Page 1

B-100AP

B-100 Series Ultraviolet Lamps

Operating Instructions

These Instructions cover UVP’s high-intensity 100-watt

B-100 series lamps (115V and 220V). The B-100AP,

B-100AP/R and B-100YP models are manufactured with

UVP’s Cool-Touch™ plastic housing. B-100A, B-100A/R

and B-100Y models are manufactured of a durable

scratch-resistant, powder-painted aluminum. The

B-100Y and B-100YP models feature a yellow filter.

Lamp and accessory drawings and replacement parts

lists for each model are included in these instructions.

This manual covers the following lamp part numbers:

Part Numbers

Model 115V 230V

B-100AP 95-0127-01 95-0127-02

B-100AP/R 95-0127-06 95-0127-07

B-100YP 95-0127-03 95-0127-04

B-100Y 95-0044-24 95-0044-18

B-100A 95-0044-22 95-0044-02

B-100A/R 95-0044-03 95-0044-03

General Information for Ultraviolet Inspection

Make tests in a darkened area for best contrast. Fluorescence may be bright or dim, depending on amount

of fluorescing agent present. Be careful to distinguish fluorescence from blue light reflection on polished

metal surfaces. UVP Model UVC-503 Safety Goggles are recommended to eliminate blue haze resulting

from eye fluorescence caused by reflected longwave ultraviolet radiation.

Installation

An 8-foot primary and secondary line cord is supplied on all units except the B-100AP/R and B-100A/R wh ich

come with 8-foot primary and 20-foot secondary line cords. If the receptacle is not fitted with 3-prong plug,

use a 2-prong adapter and attach gr oun ding lea d to screw center of receptacle plate. Some units may ship

with bare wire leads. Connect the appropriate plug for your area.

Operation

Turn on/off switch on transformer base to ON position for starting. Although a cool lamp starts immediately,

allow approximately five minutes to reach full brilliance. When use is intermittent, it is preferable to leave the

lamp burning. This assures longer bulb life and avoids delay in restarting. Restarting does not take place

immediately as the mercury vapor within the bulb must cool. Delay is typically 4 to 8 minutes. Any interruption

in the power supply, such as an excessive drop in voltage, will extinguish the arc. Restarting typically will be

delayed while the mercury vapor cools. Full voltage must be restored to permit the arc to strike.

While mounted on the transformer base, the lamp housing can rotate 360°. For handheld use, detach the lamp

housing from the transformer base.

81-0093-01 Rev N

Page 2

Replacement Parts List

B-100A, B-100A/R, B-100Y

PA RT NO. PART NAME

B-100AP, B-100AP/R, B-100YP

PART NO. PART NAME

Models:

Models: B-100A,

Transformer

Bezel & Filter

Lamp Head

Bulb Replacement

light meter will not deliver readings of ultraviolet ener gy.

Parts lists are provided for the B-100 lamp models. Two

parts lists are shown: one for the Cool-Touch housing

lamps and one for the aluminum housing lamps. For

additional ordering information or an authorized

dealer, contact:

UVP, LLC, Upland, California | (800) 452-6788

(909)946-3197

Ultra-Violet Products Ltd., Cambridge UK

+44(0)1223 420022

NOTE: An RGA (returned goods authorization) number

is required prior to returning any products to UVP.

Contact UVP’s offices to obtain a number.

115 VOLT, 60 Hz; 220 VOLT, 50 Hz

34-0054-01 SPOT BULB

36-0043-02 SOCKET, MEDIUM BASE

38-0168-01 BEZEL AND UV FILTER ASSEMBLY

38-0168-02 BEZEL & YELLOW FILTER ASSEM.

88-0016-01 BALLAST REPLACEMENT KIT, 115V

88-0016-02 BALLAST REPLACEMENT KIT, 220V

77-0007-01 B-100AP LAMP HEAD ASSEMBLY, 115V

77-0007-04 B-100AP LAMP HEAD ASSEMBLY, 220V

77-0007-05 B-100AP LAMP HEAD ASSEMBLY, 115V

77-0007-06 B-100AP/R LAMP HEAD ASSEM BL Y, 22 0 V

77-0007-07 B-100YP LAMP HEAD ASSEMBLY, 115V

77-0007-08 B-100YP LAMP HEAD ASSEMBLY, 220V

115 VOLT, 60 Hz; 220 VOLT, 50 Hz

(Note: B-100A/R NSN 6635-611-5617 ordering number)

34-0054-01 SPOT BULB

36-0043-02 SOCKET, MEDIUM BASE

38-0168-03 BEZEL & UV FILTER ASSEM.

38-0168-04 BEZEL & YELLOW FIL TER ASSEM.

77-0005-01 LAMP HEAD ASSEMBLY WITH 8ft. CORD, 115V

77-0005-02 LAMP HEAD ASSEMBLY WITH 8ft. CORD, 220V

77-0005-03 LAMP HEAD ASSEM. WITH 20ft. CORD, 115V

77-0005-04 LAMP HEAD ASSEM. WITH 20ft. CORD, 220V

88-0016-01 BALLAST REPLACEMENT KIT, 115V

88-0016-02 BALLAST REPLACEMENT KIT, 220V

19-0124-01 LAMP VISOR

B-100A

B-100A/R

B-100Y

Ballast Base

Assembly

Assembly

B-100A/R, B-100Y

To replace the bulb, first remove the filter assembly:

Expand front bezel tabs and slide front bezel off the

lamp assembly. Expand the two silver filter assembly

spring clips outward to release filter assembly from the

lamp body.

When replacing the bulb, screw bulb in tightly to prevent

loosening from heat expansion and contraction during

lamp operation.

Bulb Standardization

For testing uniformity, a standard bulb intensity is

required.

A special light meter calibrated for measuring ultraviolet

intensity is required to check bulb standardization.

The UVX Radiometer and UVX-36 sensor or the J-221

UV Meter employ a dense ultraviolet filter and is

specifically calibrated to read ultrav io let intensity of

365nm in mW/cm² from a line source lamp. An ordinary

Page 3

CAUTION

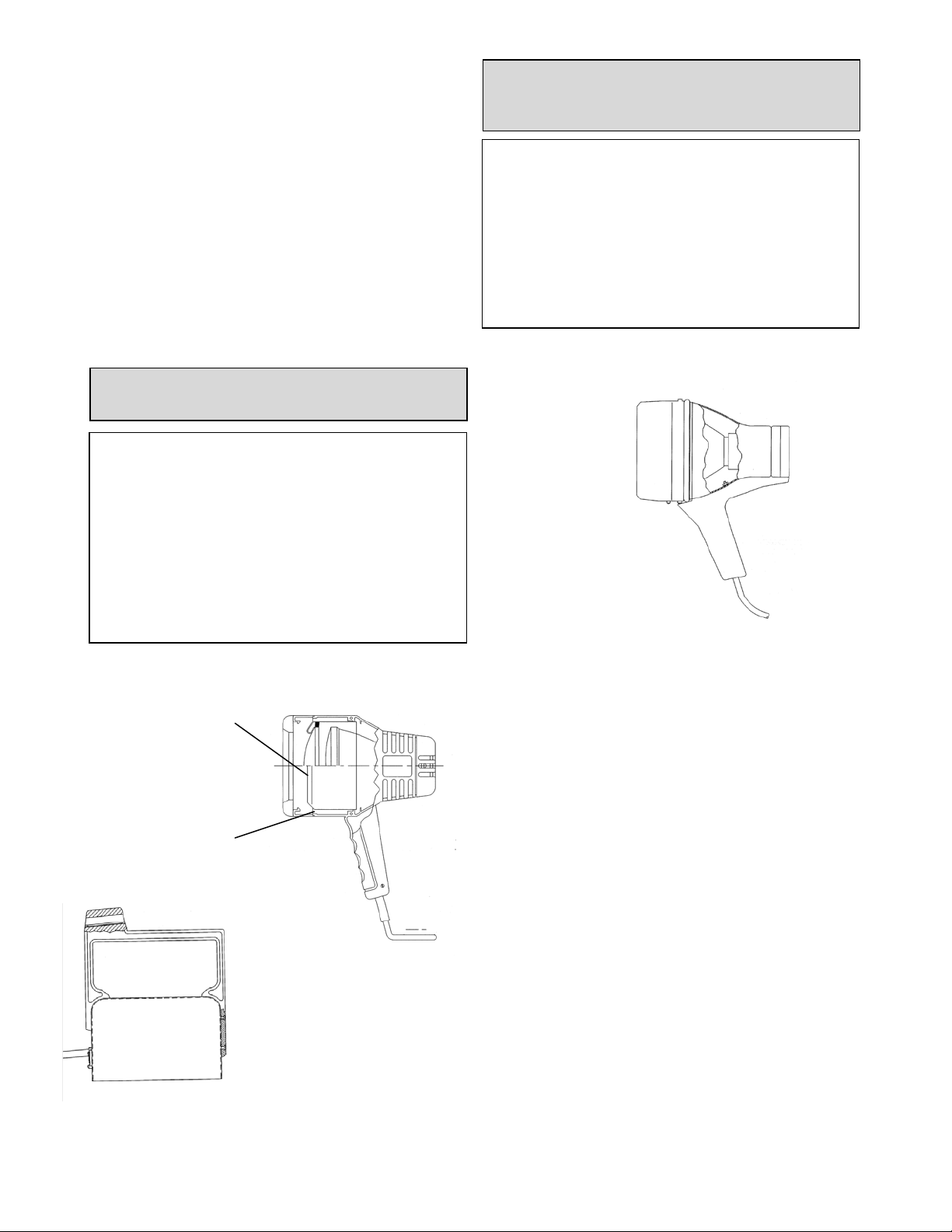

Accessories

2

3

Funnel

Lamp

Retaining

Section A

Tab

2

3

The Lamp Visor shields the user’s eyes from the UV

models.

Side View

Front View

Clips

Fig. 2 Visor shown below is used with Cool-Touch

Front View

Side view

Clip

Clips

PART NO. PART NAME (Where Used)

1. Wear hand and eye protection if filter glass is cracked.

Replace filter as soon as possible.

2. To avoid electrical shock hazard, unplug lamp

before servicing.

3. Bulb runs very hot; allow unit to fully cool before

servicing.

4. Bulb contains mercury. If bulb breaks, wear

gloves to remove. Dispose according to local

regulations.

5. B-100A, B-100A/R and B-100Y lamp housings become

hot during operation and care should be taken not to

touch them. Lamp handles do not heat even after

several hours of use.

The Lamp Funnel, for use with the Cool-Touch models,

can be used to direct the UV source directly where you want

it, eliminating stray UV radiation. To attach, remove the

plastic bezel from lamp by pulling side tabs apart and sliding

the bezel off the housing. Insert the retaining clips in the

four slots of the interior bezel as shown in Section A

Place the funnel in the lamp housing, reattach the bezel,

over funnel, by pulling tabs on the side of the lamp apart

and snapping into place.

and directs the UV onto the object of analysis. The

Visor clips onto the sides of the lamp head. Side and

front facing views shown. Fig. 1 shows installation of

the Visor on the B-100A, B-100A/R and B-100Y

Fig. 1

PAR T NO. PART NAME (Where Used)

19-0126-01 LAMP FUNNEL (for B-100AP, YP models)

lamps. Visor clips onto the top of the lamp head.

Front and side facing views shown.

Clips

Fig. 2

19-0124-01 LAMP VISOR (for B-100A, Y models)

19-0125-01 LAMP VISOR (for B-100AP, YP models)

Page 4

The Finger Guard, to keep fingers away from the filter

Tabs

Finger Guard

Lamp Bezel

Clip

Use the optional Exposure Box for exposure

PART NO. PA RT NAME

glass, easily snaps into place on the face of the Cool-Touch

lamps. To install, remove the lamp bezel by slightly pulling

the tabs outwards on each side of the lamp to release. Lift

the bezel off the lamp. Turn the bezel over so the side tabs

are facing up. Place the finger guard in the lamp housing

so that the four clips can be snapped over the fi nger guard .

PART NO. PA RT NAME

89-0068-01 Finger Guard (for B-100AP)

of samples at close range to the UV source in

a semi-enclosed area.

Installation: Slide the Box onto the lamp

housing, placing the metal tabs on the top of

the Box into the “fins” on the body of the

Lamp.

76-0055-01 Exposure Box (for B-100AP, B-100YP)

Product Warranty

UVP’s products are guaranteed to be free of defects in materials, workmanship and manufacture for one (1) years from the

date of purchase; transilluminators are guaranteed for (2) years. Consumable and disposable parts including, but not limited

to bottles, tubes and filters, are guaranteed to be free from defects in manufacture and materials for ninety (90) days from

date of purchase. If equipment failure or malfunction occurs during the warranty period, UVP shall examine the inoperative

equipment and have the option of repairing or replacing any part(s) which, in the judgment of UVP, were originally defective

or became so under conditions of normal usage and service.

No warranty shall apply to any instrument, or part thereof, that has been subject to accident, negligence, alteration, abuse or

misuse by the end-user. Moreover, UVP makes no warranties whatsoever with respect to parts not supplied by UVP or that

have been installed, used and/or serviced other than in strict compliance with the instructions appearing in the operational

manual supplied to the end-user.

In no event shall UVP be responsible to the end-user for any incidental or consequential damages, whether foreseeable or

not, including, but not limited to property damage, inability to use equipment, lost business, lost profits, or inconvenience

arising out of or connected with the use of instruments produced by UVP. Nor is UVP liable or responsible for any personal

injuries occurring as a result of the use, installation and/or servicing of equipment. This warranty does not supersede any

statutory rights that may be available in certain coun tr ie s.

Corporate Headquarters: UVP, LLC 2066 W. 11th Street, Upland, California 91786

European Operations: Ultra-Violet Products Ltd, Unit 1, Trinity Hall Farm Estate, Nuffield Road, Cambridge, CB4 1TG UK

Tel: (909) 946-3197 or Toll Free (800) 452-6788 • Fax: (909) 946-3597 • Email: info@uvp.com

Tel: +44(0)1223-420022 • Fax: +44(0)1223-420561 • Email: uvp@uvp.co.uk

Web Site: www.uvp.com

Loading...

Loading...