Page 1

r

USER'S GUIDE

Vaisala HUMICAP® Hand-Held

Humidity and Temperature Mete

HM70

M210297EN-E

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2007

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION............................................................................5

About This Manual...................................................................5

Version Information...............................................................5

General Safety Considerations...............................................5

Recycling ..................................................................................6

Warranty....................................................................................7

CHAPTER 2

PRODUCT DESCRIPTION ............................................................................9

Vaisala HUMICAP® Hand-Held Temperature and Humidity

Meter HM70 ............................................................................... 9

Display Parameters..................................................................9

CHAPTER 3

PREPARATIONS BEFORE USE.................................................................13

Installing and Recharging the Batteries ..............................13

Turning ON the Device...........................................................14

CHAPTER 4

TAKING MEASUREMENTS ........................................................................15

Beware of Temperature Differences.....................................16

CHAPTER 5

BUTTONS, DISPLAYS AND MENUS..........................................................17

Buttons and Navigation.........................................................17

Basic Display.......................................................................... 18

Graphical Display...................................................................19

Menus......................................................................................19

CHAPTER 6

SETTINGS....................................................................................................21

Pressure Setting.....................................................................21

Display Settings .....................................................................22

Quantities and Units............................................................22

Rounding.............................................................................22

Hold/Save Display...............................................................23

Graphic History ...................................................................23

User Interface .........................................................................24

VAISALA________________________________________________________________________ 1

Page 4

User's Guide ______________________________________________________________________

Selecting Language.............................................................24

Automatic Power OFF.........................................................25

Changing Shortcut Keys......................................................25

Button Click and Backlight on Button Press........................26

Setting Date and Time.........................................................26

Device Information.................................................................27

Reverting to Factory Settings..............................................27

CHAPTER 7

RECORDING DATA.....................................................................................29

Recording................................................................................29

Stopping Recording ...............................................................30

Viewing Recorded Data..........................................................30

Checking Memory Status.......................................................31

Deleting All Recorded Files...................................................31

MI70 Link Program for Transferring Recorded Data to PC 32

MI70 Link Program for Real-Time PC Monitoring................32

CHAPTER 8

OTHER FUNCTIONS....................................................................................33

Setting Alarm Levels..............................................................33

Chemical Purge (Optional) ....................................................34

Turning Chemical Purge ON...............................................34

Sensor Preheat (Optional).....................................................36

Turning Sensor Preheat ON/OFF........................................37

CHAPTER 9

CALIBRATION AND ADJUSTMENT OF TRANSMITTERS .......................39

HM70 in Checking and Adjusting..........................................39

Calibration Cables..................................................................39

Calibration and Adjustment of HMD/W 60/70, HMD/W 20/30

and HMP130 Series Transmitters..........................................40

Calibration and Adjustment of HMT100

Series Transmitters................................................................42

Field Checking and Adjustment Using a Calibrated

Reference Probe .................................................................42

One-Point Adjustment Using a Calibrator ...........................43

Two-Point Adjustment Using a Calibrator ...........................44

LiCl-NaCl Adjustment..........................................................45

Calibration and Adjustment of HMP230/240 Transmitters

and HMM210 Modules............................................................45

Field Checking and Adjustment of Humidity by Using a

Calibrated Reference Probe................................................47

1-Point Humidity Adjustment by Using a Calibrator............47

2-Point Adjustment by Using a Calibrator ...........................48

Calibration and Adjustment of HMT320

Series Transmitters................................................................49

2 ___________________________________________________________________ M210297EN-E

Page 5

________________________________________________________________________________

Field Checking and Adjustment by Using a Calibrated

50

Reference Probe.................................................................

1-Point Adjustment by Using a Calibrator...........................50

2-Point Adjustment by Using a Calibrator...........................51

Calibration and Adjustment of HMT330

Series Transmitters................................................................ 52

Field Checking and Adjustment by Using a Calibrated

Reference Probe.................................................................53

1-Point Adjustment by Using a Calibrator...........................53

2-Point Adjustment by Using a Calibrator...........................54

LiCl-NaCl Adjustment..........................................................55

Field Checking of DMW19 Transmitter ................................56

CHAPTER 10

MEASURING OTHER PARAMETERS SIMULTANEOUSLY ..................... 57

CHAPTER 11

ANALOG OUTPUT CONNECTION.............................................................59

Selecting and Scaling the Analog Output ...........................59

CHAPTER 12

CALIBRATION AND ADJUSTMENT OF HM70 SERIES PROBES...........61

General Information about Calibrations ..............................61

Relative Humidity Adjustment..............................................61

LiCl-NaCl Automatic Adjustment.........................................61

2-Point Adjustment..............................................................62

1-Point Adjustment..............................................................63

Temperature Adjustment....................................................... 63

1-Point Adjustment..............................................................64

2-Point Adjustment..............................................................65

Last Adjustment Date ............................................................65

CHAPTER 13

MAINTENANCE ...........................................................................................67

Changing the Filter.................................................................67

Changing the Battery Pack....................................................67

Error Messages ......................................................................68

Technical Support..................................................................69

Return Instructions................................................................69

Vaisala Service Centers......................................................... 70

CHAPTER 14

TECHNICAL SPECIFICATIONS..................................................................71

Probes HMP75, HMP76 and HMP77......................................71

Measured Variables............................................................71

Relative Humidity...........................................................71

Temperature...................................................................72

Calculated Variables..............................................................72

VAISALA________________________________________________________________________ 3

Page 6

User's Guide ______________________________________________________________________

Typical Ranges....................................................................72

Accuracies of Calculated Variables................................73

Accuracy of Dewpoint Temperature °C..........................73

Accuracy of Mixing Ratio g/kg........................................73

Accuracy of Wet Bulb Temperature °C..........................74

Accuracy of Absolute Humidity g/m³..............................74

General ....................................................................................74

MI70 Indicator..........................................................................75

Indicator General.................................................................75

Battery Pack...................................................................76

General about Vaisala Hand-Held Humidity and

Temperature Meter HM70..............................................76

Electromagnetic Compatibility........................................76

Accessories.............................................................................77

Dimensions in mm (inches)...................................................78

4 ___________________________________________________________________ M210297EN-E

Page 7

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

About This Manual

This manual provides information for operating, and maintaining the

Vaisala HUMICAP® Hand-Held Humidity and Temperature Meter

HM70.

Version Information

Table 1 Manual Revisions

Manual Code Description

M210297EN-A May 2002 - First release

M210297EN-B April 2004

M210297EN-C January 2005

M210297EN-D April 2006

M210297EN-E May 2007 - Sensor types updated to

HUMICAP

M210297EN-F October 2007 - USB connectivity option added,

new display languages (Chinese, Japanese,

Russian) added.

®

180R and HUMICAP® 180RC

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

Warning alerts you to a potential hazard. If you do not read and

follow instructions very carefully at this point, there is a risk of injury

or even death.

VAISALA________________________________________________________________________ 5

Page 8

User's Guide ______________________________________________________________________

CAUTION

NOTE

Recycling

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

Note highlights important information on using the product.

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

6 ___________________________________________________________________ M210297EN-E

Page 9

Chapter 1 ________________________________________________________ General Information

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be

free from defects in workmanship or material during

a period of twelve (12) months from the date of

delivery save for products for which a special

warranty is given. If any Product proves however to

be defective in workmanship or material within the

period herein provided Vaisala undertakes to the

exclusion of any other remedy to repair or at its own

option replace the defective Product or part thereof

free of charge and otherwise on the same conditions

as for the original Product or part without extension

to original warranty time. Defective parts replaced in

accordance with this clause shall be placed at the

disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to

products sold by it. In case the repair or service

works should appear inadequate or faulty and should

this cause malfunction or nonfunction of the pro duct

to which the service was performed Vaisala shall at

its free option either repair or have repaired or

replace the product in question. The working hours

used by employees of Vaisala for such repair or

replacement shall be free of charge to the client.

This service warranty shall be valid for a period of

six (6) months from the date the service measures

were completed.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala

within thirty (30) days after the defect or fault

became known or occurred, and

b) The allegedly defective Product or part shall,

should Vaisala so require, be sent to the works of

Vaisala or to such other place as Vaisala may

indicate in writing, freight and insurance prepaid

and properly packed and labelled, unless Vaisala

agrees to inspect and repair the Product or

replace it on site.

This warranty does not however apply when the

defect has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to

service the Product or otherwise follow Vaisala's

service instructions including any repairs or

installation or assembly or service made by

unauthorized personnel not approved by Vaisala

or replacements with parts not manufactured or

supplied by Vaisala;

d) modifications or changes of the Product as well

as any adding to it without Vaisala's prior

authorization;

e) other factors depending on the Customer or a

third party.

Notwithstanding the aforesaid Vaisala's liability

under this clause shall not apply to any defects

arising out of materials, designs or instructions

provided by the Customer.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express

or implied, whether under law, statute or otherwise,

including without limitation any implied warranties

of merchantability or of fitness for a particular

purpose and all other obligations and liabilities of

Vaisala or its representatives with respect to any

defect or deficiency applicable to or resulting

directly or indirectly from the Products supplied

hereunder, which obligations and liabilities are

hereby expressly cancelled and waived. Vaisala's

liability shall under no circumstances exceed the

invoice price of any Product for which a warranty

claim is made, nor shall Vaisala in any

circumstances be liable for lost profits or other

consequential loss whether direct or indirect or for

special damages.

VAISALA________________________________________________________________________ 7

Page 10

User's Guide ______________________________________________________________________

This page intentionally left blank.

8 ___________________________________________________________________ M210297EN-E

Page 11

Chapter 2 ________________________________________________________ Product Description

CHAPTER 2

PRODUCT DESCRIPTION

Vaisala HUMICAP® Hand-Held Temperature and Humidity Meter HM70

HM70 consists of two main units: MI70 indicator and

HMP75/HMP76/HMP77 probe. HM70 Hand-held humidity meter

incorporates Vaisala's advanced HUMICAP® technology which

enables reliable and high performance humidity measurement.

HM70 is available with an optional, ready-to-use Microsoft

Windows® software, which allows an easy way to handle

measurement data using a serial line or a USB instrument cable.

Vaisala HM70 is delivered with a factory calibration certificate.

Display Parameters

- RH relative humidity (% RH)

- T temperature (°C/°F)

- T

- T

- a : absolute humidity (g/m

- x : mixing ratio (g/kg / gr/lb)

- T

- H2O: humid air volume/ dry air volume (ppm)

- pw: water vapour pressure (hPa/ lb/in

- pws: saturation water vapour pressure(hPa/ lb/in

- h : enthalpy (kJ/kg / Btu/lb)

- aw : water activity

1)

T

(0°°C/32 °°F) and frostpoint temperature T

below the freezing point.

: dewpoint/frostpoint1) temperature (°C/°F)

d/f

: dewpoint temperature2) (°C/°F)

d

: wetbulb temperature (°C/°F)

w

shows dewpoint temperature above the freezing point

d/f

3

/ gr/ft3)

2

)

(dewpoint over ice)

f

2

)

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

2)

Td shows dewpoint over water throughout the entire measurement

range.

1

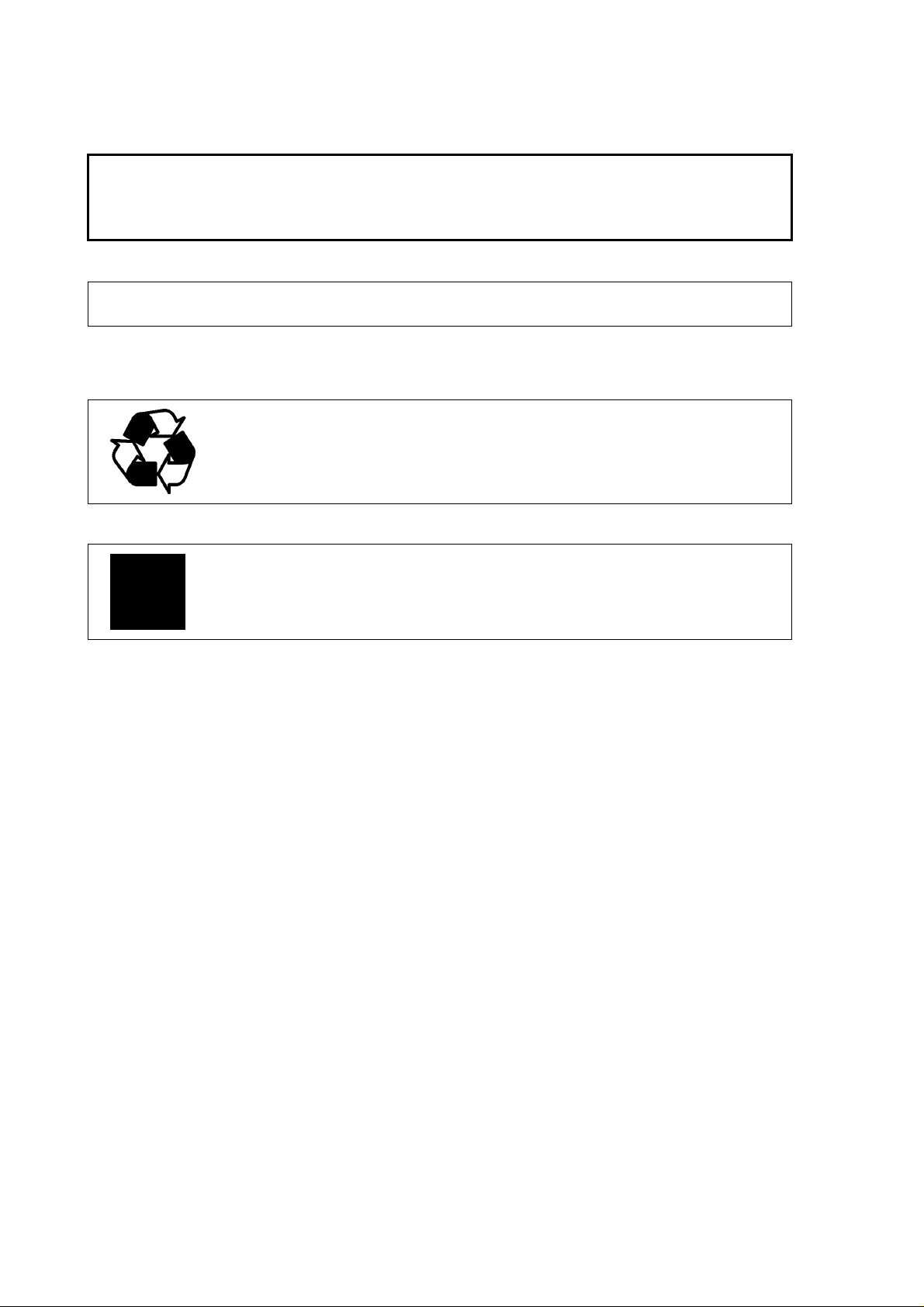

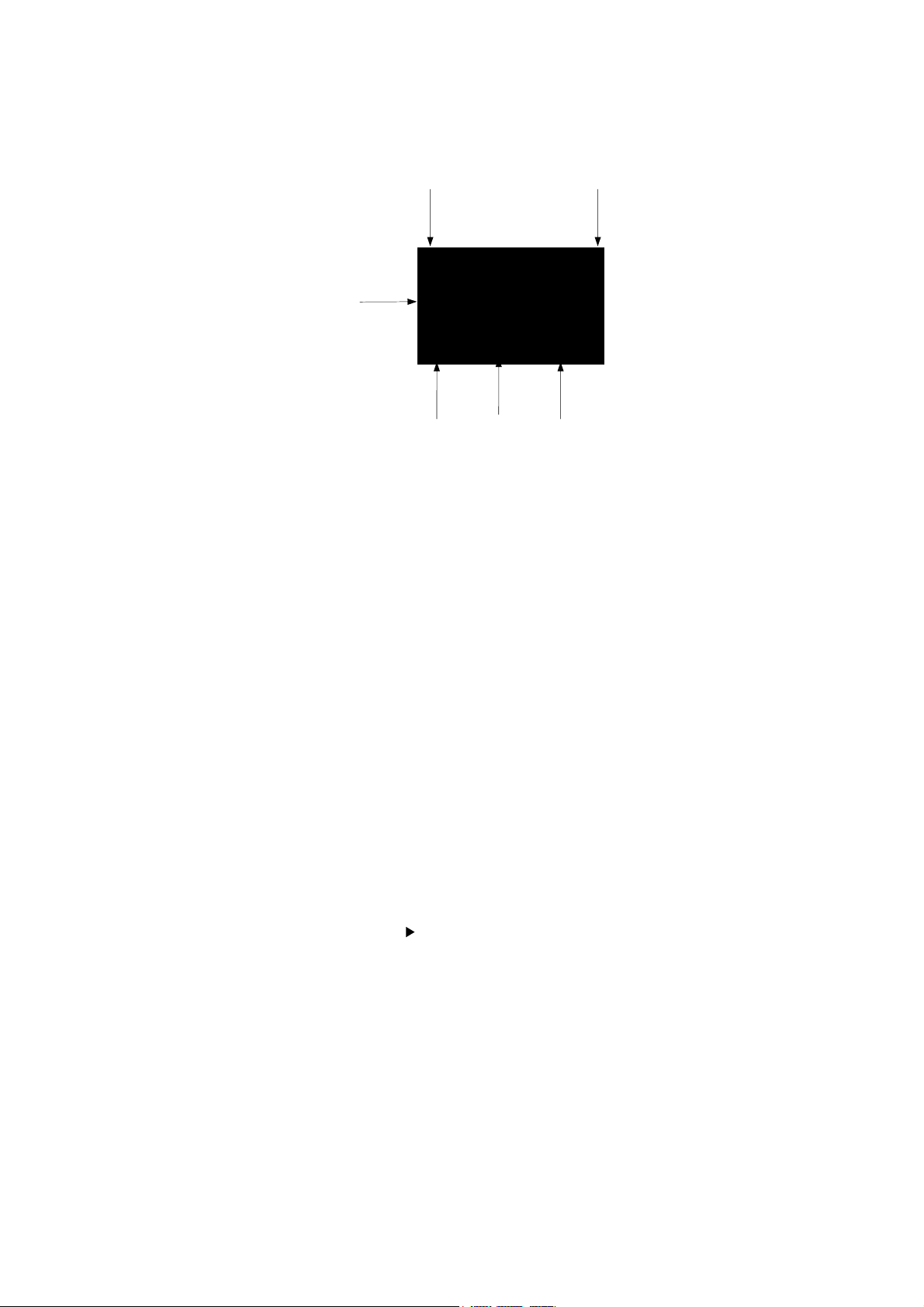

1 Recharger connector

2 Connector ports for

probes and cables

3 Power ON/OFF

3

Port I 2

Port II

Figure 1 MI70 indicator

10 __________________________________________________________________ M210297EN-E

Page 13

________________________________________________________________ Product Description

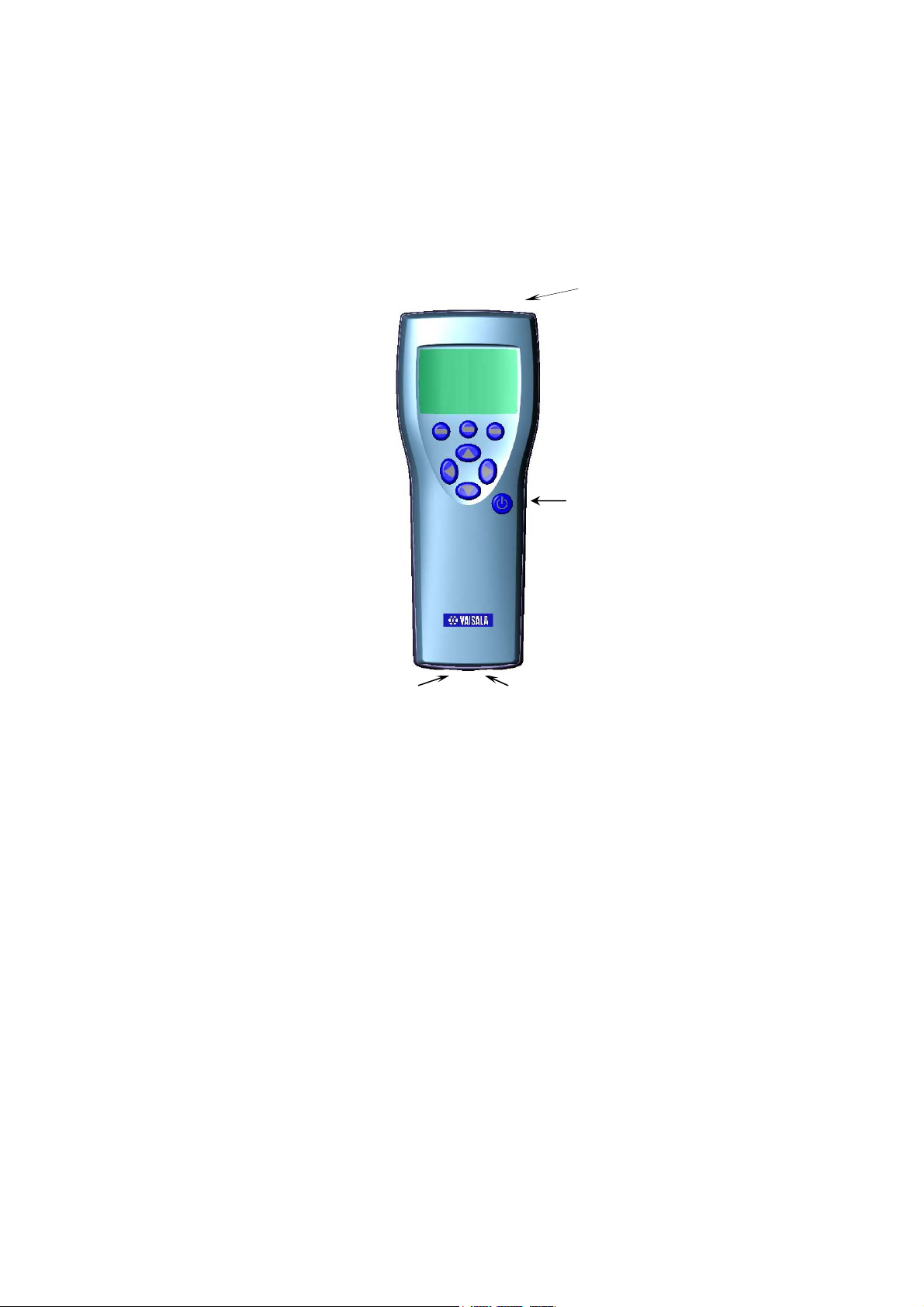

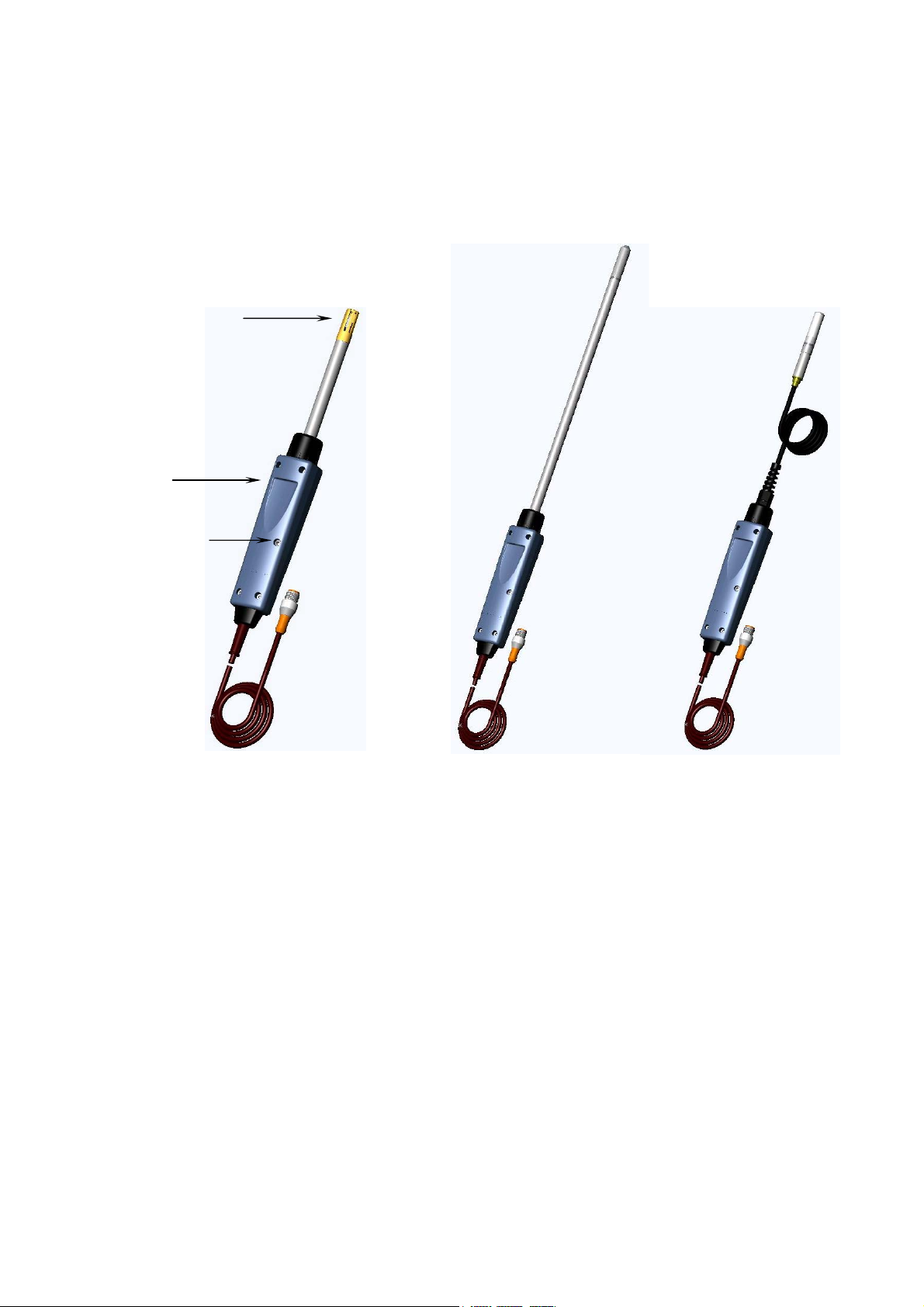

1 Probe filter

2 Probe HMP75/76/77

3 Calibration button under

the screw

1

1

2

3

HMP75 PROBE

Basic probe for relative humidity

and temperature measurement

Preheat and chemical purge

options available (HMP75B).

HMP76 PROBE

Rugged probe with a

long stainless steel

shaft. Preheat and

chemical purge options

available (HMP76B).

HMP77 PROBE

Cable probe for industrial

processes up to 180 °C.

Preheat and chemical purge

options available (HMP77B).

Figure 2 HMP75, HMP76, and HMP77 probes

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

This page intentionally left blank.

12 __________________________________________________________________ M210297EN-E

Page 15

Chapter 3 ____________________________________________________ Preparations Before Use

CHAPTER 3

PREPARATIONS BEFORE USE

Installing and Recharging the Batteries

1. If you are using alkaline batteries, remove the back plate of the

indicator and insert the batteries. If the HM70 is ordered with a

rechargeable battery pack, it is already in place as shipped from

the factory.

2. Recharge the battery pack as follows: Plug in the recharger

connector to the base of the indicator and connect the recharger to

a wall socket. A battery symbol in the corner of the display starts

to roll.

- It is not recommended to use HM70 during the first recharging.

After the first charge cycle is complete, you can use the HM70

while recharging.

- The duration of recharging depends on the charge level of the

battery pack. 4 hours is a typical recharging time. The

recommended first charging time is 6 hours.

3. When the battery symbol stops rolling, the battery is fully

recharged. Disconnect the recharger.

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

Turning ON the Device

1. Connect the probe to the either of the base connectors of the

indicator.

2. Press the button to turn on the device.

3. Select the language by using the buttons. Confirm by

pressing SELECT. You can select the language later as well,

see page 24.

4. To change the date, select Date and press SET. Change the date

by using any of the buttons. To confirm the date,

press OK. The default date presentation format is:

year-month-date. If you want to change the format, see page 26.

5. To change the time, select Time and press SET. Change the

time by using arrow buttons. To confirm the time, press OK.

The default time presentation format is 24-hour clock. If you

want to use 12-hour clock, select 12-hour clock, and press ON.

6. Press EXIT. To check and change the pressure setting, select

YES. Otherwise select NO to enter the basic display.

14 __________________________________________________________________ M210297EN-E

Page 17

Chapter 4 ______________________________________________________ Taking Measurements

CHAPTER 4

TAKING MEASUREMENTS

If you are starting the HM70 for the first time, see Chapter 3

Preparations Before Use first.

To take measurements with the HM70, follow the instructions below:

CAUTION

1. Connect the probe to MI70-indicator.

2. Press POWER ON/OFF button.

3. If you have a chemical purge option in your probe (HM70 series

probe versions B), remember to carry out chemical purge

regularly, see page 34.

4. In case there is a risk for condensation, use the optional preheat

(HM70 series probe versions B) when installing the probe, see

page 36.

5. Install the probe to the measuring position. If measuring in

pressurized processes, see the instructions on page 21.

6. Before measurements, ensure that the air pressure setting of

HM70 is correct. See page 21.

7. The basic display opens. Let the reading stabilize.

If you need to disconnect the probe from the indicator, first press

POWER ON/OFF button to turn the indicator OFF. This ensures that all

settings and data are saved properly.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

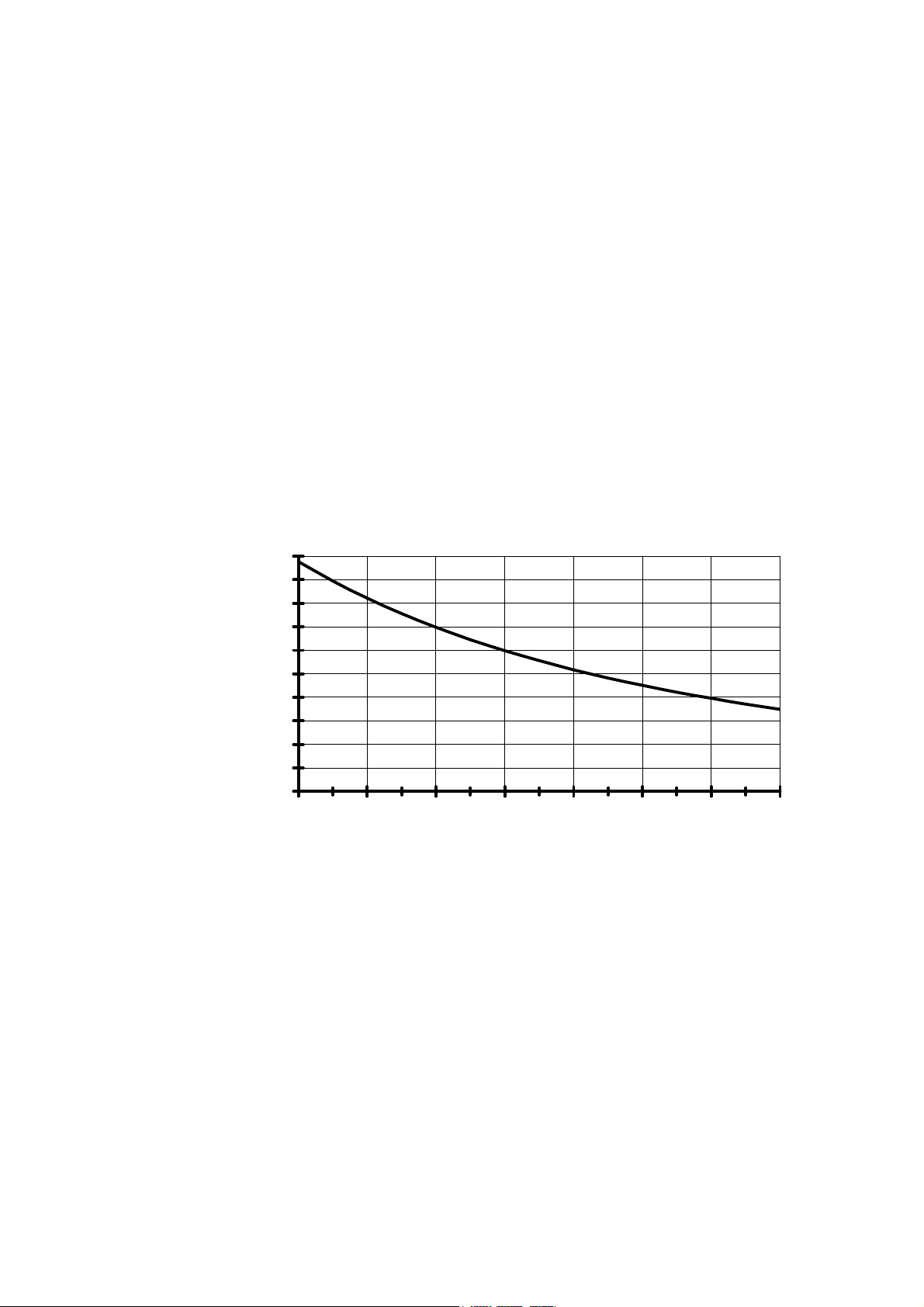

Beware of Temperature Differences

In humidity measurement and especially in calibration it is essential

that temperature of the probe and measuring environment is the same.

Even a small difference in temperature between the environment and

the probe causes an error. As the curve below shows, if the

temperature is +20 °C and the relative humidity 100 %RH, a

difference of ±1 °C between the environment and the probe causes an

error of ±6 %RH. When the humidity is 90 %RH, the corresponding

error is ±5.4 %RH.

A temperature difference of a few degrees can also cause water to

condense on the sensor surface. HUMICAP®® sensor starts to function

normally as soon as the water has evaporated. If the condensed water

is contaminated, the life span of the probe may shorten and calibration

may change. See also information about sensor preheat, page 36.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Figure 3 Measurement error at 100 %RH with 1 °C

difference between the ambient and sensor temperature

16 __________________________________________________________________ M210297EN-E

Page 19

Chapter 5 _________________________________________________Buttons, Displays and Menus

CHAPTER 5

BUTTONS, DISPLAYS AND MENUS

Buttons and Navigation

To open a menu view

1. Press an arrow button

2. Press this shortcut button

Press down the POWER ON/OFF button until the indicator turns on/off.

Press the SHORTCUT buttons to activate the function shown above the button.

Shortcut buttons

Arrow buttons

Power ON/OFF

Figure 4 MI70 buttons

Press any of the ARROW buttons to open the MENUS. In the MENUS you can navigate

with ARROW buttons.

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

Basic Display

1. Selected quantities. Up to three of the quantities can be selected at

a time.

- RH relative humidity (% RH)

- T temperature (ºC/ ºF)

- T

- Td : dewpoint temperature2) (ºC/ ºF)

- a : absolute humidity (g/m3/ gr/ft3)

- x : mixing ratio (g/kg / gr/lb)

- Tw: wetbulb temperature (ºC/ ºF)

- H2O: humid air volume/ dry air volume (ppm)

- pw: water vapour pressure (hPa/ lb/in2)

- pws: saturation water vapour pressure(hPa/ lb/in2)

- h : enthalpy (kJ/kg / Btu/lb)

- a

2. Shortcut button Graphic

5 6

1

2

3

4

Figure 5 MI70 basic display

: dewpoint/frostpoint1 temperature (ºC/ ºF)

d/f

: water activity

w

1

changes display into curve mode

3. Shortcut button Hold/Sa

1

freezes display and you may save the

reading into the memory.

4. Shortcut button Record

5. State of battery.

6. Pressure setting.

1

takes you to the Recording/Viewing menu.

1

Graphic, Hold/Sa and Record -functions above the shortcut buttons are set

in the factory. You can change them to refer other functions (see page

25).

18 __________________________________________________________________ M210297EN-E

Page 21

Chapter 5 _________________________________________________Buttons, Displays and Menus

Graphical Display

Graphical display shows you the measurements in a form of curve.

From the curve you can examine the data trend and history of the last

minutes. Graphical display shows firstly the curve of the uppermost

quantity shown in a basic display.

1. In basic display, press Graphic or (alternatively open the MENU,

select Display, select Graphic history

2. Graphical display opens. More information on page 23 Graphic

history

.

Menus

3. Press

BACK to return to the basic display.

In the menus you can change settings and select the functions.

1. Open the main menu by pressing any of the buttons.

2. Press OPEN within 5 seconds. The basic display returns if you

do not open the MENU shortly. If this happens, begin with the item

1 again.

3. Move in the menus by using buttons.

4. Select the item with buttom.

5. Press to return to the earlier level.

6. EXIT returns back to normal operation.

Main menu Display menu

Functions menu

Recording/Viewing menu

Settings menu Environment menu

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

This page intentionally left blank.

20 __________________________________________________________________ M210297EN-E

Page 23

Chapter 6 __________________________________________________________________Settings

CHAPTER 6

SETTINGS

Pressure Setting

When measuring in pressurized environments, the actual process

pressure value must be given to the HM70. The pressure can be given

in the following units:

hPa: Absolute pressure given in the unit of hPa.

barg

bara: Absolute process pressure given in the unit of bar.

psia

Follow the instructions below:

1. Open the

2. Select

3. Press

4. Press SET to set the ambient pressure value.

5. Set the pressure value by using buttons. Press +/- to

6. Press

Gauge pressure given in the unit of bar. Indicates the pressure

:

difference between normal atmospheric pressure and the actual

process pressure.

Absolute pressure given in the unit of psi.

:

MENU; press OPEN

ENVIRONMENT with and press .

UNIT to change the pressure unit. Default unit is hPa.

change the sign of the pressure value. Press OK to save the

value.

EXIT to return to the basic display.

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

Display Settings

→

Quantities and Units

All the quantities and units are shown in page 9.

1. Open the MENU; press OPEN.

2. Select Display, press .

3. Select Quantities and units, press

4. To select a quantity, move on the quantity you want by using the

arrow buttons, press SELECT.

5. To change the unit, move on the quantity you want by using the

arrow buttons, then press UNIT .

6. To hide a quantity, move on the quantity you want to hide by using

the arrow buttons, then press HIDE.

7. Press EXIT to return to the basic display.

8. If asked, press

otherwise press

YES, if you want to check environment settings,

NO.

Rounding

You can turn on the decimal display by using the Rounding function.

The default setting is rounding off .

1. Open the MENU: press OPEN

2. Select the Display, press

3. Select Rounding.

4. Press ON to have rounding on. Press OFF to deactivate

rounding (two decimal display).

5. Press

22 __________________________________________________________________ M210297EN-E

EXIT to return to the basic display.

Page 25

Chapter 6 __________________________________________________________________Settings

Hold/Save Display

Hold/Save function enables you to freeze a certain display reading.

This reading can be saved into the memory.

1. Open MENU: press OPEN.

2. Select Display, press

3. Select Hold/Save display.

4. Press HOLD to freeze the display. The frozen measurement data is

displayed.

5. Press SAVE to save the reading and CANCEL to return to the

menu.

6. You can save several readings with HOLD-SAVE function. The data

points are identified on the basis of the saving date and time. All

the individual readings (data points) are stored in a same file

marked with . The file remains in the indicator memory even if

the indicator is switched OFF.

7. To view the saved readings, press Record, select View recorded

press .

data,

8. Select the file marked with , press . Now you can see the

saved data readings. Press TIMES to see the recording

timestamps.

9. Press EXIT to return to the basic display.

Graphic History

Graphic history shows the data curve of the last hour. To see longer

graphs, use the data recording function to save the data and then view

it as a graph.

1. Open the

2. Select Display, press

3. Select Graphic history, press SHOW to have a graphical history

display.

4. To get the statistical info on the graph area (minimum, maximum

and mean values), press

MENU: press OPEN.

INFO.

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

5. To get the curve of the other selected quantities, press NEXT.

To get the curves of the all quantities, press NEXT until text

ALL is shown instead of NEXT. Then press ALL.

6. To zoom in the curve, press the arrow button . To zoom out,

press the button . To move the curve in horizontal directions,

press the buttons .

7. Press BACK and EXIT to return to the basic display.

User Interface

→ →

Selecting Language

You can select any of the following languages as an user interface

language: English, German, French, Finnish, Spanish, Swedish,

Chinese, Russian or Japanese.

1. Open the MENU: press OPEN.

2. Select Settings, press .

3. Select User interface, press .

4. Select Language, press SET.

5. Select the language you want, press SELECT.

6. Press EXIT to return to the basic display.

If you accidentally select a wrong language, first go back to the basic

display by pressing rightmost key as many times as required, then

go to the language selection menu by pressing: , middle key

, , , middle key.

24 __________________________________________________________________ M210297EN-E

Page 27

Chapter 6 __________________________________________________________________Settings

Automatic Power OFF

As shipped from factory, HM70 has a default setting which turns the

power off automatically after 15 minutes of inactivity. This is to

conserve the battery. In case you want to change the inactivity time

setting to 60 minutes or turn off the automatic power off function,

follow the instructions.

1. Open the MENU: press OPEN.

2. Select

3. Select

4. Select

5. Select the choice you want, press

Settings, press

User interface, press .

Auto power off, press SET.

SELECT.

6. Press EXIT to return to the basic display.

Changing Shortcut Keys

As a default, the three shortcut keys refer to the functions Graphic,

Hold/Save and Record. If needed, a shortcut for the functions can be

changed to correspond to your needs.

1. Open the MENU: press OPEN.

2. Select Settings, press .

3. Select User Interface, press .

4. Select Program shortcut keys, press START.

5. Press the shortcut key you want to change, e.g.

6. If you want to replace

Hold/Save with Chemical purge-function

Hold/Save.

(as an example), select Chemical Purge by using arrow buttons

( Functions) Chemical Purge, press SELECT. Answer YES to confirm

your selection, otherwise answer NO and continue from item 4.

7. Press EXIT to return to the basic display.

Hold/Save -shortcut key replaced

by Chemical purge -shortcut key

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

Button Click and Backlight on Button Press

1. Open the MENU: press OPEN.

2. Select Settings, press .

3. Select User interface, press .

4. To turn OFF or ON sound effect while pressing the buttons,

select Key Click and press ON/OFF.

5. To turn OFF and ON backlight while pressing the buttons, select

Backlight on key press ON/OFF.

6. Press

EXIT to return to the basic display.

Setting Date and Time

To have correct date and time in recorded data files, set the date and

time according to the following instructions.

1. Open the MENU: press OPEN.

2. Select Setting, press .

3. Select Date and time, press .

4. To change the date, select Date and press SET. Change the date

by using arrow buttons. To confirm the date, press.

default date presentation format is year-month-date, e.g.200206-05. If you want to change the format, select

SET , select either D.M.Y or M/D/Y, press SELECT .

press

5. To change the time, select Time and press SET. Change the

time by using arrow buttons. To confirm the time, press

The default time presentation format is 24-hour clock. If you

want to change the format, select

12-hour clock, press ON/OFF.

Date format: Y-M-D,

OK. The

OK.

6. Press

26 __________________________________________________________________ M210297EN-E

EXIT.

Page 29

Chapter 6 __________________________________________________________________Settings

Device Information

→

The basic information about the indicator and the probe is found as

follows:

1. Open the MENU: press OPEN

2. Select Settings, press .

3. Select Device information, press SHOW.

4. The first display gives the information on the MI70 indicator.

Press MORE to get the information on the probe. Press OK

and EXIT to return to the basic display.

MI70 indicator

information

Probe type information

Reverting to Factory Settings

You can revert to factory settings to clear all changed settings and

recorded data on the indicator. Reverting to factory settings does not

affect probe calibration.

1. Open the MENU: press OPEN.

2. Select Settings, press .

3. Select Factory settings, press REVERT. Press YES to confirm the

reverting.

4. The power turns off automatically. When switching on again,

the factory settings are reverted. After reverting to the factory

settings, you must set the language, date and time again. See

Chapter 3.

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

This page intentionally left blank.

28 __________________________________________________________________ M210297EN-E

Page 31

Chapter 7 ____________________________________________________________Recording Data

CHAPTER 7

RECORDING DATA

Recording

→

You can record measurement data and view the recorded data on the

display.

1. Press the shortcut Record, (alternatively open the MENU, select

Recording/Viewing).

2. Select Record data, press .

3. To change interval, select Interval, press SET.

4. Select the measurement interval with arrow buttons.

Measurement intervals and the maximum recording times are

shown in the table below.

Maximum recording time (memory full) Recording interval

1

quantity

1 s 45 min 22 min 15 min

5 s 3 h 113 min 75 min

15 s 11 h 5 h 3 h

30 s 22 h 11 h 7 h

1 min 45 h 22 h 15 h

5 min 9 days 4 days 3 days

15 min 28 days 14 days 9 days

30 min 56 days 28 days 18 days

1 h 113 days 56 days 37 days

3 h 339 days 169 days 112 days

12 h 1359 days 678 days 451 days

2

quantities

3

quantities

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

5. Press SELECT.

6. To set the recording duration, select Duration, press SET.

7. Select the recording duration (1 min, 5 min, 15 min, 30 min, 1 h, 3

h, 12 h, 24 h, 7 d, 30 d, memory full) with arrow buttons and

press SELECT.

8. Start recording: select Start/Stop recording, press START. If you

chose 'Memory full', you see the maximum recording time on

the display. You can also delete files in order to empty the

memory. Press START again to accept maximum recording

time.

9. You can switch the HM70 off during recording to save battery.

Display message tells you that recording continues undisturbed

even when power is off. If the indicator is switched off during

recording, the progress bar is shown on the display every

10 seconds (all the time, if charger is connected). This bar shows

the amount of recorded data.

CAUTION

Do not disconnect the probe when the data recording is on,

even if the indicator is off. This may cause loss of recorded

data.

Stopping Recording

1. To stop recording press Record, select Record data and press ,

select Start/Stop recording and press STOP.

2. Now you can go and see the recorded file by selecting

You can save individual measurement data points with Hold/Save

function described in page 23.

Viewing Recorded Data

SHOW.

1. Open the MENU: press OPEN .

2. Select Recording/Viewing, press .

3. Select View recorded data, press .

30 __________________________________________________________________ M210297EN-E

Page 33

Chapter 7 ____________________________________________________________Recording Data

4. Select the file you want to view, press . The files are

identified according to the starting date and time of recording.

5. Press GRAPH to get the graphical view, press TIMES to get

the recording timestamps (press VALUES to go back the

recorded values).

6. Press EXIT to return to the basic display.

Checking Memory Status

You can check how much there is free space in the memory.

1. Open the MENU: press OPEN .

2. Select Recording/Viewing, press .

3. Select Memory status, press SHOW to see the amount of memory

in use and the estimated free space.

4. To return to the basic display, press OK and EXIT.

Note that the estimate of the free space is calculated for current

number of active quantities. If you change the displayed quantities, the

estimate is different.

Deleting All Recorded Files

The data memory can be cleared as follows:

1. Open the MENU: press OPEN.

2. Select

3. Select

deletion of all recorded data files.

4. To return to the basic display, press

Recording/Viewing, press .

Clear data memory, press CLEAR. Press YES to confirm

EXIT.

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

MI70 Link Program for Transferring Recorded Data to PC

The recorded data can be transferred to a PC by using MI70 Link

program.

MI70 Link program can be ordered from Vaisala, see the list of

accessories on page 77. You can examine the recorded data easily in

Windows® environment and transfer it further to a spreadsheet

program (such as Microsoft® Excel) to be modified.

MI70 Link Program for Real-Time PC Monitoring

You can monitor HM70 readings directly with a PC by using MI70

Link program. MI70 Link program can be ordered from Vaisala, see

the list of accessories on page 77.

Together with the USB instrument cable (optional accessory 219687)

or the serial connection cable it is easy to transfer logged and real time

measurement data from the HM70 to a PC.

When using the USB cable consider the following: the MI70 Link

program contains the driver needed for the USB connection. For the

system requirements and installation, see the back of the installation

CD. Follow the installation instructions on the CD. Check that the

USB cable is not connected. The MI70 Link Setup Wizard will install

Vaisala MI70 Link on your computer. Installing the USB instrument

driver can take a few minutes. After the installation is finished,

connect the USB cable to the USB port on your PC. Windows will

detect the new device, and use the driver automatically.

You can now start monitoring the HM70 readings in real time with a

PC using the MI70 Link program. In case the MI70 Link cannot find

the instrument, check the following:

- the HM70 is switched on

- the USB instrument cable/serial connection cable is properly

connected to the USB/serial port of your PC

- another application has not reserved the connection

32 __________________________________________________________________ M210297EN-E

Page 35

Chapter 8 ___________________________________________________________ Other Functions

CHAPTER 8

OTHER FUNCTIONS

Setting Alarm Levels

→

HM70 is alarming by beeping and blinking the backlight. The alarm

turns on when the measured value is not between the alarm limits

(permissible area). Alarm level(s) can be set for only one quantity at a

time. Set the alarm levels as follows:

1. Open the MENU: press OPEN.

2. Select Functions, press .

3. Select

4. Select Quantity and press SET to choose a quantity.

5. Select quantity, press

chosen at a time. Only active quantities can be selected. To

change the active quantities, go to

units

6. Select the first limit, press SET (if the alarm function is ON,

take it OFF). Set the alarm level by using arrow buttons. Press

save the setting.

Alarm, press .

SELECT.(Only one quantity can be

MENU- Display- Quantities and

).

+/- button to choose the sign of the alarm level. Press OK to

7. Select the second limit, then follow instructions in item 6. The

alarm will go off when the upper limit is exceeded or when

lower limit is gone below.

If you have only one limit, e.g. if you want to detect if the

humidity is rising above 50 % RH, set the upper limit to 50 %

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

RH and the lower limit so low that it never will be reached (for

example 0 % RH). Thus, the HM70 will alert when RH rises

above 50 % RH.

8. Select Alarm ON/OFF, press ON to activate the alarm and return

back to the basic display.

9. A note picture sign appears on the upper left corner.

10. When the alarm level is reached, you can stop alarming by

pressing OK. To reactivate the alarm function, answer YES.

To stop the alarm function completely, answer NO.

NOTE

The alarm is not in function when the device is turned off. Remember

to turn off the automatic power off, see page 25.

Chemical Purge (Optional)

Chemical purge is an optional feature of the HM70 series humidity

probes (B-version probes). In some specific applications the sensor

gain may decrease gradually due to an interference caused by some

particular chemical present in the ambient. The sensor polymer

absorbs the interfering chemical; this reduces the polymer's ability to

absorb water molecules and so decreases the sensor sensitivity. In

chemical purge the interfering chemical is evaporated by heating the

humidity sensor to a temperature of +160 °C for 2 minutes.

For the most applications it will be sufficient to perform the chemical

purge once a week. For applications where HM70 is subject to high

concentrations of chemicals, chemical purge should be performed

more frequently, in extreme cases before each measurement.

Turning Chemical Purge ON

The following applies only with humidity probes HMP75B, HMP76B

and HMP77B:

34 __________________________________________________________________ M210297EN-E

Page 37

Chapter 8 ___________________________________________________________ Other Functions

1. Open the MENU: press OPEN.

2. Select Functions, press .

3. Select Chemical Purge, press START.

4. Confirm the starting by pressing YES. Chemical purge takes up to

6 minutes. During that time there are no readings on a display. A

message display appears once in 15 seconds and it tells you the

time required to complete the chemical purge. The chemical

purge symbol is shown on upper left corner.

5. When the chemical purge is done the basic display with readings

returns.

6. Stabilization of temperature reading can take a few minutes.

You can make a shortcut to the chemical purge function by setting one

shortcut key to refer Chemical Purge function, see page 25.

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

Sensor Preheat (Optional)

Sensor preheat is an optional feature of the HM70 series humidity

probes (B-version probes).

In some measurement applications, unwanted dew formation makes

humidity measurement difficult or even impossible. High humidity

combined with rapidly changing outdoor temperature can condense

the water vapour in the air onto the sensor. Until this dew evaporates

or dries, it is impossible to obtain a true reading. In sensor preheat the

sensor is heated to a temperature level of approximately +100 °C for

up to 4 minutes. This is to prevent possible condensate from the

sensor.

When setting the probe from outdoor conditions into warm and humid

conditions there can be large temperature difference between the

probe and external environment. In such a conditions turn on the

sensor preheat immediately before installing the probe to prevent

condensation forming on the probe.

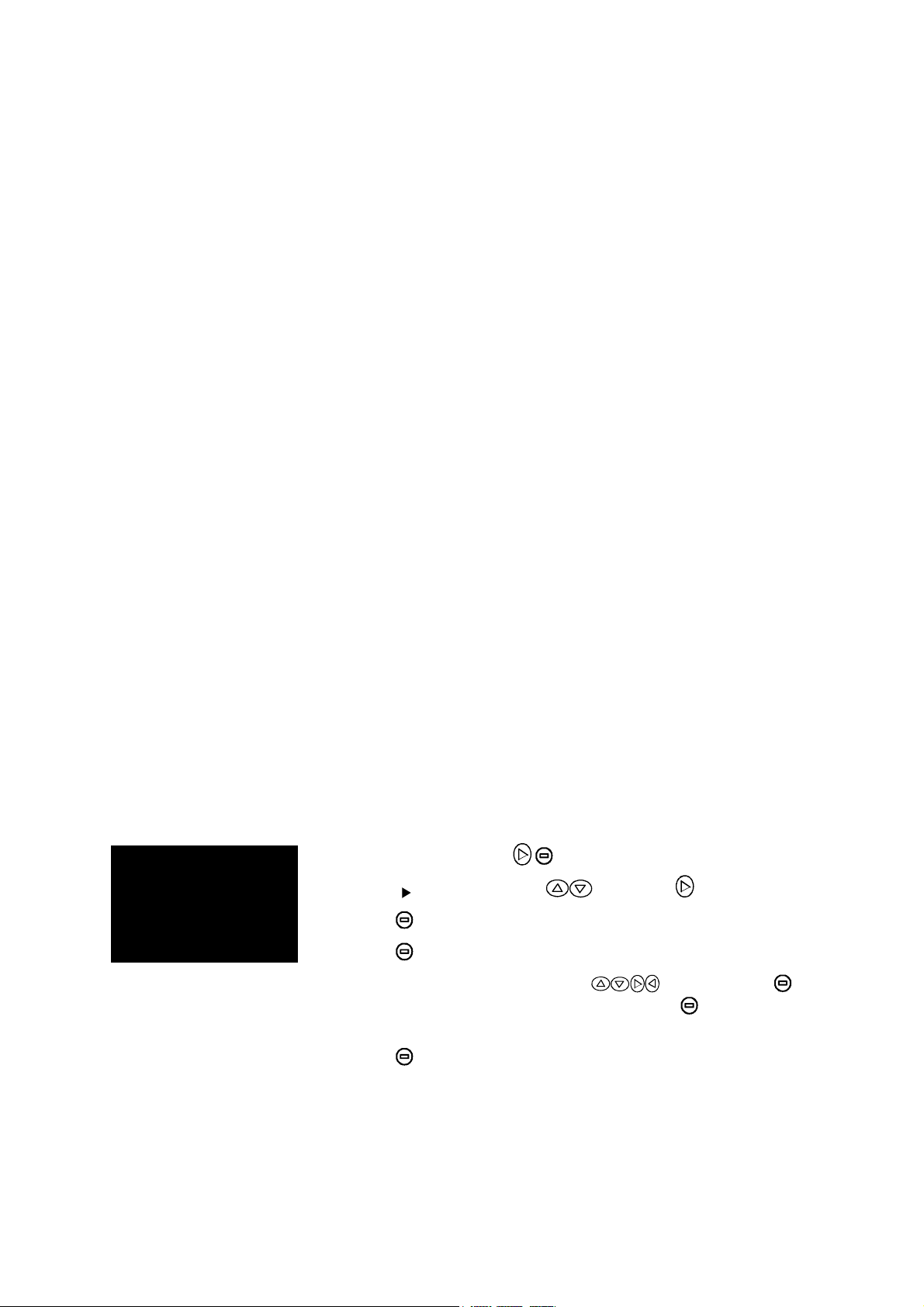

Figure below shows how response time can be dramatically shortened

and water condensation on the sensor avoided when using sensor

preheat.

Response time to high RH/T enviroment

120

100

80

60

%RH

40

20

0

0 1020304050607080

time (s)

No Preheat Preheat for 12s

This curve shows how

relative humidity

increases as a

consequence of

condensation on the

sensor. The correct

response is achieved

not until the sensor is

When using preheat,

response time is

shortened.

Figure 6 Response time to high RH/T environment

36 __________________________________________________________________ M210297EN-E

Page 39

Chapter 8 ___________________________________________________________ Other Functions

Turning Sensor Preheat ON/OFF

The following applies only with humidity probes HMP75B, HMP76B

and HMP77B:

1. Open the MENU: press OPEN.

2. Select Functions, press .

3. Select Sensor Preheat, press START. Confirm the starting by

pressing YES.

4. Insert the probe to the process.

5. When sensor preheat is done, a display message tells that

operation is completed and the basic display with readings

returns.

Sensor preheat is taking about 4 minutes at maximum. During

that time there are no readings on a display. A message display

appears once in 15 seconds and it tells you the time required to

complete the sensor preheat. Sensor preheat symbol is

shown on upper left corner. Stabilization of the temperature can

take a few minutes.

You can make a shortcut to the sensor preheat function by

setting one shortcut key to refer sensor preheat function, see

page 25.

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

This page intentionally left blank.

38 __________________________________________________________________ M210297EN-E

Page 41

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

CHAPTER 9

CALIBRATION AND ADJUSTMENT OF TRANSMITTERS

HM70 in Checking and Adjusting

The following transmitters can be calibrated by using HM70: HMDW

60/70, HMW 61/71, HMD/W 20/30, HMP130, HMP230/240 series,

HMT320/330 series, HMM210 series and DMW19 transmitter.

When calibrating in the field, check and adjust a fixed transmitter's

reading against a calibrated reference probe on the HM70.

One or two point calibrations can be done to industrial transmitters

and modules (HMP230/240 series, HMT320/330 series, HMM210

modules) by using a MI70 indicator and Vaisala's humidity calibrator

HMK15.

Calibration Cables

For calibration and adjustment connect HM70 to fixed transmitter by

using one of the following connection cables:

- HMA6070-cable for HMD/W 60/70 and HMW 61/71 transmitters

- HMA2030-cable for HMD/W 20/30 and HMP130 transmitters

- 27159ZZ-cable for HMP230/240 series transmitters and HMM210

series modules.

- 211339-cable for HMT320/330 series transmitters

- 211917ZZ-cable for DMW19 transmitter.

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

Figure 7 Connectors for connection cables

Connector ports

Calibration and Adjustment of HMD/W 60/70, HMD/W 20/30 and HMP130 Series Transmitters

For checking and adjusting HM60/70 series and HM20/30/130 series

transmitters you need a MI70 and a HMP70 calibrated reference probe

and a connection cable. Only relative humidity channel of these

transmitters can be checked.

1. Connect the end of the HMA6070 (connection cable for

HM60/70-series) or HMA2030 (connection cable for HM20/30series) cable to either of the HM70's connector port located on

the bottom of the indicator, see Figure 7 on page 40.

2. Connect the other end of the HMA6070 or HM20/30/130-cable

to the

motherboard.

RH TEST connector (or TEST connector) of the transmitter's

3. Turn on MI70 indicator.

4. This concerns ONLY calibration of HM60/70-series: If a

transmitter has voltage output, select the RH input scale setting

0... 20 mA. If a transmitter has current output, set the indicator's

default setting to correspond the transmitter's signal (0... 20

mA/4...20 mA) as follows:

− Open the

40 __________________________________________________________________ M210297EN-E

MENU: press OPEN.

Page 43

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

− Select Settings, press

− Select Measurement settings, press

− Select RH scale: 4...20 mA or 0...20 mA, press ON

− To return to the basic display, press EXIT

5. Now the reading of the transmitter is shown on the first or

middle row of the display, depending on the connector port to

which the calibration cable is connected. Value of the port I is

shown on the upper row of the display and the value of the

port II on the lower row of the display. Difference of the

readings is shown in the lowest row.

6. Ensure that the probes are located in the same conditions. You

can have an optional probe holder for the HMP76 probe to

attach the probe next to the probe of HMD60/70 or HMD20/30

(order code for the probe holder: HM36915).

7. Wait until the readings have stabilized (can take up to 20

8. Adjust the transmitters reading to correspond the HM70

9. When the transmitter reading is equal with the HM70 reference

10. Switch off HM70 and detach the cable from the transmitter and

minutes). If the difference between the humidity readings is less

than 2 % RH, there is no immediate need for adjustment.

reference probe by turning the small screw on the modules on

the transmitter's mother board marked with RH offset/ RH gain. If

the RH reading is < 65 %, turn the RH offset screw and if the RH

reading is >65 %, turn the

RH gain screw. Turning to the

clockwise direction increases the reading, turning to opposite

direction decreases the reading.

Do not breathe towards the transmitter probes when adjusting

the reading.

probe's reading, adjustment is done.

the HM70 indicator.

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

Calibration and Adjustment of HMT100 Series Transmitters

You can check and adjust the HMT100 relative humidity

measurement with Vaisala HM70 Hand-Held Humidity and

Temperature meter. A HM70-connection cable is needed, Vaisala

order code: 211339.

There are four types of adjustments available: field checking and

adjustment using a calibrated reference probe, one-point adjustment

using a calibrator, two-point adjustment using a calibrator and LiClNaCl adjustment.

Follow the 7 first steps and continue according to the chosen

adjustment method:

1. Connect the 211339 HM70-connection cable to the SERVICE PORT

connector on the HMT100 motherboard.

2. Connect the other end of the connection cable to either of the

HM70's connector ports located on the bottom of the indicator.

3. Turn on both devices (or just the HM70 if HMT100 is on

continuously).

4. The reading of the transmitter is shown on the top or middle row

of the indicator display, depending on which connector port the

connection cable is connected to.

5. Press the ADJ button on the HMT100 motherboard to open the

adjustment mode. The indicator led on the HMT100

motherboard starts flashing. From now on the adjustment is

carried out using the MI70 indicator.

6. Press

7. Check the environment settings if needed. Otherwise press NO.

OK to start adjustment.

Continue according to the directions of the desired adjustment

method.

Field Checking and Adjustment Using a Calibrated Reference Probe

Follow steps 1 to 7 above and continue as follows:

8. Check that the probes are located in equal conditions and wait

until the readings have stabilized (may take 30 minutes or

42 __________________________________________________________________ M210297EN-E

Page 45

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

more). If you are near the probes, do not breath in their

direction.

9. Press ADJUST to continue adjusting.

10. Choose To same as RH

SELECT (MI70 automatically recognizes which port the HMP70-

from the MI70 adjustment menu, press

I/II

series probe is connected to).

11. Confirm the adjustment by pressing YES.

12. The adjustment is done. Press

BACK and EXIT to return to the

basic display.

13. Turn off the MI70 and detach the connection cable.

One-Point Adjustment Using a Calibrator

When adjusting the transmitter in only one reference condition, please

take care that the reference condition represents the measuring

environment. MI70 indicator is used now only as a terminal for

visualizing and setting the transmitter's RH reading.

Follow steps 1 to 7 on page 42 and continue as follows:

8. Remove the filter from the transmitter's probe and insert the

probe into the reference condition.

9. Press ADJUST to continue adjusting.

10. Choose

SELECT.

11. Press

1-point adjustment from the MI70 adjustment menu, press

READY when the reading has stabilized in the reference

condition (may take 30 minutes or more). You can follow the

stabilization from the GRAPH display.

12. Enter the correct reference value with the arrow buttons. Press

OK.

13. Confirm the adjustment by pressing YES.

14. The adjustment is done. Press BACK and EXIT to return to the

basic display.

15. Turn off the MI70 and detach the connection cable.

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Two-Point Adjustment Using a Calibrator

Note that the difference between the two reference humidities must be

at least 50 %. MI70 indicator is used now only as a terminal for

visualizing and setting the transmitter's RH reading.

Follow steps 1 to 7 on page 42 and continue as follows:

8. Remove the filter from the transmitter's probe and insert the

probe into the lower humidity reference condition.

9. Press ADJUST to continue adjusting.

10. Choose 2-point adjustment from the MI70 adjustment menu,

press SELECT.

11. Press READY when the reading has stabilized in the first reference

condition (may take 30 minutes or more). You can follow the

stabilization from the GRAPH display.

12. Enter the correct reference value in the first condition with the

arrow buttons. Press OK.

13. Remove the probe from the first reference conditions and insert

the probe into the higher humidity reference condition.

14. Press READY when the reading has stabilized in the second

reference condition (may take 30 minutes or more). You can

follow the stabilization from the

15. Enter the correct reference value in the second condition with

the arrow buttons. Press

16. Confirm the adjustment by pressing YES (by pressing NO you

return to adjustment mode display and no changes are made). If

the difference between the two reference conditions is less than

50 %RH, adjustment can not be done.

17. The adjustment is done. Press BACK and EXIT to return to the

basic display.

18. Turn off the MI70 and detach the connection cable.

OK.

GRAPH display.

44 __________________________________________________________________ M210297EN-E

Page 47

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

LiCl-NaCl Adjustment

This adjustment is done using relative humidity references 11.3 % RH

(LiCl) and 75.5 % RH (NaCl).

Follow steps 1 to 7 on page 42 and continue as follows:

8. Remove the filter from the transmitter's probe and insert the

probe into the LiCl salt chamber.

9. Press

10. Choose

11. Press READY when the reading has stabilized in the LiCl salt

12. Remove probe from the LiCl salt chamber and insert the probe

13. Press READY when the reading has stabilized in the NaCl salt

14. Confirm the adjustment by pressing YES (by pressing NO you

15. The adjustment is done. Press BACK and EXIT to return to the

ADJUST to continue adjusting.

LiCl-NaCl autom. from the MI70 adjustment menu, press

SELECT. Press OK to accept the note telling about references.

chamber (may take 30 minutes or more). You can follow the

stabilization from the GRAPH display.

into the NaCl salt chamber.

chamber (may take 30 minutes or more). You can follow the

stabilization from the GRAPH display.

return to adjustment mode display and no changes are made).

basic display.

16. Turn off the MI70 and detach the connection cable.

Calibration and Adjustment of HMP230/240 Transmitters and HMM210 Modules

You are able to check and adjust only humidity channel, temperature

channel can only be checked. Calibrate your transmitter/module

against a calibrated reference probe of HM70 or against a calibrator's

reference humidity by using MI70 indicator in communication.

Follow the first 12 steps and continue according to the chosen

calibration method.

1. In case you have a transmitter provided with heated probe, carry

out these preparations before calibration.

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

HMP240 transmitter with a probe heating: The heating

function is turned off automatically when the connection has

been established in step 10.

HMM210 module with chemical purge function (re-gain) or

with probe heating option: Before calibration activate the re-

gain function by resetting the device. Let stabilize to the ambient

conditions. Turn off the heating; use a calibration jumper

(HMM211) specified in the HMM211's User's Guide (section:

Temperature calibration of dewpoint module) or serial

commands (HMM213). For further information, see User's

Guide of the modules.

2. Connect the 27159ZZ-calibration cable to the

X5 connector of the HMP230/HMP240-series transmitter

(

X5 connector = 6-pin connector on the left side of the

motherboard).

- calibration connector of the HMM210 module.

3. Connect the other end of the calibration cable to either of the

HM70's connector port located on the bottom of the indicator,

see Figure 7 on page 40.

4. Turn on the HM70.

5. Open the MENU: press OPEN.

6. Select Functions, press .

7. Select Calibrate transmitters, press .

8. Select 1.Baud rate and 2.Serial format. Press SET to change the

serial settings. Serial settings of the transmitter/module and

HM70 shall be the same. HMP230/240 default serial settings:

4800, 7, even 1. HMM210 module's default settings: 1200, 8,

None. Note! HMM213 shall be in RUN or STOP mode.

9. Select

3.Start calibration, press START. If the serial settings of

HM70 are not compatible with the settings of HMP230, or the

cable connection is not working check that the serial settings of

HMP230 and the settings of HM70 are the same. Check the

cable connection. Then retry connection in step 6.

10. After connection has been established start the adjustment by

pressing

OK.

11. Select the quantity to check RH/T (view only), press SELECT.

12. If RH selected, check the environment settings of HM70 probe,

if needed. Press YES or NO.

46 __________________________________________________________________ M210297EN-E

Page 49

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

The first row shows the reading of the probe/transmitter

connected to the port I, the second row shows the reading of the

probe/transmitter connected to the port II. The third row RH/T is

the difference between the readings of the ports. By pressing

BACK you return to the selection display.

Figure 8 Example of the RH display

Field Checking and Adjustment of Humidity by Using a Calibrated Reference Probe

Follow the steps from 1 to 12 and continue as follows:

13. Ensure that the probes are located in the same conditions.

14. Wait until the readings have stabilized. If the difference between

the humidity readings is less than 2 % RH, there is no immediate

need for adjustment.

15. Adjust the transmitter reading to correspond a reading of the

reference probe by pressing ADJUST.

16. Select

17. Confirm by pressing YES

18. Press BACK, EXIT, EXIT to return to the basic display.

To same as RH

. Press SELECT.

I/II

1-Point Humidity Adjustment by Using a Calibrator

You can use Vaisala humidity calibrator HMK15 to achieve the

reference humidities. MI70 indicator is working as a communicator in

the calibration procedure.

Follow the steps from 1 to 12 and continue as follows:

13. Insert the transmitter probe to the reference humidity

VAISALA_______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

14. Press ADJUST

15. Select 1-point adjustment. press SELECT

16. Wait until the reading is stabilized (takes about 30 minutes).

You can follow the stabilization from the GRAPH display.

17. Press READY when the value is stabilized in the reference

humidity.

18. Enter the correct humidity value by using the arrow buttons.

Press OK.

19. Confirm by pressing YES

20. Press BACK, EXIT, EXIT to return to the basic display.

2-Point Adjustment by Using a Calibrator

You can use Vaisala humidity calibrator HMK15 in calibration and

adjustment. Note that the difference between the two reference

humidities shall be at least 50 %. MI70 indicator is working as a

communicator in the calibration procedure.

Follow the steps from 1 to 12 and continue as follows:

13. Insert the transmitter probe to the first reference humidity.

14. Press ADJUST

15. Select 2-point adjustment. press SELECT

16. Wait until the reading is stabilized (takes about 30 minutes).

You can follow the stabilization from the

17. Press

humidity.

18. Enter the first reference humidity value by using the arrow

buttons. Press OK.

19. Insert the transmitter probe to the second reference humidity.

20. Wait until the reading is stabilized (takes about 30 minutes or

more). You can follow the stabilization from the GRAPH

display.

READY when the value is stabilized in the first reference

GRAPH display.

21. Press READY when the value is stabilized in the second

reference humidity.

22. Enter the second reference humidity value by using the arrow

buttons. Press OK.

48 __________________________________________________________________ M210297EN-E

Page 51

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

23. Confirm by pressing YES

24. Press BACK, EXIT, EXIT to return to the basic display.

Calibration and Adjustment of HMT320 Series Transmitters

You can check and adjust both humidity and temperature channels.

Make the temperature adjustment first in case you adjust both

channels. Calibrate your transmitter against a calibrated reference

probe of HM70 or against a calibrator's reference humidity by using

MI70 indicator in communication. Follow the first 8 steps and

continue according to the chosen calibration method.

1. Connect the 211339-calibration cable to the RS232 connector in

the mother board of the HMP300-series transmitter

2. Connect the other end of the calibration cable to either of the

HM70's connector port located on the bottom of the indicator,

see Figure 7 on page 40.

3. Turn on both devices (the HMT300-series transmitter can be on

all the time).

4. The reading of the transmitter is shown on the first or middle

row of the display, depending on the connector port to which the

calibration cable is connected. Value of the port I is shown on

the upper row of the display and the value of the port II on the

lower row of the display. Difference of the readings is shown in

the lowest row.

5. Take off the CAL.DIS jumper from the motherboard of the

HMT300 transmitter. Now MI70 is moved into Adjustment

mode.

6. Press OK to start adjustment.

7. Select

8. Check the environment settings, if needed. Otherwise press

RH or T, press SELECT.

NO.

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

Field Checking and Adjustment by Using a Calibrated Reference Probe

Follow the steps from 1 to 8 and continue as follows:

9. Check that the probes are located in equal conditions and wait until

the readings are stabilized (can take 30 minutes or more). If you

are near the probes, do not breathe in their direction.

10. Press ADJUST to continue adjusting.

11. Press

12. Confirm by pressing

13. Adjustment is done. Press BACK and EXIT to return to the

14. Replace the CAL.DIS jumper.

15. Switch off the MI70 and detach the calibration cable from MI70

To same asRH

port to which the HMP70-series probe is connected).

basic display.

and from the transmitter.

., press SELECT. (MI70 recognizes always the

Ii/I

YES.

1-Point Adjustment by Using a Calibrator

When adjusting a transmitter only in one reference condition, please

take care that the reference condition represents well the measuring

environment.

If you use humidity calibrator HMK15, please use the adapter fitting

(13.5 mm) on the measurement hole if you calibrate probes of

HMT324, HMT325, HMT327 and HMT328.

Follow the steps from 1 to 8 and continue as follows:

9. Remove the filter from the transmitter's probe and insert the

probe into the reference condition.

10. Press ADJUST to continue adjusting.

11. Select 1-point adjustment, press SELECT.

12. Press READY when the reading is stabilized in the reference

condition (takes about 30 minutes or more). You can follow the

stabilization from the GRAPH display.

50 __________________________________________________________________ M210297EN-E

Page 53

Chapter 9 ______________________________________ Calibration and Adjustment of Transmitters

13. Enter correct reference value by using the arrow buttons. Press

OK.

14. Confirm by pressing YES.

15. Adjustment is done. Press BACK and EXIT to return to the

basic display.

16. Replace the jumper to CAL.RH pins.

17. Switch off HM70 and detach the calibration cable from MI70

and from the transmitter.

2-Point Adjustment by Using a Calibrator

Note that the difference between the two reference humidities shall be

at least 50 %. MI70 indicator is used now as a communicator. HMP70

probe can be connected or it can be removed while making this

adjustment.

If you use humidity calibrator HMK15, please use the adapter fitting

(13.5 mm) on the measurement hole if you calibrate probes of

HMT324, HMT325, HMT327 and HMT328.

Follow the steps from 1 to 8 and continue as follows:

9. Remove the filter from the transmitter's probe and insert the

probe into lower reference humidity.

10. Press ADJUST to continue adjusting.

11. Select

12. Press

reference condition (takes about 30 minutes or more)

13. Enter correct reference value by using the arrow buttons. Press

14. Remove the probe and insert the probe into higher reference

humidity. You can follow the stabilization from the GRAPH

display (takes about 30 minutes or more).

15. Press READY when the reading is stabilized in the second

reference condition.

2-point adjustment, press SELECT.

READY when the reading is stabilized in the first

.

OK.

16. Give the higher reference humidity value by using the arrow

buttons. Press OK.

17. Confirm the adjustment, press

return to adjustment mode display and no changes are made). If

VAISALA_______________________________________________________________________ 51

YES (by pressing NO you

Page 54

User's Guide ______________________________________________________________________

the difference between two references is less than 50 %,

adjustment can not be done.

18. Adjustment is done. Press BACK to exit the adjustment mode

press EXIT to return to the basic display.

19. Replace the jumper to CAL.RH pins.