Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

C75

INSTRUCTION MANUAL

Page 2

Introduction

The goal of combustion analysis is to maximize the energy obtained

from a fuel while minimizing the risk of toxic gases and additional maintenance needs. Using an electronic combustion analyzer will give you

the needed values quickly for proper equipment set-up and tuning of

combustion equipment.

Common parameters to measure are CO2 and efficiency. This analyzer

measures O2, CO and flue temperature, and then calculates those. The

rotary selector makes choosing what is displayed fast, and easy, and

you can quickly move between parameters based on your needs.

This analyzer is designed for easy use, down to these simple steps

1 Power on the analyzer

2 Select the fuel

3 Place probe in the flue and measure combustion gases

More specific information on using the analyzer is included in this user

guide, including some basics of combustion.

Maximizing CO2 and efficiency has been used as a general guide, but

UEi recommends consulting technical information from the equipment

manufacture for targeted gas values.

Features include

• Measures: Flue temperature, oxygen, carbon monoxide (CO)

• Calculates: Carbon dioxide, gross efficiency, excess air, CO air free

• Unique DMM style rotary selector

• Real time clock

• CO readings to 1 ppm

• Large 2 line back-lit display

• Infrared printer port

• User programmable header

• 16 memory positions

Safety Notes

Before using this meter, read all safety information carefully. In this

manual the word "WARNING" is used to indicate conditions or actions

that may pose physical hazards to the user. The word "CAUTION" is

used to indicate conditions or actions that may damage this instrument.

WARNING!

This analyzer extracts combustion gases that may be toxic in relatively

low concentrations. These gases are exhausted from the back of the

instrument. This instrument must only be used in well-ventilated locations. It must only be used by trained and competent persons

after due consideration of all the potential hazards.

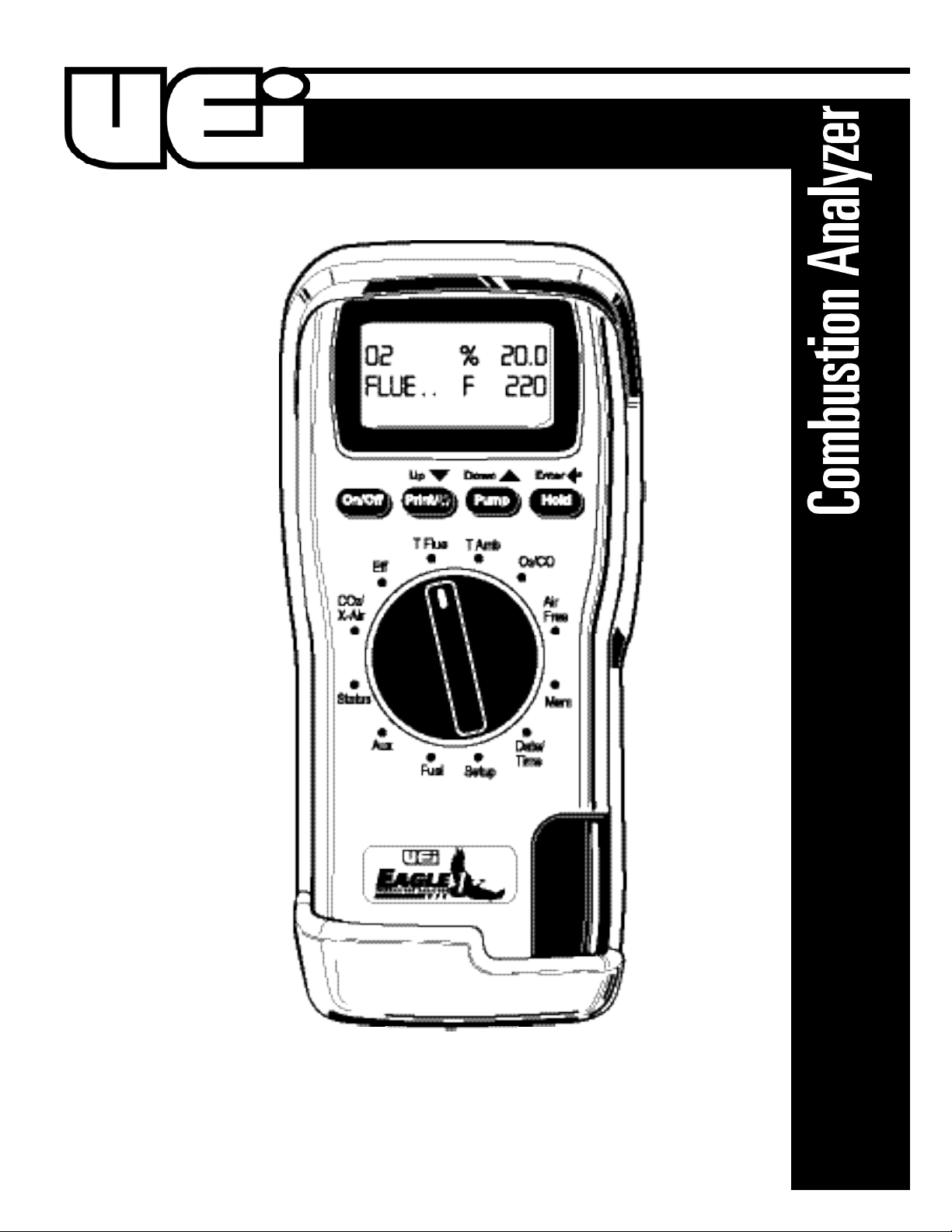

C o n t r ols and Indicators

1. Display

2. Infrared Print Emitter

3. ON/OFF: Turns analyzer ON and OFF.

4. Print/Back-Light: Print data - press briefly until “PRINTING”

appears. Back-light - press and hold to toggle back-light ON or OFF.

5. Pump: Turns pump ON and OFF. (Readings change to “ - - - -”

when the pump is OFF )

6. Hold/Store: Hold - Freezes reading on display. Entire

display flashes.

Store - press and hold for 2 seconds to store data in memory.

7. Rotary Selector

8. Particle Filter: (Inside water tra p )

9. Water Trap

10. Analyzer Connections

C75-MAN P. 1

2

1

3

4

5

6

7

8

9

10

Page 3

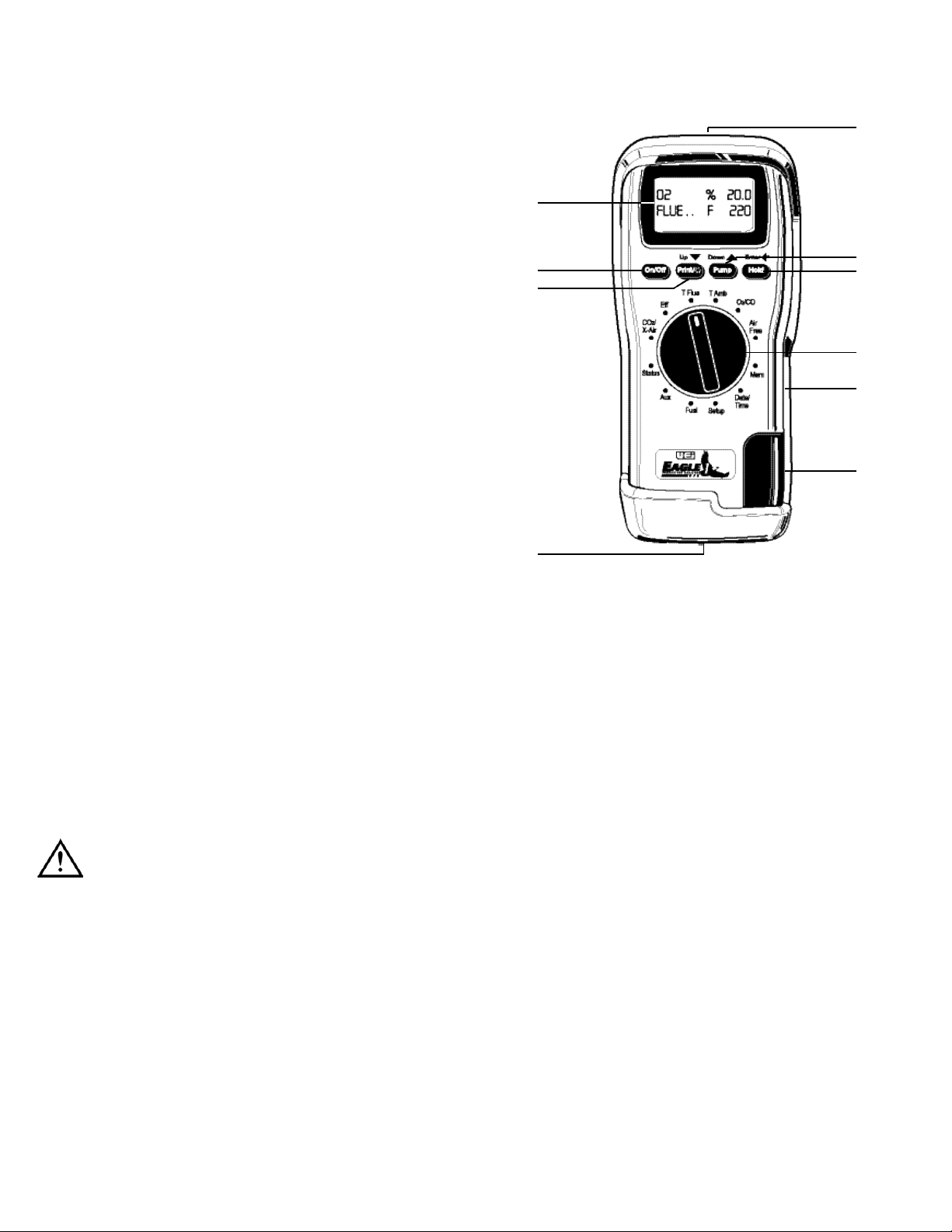

Probe Configuration

Operating Instructions

Before Use Each Time

• The particle filter is not dirty

• The water trap and probe line are empty of water

• All hose and thermocouple connections are properly made

• The flue gas probe is sampling ambient FRESH air

• The water trap is fitted correctly to the instrument

• The Flue temperature probe is connected if required to set the

inlet air temperature

NOTE: If using ambient air for combustion leave disconnected

Switch ON the instrument by pressing “ON/OFF“.

After switch-on, the analyzer will scroll through the following

information while performing a zero countdown:

• Currently Set Date

• Currently Set Time

• Remaining Battery Level

• Fuel Selected

• Model and Analyzer Firmware Level

NOTE: The count begins at 59 seconds, and will display the parameter

selected with the rotary knob when the sensors are detected as stable.

If the analyzer will not auto-zero, the sensors are in need of replacement and the unit should be returned to the authorized service center.

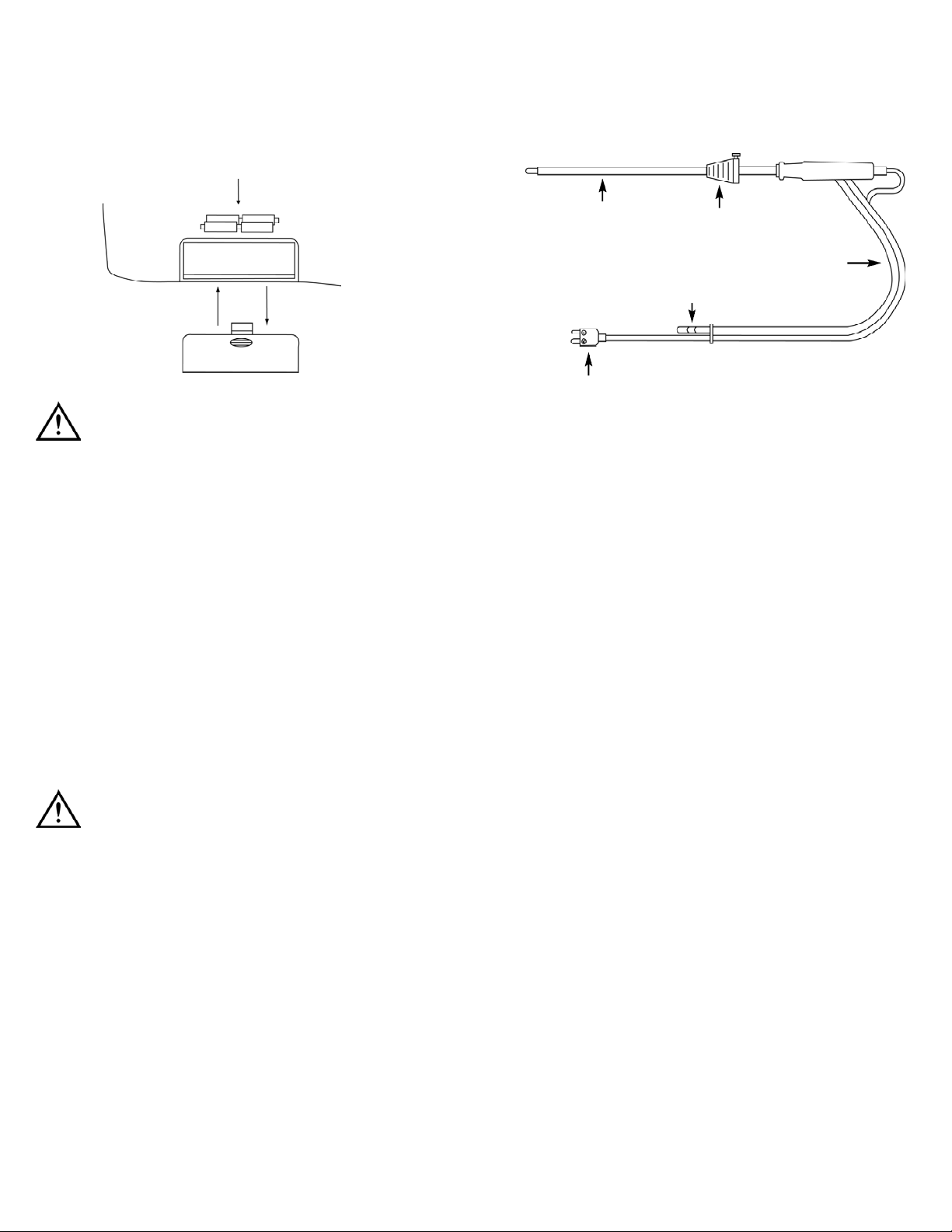

Battery Replacement

This meter has been designed for use with both alkaline and

rechargeable Nickel Metal Hydride (NiMH) batteries. No other types

are recommended. The analyzer is supplied with 4 “AA” size alkaline

batteries. These should be installed into the instrument as shown

below (Fig 1) and indicated on the back of the unit.

CAUTION!

Take great care when installing the batteries to observe correct polarity.

Always check the meter for operation immediately after installing

new batteries.

Using Re-Chargeable Batteries

The battery charger must only be used when NiMH batteries are fitted.

Alkaline batteries are not re-Chargeable. Attempting to recharge alkaline

batteries may result in damage to the product and may create a fire risk.

Charging

Ensure that you use the correct charger. This unit uses a 9V DC

regulated charger.

Ensure that the batteries are fitted in the correct manner, and then

charge for at least 16 hours. Subsequent charges should be overnight.

NiMH batteries may be charged at any time, even for short periods to

conduct testing.

WARNING!

Under NO c i r cumstance should you expose batteries to ex t reme heat or

f i r e as they may explode and cause injury. Always dispose of old batteries

p romptly in a manner consistent with local disposal re g u l a t i o n s .

C75-MAN P. 2

Type K-Thermometer plug

Stainless steel shaft

Depth stop cone

9 foot neoprene hose

Flue temperature probe connector

Flue gas connector

Fit probe connector to end of

tube using barbed end.

(Fig 1)

Page 4

Selecting Fuel

To set the fuel simply rotate the selector to “FUEL” then press the “U P”

or “DOWN” arrows to scroll through the choices. When the correct fuel

is displayed on the bottom line press “ENTER” to choose this fuel.

Symbol Legend

Setting Inlet Temperature

During the automatic calibration sequence the burner INLET (Ti)

temperature used in the NET temperature calculation is stored in the

analyzer. There are two methods of storing the INLET temperature.

A. Without the flue probe connected temperature inside the analyzer

is used (ambient temperature).

B. If the flue probe is connected the temperature of the probe tip is

used. This can be useful when the temperature of the air entering

the burner is different than the ambient temperature of the room.

NOTE: On ducted inlets, insert the probe tip into the inlet air during the

zero countdown. The analyzer will then store this temperature as the

ambient (inlet) for use in efficiency calculations. Do not sample flue gas

during the zero countdown.

WARNING!

If the INLET temperature is set incorrectly, then errors will be made in

the calculation of net temperature and efficiently.

Sampling the Flue Gas

Once the automatic calibration procedure has been completed and the

specific fuel has been selected (see menu options) the probe can be

inserted into the desired sampling point.

It is recommended that the sampling point be located at least two flue

diameters downstream of any bend, as close to the source as possible,

and that the probe tip is in the center of the flue. With balanced flues

and other domestic units the probe should be positioned far enough

into the flue so that no air can “back flush” into the probe.

Symbol Description Notes

Efficiency (gross) Calculated percentage efficiency based on

net temperature, O2 value and fuel selected.

Battery Level Battery level indication with percentage

remaining.

Excess Air Theoretical amount of air in excess of level

needed to completely burn fuel.

Losses Losses calculated from Oxygen and type of

fuels. Displays reading during a combustion

test. “- - - -” is displayed while in fresh air.

∆T Delta Temperature Net Te m p e r ature of Flue and Ambient (or inlet).

TF Flue Temperature Measure of Flue Temperature.

Analyzer Connections

NOTE: Take care when inserting the temperature probes as the pins are

polarized. Insert with the smaller pin (+) to the right. A view of the

sockets is shown below.

Automatic Calibration

During this sequence the analyzer pumps fresh air into the Oxygen and

CO (C75 only) sensors to allow them to be set to 20.9% and zero

respectively. See “Setting Inlet Temperature) for information on options.

Changing the Display

The parameters on the display are selected from the following using the

rotary selector knob. Certain items are available on the AUX display by

selecting through the menu.

Selector Top Line Bottom Line

Fuel Fuel Selected Fuel Indicator

(Scroll selection with the up/down • NAT GAS Natural Gas

arrows and then press the enter key • PROPANE

“HOLD” to choose • BUTANE

• L OIL Light Oil

• LPG Liquid

Petroleum Gas

• H OIL Heavy Oil

Aux User selectable line 1 User selectable line 2

Status Fuel selected Battery level

CO2 / X-Air CO2 in percentage Excess Air % (represented by

Greek Lambda )

Eff (Efficiency ) Flue Te m p e rature (TF) E f f i c i e n cy % (represented by

Greek eta )

T Flue TF (Flue temp) Net Te m p e r ature (∆T )

T Amb (Ambient) Ambient Temp (or set inlet tempera t u r e Net Te m p e r ature (∆T )

See page 7)

O 2 / CO Measured O2% Measured CO ppm

Air Fr e e Calculated value for

CO Air Free (see page 17)

Mem (Memory ) Used to view or delete stored readings

D a t e / T i m e D a t e T i m e

S e t u p Used to setup instrument Adjustment position for Time,

Date, Te m p e r ature scale,

Screen Contrast, Language,

Header, Aux selector display,

or entering Service mode.

C75-MAN P. 3

Flue (Tf) temperature

socket

Mains adapter socket Flue gas inlet

Water trap drain plug

Page 5

The probe depth stop cone provided with the instrument allows the

probe to be used in holes whose diameters range from 1/4 to 4/5 inch

(6 mm to 21 mm).

The standard probe is rated at 1112˚F (600˚C).

Where To Te s t

Boiler & Water Heaters

Boiler

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

Water Heater

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

Furnaces: 80%

80% Furnace

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

(Note: The following may require additional

test instruments)

Set Up

• Gas pressure

Test

• Limit switch

• Pressure switch

Verify proper combustion:

• Static duct pressure

• Temperature rise

• AC side static pressure drop

across coils

Atmospheric, Gas & Oil

Atmospheric Furnace

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

(Note: The following may require additional

test instruments)

Draft

Ve r i f y proper

• Temperature

• AC side static pressure drop

across coils

C75-MAN P. 4

Page 6

C75-MAN P. 5

Furnaces (

CONTINUED

): Atmospheric, Gas & Oil

Gas Furnace

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

(Note: The following may require additional

test instruments)

Test

• Limit switch

• Pressure switch

Set Up

• Gas pressure

Verify proper:

• Static duct pressure

• Temperature rise

• AC side static pressure drop

across coils

Oil Furnace

Verify proper combustion:

• O2

• CO

• Stack temp

• Efficiency

(Note: The following may require additional

test instruments)

Test

• Smoke

Set Up

• Over fire draft

Verify proper:

• Static duct pressure

• Temperature rise

• AC side static pressure drop

across coils

Regular Checks During Sampling

Care must be taken at all times not to exceed the analyzer’s operating

specifications. In particular ensure the following:

• Do not exceed the maximum temperature of the flue probe

• The analyzer internal temperature does not exceed normal

operating range

• DO NOT PLACE THE INSTRUMENT ON A HOT SURFACE

• The water trap is correctly attached at all times - Water condenses

in the probe line and can quickly fill the water trap when the

probe is moved - Take care and watch the water trap closely

• The particle filter is clean and does not become blocked

Normal Shutdown Sequence

WARNING!

Turning the pump off while the probe is in the flue will leave toxic

gases inside the analyzer. Once data has been printed or copied it is

advisable to purge the unit with fresh air as soon as possible. To do

this, with the probe removed from the flue, turn ON the pump. Always

allow the readings to return to zero (20.9 for O2) prior to shutting the

unit off. The meter will not switch off until the CO reading is

below 20 ppm.

WARNING!

The probe will be hot from flue gases.

Remove the probe from the flue and allow it to cool naturally. Do not

immerse the probe in water, as this will be drawn into the analyzer and

damage the pump and sensors. Once the probe is removed from the

flue and the readings have returned to ambient levels hold down

“ON/OFF“ button and switch off the analyzer.

The instrument will count down from 30 to switch off.

If you pressed “ON/OFF“ button by mistake, pressing “HOLD“ button

will return you to normal operation.

Page 7

C75-MAN P. 6

SERVICE

1. The service mode is used for repair and calibration, and

should only be entered

by authorized service facilities.

2. The firmware can be displayed by entering “2222” for

the code.

You may exit the menu at any time by rotating the selector to a

different position unless the final logical “ENTER” is pressed, no

changes are made.

Storing and Viewing Test Results

At any time during a test you may store the readings in one of the 1

memory positions. Press “HOLD” button for 2 seconds or more to

store a reading. The memory location will be displayed briefly after the

two beeps.

To review stored readings select “Mem” on the selector.

VIEW

1. Pressing “ENTER” will allow you to view stored readings.

2. Press “ “ or “ “ to select different memory positions.

Note: You may print this test at any time by pressing

“PRINT” for 2 seconds.

DEL ALL

1. Clears all values stored in memory - Confirm with “YES”

then “ENTER”.

Rotate selector to any other position to exit Memory mode.

Printing Information

Supplied as an accessory for the analyzer is an infrared thermal printer.

Read the manual supplied with the printer prior to operation.

Connection to the analyzer is detailed below:

• Infrared thermal printer - this does not require a cable to transmit

the data but uses an infrared (IR) link similar to a TV remote

control. The IR emitter is positioned on the top of the analyzer

and the bottom of the printer. Ensure they are pointing at each

other and within 3 feet, with no obstructions in the way. Data may

be lost if transmission is interrupted. Keep the analyzer pointing at

the printer until the printout has finished.

Moving Through the Menu

The options in the menu system are in the following sequence by

pressing the down arrow:

Note: The menu choices are selected using the text printed on the case

above the function keys. The three keys are “ “ increases, “ “

decrease and “ “ enter.

Set Time

1. Press “ENTE R”.

2. Use the up and down keys to select the correct time.

3. Press “ENTER” to move to the next digit.

Note: Time is displayed in military format, example 7:00 pm

is 19:00.

Date

1. Press “ENTE R”.

2. Use the up or down arrows to select the correct data.

3. Press “ENTER” to move to the next digit and then exit.

Note: Time is displayed in military format. For example 7:00 pm

is displayed 19:00.

C F

1. Press “ENTE R”.

2. Select degrees displayed in Fahrenheit or Centigrade using the

up or down keys.

3. Press “ENTER” to save and exit.

CONTRAST

1. Press “ENTE R”.

2. Select a value between 02 and 254 for desired contrast using

the up or down keys.

Note: Lower values result in a darker display.

LANGUAGE

1. Press “ENTE R”.

2. Select the desired language using the up or down keys.

3. Press “ENTER” to save and exit.

Header

1. Press up or down and “E NTER” to select desired header.

2. 2 lines of up to 16 characters will appear on the printout.

3. After entering text for header use the up or down buttons to

select “EXIT”.

AUX

1. Line 1 or Line 2.

• Press “ENTER”

• Press “ “ or “ “ to scroll through options

• Press “ENTER” again to choose the displayed option

2. Exit.

• Select “EXIT“, and then press “E NTER” to return to

the menu

Page 8

C75-MAN P. 7

Printing A Test

During combustion tests the analyzer can print data on request. With

the analyzer showing the data, briefly press the “PRINT“ button until

“PRINTING” is displayed.

The standard printout is:

NOTE: Printouts of stored

readings will also include

the TEST NO. below the

header.

SMOKE area on printout

is for adding data from

manual test.

M a i n t e n a n c e

Periodic Service

WARNING!

Repair and service of this instrument is to be performed by qualified

personnel only. Improper repair or service could result in physical

degradation of the instrument. This could alter the protection from

personal injury this meter provides to the operator. Perform only those

maintenance tasks that you are qualified to do.

These guidelines will help you attain long and reliable service from your

meter:

• Calibrate your instrument annually to ensure it meets original

performance specifications

• Keep your instrument dry. If it gets wet, wipe dry immediately.

Liquids can degrade electronic circuits

• Whenever practical, keep the instrument away from dust and

dirt that can cause premature wear

• Although your instrument is built to withstand the rigors of daily

use, it can be damaged by severe impacts. Use reasonable caution

when using and storing the meter

Cleaning

Periodically clean your instruments case using a damp cloth. DO NOT

use abrasive, flammable liquids, cleaning solvents, or strong detergents

as they may damage the finish, impair safety, or affect the reliability of

the structural components.

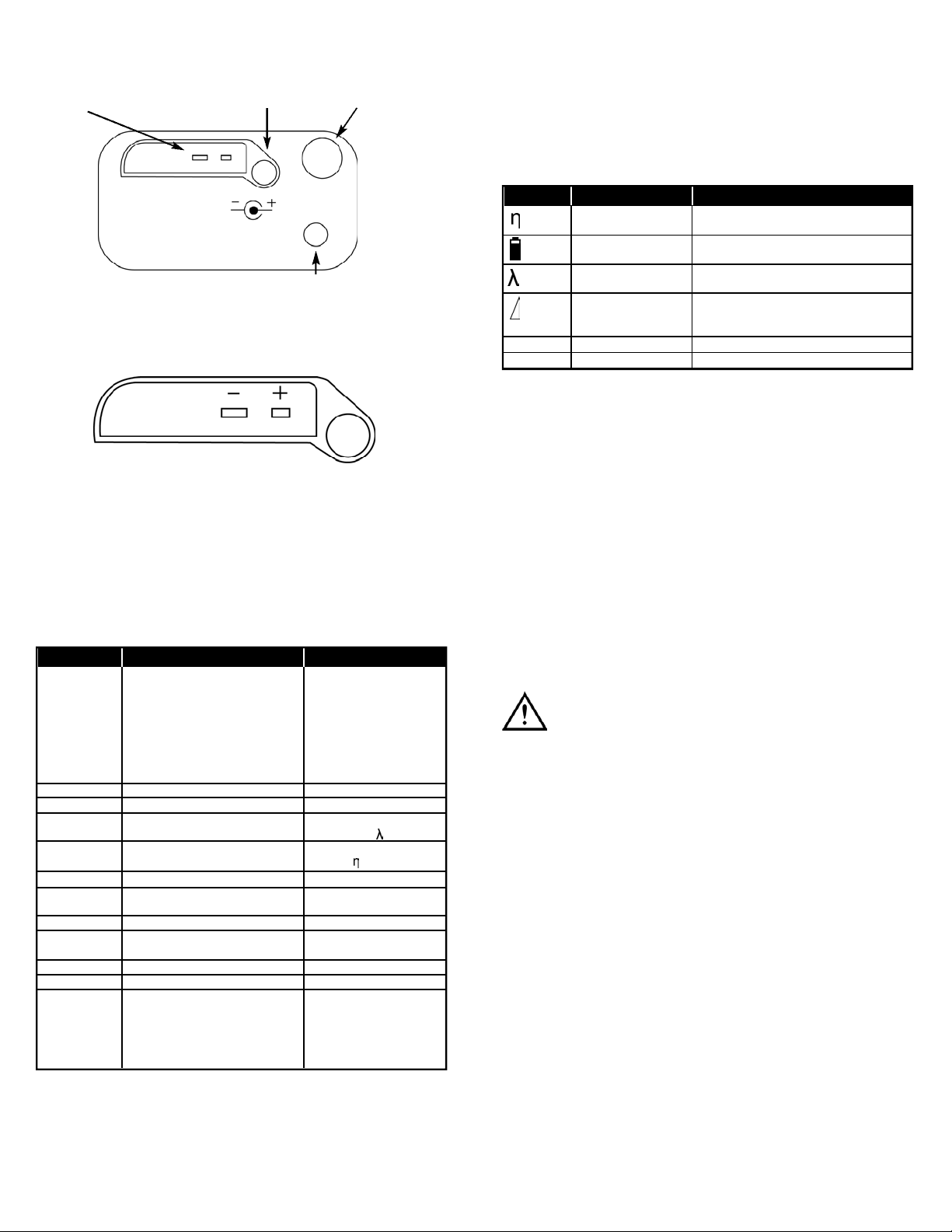

Emptying and Cleaning the In-line Water Trap

The in-line water trap should be checked and emptied on a regular

basis. Water vapor will condense in the probe line, which may cause the

water trap to fill suddenly if the probe is moved. Care should be taken

at all times.

Carefully remove the rubber plug from the bottom of the water-trap

housing. Dispose of the condensate in a suitable drain, care must be

taken as it could be acidic.

UEI C75

16 character header

16 character header

503 644 8723

Date: 06-26-02

Time: 14:27

Fuel NATU GAS

O2 % 20.9

CO2 % 0.0

CO* PPM 00

COaf* PPM 00

FLUE ˚F ---AMB ˚F ---NETT ˚F ----

EFF% (G) ---LOSSES** % ---XAIR % ----

SMOKE................................................................

Slide outward

Pull plug out

to drain

Page 9

C75-MAN P. 7

Below is a graph of typical combustion, showing the point of perfect

combustion and an approximate location for ideal combustion. You will

notice that by moving farther to the right on the air rich side (high

amounts of excess air), the pollutants (CO) don’t drop any further. This

is where you only lower efficiency. On the left side (fuel rich or starved

for air) you see a dramatic increase in carbon monoxide (CO), indicating that a portion of the fuel is not being converted to heat.

Combustion Efficiency Calculation

The efficiency calculation is based upon British Standards BS845.

This identifies three sources of loss associated with fuel burning:

Losses due to flue gasses: Dry Flue gas loss, moisture and

hydrogen, sensible heat of water

vapor, unburned gas

Losses due to refuse: Combustible in ash, riddlings

and dust

Other losses: Radiation, convection, conduction

other unmeasured losses

Since the fuel air mixture is never consistent there is the possibility of

unburned/partially unburned fuel passing through the flue. This is represented by the unburned carbon loss.

Losses due to combustible matter in ashes, riddlings, dust and grit,

radiation, convection and conduction are not included.

If condensate spills onto the skin or clothing, clean off immediately

using fresh water, seek medical advice if problems occur. Ensure plug is

replaced before performing combustion tests.

Changing the Particle Filter

This is a very important part of the analyzer and should be changed regularly. It prevents dust and dirt particles from entering the pump and

sensors that will cause damage. The filter MUST be changed when it

appears discolored.

Remove water-trap assembly from the analyzer as shown above.

Remove the filter and plastic holder from the housing. Discard the filter

element but keep the holder to fit to the new filter. Clean the inside of

the filter housing with a suitable soft cloth. Fit the holder onto the new

filter element and then insert into the housing. Refit the housing onto

the analyzer.

C o m b u s t i o n

Combustion Theory

In its simplest form, combustion is the combining of oxygen (O2) from

the air with hydrogen (H) and carbon (C) from the fuel to form carbon

dioxide (CO2), water (H2O) and energy (light and heat).

Perfect combustion occurs when all of the carbon and hydrogen in the

fuel unite with all of the oxygen supplied by the air. This is also referred

to as “STOICHIOMETRIC Combustion”.

In the real world perfect combustion is nearly impossible to achieve.

When tuning a combustion appliance, the goal is to come close to this

target to minimize losses and excess emissions. One method is to adjust

the amount of air supplied to the combustion area. Too little combustion air, and there will not be enough oxygen to unite with the hydrogen

and carbon. This will result in partially burnt fuel, and the creation of

carbon monoxide (CO), smoke, and lower efficiency. Too much air will

also lower efficiency because the high amount of excess air draws heat

away from the combustion area up the flue (increase in ∆T, difference

between flue temperature and ambient or inlet). If the amount of excess

air is too high, it will also move past the heat exchanger too quickly,

resulting in a lower amount of heat transferring to the target.

Insert a new filter

Rich

Lean

Page 10

The formula for K4 is based on the gross calorific value Qgr. To obtain

the loss based on net calorific value multiply by Qgr/Qnet. Since this

loss is usually small, this conversion has been ignored. This loss is

subtracted from the efficiency.

CO AIR-FREE and Converting to mg/m

3

Certain standards (ANSI Z21.1) for Carbon Monoxide are stated in

terms of air-free. Air-free refers to the concentration of CO in combustion gases undiluted with flue, or other gases containing little CO.

This value is computed using an equation that takes into account the O

2

concentration of the flue gas.

If 5% is measured (O2m) in the flue then the CO gas value will be recalculated as if 0% were measured. The equation for air-free is as follows:

COa = CO PPM x [(20.9) / (20.9 - O2m)]

Annual Re-Calibration

While the sensor has an expected life of more than two years in

normal use it is recommended that the analyzer is re-calibrated at

least annually, This is so that long-term drift on the sensor and

electronics can be eliminated. local regulations may require more

frequent re-calibration and users should check with appropriate

authorities to ensure the comply with relevant guidelines.

C50/C75-MAN P. 7

Efficiency Calculation:

Known Data - Fuel: Qgr = Gross Calorific Value (kJ/kg)

Qnet = Net Calorific Value (kJ/kg)

K1 = Constant based on Gross or net Calorific Va l u e

K1g = (255 x % Carbon in fuel)/Qgr

K1n = (255 x % Carbon in fuel)/Qnet

K2 = % max theoretical CO2

( d r y basis)

K3 = % Wet loss

H2= % Hydrogen

H2O = % Wa t e r

Measured Data: Tf = Flue Temperature

Ti = Inlet Temperature

O2m = % Oxygen in flue gas

O2r = Oxygen reference %

Calculated Data: Tnet = Net Temperature

% CO2content in flue gas

% Dry flue gas losses

% Wet losses

% Unburned carbon loss

% Efficiency

Tnet = Flue Temperature - Inlet Temperature

(or ambient)

D ry flue gas loss % = 20.9 x K1 x (Tnet)/K2 x (20.9 - O2m)

Wet loss % = 9 x H2+ H2O/Qgr x [2488 + 2.1 Tf - 4.2 Ti]

S i m p l i f i e d = [(9 x H2+ H2O)/Qgr] x 2425 x [1 + 0.001 Tnet]

Wet loss % = K3 (1 + 0.001 x Tnet)

Where K3 = [(9 x H2+ H2O)/Qgr] x 2425

Net efficiency % = 100 - dry flue gas losses

= 100 - 20.9 x K1n x (Tnet)/K2 x (20.9 - O2m)

Gross efficiency % = 100 - {dry flue gas losses + wet losses}

= 100 - {[20.9 x K1g x (Tnet)/K2 x (20.9 - O2m)]

+ [K3 x (1 + 0.001 x Tnett)]}

Excess Air = [20.9/(20.9 - O2m) - 1] x 100

CO2% = [(20.9 - O2m) x K2/20.9]

U n b u r n e d = K4 x CO/(CO + CO2) Note: CO scaled in %

fuel loss %

Where K4 = 70 for coke

= 65 for anthracite

= 63 for Bituminous coal

= 62 for coal tar fuel

= 48 for liquid petroleum fuel

= 32 for natural gas

Page 11

E l e c t r omagnetic Compatibility (EMC)

This product has been tested for compliance with the following

generic standards:

EN 50081-1, EN 50082-1

and is certified to be compliant.

The European Council Directive 89/336/EEC requires that electronic

equipment does not generate electromagnetic disturbances that exceed

defined levels and has an adequate level of immunity to enable it to be

operated as intended.

Since there are many electrical products in use that pre-date this

Directive and may emit electromagnetic radiation in excess of the

standards defined in the Directive there may be occasions where it

would be appropriate to check the analyzer prior to use. The following

procedure should be adopted.

• Go through the normal start up sequence in the location where the

equipment is to be used

• Switch on all localized electrical equipment that might be capable

of causing interference

• Check that all readings are as expected (a level of disturbance in

the readings is acceptable)

• If not, adjust the position of the instrument to minimize

interference or switch off, if possible, the offending equipment for

the duration of the test

At the time of writing this manual (July 200) Kane International Ltd is not

aware of any field based situation where such interference has ever occurred

and this advice is only given to satisfy the requirements of the Directive.

C75-MAN P. 8

Tro u b l e s h o o t i n g

The following is a list of problems that may occur on the instrument

through its operating life. If the cause of the fault is not easy to

identify then we advise you to contact UEi Technical Support line

at (800) 547-5740.

Fault Symptom Causes

• Analyzer will not power off CO reading too high, or faulty sensor.

The analyzer will not power off completely

if the CO reading is above 20 ppm, or the

sensor has an error (indicated by “----” in

the display for CO

• Oxygen too high Air leaking into probe, tubing, water trap,

• CO2too low connectors or internal to instrument,

or water trap plug missing

Oxygen cell needs replacing

• Oxygen error “----” Instrument has been stored in a

• CO sensor error “----” cold environment and is not

at normal working tempera t u r e

Oxygen cell or CO sensor needs replacing

• Display flashes Display “HOLD” is activated

B a t t e ry level is low

• Analyzer not running on AC charger not giving correct output

mains adapter

• Analyzer does not respond Particle filer blocked

to flue gas Probe or tubing blocked

Pump not working or damaged

with contaminant's

• Net temperature or efficiency Inlet (or ambient) temperature set wrong

calculation incorrect during automatic ca l i b r a t i o n

• Flue temperature readings Te m p e rature plug reversed in socket

e r r a t i c Fa u l ty connection or break in cable or plug

• X-Air, EFF, COa or CO 2 Oxygen reading is above 18 %

display (----)

• Meter just continually beeps Turn dial back to “MENU” and press

“ENTER” .

Page 12

EFF (G): Combustion efficiency calculation displayed in percentage.

Gross (G) or Net (N) can be set (see MENU). The calculation

is determined by the fuel type and uses the calculation in

British Standard BS845. The efficiency is displayed during a

combustion test, “- - - -” is displayed while in fresh air.

XA IR % : Excess air calculated from the measured oxygen and type of

fuel used. Displays reading during a combustion test. “- - - -” is

displayed while in fresh air.

A M B : Boiler air INL E T t e m p e r ature used to calculate the

NET t e m p e r a t u r e .

: Displays the approximate battery level as follow s :

• Full battery level

• B a t t e ry at 75 %

• B a t t e ry at 50 %

• B a t t e ry at 25 %

When the display flashes this, it indicates the batteries are at less than 10 %

of charge and should be replaced, readings may be affected if the analyzer

is used with low power batteries.

C75-MAN P. 9

S p e c i f i c a t i o n s

*1

Using dry gases at STP

*2

Calculated

A p p e n d i c e s

Main Display Parameters

O 2 : Oxygen reading in percentage (%).

T f : Te m p e rature is measured by the flue gas probe in Centigrade

or Fahrenheit. Will show ambient temperature after fresh air

ca l i b r ation and “- - - - ” if the flue probe is disconnected.

C O : Carbon Monoxide reading displayed in ppm (parts per

million). “- - - -” is displayed if there is a fault with the CO

sensor or the instrument has not set to zero correctly,

switch off instrument and try again.

C O a : Carbon Monoxide air-free reading referenced to an oxygen

level of 0%. Do not confuse this reading with the actual CO

reading as detailed above.

C O2: Carbon Dioxide calculation determined by the type of fuel.

This only shows a reading when a combination test is being

carried out. “- - - - ” is displayed while in fresh air.

∆T : Net temperature calculated by deducting the A MBIENT

(or INL ET) temperature from the measured FL UE

t e m p e r ature. Displays in either Centigrade (˚C) or Fahrenheit

(˚F) and will display “- - - - ” if the flue probe is not connected.

Parameter Range Resolution Accuracy

Temp Measurement

Flue temperature 1.0˚ F/C ±5˚F (2.0˚C) 32 - 1112˚F

±0.3% reading 0 - 600˚C

Inlet temperature 1˚ F/C ±1˚ F/C 32 - 212˚F

±0.3% reading 0 - 100˚C

Temp (Nett)

*2

1.0˚ F/C ±5˚F (2˚C) 32 - 1112˚F

±0.3% reading 0 - 600˚C

Gas Measurement

Oxygen 0.1% ±0.2%

*1

0 - 21%

*Carbon Monoxide 1 ppm ±10 ppm <100 ppm*10 - 1000 ppm

±5% reading

Carbon Dioxide

*2

0.1% ±0.3% reading 0 - 30%

Efficiency

*2

0.1% ±1.0% reading 0 - 99.9%

Excess Air

*2

0.1% ±0.2% 0 - 250%

Pre-programmed fuels Natural gas, Light Oil, Propane, Butane, LPG

Dimensions

Weight 1 kg. / 2.2 lb.

Handset 200mm/7.9” x 45mm/1.8” x 90mm/3.5”

Probe (L) 300mm/7.9” x (Dia) 6mm/0.25” with 200mm/7.8”

long stainless steel shaft, type K thermocouple and

3m/6ft long neoprene hose

Ambient operating +32˚ - 104˚F (0˚ - 40˚C)

10% to 90% RH non-condensing

Battery life 4 “AA” cells

range >8 hours using Alkaline “AA” cells

AC adapter (optional) Input: 110 V AC

Output: 9 V DC regulated

Page 13

Limited Warranty

The C75 is warranted to be free from defects in materials and workmanship for a period of

three years (two years on sensors) from the date of purchase. If within the warra n ty period

your instrument should become inoperative from such defects, the unit will be repaired or

replaced at UEi’s option. This warra n ty covers normal use and does not cover damage which

occurs in shipment or failure which results from alteration, tampering, accident, misuse,

abuse, neglect or improper maintenance. Batteries and consequential damage resulting from

failed batteries are not covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired (when

r e p a i r able) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

C75

Combustion Analyzer

Copyright © 2006 UEi C75-MAN 9/06

PLEASE

RECYCLE

Loading...

Loading...