Page 1

INSTRUCTION MANUAL

HA1

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

Hermetic Compressor Analyzer

Page 2

Introduction

The HA1 analyzes and tests hermetic compressors at up to 25 amps of

running current. Connects directly to the compressor motor eliminating the

ation system start capacitor.

refriger

Features include

• 3 Ranges of 250 V AC starting capacitors between 88-301 MFD

• Dual voltage oper

ation of 120/240 V AC

• Indicates continuity & ground faults in motor windings

with LED lights

• Free locked rotors by reversing motor action

• Convenient breakout jacks for measuring voltage and resistance

Safety Notes

Before using this instrument, read all safet

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

• Do not attempt to measure any voltage that exceeds the

category based rating of this meter

• Do not attempt to use this instrument if either the meter or the test

leads have been damaged. Turn it in for repair at a qualified

repair facility

• Ensure instrument leads are fully seated by making a quick continuity

check of the leads prior to making voltage measurements

• Keep your fingers away from the test lead’s metal probe

contacts when making measurements. Always grip the leads behind

the finger guards molded into the probes

• Use a current clamp adapter when measuring current that may

exceed 10 amps. See the accessories in UEi’s full-line catalog

• Do not open the instrument to replace batteries or fuses while the

probes are connected

y information carefully. In

• In the event of electrical shock, ALWAYS bring the victim to

the emergency room for evaluation, regardless of the victim’s

apparent recovery - Electrical shock can cause an unstable heart

rhythm that may need medical attention

• Higher voltages and currents require greater awareness of

al safety hazards - Before connecting the test leads; turn

physic

wer to the circuit under test; set the instrument to the

off po

desired function and range; connect the test leads to the

instrument first, then to the circuit under test. Reapply power

• If any of the following indications occur during testing, turn

off the power source to the circuit under test:

• Arcing

• Flame

• Smoke

• Extreme Heat

• Smell of Burning Materials

• Discoloration or Melting of Components

CAUTION!

Do not attempt to remove the instruments leads from the circuit under

test. The leads, the meter, or the cir

cuit under test may have degraded

to the point that they no longer provide protection from the voltage and

current applied. If any of these erroneous readings are observed,

disconnect power immediately and recheck all settings and connections

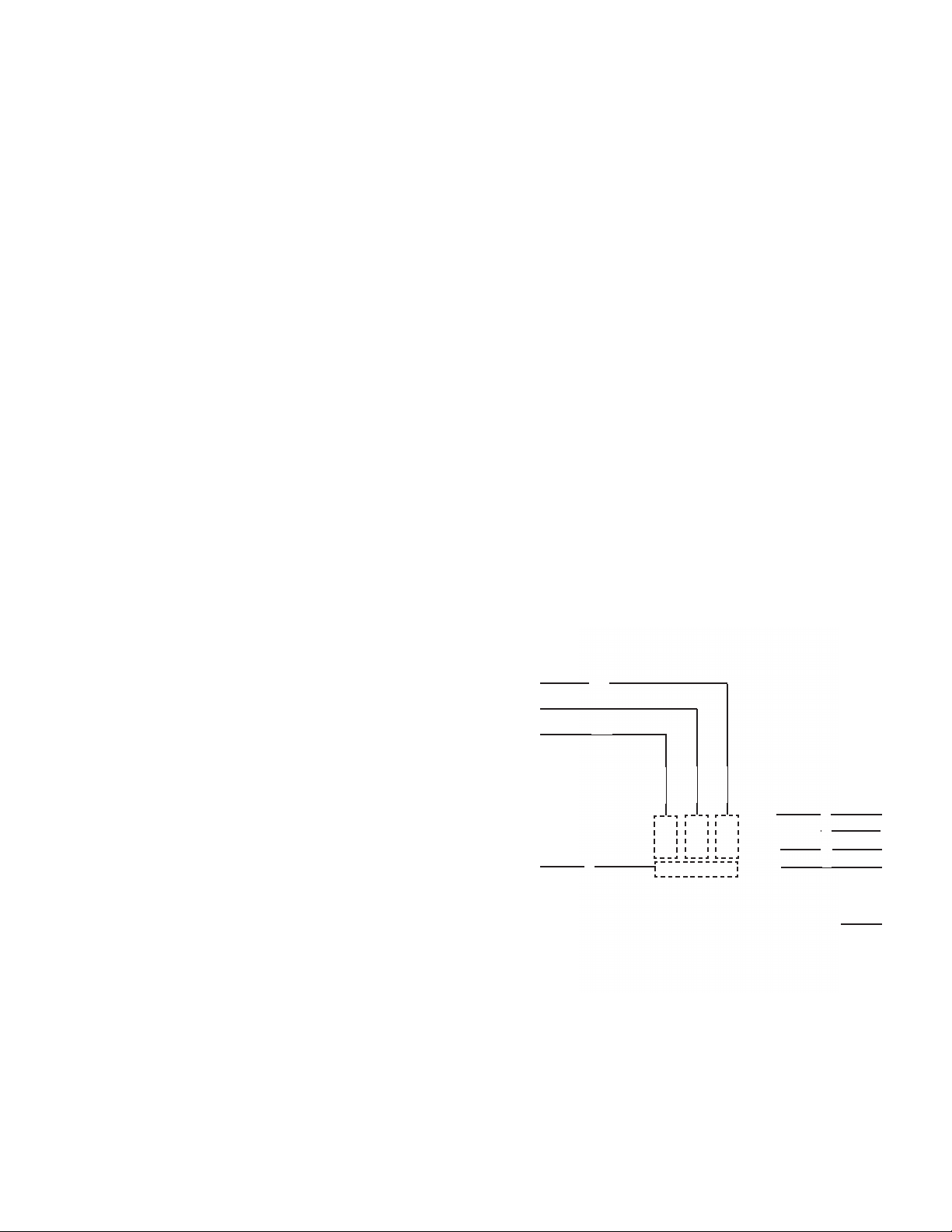

Controls and Indicators

7

6

5

WARNING!

Exceeding the specified limits of this instrument is dangerous and can

expose the user to serious or possibly fatal injury.

• Voltages above 60 volts DC or 25 volts AC may constitute a

serious shock hazard

• Always turn off power to a circuit (or assembly) under test

before cutting, unsoldering, or breaking the current path Even small amounts of current c

Always disconnect the live test lead before disconnecting the

•

an be dangerous

common test lead from a circuit

HA1-MAN

2

1

3

8

4

9

1. PWR Breaker: This is a combination 25A circuit breaker and a

POWER ON switch.

2. CAP 100/300/200: Selects one of the three starting capacitor ranges:

osition

P

FD 88-108MFD

00M

1

Range

200MFD 161-193MFD

300MFD 249-301MFD

P. 1

Page 3

EV/OFF/FWD:

3. R

the compressor. In the “

compressor motor run winding, and the start capacitor is

connected to the ST

applied to the compressor motor start winding and the start

capacitor is connected to the RUN cable. In the “

the power circuit to the motor is broken.

This switch determines the mode of oper

FWD” position, power is applied to the

ART cable. In the “REV” position, po

OFF” position,

ation of

wer is

est Jacks:

9. T

cable of the corresponding color:

GROUND = yellow, START = red, and RUN = black. The purpose

of the test jacks is to facilitate resistance and voltage readings by

enabling voltmeter/ohm meter test leads to be connected to the

compressor motor circuit by inserting them into the appropriate

jack at the HA1 front panel.

The four test jacks are connected directly to the test

COMMON = white,

REV” position is momentary. The “OFF” and “FWD”

The “

positions are sustained.

4. FAULT/CONT./START: This is a multi-function switch. The

“FAU LT” (momentary action) position is used to check for shorts

between the “COM” and the “RUN/START” windings. The

“CONT.” (sustained action) position is used to check for

GROUND, RUN and START continuity. In the “

(momentary action) position the start capacitor is connected to

the compressor motor through the “

5. Ground Test (Yellow): Push-button switch tests for ground

continuity between system ground and the frame of the appliance

being tested.

The HA1 introduces an “artificial ground” to make possible the

testing for short circuits between the motor winding and the

frame of appliances which may not be directly grounded. For

example, units with two wire power cords would not be

connected to systems ground (unless a separate ground

connection were present).

6. Start Test (Red): Push-button switch tests two conditions,

depending on the position of the “FUALT/CONT./START” switch.

Switch Position Condition Tested

FAU LT Short between START winding and frame

CONT. Continuity of START winding

7. Run Test (Black): Push-button switch tests two conditions,

depending on the position of the “FUALT/CONT./START” switch.

REV/OFF/FWD” switch.

START”

*Since this cable is an “artificial” ground line it is colored yellow

instead of green.

Operating Instructions

NOTE: Every effort has been made to make the HA1 a safe and

versatile tester. However, under some circumstances line voltage may

be present on the HA1 test cables when the control switches are in the

OFF position. For this reason it is very important to read and become

familiar with the section on operation.

The following procedures have been detailed so a thorough

understanding of the operation sequence may be gained. In practice,

the following tests may be performed very quickly.

110 V AC Operation

CAUTION!

The HA1 is wired so that the white COMMON test cable is connected

to the neutral side of the line. The red START and black RUN cables

are connected to the hot side of the line by the “POWER BREAKER”

switch and the “REV/OFF/FWD” switch. If the 110 V AC receptacle has

been accidently reverse wired, the white

as soon as the HA1 is plugged into the power receptacle. To warn

against such a condition, the red REV LINE indicator will light as soon

as the HA1 is plugged into a grounded receptacle. In this case follow

procedure B for reversed line condition.

COMMON cable will be “hot”

Switch Position Condition Tested

FAU LT Short between RUN winding and frame

CONT. Continuity of RUN winding

8. Indicator Lights: LINE NORM (white)/REV (red). These lights are

used to indicate the condition of the power source to which the

HA1 is connected.

Line Voltage Indicator Light Status

110 V AC NORM on/REV off Normal

REV on/NORM off Neutral and line wires

reversed at po

receptacle. Refer to

section on “110 V AC”

operation.

V

M and R

NOR

on (half intensity) or not connected at

220 V AC NORM and REV Normal

on (full intensity)

E

System ground open

power receptacle.

wer

A. Normal Test Procedure

1. The “REV/OFF/FWD” switch must be in the “OFF” position.

Plug the HA1 into a grounded 110 V AC receptacle and turn on

2.

R

E

W

PO

the “

white NORM LINE indicator should light.

NOTE: If the receptacle is ungrounded, both the “NORM” and the

EV LINE”

“R

of a g

from being made.

IMPORTANT: Verify that the receptacle is not also reverse wired

by measuring the voltage between the white COM cable and a

ground connection. A reversed line will measure 110 V AC. A

normal line will measure zero volts. If the receptacle is reverse

wired, follow procedure B.

3. Remove power to the unit which is to be tested.

Remove and identif

4.

and run terminals of the compressor motor

” switch. This is a push-on and push-off switch. The

indicator will lig

ounded line will not pr

r

y the connectors going to the common, start,

ht, but at half intensity. The absence

event an

y of the following tests

.

HA1-MAN

P. 2

Page 4

5. Connect the test cables of the HA1 to the compressor motor.

ellow “GROUND

A. Y

B. Red “

START” cable to the start terminal.

C. Black “RUN” cable to the run terminal.

D. Leave the white “

step 7.

6. Push the “FAULT/CONT./START” switch to the “FAULT” position

and hold it there while pressing the red “START TEST” and black

“

RUN TEST” switches in turn. If either the “START” indicator or

RUN” indicator lights, there is a short between that winding and

“

the frame. STOP the test and replace the unit.

7. Connect the white “

of the compressor motor.

8. Press, in turn, the “

” switches. The appropriate indicator will light indicating

TEST

continuity in the circuit being tested.

able to compressor motor frame.

” c

COMMON” cable disconnected until

COMMON” cable to the common terminal

GROUND TEST, START TEST, and RUN

Reversed Line Operation

B.

10 V AC receptacle is reverse wired the main thing to

If the 1

remember is that the white “COMMON” cable will be HOT

regardless of any HA1 switch setting. Therefore, exercise

extreme care.

ollow the same procedure as for Normal Operation (A) steps 1

F

through 6, but keep the white “COMMON” cable isolated to prevent

accidental contact with it.

Before doing step 7, unplug the HA1 from the power receptacle,

connect the white “COMMON” cable to the common terminal of the

motor, and then plug the HA1 into the power receptacle.

Proceed with the tests outlines in steps 8 though 12, section A.

220 V AC Operation

NOTE: To test for ground continuity the appliance must be

plugged into a grounded 110 V AC receptacle or be grounded

through an external connection

If either the run start winding indicator open, stop the test and

replace the unit.

9. Select the appropriate motor start capacitor.

10. Press the “FAULT/CONT./START” switch to the “START” position

and, holding it there, throw the “REV/OFF/FWD” switch to the

“FWD” position. If the compressor starts, release the “START”

switch. The compressor will continue to run. The compressor may

be stopped by returning the “REV/OFF/FWD” switch to the

“OFF” position.

If the compressor does not start immediately, the rotor may be

locked. Release the “START” switch and return the

“REV/OFF/FWD” switch to the “OFF” position.

11. To “ Bump” the compressor, press the “FAULT/CONT./START”

switch to the “START” position and holding it there, throw the

“REV/OFF/FWD” switch to the “REV” position. If the

compressor starts immediately, then release both switches.

Repeat step 10 to assure that the compressor will run in the

forwards direction.

If the compressor does not start immediately in reverse, then

release both switches. A locked rotor will result in excessive

current being drawn by the compressor.

12. Steps 10 and 11 may be repeated a few times in an attempt to

free a locked rotor, but care should be taken not to overheat the

motor windings. If the compressor still does not start, then it

should be replaced.

13. Push the “POWER BREAKER” switch OFF. Disconnect the HA1

test cables from the motor.

CAUTION!

The white COM cable will be hot as soon as the HA1 line cord is connected to 220 V AC. Always make sure that power to the HA1 is shut off

before connecting the HA1 cables to the compressor motor on 220 V AC

operation.

1. The “REV/OFF/FWD” switch and the “POWER BREAKER” switch

must be in the off position.

2. Remove power to the unit which is to be tested.

3. Some compressor units have fans mounted in the same housing

as the compressor. If possible turn down the thermostat, or

disconnect the fan, so that the fan will not operate during the

compressor tests. The fan noise could make it difficult to listen to

the action of the compressor.

4. Remove and identify the connectors going to the common, start,

and run terminals of the compressor motor.

5. Connect the test cables of the HA1 to the compressor motor.

A. Yellow “

B. Red “S

C. Black “RUN” cable to the run terminal.

D. Leave the white “COMMON” cable disconnected until

6. Use an adapter cord of at least #14 AWG wire size to connect the

HA1 to the 2

7. Turn on the power to the HA1.

NOTE: Remember to keep the white “COM” cable out of the way.

It will have 110 V AC on the clip.

8. Push the “POWER BREAKER” switch to the “ON” position. Both

“LINE NORM/REV” indicators will light on.

Push the “FAU

9.

and hold it there while pressing the red “S

“RUN TEST” switches in sequence. If either the “START”

ator or “RUN

indic

winding and the frame. Stop the test and replace the unit.

GROUND” cable to compressor motor frame.

T

AR

step 1

T

0.

2

able to the start terminal.

” c

AC input terminals.

0 V

NT./START

T/CO

L

ator lights, there is a short between that

” indic

” switch to the “F

T

AU

ART TEST

T

L

” position

” and black

HA1-MAN P. 3

Page 5

0. Turn off the 220 V AC power source to the HA1. Connect the

1

white “COM” cable to the common terminal of the

compressor motor.

11. Turn Power back on andPress, in turn, the “GROUND, TEST,

TART TEST

S

tor will light indicating continuity in the circuit being tested. If

either the run or start winding indicate open, stop the test and

replace the unit.

12. Select the appropriate motor start capacitor.

13. Press the “FAULT/CONT./START” switch to the “START”

position and, holding it there, throw the “

FWD” position. If the compressor starts, release the

to the “

“START” switch. The compressor will continue to run. The

compressor may be stopped by returning the “REV/OFF/FWD”

switch to the “OFF” position.

If the compressor does not start immediately, the rotor may be

locked. Release the “S

“REV/OFF/FWD” switch to the “OFF” position.

14. To “Bump” the compressor, press the “FAULT/CONT./START”

switch to the “START” position and, holding it there, throw the

“REV/OFF/FWD” switch to the “REV” position. If the

compressor starts immediately then release both switches.

Repeat step 13 to assure that the compressor will run in the

forwards direction.

If the compressor does not start immediately in reverse, then

release both switches. A locked rotor will result in excessive

current being drawn by the compressor.

15. Steps 13 and 14 may be repeated a few times in an attempt to

free a locked rotor, but care should be taken not to overheat the

motor windings. If the compressor still does not start, then it

should be replaced.

, and R

UNTEST

” switches. The appropriate indic

TART

” switch and return the

REV/OFF/FWD” switch

Maintenance

eriodic Service

P

a

WARNING!

Repair and service of this instrument is to be performed by qualified

personnel only

radation of the meter. This could alter the protection from

deg

electrical shock and personal injury this meter provides to the

operator. Perform only those maintenance tasks that you are

qualified to do.

These guidelines will help you attain long and reliable service from

your meter:

• Calibrate your meter annually to ensure it meets original

performance specifications

• Keep your meter dry. If it gets wet, wipe dry immediately.

Liquids can degrade electronic circuits

• Whenever practical, keep the meter away from dust and

dirt that can cause premature wear

• Although your meter is built to withstand the rigors of daily

use, it can be damaged by severe impacts. Use reasonable

caution when using and storing the meter

Cleaning

Periodically clean your meter’s case using a damp cloth. DO NOT use

abrasive, flammable liquids, cleaning solvents, or strong detergents as

they may damage the finish, impair safety, or affect the reliability of the

structural components.

. Improper repair or service could result in physical

16. Turn off the 220 V AC power source to the HA1. Disconnect the

HA1 test cables from the motor.

HA1-MAN

P. 4

Page 6

HA1

Hermetic Compressor Analyzer

Limited Warranty

The HA1 is warranted to be free from defects in materials and workmanship for a

period of three years from the date of purchase. If within the warranty period your instrument

should become inoperative from such defects, the unit will be repaired or replaced at UEi’s

option. This warranty covers normal use and does not cover damage which occurs in shipment or failure which results from alteration, tampering, accident, misuse, abuse, neglect or

improper maintenance. Batteries and consequential damage resulting from failed batteries are

not covered by warranty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warranty repairs will be rendered. Instruments out of warranty will be repaired (when

repairable) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

PLEASE

RECYCLE

Copyright © 2007 UEi

HA1-MAN 1/07

Loading...

Loading...