Page 1

USER'S GUIDE

Vaisala CARBOCAP®

Carbon Dioxide Probe

GMP343

M210514EN-C

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2007

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Safety Considerations . . . . . . . . . . . . . . . . . . . . .10

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Introduction to GMP343 . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

GMP343 Transmitter Components . . . . . . . . . . . . . . . . . . .14

User Configurable CO2 Measurement . . . . . . . . . . . . . . . .15

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Optics Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Gas Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Diffusion Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Flow-Through Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Sampling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Soil Adapter Kits for In-Soil Applications . . . . . . . . . . . . . .19

MI70 Indicator Connection . . . . . . . . . . . . . . . . . . . . . . . . .19

Recharging the Battery Pack. . . . . . . . . . . . . . . . . . . . 19

Structure of the MI70 Indicator . . . . . . . . . . . . . . . . . . 20

Using MI70 as a Display . . . . . . . . . . . . . . . . . . . . . . . 21

Introduction of Function Keys and Menu Structure. 21

Initialization of MI70 . . . . . . . . . . . . . . . . . . . . . . . . 21

Navigation in Menu. . . . . . . . . . . . . . . . . . . . . . . . . 22

Using MI70 in Recording . . . . . . . . . . . . . . . . . . . . . . . 23

Transferring Recorded Data to PC . . . . . . . . . . . . . . . 23

CHAPTER 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Wiring of the Junction Box . . . . . . . . . . . . . . . . . . . . . . . . .27

VAISALA________________________________________________________________________ 1

Page 4

________________________________________________________________________________

CHAPTER 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Connecting GMP343 to PC . . . . . . . . . . . . . . . . . . . . . . . . . .29

Connection Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Installing the Driver for the USB Cable . . . . . . . . . . . . 29

Opening a Terminal Connection . . . . . . . . . . . . . . . . . . . .30

Operation modes of the GMP343 . . . . . . . . . . . . . . . . . . . . .32

Getting the Measurement Message . . . . . . . . . . . . . . . . . . .33

Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Starting the Continuous Outputting . . . . . . . . . . . . . . . . . .33

Stopping the Continuous Outputting . . . . . . . . . . . . . . . . .33

Setting the Continuous Outputting Interval . . . . . . . . . . . .34

Outputting the Reading Once . . . . . . . . . . . . . . . . . . . . . . .34

Setting the Serial Interface Measurement Mode . . . . . . . .35

Setting Communication Hardware . . . . . . . . . . . . . . . . . . .35

Serial Communication Settings . . . . . . . . . . . . . . . . . . . . .36

Formatting the Measurement Message . . . . . . . . . . . . . . . .36

Formatting the Message . . . . . . . . . . . . . . . . . . . . . . . . . .36

Setting Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Networking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting the Transmitter Address . . . . . . . . . . . . . . . . . . . . .39

Open and Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting Echoing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Preparation for Network Operation . . . . . . . . . . . . . . . . . .40

Commands during Network Operation . . . . . . . . . . . . . . . .41

Measurement Range, Data Filtering and Linearization . . .41

Setting the Measurement Range . . . . . . . . . . . . . . . . . . . .41

Measurement Data Filtering . . . . . . . . . . . . . . . . . . . . . . . .42

Median Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Averaging Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Smoothing Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

How the Filtering Affects the Response Time . . . . . . . 44

Setting the Median Filter . . . . . . . . . . . . . . . . . . . . . . . . . .45

Setting the Averaging Filter . . . . . . . . . . . . . . . . . . . . . . . .45

Setting the Smoothing Filter . . . . . . . . . . . . . . . . . . . . . . . .45

Flushing the Filters (Resynchronization) . . . . . . . . . . . . . .46

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Setting the Linearization ON/OFF . . . . . . . . . . . . . . . . . . .46

Temperature, Pressure, Relative Humidity, and Oxygen

Compensations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Temperature Compensation ON/O FF . . . . . . . . . . . . . . . .48

Setting the Oxygen Concentration . . . . . . . . . . . . . . . . . . .49

Setting Oxygen When the Device Is in POLL-mode . . 49

Oxygen Compensation Mode . . . . . . . . . . . . . . . . . . . . . . .49

Setting the Ambient Pressure (hPa) . . . . . . . . . . . . . . . . . .50

Setting Pressure When the Device Is in POLL-mode . 50

Pressure Compensation ON/OFF . . . . . . . . . . . . . . . . . . .51

Setting Ambient Relative Humidity . . . . . . . . . . . . . . . . . . .51

Setting Humidity When the Device Is in POLL-mode. . 51

Relative Humidity Compensation ON/OFF . . . . . . . . . . . .52

2 _______________________________________________________________________________

Page 5

________________________________________________________________________________

Setting and Testing the Analog Outputs . . . . . . . . . . . . . .52

Analog Output Hardware . . . . . . . . . . . . . . . . . . . . . . . . . .53

Setting the Limit of the Current Output Range . . . . . . . . . .53

Setting the High Limit of the Voltage Output Range . . . . .54

Setting the High Limit of the Concentration Range . . . . . .54

Setting the Low Limit of the Concentration Range . . . . . . .55

Setting the Analog Output Overrange Clip . . . . . . . . . . . . .55

Testing the Analog Output . . . . . . . . . . . . . . . . . . . . . . . . .56

Setting the Analog Output Error Level . . . . . . . . . . . . . . . .56

Device Information and Other General Commands . . . . . .57

Device Information List . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Show the Output Quantities . . . . . . . . . . . . . . . . . . . . . . . .57

Linear and Multipoint Corrections . . . . . . . . . . . . . . . . . . .58

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Showing the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . .59

Software Version Information . . . . . . . . . . . . . . . . . . . . . . .60

Memory Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Reverting the Factory Parameters . . . . . . . . . . . . . . . . . . .60

Saving the Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Setting the Optics Heating ON/OFF . . . . . . . . . . . . . . . . . . .61

Resetting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . .61

CHAPTER 5

CALIBRATION AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Calibration Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Factory Calibration and Adjustment . . . . . . . . . . . . . . . . . .64

Calibration and Adjustment by the User . . . . . . . . . . . . . . .64

Calibration (Checking) . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Checking the Compensations . . . . . . . . . . . . . . . . . . . 64

Measurements in Reference Gases . . . . . . . . . . . . . . 65

Adjustment in 1...2 Points . . . . . . . . . . . . . . . . . . . . . . . . .66

Adjustment in 3...8 Points . . . . . . . . . . . . . . . . . . . . . . . . .67

Example of the 2-Point Adjustment Procedure . . . . . . 67

CHAPTER 6

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Cleaning the Optics (Diffusion Model Only) . . . . . . . . . . . .71

Changing the Filter (Diffusion Model Only) . . . . . . . . . . . .73

Error States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Return Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Vaisala Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

VAISALA________________________________________________________________________ 3

Page 6

________________________________________________________________________________

CHAPTER 7

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Effects of Temperature, Pressure, Relative Humidity,

and Oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Response time (90 %) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . .82

APPENDIX A

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

GMP343 (Flow-through) . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

GMP343 (Diffusion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Calibration Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Mounting Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

APPENDIX B

LIST OF COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Filtering Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

P, T and RH Compensation Commands . . . . . . . . . . . . . . .92

Device Handling Commands . . . . . . . . . . . . . . . . . . . . . . . .92

Device Information Display Commands . . . . . . . . . . . . . . .92

Calibration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Setting and Testing the Analog Outputs . . . . . . . . . . . . . . .93

Advanced Measurement Commands . . . . . . . . . . . . . . . . .93

4 _______________________________________________________________________________

Page 7

________________________________________________________________________________

List of Figures

Figure 1 Two Models of GMP343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 2 Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 3 Components of the Sampling System . . . . . . . . . . . . . . . . . . .18

Figure 4 Examples of Optional Accessories. . . . . . . . . . . . . . . . . . . . . .18

Figure 5 Structure of the MI70 Indicator. . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 6 Keyboard of MI70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 7 Mounting GMP343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 8 Entering Measurement Values. . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 9 The Difference of the Two Filters in Time Response. . . . . . . .44

Figure 10 Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 11 GMP343 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . .81

VAISALA________________________________________________________________________ 5

Page 8

________________________________________________________________________________

6 _______________________________________________________________________________

Page 9

________________________________________________________________________________

List of Tables

Table 1 Manual Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Table 2 Wiring Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Table 3 Communication Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 4 Quantities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 5 Modifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 6 Averaging Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table 7 Troubleshooting Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Table 8 Effect of Temperature on Accuracy with Temperature

Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 9 Effect of Pressure on Accuracy with Pressure Compensation. . .79

Table 10 Diffusion Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 11 Flow-through Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 12 List of Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . .82

VAISALA________________________________________________________________________ 7

Page 10

________________________________________________________________________________

8 _______________________________________________________________________________

Page 11

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the product.

About This Manual

This manual provides information for installing, operating, and

maintaining the Vaisala CARBOCAP® Carbon Dioxide Probe

GMP343.

Version Information

Table 1 Manual Revisions

Manual Code Description

M210514EN-A October 2003 - First version.

M210514EN-B April 2005

M210514EN-C August 2007 - New probe housing

and software.

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

WARNING

CAUTION

NOTE

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.To

make sure you are not delivering high static voltages yourself handle

ESD sensitive components on a properly grounded and protected ESD

workbench. When this is not possible, ground yourself to the equipment

chassis before touching the connections. Ground yourself with a wrist

strap and a resistive connection cord. When neither of the above is

possible, touch a conductive part of the equipment chassis with your

other hand before touching the boards.

10 __________________________________________________________________ M210514EN-C

Page 13

Chapter 1 ________________________________________________________ General Information

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be free

from defects in workmanship or material during a

period of twelve (12) months from the date of delivery

save for products for which a special warranty is given.

If any Product proves however to be defective in

workmanship or material within the period herein

provided Vaisala undertakes to the exclusion of any

other remedy to repair or at its own option replace the

defective Product or part thereof free of charge and

otherwise on the same conditions as for the original

Product or part without extension to original warranty

time. Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to products

sold by it. In case the repair or service works should

appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the

service was performed Vaisala shall at its free option

either repair or have repaired or replace the product in

question. The working hours used by employees of

Vaisala for such repair or replacement shall be free of

charge to the client. This service warranty shall be

valid for a period of six (6) months from the date the

service measures were completed.

This warranty does not however apply when the defect

has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to se rv ice

the Product or otherwise follow Vaisala's service

instructions including any repairs or installation or

assembly or service made by unauthorized personnel

not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as

any adding to it without Vaisala's prior authorization;

e) other factors depending on the Customer or a third

party.

Notwithstanding the aforesaid Vaisala's liability under

this clause shall not apply to any defects arising out of

materials, designs or instructions provided by the

Customer.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala within

thirty (30) days after the defect or fault became known

or occurred, and

b) The allegedly defective Product or part shall, should

Vaisala so require, be sent to the works of Vaisala or to

such other place as Vaisala may indicate in writing,

freight and insurance prepaid and properly packed and

labelled, unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express or

implied, whether under law, statute or otherwise,

including without limitation any implied warranties of

merchantability or fitness for a particular purpose and

all other obligations and liabilities of Vaisala or its

representatives with respect to any defect or deficiency

applicable to or resulting directly or indirectly from the

Products supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and waived.

Vaisala's liability shall under no circumstances exceed

the invoice price of any Product for which a warranty

claim is made, nor shall Vaisala in any circumstances

be liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

12 __________________________________________________________________ M210514EN-C

Page 15

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features of the GMP343.

Introduction to GMP343

Vaisala CARBOCAP® Carbon Dioxide Probe GMP343 is designed for

high accuracy CO2 measurements. The measurement is based on the

advanced CARBOCAP® Single-Beam Dual-Wavelength NDIR

technology. GMP343 consists of a CO2 sensor, electronics, and a

housing suitable for long-term outdoor use.There are two GMP343

models available: a flow-through model and a diffusion model. One

adjustable analog output can be configured to output voltage or current

signal (0 ... 2.5 V, 0 ... 5 V, 4 ... 20 mA). A digital output for RS232/

RS485 communication is available. The measuring range options vary

from 0 ... 1000 ppm to 0 ... 2 %CO2.

The GMP343 can be ordered with various adapter, filter, and

connection cable options. For a list of spare parts and accessories, see

section Spare Parts and Accessories on page 82.

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

GMP343 Transmitter Components

NOTE

Figure 1 Two Models of GMP343

The following numbers refer to Figure 1 above.

1=Filter

2 = Wiring connector

3=Gas in

4 = Gas out

5 = Back flange (do not open)

Warranty is void if the back flange of the GMP343 has been opened

by the user.

14 __________________________________________________________________ M210514EN-C

Page 17

Chapter 2 __________________________________________________________ Product Overview

User Configurable CO2 Measurement

The measurement output of the GMP343 is user configurable. You may

have the raw data without filtering or compensation, or you may set the

filtering levels, enable compensation (pressure, temperature, relative

humidity, and oxygen) and linearization.

You can also select the measurement range to optimize the performance

of the GMP343 for a certain concentration level. Selecting an

appropriate measurement range increases accuracy, since it enables the

range-specific compensation and linearization settings. For more

information, see sections Setting the Measurement Range on page 41

and Temperature, Pressure, Relative Humidity, and Oxygen

Compensations on page 47.

Principle of Operation

The infra-red sensor of GMP343 is based on the proprietary Vaisala

CARBOCAP® sensing technology. Here the pulsed light from a

miniature filament lamp is reflected and re-focused back to an IR

detector which is behind a silicon-based Fabry-Perot Interferometer

(FPI). This tiny FPI is tuned electrically so that its measurement

wavelength is changed between the absorption band of the CO2 gas and

a reference band.

Figure 2 Principle of Operation

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

When the passband of the FPI coincides with the absorption wavelength

of the CO2 gas, the IR detector sees a decrease in the light transmission.

The measurement wavelength of the FPI is then changed to the

reference band (that has no absorption lines) and the IR detector sees a

full light transmission. The ratio of these two signals indicates the

degree of light absorption in the gas and is proportional to the gas

concentration. It takes 2 seconds to measure this sequence and to

calculate one reading.

Use of numerical filtering reduces the noise of the raw data. On the

other hand, the filtering increases the response time of the device (see

Figure 9 on page 44).

Optics Heating

Two heating elements are placed in the optics; one behind the mirror

and one behind the window of the sensor. Heating should always be

turned on when there is a risk of dew formation on the optics surface.

The heating maintains the surface temperature of the optics a few

degrees above the ambient temperature.

The heating is disabled by default. For instructions on how to control

the optics heating, refer to section Setting the Optics Heating ON/OFF

on page 61.

NOTE

The optics heating is automatically disabled when you connect the

GMP343 to a MI70 indicator.

Gas Sampling

There are two GMP343 models available: a flow-through model and a

diffusion model.

Diffusion Sampling

No sampling system is needed with the GMP343 diffusion model. The

diffusion filter and the plastic filter cover protect the measuring

chamber from dirt, water, and contaminants.

16 __________________________________________________________________ M210514EN-C

Page 19

Chapter 2 __________________________________________________________ Product Overview

In order to have a quick measurement with very short response time the

filter can be removed; see section Response time (90 %) on page 80. In

this case the optics are openly exposed to contamination and cleaning

of optics may be necessary more often. For instructions on cleaning the

optics, refer to section Cleaning the Optics (Diffusion Model Only) on

page 71. Removal of the filter is not recommended if there is a risk of

getting water or dirt particles on the optics.

Flow-Through Sampling

The maximum gas flow rate is 10 liters/min. When using high flow

rates, please note how the flow rate affects the accuracy, see

Specifications, Oxygen, on page 79 (flow dependence). The volume of

the internal measurement chamber is 59 ml ± 1 ml.

The gas sample must not include acidic gases.

CAUTION

Liquids or acidic vapors may seriously damage the sensor.

Sampling System

The GMP343 flow-through model has no diffusion filter inside the

measuring chamber and the optics of the flow-through model cannot be

cleaned by the user. Therefore the sample gas must always be filtered

and dried before it is pumped to the measuring chamber. A hydrophobic

diffusion filter before the inlet of the measuring chamber is needed in

order to prevent particles and water from the surroundings from getting

into the sensor. The diffusion filter needs to be exchanged often enough

to provide a sufficient flow.

In humid environments it is important to avoid water condensation

inside the measuring chamber. This can be avoided by drying the

sample air. The most common method of drying the sample air is

cooling and re-heating the air. A simple system may consist for example

of a cooling coil and a water trap which are either cooled or located in

a cool environment, followed by a re-heating system. The idea is to get

the moisture in the sample to condensate on the walls of the copper tube,

trap this water and then lower the relative humidity by heating the

sample. If the temperature inside the measurement chamber is

essentially higher than the surroundings the cooling coil and the water

trap can be simply located outside the chamber. For re-heating, the heat

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

generated by a pumping system may sometimes be adequate, meaning

that no additional heater is needed. A simplified schema of a sample

system removing particles and moisture is illustrated below.

All sampling system components are commercially available.

Figure 3 Components of the Sampling System

Optional Accessories

Various adapter and filter options are available for the GMP343. For a

complete list, see section Spare Parts and Accessories on page 82.

Figure 4 Examples of Optional Accessories

18 __________________________________________________________________ M210514EN-C

Page 21

Chapter 2 __________________________________________________________ Product Overview

Soil Adapter Kits for In-Soil

Applications

The vertical/horizontal soil adapter kit consists of a soil adapter and a

hydrophobic sintered PTFE filter. The kits are designed for in-soil CO2

measurements to be used with the diffusion model of GMP343.

MI70 Indicator Connection

Vaisala MI70 indicator is an optional accessory to be used as a display,

communication, and data-logging device for GMP343. When taking

measurements GMP343 is powered via MI70.

Recharging the Battery Pack

MI70 indicator is equipped with a rechargable battery pack when

shipped from factory. The battery pack is located behind the back plate

of the indicator. The recharger is provided with one of the following

AC-adapters: Euro, UK, US or AUS.

1. Recharge the battery pack as follows: Plug in the recharger

connector into the connector on top of the indicator and connect the

recharger to a wall socket. A battery symbol in the corner of the

display starts to roll.

- It is not recommended to use MI70 during the first recharging.

Later on MI70 can be used while recharging.

- Duration of recharging depends on the charge level of the

battery pack being 4 hours typical. The recommended first

recharging time is 6 hours.

2. The battery pack is full when the battery symbol in the display

stops rolling.

3. Disconnect the recharger.

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

Structure of the MI70 Indicator

Figure 5 Structure of the MI70 Indicator

The following numbers refer to Figure 4 above:

1 = Recharging connector

2 = Power On/Off key

3 = Connection cable (DRW216050SP) for GMP343 connection

20 __________________________________________________________________ M210514EN-C

Page 23

Chapter 2 __________________________________________________________ Product Overview

Using MI70 as a Display

Introduction of Function Keys and Menu Structure

NOTE

0704-034

Figure 6 Keyboard of MI70

The following numbers refer to Keyboard of MI70 on page 21:

1 = Function keys left/middle/right (can be assigned to shortcuts)

2 = Arrow keys up/down/left/right

3 = Power on/off key

Initialization of MI70

The optics heating is automatically disabled when you connect the

GMP343 to the MI70 indicator.

1. Install the connection cable between MI70 and GMP343 (GMP343

is powered from MI70).

2. Turn on MI70 by pressing the Power On/Off key.

3. Select the language by using the up/down arrow keys. Confirm by

pressing the SELECT key.

4. To change the date, select Date and press the SET key. Set the date

by using the up/down/left/right arrow keys. To confirm the date,

press the OK key.

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

5. To change the time, select Time and press the SET key. Set the

time by using the up/down/left/right arrow keys. To confirm the

time, press the OK key.

6. To check and change the environment settings, select YES. Enter

ambient pressure, humidity, and oxygen values. Press the EXIT

key.

Navigation in Menu

- To turn the indicator on or off, press the Power On/Off key.

- To open the main menu, press any of the arrow keys and then the

middlemost function key in sequence.

- To move in a menu and select an option, press the up/down arrow

keys. To enter sub-menu of selected option, press the right arrow

key. To return to the previous menu level, press the left arrow key.

- To activate a function: press a function key according to the

guiding text below the key.

- To return to the basic display directly from any menu levels, press

the function key EXIT.

The main settings are found in the following menu locations:

- To change language, enter: Settings - User interface - Language.

- To select display quantities (carbon dioxide and temperature),

enter: Display - Quantities and units. The carbon dioxide

concentration is shown in ppm or in %-units and temperature in

°C or °F.

- To set the ambient conditions enter Environment menu. Options

to choose from: 1013 hPa, 50 % RH, and 20.9 % O2.

22 __________________________________________________________________ M210514EN-C

Page 25

Chapter 2 __________________________________________________________ Product Overview

Using MI70 in Recording

Record continuous measurement data and view the recorded data by

using the MI70. This function is found from the menu RECORDING/

VIEWING.

You can switch MI70 off during recording to save battery power.

Display message tells you that recording continues undisturbed even

when the power is off. If the indicator is switched off during recording,

the progress bar is shown on the display every 10 seconds (all the time,

if the charger is connected). This bar shows the amount of recorded

data.

Save individual measurement data points with Hold/Save function

(DISPLAY-HOLD/SAVE DISPLAY) and view the saved data from

the RECORDING/VIEWING menu.

CAUTION

Do not disconnect the probe when the data recording is on, even if the

indicator is off. This may cause loss of recorded data.

Transferring Recorded Data to PC

The recorded data can be transferred to a PC by using MI70 Link

program. MI70 Link program can be ordered from Vaisala, see Table

12, List of Spare Parts and Accessories, on page 82. You can examine

the recorded data easily in Windows and transfer it further to a

®

spreadsheet program (such as Microsoft

More information on the data transfer and software features is found in

the HELP-file of MI70 Link program.

Excel) for modification.

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

24 __________________________________________________________________ M210514EN-C

Page 27

Chapter 3 _______________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install this product.

Mounting

A horizontal mounting position is recommended in order to minimize

the problems caused by possible condensation.

0704-020

Figure 7 Mounting GMP343

1. Fasten the GMP343 to the mounting bracket by using the screw

provided.

2. Mount the mounting bracket with 4 screws (on corners of the

plate).

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

Wiring

As it is shipped from the factory, the measurement range and output of

the GMP343 are scaled according to the order form completed by the

customer. The unit is calibrated at the factory. The device is ready for

use when the wiring is done and power is switched on.

GMP343 can be connected to a PC using an optional PC connection

cable, see Table 12, List of Spare Parts and Accessories, on page 82.

For more information on serial commands, see Chapter 4, Operation, on

page 29.

WARNING

Make sure that the main power is switched off before making any

electrical connections.

Table 2 Wiring Pins

Pin Wire Serial signal (RS232 or 2-

Wire RS485 interface)

1 White RS232C: TX RS485: A(+) 2 Brown RS232C: TX RS485: A(+) 3 Green RS232C: RX RS485: B(-) 4 Yellow - - Signal +

5 Grey Supply GND Supply GND Supply GND

6 Pink +11...36 V DC +11...36 V DC +11...3 6 V DC

7 Blue RS232C: RX RS485: B(-) 8 Shield - - Signal GND

Analog signal

26 __________________________________________________________________ M210514EN-C

Page 29

Chapter 3 _______________________________________________________________ Installation

There are two pins per signal internally hardwired in parallel (pins 1 and

2, pins 3 and 7). You should connect the RS232C signal 'TX' (or 2-Wire

RS485 signal 'A') either to the pin 1 or 2 and the RS232C signal 'RX' (or

2-Wire RS485 signal 'B') either to the pin 3 or 7.

Note that there is either an RS232 or a 2-wire RS485 communication

interface available according to initial configuration. However, if the

device is configured in RS485 output mode, the device can still be

switched into RS232 mode by re-configuration via PC . For more

information on serial commands and RS232/485 modes, see Chapter 4,

Operation, on page 29.

Wiring of the Junction Box

The optional 8-pole junction box enables practical in-line connection.

The box is provided with 8 numbered terminals.

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

28 __________________________________________________________________ M210514EN-C

Page 31

Chapter 4 ________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate the

GMP343.

Connecting GMP343 to PC

Connection Cables

To connect the GMP343 to a PC, you need the PC Connection Cable

(optional accessory 213379). If your PC does not have a serial port, you

also need the USB-D9 Serial Connection Cable (optional accessory

219686). By connecting the two cables, you can use a standard type A

USB port to connect the GMP343 to a PC.

Both cables are included in the PC Connection Kit that can be ordered

with the GMP343.

Installing the Driver for the USB Cable

Before taking the USB cable into use, you must install the provided

USB driver on your PC. When installing the driver, you must

acknowledge any security prompts that may appear. The driver is

compatible with Windows 2000, Windows XP, Windows Server 2003,

and Windows Vista.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

1. Check that the USB cable is not connected. Disconnect the cable if

you have already connected it.

2. Insert the media that came with the cable, or download the driver

from www.vaisala.com.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

4. After the driver has been installed, connect the USB cable to a USB

port on your PC. Windows will detect the new device, and use the

driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu. The reserved ports are also visible in the

Ports section of the Windows Device Manager.

Remember to use the correct port in the settings of your terminal

program. Windows will recognize each individual cable as a different

device, and reserve a new COM port.

There is no reason to uninstall the driver for normal use. However, if

you wish to remove the driver files and all Vaisala USB cable devices,

you can do so by uninstalling the entry for Vaisala USB Instrument

Driver from the Add or Remove Programs (Programs and Features

in Windows Vista) in the Windows Control Panel.

Opening a Terminal Connection

The communication interface of GMP343 is RS-232 or RS-485. In case

your device is configured to RS-485 communication mode you can still

start communication in RS-232 mode (for example when changing the

probe setting). See step number 4 in the following instructions.

1. Connect the GMP343 to the PC using the connection cable(s).

Refer to section Connection Cables on page 29.

2. Connect the power cables to a 11 ... 36 V power supply.

30 __________________________________________________________________ M210514EN-C

Page 33

Chapter 4 ________________________________________________________________ Operation

3. Open a terminal program and set the communication parameters.

When using the terminal session for the first time, save the settings

for future use.

Table 3 Communication Parameters

Parameter Value

baud rate 19200

parity no

data bits 8

stop bits 1

flow control none

4. Power-up the GMP343. The device should prompt as follows:

GMP343 - Version STD 2.0

Copyright: Vaisala Oyj 2003 - 2006

5. If your device is configured to RS-485 communication mode,

switch the device into the service mode by sending a string

containing at least 6 capital 'Z' while powering up. The most

convenient way using PC is:

Press and keep pressing SHIFT + 'z' while powering up GMP343.

Keep pressing SHIFT + 'z' until GMP343 starts up in the service

mode. The device should prompt as follows:

COMM PARAMETERS IN EEPROM:

SMODE : STOP

BAUD RATE: 19200

DATA BITS: 8

PARITY: NONE

STOP BITS: 1

ADDR: 0

HARDWARE CONFIGURATION:

COMM CHANNEL: RS485

ANALOG OUTPUT: VOLTAGE

GMP343 - VERSION STD 2.0

COPYRIGHT: VAISALA OYJ 2003 -2006

>ZZZZZZZZZZZ

6. Key in the commands with the keyboard of your computer and

press enter. In this guide <cr> stands for pressing ENTER .

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

NOTE

Responses from the GMP343 are terminated by the following string:

[cr][lf]>

That is a carriage return character, a line feed, and a right angle

bracket.

Operation modes of the GMP343

The GMP343 can operate in three different modes:

- RUN mode

- STOP mode

- POLL mode

In the RUN mode, the GMP343 sends measurement results at regular

intervals. The included parameters and the interval can be set by the

user. While in the RUN mode, the device will not answer any other

command except the S command, which stops the RUN mode and

switches the device to STOP mode.

The STOP mode is the default mode of operation for the GMP343,

where most of the commands listed in this document are available. You

can enter the STOP mode from the RUN mode with the S command, or

from the POLL mode with the OPEN <addr> command, where <addr>

is the unique address of the GMP343. While in the STOP mode, the

GMP343 will respond to all unknown commands with the following

string:

Unknown command.[cr][lf]>

The POLL mode is dedicated for bus interfacing. To work in the poll

mode, each device must have its own unique address. You can enter the

POLL mode by giving the CLOSE command in the STOP mode.

Only a single device can be accessed at a time in the POLL mode. In the

POLL mode, you can request a single measumement message from the

GMP343 using the SEND <addr> command. While in the POLL

mode, the GMP343 will ignore all unknown commands.

32 __________________________________________________________________ M210514EN-C

Page 35

Chapter 4 ________________________________________________________________ Operation

Getting the Measurement Message

Measurement Units

GMP343 outputs the following units:

- Carbon dioxide (ppm)

- Temperature (ºC)

For other measurement units (%, non-metric units), use the Vaisala

MI70 indicator.

NOTE

Measurement units (ppm and %) express the CO2 concentration by gas

volume.1 % CO

= 10 000 ppm CO

2

2

Starting the Continuous Outputting

R <cr>

This command starts the continuous outputting of results (output form

defined with the command FORM). Data is printed with the interval

defined with the command INTV. Printing can be stopped with the

command S.

>r 345.0 ppm

344.1 ppm

343.6 ppm

345.6 ppm

346.1 ppm

344.1 ppm

343.5 ppm

345.5 ppm

>

Stopping the Continuous Outputting

S <cr>

Ends the RUN mode; after this command all other commands can be

used.

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Setting the Continuous Outputting Interval

INTV xxxx yyy <cr>

SAVE <cr>

xxxx=output interval (1...1000) default=1 s

yyy=unit (s, min or h)

Example: Output interval is changed to 5 seconds

>intv 5 s

INTERVAL : 5

UNIT : S

>

Outputting the Reading Once

In STOP mode:

SEND <cr>

In POLL mode:

SEND aa <cr>

aa=address of the transmitter when more than one transmitter is

connected to a serial bus (0...99).

The output mode can be changed with the command FORM.

>send

348.7 ppm

>

34 __________________________________________________________________ M210514EN-C

Page 37

Chapter 4 ________________________________________________________________ Operation

Setting the Serial Interface Measurement Mode

SMODE xxxx <cr>

SAVE <cr>

xxxx= STOP/RUN/POLL

In STOP mode: Measurements output only by command, all commands

can be used (default mode).

In RUN mode: Outputting automatically, only command S can be used.

In POLL mode: Measurements output only with command SEND. For

more details on POLL mode, see section, Networking Operation, on

page 39.

The settings are not valid until the device is reset.

Setting Communication Hardware

Communication hardware can be chosen between RS-232 or RS-485.

Command parameters are correspondingly 232 and 485.

RSMODE <cr>

SAVE <cr>

The setting is not valid until the device is reset.

>rs mode

RSMODE : 232? 485

>save

EEPROM saved successfully.

>

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

Serial Communication Settings

Save the changed settings by entering the SAVE command. The

settings are not valid until the device is reset.

SERI <cr>

SAVE <cr>

Baud rate: (300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200)

Note: When baud rate is > 19200 the character spacing must be > 1 ms.

If the character spacing is not in use the device may lose some

characters.

Data bits: (7/8)

Parity: (none, even, odd)

Stop bits: (1/2)

Key in the settings after the question mark and press ENTER.

>seri

BAUD RATE : 19200 ? 19200

DATA BITS : 8 ? 8

PARITY : NONE ? none

STOP BITS : 1 ? 1

>save

EEPROM saved successfully.

>

Formatting the Measurement Message

Formatting the Message

This command is used to change the serial output format of the

commands SEND and R.

FORM x <cr>

SAVE <cr>

36 __________________________________________________________________ M210514EN-C

Page 39

Chapter 4 ________________________________________________________________ Operation

x= format string

Format string consists of quantities and modifiers. You can select one

or more of the following quantities by keying in the abbreviation after

FORM command:

Table 4 Quantities

Abbreviations Quantities

CO2 Filtered CO

CO2RAW Unfiltered CO

CO2RAWUC Unfiltered CO

and corrections (MPC/LC) do not apply.

TIME Time passed from last reset

ADDR Transmitter address

ERR Error flag (0=no error/1=error) in POLL or RUN modes.

T Measured temperature

P User-set pressure value

RH User-set relative humidity value

O User-set oxygen value

results. Factory setting.

2

results.

2

results. Compensations (P/T/RH/O2)

2

Table 5 Modifiers

Abbreviations Explations

x.y length modifier (whole numbers and decimal places)

#t tabulator

#r carriage-return

#n line feed

"" string constant

U5 unit field and length

Example 1:

>form CO2 " " "ppm" #r#n

>save

EEPROM saved successfully.

>send

336.3 ppm

Example 2:

>form "Filtered data" CO2 "ppm" #r#n

>save

EEPROM saved successfully

>

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

>send

Filtered data 336.9ppm

>

Example 3 (both filtered and raw data chosen):

>form CO2 "ppm" " " CO2RAWUC "ppm" #r#n

>send

296.5ppm 270.1ppm

Setting Time

TIME x <cr>

SAVE <cr>

x=hh:mm:ss

NOTE

Time passed since the last power on was displayed. Time always resets

to 00:00:00 when power is switched off. However, the user can set the

time.

Example (time inquiry):

>time

04:00:52

>

Example (time setting):

>time 12:15:00

12:15:00

>time

12:15:02

>

>save

EEPROM saved successfully.

>

Only approximately 1 % accuracy is obtained with the software clock.

38 __________________________________________________________________ M210514EN-C

Page 41

Chapter 4 ________________________________________________________________ Operation

Networking Operation

When several transmitters are connected to the same RS485 bus it is

recommended to use separate power supplies for each transmitter.

Make sure that the devices are grounded to the same potential.

Otherwise harmful ground currents may be generated or RS-485

common-mode limits may be exceeded.

For long RS485 bus lengths a proper termination should be provided.

Setting the Transmitter Address

ADDR aa <cr>

SAVE <cr>

aa=address (0...99)

Example (changing address from 0 to 1):

>addr

ADDR : 0 ? 1

>

>save

EEPROM saved successfully.

>

Open and Close

OPEN nn <cr>

nn=address of the transmitter (0...99)

The OPEN command sets the bus temporarily in STOP mode so that the

SMODE command can be entered.

CLOSE <cr>

In STOP mode: Command OPEN has no effect, CLOSE sets the

transmitter temporarily in POLL mode.

In POLL mode: Command OPEN sets the transmitter temporarily in

STOP mode.

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

Example:

>close

line closed

GMP343: 1 line opened for operator commands

>send

351.1 ppm

>smode stop

SMODE : STOP

>

Setting Echoing Mode

ECHO x <cr>

SAVE <cr>

x=ON/OFF (default ON)

In RS232 mode the device echoes everything back to the user. In RS485

mode echoing is automatically disabled.

Preparation for Network Operation

Before GMP343 is connected to the network it must be configured.

Normal procedure is shown below:

First connect the device to PC by using RS-232 and when

communication is currently open, key in the following commands:

RSMODE 485

ADDR addr

(where addr is 1...99)

SMODE POLL

SAVE

Next turn the power off. Then you can connect the device to RS-485

network.

40 __________________________________________________________________ M210514EN-C

Page 43

Chapter 4 ________________________________________________________________ Operation

Commands during Network Operation

When GMP343 is connected to the network, the following commands

can be entered:

SEND addr Return latest CO2 value

XP addr pressure Set pressure for compensation

XO addr oxygen Set oxygen for compensation

XRH addr

humidity

OPEN addr Open device for normal communication (i.e. to

CLOSE Switch the device from STOP-mode to POLL-

Compensation values that are entered with compensation commands

(XP, XO, XRH) are used for compensation but they are not stored

permanently. Note that compensation commands do not give any reply.

If value in command is not acceptable, the command is rejected.

Set humidity for compensation

STOP-mode)

mode.

Measurement Range, Data Filtering and Linearization

Setting the Measurement Range

The measurement range of the GMP343 has been set at factory

according to the order form. However, you can change the measurement

range to optimize measurement performance for a certain concentration

level.

To achieve the most accurate 'ppm CO

measurement should be compensated for T, P, %RH, and O2

concentration in the environment. The compensation settings are

specific to the selected measurement range, so selecting a suitable

measurement range optimizes the compensation performance. Each

range also has its own linearization function; see section Linearization

on page 46.

VAISALA_______________________________________________________________________ 41

' measurement, the

2

Page 44

User's Guide ______________________________________________________________________

There are 6 measurement ranges available. The range always begins

with zero and only upper end value is changed.

RANGE x

SAVE

x = 1...6

Example:

>range 4

1. SPAN (ppm) : 1000.00

2. SPAN (ppm) : 2000.00

3. SPAN (ppm) : 3000.00

4. SPAN (ppm) : 4000.00

5. SPAN (ppm) : 5000.00

6. SPAN (ppm) : 20000.00

RANGE : 4

>

>save

EEPROM saved successfully.

NOTE

RANGE-command only optimizes measurement. The scaling of the

analog output is an independent issue. Normally it is necessary to

change also ALOW and AHIGH values. For more information, see

section, Setting and Testing the Analog Outputs, on page 52.

Measurement Data Filtering

The raw measurement values (measurement interval = 2 seconds) are an

input to a chain of three filters: a median, an averaging, and a smoothing

filter. The filters can be individually enabled or disabled by setting the

filter coefficient to 0 (zero) or by choosing CO2RAW instead of CO2 for

the measurement output quantity (see FORM command).

Figure 8 Entering Measurement Values

42 __________________________________________________________________ M210514EN-C

Page 45

Chapter 4 ________________________________________________________________ Operation

Median Filter

Median filter is the first section in the filter chain, removing random

peak values caused by external interference. The output of the median

filter is the moving median of the values over the set number of

measurements. The median filter arranges the values in the order of

magnitude and outputs the middle value (not the average) if the number

of the measurements is odd. In case an even number is set, the output is

the average of the two middlemost measurements.

The lowest reasonable set number of measurements is 3. Note that if the

noise distribution is somewhat uniform the median filter does not give

any additional value.

The number of the measurements is set by the MEDIAN command.

Maximum number of measurements is 13. The default value is 0

(meaning that the median filter is disabled).

Averaging Filter

The averaging filter calculates a moving average over the user-set

period of time. The longer the averaging time is the lower the noise at

the measurement signal. For example, if the averaging is set to 30

seconds, the most recent average filter output is the average of the last

15 measurements (2 seconds measurement interval).

The averaging time is set by the AVERAGE command. The default

value is 10 seconds, and the maximum filter length is 60 seconds. For

longer averaging times, use the smoothing filter instead. Table 6 on

page 43 presents the measurement noise as a function of averaging time

at 370 ppm CO2:

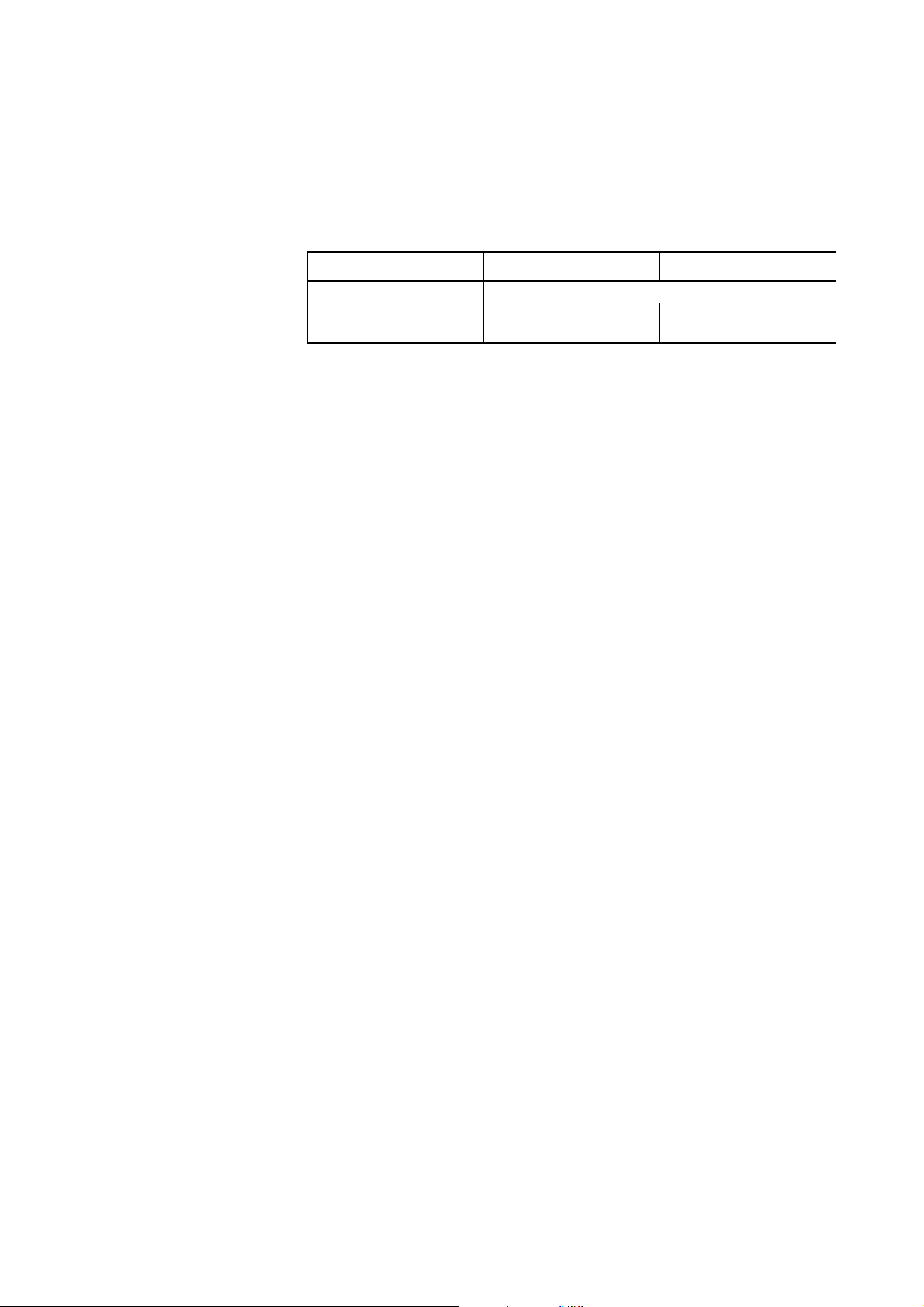

Table 6 Averaging Times

Averaging Time Noise

0 s 3 ppm

10 s 2 ppm

30 s 1 ppm

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Smoothing Filter

The smoothing filter calculates the running average by weighting the

most recent measurement by the user-set proportion of the preceding

measurement.

By using the smoothing filter, averaging up to even 15 minute periods

can be accomplished. The smoothing filter is feasible for the

background measurement where fast changes in the CO2 concentration

are not common. See the next section to find the difference between

smoothing and averaging in regard to response time.

The smoothing factor is set by the SMOOTH command, where the

range of the factor is 0 ... 255. The relationship between averaging and

smoothing from the noise reducing point of view is like follows:

(SMOOTHING FACTOR × 4) = approx. AVERAGING TIME (s)

The default value is 0 (meaning that the smoothing filter is disabled).

How the Filtering Affects the Response Time

The following figure illustrates the difference of the two filters in regard

to time response. The averaging time is set to 40 seconds while the

smoothing factor is set to 10 to have about equal noise rejection

properties. See also the response time tables presented in Specifications,

Response time (90 %), on page 80.

Figure 9 The Difference of the Two Filters in Time Response

44 __________________________________________________________________ M210514EN-C

Page 47

Chapter 4 ________________________________________________________________ Operation

Setting the Median Filter

Use the median filter to remove random peak values caused by possible

external interference.

MEDIAN x <cr>

SAVE <cr>

x=0...13 (default=0)

>median 3

MEDIAN : 3

>save

EEPROM saved successfully (829 ms).

>

Setting the Averaging Filter

Use the averaging filter to reduce the noise of the measurement. Notice

the effect on the response time.

AVERAGE x <cr>

SAVE <cr>

x=0...60 seconds (default =10 s)

>average 20

AVERAGING (s) : 20

>save

EEPROM saved successfully (829 ms).

>

Setting the Smoothing Filter

Use the smoothing filter to reduce the noise of the measurement for long

averaging periods. Notice the effect on the response time.

SMOOTH x <cr>

SAVE <cr>

x=0...255 (default =0)

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

>smooth 10

SMOOTH : 10

>save

EEPROM saved successfully (829 ms).

>

Flushing the Filters (Resynchronization)

With this command you can flush the filters to get rid of the effect of the

past measurements. This feature is useful if long filtering lengths are

used.

RESYNC <cr>

>resync

>

Linearization

Due to the principle of the CO2 absorption, the sensor of GMP343

produces a signal which is not linear in relation to the CO2

concentration. However, the output signal is linearized with the internal

linearization function. The user can disable the internal linearization

function to achieve a signal proportional to the absorption.

Setting the Linearization ON/OFF

LINEAR x <cr>

SAVE <cr>

x=ON or OFF (default=ON)

Example:

>linear

LINEAR : ON ?

>

>save

EEPROM saved successfully.

>

46 __________________________________________________________________ M210514EN-C

Page 49

Chapter 4 ________________________________________________________________ Operation

Temperature, Pressure, Relative Humidity, and Oxygen Compensations

The measurement result of an NDIR CO2 sensor such as the GMP343

is proportional to the absolute number of CO2 molecules in the active

volume of the sensor. Hence, according to the ideal gas law, the 'ppm

CO2' output is pressure and temperature dependent. Additionally,

background gases such as humidity and oxygen have an effect on the

absorption strength of CO2.

The factory calibration of GMP343 is carried out using dry N2 and CO2

mixtures. In other words, the relative humidity and the oxygen

concentration of the calibration gases are 0 %.

To achieve the most accurate 'ppm CO

measurement should be compensated for T, P, % RH, and O

concentration in the environment. In GMP343 these compensations are

a built-in option. The compensated output corresponds to 'ppm CO2' in

the actual environment (T, P, RH, and O2). The temperature, pressure,

relative humidity, and oxygen compensations are enabled as a factory

default (default environmental parameters: pressure 1013 hPa, relative

humidity 50 % RH, oxygen 20.95 % O2). The compensation settings are

specific to the selected measurement range, so selecting a suitable

measurement range also optimizes the compensation performance.

The compensation algorithm of GMP343 eliminates the dependences of

the CO

measurement or the instrument itself. The temperature compensation of

GMP343 is based on built-in temperature sensor while the values of the

other environmental parameters should be changed by the user, if they

vary from the default.

Note, that from the measurement accuracy point of view, the effect of

humidity and oxygen is less significant compared to the effect of

temperature and pressure.

measurement, whether they are related to the physics of the

2

' measurement, the

2

2

Without compensation, the effect of oxygen on the CO

approximately - 0.09 % of reading / % O2. In most circumstances, the

oxygen concentration does not vary from the default, so normally there

is no need to change the oxygen concentration settings.

VAISALA_______________________________________________________________________ 47

reading is

2

Page 50

User's Guide ______________________________________________________________________

Without compensation, the effect of humidity on the CO2 reading is

approximately 0.05 % of reading / g/m3 H2O. Since relative humidity is

strongly dependent on temperature, the humidity dependence is in terms

of absolute humidity, g/m3 H2O.

Compensation of each environmental parameter can be disabled/

enabled individually by setting the corresponding software parameter

'OFF' or 'ON', or by choosing CO2RAWUC for the measurement

quantity (see FORM command).

The internal compensation of GMP343 is the most accurate way to

compensate for changing environmental parameters. However, if more

information is needed on different compensations, please contact your

Vaisala representative.

Temperature Compensation ON/ OFF

The internal temperature sensor is located in the measurement chamber.

Temperature compensation is done automatically unless for some

reason you want to take the compensation feature off.

To enable or disable temperature compensation, use the commands:

TC x <cr>

SAVE <cr>

x=ON/OFF (default =ON)

>tc on

TC : ON

>tc off

TC : OFF

>

>save

EEPROM saved successfully.

>

48 __________________________________________________________________ M210514EN-C

Page 51

Chapter 4 ________________________________________________________________ Operation

Setting the Oxygen Concentration

To set the oxygen concentration value, use the commands:

O x <cr>

SAVE <cr>

x=0...100 % (default =20.95 %)

>o 21

OXYGEN (%): 21.00

>save

EEPROM saved successfully.

>

Setting Oxygen When the Device Is in POLL-mode

To set oxygen value in POLL-mode, use the following addressable

command:

XO addr x <cr>

The device does not reply to the command. If given oxygen value is not

within limits, the command is rejected. The given value is written to

volatile memory, where it will be overwritten either by next XO-

command or O-command. At start the first compensation value is a

value given by O-command if it was saved by SAVE-command.

Purpose of the XO-command is continuous update of compensation

value sent by another measurement device.

Oxygen Compensation Mode

To enable or disable the oxygen compensation, use the commands:

OC x <cr>

SAVE <cr>

x=ON/OFF (default =ON)

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

NOTE

Check that the ambient pressure value is correct. The correct pressure

value is needed for oxygen compensation even if the pressure

compensation is disabled.

>oc on

OC: ON

>

>save

EEPROM saved successfully.

>

Setting the Ambient Pressure (hPa)

The pressure value is needed in pressure, humidity, and oxygen

compensations. To set the ambient pressure value, use the commands:

P x <cr>

SAVE <cr>

x=700...1300 hPa (default =1013 hPa)

Sets ambient pressure (hPa) to be used in compensation calculations.

>p 1100

PRESSURE (hPa)): 1100.000

>p

PRESSURE (hPa) : 1100.000 ?

>

>save

EEPROM saved successfully.

>

Setting Pressure When the Device Is in POLL-mode

To set pressure value in POLL-mode, use the following addressable

command:

XP addr x <cr>

The device does not reply to the command. If given pressure value is not

within limits, the command is rejected. The given value is written to

volatile memory, where it will be overwritten either by next XP-

command or P-command. At start the first compensation value is a

50 __________________________________________________________________ M210514EN-C

Page 53

Chapter 4 ________________________________________________________________ Operation

value given by P-command if it was saved by SAVE-command.

Purpose of the XP-command is continuous update of compensation

value sent by another measurement device.

Pressure Compensation ON/OFF

To enable or disable the pressure compensation, use the commands:

PC x <cr>

SAVE <cr>

x=ON/OFF (default =ON)

>pc off

PC: OFF

>pc on

PC : ON ?

>save

EEPROM saved successfully.

>

Setting Ambient Relative Humidity

To set the ambient relative humidity value, use the commands:

RH x <cr>

SAVE <cr>

x=0 ... 100 % RH (default =50 %)

>rh

HUMIDITY (%RH): 0.00 ? 24

>save

EEPROM saved successfully.

>

Setting Humidity When the Device Is in POLL-mode

To set relative humidity value in POLL-mode, use the following

addressable command:

XRH addr x <cr>

VAISALA_______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

The device does not reply to the command. If given humidity value is

not within limits, the command is rejected. The given value is written to

volatile memory, where it will be overwritten either by next XRH-

command or RH-command. At start the first compensation value is a

value given by RH-command if it was saved by SAVE-command.

Purpose of the XRH-command is continuous update of compensation

value sent by another measurement device.

Relative Humidity Compensation ON/OFF

To enable or disable the humidity compensation, use the commands:

RHC x <cr>

SAVE <cr>

x=ON/OFF (default =ON)

NOTE

Check that the ambient pressure value is correct. The correct pressure

value is needed for RH compensation even if the pressure

compensation is disabled.

>rhc on

RHC : ON

>rhc off

RHC : OFF

>

>save

EEPROM saved successfully.

>

Setting and Testing the Analog Outputs

GMP343 has one analog output channel. The channel outputs either

current or voltage signal according to the order configuration. The

analog output always gives the filtered CO2 results regardless of the

quantity set with FORM command.

52 __________________________________________________________________ M210514EN-C

Page 55

Chapter 4 ________________________________________________________________ Operation

Analog Output Hardware

AMODE <cr>

SAVE <cr>

Analog output hardware can be chosen between current or voltage

output. Command parameters are correspondingly I (for current) and U

(for voltage).

>amode

AMODE : I ? U

>

>save

EEPROM saved successfully.

>

You can scale the chosen analog output signal as follows:

- When you have current output, you can set any value between 0 ...

4 mA for the current signal low level. The default value is 4 mA

(command ILOW). The high value is always 20 mA.

- When you have voltage output, you can set any value between 0 ...

5 for the voltage signal high level (command UHIGH). The low

value is always 0 V.

Remember to set the analog output error value within the range of

current/voltage output. See the command AERR.

The concentration range of the analog output, corresponding to the

signal range set above, can be chosen by determining the low and high

values for the measurement range (AHIGH, ALOW).

Setting the Limit of the Current Output Range

You can expand the current output range for example 4...20 mA to

0...20 mA. The range available is 0...4 mA.

ILOW <cr>

SAVE <cr>

VAISALA_______________________________________________________________________ 53

Page 56

User's Guide ______________________________________________________________________

Key in the low current value (mA) and press ENTER.

>ilow

ILOW (mA) : 4.000 ? 0

>save

EEPROM saved successfully.

>

Setting the High Limit of the Voltage Output Range

You can set the hight voltage value: 0...5 V.

UHIGH <cr>

SAVE <cr>

Key in the high voltage value (V) and press ENTER.

>uhigh

UHIGH (V) : 5.000 ? 1

>

>save

EEPROM saved successfully.

>

Setting the High Limit of the Concentration Range

Sets the hight CO2 concentration value, which corresponds to the

analog output high value.

AHIGH <cr>

SAVE <cr>

Key in the highest concentration value (ppm) and press ENTER.

>ahigh

AHIGH (ppm) : 1000.0 ? 1200

>

>save

EEPROM saved successfully.

>

54 __________________________________________________________________ M210514EN-C

Page 57

Chapter 4 ________________________________________________________________ Operation

Setting the Low Limit of the Concentration Range

Sets the low CO2 concentration value, which corresponds to the analog

output low value.

ALOW <cr>

SAVE <cr>

Key in the lowest concentration value (ppm) and press ENTER.

>alow

ALOW (ppm) : 0.0 ? 20

>

>save

EEPROM saved successfully.

>

Setting the Analog Output Overrange Clip

This command clips the analog output signal at the high value when the

signal goes over range. In case of the current output the current will not

go higher than 20 mA or below the low value current (set with ILOW).