Page 1

See product literature for part numbers of Reveal additives, lamps and

injectors. Reveal is a trademark of UVP, LLC.

WARNING

KEEP ALL ADDITIVES OUT OF THE REACH OF CHILDREN.

MAYBE HARMFUL OR FATAL IF SWALLOWED.

http://www.uvp.com

Upland, CA 91786-3509 / (800) 452-6788, (909) 946-3197

Fax: (909)946-3597 E-Mail: info@uvp.com

Ultra-Violet Products Ltd., Unit 1, Trinity Hall Farm Estate,

Nuffield Road, Cambridge CB4 1TG UK +44(0) 1223-420022

Fax: +44(0)1223-420561 / E-Mail: uvp@uvp.co.uk

UVP, LLC 2066 W. 11th Street

81-0126-01 Rev E

REVEAL™ Plus

Leak Detection Additives

Instructions for use of the following additives from UVP:

A-680Plus for Oil, Fuel and ATF Systems

A-690Plus for Coolant Systems

A-670Plus and A-671Plus for Air Conditioning Systems

A-672Plus Universal A/C Dye

A-680Plus OIL, FUEL AND ATF ADDITIVE

A-690Plus WATER COOLANT ADDITIVE

A-680Plus is designed for instant location of leaks in automotive engines,

manual and automatic transmissions, power steering systems, and gasoline

and diesel fuel systems. A-690Plus is designed for instant location of leaks in

automotive cooling systems.

NOTE: NOT INTENDED FOR USE IN BRAKE FLUID SYSTEMS.

INSTRUCTIONS FOR USE

1. Dilution for A-680Plus is 1 oz. per 4 to 5 quarts of system fluid. Dilution

for A-690Plus is 1 oz. per 2 gallons of coolant. Pour 1 oz. of additive into

suspect system. To avoid the possibility of splashing, do not operate

engine while adding dye into the system.

2. Run the engine for five to six minutes to circulate the dye. NOTE: For

some systems, it may be necessary to drive three or four miles to allow

sufficient circulation of the dye.

3. Check for proper fluorescence by shining a blacklight on the system

dipstick or filler hole. NOTE: In some cases, it may be necessary to add

a second container of additive, ie: in dirty oil, graphite or molybdenum

sulfide based oils, or a crankcase greater than 5 quarts.

Page 2

4. Inspect the system being tested by shining an ultraviolet inspection

lamp (blacklight) over the suspected leak areas. The origin of the leak

can quickly be identified by the bright yellow-green fluorescent glow.

5. After inspection and repair, the additives may remain in the system

without harm to engine parts or diminished lubrication, to identify

potential future leaks.

A-670Plus, A-671Plus and A-672Plus

AIR CONDITIONING ADDITIVE

Reveal A-670Plus is designed for instant leak detection of Freon in mineral

oil lubricated automotive air conditioning systems. This product is designed

for use with the AC-1 injector.

Reveal A-671Plus is designed for instant leak detection of R-134a in PAG

lubricated air automotive conditioning systems. This product is designed for

use with the AC-2 injector.

A-672Plus is designed for use in Ester Oil, PAG Oil Mineral Oil and low

temperature Alkyl Benzene Systems: R-11, 12, 22, 113, 114, 123, 134A, 500,

HP-62, A-Z50, AC-9000 & A-220. A-672Plus Meets ASRAE Test Standards

86 & 97 and comes in a convenient six-pack of one-ounce containers.

Both A-670Plus and A-671Plus come in one-ounce bottles. Each bottle

contains four 1/4-oz. applications (reference increment marks on bottle).

USE INSTRUCTIONS

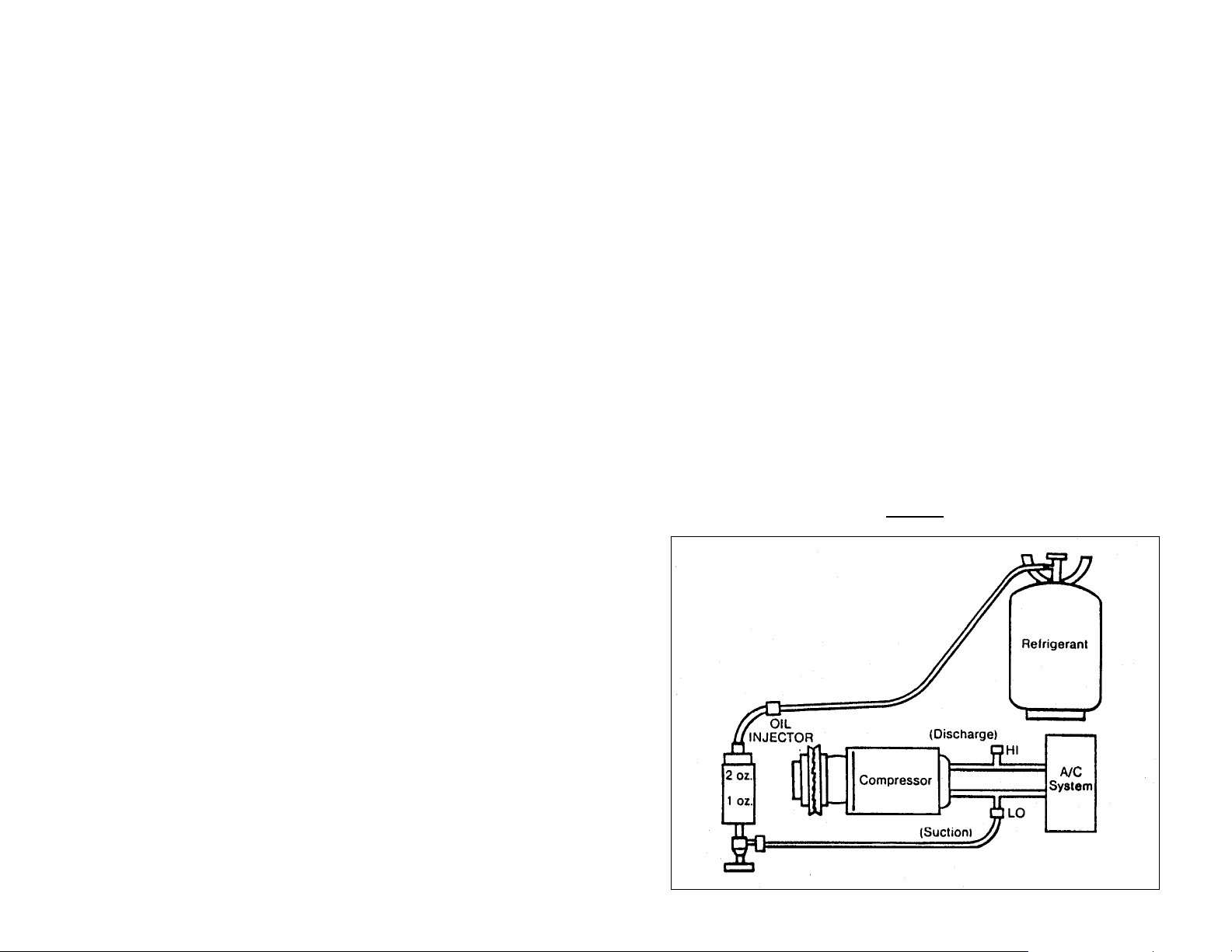

NOTE: The injector should always be used in a vertical position with the

valve end down (refer to Figure A).

1. Dilution: 1/4 oz. per air conditioning system. Pour one application (1/4

oz.) of A/C additive into its corresponding oil injector.

2. With the engine and refrigeration system OFF and all valves closed,

connect the injector to the refrigerant supply and to the low-pressure

service valve.

3. To purge the injector, open the refrigerant supply valve and slowly crack

open the injector cylinder. When you hear refrigerant escaping, close

the cylinder. The injector is now purged of air.

4. With the engine and air-condition system ON, open the refrigerant

valve. Slowly open the injector valve allowing refrigerant to charge

additive into the system. Charging requires no more than 2 to 3 ounces

of refrigerant. Continue charging the system with just enough refrigerant

to test the system.

5. Close all valves and disconnect the injector from the system.

6. Run the system on HIGH for 5 to 6 minutes, or long enough to allow the

additive to circulate.

7. Search the surface of the air conditioning system with a blacklight lamp.

The origin of the leak can quickly be identified by a bright yellow-green

fluorescent glow.

8. After repairs have been made, recharge the system with refrigerant and

re-inspect following these steps.

A-670Plus and A-671Plus are system friendly. Both additives safely remain in

the air conditioning system to identify potential future refrigerant leaks.

Add appropriate amount of Dye to system and allow to operate under normal

conditions for a short period. Longer operation may be required if leak is minimal.

Operate Ultraviolet light in the suspected area and a green glow will appear at the leak

source. Dye ratio to system is based on 1/4 oz. per typical automotive applications or

1/4 oz. up to 2.9 lbs. of refrigerant. Add 1/2 oz. from 2.9 lbs. to 25 lbs. of refrigerant.

On systems of 25 lbs. of refrigerant or more, add 1/2 oz. per every 4 gallons of

lubricant.

Figure A

Loading...

Loading...