Page 1

USER'S GUIDE

Vaisala Humidity and Temperature Probes

HMP60 and HMP110 Series

M211060EN-G

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com

© Vaisala 2016

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

Local rules and regulations may vary and they shall take precedence over the

information contained in this manual. Vaisala makes no representations on this

manual’s compliance with the local rules and regulations applicable at any given time,

and hereby disclaims any and all responsibilities related thereto.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 5

About This Manual ................................................................... 5

Contents of This Manual ....................................................... 5

Version Information ............................................................... 6

Related Manuals ................................................................... 6

Documentation Conventions ................................................. 6

Safety ......................................................................................... 7

ESD Protection ......................................................................... 7

Recycling .................................................................................. 8

Regulatory Compliances ......................................................... 8

Trademarks ............................................................................... 9

License Agreement .................................................................. 9

Warranty .................................................................................... 9

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 10

Introduction to HMP60 and HMP110 Series......................... 10

Basic Features and Options .................................................. 12

Filter Options ....................................................................... 13

Installation Accessories (Optional) ...................................... 14

Probe Mounting Clamp ....................................................... 14

Probe Mounting Flange ....................................................... 16

Plastic Locking Bushing for HMP63 and HMP113 .............. 16

Duct Installation Kit for HMP60, HMP110,

HMP110D and HMP110T ................................................... 17

Loop Power Converter ........................................................ 18

Cables ................................................................................. 19

CHAPTER 3

INSTALLATION ............................................................................................ 20

Dimensions for HMP60, HMP110, HMP110D

and HMP110T .......................................................................... 20

Dimensions for HMP63 and HMP113 .................................... 21

Mounting the HMP60, HMP110, HMP110D

and HMP110T Probes ............................................................. 22

Probe Assembly with Duct Installation Kit ..................... 22

Drilling Instructions for Duct Installation Kit ................... 23

Mounting the HMP63 and HMP113 Probes .......................... 24

Wiring ...................................................................................... 25

Wiring with the Loop Power Converter ............................... 27

Power Supply Requirements ............................................... 28

Recommendations ......................................................... 28

CHAPTER 4

VAISALA _________________________________________________________________________ 1

Page 4

User's Guide _______________________________________________________________________

OPERATION ................................................................................................. 29

Getting Started ........................................................................ 29

Serial Line Communication ................................................... 29

Connecting to the Serial Interface ....................................... 30

Installing the Driver for the USB Cable ................................ 31

Terminal Application Settings for Digital Probes ................. 32

Accessing Serial Line Command Interface

(RS-485 Mode) from Analog or Modbus Mode ................... 34

Modbus Communication ........................................................ 35

List of Serial Commands ....................................................... 36

Device Information and Status .............................................. 37

View Device Information ...................................................... 37

View Calibration Information ............................................... 38

Enter Calibration Information ............................................... 38

View Order Code ................................................................. 38

View Serial Number ............................................................. 39

View Software Version ........................................................ 39

Serial Line Output Commands .............................................. 39

Start Measurement Output .................................................. 39

Stop Measurement Output .................................................. 40

Output the Measurement Message Once ........................... 40

Configuring Serial Line Operation ........................................ 40

Set Serial Line Settings ....................................................... 40

Set Serial Interface Mode .................................................... 41

Set Output Interval ............................................................... 42

Set Measurement Filtering .................................................. 42

Set Probe Address .............................................................. 43

Set Serial Interface Delay .................................................... 43

Set Measurement Units ....................................................... 44

Calibration Commands .......................................................... 45

Calibrate Humidity Measurement ........................................ 45

Clear Adjustment of RH Measurement ................................ 46

Calibrate Temperature Measurement ................................. 46

Clear Adjustment of T Measurement ................................... 47

View User Adjustment Parameters ..................................... 47

Other Commands.................................................................... 48

Set Analog Output Mode ..................................................... 48

Set Analog Output Parameters and Scaling ........................ 49

Set Analog Output Error Indication Le ve l ............................ 50

Extend Analog Output Range .............................................. 51

Extend Maximum RH Reading ............................................ 51

Display Command List......................................................... 52

Display the Currently Active Errors ..................................... 52

Connect to the Probe in POLL Mode .................................. 52

Close the Connection in POLL Mode .................................. 53

Reset the Probe ................................................................... 53

Restore Factory Settings ..................................................... 53

CHAPTER 5

MAINTENANCE ............................................................................................ 54

Periodic Maintenance ............................................................. 54

Cleaning .............................................................................. 54

Changing the Filter .............................................................. 54

Calibration Procedure ............................................................ 55

2 ____________________________________________________________________ M211060EN-G

Page 5

_________________________________________________________________________________

Adjustment Procedure Using Serial Line (HMP110,

HMP110D and HMP113) ......................................................... 56

One-Point Adjustment of RH Measurement (HMP110,

HMP110D and HMP113) .................................................... 56

Two-Point Adjustment of RH Measurement (HMP110,

HMP110D and HMP113) .................................................... 57

One-Point Adjustment of T Measurement (HMP110,

HMP110D, HMP113, and HMP110T ) ................................. 59

Adjustment Procedure Using MI70 Indicator (HMP110,

HMP110D and HMP113) ......................................................... 60

One-Point Adjustment of RH Measurement (HMP110,

HMP110D and HMP113) .................................................... 60

One-Point Adjustment of Temperature Measurement ........ 61

Repair Maintenance ............................................................... 63

Changing the INTERCAP® Sensor (HMP60 and HM P 63) . 63

Changing the HUMICAP® 180R Sensor (HMP110,

HMP110D and HMP113) .................................................... 64

CHAPTER 6

TROUBLESHOOTING ................................................................................. 65

Analog Output Error Notification .......................................... 65

Solving Typical Problems...................................................... 65

Technical Support .................................................................. 66

CHAPTER 7

TECHNICAL DATA ...................................................................................... 67

Specifications ......................................................................... 67

Performance (HMP60 and HMP63) .................................... 67

Relative Humidity ........................................................... 67

Temperature ................................................................... 67

Dewpoint ........................................................................ 67

Performance (HMP110 and HMP110D) ............................. 68

Relative Humidity ........................................................... 68

Temperature ................................................................... 68

Dewpoint ........................................................................ 68

Performance (HMP113) ...................................................... 69

Relative Humidity ........................................................... 69

Temperature ................................................................... 69

Dewpoint ........................................................................ 69

Performance (HMP110T) .................................................... 69

Temperature ................................................................... 69

Operating Environm ent ....................................................... 70

Inputs and Outputs .............................................................. 70

Mechanics (HMP60, HMP110, HMP110D and HMP110T) 71

Mechanics (HMP63 and HMP113) ..................................... 71

Options and Accessories ...................................................... 72

APPENDIX A

MODBUS REFERENCE ............................................................................... 73

Supported Modbus Functions .............................................. 73

Modbus Register Map ............................................................ 74

Device Identification Objects ................................................ 76

Communication Test Registers ............................................ 76

VAISALA _________________________________________________________________________ 3

Page 6

User's Guide _______________________________________________________________________

List of Figures

Figure 1 HMP60 and HMP110 Series Probes ........................................ 11

Figure 2 Filters for HMP60, HMP110, HMP110D, and HMP110T.......... 13

Figure 3 Filters for HMP63 and HMP113 ................................................ 13

Figure 4 Probe Mounting Clamp in Use .................................................. 14

Figure 5 Aligning Mounting Clamp Slots ................................................. 14

Figure 6 Sliding the Lower Clamp Part ................................................... 15

Figure 7 Securing the Upper Clamp Part ................................................ 15

Figure 8 Probe Mounting Flange ............................................................ 16

Figure 9 HMP113 with Plastic Locking Bushing ..................................... 16

Figure 10 Probe Installation with the Duct Insta llati on Kit ........................ 17

Figure 11 Loop Power Converter .............................................................. 18

Figure 12 Cable with Threaded Connector ............................................... 19

Figure 13 USB Serial Interface Cable ....................................................... 19

Figure 14 HMP60, HMP110, HMP110D, and HMP110T Dimensions ...... 20

Figure 15 Installation with Plastic M12 Nuts, Dimensions ........................ 20

Figure 16 HMP63 and HMP113 Dimensions ............................................ 21

Figure 17 HMP63 and HMP113 with Plastic Locking Bushing,

Dimensions ............................................................................... 21

Figure 18 Assembly of the Probe with Duct Install ation Ki t ...................... 22

Figure 19 Drilling Instructions ................................................................... 23

Figure 20 Wiring of Analog Output ........................................................... 25

Figure 21 Wiring of Digital Output ............................................................. 25

Figure 22 Wiring with the Loop Power Converter Module ........................ 27

Figure 23 PuTTY Terminal Application ..................................................... 33

Figure 24 INTERCAP® Sensor ................................................................ 63

Figure 25 Removing the Sensor ............................................................... 63

Figure 26 HUMICAP® 180R Sensor ........................................................ 64

List of Tables

Table 1 Manual Revisions ....................................................................... 6

Table 2 Related Manuals ......................................................................... 6

Table 3 Parameters Measured by HMP60 and HMP110 Series ........... 10

Table 4 Grounding Methods .................................................................. 25

Table 5 Pinout of the Probe Connector ................................................. 26

Table 6 Operating Voltage Ranges ....................................................... 28

Table 7 Default Serial Communication Settings .................................... 30

Table 8 Default Modbus Communication Settings ................................ 35

Table 9 Configuration Commands for Modbus RTU ............................. 35

Table 10 List of Serial Commands (software version 2.0.7) .................... 36

Table 11 Additional Commands for Probes with RS-485 Output ............ 37

Table 12 Serial Interface Modes .............................................................. 41

Table 13 Troubleshooting Table .............................................................. 65

Table 14 Options and Accessories .......................................................... 72

Table 15 Connection Cables ................................................................... 72

Table 16 Supported Function Codes ....................................................... 73

Table 17 Modbus Register Map (Measurement Values and Settings) ... 74

Table 18 Device Identification Objects .................................................... 76

Table 19 Communication Test Registers ................................................ 76

4 ____________________________________________________________________ M211060EN-G

Page 7

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORM ATION

This chapter provides general notes for the manual and the HMP60 and

HMP110 series probes.

About This Manual

This manual provides information for installing, operating, and

maintaining HMP60 and HMP110 series probes.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Informati on, provides general notes for the manual

and the HMP60 and HMP110 series probes.

- Chapter 2, Product Overview, introduces the features and options of

the HMP60 and HMP110 series probes.

- Chapter 3, Installation, provides you with information that is intended

to help you install the HMP60 and HMP110 series probes.

- Chapter 4, Operation, contains information that is needed to operate

the HMP60 and HMP110 series probes.

- Chapter 5, Maintenance, provides information that is needed in basic

maintenance of the HMP60 and HMP110 series probes.

- Chapter 6, Troubleshooting, describes common problems, their

probable causes and remedies, and contact information for technical

support.

- Chapter 7, Technical Data, provides the technical data of the HMP60

and HMP110 series probes.

VAISALA _________________________________________________________________________ 5

Page 8

User's Guide _______________________________________________________________________

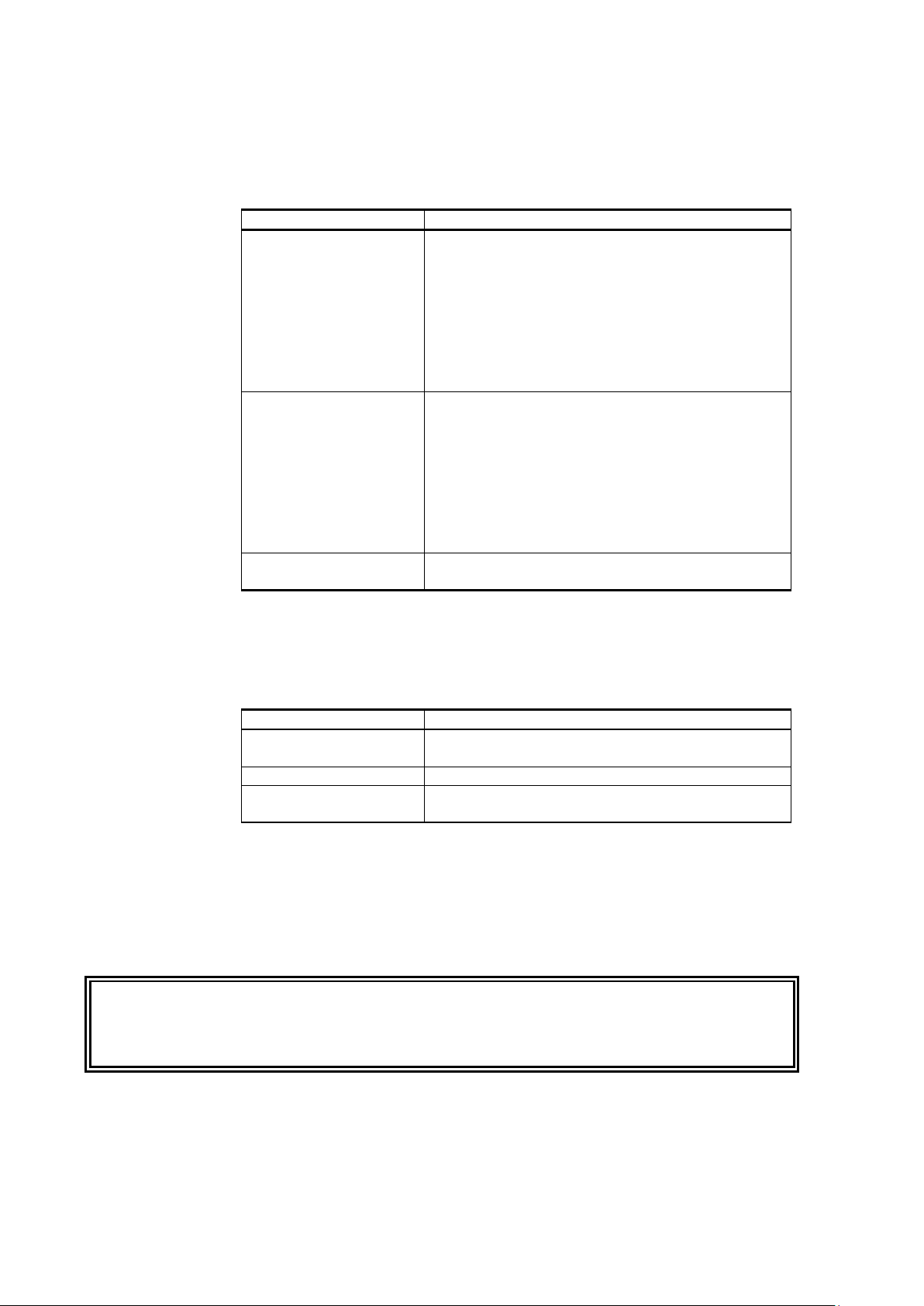

Manual Code

Description

M211060EN-G

January 2016. This manual. Modbus protocol

commands.

M211060EN-F

March 2015. Previous version. Applicable to

new error code.

M211060EN-E

January 2013. Previous version. Updated

description of SMODE command.

Manual Code

Manual Name

M211059EN

HMP60 and HMP110 Series Multilingual Quick

Guide

M211106EN

Loop Power Converter Quick Reference Guide

M211080EN

Mounting Flange for Humidity Probes

Quick Reference Guide

Version Information

Table 1 Manual Revisions

added. Updated instructions for switching the probe

to serial mode from analog or Modbus mode.

Relative humidity factory calibration uncertainty

specification updated. Added information about

using HMP110 with an MI70 indicator when in

analog mode. Added instructions for entering

calibration information with the CDATE and CTEXT

software version 2.0.7.

Added new probe type HMP110D. Updated

technical specification, updated options and

accessories. Added AERR and RHLIMIT serial line

commands, removed the ADJD command. Added

adjustment instructions for MI70 indicator. Added a

WARNING

Related Manuals

Table 2 Related Manuals

Documentation Conventions

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

6 ____________________________________________________________________ M211060EN-G

Page 9

Chapter 1 _________________________________________________________ General Information

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important

Do not modify the unit. Improper modification can damage the product

or lead

Before you connect

recommended to power off the device.

CAUTION

NOTE

Safety

The product delivered to you has been tested for safety and approved as

shipped from the factory. Note the following precautions:

CAUTION

to malfunction.

NOTE

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. It is possible to damage the product,

however, by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

information on using the product.

an HMP60 or HMP110 series probe to a device, it is

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench.

- When an ESD workbench is not available, ground yourself to the

equipment chassis with a wrist strap and a resistive connection cord.

- If you are unable to take either of the above precautions, touch a

conductive part of the equipment chassis with your other hand before

touching ESD sensitive components.

- Always hold component boards by the edges and avoid touching the

component contacts.

VAISALA _________________________________________________________________________ 7

Page 10

User's Guide _______________________________________________________________________

Recycling

Recycle all applicable material.

Do not dispose of with regular household refuse.

Regulatory Compliances

HMP60 and HMP110 series probes are in conformity with the provisions

of the following EU directive(s):

ROHS Directive

EMC Directive

The electromagnetic compatibility of HMP60, HMP110, HMP110D and

HMP110T and HMP110REF has been tested according to the following

product family standards:

- EN 61326-1: Electrical equipment for measurement, control and

laboratory use - EMC requirements – for use in industrial locations.

- EN 55022 Class B: Information technology equipment - Radio

disturbance characteristics - Limits and methods of measurement.

The electromagnetic compatibility of HMP63 and HMP113 has been

tested according to the following product family standards:

- EN 61326-1: Electrical equipment for measurement, control and

laboratory use - EMC requirements – Basic immunity test

requirements.

- EN 55022 Class B: Information technology equipment - Radio

disturbance characteristics - Limits and methods of measurement.

8 ____________________________________________________________________ M211060EN-G

Page 11

Chapter 1 _________________________________________________________ General Information

Trademarks

Vaisala INTERCAP® and Vaisala HUMICAP® are registered

trademarks of Vaisala Oyj.

Windows® is a registered trademark of Microsoft Corporation in the

United States and/or other countries.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is provided

by the applicable supply contract or Software License Agreement.

Warranty

Visit our Internet pages for more information and our standard warranty

terms and conditions: www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

VAISALA _________________________________________________________________________ 9

Page 12

User's Guide _______________________________________________________________________

Parameter

Abbreviation

Metric Unit

Non Metric Unit

Relative humidity

RH

%RH

%RH

Dewpoint/Frostpoint

temperature*

T

ºC

ºF

Temperature

T

ºC

ºF

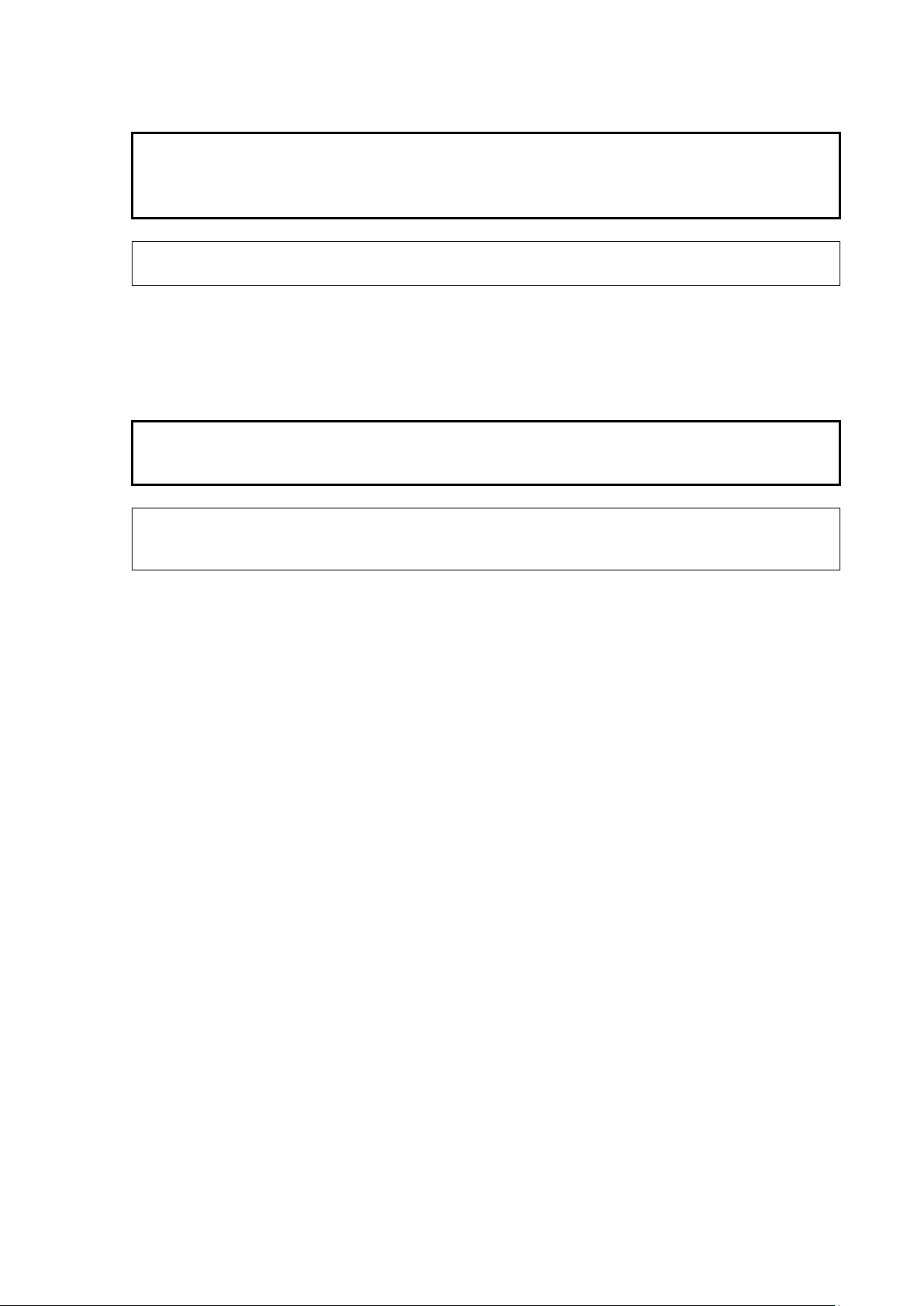

CHAPTER 2

PRODUCT OVERVIE W

This chapter introduces the features and options of the HMP60 and

HMP110 series probes.

Introduction to HMP60 and HMP110 Series

Vaisala Humidity and Temperature Probes HMP60 and HMP110 Series

are simple and cost-effective humidity transmitters suitable for various

volume applications:

- Integration into other manufacturers’ equipment.

- Incubators.

- Glove boxes.

- Greenhouses.

- Fermentation chambers.

- Data loggers.

- Hand-held meters.

HMP60 series probes use the interchangeable Vaisala INTERCAP®

sensor. No recalibration is required after sensor replacement.

HMP110 series probes use the Vaisala HUMICAP® 180R sensor for

increased accuracy. HMP110 series probes require calibration after

sensor replacement. This can be done on the serial line using the optional

Vaisala USB cable.

Table 3 Parameters Measured by HMP60 and HMP110 Series

d/f

10 ___________________________________________________________________ M211060EN-G

* When the dewpoint is below 0 °C, the probe outputs frostpoint for T

d

Page 13

Chapter 2 ___________________________________________________________ Product Overview

No.

Model

Description

1

HMP60

IP65 rated stainless steel probe with INTERCAP®

analog output channels.

2

HMP110

IP65 rated stainless steel p robe w ith HUMIC A P® 180 R

demanding applications. Two analog output channels.

3

HMP110D

IP65 rated stainless steel probe with HU MIC A P® 180 R

demanding applications. Digital output only.

4

HMP110T

IP65 rated stainless steel probe with temperature

performance as HMP110. One analog output channel.

5

HMP110REF

IP65 rated stainless steel probe. Does not measure;

readings on serial line. Useful for validating installations

Digital output only.

6

HMP63

IP54 rated probe with PC/ABS plastic housing and

Two analog output channels.

7

HMP113

IP54 rated probe with PC/ABS plastic housing and

special software configuration).

1210-009

Figure 1 HMP60 and HMP110 Series Probes

sensor. Rugged probe for demanding applications.Two

sensor. Rugged probe with higher accuracy for

sensor. Rugged probe with higher accuracy for

sensor only. Has the same temperature measurement

instead, outputs constant humidity and temperature

of HMT120 and HMT130 transmitters, for example.

INTERCAP® sensor. Lightweight probe with faster

thermal response time. Not for permanent outdoor use.

VAISALA ________________________________________________________________________ 11

HUMICAP® 180R sensor. Lightweight probe with

higher accuracy and faster thermal response time.

Not for permanent outdoor use. Two analo g output

channels.

Used with the Vaisala HM40 hand-held meter (requires

Page 14

User's Guide _______________________________________________________________________

Basic Features and Op ti ons

- Analog and digital output options:

- HMP60, HMP63, HMP110 and HMP113 analog output mode:

two analog output channels, selectable from 0 ... 1 V / 0 ... 2.5 V /

0 ... 5 V / 1 ... 5 V.

- HMP110T analog output mode: single analog output channel

(CH1), selectable from 0 ... 1 V / 0 ... 2.5 V / 0 ... 5 V / 1 ... 5 V.

- RS-485 interface available for all models (Modbus RTU and

Vaisala Industrial Protocol serial line communication).

- Small size.

- Low power consumption.

- IP65 stainless steel body on HMP60 and HMP110 models.

- IP54 lightweight plastic body on HMP63 and HMP113 models.

- Options and accessories:

- Several filter options; see section Filter Options on page 13.

- Probe mounting clamp.

- Probe mounting flange.

- Duct installation kit for HMP60, HMP110, HMP110D and

HMP110T.

- One channel loop power converter 4 ... 20 mA (separate module,

compatible with humidity accuracy only).

- Shielded 0.3 m and 3.0 m connection cables with threaded

connector for probe connection, open end wires on the other end.

- Plastic M12 installation nuts for HMP60, HMP110, HMP110D and

HMP110T.

- Plastic locking bushing for HMP63 and HMP113 (for use with

Vaisala products, for example HM40 hand-held meter).

12 ___________________________________________________________________ M211060EN-G

Page 15

Chapter 2 ___________________________________________________________ Product Overview

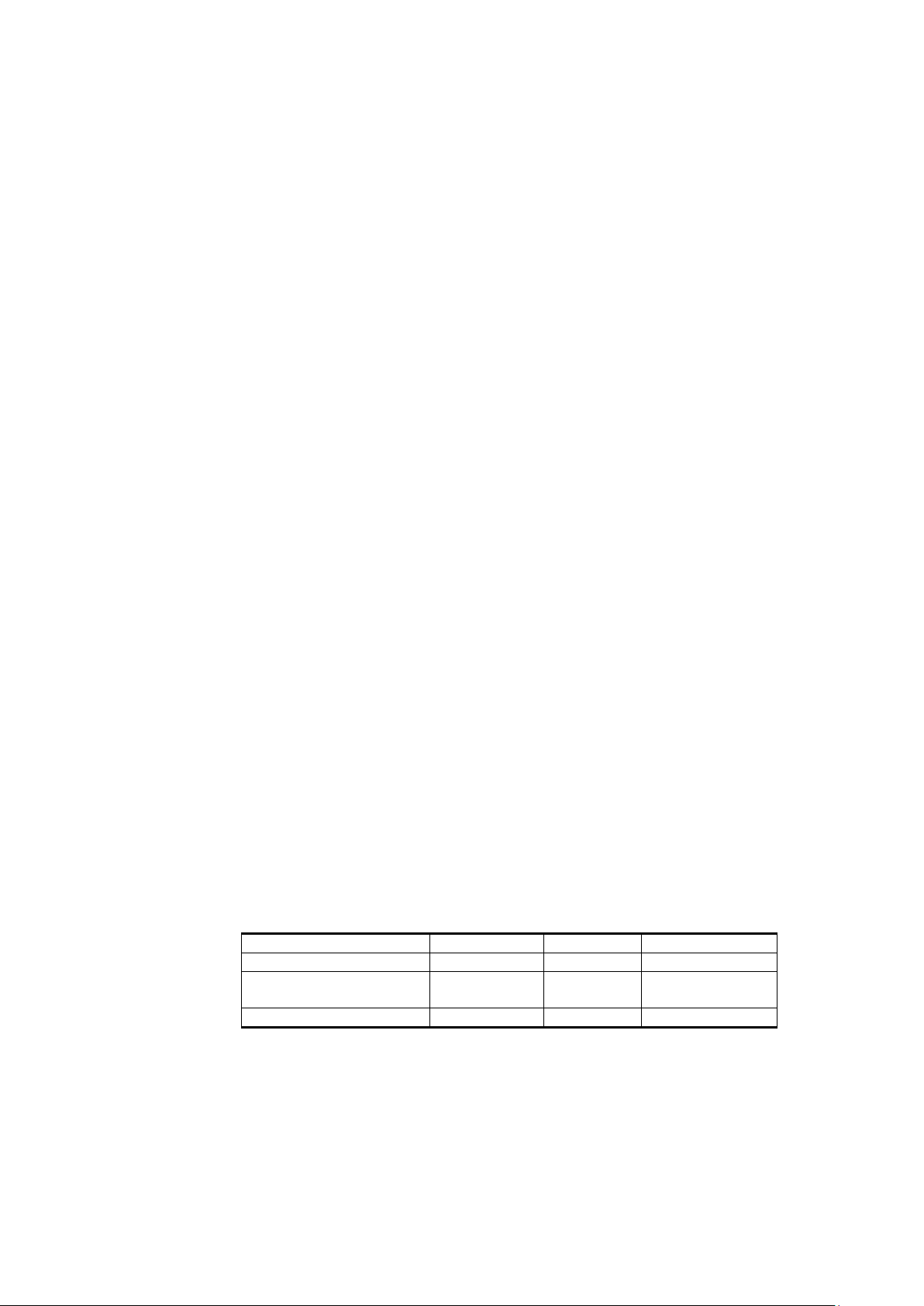

No.

Filter

Diameter

Pore Size

1

Plastic grid filter (fastest response time)

12 mm

- 2 Membrane filter

12 mm

0.2 µm

3

Stainless steel sintered filter

12 mm

38 µm

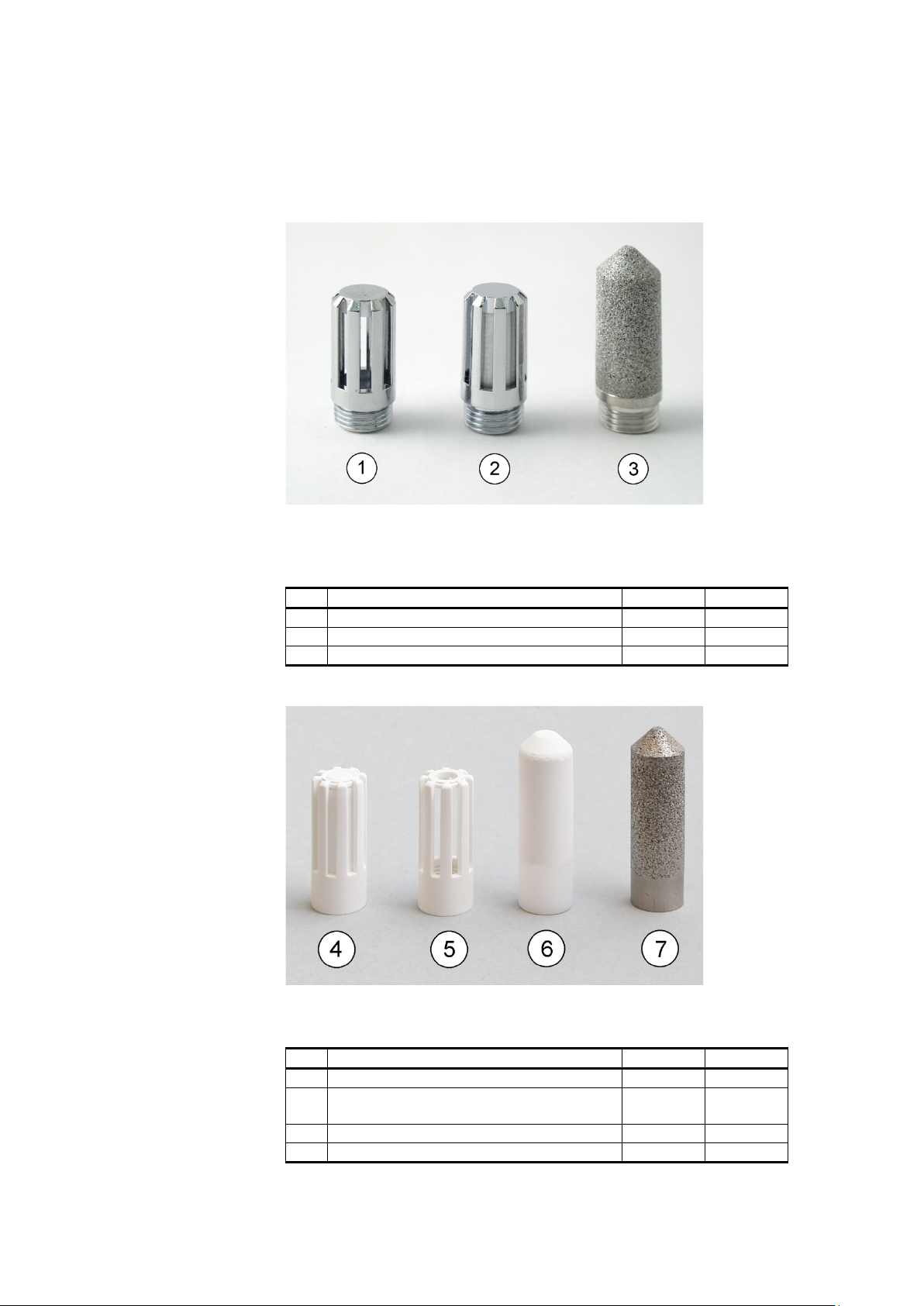

No.

Filter

Diameter

Pore Size

4

Plastic membrane filter

12 mm

0.2 µm

5

Plastic grid filter for (portable use only,

fastest response time)

12 mm

6

Porous PTFE filter

12 mm

8 µm

7

Stainless steel sintered filter

12 mm

38 µm

Filter Options

For order codes, see section Options and Accessories on page 72.

1001-008

Figure 2 Filters for HMP60, HMP110, HMP110D, and

HMP110T

1210-010

Figure 3 Filters for HMP63 and HMP113

VAISALA ________________________________________________________________________ 13

Page 16

User's Guide _______________________________________________________________________

Installation Accessories (Optional)

For order codes, see section Options and Accessories on page 72.

Probe Mounting Clamp

The optional mounting clamp makes it easy to install the probe on the

wall of the measurement environment. The probe can be detached for

calibration simply by loosening the lower screw.

1001-138

Figure 4 Probe Mounting Clamp in Use

The probe mounting clamp is delivered in two parts that must be

connected when it is used:

1. Align the slots on the clamp parts as shown in Figure 5 below.

1209-001

Figure 5 Aligning Mounting Clamp Slots

14 ___________________________________________________________________ M211060EN-G

Page 17

Chapter 2 ___________________________________________________________ Product Overview

2. Slide the lower clamp part over to the bottom end of the upper part

as shown in Figure 6 below.

1209-002

Figure 6 Sliding the Lower Clamp Part

3. Place the clamp to the intended location and secure the upper

clamp part with a screw. See Figure 7 below.

1209-003

Figure 7 Securing the Upper Clamp Part

4. Place the probe in the clamp.

5. Tighten the lower clamp part with a screw.

VAISALA ________________________________________________________________________ 15

Page 18

User's Guide _______________________________________________________________________

Probe Mounting Flange

The probe mounting flange is a silicone flange that can be used to hold

the probe in a through-wall installation. The flange is a general purpose

mounting accessory for Ø 12mm probes, and comes with a sealing plug

for coaxial cables that is not needed when the flange is used with HMP60

and HMP110 series probes.

0911-109

Figure 8 Probe Mounting Flange

Plastic Locking Bushing for HMP63 and HMP113

HMP63 and HMP113 can be connected to compatible Vaisala

instruments using a plastic locking bushing that is placed over the probe.

The bushing has a M15x1 thread. It is compatible with the HMT120 and

HMT130 transmitters, and the HM40 hand-held meter.

1210-029

Figure 9 HMP113 with Plastic Locking Bushing

16 ___________________________________________________________________ M211060EN-G

Page 19

Chapter 2 ___________________________________________________________ Product Overview

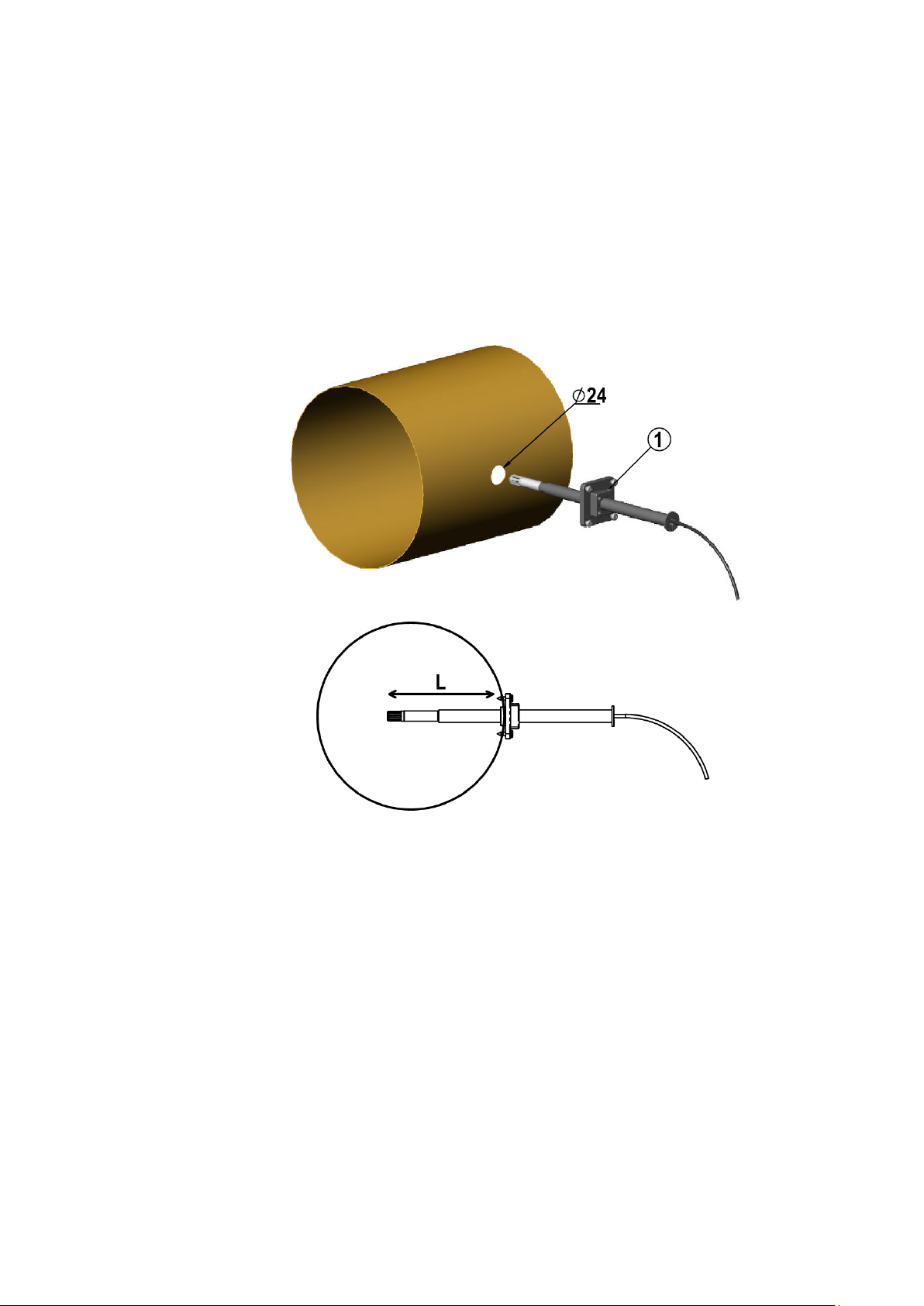

The following explanations refer to Figure 10 above:

1 = Tension screw

Distance L can be adjusted and locked in place with the tension screw.

Duct Installation Kit for HMP60, HMP110, HMP110D and HMP110T

The duct installation kit includes a plastic pipe with a flange (Vaisala

order code: 215619). To install the probe with the duct installation kit,

drill a hole to the duct wall, assemble the probe to the duct installation

kit, slide the probe head through the hole, and attach the flange to the

duct wall with four screws. See page 22 for details.

1301-002

Figure 10 Probe Installation with the Duct Installation Kit

VAISALA ________________________________________________________________________ 17

Page 20

User's Guide _______________________________________________________________________

Loop Power Converter

The loop power converter is an open frame module that converts one

0 ... 2.5 VDC voltage output to a 4 ... 20 mA current output. To use the

loop power converter module, the probe:

- must be in the analog output mode

- the desired quantity is on channel 1

- channel 1 must be scaled to 0 ... 2.5 V

Wiring instructions are provided in section Wiring with the Loop Power

Converter on page 26.

1001-001

Figure 11 Loop Power Converter

18 ___________________________________________________________________ M211060EN-G

Page 21

Chapter 2 ___________________________________________________________ Product Overview

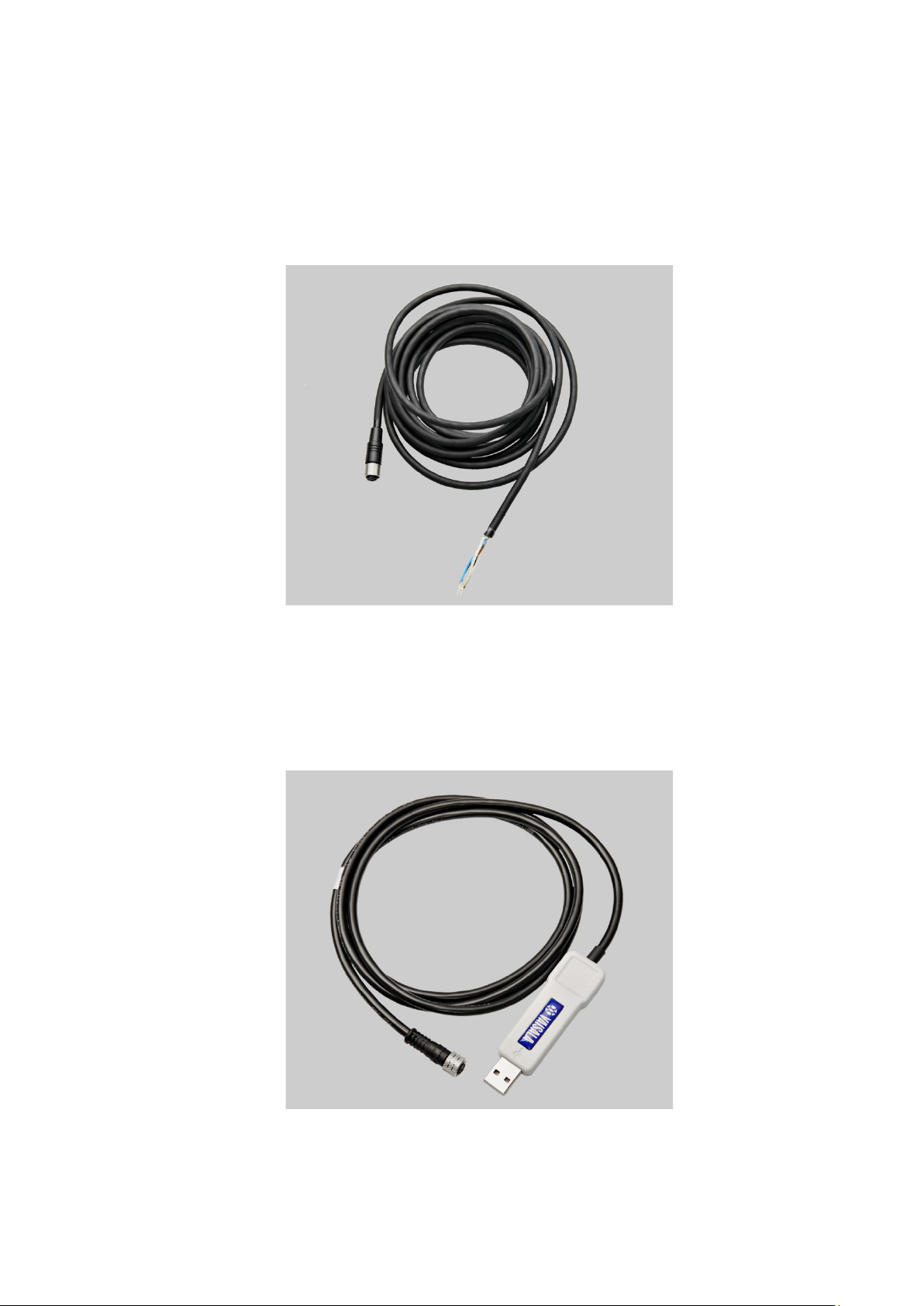

Cables

Connection cables have a straight, threaded female M8 connector on one

end and open wires on the other end. Also other compatible M8 series

cables can be used.

1210-063

Figure 12 Cable with Threaded Connector

The USB Serial Interface Cable has a straight, threaded female M8

connector on one end, and a USB Type A male plug on the other. The

USB cable is intended for maintenance purposes only, not for permanent

installation.

1210-062

Figure 13 USB Serial Interface Cable

VAISALA ________________________________________________________________________ 19

Page 22

User's Guide _______________________________________________________________________

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install the HMP60 and HMP110 series probes.

NOTE

Before you connect an HMP60 or HMP110 series probe to a device, it is

recommended to power off the device.

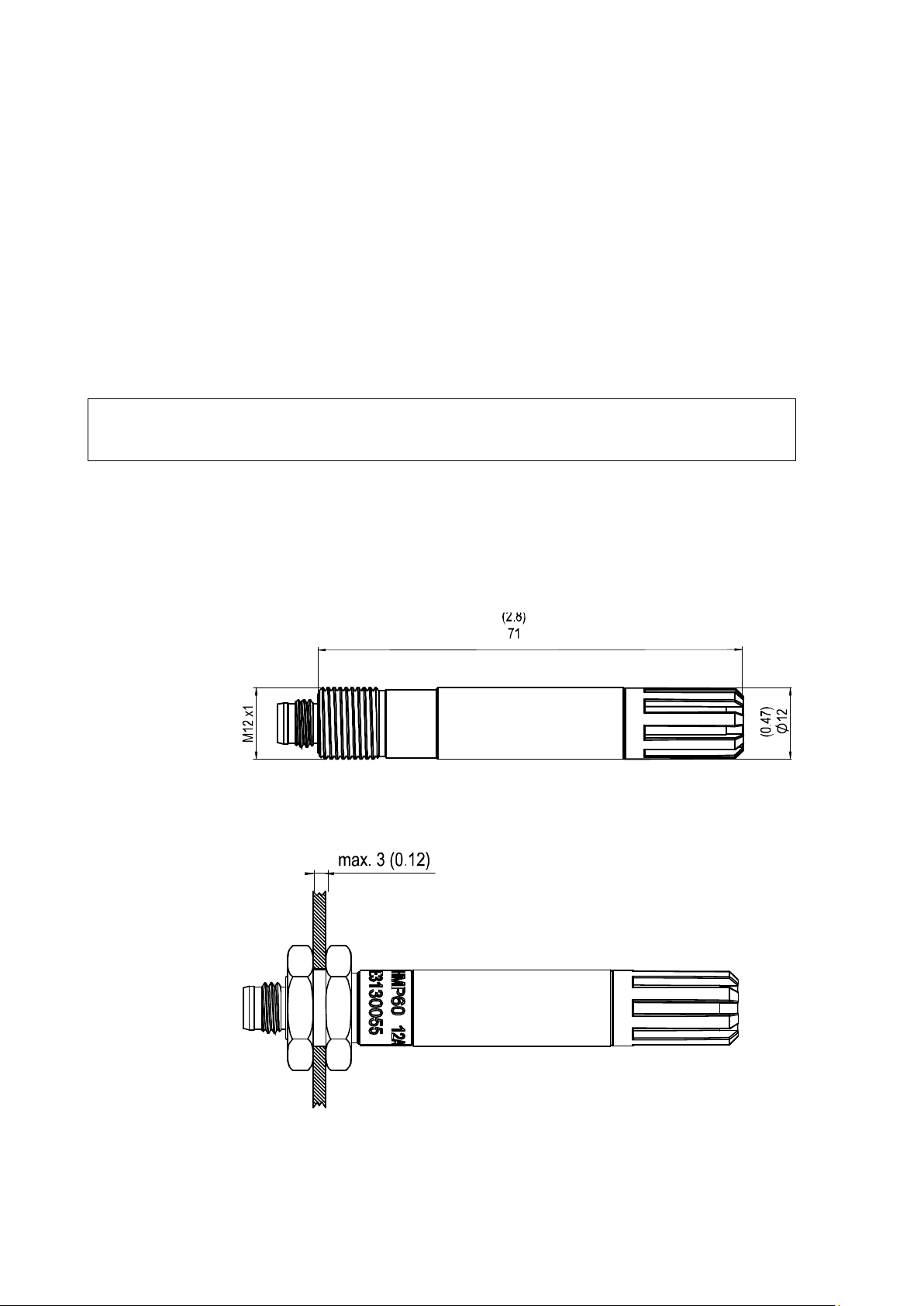

Dimensions for HMP60, HMP110, HMP110D and HMP110T

0912-103

Figure 14 HMP60, HMP110, HMP110D, and HMP110T

Dimensions

0912-102

Figure 15 Installation with Plastic M12 Nuts, Dimensions

20 ___________________________________________________________________ M211060EN-G

Page 23

Chapter 3 ________________________________________________________________ Installation

85

Ø1

2

30

Ø14

3

.

5

M15x 1

73

.5

21.5

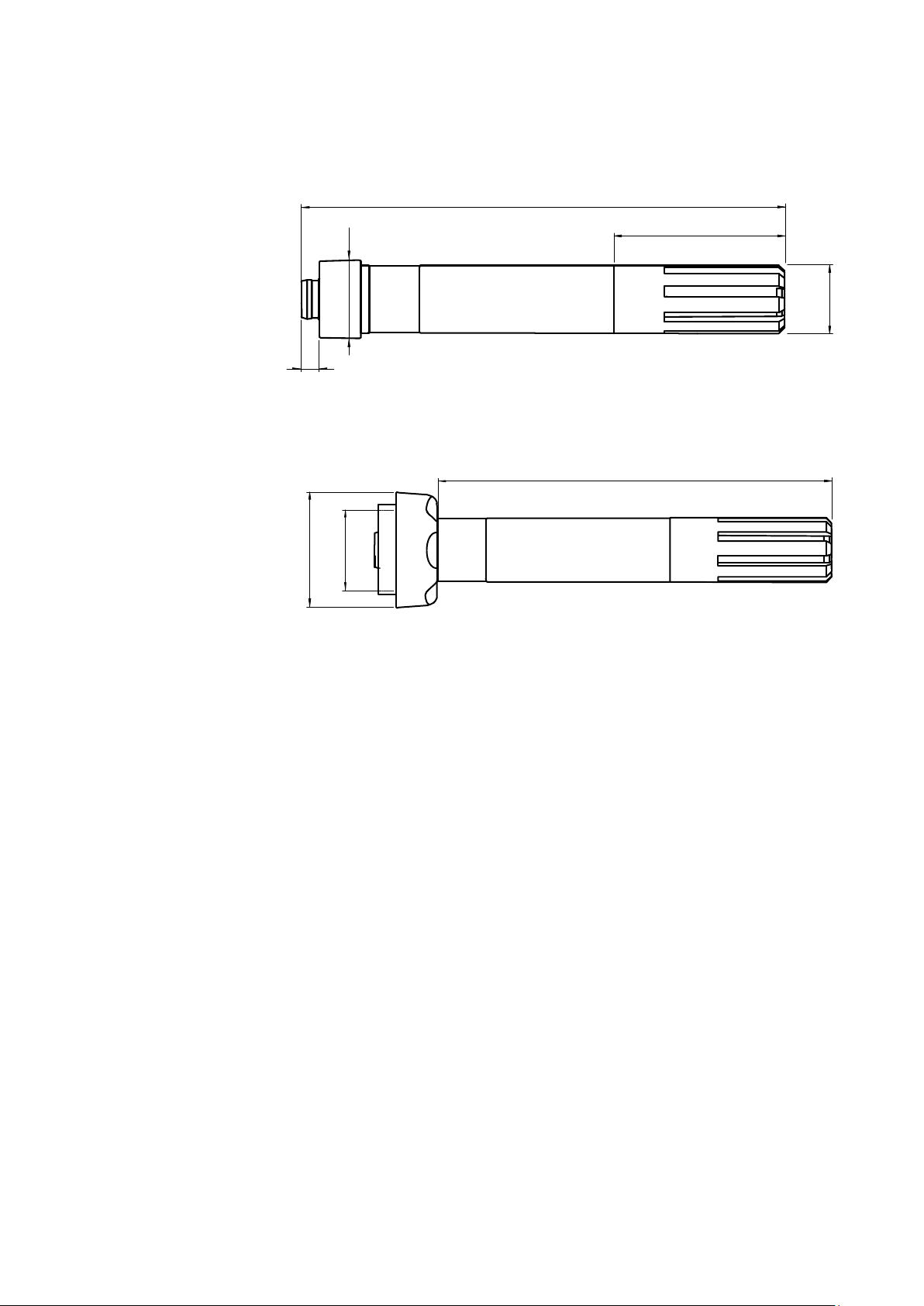

Dimensions for HMP63 and HMP113

0912-103

Figure 16 HMP63 and HMP113 Dimensions

0912-102

Figure 17 HMP63 and HMP113 with Plastic Locking Bushing,

Dimensions

VAISALA ________________________________________________________________________ 21

Page 24

User's Guide _______________________________________________________________________

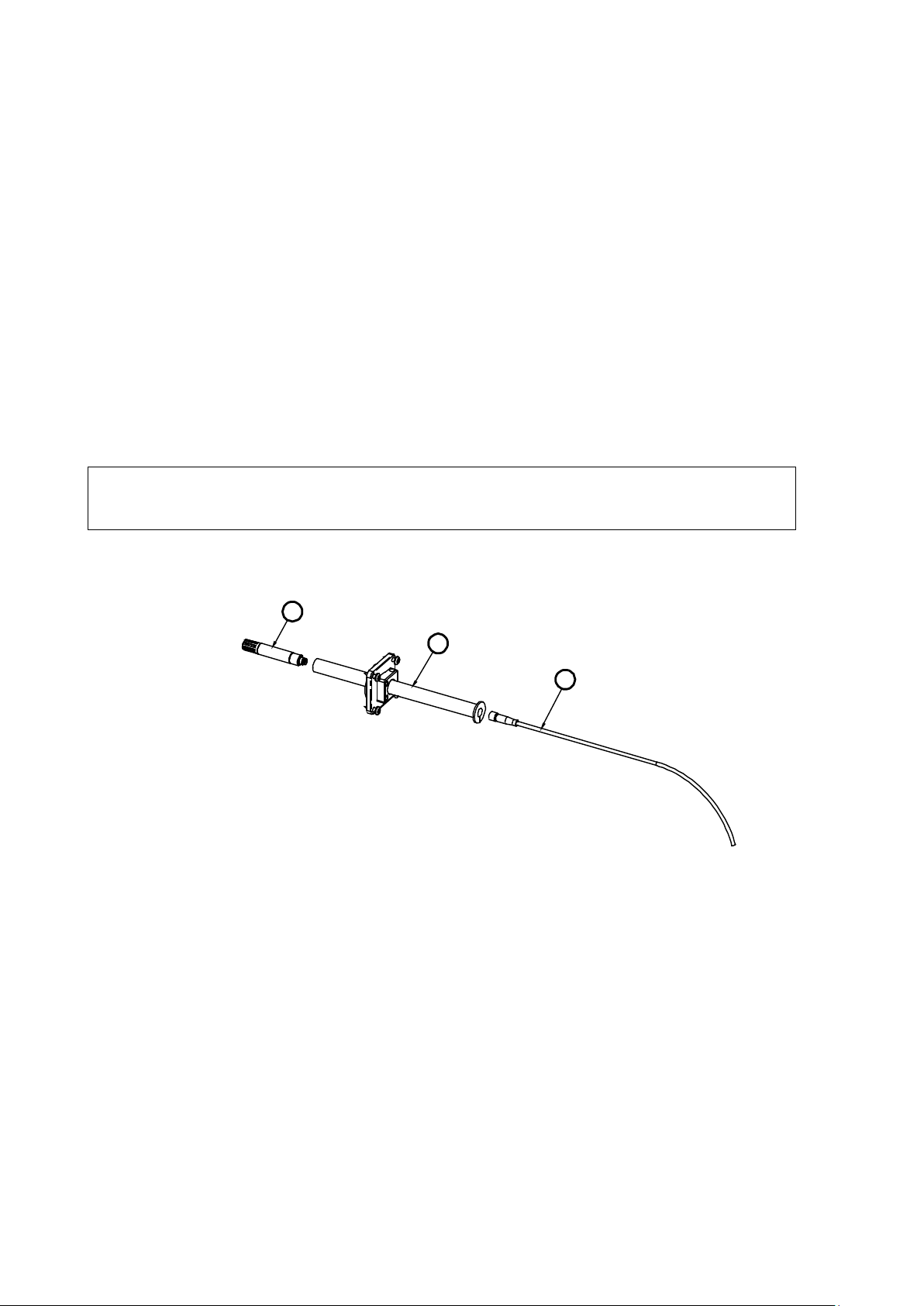

The following numbers refer to Figure 18 above:

1 = HMP60, HMP110, HMP110D or HMP110T probe

2 = Duct installation kit

3 = Probe cable

2

1

3

Mounting the HMP60, HMP110, HM P110D and HMP110T Probes

HMP60, HMP110, HMP110D and HMP110T are designed to be

mounted from the M12 thread on the probe body or from the smooth part

of the probe body. For a convenient installation, use the optional

installation accessories:

- Use the plastic mounting nuts to hold the probe in a through-wall

installation.

- Use the probe mounting clamp to hold the probe on a wall.

- Use the probe mounting flange to hold the probe in a through-wall

installation.

NOTE

Avoid placing the probe in a place where condensation can run onto the

sensor.

Probe Assembly with Duct Installation Kit

0505-177

Figure 18 Assembly of the Probe with Duct Installation Kit

22 ___________________________________________________________________ M211060EN-G

1. Slide the probe cable through the duct installation kit plastic pipe.

2. Attach the cable to the probe.

3. Attach probe assembly to the duct.

Page 25

Chapter 3 ________________________________________________________________ Installation

The following numbers refer to Figure 19 above:

1 = Mounting screw

2 = Tension screw

3 = Probe assembled in duct installation kit plastic pipe

42

1

2

3

Ø24

Ø3.2

Drilling Instructions for Duct Installation Ki t

0505-178

Figure 19 Drilling Instructions

Drill the holes for the duct installation kit as follows:

1. Use a 24-mm drill bit to drill a hole to the duct wall for the

humidity probe.

2. Drill holes for the duct installation kit mounting screws around the

hole in a square arrangement, 42 mm apart from each other. Use a

3.2-mm drill bit to drill the holes for the mounting screws

(four ST4.2×16-C-Z DIN 7981 screws).

VAISALA ________________________________________________________________________ 23

Page 26

User's Guide _______________________________________________________________________

Mounting the HMP63 and HMP113 Probes

HMP63 and HMP113 probes do not have a thread on the probe body.

For a convenient installation, use the optional installation accessories:

- Use the probe mounting clamp to hold the probe on a wall.

- Use the probe mounting flange to hold the probe in a through-wall

installation.

- If you are using the probe with a HMT120, HMT130, or HM40 handheld meter, use the plastic locking bushing.

For information on these accessories, see section Installation Accessories

(Optional) on page 14.

NOTE

Avoid placing the probe in a place where condensation can run onto the

sensor.

24 ___________________________________________________________________ M211060EN-G

Page 27

Chapter 3 ________________________________________________________________ Installation

Probe

Grounding method

HMP63 and HMP113

It is recommended to use a shielded cable and

probe housing.

HMP60, HMP110,

There are two ways to ground the probe depending

connects the shield to the probe housing.

Wiring

For a secure connection to the probe, connect to the 4-pin M8 connector

using a threaded connector.

The grounding method depends on the probe and the installation type.

See Table 4 below.

Table 4 Grounding Methods

connect the shield to ground.

In the shielded cables supplied by Vaisala, the

threaded connector connects the shield to the

HMP110D, HMP110T,

HMP110REF

on installation type. Choose only one of these

ways:

- Grounding is provided by the metal cover of

the probe. If using shielded cables, shield is

NOT connected to ground.

- A shielded cable is used, and the shield is

connected to ground. In the shielded cables

supplied by Vaisala, the threaded connector

Figure 20 Wiring of Analog Output

0912-104

Figure 21 Wiring of Digital Output

VAISALA ________________________________________________________________________ 25

0912-105

Page 28

User's Guide _______________________________________________________________________

Pin

HMP60 / HMP63 / HMP110 /

HMP113 / HMP110T

HMP110D /

HMP110REF

Wire

color

1

5 ... 28 VDC (V

0 ...1 / 0 ... 2.5 V)

8 ... 28 VDC (V

out

0 ... 5 / 1 ... 5 V)

5 ... 28 VDC

Brown

2

Channel 1: RH / Td / T

0 ... 1 / 2.5 / 5 V, 1 ... 5 V

RS485: - / B

White

3

GND / AGND

GND

Blue

4

Channel 2: RH / Td / T

0 ... 1 / 2.5 / 5 V, 1 ... 5 V *

RS485: + / A

Black

Table 5 Pinout of the Probe Connector

out

* HMP110T has no output on channel 2.

26 ___________________________________________________________________ M211060EN-G

Page 29

Chapter 3 ________________________________________________________________ Installation

Wiring with the Loop Power Converter

To use the loop power converter module with a HMP60 or HMP110

series probe, make sure that:

- The probe is in the analog output mode

- The desired quantity must be on channel 1

- Channel 1 is scaled to 0 ... 2.5 V

The loop power converter cannot be used with HMP110D.

When using the loop power converter module, power the module with

8 ... 28 VDC. The operating voltage for the probe (5 VDC) is delivered

by the module.

For more information, see the Loop Power Converter Quick Reference

Guide.

1210-031

Figure 22 Wiring with the Loop Power Converter Module

VAISALA ________________________________________________________________________ 27

Page 30

User's Guide _______________________________________________________________________

HMP60 / HMP63 / HMP110 / HMP113 /

HMP110T

HMP110D / HMP110REF

5 ... 28 VDC (V

out

0 ...1 / 0 ... 2.5 V)

5 ... 28 VDC

8 ... 28 VDC (V

out

0 ... 5 / 1 ... 5 V)

Power Supply Req uirements

The operating voltage for the HMP60 and HMP110 series probes must be

in the following range:

Table 6 Operating Voltage Ranges

Current consumption is 1 mA on average, which makes the probes well

suited for running on battery power. The maximum peak consumption is

5 mA.

Recommendations

- Continuous use over high operating voltage may cause heating.

To conserve power and minimize the warming of the probe, use the

lowest operating voltage in the allowed range.

- Using low impedance loads on the signal outputs increase the current

consuption by up to 0.5 mA. High impedance loads are recommended

to minimize warming of the probe.

- Frequent interrogation of the probe using the RS-485 interface will

also increase current consumption from the average value. More

frequent interrogation than once per second is not recommended.

28 ___________________________________________________________________ M211060EN-G

Page 31

Chapter 4 _________________________________________________________________ Operation

Before you connect a

recommended to power off the device.

In analog probes,

only.

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate the HMP60

and HMP110 series probes.

Getting Started

NOTE

When the probe is connected to a power supply, there is a delay as the

probe starts up and the analog output stabilizes. The delay depends on the

output type, and on the operating voltage that is supplied to the probe:

- Probes with analog output:

- 4 s at operating voltage 13.5 ... 16.5 VDC

- 2 s at other valid operating voltages

- Probes with digital output: 1 s

n HMP60 or HMP110 series probe to a device, it is

Serial Line Communication

NOTE

serial line communication is intended for service use

VAISALA ________________________________________________________________________ 29

HMP60 and HMP110 series probes support two-wire RS-485

communication. The RS-485 interface is non-isolated and offers a

maximum communications rate of 57600 bits/s.

There is no internal termination for the RS-485 on the probe. Use of

termination resistors is not recommended. If the resistors are used, the

possible increase in current consumption should be taken into account.

Page 32

User's Guide _______________________________________________________________________

Parameter

Value

Baud rate

19200

Parity

None

Data bits

8

Stop bits

1

Flow control

None

Connecting to the Serial Interface

The connection to the serial interface is via the 4-pin connector on the

probe; see connector pinout on page 22.

For temporary use of the serial interface (for example, calibration), you

can use the optional USB cable (Vaisala order code: 219690). Before you

can use the USB cable, you must install the provided USB driver on your

PC, see Installing the Driver for the USB Cable on page 30.

NOTE

The Vaisala USB cable is not designed for permanent installation.

When using the USB cable, no separate power unit is needed. The probe

is powered through the USB port.

For permanent interfacing to a host system, use a shielded cable with a

threaded connector. See list of available cables in section Options and

Accessories on page 72.

The probe does not echo typed characters back to the terminal screen. To

see the commands you type, you need to enable the "local echo" setting

in your terminal program.

A new command cannot be received while the probe is sending data out.

Wait until the instrument has completed its response before entering the

next command.

Table 7 Default Serial Communication Settings

You can change the serial settings and operate in RUN, STOP, POLL

and MODBUS modes.

After power-up the probe (in STOP mode) outputs the software version

and the command prompt.

- In RUN mode, a measurement output starts immediately after powerup.

- In POLL mode, the probe does not output anything after power-up. It

must be accessed with an addressed command.

- In MODBUS mode, the probe does not output anything after powerup: serial line commands are not in use and the probe must be used

with the Modbus protocol. For instructions on returning to serial

mode, see Accessing Serial Line Command Interface (RS-485 Mode)

from Analog or Modbus Mode on page 34.

30 ___________________________________________________________________ M211060EN-G

Page 33

Chapter 4 _________________________________________________________________ Operation

For a description of the modes and the SMODE command that is used to

change the mode, see section Set Serial Interfa ce M ode on page 41.

Installing the Driver for the USB Cable

Before taking the USB cable into use, you must install the provided USB

driver on your PC. When installing the driver, you must acknowledge

any security prompts that may appear.

1. Check that the USB cable is not connected. Disconnect the cable if

you have already connected it.

2. Insert the media that came with the cable, or download the latest

driver from www.vaisala.com/software.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

4. After the driver has been installed, connect the USB cable to a USB

port on your PC. Windows will detect the new device, and use the

driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu. The reserved ports are also visible in the

Ports section of the Windows Device Manager.

Remember to use the correct port in the settings of your terminal

program. Windows will recognize each individual cable as a different

device, and reserve a new COM port.

There is no reason to uninstall the driver for normal use. However, if you

wish to remove the driver files and all Vaisala USB cable devices, you

can do so by uninstalling the entry for Vaisala USB Instrument Driver

from the Programs and Features menu in the Windows Control Panel.

In Windows XP and earlier Windows versions the menu is called Add or

Remove Programs.

VAISALA ________________________________________________________________________ 31

Page 34

User's Guide _______________________________________________________________________

Terminal Application Settings for Digital Probes

The steps below describe how to connect to digital probes using the

PuTTY terminal application for Windows (available for download at

http://www.vaisala.com/software) and the USB serial interface.

If you have an analog probe, you can still connect to the serial line by

following the instructions in section Accessing Serial Line Command

Interface (RS-485 Mode) from Analog or Modbus Mode on page 34.

1. Connect the USB serial interface cable between your PC and the

probe.

2. Start the PuTTY application.

3. Select the Serial settings category, and check that the correct COM

port is selected in the Serial line to connect to field.

You can check which port the USB cable is using with the Vaisala

USB Instrument Finder program that has been installed in the

Windows Start menu.

4. Check that the other serial settings are correct for your connection,

and change if necessary. Refer to Table 7 on page 30 for the default

serial line settings of the probe.

5. Click the Open button to open the connection window and start

using the serial line.

If PuTTY is unable to open the serial port you selected, it will show

you an error message instead. If this happens, restart PuTTY and

check the settings.

6. You may need to adjust the Local echo setting in the Terminal

category to see what you are typing on the serial line. To access the

configuration screen while a session is running, click the right

mouse button over the session window, and select Change

Settings... from the pop-up menu.

If the probe is in Modbus mode, to access the serial port command interface,

follow the instructions in

485 Mode) from Analog or Modbus Mode on page 34.

Accessing Serial Line Command Interface (RS-

32 ___________________________________________________________________ M211060EN-G

Page 35

Chapter 4 _________________________________________________________________ Operation

Figure 23 PuTTY Terminal Application

0807-004

VAISALA ________________________________________________________________________ 33

Page 36

User's Guide _______________________________________________________________________

Accessing Serial Line Command Interface (RS-485 Mode) from Analog or Modbus Mode

Follow the steps below to connect to the serial line when the probe is in

analog or Modbus mode, or if you have entered incorrect communication

settings, for example, with Modbus configuration registers and the

settings need to be restored using the serial interface. You must use the

Vaisala USB cable (Vaisala order code: 219690) in this case.

1. Connect the USB cable to the PC and install the driver, if

necessary. Do not connect the cable to the probe yet.

2. Open the terminal program and open a connection to the

corresponding COM port using the default settings 19200, 8, N, 1,

no flow control.

3. Select the Serial settings category, and check that the correct COM

port is selected in the Serial line to connect to field.

You can check which port the USB cable is using with the Vaisala

USB Instrument Finder program that has been installed in the

Windows Start menu.

NOTE

4. Click the Open button to open the connection window and start

using the serial line.

5. Keep the Enter key pressed down and connect the other end of the

USB cable to the probe. This will cause the probe to start in RS485 mode, using the default serial settings. You can now use the

probe with the terminal program (for information on available

serial commands, see List of Serial Commands on page 36).

6. To prevent the analog or Modbus mode from being restored on the

next power-up, select a different serial mode with the smode

command (see Set Serial Interface Mode on page 41).

7. To switch back to analog mode or Modbus mode from the serial

mode, use the smode analog command or the smode modbus

command to select analog or Modbus mode. Reset or power cycle

the probe to restart in the selected mode..

The probe cannot be used with the MI70 hand-held indicator when the

probe is in analog mode. To use the probe with MI70, enable the serial

mode as instructed above.

34 ___________________________________________________________________ M211060EN-G

Page 37

Chapter 4 _________________________________________________________________ Operation

Setting

Default value (when Modbus is

enabled at the factory)

Device address

240

Bit rate

19200

Number of data bits

8

Parity

N

Number of stop bits

2

Response delay

0

Communication mode

MODBUS

Serial Command

Description

SMODE MODBUS

Enable Modbus communication protocol

SERI b p 8 s

Change baud rate and parity

Bit rates less than 9600 b/s are not supported with Modbus.

ADDR a

Set Modbus address: a = new address (1…247)**

SDELAY d

Add extra Modbus response delay***

d = new delay in units of 1/250 seconds (0…255)

The instrument must be switched off and on before the

setting change

Modbus Communication

The Modbus variant used in HMP60 and HMP110 series probes is

Modbus RTU. For a list of the available Modbus registers, see Appendix

A, Modbus Reference on page 73. The default communication settings

used when Modbus is enabled at the factory (chosen when ordering) are

listed in Table 8 below.

Table 8 Default Modbus Communication Settings

The communication settings can be changed with either serial line

commands (see Table 9 below) or with the related Modbus configuration

registers (see Table 17 on page 74).

NOTE

If the device is already in Modbus mode, open the serial line interface as

instructed in Accessing Serial Line Command Interface (RS-485 Mode)

from Analog or Modbus Mode on page 34.

Table 9 Configuration Commands for Modbus RTU

b = baud rate (9600, 19200, 38400, 57600)

p = parity (E, N, or O)

8 = number of data bits must be 8

s = number of stop bits (2 if parity is N, 1 otherwise*)

* Modbus specification defines that two stop bits must be used if p arity is N.

** Addresses 248 … 255 are not supported by the Modbus standard but work with

HMP 60 and HMP110 series. Address 0 cannot be used on Modbus.

*** Extra response delay can be used, for example, to avoid problems caused by

direction-switchi ng delays in bus converters.

communication

s take effect.

VAISALA ________________________________________________________________________ 35

Page 38

User's Guide _______________________________________________________________________

Command

Description

?

Output information about the device

AERR

Set analog output error level

AMODE

View or set the analog output mode

AOVER [ON/OFF]

Allow analog outputs to exceed their range

10%

ASEL

Set analog output parameters and scaling

CDATE

View or set the calibration date

CODE

View the order code of the probe

CRH

Calibrate and adjust RH measurement

CRHCLR

Clear adjustment of RH measurement

CT

Calibrate and adjust T measurement

CTCLR

Clear adjustment of T measurement

CTEXT

View or set the calibration information field

ERRS

List present probe errors

FILT [0.001 … 1]

Set the result filtering

FRESTORE

Restore factory settings

HELP

List available commands

INTV [0 ... 255 S/MIN/H]

Set the continuous output interval (for RUN

mode)

L

Displays user adjustment parameters

R

Start the continuous outputting

RESET

Reset the probe

RHLIMIT

Extend maximum RH reading

S

Stop the continuous outputting

SDELAY [0 … 255]

View or set serial line answer minimum

delay

SEND [0 ... 255]

Output the reading once

SNUM

View the serial number of the probe

UNIT

Select metric or non-metric output units

VERS

View software version of the probe

List of Serial Commands

All commands can be issued either in uppercase or lowercase. In the

command examples, the keyboard input by the user is in bold type.

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard. Press Esc to clear the command buffer before

starting to enter commands.

Table 10 List of Serial Commands (software version 2.0.7)

36 ___________________________________________________________________ M211060EN-G

Page 39

Chapter 4 _________________________________________________________________ Operation

Command

Description

??

Output information about the device in

POLL mode

ADDR [0 ... 255]

Set the probe address (for POLL mode)

CLOSE

Close the temporary connection (Back to

POLL mode)

OPEN [0 ... 255]

Open a temporary connection to a POLL

mode device

SERI [baud p d s]

User Port settings (Default: 19200 N 8 1)

baud: 300 ... 57600

SMODE

VDIGI/ANALOG]

Set the serial interface mode

Table 11 Additional Commands for Probes with RS-485 Output

[STOP/RUN/POLL/MODBUS/

Device Information and Status

View D evice Informatio n

The ? command outputs a listing of device information.

?<cr>

Example (output from HMP63):

?

HMP63 / 1.0.4

Serial number : H3640004

Batch number : T0001109

Sensor number : H0000322

Sensor model : Intercap

Order code : A12A0A2B0

Cal. date : 20120907

Cal. info : VAISALA/HEL

Time : 00:21:05

Serial mode : ANALOG

Baud P D S : 19200 N 8 1

Output interval: 1 S

Serial delay : 30

Analog delay : 10 S

Address : 0

Filter : 1.000

Ch1 output : 0 ... 1 V

Ch2 output : 0 ... 1 V

Ch1 RH lo : 0.00 %RH

Ch1 RH hi : 100.00 %RH

Ch2 T lo : -40.00 'C

Ch2 T hi : 60.00 'C

If the probe is in poll mode, but a connection has not been opened using

the OPEN command, issue the ?? command. For a description of the

serial interface modes, see section Set Serial Line Settings on page 40.

VAISALA ________________________________________________________________________ 37

??<cr>

Page 40

User's Guide _______________________________________________________________________

View Calibration Information

Use the CDATE command to view the calibration date and CTEXT to

view the calibration info text. Date format for CDATE is

YYYYMMDD.

CDATE<cr>

CTEXT<cr>

Examples:

cdate

Cal. date : 20150109

ctext

Cal. info : VAISALA/HEL

Enter Calibration Inf ormation

To enter the calibration date, use the CDATE command (cdate

[YYYYMMDD]

). To enter a text string with information about the

calibration, use the CTEXT command (ctext [string]).

CDATE [yyyymmdd] <cr>

CTEXT [text string] <cr>

Example:

cdate 20151125

Cal. date : 20151125

ctext Calibrated in Room 1

Cal. info : Calibrated in Room 1

View Order Code

Use the CODE command to view the order code that has been stored in

the probe. This command is useful if you need to order a new probe with

the same options.

CODE<cr>

Example:

code

Order code : A12A0A2B0

38 ___________________________________________________________________ M211060EN-G

Page 41

Chapter 4 _________________________________________________________________ Operation

View Serial Number

Use the SNUM command to view the serial number of the probe.

SNUM<cr>

Example:

snum

Serial number : H3640004

View Software Version

Use the VERS command to display the software version of the probe.

VERS<cr>

Example:

vers

HMP63 / 1.0.4

Serial Line Output Commands

Start Measurement Output

Use the R command to start the continuous outputting of measurement

values as an ASCII text string to the serial line.

For HMP60, HMP110 and HMP110D, the output always includes

readings for temperature, RH and Td. For HMP110T, the output includes

only temperature.

R<cr>

Example (HMP60, HMP110 and HMP110D):

r

T= 22.6 'C RH= 22.8 %RH Td= 0.3 'C

T= 22.6 'C RH= 22.5 %RH Td= 0.2 'C

T= 22.6 'C RH= 22.5 %RH Td= 0.2 'C

…

Example (HMP110T):

r

T= 22.6 'C

T= 22.6 'C

T= 22.6 'C

…

VAISALA ________________________________________________________________________ 39

Page 42

User's Guide _______________________________________________________________________

where

aaa = Address of the probe, range 0 ... 255. Set with the ADDR

command.

where

b = baud rate

(300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

Outputting the results continues in intervals issued with the command

INTV. You can stop the output by entering the S command.

Stop Measurement Output

Use the S command or press the Esc key to stop the continuous

measurement output.

S<cr>

Output the Measurement Message On ce

Use the SEND command to output the measurement values once. If the

probe is in POLL mode and the line is not open for commands, specify

the address of the probe to receive the measurement message.

SEND [aaa]<cr>

Example (probe in STOP mode, no address needed):

send

T= 22.7 'C RH= 20.0 %RH Td= -1.5 'C

Example (probe in POLL mode, with address 10):

send 10

T= 22.8 'C RH= 20.1 %RH Td= -1.3 'C

Configuring Serial Line Operation

Set Serial Line Settings

Use the SERI command to show or set the serial line settings. The new

settings will be taken into use when the probe is reset or powered up.

SERI [b p d s]<cr>

40 ___________________________________________________________________ M211060EN-G

Page 43

Chapter 4 _________________________________________________________________ Operation

where

xxx

=

Operation mode of the serial interface. See Table 12 below.

Mode

Description

STOP

Probe outputs onl y when a command is issued. Any command

can be used.

RUN

Probe automatically outputs measurement messages on the

the output.

POLL

Probe outputs only when a command is issued. Probes

on page 52.

MODBUS

Measurement outputs must be read from the transmitter using the

on page 73.

VDIGI

Special serial interface mode that is only used for interoperability

mode is set at Vaisala for probes that are ordered for such use.

ANALOG

No serial line, analog outputs active. For instructions on how to

Modbus Mode on page 34.

Example (shows default settings):

seri

Baud P D S : 19200 N 8 1

Set Serial Interf ace Mode

Use the SMODE command to set the operation mode of the serial

interface. The new mode is applied when probe is reset.

SMODE [xxx]<cr>

Table 12 Serial Interface Modes

serial line. Only command S or the Esc key can be used to stop

communicate one at a time when the specific address is called on

the serial line, which is useful when more than one probe is

connected to one serial bus. Any command can be used after the

line has been opened using the OPEN command.

See descriptions of the commands ADDR on page 43

Modbus protocol. For more information on Modbus, see Modbus

Communication on page 35 and Appendix A, Modbus Reference

with Vaisala devices such as HMT120, HMT130, and HM40. This

enter the serial line when in analog mode, see section Accessing

Serial Line Command Interface (RS-485 Mode) from Analog or

Example (check current mode):

smode

Serial mode : STOP ?

Example (change mode to POLL mode):

and OPEN

smode poll

Serial mode : POLL

VAISALA ________________________________________________________________________ 41

Page 44

User's Guide _______________________________________________________________________

where

n = Time interval in range 1 ... 255

xxx

=

time unit = "S", "MIN", or "H"

where

a.aaa

=

Range 0.001 ... 1.0.

1.0 = No filtering

without averaging

0.5 = Average of last two measurements

0.1 = Average of approximately 16 measurements

NOTE

In the RUN mode, the probe may send the measurement data message

right as you are typing the S command to stop the sending. Therefore,

you may need to repeat the S command. This must be noted especially

when designing computer programs to access the probe.

Set Output Interval

Use the INTV command to show or set the output interval of the serial

line measurement messages (applies when R command or RUN mode is

used). The shortest output interval is one second. This command has no

effect on the operation of the analog output.

INTV [n xxx]<cr>

Example:

intv 1 s

Value : 1

Unit : S

Set Measurement Filtering

Use the FILT command to view or set the speed at which the latest

measurement result is integrated into the humidity and temperature

readings. The command affects both analog output and serial line output.

FILT [a.aaa]<cr>

, latest measurement is output

Example (default setting, no filtering):

filt

Filter : 1.000 ?

Example (set filtering to 0.5):

filt 0.5

Filter : 0.500

42 ___________________________________________________________________ M211060EN-G

Page 45

Chapter 4 _________________________________________________________________ Operation

where

nn = address (0 ... 255)

where

delay

=

Range 0 ... 255. Value corresponds to four

milliseconds (for example, 5 = 0.020 second

minimum answer delay)

Set Probe Address

Use the ADDR command to view or set the probe address. To operate in

the POLL mode, the probe must have an address. If multiple probes share

the same serial line, each probe must have a different address.

For a description of the serial interface modes, see section Set Serial Line

Settings on page 40.

ADDR [nn]<cr>

Example:

addr

Address : 0

Set Serial Interf ace Delay

Use the SDELAY command to view or set the serial interface answer

minimum delay.

SDELAY [delay]<cr>

Example:

sdelay

Serial delay : 30

sdelay 50

Serial delay : 50

VAISALA ________________________________________________________________________ 43

Page 46

User's Guide _______________________________________________________________________

Quantity

Metric Unit

Non-Metric Unit

RH

%RH

%RH

Td

ºC

ºF T ºC

ºF

Set Measurement U nits

Use the UNIT command to view or set the measurement units that are

used in the serial line measurement messages.

UNIT [M/N]<cr>

M is for metric units, N is for non-metric units.

Examples:

unit

Units : Metric

unit n

Units : Non metric

44 ___________________________________________________________________ M211060EN-G

Page 47

Chapter 4 _________________________________________________________________ Operation

Calibration Commands

Calibrate Humidity Measuremen t

Use the CRH command to perform a one-point or two-point correction to

the capacitance measurement of the probe. This command changes the

offset and/or gain of the humidity measurement, depending on the

calibration and reference:

- one-point calibration with a single < 50 %RH reference will adjust the

offset of the capacitance measurement

- one-point calibration with a single > 50 %RH reference will adjust the

gain of the capacitance measurement

- two-point calibration will adjust both offset and gain. The first point

requires a < 50 %RH humidity reference, the second point must be

> 50 %RH. There must also be at least 30 percentage point difference

between the references.

CRH [reference]<cr>

This command is not available on the HMP110T.

When performing a one-point calibration, you need to place the probe in

the reference humidity and wait for 20 – 40 minutes for the humidity to

stabilize. To apply the adjustment, enter the CRH command with the

reference %RH as a parameter.

Example: one-point calibration (LiCl reference, 11 %RH):

crh 11

OK

Example: one-point calibration with NaCl reference (75 %RH):

crh 75

OK

Giving the command without parameters starts the two-point calibration.

Remember to allow the humidity to stabilize for 20 - 40 minutes after

changing the reference.

Example: two-point calibration with LiCl (11 %RH) and NaCL

(75 %RH) references:

crh

RH : 11.2684 1. ref ? 11

Press any key when ready ...

RH : 75.0612 2. ref ? 75

OK

VAISALA ________________________________________________________________________ 45

Page 48

User's Guide _______________________________________________________________________

Clear Adjustment of RH Measuremen t

Use the CRHCLR command to clear the adjustment of RH measurement

that has been done using the CRH command. This command is not

available on the HMP110T.

CRHCLR<cr>

Example:

crhclr

OK

Calibrate Temp er at ure Measurement

Use the CT command to perform a one-point or two-point temperature

(T) calibration. One-point calibration adjusts the offset for the

measurement, two-point calibration adjusts offset and gain.

CT [reference]<cr>

When performing a one-point calibration, you need to place the probe in

a single temperature reference and wait for 20 – 40 minutes for the

temperature to stabilize. To apply the adjustment, enter the CT command

with the reference temperature as a parameter.

Example: one-point calibration

ct 23.5

OK

Giving the command without parameters starts the two-point calibration.

Remember to allow the temperature to stabilize for 20 - 40 minutes after

changing the reference. The first reference point must be smaller than the

second point, and the difference between the reference points must be

more than 30 ºC. To update the measured value while the command is

running, press enter without inputting a value.

Example: two-point calibration

ct

T : 22.03 Ref1 ? 22

Press any key when ready ...

T : 55.12 Ref2 ? 55

OK

46 ___________________________________________________________________ M211060EN-G

Page 49

Chapter 4 _________________________________________________________________ Operation

Clear Adjustment of T Measurement

Use the CTCLR command to clear the adjustment of temperature

measurement that has been done using the CT command.

CTCLR<cr>

Example:

ctclr

OK

View U ser Adjustment Parameters

Use the L command to view the current user adjustment parameters. This

command is useful for checking the currently applied customer

calibration.

L<cr>

The output values are as follows:

- Cp offset and gain: capacitance, calibrated using the CRH command

- T offset and gain: calibrated using the CT command

Example (shows default values, no user calibration done):

l

Cp offset : 0.00000000E+00

Cp gain : 1.00000000E+00

T offset : 0.00000000E+00

T gain : 1.00000000E+00

VAISALA ________________________________________________________________________ 47

Page 50

User's Guide _______________________________________________________________________

where

ch1

=

Analog output mode for channel 1, range 0 ...3.

The options are:

0 (

1 (0 .

2

3 (1 ... 5

ch2

=

Analog output mode for channel 2, range 0 ...3.

The options are the same as for channel 1.

Other Commands

Set Analog Output Mode

Use the AMODE command to show or set the operation mode of the

analog output. This command is not available on the HMP110D.

AMODE [ch1] [ch2]<cr>

0 ... 1 V)

.. 2.5 V)

(0 ... 5 V)

V)

Example (show current output modes):

amode

Ch1 output : 0 ... 1 V

Ch2 output : 0 ... 1 V

Example (set channel 1 to 0 ... 1 V and channel 2 to 0 ... 5 V):

amode 0 2

Ch1 output : 0 ... 1 V

Ch2 output : 0 ... 5 V

48 ___________________________________________________________________ M211060EN-G

Page 51

Chapter 4 _________________________________________________________________ Operation

where

ch1

=

Output parameter for channel 1. The options are:

T = Temperature

ch2

=

Output parameters for channel 2. The options are same as

for channel 1.

ch1low

=

Low limit for channel 1 output scaling.

ch1high

=

High limit for channel 1 output scaling.

ch2low

=

Low limit for channel 2 output scaling.

ch2high

=

High limit for channel 2 output scaling.

Set Analog Output Parameters and Scaling

Use the ASEL command to show or set the output parameters and

scaling of the analog outputs. This command is not available on the

HMP110D.

ASEL [ch1 ch2] [ch1low ch1high ch2low ch2high]<cr>

RH = Relative humidity

TD = Dewpoint temperature

Example (show current output parameters and scaling):

asel ?

Ch1 RH lo : 0.00 %RH ?

Ch1 RH hi : 100.00 %RH ?

Ch2 T lo : -20.00 'C ?

Ch2 T hi : 80.00 'C ?

Example (change channel 1 to output dewpoint temperature, adjust

scaling to -40 ... 60 °C for channel 1 and to -20 ... 80 °C for channel 2):

asel td t -40 60 -20 80

Ch1 Td lo : -40.00 'C

Ch1 Td hi : 60.00 'C

Ch2 T lo : -20.00 'C

Ch2 T hi : 80.00 'C

Example (change channel 1 to output temperature and channel 2 to

output relative humidity, adjust scaling for channel 1 to -40 ... 60 °C

when prompted):