement system. It is sufficient to compare the HMP45A

reading with the reading measured by a calibrated reference probe head. Check

2

Page 5

HMP45A and HMP45D

U274en-1.2 Operating Manual

the ambient relative humidity and temperature level with the reference probe

head, and then connect the HMP45A probe head on the HMH45 handle and

check the output readings.

Prepare the HMI41 indicator for measurements with the HMP45A probe head

as follows: turn the HMI41 indicator on and within 1-2 seconds press

simultaneously buttons ENTER and MODE until the text SEtUP appears on

the display.

Wait a few seconds, and the text Unit appears; press ENTER repeatedly until

a text similar to the following appears on the display:

set

Select PROBE TYPE 3 with buttons ▲ (number up) or ▼ (number down) and

turn the indicator off. Turn it on again by pressing the ON/OFF button. After a

few seconds, the relative humidity and temperature readings appear

automatically on the display. The HMP45D cannot be used w ith the HMI41

indicator as the passive temperature signal results in error messages on

the HMI41.

3.2 Humidity calibration

For a high-accuracy two-point calibration use a Vaisala HMK15 or HMK13B

calibrator and saturated salt solutions as described in the respective manuals.

Leave the calibrator, the HMI41 and the probe head in the same space for at

least four hours so that their temperatures have time to equalize. Unscrew the

plastic grid of the probe.

The calibration is done first for the dry end and then for the wet end by

adjusting trimmer potentiometers marked “D” (dry, <50 %RH) and “W” (wet,

>50 %RH). The potentiometers are located under a protective plug; see Figure

2. Use a ceramic screw driver with 2.5 mm blade for adjusting the

potentiometers. Note: if zero point is calibrated in Nitrogen (N2), the

minimum output signal of 0.008 V corresponds to a relative humidity of 0.8

%RH.

Greenspan’s calibration table

Temperature °C 15 20 25 30 35

LiCl %RH *) 11.3 11.3 11.3 11.3

NaCl %RH 75.6 75.5 75.3 75.1 74.9

K2SO

4

*) Do not use or store the LiCl solution in temperatures below +18°C as its humidity

equilibrium may change permanently

%RH 97.9 97.6 97.3 97.0 96.7

3

Page 6

HMP45A and HMP45D

Operating Manual U274en-1.2

As the D (dry) and W (wet) adjustments may affect each other, check again

the humidity reading at the low end. If necessary, repeat the adjustments in

both the low and the high humidity points until the reading is correct.

3.3 Changing the HUMICAP®180 humidity sensor

Unscrew the filter. Remove the damaged sensor and mount a new

HUMICAP®180 humidity sensor in its place. Handle the sensor with care.

Calibrate the probe using a two-point calibration procedure. Note that if the

probe is not calibrated, the accuracy is still better than ±7 %RH.

4. SPARE PARTS AND ACCESSORIES

Order code Description

HUMICAP180

18921 Temperature sensor Pt 1000 IEC 751 1/3 Class B (HMP45A)

19159 Temperature sensor Pt 100 IEC 751 1/3 Class B (HMP45D)

2787HM Membrane filter (standard)

6685 Sintered filter 37 µm

6686 Sintered filter 216 µm

6597 Plastic grid

HMP45ASP HMP45A probe head

HMP45DSP HMP45D probe head

HMH45ASP Probe handle for HMP45A and HMP45D

HMI41 Humidity and temperature indicator

HMH45 Probe handle for HMP45A with a connector to HMI41

HMK11 Humidity Calibrator

HMK13B Humidity Calibrator

Humidity sensor

5. TECHNICAL DATA

5.1 Humidity (HMP45A & HMP45D)

Measurement range 0.8...100 %RH

Output scale 0...100 %RH equals 0-1 VDC

Accuracy at +20 °C (including non-linearity and hysteresis):

against factory references ±1 %RH

field calibration against references ±2 %RH (0...90 %RH)

Typical long-term stability better than 1 %RH per year

Temperature dependence ±0.05 %RH/°C

Response time (90%) at +20 °C 15 s with membrane filter

Humidity sensor HUMICAP

4

±3 %RH (90...100 %RH)

®

180

Page 7

HMP45A and HMP45D

C

U274en-1.2 Operating Manual

5.2 Temperature

HMP45A

Measurement range -39.2...+60 °C

Output scale -40...+60 °C equals 0...1 VDC

Accuracy at 20°C ±0.2 °C

Accuracy over the whole measurement range:

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

-30-40

-20

-10 0

10

20

30

40

50

60

°

Temperature sensor Pt 1000 IEC 751 1/3 Class B

HMP45D

Measurement range -40...+60 °C

Output signal resistive four wire connection

Temperature sensor Pt 100 IEC 751 1/3 Class B

5.3 General

Operating temperature range -40...+60 °C

Storage temperature range -40...+80 °C

Supply voltage 7...35 VDC

Settling time 500 ms

Power consumption < 4 mA

Output load >10 kohm (to ground)

Weight 350 g (including package)

Cable length 3.5 m

Housing material ABS plastic

Housing classification (electronics) IP 65 (NEMA 4)

Sensor protection (standard) membrane filter, part no. 2787HM

Dimensions in mm (inches):

5

Page 8

HMP45A and HMP45D

Operating Manual U274en-1.2

240 (9.45)

118 (4.65)

A

3500 (137.8)

24

A

A-A

20.5

(0.81)

(0.94)

5.4 Electromagnetic compatibility

5.4.1 Emissions

Radiated interference, test setup according to EN55022

5.4.2 Immunity

Test: Test setup Performance:

according to:

24

(0.94)

18.5

( 0.72)

REMOVABLE

PROBE HEAD

(132 mm)

Radiated interference IEC 1000-4-3 HMP45A level 1 (3V/m)

HMP45D level 3 (10 V/m)

Electrostatic discharge IEC 801-4 level 4 (HMP45A&D)

GUARANTEE

Vaisala issues a guarantee for the material and workmanship of this product

for one (1) year from the date of delivery. Damage due to exceptional

operating conditions, careless handling or misapplication will void the

guarantee. Detailed warranty information is given in the Warranty and the

Standard Conditions of Sale of Vaisala Oy.

6

Page 9

Page 10

*U274

EN

*

www.vaisala.com

Loading...

Loading...