Page 1

C125 & C127 SENSOR CALIBRATION & REPLACEMENT

QUICK START GUIDE

Calibration Instructions;

Note: Disclaimer of Liability

These instructions are prepared for use by trade professionals familiar with gas analysis and detection,

and are familiar or have experience in calibrating gas measurement systems. They are intended to be

as complete and simple as possible to eliminate the chance for error. Certain factors related to analyzer

field recalibration are beyond the control of UEi, and the user should be aware of these factors such as

proper delivery of gas to the analyzer during calibration, the age of the calibration gas, and the accuracy of the calibration gas.

By using these instructions to recalibrate your instrument, you assume all risks and liability associated

with the measurement of carbon monoxide (CO) gas concentrations.

Indemnification

esentatives,

epr

zer, you

ate your analy

xtent permitted b

o the e

T

ee to defend, indemnify, and hold harmless, U

r

ag

ents from and against all claims and expenses, including attorneys’ fees, arising out of the use of

and ag

this material.

y applicable law, b

y using these instructions to r

Ei, its ag

encies, officers, emplo

ecalibr

yees, r

SENSOR CALIBRATION & REPLACEMENT QUICK START GUIDE .

Page 2

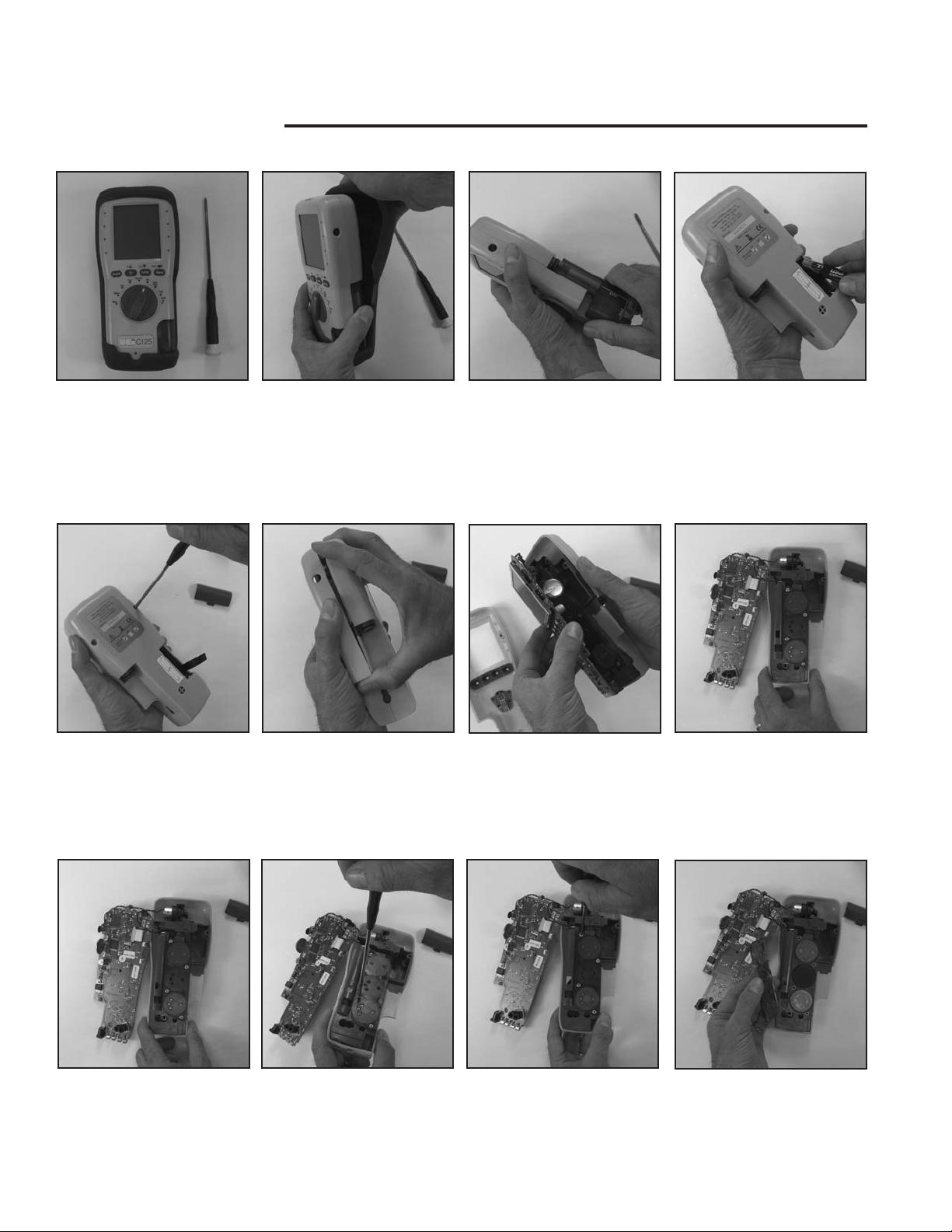

SENSOR REPLACEMENT

1. Tools required to replace the

sensor include a standard

Phillips screw driver and a

source of calibration gas.

5. Remove the two screws

securing the case halves

together.

2. Remove the protective boot

from the instrument.

6. Separate the case by gently

pressing up on the front

housing with pulling the top

apart.

3. Remove the water trap by

sliding down and then away

from the housing.

7. Lift the main circuit board up

and away from the instrument.

4. Remove the batteries.

a. Be careful of the wiring

harness that powers the pump

and connects to the battery

compartment.

8. Place the instrument on a flat

surface with the circuit board

positioned as shown.

9. Remove the four screws

holding the sensor cover

in place.

10. Remove the sensor cover.

11. Lift the sensor to be replaced

out of the manifold.

ensor located at the top is

S

a.

O2, and the bottom

position is CO.

Page 3

Note the position of the

b.

alignment pin on the O2

and pin orientation on the

CO sensors. These will only

fit into the sensor cover in

one position.

12. Install the sensor to be

replaced.

13. Reinstall sensor cover.

a. Verify that the sensor cover

is seated on the manifold

e tightening screws.

befor

14. Set circuit board back on

manifold.

a. Align sensor pins with sockets

on circuit board.

14. Join case halves together

starting at the bottom edge as

shown

15. Reinstall case screws

Page 4

GAS CALIBRATION

It is recommended to allow the sensors to stabilize a minimum of four hours before calibration.

1. Turn instrument on in fresh air

and allow to zero.

5. Select “Cal_CO”.

2. Select “Menu”.

6. Enter gas concentration.

3. Scroll to “Service”.

7. Connect Gas.

4. Enter user code “1

234

”.

8. Adjust regulator to match flow

of instrument.

a. Floating ball should be in

the middle of the second

om the bottom.

space fr

b. Note the pitch of the pump.

It should match the pitch

when drawing in ambient

air.

9. Allow to sample gas three

minutes.

a. Reading does not indicate

ppm value.

b. Slight fluctuation of display

is normal.

CANADA: 1-877-475-0648 • Fax: 604.278.8299

GLE Combustion

EA

YRIGHT © 20

COP

07 UEi.

10. Press “Enter” at the end of

3 minutes.

eading is not ppm,

Note r

and may still fluxuate slig

11. Scroll to “

press “

htly.

Exit” and then

Enter”.

USA: 1.800.547.5740 • Fax: 503.643.6322

W W W.UEiTEST.COM

Analyzers™ is a trademark of UEi. CALKIT-MAN 11/07

Loading...

Loading...