Page 1

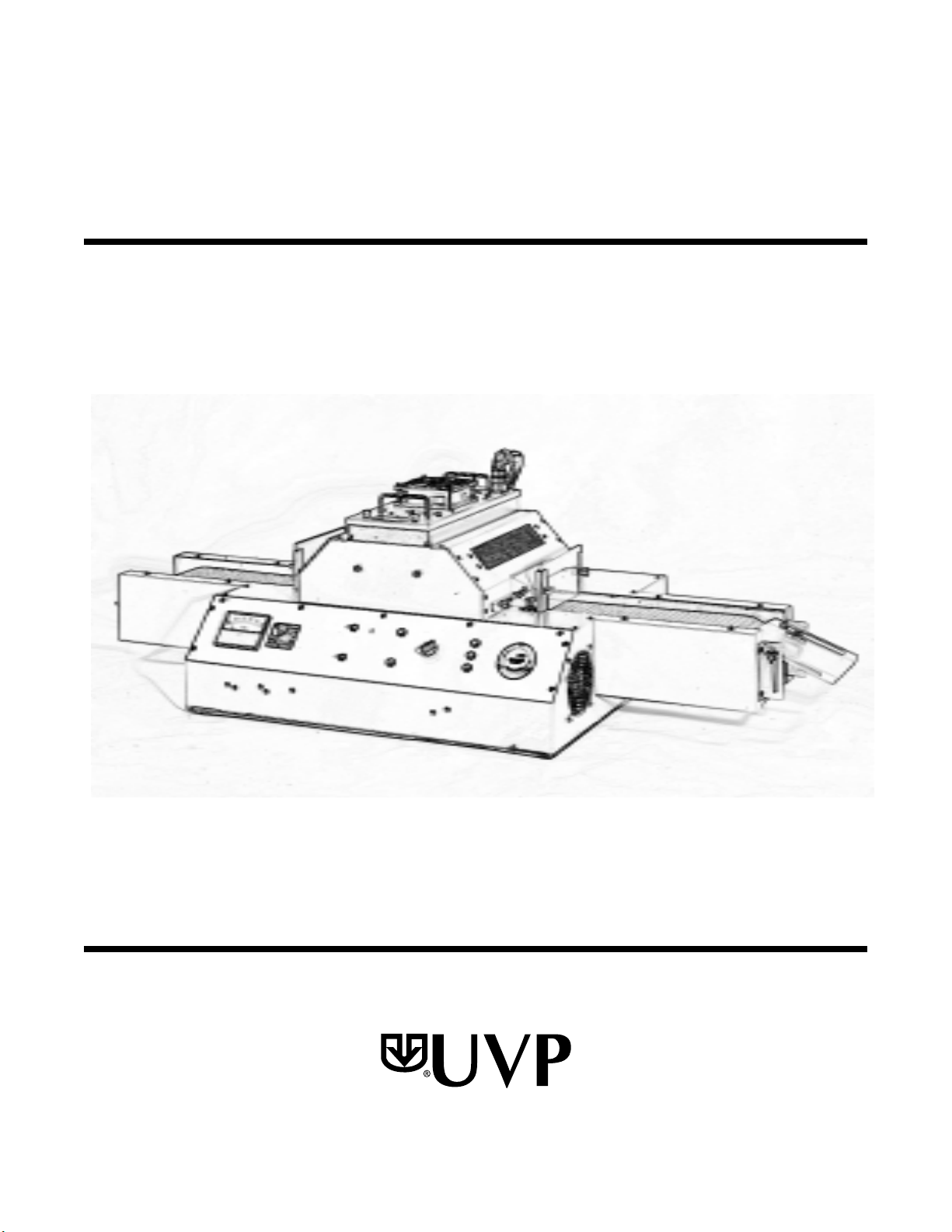

Benchtop UV Curing System

Installation and User Manual

CAUTION: ULTRAVIOLET LAMPS EMIT RADIATION THAT IS HARMFUL TO EYES AND SKIN. GREAT

CARE SHOULD BE TAKEN TO INSURE THAT PERSONNEL ARE NOT EXPOSED TO DIRECT OR REFLECTED RADIATION. SUITABLE EYE PROTECTION, SUCH AS UVP, INC. UV BLOCKING SPECTACLES

OR GOGGLES, SHOULD BE WORN WHEN LAMP IS IN OPERATION. BEFORE CLEANING OR

RELAMPING, ALWAYS TURN THE POWER OFF.

81-0180-01 Rev A

Page 2

BC-300 Benchtop UV Curing System

ULTRAVIOLET RADIATION

The band of radiation just below the violet end of the visible spectrum is called ultraviolet. This invisible band

is divided into several regions.

COSMIC RAYS GAMMA RAYS ULTRAVIOLET VISIBLE INFRA-RED RADIO WAVES

X-RAYS

--- GERMICIDAL ----- BLACKLIGHT ---

-------------- SCHUMAN ----------------

X-RAYS 1.0 100 200 300 400 VISIBLE

-------------- ERYTHEMAL --------------

Various bands exist with the lower band overlapping into the X-ray band. Near ultraviolet, between 320nm

and 440nm, is also known as blacklight or longwave ultraviolet. Middle ultraviolet, between 280nm and

320nm, is called erythemal or sun tan ultraviolet. Far ultraviolet, between 300nm and 400nm, is known as

germicidal ultraviolet.

Industrial UV curing ultraviolet extends lower to 180nm and higher to 420nm.

Ultraviolet is produced artificially by various sources: UV curing lamps, blacklight lamps, sun tan lamps,

germicidal lamps, carbon arcs, welding and cutting torches, furnaces, laboratory test and analysis equipment. Nature, in the form of the sun is a major natural source.

UV Curing is a process involving polymerization, or crosslinking of monomers upon exposure to UV radiation.

Applications comprise curing of printing inks, curing coatings for wood and paper, particleboard fillers, metal

coatings, adhesives, and prepegs.

All monomers do not polymerize when exposed to UV radiation. UV curable monomers usually include a

sensitizer, which absorbs UV energy initiating polymerization reaction in the monomer.

ADVANTAGES OF UV CURING

UV curable materials are 100% solids, with no solvents to be discharged into the atmosphere. As they

polymerize entirely, a noted reduction in air pollution results.

Plant space is saved, as the UV curing line is considerably shorter than a gas oven. Time is saved as material

reacts immediately to UV exposure negating the time lag necessary to raise coating temperature to induce

thermal curing.

1

Page 3

BC-300 Benchtop UV Curing System

Lower number of processing and handling procedures provide labor savings. Printed matter is ready for

cutting and folding after UV processing. Wood and particleboard panels can be stacked and processed

immediately. UV curing lamps, placed between stations in multi-color offset printing, cure one color before

next color is applied, eliminating color bleed, scratches, scuffs, etc. Controlled temperature can be obtained

where UV curing is used on heat sensitive substrates.

Rate or speed of UV curing is affected by the following:

• UV curable compounds vary in composition. The type and amount of sensitizer, type and amount of

pigment, etc. used in UV curable formulations will dictate UV curing speed.

• UV curing time is not directly proportional to coating thickness. A two-fold thickness requires 10 times the

radiation energy of a single thickness. UV energy received inside a layer of coating decreases exponentially with depth.

• UV curing time will rise with the increase of UV energy per unit surface, up to the saturation point. This is

not linear. The curing rate of most monomers, in the presence of air, at a rate greater than the increase

in UV energy per unit surface. If the amount of UV energy per unit surface is doubled, curing speed may

be tripled, quadrupled, or even rise ten-fold.

Two lamps of even power will not cause a cure as quickly as one UV lamp with twice the radiation power.

One lamp with twice the power doubles the energy radiated to the same surface and curing speed will

double. UV curing lamps with the highest power-to-size ratio should be sued. The non-linear relation

between curing rate and UV energy dictates the UV processor reflector design. Focused reflectors,

incorporated in UVP, Inc. processors, concentrate the UV energy on a small surface, rather than a

uniform distribution over a larger surface.

• Various UV sensitizers require different ranges of UV wavelength for proper reaction. Sensitizers should

react to UV in a range other than those absorbed by the monomer or pigment. UVP, Inc. medium pressure Mercury lamps emit UV (180nm to 420nm), suitable for all UV curing applications.

BENCHTOP CURING SYSTEM SPECIFICATIONS

UVP processors consist of the following:

1. High Intensity UV Source (Lamp)

2. Irradiators (Lamp Housing and Reflector Assembly)

3. Shielding, Cooling, and Safety Equipment

4. Power Supply and Electrical Controls

Technical Data

• Length: 30, width: 24, • Elliptical focused heat sink reflector

height: 18, weight 100 lbs. • 6, 300W/inch curing lamp

• Central located exhaust fan • Nomex-coated fiberglass belt

• Optical shielding • Vacuum hold-down

• 1-100 FPM variable speed control • Tri-power lamp switching (300, 200, 125W/inch)

with FPM indicator • 8, 14/3 grounded electric cord

• Elasped-time indicator

2

Page 4

BC-300 Benchtop UV Curing System

Part Numbers

Model Part Number Watts Volts

BC-300 95-0194-01 300 120V/60Hz

BC-300 95-0194-02 300 220V/50Hz (CE Certified)

BC-300 95-0194-03 400 220V/50Hz (CE Certified)

GENERAL INSTRUCTIONS

1. After unpacking, check all electrical connections and mounting hardware to insure there is no damage.

2. If all items appear satisfactory, install ultraviolet lamp (see Lamp Installation Instructions sheets page 4).

3. to install the drop off plate on each of the curing system, refer to the Installation of Drop Off Plate under

Diagrams (see sheet 1979-13).

3. A) Main power and lamp on switch to OFF position. B) High/low lamp intensity (1/2) switch to high

position. C) 300 WPI systems - switch to 300 WPI setting. D) Variable speed control knob to ZERO.

4. Plug input cord into Grounded, 120 Volt 60 Hertz, 10 Amps A.C. Outlet. Do not remove ground contact

from power cord under any circumstances.

5. Switch Main Power switch to on position. This switch sends power to the lamp switch variable speed

control and activates center lamp cooling fan.

CAUTION: When fixture is operating, ultraviolet rays are emitted which are harmful to eyes and skin. Great

care should be taken to insure personnel are not exposed to direct or reflected radiation. Suitable eye protection, such as UVP UV Blocking Spectacles or Goggles should be employed when lamp is in operation.

6. When shielding is in place and/or operators are utilizing ultraviolet absorbing safety glasses, the lamp

switch may be turned on. This will light the ultraviolet lamp. The lamp requires a 3-4 minute warm-up prior

to curing applications.

7. Start conveyor belt moving. Belt should always be moving when lamp is on.

8. High/Low lamp intensity option may be utilized to operate lamp at idle mode when curing application are

on hold. Lamp will operate at approximately 1/2 the rated output and rapidly return to full power. On tripower models switch lamp to 125 WPI when curing applications are on hold.

9. Shut-Down Procedure:

A. High/Low lamp intensity switch to high position.

B. Tri-Power models intensity switch to 300 WPI.

C. Lamp switch to off position.

D. Reduce belt speed.

E. Allow main switch to operate cooling fan for 3-5 minutes before total shutdown. This will allow lamp

to cool evenly and will prolong lamp life.

F. Main power switch to off position.

3

Page 5

BC-300 Benchtop UV Curing System

Lamp Installation and Relamp Instructions

A drawing illustrating the lamp installation is included under the Diagrams section (see sheet 1874 1 of 4).

1. Turn power OFF.

2. Disconnect Hi-Voltage cable from irradiator cover. Refer to Wiring Diagram drawing number 1871.

3. Remove lamp irradiator cover by removing the 2 screws at each and of irradiator.

4. Place irradiator on its handles.

5. Remove top lampholder bracket from each side of lamp.

6. Side opposite the connector, remove aluminum cover and ceramic washer.

7. Slide lamp out.

8. When installing lamp, slide lamp between ceramic washer and aluminum holder. Use gloves to prevent

fingerprints on lamp.

9. Replace aluminum holder and ceramic washer to assembly.

10. Center lamp so lamp ends are equally spaced on large lampholder bracket.

11. Replace top lampholder brackets, tightening each side equally. Clean lamp a with dry cloth and alcohol.

12. Replace assembly into side extrusion and secure with the 4 screws.

13. Re-connect Hi-Voltage connector.

14. Return to Step 3 of General Instructions.

CAUTION: When fixture is operating, ultraviolet rays are emitted which are harmful to eyes and skin. Great

care should be taken to insure personnel are not exposed to direct or reflected radiation. Suitable eye and

skin protection, such as UVPs UV Blocking Spectacles or Goggles should be employed when lamp is in

operation. BEFORE CLEANING OR RELAMPING, TURN POWER OFF.

Non-Focused Lamp Installation Instructions

A drawing illustrating the lamp installation is included under the Diagrams section (see sheet 1874 3 of 4).

1. Turn power off.

2. Disconnect all power and high voltage cable to irradiator cover.

3. Remove lamp irradiator cover by removing the (2) 10-32 knobs at each end of the irradiator.

4. Place the irradiator upside down on its handles.

5. Refer to drawing 1874 sheet 3 of 4 (see Diagrams section).

4

Page 6

BC-300 Benchtop UV Curing System

6. Note: metal air diffuser used only with 4, 6 lamp assemblies and laboratory conveyorized system.

A. Remove one metal air diffuser.

Clean the UV lamp and reflectors with a lint free cloth and denatured isopropyl alcohol (we recommend the use of disposable latex or vinyl gloves to keep the lamp free of fingerprints which will burn

into the lamp or liners and create hot spots, disallowing the transmission of the UV rays.)

B. Place one wire & ceramic end of the lamp through the mounted metal air diffuser and on top of the

lampholder. Place the loose metal air diffuser around the other lamp end and place the lamp end

onto the lampholder.

C. Remount metal air diffuser with 8-32 x 3/16 screws. Remove the non-focused bracket and the 8/32

x 1/2 screws from the package. At one end feed the wire ceramic end through the lager hole in the

non-focus bracket. Mount non-focus bracket to the lampholder with the 8/32 x 1/2 screws provided.

Mount the wire lead from the lamp end to the ceramic stand off and replace the 8-32 nut. Repeat on

opposite end.

7. Place the irradiator back in place and tighten the (4) 10-32 knobs. Reconnect the high voltage cable by

matching index insuring proper connection and screw connector cable down completely.

CAUTION: when fixture is operating, ultraviolet rays are emitted which are harmful to eyes and skin. Great

care should be taken to insure personnel are not exposed to direct or reflected radiation. Suitable eye and

skin protection, such as uvps uv blocking spectacles or goggles should be worn when lamp is in operation.

Before cleaning or relamping, ALWAYS TURN POWER OFF.

Focused Lamp Installation Instructions

1. Turn Power Off.

2. Disconnect all power and high voltage cable to irradiator cover.

3. Remove lamp irradiator cover by removing the (2) 10-32 knobs at each end of the irradiator.

4. Place the irradiator upside down on its handles.

5. Refer to drawing 1874 sheet 1 of 4 (see Diagrams section).

6. NOTE: mertal air diffuser use only with 4, 6 lamp assemblies and laboratory conveyorized system.

A. Remove one metal diffuser. Loosen the 8-32 screws on the lampholder to release the top bracket.

Do not remove the bracket--this will swing away.

Clean the UV lamp and reflectors with a lint free cloth and denatured isopropyl alcohol (we recommend the use of disposable latex or vinyl gloves to keep th elamp free of ingerprints which will burn

into the lamp or liners and create hotspots, disallowing the transmission of the UV rays).

B. Place one wire and ceramic end of the lamp through the mounted metal air diffuser and on top of the

lampholder. Place the loose metal air diffuser around the other lamp end and place the lamp end

onto the lampholder.

5

Page 7

BC-300 Benchtop UV Curing System

C. Remount the metal air diffuser with 8-32x3/16 screws. Place the top bracket over the lamp end and

tighten both screws. Mount the wire lead from the lamp end to the ceramic standoff and replace the

8-32 nut. Repeat on the oppositve side of the lamp.

7. Place the irradiator back in place and tighten the (4) 10-32 knobs. Reconnect the high voltage cable by

matching index to index insuring proper connection and screw connector cable down completely.

CAUTION: When the fixture is opeating, ultraviolet rays are emitted which are harmful to eyes and skin.

Great care should be taken to insure personnel are not exposed to direct or reflected radiation. Suitable eye

and skin protection, such as UVP UV Blocking Spectacles and Goggles should be worn when the lamp is in

operation. Before cleaning or relamping, ALWAYS TURN POWER OFF.

REPLACEMENT PARTS AND TECHNICAL SUPPORT

Contact UVP for a list of replacement parts for the BC-300 Benchtop Curing System. UVP offers technical

support for all of its products. If you have any questions about the products use, operation or repair, contact

our offices below.

NOTE: A Returned Goods Authorization (RGA) number must be obtained from UVP Customer Service

before returning a product to UVP.

UVP, Inc. Ultra-Violet Products Ltd.

2066 W. 11th Street Unit 1, Trinity Hall Farm Estate

Upland, CA 91786 Nuffield Road

Tel: (800) 452-6788 or Cambridge CB4 1TG UK

(909) 946-3197 Tel: +44(0) 1223-420022

Fax: (909) 946-3597 Fax: +44(0) 1223-420561

E-Mail: uvp@uvp.com E-Mail: uvpuk@uvp.com

TROUBLE SHOOTING AND PRODUCT DIAGRAMS

A troubleshooting check list for 208/220/420/440 volt 50/60 hertz conveyorized curing system models is

shown on page 7.

NOTE: Because of the high voltage used throughout the power supply, only qualified personnel

should work on it.

Wiring Diagrams, Lamp Installation Instruction Sheets, and Installation of Drop Off Plate are provided on the

following pages.

6

Page 8

BC-300 Benchtop UV Curing System

TROUBLESHOOTING CHECK LIST

PROBLEM CHECK SOLUTION

House power on but no belt F1 in control box Replace fuse

movement or panel lights 5 Amp fuse

Control box and belt working but F1 in rear of power supply Replace fuse

no control power to power supply 5 Amp fuse

Lamp does not light Lamp condition Replace fuses or lamp

Main fuses

Primary voltage

Check all primary and secondary Repair or replace wires or

wiring for burnt or loose connections connectors

Check all capacitors Replace if bad

Check high voltage cable in rear of Replace if needed

power supply and in irradiator for

loose connections

Check for proper seating between

the male and female on top of

the irradiator

Conveyor motor will not start Check DC output from SCR in If AC input with no DC output,

control box terminal block A+, A-. replace SCR

If no DC output, check all AC input

to SCR.

Check at motor for DC power. If Replace motor

you have power remove motor from

chain and try with no load. If it does

not run, replace.

If it does move, check chain and Repair as needed

drive for loose or broken parts

Vacuum blower will not run Check fuses F2, F3 in control box Replace if blown

With blower switch on, check for Replace switch or receptacle

power at blower receptacle as needed

If blower receptacle has power, Replace motor if needed

check blower cord and connections.

If OK, replace motor.

Lamp comes on but secondary Check lamp condition and hours Replace lamp

ammeter does not drop to

proper reading after 5 minutes

Lamp will not come up to full Check for bad capacitor. Check for Replace if needed

power and start up mercury relay stuck in open position

Lamp intensity will not change With power off, check mercury relays. Replace relays if needed

using rotary switch They are normally closed.

7

Page 9

BC-300 Benchtop UV Curing System

8

Page 10

BC-300 Benchtop UV Curing System

9

Page 11

BC-300 Benchtop UV Curing System

10

Page 12

BC-300 Benchtop UV Curing System

11

Page 13

BC-300 Benchtop UV Curing System

12

Page 14

BC-300 Benchtop UV Curing System

13

Page 15

BC-300 Benchtop UV Curing System

14

Page 16

BC-300 Benchtop UV Curing System

15

Page 17

BC-300 Benchtop UV Curing System

16

Page 18

BC-300 Benchtop UV Curing System

17

Page 19

BC-300 Benchtop UV Curing System

18

Page 20

BC-300 Benchtop UV Curing System

LIMITED WARRANTY

UVPs quality products are guaranteed to be free of defects in material and workmanship for one (1) year

from date of shipment under the conditions of normal usage and service. However, double shift operations

limit the warranty to six months and twenty-four (24) hour operations limit the warranty to 90 days. If product

failure or malfunction occurs during the warranty period, UVP shall examine the inoperative product and have

the option to repair or replace any components, which, in the judgment of UVP, were originally defective or

become so under conditions of normal usage and service. Customers must first obtain Returned Goods

Authorization number (RGA#) from UVP prior to making any returns. The components or product must

shipped freight prepaid insured, to UVP Inc., 2066 W. 11th Street, Upland, CA 91786.

No warranty shall apply to any products, or component of it, which has been subject to accident, negligence,

altercation, abuse or misuse by the end-user. No warranty is offered on components or service supplied by

a source other than UVP except for those in strict compliance with the instructions outlined in the end-users

operational manual. Ultraviolet Curing lamps are warranted on a prorated basis based on 1,000 hours of

usage. When lamps are used at 300 WPI constantly, warranty is for 750 hours.

Consequential damages, lost time, inconveniences or contingent liabilities are not covered by this warranty.

Repair time is based open the availability of labor, and all parts and components required to make the repair,

UVP is not responsible or liable for any personal injuries occurring because of the use, installation and/or

servicing of products.

All labor, travel costs and sustenance, for service technicians, is the purchasers responsibility. Expendable

components such as conveyor belts, UV Lamps, or fuses are not covered by this warranty.

CAUTION

ULTRAVIOLET LAMPS EMIT RADIATION THAT IS HARMFUL TO EYES AND SKIN. GREAT CARE

SHOULD BE TAKEN TO INSURE THAT PERSONNEL ARE NOT EXPOSED TO DIRECT OR REFLECTED

RADIATION. SUITABLE EYE PROTECTION, SUCH AS UVP, INC. UV BLOCKING SPECTACLES OR

GOGGLES, SHOULD BE WORN WHEN LAMP IS IN OPERATION. BEFORE CLEANING OR RELAMPING,

ALWAYS TURN POWER OFF.

19

Page 21

BC-300 Benchtop UV Curing System

Other quality products from UVP:

UV Intensity Meters, UV Blocking Eyewear, Handheld Ultraviolet Lamps,

High Intensity Ultraviolet Lamps, Display and Bench UV Lamps,

UV Transilluminators, UV Crosslinkers

UVP, Inc.

2066 W. 11th Street, Upland, CA 91786

Tel: (909) 946-3197 (800) 452-6788

Fax: (909) 946-3197 E-Mail: uvp@uvp.com

Ultra-Violet Products Ltd.

Unit 1, Trinity Hall farm Estate, Nuffield Road

Cambridge CB4 1TG UK

Tel: +44(0)1223-420022 Fax: +44(0)1223-420531

E-Mail: uvpuk@uvp.com

20

Loading...

Loading...