Universal Enterprise C155 Installation Manual

Eagle & Eagle X Owners Manual

1

EAGLE & EAGLE X OV

ERVIEW

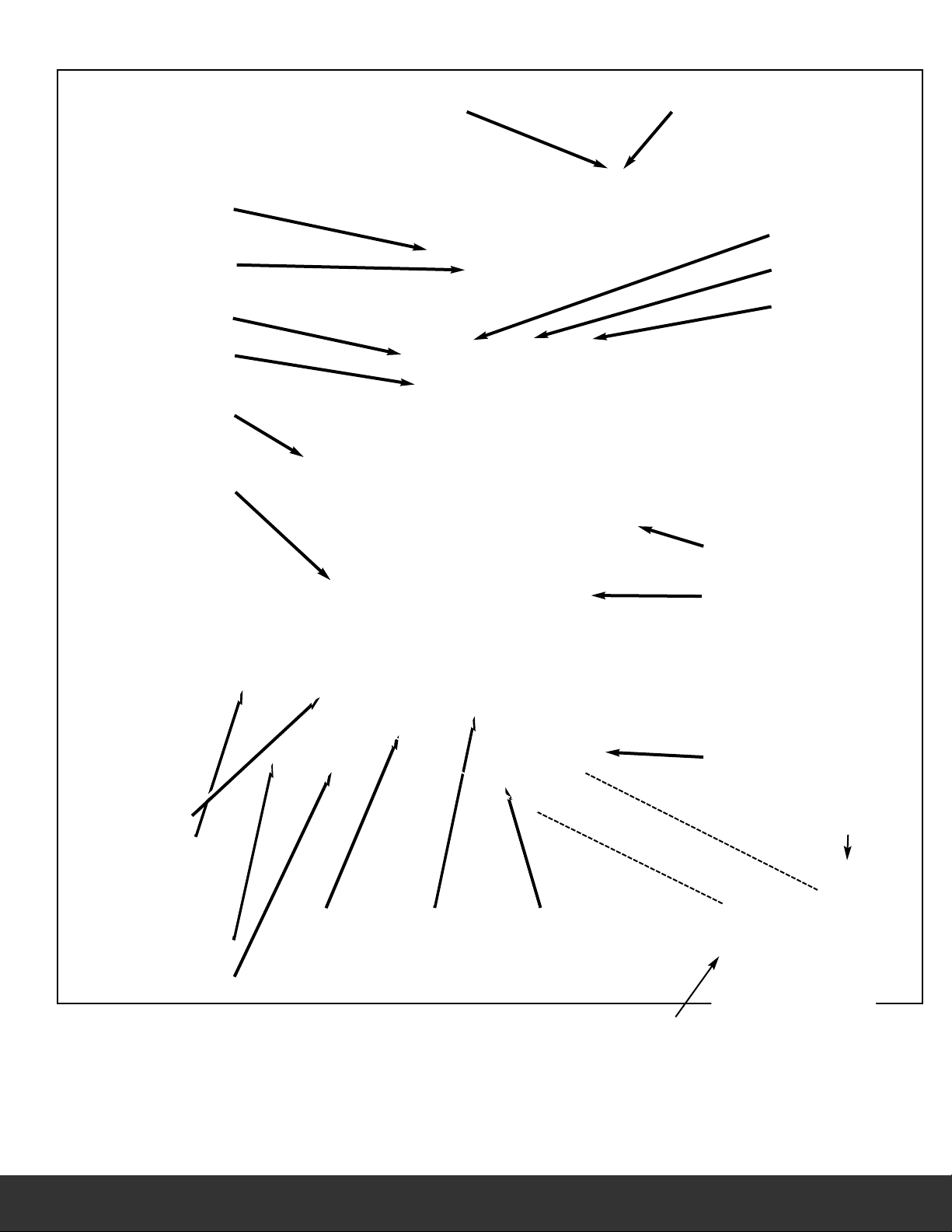

Display Line Lights

4 Line Backlit Display

On/Off Button

Rotary Test Selector Dial

Battery Compartments

in back under boot

AC Power/Charge

Indicator Light

1.800.547.5740 • WWW.UEiTEST.COM

nfrared Printer Port Worklight

I

Particle Filter

Inside Water Trap

Navigation “s“UP

and Backlight

Navigation “t“DOWN

and PUMP

SEND/ENTER

to Select and Print

Temperature

Connections

Flue Probe Temp: T1

Inlet Temp: T2

Pressure Connections

• Single Input (Draft): P1

• Differential Input Testing

(Pressure drop test) P2

Battery Charge

AC Adapter

Flue Gas

Inlet Connection

Water Trap

Protective Rubber Boot

w/ built-in Magnets

Flue Probe

Gas Inlet Plug

Water Trap

Drain

Flue Probe Temperature Plug

(Plugs into T1)

Narrow Pin MUST be on the

Right hand side.

2

DISPLAY PARAMETERS ON UEI COMBUSTION ANALYZERS

• TF = Flue Temperature: Calculate net temperature in °F or °C.

- Shows ambient temp after fresh air calibration and ‘-OC-’ when probe is disconnected.

• T = N

∆

• T

• O2 = Oxygen: O2 percentage displayed

• CO = Carbon Monoxide: CO ppm (parts per million) displayed.

• CO2 = Carbon Dioxide:

X = Excess Air:

•

• EFF = Efficiency:

∆ = Loss:

•

CO a = Carbon Monoxide Air-Free: Referenced to an oxygen level of 0%.

•

AMB = Air Inlet:

•

CO/CO2 = CO/CO2 Ratio: The ratio of measured CO divided by CO2.

•

• D = D

• P = Pressure

• NO = Nitric Oxide:

• -PO- = P

• -O>- = High O2 level:

-OC- = Probe Not Connected:

•

et Temperature

- Differential of flue temperature minus ambient (or inlet) temperature

- Differential of T1 - T2

emperature Differential

= T

-‘- - - -’ or ‘- OC -’ is displayed if there is a fault with the CO sensor or

the instrument has not been zeroed correctly, switch off instrument and try again.

- EAGLE (C125 & C127) Calculated from the fuel selected and the measured O2 level

- EAGLE (C125 & C127) Will display ‘- - - -’ or ‘-O>-’ if the O2 level is too

high to calculate CO2 or in fresh air.

- Calculated value is only displayed during the combustion test.

- EAGLE X (C155 & C157) Direct measurement CO2 ppm (parts per million) displayed.

- Indicated as ‘XAIR %’ on the printout

- A calculated percentage of O2 above the theoretical level required for complete combustion.

- Is required to completely burn the fuel due to poor mixing and assisting in venting flue gases

- Only displays a reading during combustion test.

-‘- - - -’ or ‘-O>-’ is displayed in fresh air.

- Calculated based on gas readings, net temperature and fuel selected.

- Value is combustion efficiency, not appliance efficiency.

- Total losses calculated from Combustion Theory. A summation of the next three parameters

• Dry %: Calculated heat lost turning the Carbon in the fuel to Carbon Dioxide (CO2)

• Wet %: Calculated heat lost turning the Hydrogen in the fuel into water (H2O)

• CO Loss %: Calculated loss due to partially burnt Carbon.

Any CO in the flue has the potential to be turned into CO2 releasing and losing more

heat up the flue.

Do not confuse this reading with the actual CO reading as detailed above.

-

- See the Combustion Efficiency Calculation sections for more details.

- Temperature used to calculate the NET temperature.

- It gives an indication of:

• How good a gas sample the instrument is reading.

• How clean the boiler is running.

- Example: A new or clean domestic boiler will display a ratio of less than 0.004, a unit in need

of cleaning 0.004 - 0.008 and a unit needing a major overhaul will show at least 0.008.

- Only displays a reading during combustion test. ‘

raft Pressure

ump Off

easured gases will display this when pump is off.

M

-

Calculated v

-

- Values are calculated with fuel choice and the O2 readings

- Temperature values will display this when the probe is not connected or is open

- Press and hold the “PUMP” button to Zero the pressure sensor in selector positions that display

measured or calculated values “Aux” & “Flue Test”.

:

:

:

alues will display this when O2 levels are greater than 18%

- - - -’ is displayed while in fresh air.

• N/F = N

NOTE: See page 8 for complete auxiliary display listings.

ot Found

- Displayed when not available or not installed ie: NO on a C155 or C125.

:

3

SAFETY NOTES

efore using this meter, read all safety information carefully.

B

"WARNING" is used to indicate conditions or actions that may pose physical hazards to the user.

"CAUTION" is used to indicate conditions or actions that may damage this instrument.

ARNING!

W

This analyzer extracts combustion gases that may be toxic in relatively low concentrations. These gases are

exhausted from the back of the instrument. This instrument must only be used in well-ventilated locations.

It must only be used by trained and competent persons after due consideration of all the potential hazards.

PREFLIGHT CHECKLIST

Getting Started

• Clean particle filter

• Water trap and probe line are empty of water

• Power on and zero

• All hose and thermocouple connections are properly secured

• Flue gas probe is sampling ambient FRESH air

•

Water trap is fitted correctly to the instrument

• Flue temperature plug is connected

• Inlet temperature probe is connected if required

ANALYZER CONNECTIONS

NOTE: Take care when inserting the temperature probes as the pins are polarized. Insert with the smaller

pin (+) to the right.

WARNING!

Turning the pump off while the probe is in the flue will leave toxic gases inside the analyzer. Once data

has been printed or copied it is advisable to purge the unit with fresh air as soon as possible. Use the GAS

ZERO function (Eagle X only) to purge the analyzer of excess gases. To do this on a standard Eagle remove

the probe from the flue and turn ON the pump. Always allow the readings to return to zero (20.9 for O2)

prior to shutting the unit off. The meter will not switch off until the CO reading is below 20 ppm.

WARNING!

The probe will be hot from flue gases. Remove the probe from the flue and allow it to cool naturally. Do

not immerse the probe in water, as this will be drawn into the analyzer and damage the pump and sensors.

Once the probe is removed from the flue and the readings have returned to ambient levels hold down

“On/Off” and switch off the analyzer. The instrument will count down from 30 to switch off. If

you pressed “On/Off“ by mistake, pressing “Send“ will return you to normal operation.

• Setting Inlet Temperature

- Turn on and zero the analyzer with

out the flue probe connected to use

ambient temperature

- Connect flue probe thermocouple to

T1 during zero countdown to store

probe tip temperature as inlet

(ducted system)

POST FLIGHT

(1)

(2)

(3) Check particle filter

4

Remove the probe from the flue and allow the analyzer to purge with fresh air until readings return to zero.

- O2 to 20.9%, CO to Z

rain water trap

D

ero

eful as the probe tip will be HOT)

(Be car

Drain water trap by unplug-

ing the dr

g

shake to get excess water

out.

ain plug and

Check particle filter for dirt

y other sediment and

and an

replace if necessary.

QUICK START GUIDE .

GETTING STARTED

Turn Power on in area of

fresh air and allow to

countdown

Rotate test selector to Fuel.

“s“UP or “t“DOWN

Press

to scroll and select desired

fuel. Top line is selected fuel.

GAS ZERO (EAGLEX SERIES ONLY)

Re-Zero the analyzer in fresh air if needed for different fuel type or after large temperature rise.

Connect flue probe

thermocouple connector to T1,

and connect flue probe to

water trap as shown above.

Use optional probe with T2 for

inlet temperature.

WORKLIGHT AND DISPLAY

After the Analyzer has

zeroed turn test selector to

ppropriate test screen.

a

ress

P

turn on the backlit display

and worklight.

NOTE: backlight does not

work in the fuel menu.or

during purge.

P at any point to

“s“U

QUICK START GUIDE .

Rotate test selector to Menu.

“s“ UP Button to

Press

GAS ZERO and press ENTER.

Make sure Analyzer is in

fresh air and press ENTER.

Analyzer will then Zero This

takes 90 seconds.

NOTE: The Eagle X will automatically initiate Gas Zero if required for continued accurate results.

BASIC CO/COMBUSTION ANALYSIS

Best results are obtained at Steady State Efficiency (SSE). Allow equipment adequate warm-up time prior to testing.

Insert Flue Probe in stack.

djust the cone so the end

A

of the probe is approximately. at the center of the stack

(4” stack adjust cone to

aprox 2” from end of

probe.)

NOTE: you will have to drill a hole at least 3/8”.

Use a high temp silicone to seal after testing.

Rotate test selector to

est” and begin test

“Flue T

ing.

Press and Hold the “s“ UP

-

button to toggle between

fuel test screens 1 and 2.

Flue Test Pg.1: O2, CO, Draft

(P) and TF

Flue T

Efficiency and Excess Air.

(NO

Eag

NO

Eagle 3 and 3X.)

.

est Pg. 2: CO2, NO,

1

ade available on

r

upg

le 2 and 2X.

1

comes standard on

Make any adjustments as

needed for pr

combustion and wait for

analyzer to display any

change in the readings.

(repeat if necessary)

oper

Once complete, remove

pr

allow the analyzer to purge

in fresh air until CO sensor

readings return to ZERO

and O2 reads 20~21%

(20.9%). Continue to the

ne

analyzer if finished.

NOTE: print and store functions may be used at an

point during testing

obe from the stack and

xt test or turn off your

y

.

5

Loading...

Loading...