Page 1

OPERATING MANUAL

HMI41 Indicator

and HMP42 Probe

M210317EN-A

Page 2

© Vaisala Oy 2004

No part of this document may be reproduced in any form or by any

means, electronic or mechanical (including photocopying), nor may

its contents be communicated to a third party without a prior written

notice of the copyright holder.

The instruction manuals may be changed without prior notice.

Page 3

HMI41 AND HMP42

M210317EN-A Operating Manual

Contents

1. THE HMI41 INDICATOR AND PROBES...............................................................................1

2. TO BE NOTED IN THE M EASUREMENT OF HUM IDIT Y.....................................................3

3. GETTING STARTED............................................................................................................4

3.1 Inserting the batteries............................................................................................. 4

3.2 Connecting the HMP42 probe ................................................................................. 4

3.3 Starting the measurements ....................................................................................4

3.4 Using the HMP42 for measuring equilibrium humidity in structures ................... 5

3.4.1 Example 1: measuring hum idity in a bathroom .......................................... 5

3.4.2 Example 2: measuring hum idity in a concrete floor .................................... 6

3.4.3 Erroneous installations..............................................................................7

4. HOW TO USE THE HM I41 INDICATOR AND HMP42 PROBE............................................. 8

4.1 Turning the indicator on......................................................................................... 8

4.2 Measurement readings on display ......................................................................... 9

4.3 HOLD-mode........................................................................................................... 10

4.3.1 MIN-mode............................................................................................... 10

4.3.2 MAX-mode.............................................................................................. 10

5. CALIBRATION...................................................................................................................11

5.1 How to use the HMP42 calibration adapter .......................................................... 11

5.2 Calibration with trimmer potentiometers............................................................. 12

5.2.1 Humidity calibration................................................................................. 12

5.3 Calibration with HMI41 software commands ....................................................... 14

5.3.1 One point humidity calibration ................................................................. 16

5.3.2 Two point humidity calibration ................................................................. 18

5.3.3 One point temperature calibration ...........................................................20

5.3.4 Two point temperature calibration ...........................................................22

6. HMI41 AND DATA COLLECTING ...................................................................................... 25

6.1 Entering the data collecting mode....................................................................... 25

6.2 Manual data collecting..........................................................................................26

6.3 Setting the measurement duration ....................................................................... 27

6.4 Setting the measurement interval ........................................................................ 27

6.5 Reading the measurement results ....................................................................... 28

6.5.1 MIN and MAX in data collecting

REC READ mode ..................................... 30

7. TRANSFERRING THE STORED READINGS TO A PC...................................................... 31

7.1 Giving the communication parameters................................................................31

7.2 Transferring the data ............................................................................................ 34

8. SETUP PROCEDURE ........................................................................................................ 37

8.1 Entering the setup mode ...................................................................................... 37

8.2 Selecting the display units................................................................................... 38

8.3 Setting the automatic power-off function............................................................ 39

i

Page 4

HMI41 AND HMP42

Operating Manual M210317EN-A

8.4 Selecting the display quantities ........................................................................... 39

8.5 Setting the pressure for mixing rat io and w et bu lb temperat ure calculatio ns..40

8.6 Selecting the probe type.......................................................................................40

9. MAINTENANCE.................................................................................................................. 41

9.1 Changing the filter and the sensor head set........................................................ 41

9.2 Chemical tolerances of the HUMICAP

MINI sensor.............................................41

9.3 Spare parts and accessories.................................................................................42

10. IN CASE OF ERROR.......................................................................................................... 43

10.1 Trouble shooting ...................................................................................................43

10.2 Checking the settings ........................................................................................... 44

11. TECHNICAL DATA.............................................................................................................45

11.1 HMI41 indicator......................................................................................................45

11.2 HMP42 probe.......................................................................................................... 46

11.4 Accuracy of the calculated quantities..................................................................48

11.5 Electromagnetic compatibility..............................................................................51

APPENDIX 1: QUICK REFERENCE GUIDE ...............................................................................52

WARRANTY

This manual is valid for programme versions 2.01 or greater.

ii

Page 5

HMI41 AND HMP42

M210317EN-A Operating Manual

1. THE HMI41 INDICATOR AND PROBES

The HMI41 is an easy-to-use portable humidity and temperature indicator for

a variety of applications, including such as industrial monitoring and

inspections, occupational health and safety, laboratory and research use, spot

checking etc. When equipped with optional calibrati on cables, the HMI41 can

also be used as a field calibrator for most Vaisala transmitters.

The HMI41 has as many as six different probe types to choose from. The

indicator recognizes the probe type automatically, so there is no need to

change settings each time the probe is changed. However, please, note that this

feature is active only in indicators and probes with letters ID in the instrument

label. For previous versions, the probe type has to be set manually. The

HMP44 is an exception, as indicators marked with ID recognize automatically

all versions of this probe. All probe types are optimized for different

applications:

• HMP41 probe can be used for measuring humidity and temperature in

numerous applications, for example in spot checks.

• HMP42 probe head has a diameter of only 4 mm. The HMP42

consists of a handle a 23.5 cm long probe head. This remarkably small

and round probe structure is specially indicated for measurements in

very tight spaces, e.g. in joint spaces between tiles and in air

conditioning channels, as well as for measuring the equilibrium

humidity of e.g. timber; the operating temperature range is

-40 - +100 °C.

• HMP44 and HMP44L are used for measuring humidity in concrete

and other structures.

• HMP45 probe is indicated for measurements in channels and other

places that are difficult to reach and therefore require a probe head

with cable.

• HMP46 probe is optimized for measurements in relatively high

temperatures (up to +100 °C, temporarily even +180 °C), in dirty

processes and in general in applications that require a robust probe

structure.

1

Page 6

HMI41 AND HMP42

Operating Manual M210317EN-A

The HMI41 indicator displays relative humidity, temperature and dewpoint

temperature readings. In addition to these, one of the following quantities can

also be chosen: absolute humidity, wet bulb temperature or mixing ratio.

The indicator also features an automatic power-off function which can be

disabled, and a continuously updated display. The display can be frozen to

show the current readings, and it can be used for checking the minimum and

maximum readings measured during data collecting. The automatic power-off

function is not active during data collecting even if it was previously selected.

The versatile HMI41 indicator also includes a data collecting feature. Data

collecting can be either automatic or manual, and it can be optimized for each

application: both the measurement interval and duration can be set by the user.

During automatic data collecting, the probe takes measurements only just

before storing each measurement. In order to minimize the consumption and to

maximize the battery life, the power is automatically turned off for the

measurement interval and the display is dim except when the readi ngs on the

display are updated (once a minute). The stored readings can be transferred to

a PC via a serial interface (order code 19446ZZ) and then printed, if required.

The humidity measurement range is 0 - 100 %RH. The temperature measure-

ment range with the HMP42 probe is -40 - +100 °C. Relative humidity is

measured with the accurate and stable HUMICAPMINI humidity sensor

which uses an operating principle based on the changes in the capacitance of

the sensor as its thin polymer film absorbs water molecules.

2

Page 7

HMI41 AND HMP42

M210317EN-A Operating Manual

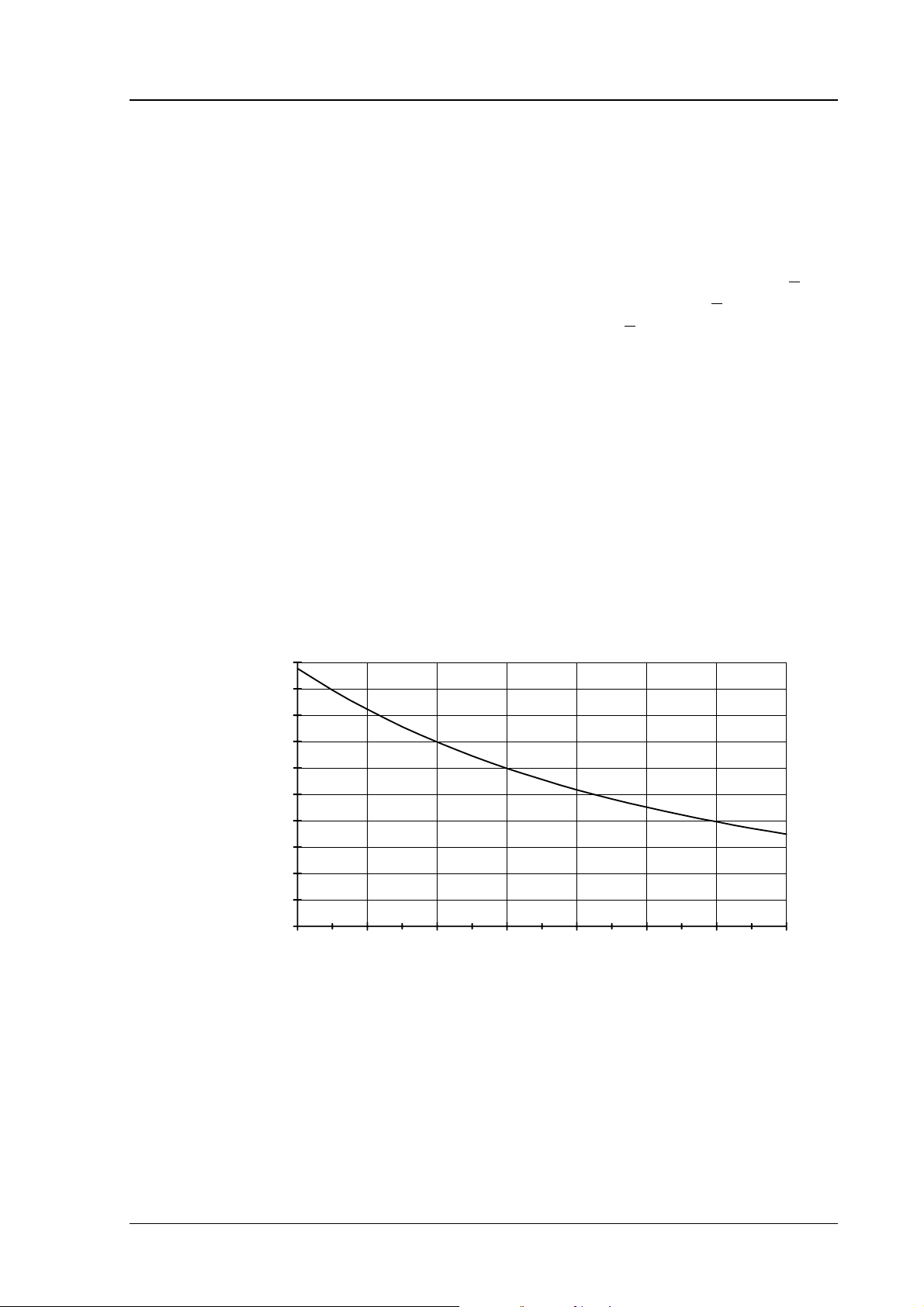

2. TO BE NOTED IN THE MEASUREMENT OF HUMIDITY

In the measurement of humidity and especially in calibration it is essential that

temperature equilibrium is reached. Even a small difference in temperature

between the measured object and the sensor causes an error. If the t emperature

is +20 °C (+68 °F) and the relative humidity is 50 %RH, a difference of +1 °C

between the measured object and the sensor causes an error of +3 %RH. When

the humidity is 90 %RH, the corresponding error is + 5.4 %RH.

The error is at its greatest when the sensor is colder or warmer than the

surroundings and the humidity is high. Although the humidity sensor reacts

rapidly to changes in the amount of water vapour in the air, the probe

temperature changes more slowly. To avoid errors caused by temperature

differences the probe must always be left to stabilize to ambient temperature

before starting measurements: the bigger the temperature difference, the

longer the stabilization time.

Indoors relative humidity should be measured in a place where the temperature

is as close to the average temperature of the room as possible. Measurements

taken close to heat sources will not give a true picture of the relative humidity

in the whole room.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Figure 2.1 Measurement error at 100 %RH when the dif ference

between the ambient and the sen sor temperature is 1 °C

3

Page 8

HMI41 AND HMP42

Operating Manual M210317EN-A

3. GETTING STARTED

3.1 Inserting the batteries

When taking the HMI41 indicator into use, first insert the batteries (4 pcs of

size AA [LR6] batteries). Open the lid on back of the device and insert the

batteries as indicated in the housing. Then close the lid carefully.

3.2 Connecting the HMP42 probe

Connect the HMP42 probe cable to the connector marked 'PROBE' at the

bottom of the HMI41 indicator (see Figure 3.2.1).

NOTE

If the indicator does not have letters ID in the

instrument label (on the back of the indicator), you

must give the probe setting manually before starting the

measurements (see Chapter 8).

HMP42

cable

Figure 3.2.1 Connecting the HMP42 probe to the HMI41

3.3 Starting the measurements

Before starting the measurements with the HMP42, remember to allow enough

time for stabilization.

Turn the power on with the ON/OFF button and the following appears:

RH

Td

T

P

set min max hyst hold Lo bat Hi

%

°C °F

°C

°F

Pahg/m

Within a couple of seconds, the display changes to show the software version

and the probe type (42.46):

4

Page 9

HMI41 AND HMP42

M210317EN-A Operating Manual

NOTE: if the following appears, check that the probe is correctly connected:

If the software version does not appear, it is smaller than 1.02 and the

indicator cannot be used with the HMP42 probe. If the probe type does not

appear, the indicator is of a previous version and does not recognize the probe

type automatically; give the setting manually (see Chapter 8).

In a couple of seconds, the battery charge appears and after that, the first

measurement readings:

RH

T°C

More detailed instructions of use are given in Chapter 4.

%

3.4 Using the HMP42 for measuring equilibrium humidity in structures

The HMP42 has been optimized for taking measurements in structures and

tight places. The following photos illustrate some examples of use in these

applications.

3.4.1 Example 1: measuring humidity in a bathroom

In this example, the screw of the shower holder is removed; no drilling is

needed as the HMP42 is small enough to enter this screw hole.

Figure 3.4.1 Taking measurements in a bathroom

5

Page 10

HMI41 AND HMP42

Operating Manual M210317EN-A

3.4.2 Example 2: measuring humidity in a concrete floor

Bore a hole and clean it thoroughly so that all drilling dust comes out; blowing

air is a good method for cleaning. However, please, note that if you clean

several holes, you should use a mask to protect yourself against dust. You can

also use a vacuum cleaner. Seal the hole e.g. with tape. Let stabilize (e.g. 24

hours in concrete). Cut the tape, insert the probe in the hole and take

measurements. See photos below for steps 1 - 6.

1. Bore a hole. 2. Clean it. 3. Seal it and let stabilize.

4. Cut the tape. 5. Insert the probe. 6. Take measurements.

Figure 3.4.2 Taking measurements in concrete floors

6

Page 11

HMI41 AND HMP42

M210317EN-A Operating Manual

3.4.3 Erroneous installations

Please, note that although with a metal probe head, the HMP42 is a delicate

instrument and requires careful handling. The probe must never be strongly

bent or forced through anything; if necessary, use e.g. a sharp edged pin with a

diameter of 5 mm. The filter must not be twisted. When taking measurements

in structures, never leave the cable and indicator hanging down while leaving

the probe to stabilize (see photos below). Make sure that when mounted

horizontally, the probe is at least 4 cm inside the structure in order to avoid

bending. See the following photos and make sure that your installation is not

like the one on the right.

at least 4 cm

inside the

structure

Figure 3.4.3 Installation: correct way on the left,

erroneous on the right

7

Page 12

HMI41 AND HMP42

Operating Manual M210317EN-A

4. HOW TO USE THE HMI41INDICATOR AND HMP42 PROBE

4.1 Turning the indicator on

To start the measurements with the HMI41, just press the ON/OFF button and

the following text appears:

RH

Td

T

P

set min max hyst hold Lo bat Hi

%

°C °F

°C

°F

Pahg/m

After a few seconds, the software version and probe type indication appear:

If the software version does not appear, it is smaller than 1.02 and the HMI41

cannot be used with the HMP42. Contact Vaisala or a Vaisala representative

for further information.

Make sure that you can see the text 42.46 on the display. If not, the indicator

is of a previous version and does not recognize the probe type automatically.

Give the probe type setting manually (see Chapter 8).

After a couple of seconds, the battery voltage appears on the display with an

indication of the battery charge (high or low):

Hi

bat

If the battery voltage is higher than 4.75 V, the text on the lower righthand

corner is “bat HI” and after a few seconds, the HMI41 automatically displays

the RH and T readings. If the voltage is 4.65...4.75 V, the text is “Lo bat” and

the batteries should be replaced (see Chapter 3.1). If the voltage is lower than

4.65 V, the indicator turns itself off to prevent erroneous measurements and

readings. Should this happen, replace the batteries.

8

Page 13

HMI41 AND HMP42

M210317EN-A Operating Manual

4.2 Measurement readings on display

Relative humidity and temperature readings appear automatically after the

battery charge indication:

RH

%

T°C

If MODE button is pressed, dewpoint temperature (Td) reading is displayed:

Td

T

When the MODE button is pressed again, one of the following is displayed or

°C

°C

the HMI41 returns to showing the RH and T readings according to what has

been chosen for the measurement quantities (see Chapter 4.4):

°C

g/m

Temperature and absolute humidity

T

abs

T

°C

°C

Temperature and wet bulb temperature; the

arrow in the lower righthand corner indicates that

wet bulb temperature has been chosen

T

°C

Temperature and mixing ratio; the arrow in the

lower righthand corner indicates that mixing ratio

has been chosen (the unit is g/kg or gr/lb).

9

Page 14

HMI41 AND HMP42

Operating Manual M210317EN-A

4.3 HOLD-mode

In any of the previously mentioned measurement reading displays, the HOLD

button freezes the display to show the current readings, e.g. RH & T readings:

RH

T

With MODE or ENTER, the display returns to the normal display mode.

If the indicator turns itself off with the automatic power-off function during

%

°C

hold

the HOLD-mode, it wakes up in the same mode when turned on again. The

'hold'-text is blinking and the indicator can be returned to the normal display

mode with any button except ON/OFF.

4.3.1 MIN-mode If you wish to know the minimum readings that have been measured after

power up, press HOLD when the indicator is in the HOLD-mode. The

minimum readings of the currently displayed quantities are shown (if the

‘hold’-text is blinking, the HMI41 must first be returned to the normal display

mode in order to activate the MIN-mode; see Chapter 4.3 above):

RH

T

min

With MODE or ENTER, the indicator returns to the normal display mode.

4.3.2 MAX-mode If you wish to know the maximum readings that have been measured after

%

°C

power up, press HOLD when the indicator is in the MIN-mode. The maximum

readings of the currently displayed quantities are shown:

RH

T

max

The indicator returns to the normal display mode with any button except

%

°C

ON/OFF.

10

Page 15

HMI41 AND HMP42

M210317EN-A Operating Manual

5. CALIBRATION

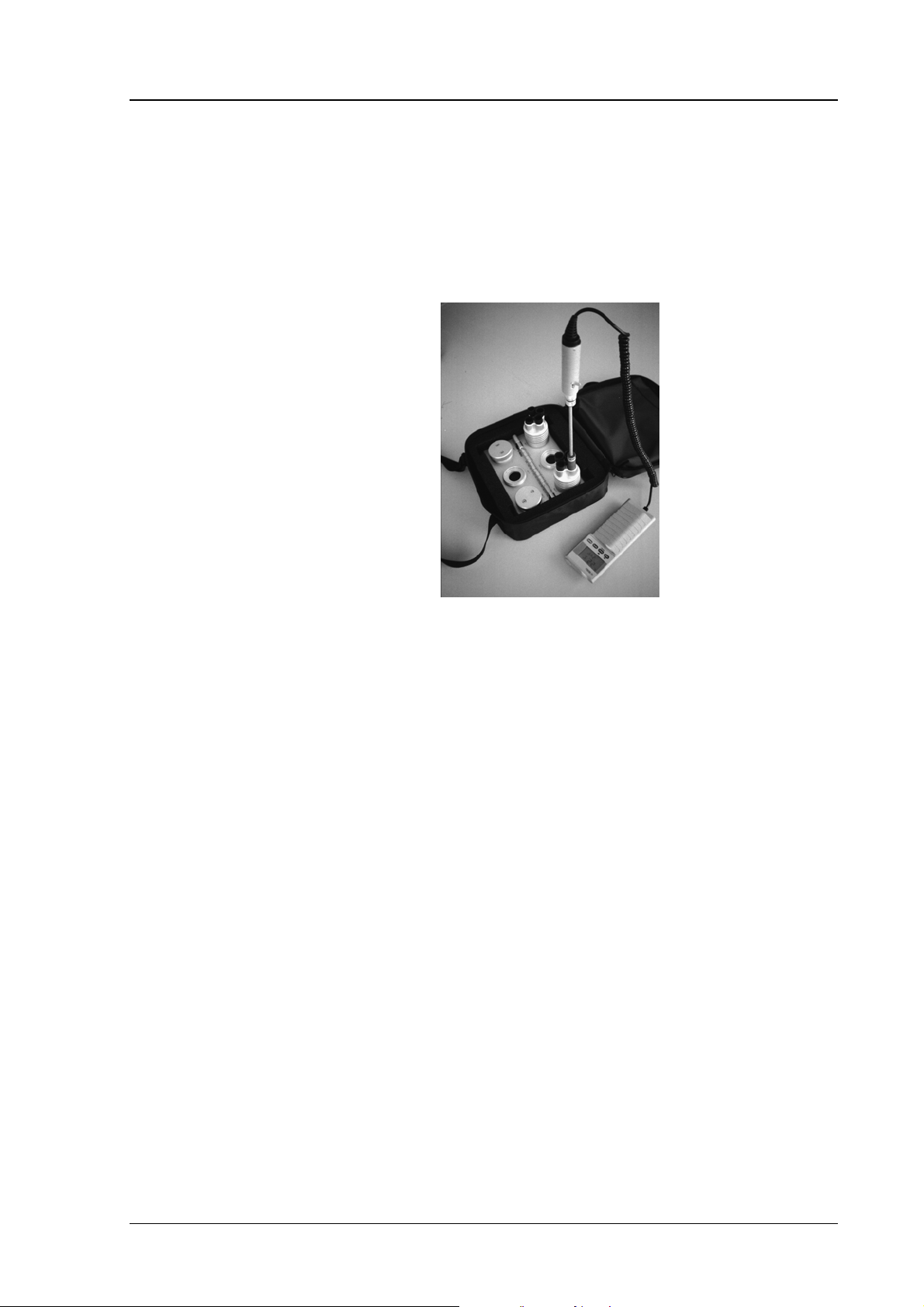

5.1 How to use the HMP42 calibration adapter

As the HMP42 probe diameter is extremely small, the probe has a special

calibration adapter for inserting the probe into a salt chamber (e.g. in the

HMK15 calibrator).

NOTE

Be extremely careful when inserting the probe into the

calibration adapter: do not bend or break it.

The probe is inserted into the adapter with the steel grid on; this protects the

sensor and prevents it from breaking. Unlike other humidity probes, the

HMP42 is calibrated with the steel grid on and thus, the probe naturally

requires a slightly longer stabilization time (approx. 30 minutes).

Figure 5.1.1 HMI41, HMP42 and calibration accessories

Figure 5.1.2 Insert the probe head into the calibration adapter

11

Page 16

HMI41 AND HMP42

Operating Manual M210317EN-A

5.2 Calibration with trimmer potentiometers

5.2.1 Humidity calibration The HMI41 indicator and HMP42 probes are fully calibrated at the factory so

there should be no immediate need for re-calibration. The recommended

calibration interval is one year. However, calibration should be performed

always when there is a reason to believe that the adjustments have changed.

Humidity calibration of the HMP42 probe is done by adjusting trimmer

potentiometers. The potentiometers are located under a protective plug. The

potentiometer marked T (temperature) is for factory use only; DO NOT make

any adjustments. To make sure that this potentiometer is not accidentally

touched when adjusting the other two, turn the plastic plug aside without

removing it completely (see Figure 5.2.1).

For adjusting the potentiometers, use a trimming wrench provided with the

probe, or some other suitable tool, e.g. a ceramic 1.5 mm slot screwdriver.

12

T

wet

W

D

W

D

dry

Figure 5.2.1 Adjusting the trimmer potentiometers

A two point calibration is performed with the HMK15. Calibrator or the probe

can be sent to Vaisala. The probes must always be re-calibrated if the sensor

head set is changed.

Page 17

HMI41 AND HMP42

M210317EN-A Operating Manual

The calibration procedure is as follows (see also the calibrator manual):

• Leave the calibrator and the probe at the calibration site for at least 30

minutes before starting the calibration in order to let the probe

temperature stabilize to the room temperature.

• Insert the probe into a measurement hole of the LiCl salt chamber (see

Figure 5.2.2).

Figure 5.2.2 The HMP42 in a salt chamber of the

HMK15 calibrator

• Wait until the humidity reading stabilizes (approx. 30 minutes).

Check the temperature and read the closest humidity value in the

calibration table. Adjust the dry end reading with the potentiometer D

(dry) in the probe body to correspond to the value given in the

calibration table; use a suitable trimming screw wrench (see Figure

5.2.1).

• Insert the thermometer into the 13.5 mm hole of the NaCl salt

chamber and the probe into another hole of the NaCl chamber.

NOTE

When calibrating probes that are being used for long

term measurements (over 1 hour) in high humidities

(90 - 100 %RH), use the K2SO4 salt as the high end

reference.

• Wait until the humidity reading stabilizes. Read the salt chamber

temperature from the thermometer and then the closest humidity value

from the calibration table. Adjust the wet end reading with the

potentiometer W (wet) to correspond to the value given in the

calibration table.

13

Page 18

HMI41 AND HMP42

Operating Manual M210317EN-A

Table 5.2 Greenspan’s calibration table

°C

LiCl NaCl K2SO

4

0 * 75.5 98.8

5 * 75.7 98.5

10 * 75.7 98.2

15 * 75.6 97.9

20 11.3 75.5 97.6

25 11.3 75.3 97.3

30 11.3 75.1 97.0

35 11.3 74.9 96.7

40 11.2 74.7 96.4

45 11.2 74.5 96.1

50 11.1 74.4 95.8

* If the LiCl solution is used or stored in temperatures below +18°C, its equilibrium

humidity changes permanently

As the D (dry) and W (wet) adjustments may affect each other, check again

the humidity reading in the LiCl salt chamber: insert the probe into the

calibration hole and wait until the reading stabilizes. If necessary, repeat the

adjustments in both the LiCl and the NaCl (K2SO4) salt chambers until the

reading is correct.

5.3 Calibration with HMI41 software commands

Calibration can also be done with the HMI41 software commands by entering

the corrections in the indicator memory with pushbuttons. If only one probe is

being used, the HMI41 software calibration is useful. However, when several

probes are in use, it is recommended that calibration is done by adjusting the

probe potentiometers. Note that when the sensor head set is changed,

calibration must always be done by adjusting the potentiometers and it is

recommended that the HMI41 is reverted to factory settings by selecting

default calibration.

NOTE

If the factory calibration of the HMI41 is changed, the

correction data refers to the calibrated probe only.

Therefore, if you change the probe, always revert this

data to factory settings by selecting default calibration,

or perform a new calibration with the new probe.

14

Page 19

HMI41 AND HMP42

M210317EN-A Operating Manual

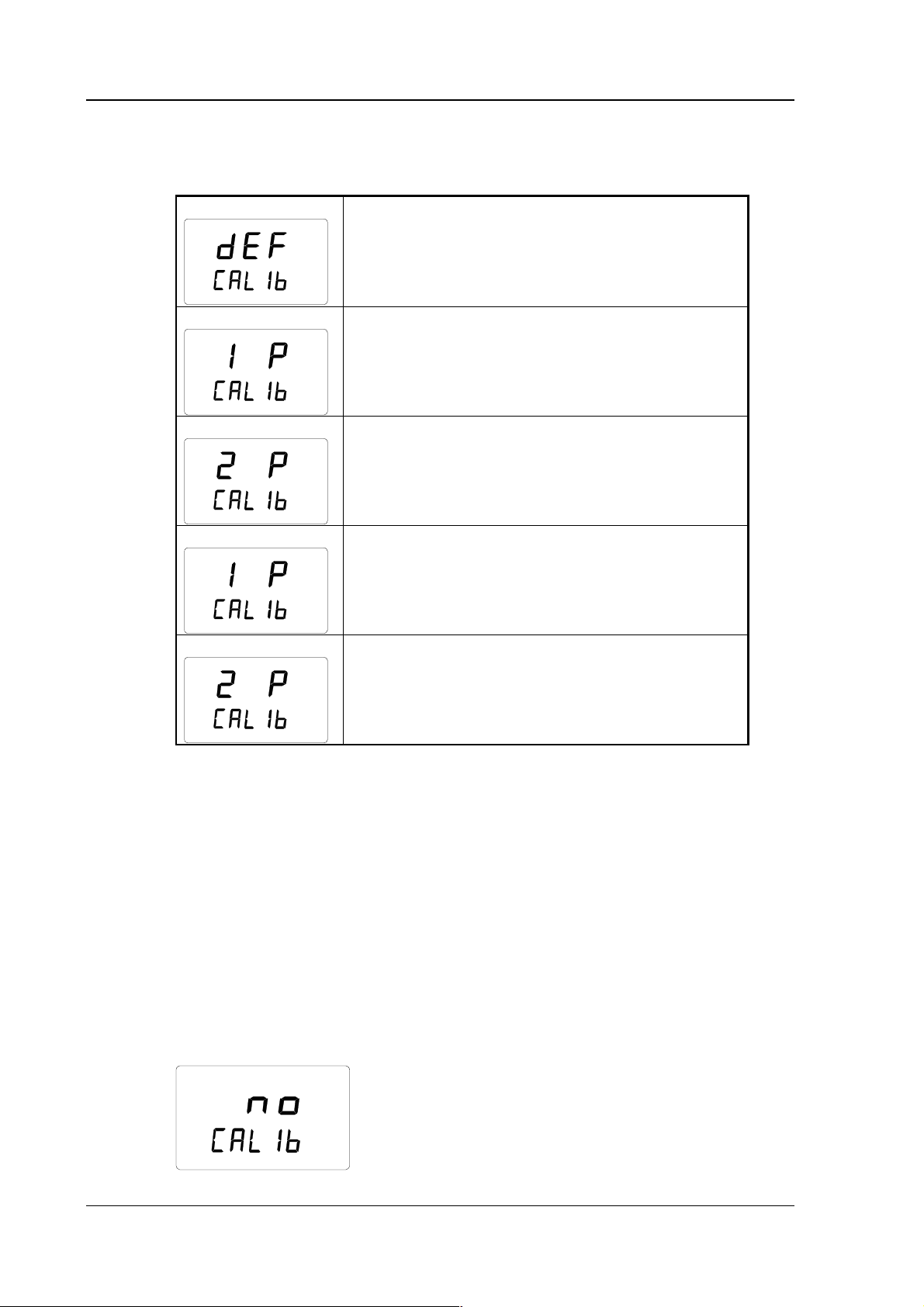

The calibration procedure is included in the HMI41 setup mode. For entering

the setup mode, first press the ON/OFF button and the following appears:

RH

Td

T

P

set min max hyst hold Lo bat Hi

%

°C °F

°C

°F

Pahg/m

Then release the ON/OFF button and press within 1...2 seconds both ENTER

and MODE buttons until the following text appears on the display:

After a few seconds, the text changes automatically to show the following:

°C

set

Press ENTER eight times until the following text appears:

set

This indicates that no calibration has been selected. In addition to this, there

are five calibration types available. The desired type is selected with buttons

▲ or ▼.

15

Page 20

HMI41 AND HMP42

Operating Manual M210317EN-A

All selections are acknowledged with ENTER. In the following, you will find

a list of these calibration options.

RH

T

Default calibration restores the factory settings of

the humidity and temperature calibrations.

set

RH

One point humidity calibration; select this for

performing humidity calibration at one point. See

Chapter 5.3.1 for further details.

set

RH

Two point humidity calibration; select this for

performing humidity calibration at two points.

See Chapter 5.3.2 for further details.

set

T

One point temperature calibration; select this for

performing temperature calibration at one point.

See Chapter 5.3.3 for further details.

set

T

Two point temperature calibration; select this for

performing temperature calibration at two points.

See Chapter 5.3.4 for further details.

set

16

5.3.1 One point humidity calibration

In one point humidity calibration, one accurate humidity reference is

sufficient. However, note that after one point calibration, the humidity reading

is most accurate near the reference value. For a better accuracy over the whole

range, perform a two point calibration if possible.

Leave the reference instrument (HMK15) and the probe at the calibration site

at least 30 minutes so that the probe temperature stabilizes to the room

temperature. Start the calibration by inserting the probe to the reference

humidity.

In setup mode, press ENTER repeatedly until the following is displayed:

set

Page 21

HMI41 AND HMP42

M210317EN-A Operating Manual

Then press MODE twice, and the following appears:

RH

set

Press ENTER to activate the one point calibration mode. A message similar to

the following appears with the first line blinking:

RH

set

%

The blinking number indicates the humidity reference value in the HMI41

memory. Check the salt chamber temperature, read the closest humidity value

in the calibration table and adjust the display with buttons ▲ and ▼ to

correspond to the value given in the table. For example, if the temperature in

the calibrator's NaCl salt chamber is 20.5 °C, adjust the value to 75.5 %RH:

RH

set

%

Each time the button is pressed, the value changes with 0.1 %. If you keep the

button pressed, the value changes in a faster mode. Press ENTER and the

HMI41 indicator shows the value that the probe is currently measuring,

displaying a message similar to the following:

RH %

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the one point

calibration. If the calibration has been successful, the following message

appears:

17

Page 22

HMI41 AND HMP42

Operating Manual M210317EN-A

The correction data has now been calculated and stored in the HMI41 memory.

The HMI41 returns automatically to the selection of display units, and can be

turned off. When the indicator is used as a standard indicator and the

correction data differs from the factory settings, an arrow in the upper

righthand corner is displayed:

RH

T

%

°C

If the message “cal pass” does not appear (instead, some other text may

appear, e.g. “too close”, “err offst” or “err gain”), the correction has not been

stored in the memory. The error may be due to an incorrect reference value or

to measured values that are out of the range.

5.3.2 Two point humidity calibration

In two point humidity calibration, two accurate references (e.g. the HMK15

Calibrator) are needed. Leave the reference instrument and the probe at the

calibration site for at least 30 minutes so that the probe temperature stabilizes

to the room temperature.

Start the calibration by inserting the probe to the lower reference humidity. In

setup mode press ENTER repeatedly until the following is displayed:

18

set

Then press MODE three times, and the following appears:

RH

set

Press ENTER to activate the two point humidity calibration mode. A message

similar to the following appears with the first line blinking:

RH

set

%

Lo

Page 23

HMI41 AND HMP42

M210317EN-A Operating Manual

The blinking number indicates the value of the lower humidity reference

stored in the HMI41 memory. Check the salt chamber temperature, read the

closest humidity value in the calibration table and adjust the display with

buttons ▲ and ▼ to correspond to the value given in the table. For example, if

the temperature of the LiCl salt chamber is 22 °C, adjust the value to

11.3 %RH:

RH

set

%

Lo

Press ENTER, and the HMI41 shows the value that the probe is currently

measuring, displaying a message similar to the following:

RH %

Lo

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the lower point

calibration. A message similar to the following appears with the first line

blinking:

RH

%

set

Hi

The blinking number indicates the value of the higher humidity reference

stored in the HMI41 memory. Insert the probe to the higher reference

humidity. Check the salt chamber temperature, read the closest humidity value

in the calibration table and adjust the display with buttons ▲ and ▼ to

correspond to the value given in the table. For example, if the temperature in

the calibrator's NaCl salt chamber is 20.5 °C, adjust the value to 75.5 %RH:

RH

set

%

Press ENTER and the HMI41 indicator shows the value that the probe is

currently measuring, displaying a message similar to the following:

19

Page 24

HMI41 AND HMP42

Operating Manual M210317EN-A

RH %

Hi

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the calibration. If the

calibration has been successful, the following message appears:

The correction data has now been calculated and stored in the HMI41 memory.

The HMI41 returns automatically to the selection of the display units, and can

be turned off. When the indicator is used as a standard indicator and the

correction data differs from the factory settings, an arrow in the upper

righthand corner is displayed:

RH

T

%

°C

If the message “cal pass” does not appear (instead, some other text may

appear, e.g. “too close”, “err offst” or “err gain”), the correction has not been

stored in the memory. The error may be due to an incorrect reference value or

to measured values that are out of the range.

5.3.3 One point temperature calibration

In one point temperature calibration, one accurate temperature reference is

sufficient.

Start the calibration by inserting the probe to the reference temperature.

In setup mode, press ENTER repeatedly until the following is displayed:

20

set

Then press MODE four times, and the following appears:

Page 25

HMI41 AND HMP42

M210317EN-A Operating Manual

T

set

Press ENTER to activate the one point temperature calibration mode.

A message similar to the following appears with the first line blinking:

T°C

set

The blinking number indicates the temperature reference value stored in the

HMI41 memory. Check the actual temperature reference and change the

display with buttons ▲ and ▼ to correspond to the accurate value, for

example:

T°C

set

Press ENTER and the HMI41 indicator shows the value that the probe is

currently measuring, displaying a message similar to the following:

T°C

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the calibration. If the

calibration has been succesful, the following message appears:

The correction data has now been calculated and stored in the HMI41 memory.

The HMI41 returns automatically to the selection of the display units, and can

be turned off. When the indicator is used as a standard indicator and the

correction data differs from the factory settings, an arrow in the upper

righthand corner is displayed:

21

Page 26

HMI41 AND HMP42

Operating Manual M210317EN-A

RH

T

%

°C

If the message “cal pass” does not appear (instead, some other text may

appear, e.g. “too close”, “err offst” or “err gain”), the correction has not been

stored in the memory. The error may be due to an incorrect reference value or

to measured values that are out of the range.

5.3.4 Two point temperature calibration

In two point temperature calibration, two accurate temperature references are

needed. Note that you must allow enough time for all instruments to stabilize

to the temperature equilibrium.

Start the calibration by inserting the probe to the lower reference temperature.

In setup mode, press ENTER repeatedly until the following is displayed:

set

Then press MODE five times, and the following appears:

T

set

Press ENTER to activate the two point temperature calibration mode. A

message similar to the following appears with the first line blinking:

T

set

°C

Lo

The blinking number indicates the value of the lower temperature reference

stored in the HMI41 memory. Insert the probe to the lower reference

temperature. Check the reference temperature and change the display with

buttons ▲ and ▼ to correspond to the accurate value, for example:

22

Page 27

HMI41 AND HMP42

M210317EN-A Operating Manual

T

set

°C

Lo

Press ENTER and the HMI41 shows the value that the probe is currently

measuring, displaying a message similar to the following:

T

°C

Lo

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the lower point

calibration. A message similar to the following appears with the first line

blinking:

T

°C

set

Hi

The blinking number indicates the value of the higher temperature reference

stored in the HMI41 memory. Insert the probe to the higher reference

temperature. Check the reference temperature and change the display with

buttons ▲ and ▼ to correspond to the accurate value, for example:

T

set

°C

Hi

Press ENTER and the HMI41 shows the value that the probe is currently

measuring, displaying a message similar to the following:

T°C

Hi

Wait at least ten minutes for the reading to stabilize and press ENTER to

acknowledge the value. Press ENTER again to conclude the calibration. If the

calibration has been successful, the following message appears:

23

Page 28

HMI41 AND HMP42

Operating Manual M210317EN-A

The correction data has now been calculated and stored in the HMI41 memory.

The HMI41 returns automatically to the selection of the display units, and can

be turned off. When the indicator is used as a standard indicator and the

correction data differs from the factory settings, an arrow in the upper

righthand corner is displayed:

RH

T

%

°C

If the message “cal pass” does not appear (instead, some other text may

appear, e.g. “too close”, “err offst” or “err gain”), the correction has not been

stored in the memory. The error may be due to an incorrect reference value or

to measured values that are out of the range.

24

Page 29

HMI41 AND HMP42

M210317EN-A Operating Manual

6. HMI41 AND DATA COLLECTING

The HMI41 indicator can also be used for collecting the measurement data.

The data is stored in the indicator's non-volatile memory which means that it

is not lost when the indicator is turned off. P lease, note also that th e automatic

power-off function is not active during data collecting even if previously

selected (see Chapter 8.3). When the data collecting has ended, the automatic

power-off function becomes active again.

6.1 Entering the data collecting mode

To enter the data collecting mode, turn the indicator on with the ON/OFF

button and the following appears for a couple of seconds:

RH

Td

T

P

set min max hyst hold Lo bat Hi

Release the ON/OFF button and press immediately the button HOLD. The

%

°C °F

°C

°F

Pahg/m

software version and the probe type indication appear, after which the display

changes automatically to show the battery charge:

Hi

Within a couple of seconds the text REC AUTO appears on the display; release

bat

the HOLD button.

This is the main display of the data collecting mode. With the button MODE

you can enter the REC CATCH mode (manual data collecting, see Chapter 6.2)

and by pressing MODE again, the REC READ mode (reading the measurement

results, see Chapter 6.5). By pressing ENTER, you can set the measurement

duration and by pressing ENTER again, the measurement interval (Chapters

6.3 and 6.4). By pressing HOLD, you can always return to the previous

display.

25

Page 30

HMI41 AND HMP42

Operating Manual M210317EN-A

6.2 Manual data collecting

For manual data collecting, press the button MODE and the following appears:

Press ENTER and a text similar to the following appears:

RH

T°C

set

%

The probe is now taking measurements and you can store the readings at

appropriate intervals by pressing the button HOLD. The sequence number of

the reading in the indicator memory appears for a couple of seconds:

The indicator returns automatically to show the readings. You can store 199

measurement readings in the indicator memory (numbers 1 - 199). In

automatic data collecting, you can store 200 readings (0 - 199). Data

collecting is ended by turning the indicator off. The readings can be read in

the REC READ mode (see Chapter 6.5).

26

Page 31

HMI41 AND HMP42

M210317EN-A Operating Manual

6.3 Setting the measurement duration

Turn the indicator on with the ON/OFF button, press immediately the button

HOLD and keep it pressed until the text REC AUTO appears on the display.

Press ENTER and a text similar to the following on the display:

In this mode, you can set the time between the first and the last measurement

bat

(previously set duration)

stored, e.g. 30 minutes or 3 days. When entering this mode, previously set

duration time appears on the display. If the previously set duration time is too

long for the current battery charge, the longest calculated duration time

possible for this battery charge appears instead. This is also indicated with the

text 'MAX'. The duration of the measurement can be set from 15 minutes to 7

days. The batteries last for 7 days during data collecting provided that they are

of the same type as those delivered with the indicator.

Set the duration with buttons ▲ and ▼. The duration time can be selected in

steps according to the following:

• 15 min; 30 min

• 1 - 6 h: each pressing = 1 h

• 12 h

• 1 - 7 d: each pressing = 1 d

If the duration selected is too long for the current battery charge, the text 'BAT'

appears. Select a shorter duration time.

By pressing ENTER, the indicator goes on to the setting of the measurement

interval.

6.4 Setting the measurement interval

min

In this mode, you can set the time that you wish to pass between two

(previously set interval)

measurements being stored, e.g. 5 minutes or 2 hours. When entering this

mode, previously set interval appears on the display. If the previously set

measurement interval is too short for the current memory capacity of the

indicator, the shortest calculated measurement interval appears instead. This is

also indicated with the text 'MIN'.

27

Page 32

HMI41 AND HMP42

Operating Manual M210317EN-A

Select the interval with buttons ▲ and ▼. The measurement interval can be

selected in steps according to the following:

• 1 - 5 min: each pressing = 1 minute

• 10 min; 15 min; 30 min

• 1 - 6 h: each pressing = 1 hour

• 12 h

The text 'LO' on the display indicates that there is not enough memory for the

chosen interval; select a longer interval. By pressing ENTER, a text similar to

the following appears:

RH

%

T°C

set

This is the measurement mode with the dat a collecting feature activ ated. It can

be distinguished from the normal measurement mode by the text 'SET' on the

lower lefthand corner of the display. The readings on the display are updated

once a minute, and the display is dim except during this updating in order

to minimize the consumption. If the indicator is turned off, the measurements

stored so far remain in the memory and they can be read by turning the

indicator on in the REC READ mode (see section 6.5).

You can end data collecting by pressing ON/OFF.

6.5 Reading the measurement results

The measurement results can be read in the REC READ mode. This mode can be

entered from the

REC AUTO mode by pressing twice the button MODE. The

following appears:

28

Press ENTER, and a text similar to the following appears on the display:

RH

T°C

Numbers on the first line indicate the reading of the quantity in question (in

%

this example, RH). The number on the left of the second line (in this example

Page 33

HMI41 AND HMP42

M210317EN-A Operating Manual

number 0.) is the sequence number of the m easurement. This number helps to

estimate the time of the measurement during automatic data collecting

provided that the starting time and the measurement interval are known.

Numbers located on the right on the second line indicate the temperature

reading measured simultaneously with the reading on the first line; if you wish

to see the decimals, press ENTER. The reading appears on the display with

one decimal:

RH

T°C

In a couple of minutes the indicator returns to the previous display.

By pressing MODE, you can change the quantity on the first line:

d

T

T

By pressing ENTER (with any quantity on the first line), an arrow appears on

%

°C

°C

the upper righthand corner of the display:

RH

T°C

%

By pressing HOLD while the arrow is displayed, you can scroll the

measurement results (note that the sequence number changes):

RH

T°C

HOLD:

RH

T°C

If the buttons are pressed continuously, numbers change in a faster rate.

%

%

etc.

29

Page 34

HMI41 AND HMP42

Operating Manual M210317EN-A

6.5.1 MIN and MAX in data collecting REC READ mode When the data collecting REC READ mode has been activated, the HOLD

button brings four different modes on the display: MIN HI, MAX HI, MIN LO and

MAX LO. These modes indicate the maximum and minimum readings measured

for the quantities on the display. HI and LO tell you whether the reading

observed is the one on the first line (HI) or the one on the second line (LO).

MIN and MAX indicate whether the reading on the display is the minimum or

the maximum value. In other words, if the text is MIN HI it means that you are

now observing the minimum reading of the quantity on the first line.

By pressing HOLD repeatedly you can change from one display mode to

another, and by pressing MODE you can change the quantity on the first line.

In all these modes, the decimals of the second line reading are shown by

keeping the button ENTER pressed down.

Examples:

RH

%

RH

%

ENTER

T°C

min

Hi

returns automatically

T°C

min

Hi

(minimum reading of the 1st line quantity) (decimals of the 2nd line)

HOLD

RH

%

RH

%

ENTER

T°C

max Hi

returns automatically

(maximum reading of the 1st line quantity)

T°C

max

Hi

(decimals of the 2nd line)

HOLD

RH

%

RH

%

ENTER

T°C

min

Lo

returns automatically

(minimum reading of the 2nd line quantity)

T°C

min

Lo

(decimals of the 2nd line)

HOLD

30

RH

%

ENTER

T°C

max

(maximum reading of the 2nd line reading)

Lo

returns automatically

RH

T°C

max

%

Lo

(decimals of the 2nd line)

Page 35

HMI41 AND HMP42

M210317EN-A Operating Manual

7. TRANSFERRING THE STORED READINGS TO A PC

The readings that have been stored in the HMI41 memory manually or

automatically in the data collecting mode, can be transferred to a computer

and then printed if desired. In order to do this, connect a serial connection

cable (order code 19446ZZ) to the appropriate connectors:

connect the

serial cable

to the EXT

connector

Figure 7.1 Connecting the cable

7.1 Giving the communication parameters

Give the communication parameters when using this terminal session for the

first time; save them for future use. See instructions in the following tables.

Table 7.1.1 Giving parameters in Windows 3.1

MENU DESCRIPTION

PROGRAM MANAGER

ò

ACCESSORIES

ò

TERMINAL

ò

Settings

ò

Communications

ò

File

ò

Save as

double click

double click

click

click and give parameters

(see figure 7.1.1 next page);

click OK

click and save settings: type

the name of the file (e.g.

HMI41) and click OK

Turn the HMI41 on and follow the instructions in Ch. 7.2

31

Page 36

HMI41 AND HMP42

Operating Manual M210317EN-A

NOTE: select the

connector

according to

your computer.

Select the

connector first

and then other

Figure 7.1.1 Giving the communication parameters in Windows 3.1

32

Page 37

HMI41 AND HMP42

M210317EN-A Operating Manual

Table 7.1.2 Giving parameters in Windows 95 and Windows NT

WINDOWS 95 WINDOWS NT

MENU WHAT TO DO MENU WHAT TO DO

Start Start

ò

move the cursor to:

ò

move the cursor to:

Programs Programs

ò

move the cursor to:

ò

move the cursor to:

Accessories Accessories

ò

move the cursor to:

ò

move the cursor to:

HyperTerminal

ò

Hypertrm

òò

Connection

Description

ò

Phone Number

òò

click

move the cursor to:

double click

type the name of the

connection (e.g.

HMI41) in the

appropriate field

and select an icon if

available; click OK.

move the cursor to

the field CONNECT

USING

and select

'direct to COM x'

(x = serial port

available); click OK

HyperTerminal

ò

Hyperterminal

Connection

Description

Connect to

move the cursor to:

click

type the name of the

connection (e.g.

HMI41) in the

appropriate field and

select an icon if

available; click OK.

move the cursor to

the field CONNECT

and select

USING

'COM x' (x = serial

port available); click

OK

select parameters

COM x properties

according to the

COM x properties

screen in figure

7.1.2; click OK

Turn the HMI41 on and follow the instructions in Chapter 7.2

select parameters

according to the

screen in figure

7.1.2; click OK

33

Page 38

HMI41 AND HMP42

Operating Manual M210317EN-A

Figure 7.1.2 Selecting the parameters in Windows 95 and NT

7.2 Transferring the data

When you have given the communication parameters, you can start

transferring the data from the HMI41. Store the parameters for future use.

To start transferring the data, make sure that the HMI41 is connected to a

serial port of your computer and that the terminal session is open. Turn the

HMI41 on and a text similar to the following appears:

HMI41 / 2.01

>

7.2.1 PLAY Transferring the data

To transfer the data on your PC, type PLAY and press ENTER; an example of

outputting automatically collected data:

>play

Reading Log... OK

data hh:mm:ss RH T Td

0 00:00:00 12.54 21.53 -8.48

1 00:01:00 12.10 21.23 -9.16

2 00:02:00 12.18 21.18 -9.12

3 00:03:00 12.12 21.15 -9.21

4 00:04:00 12.16 21.14 -9.18

5 00:05:00 12.09 21.12 -9.27

6 00:06:00 12.09 21.09 -9.28

>

34

Page 39

HMI41 AND HMP42

M210317EN-A Operating Manual

An example of outputting manually collected data:

>play

Reading Log... OK

data RH T Td

12.54 21.53 -8.48

1 12.10 21.23 -9.16

2 12.18 21.18 -9.12

3 12.12 21.15 -9.21

4 12.16 21.14 -9.18

5 12.09 21.12 -9.27

6 12.09 21.09 -9.28

>

If you know the starting time of the automatic data collecting, you can enter it

with the command and get an output showing the actual time of measurement.

For example:

>play 15:05

Reading Log... OK

data hh:mm:ss RH T Td

0 15:05:00 8.52 23.69 -11.70

1 15:06:00 9.58 23.66 -10.26

2 15:07:00 9.60 23.50 -10.35

3 15:08:00 9.61 23.30 -10.48

4 15:09:00 9.65 23.25 -10.47

5 15:10:00 11.22 23.41 -8.44

6 15:11:00 9.93 23.30 -10.08

7 15:12:00 9.92 23.22 -10.15

>

7.2.2 CPLAY Setting characters between decimals and fields

With the CPLAY command, you can select what you want to appear between

decimals and various fields. An example:

>cplay

Desimal separator : .

Field separator : TAB

example:

1 01:00:00 38.72 21.61 7.01

>

To change the output, type CPLAY, then the character you wish to appear

between decimals, then the character you wish to use between fields and then

<cr>. An example:

>cplay , <cr>

Desimal separator : ,

Field separator : TAB

example:

1 01:00:00 38,72 21,61 7,01

>

35

Page 40

HMI41 AND HMP42

Operating Manual M210317EN-A

7.2.3 HELP Outputting all available commands and their contents

If you wish to see which commands are available, type HELP and press

ENTER. The following list appears:

>help

Available commands :

HELP ? PLAY CPLAY

Type HELP <command_name> for more help

>

To see the contents of each command, type HELP, command name (e.g. PLAY)

and press ENTER; this brings an explanation of the command and its usage on

the display:

>help play

Command : PLAY

Purpose : Send recordings from memory to serial port

Usage : PLAY hh:mm <cr>, hh:mm = rec starting time (optional)

if command is used without parameters it uses default setting

>

7.3.4 ? Outputting the HMI41 settings

If you need to know which parameters and settings are currently stored in your

HMI41 indicator, type ? and press ENTER:

>?

HMI41 / 2.01

Serial number : A0000000

Output units : metric

Baud P D S : 4800 E 7 1 FDX

Pressure : 1013.25

Auto Off : 5

Probe : 2

Start-up mode : 1

4.th variable : none

>

To exit the terminal session, move the cursor to FILE menu and select EXIT.

Confirm that you wish to quit and then select whether you wish to store the

parameters of this session for future use or not (SAVE - YES/NO).

36

Page 41

HMI41 AND HMP42

M210317EN-A Operating Manual

8. SETUP PROCEDURE

The indicator settings can be changed in the SETUP mode. Note that manual

setup procedure is necessary if some of the factory settings have to be changed

and if the indicator or the probe does not have letters ID in the instrument

label.

The factory settings of the HMI41 are the following:

• display units: 0 (metric)

• automatic power-off: 5 minutes

• display quantities: 0 (= RH, T, Td)

• pressure: 1013.25 hPa (1 hPa = 1 mbar)

(for wet bulb temperature and mixing ratio calculations)

• probe type AUT (or 1, see below)

• start 1

Indicators marked with letters ID have the automatic probe recognition as

default (AUT PROBE) and previous versions the probe type 1. If the indicator

does not recognize the probe type automatically, set th e type manually to

2 when using the HMP42. Note also that the HMP42 probe cannot be used

with the HMI41 unless the software version is 1.02 or greater. To check the

version, turn the HMI41 on with the ON/OFF button. The version appears on

the display in a couple of seconds if it is 1.02 or greater. If it does not appear,

contact Vaisala or a Vaisala representative for furt her informati on.

8.1 Entering the setup mode

For entering the setup mode, first press the ON/OFF button and the following

appears:

RH

Td

T

P

set min max hyst hold Lo bat Hi

%

°C °F

°C

°F

Pahg/m

Then release the ON/OFF button and within 1 - 2 seconds press simultaneously both ENTER and MODE buttons until the following text appears on the

display:

37

Page 42

HMI41 AND HMP42

Operating Manual M210317EN-A

After a few seconds, the text changes automatically to show the following:

°C

set

You can scroll the setup menu by pressing ENTER.

8.2 Selecting the display units

°C

set

You can now select the display units with buttons ▲ (number up) or ▼

(number down). Choose 0 for metric units or 1 for non-metric units (see Table

8.2). The temperature unit on the display changes accordingly. If you do not

wish to change any other settings, press the ON/OFF button. If you wish to

change some other settings, press ENTER; the display changes to show the

setting of the automatic power-off function.

Table 8.2 Metric and non-metric units

quantity metric non-metric

RH %RH %RH

T

Td

ag/m3gr/ft

°C °F

°C °F

3

x g/kg gr/lb

Tw

°C °F

38

Page 43

HMI41 AND HMP42

M210317EN-A Operating Manual

8.3 Setting the automatic power-off function

set

The number (or text NO) on the first line of the display indicates in minutes

(1...60) the time that the HMI41 stays on before it automatically turns itself

off if no buttons are pressed. The number is changed with buttons ▲ (number

up) and ▼ (number down). If NO is chosen, the automatic power-off function

is not activated. If you do not wish to change any other settings, press the

ON/OFF button. If you wish to change some other settings, press ENTER; the

display changes to show the selection of the display quantities.

8.4 Selecting the display quantities

set

The HMI41 displays relative humidity, temperature and dewpoint temperature

readings. In addition to these, one of the following quantities can be chosen:

absolute humidity, wet bulb temperature and mixing ratio. The number on the

display indicates the following quantities:

0 = RH, T, Td

1 = RH, T, Td, abs

2 = RH, T, Td, Tw

3 = RH, T, Td, x

The number is changed with buttons ▲ (number up) and ▼ (number down). If

you do not wish to change other settings, press the ON/OFF button. If you

wish to change other settings, press ENTER; the display changes to show the

setting of the pressure for mixing ratio and wet bulb temperature calculations.

39

Page 44

HMI41 AND HMP42

Operating Manual M210317EN-A

8.5 Setting the pressure for mixing ratio and wet bulb temperature calculations

PPah

set

The pressure is changed (in steps of 0.25 hPa) with buttons ▲ (number up)

and ▼ (number down). Acknowledge the pressure setting with ENTER and a

text similar to the following appears:

set

or

Indicators marked with letters ID have the automatic probe recognition as

default (AUT PROBE) and previous versions the probe type 1. If the indicator

does not recognize the probe type automatically, set the type manually to 2

(see below) when using the HMP42.

8.6 Selecting the probe type

set

Change the setting with buttons ▲ (number up) and ▼ (number down). You

have now completed the setup procedure; turn your indicator off.

set

NOTE

40

The HMI41 setup contains further settings (start, baud,

seri and calib) that appear after probe type setting when

pressing ENTER. Start setting is changed only when

using the HMP44/44L probes (START 5, see the HM44

Operating Manual). For calib, see Chapter 5. Other

settings are meant for the HMI41 used as a field

calibrator for other Vaisala humidity transmitters. It is

recommended that these settings are not changed.

Page 45

HMI41 AND HMP42

M210317EN-A Operating Manual

9. MAINTENANCE

9.1 Changing the filter and the sensor head set

For changing the filter, unscrew the steel grid, remove the membrane filter

(see Figure 9.1) and replace it with a new one. A set of membrane filters is

delivered with the probe. Screw the steel grid back on.

NOTE

Do not use the probe without the membrane filter in

order not to damage the sensors.

Figure 9.1 Changing the filter

If the steel grid looks dirty, remove it and clean the holes e.g. with a needle.

It is recommended that the sensor head set is changed by Vaisala authorized

maintenance personnel only. However, if for some reason it is necessary to do

this yourself, be careful not to break the sensor. Unscrew the sensor head set

and mount a new set in its place. Handle the sensor head with care. Calibrate

the probe using a two-point calibration procedure (see section 5.3.2).

9.2 Chemical tolerances of the HUMICAPMINI sensor

Long-term exposure of the HUMICAPMINI sensor to certain chemicals and

gases may affect the characteristics of the sensor and shorten its life. The

following table gives the recommended maximum ambient concentrations of

some chemicals:

ppm (typ.)

Organic solvents 1000...10 000

Aggressive chemicals (e.g. strong acids

1...10

such as SO2, H2SO4, H2S, HCl, Cl2, etc.)

Weak acids 100...1000

Bases 10 000...100 000

Detailed information on allowed concentrations can be requested from Vaisala

representatives.

41

Page 46

HMI41 AND HMP42

Operating Manual M210317EN-A

9.3 Spare parts and accessories

Order code Description

19809HM Rubber sleeve set (10 pcs)

HM37067 Calibration adapter

19858HM Membrane filter set, 5 pcs (AISI 316/PTFE)

19867HM Steel grid

HM27104 Carrying bag for HMI41 and HMP42

HM36959 Trimming screw wrench set 1.5 mm / 2.5 mm

HMP42P235SP Sensor head set: RH and T sensors, filters and installation

accessories

HMP41 RH & T probe; for fixed mounting

HMP42 RH & T probe; for tight places

HMP44/L RH & T probe; for measurements in structures

HMP45 RH & T probe; cable model

HMP46 RH & T probe; cable model, for dirty or hot processes

19446ZZ S erial interface cable for HMI41

19116ZZ C alibration cable (for HMD/W60/70, HMP140 series)

19164ZZ C alibration cable (for HMP230 series)

19165ZZ C alibration cable (for HMD/W20/30, HMP130 series)

HMK15 Humidity Calibrator

42

Page 47

HMI41 AND HMP42

M210317EN-A Operating Manual

10. IN CASE OF ERROR

The HMI41 goes through a continuous self-diagnostic procedure. If any

problems occur, it displays the corresponding error message:

where nn = the number indicating the error

Whenever you come across an error message or your indicator does not

function as it should, first check that the probe is correctly connected. Then

check that the filter and the steel grid are clean.

10.1 Trouble shooting

In the following, a short list for trouble shooting:

PROBLEM: WHAT TO DO:

the display is blank

the display is dim - during automatic data collecting, the display is dim

the readings seem to

be wrong

- check the batteries (see Chapters 3.1 and 9.1)

- if the batteries are ok, contact Vaisala or a Vaisala

representative

except when the readings are updated (once in a

minute)

- allow enough time for the probe to stabilize to

the ambient temperature

- check that the probe is correctly connected to the

indicator

- check that the steel grid and the membrane filter are

clean

- make sure that the measurement point is clean and

that there is no condensated water

- check that the settings are correct (see

Chapter 10.2)

you have accidentally

changed some settings

- enter the setup mode, select the setting with

ENTER and change it with buttons ▲ or ▼ (see

table on the next page). The pressure setting has to

be acknowledged with ENTER.

43

Page 48

HMI41 AND HMP42

Operating Manual M210317EN-A

10.2 Checking the settings

If these are in order, turn the HMI41 on and enter the setup mode (see Chapter

8). Make sure that the following settings are correct:

setting correct value

probe

start (*)

baud

seri

calib

AUT or 2 (with HMP42)

1

4.8

E.7.1

def (**)

(*) values 2, 3 and 4 are for calibration cables

(**) when the calib setting is entered, the value is always “no”; factory

settings for calibration correction data can be returned by selecting “def”

If the settings are not correct, change them: in the setup mode, select the

setting with ENTER, change it with buttons ▲ or ▼ and acknowledge with

ENTER. If the error message still appears, write it down and contact Vaisala

or a Vaisala representative for further instructions.

44

Page 49

HMI41 AND HMP42

M210317EN-A Operating Manual

11. TECHNICAL DATA

11.1 HMI41 indicator

Maximum measurement error

caused by the indicator at 20 °C

(for system accuracy, see probes’ technical specifications)

humidity +0.1 %RH

temperature +0.1 °C

Calculated variables dewpoint temperature, absolute

humidity, wet bulb temperature,

mixing ratio

Resolution 0.1 %RH; 0.1 °C

Power supply 4 batteries, type IEC LR6

Battery operation time 72 h continuous use

Operating humidity range 0...100 %RH non-condensing

Operating temperature -20...+60 °C

Storage temperature -40...+70 °C

Display two line LCD

Housing material ABS plastic

Housing classification IP 53 (with connectors blocked)

Connector type modular connector

Weight (incl. batteries) 300 g

45

Page 50

HMI41 AND HMP42

Operating Manual M210317EN-A

11.2 HMP42 probe

11.2.1 Relative humidity

Measurement range 0...100 %RH non-condensing

Accuracy (at +20 °C)

when calibrated against

salt solutions (ASTM E104-85): ±2 %RH (0...90 %RH)

±3 %RH (90...100 %RH)

Temperature dependence

of electronics ±0.05 %RH/ °C

Typical long-term stability better than 1 %RH per year

Response time (90%) at 20 °C

in still air with 30 s

Humidity sensor HUMICAP®MINI

11.2.2 Temperature

Measurement range

(sensor head) -40...+100 °C

Accuracy at +20 °C ±0.2 °C

Accuracy:

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-40

-20

0

20

40

60 80

100

°C

Temperature sensor Pt 100 (IEC 751 1/3 Class B)

46

Page 51

HMI41 AND HMP42

M210317EN-A Operating Manual

11.2.3 General

Cable length 1500 mm; extended spiral cable

Connector type modular connector

Operating temperature range

for electronics -20...+60 °C

Storage temperature range -40...+100 °C

Housing material ABS plastic

Housing classification (electronics) IP65 (NEMA 4)

Sensor protection steel grid with membrane filter

Weight 200 g

Dimensions (in mm):

38

ø4

V

ø18.5

bottom

view

235

13

ø21

30

13

106

47

Page 52

HMI41 AND HMP42

Operating Manual M210317EN-A

11.4 Accuracy of the calculated quantities

Dewpoint temperature, mixing ratio, absolute humidity and wet bulb temperature are calculated from the measured relative humidity and temperature

values. The accuracy of the calculated quantities depends on the calibration of

the probe and on performing the measurement correctly. In tables below the

accuracies of the measured values are ±2 %RH and ±0.2°C.

11.4.1 Accuracies in metric units

Accuracy of dewpoint temperature (°C)

RH/%

10 20 30 40 50 60 70 80 90 100

T/°C

-40

-20

20

40

60

80

100

120

140

160

1.82 1.00 0.74 0.61 0.53 0.48 0.44 0.42 - -

2.09 1.14 0.83 0.68 0.59 0.53 0.49 0.45 - -

2.51 1.37 1.00 0.81 0.70 0.63 0.57 0.53 0.50 0.48

0

2.87 1.56 1.13 0.92 0.79 0.70 0.64 0.59 0.55 0.53

3.24 1.76 1.27 1.03 0.88 0.78 0.71 0.65 0.61 0.58

3.60 1.96 1.42 1.14 0.97 0.86 0.78 0.72 0.67 0.64

4.01 2.18 1.58 1.27 1.08 0.95 0.86 0.79 0.74 0.70

4.42 2.41 1.74 1.40 1.19 1.05 0.95 0.87 0.81 0.76

4.86 2.66 1.92 1.54 1.31 1.16 1.04 0.96 0.89 0.84

5.31 2.91 2.10 1.69 1.44 1.27 1.14 1.05 0.97 0.91

5.80 3.18 2.30 1.85 1.57 1.38 1.24 1.14 1.06 0.99

T/°C

Accuracy of mixing ratio (g/kg) with

ambient pressure of 1013.25 mbar

RH/%

10 20 30 40 50 60 70 80 90 100

-40

-20

100

120

140

160

0.002 0.002 0.002 0.002 0.003 0.003 0.003 0.003 - -

0.014 0.015 0.017 0.018 0.019 0.020 0.022 0.023 - -

0.08 0.09 0.09 0.10 0.10 0.11 0.12 0.12 0.13 0.13

0

20

40

60

80

0.31 0.33 0.35 0.37 0.39 0.41 0.43 0.45 0.47 0.49

0.97 1.03 1.10 1.17 1.24 1.31 1.38 1.46 1.54 1.62

2.70 2.94 3.46 3.76 3.72 4.08 4.42 4.79 5.19 5.63

6.78 7.80 9.00 10. 4 12.2 14.3 16.9 20.2 24.4 29.7

16.4 21.6 29.2 41.3 62.0 101 190 462 - -

41.275.7176-------

- ---------

- ---------

48

Page 53

HMI41 AND HMP42

M210317EN-A Operating Manual

Accuracy of absolute humidity (g/m3 )

RH/%

10 20 30 40 50 60 70 80 90 100

T/°C

-40

-20

100

120

140

160

0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.005 - -

0.020 0.021 0.023 0.025 0.026 0.028 0.029 0.031 - -

0.10 0.11 0.12 0.13 0.13 0.14 0.15 0.15 0.16 0.17

0

20

40

60

80

0.37 0.39 0.41 0.43 0.45 0.47 0.49 0.51 0.53 0.55

1.08 1.13 1.18 1.24 1.29 1.34 1.39 1.44 1.49 1.54

2.73 2.84 2.95 3.07 3.18 3.29 3.40 3.52 3.63 3.74

6.08 6.30 6.51 6.73 6.95 7.17 7.39 7.61 7.83 8.05

12.2 12.6 13.0 13.4 13.8 14.2 14.6 15.0 15.3 15.7

22.6 23.3 23.9 24.6 25.2 25.8 26.5 27.1 27.8 28.4

39.1 40.0 41.0 42.0 43.0 44.0 45.0 45.9 46.9 47.9

63.5 64.9 66.4 67.8 69.2 70.7 72.1 73.5 75.0 76.4

Accuracy of wet bulb temperature (°C)

RH/%

10 20 30 40 50 60 70 80 90 100

T/°C

-40

-20

20

40

60

80

100

120

140

160

0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 - -

0.21 0.21 0.21 0.21 0.22 0.22 0.22 0.22 - -

0.27 0.28 0.28 0.29 0.29 0.29 0.30 0.30 0.31 0.31

0

0.45 0.45 0.45 0.44 0.44 0.44 0.43 0.43 0.42 0.42

0.84 0.77 0.72 0.67 0.64 0.61 0.58 0.56 0.54 0.52

1.45 1.20 1.03 0.91 0.83 0.76 0.71 0.67 0.63 0.61

2.24 1.64 1.32 1.13 0.99 0.90 0.82 0.76 0.72 0.68

3.06 2.04 1.58 1.31 1.14 1.01 0.92 0.85 0.80 0.75

3.86 2.41 1.81 1.48 1.28 1.13 1.03 0.95 0.88 0.83

4.57 2.73 2.03 1.65 1.41 1.25 1.13 1.04 0.97 0.91

5.23 3.04 2.24 1.81 1.55 1.36 1.23 1.13 1.05 0.98

11.4.2 Accuracies in non-metric units

Accuracy of dewpoint temperature (°F)

RH/%

10 20 30 40 50 60 70 80 90 100

T/°F

-40

-4

32

68

104

140

176

212

248

284

320

3.28 1.80 1.33 1.10 0.96 0.86 0.80 0.75 - -

3.76 2.05 1.50 1.22 1.06 0.95 0.88 0.82 - -

4.52 2.47 1.80 1.46 1.26 1.13 1.03 0.96 0.90 0.86

5.16 2.81 2.04 1.65 1.42 1.26 1.15 1.06 1.00 0.95

5.83 3.16 2.29 1.85 1.58 1.40 1.27 1.18 1.10 1.04

6.48 3.53 2.55 2.05 1.75 1.55 1.41 1.30 1.21 1.14

7.22 3.93 2.84 2.28 1.95 1.72 1.55 1.43 1.33 1.26

7.95 4.34 3.13 2.52 2.15 1.89 1.71 1.57 1.46 1.38

8.75 4.78 3.45 2.77 2.36 2.08 1.88 1.72 1.60 1.50

9.56 5.24 3.78 3.04 2.59 2.28 2.05 1.88 1.75 1.64

10.4 5.73 4.14 3.33 2.83 2.49 2.24 2.05 1.90 1.79

49

Page 54

HMI41 AND HMP42

Operating Manual M210317EN-A

Accuracy of mixing ratio (gr/lb)

with ambient pressure of 1013.25 mbar

RH/%

10 20 30 40 50 60 70 80 90 100

T/°F

-40

104

140

176

212

248

284

320

0.013 0.014 0.015 0.016 0.018 0.019 0.020 0.021 - -

0.099 0.108 0.116 0.125 0.134 0.142 0.151 0.159 - -

-4

32

68

0.57 0.61 0.65 0.69 0.73 0.77 0.81 0.85 0.89 0.93

2.17 2.31 2.44 2.58 2.72 2.87 3.01 3.15 3.30 3.44

6.85 7.31 7.77 8.25 8.74 9.25 9.77 10.3 10.9 11.4

18.9 20.6 22.3 24.2 26.3 28.5 30.9 33.5 36.4 39.4

47.5 54.6 63.0 73.1 85.2 100 118 141 170 208

115 151 205 289 434 709 1329 3237 - 288 530 1235 - - -----

- ---------

- ---------

T/°F

T/°F

Accuracy of absolute humidity (gr/ft3 )

RH/%

10 20 30 40 50 60 70 80 90 100

-40

104

140

176

212

248

284

320

0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 - -

0.009 0.009 0.010 0.011 0.011 0.012 0.013 0.014 - -

-4

0.046 0.049 0.052 0.055 0.058 0.060 0.063 0.066 0.069 0.072

32

68

0.16 0.17 0.18 0.19 0.20 0.21 0.21 0.22 0.23 0.24

0.47 0.49 0.52 0.54 0.56 0.58 0.61 0.63 0.65 0.67

1.19 1.24 1.29 1.34 1.39 1.43 1.48 1.53 1.58 1.63

2.65 2.74 2.84 2.94 3.03 3.13 3.22 3.32 3.41 3.51

5.33 5.50 5.67 5.84 6.01 6.18 6.35 6.52 6.69 6.86

9.87 10.2 10.4 10.7 11.0 11.3 11.5 11.8 12.1 12.4

17.0 17.5 17.9 18.3 18.7 19.2 19.6 20.0 20.5 20.9

27.7 28.3 28.9 29.6 30.2 30.8 31.4 32.1 32.7 33.3

Accuracy of wet bulb temperature (°F)

RH/%

10 20 30 40 50 60 70 80 90 100

-40

-4

32

68

104

140

176

212

248

284

320

0.36 0.36 0.36 0.36 0.36 0.36 0.36 0.37 - -

0.37 0.38 0.38 0.38 0.39 0.39 0.40 0.40 - -

0.49 0.50 0.51 0.51 0.52 0.53 0.54 0.55 0.55 0.56

0.82 0.81 0.81 0.80 0.79 0.78 0.78 0.77 0.76 0.76

1.51 1.39 1.29 1.21 1.15 1.09 1.05 1.00 0.97 0.94

2.62 2.16 1.86 1.64 1.49 1.37 1.28 1.20 1.14 1.09

4.03 2.96 2.38 2.03 1.79 1.61 1.48 1.38 1.29 1.22

5.52 3.68 2.84 2.36 2.05 1.83 1.66 1.54 1.44 1.36

6.94 4.33 3.26 2.67 2.30 2.04 1.85 1.70 1.59 1.49

8.23 4.92 3.65 2.97 2.54 2.25 2.03 1.87 1.74 1.63

9.41 5.48 4.03 3.26 2.78 2.45 2.21 2.03 1.89 1.77

50

Page 55

HMI41 AND HMP42

M210317EN-A Operating Manual

11.5 Electromagnetic compatibility

Complies with the following standard:

EN 61326-1:1997 +Am 1:1998, Electrical equipment for measurement,

control and laboratory use - EMC requirements: Light environment.

51

Page 56

HMI41 AND HMP42

Operating Manual M210317EN-A

APPENDIX 1: QUICK REFERENCE TO COMMANDS

1. DISPLAY TEXTS AND OPERATING COMMANDS ................................................................53

2. CALIBRATION WITH T HE HM I41 SOFT WARE .....................................................................55

2.1 One-point humidity calibration............................................................................55

2.2 Two-point humidity calibration............................................................................56

2.3 One-point temperature calibration...................................................................... 57

2.4 Two-point temperature calibration...................................................................... 58

3. DATA COLLECTING MODE .................................................................................................. 59

3.1 Manual data collecting ................................................................................................59

3.2 Setting the measurement duration for automatic data collecting ............................60