Unitec Wash Select II POS Installation Manual

W ash Select II and

W ash Select II POS

Installation Manual

Unitec

www.StartwithUnitec.com

(443) 561-1200

WASH SELECT II

WASH SELECT II INSTALLATION MANUAL

This manual provides comprehensive operational procedures for the Wash Select II. In this

manual, we will discuss the setup, operation and maintenance of the Wash Select II.

If further assistance is needed, please contact the distributor from which the product was

purchased.

When calling for assistance, you must have the following information available:

Wash Select II Serial Number:

Distributor Name:

COPYRIGHT

© 2012 Unitec, Incorporated. All rights reserved. No part of this book, including text, screen

examples, diagrams, or icons, may be reproduced or transmitted in any form, by any means

(electronic, photocopying, recording, or otherwise) without prior written permission of Unitec,

Incorporated.

TRADEMARKS

Enterlink, Wash Select II, Wash Select II POS, WashChange, VIP Wash Pass, Customized

VIP Wash Pass, VIP Wash Coupons, Unitec, and the Unitec Logo are trademarks, service

marks, or registered trademarks of Unitec, Incorporated.

Givex is the registered trademark of Givex Incorporated.

CoinCo is the registered trademark of Coin Acceptors, Inc.

All other products, services, and company names are trademarks or registered trademarks of

their respective owners.

Document Number: WS21001

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Table of Contents

1 Site Planning...................................................................................................................................1

1.1 Electrical Planning......................................................................................................................1

1.1.1 Site Grounding Considerations:...................................................................................................1

1.1.2 Electrical Requirements of the Wash Select II.............................................................................1

1.2 Mechanical Planning..................................................................................................................4

1.2.1 Position of the Unit.......................................................................................................................4

1.2.2 Mechanical Requirements............................................................................................................4

1.3 Miscellaneous Planning.............................................................................................................5

1.3.1 Precautionary Considerations......................................................................................................5

1.3.2 Unpacking & Checking Parts........................................................................................................5

1.3.3 Wash Select II – Option Packages...............................................................................................6

2 Tools Required for Installation......................................................................................................7

2.1 Mechanical Installation Tools.....................................................................................................7

2.2 Electrical Installation Tools ........................................................................................................7

3 Mechanical Installation..................................................................................................................9

3.1 Bricking in the Wash Select II ....................................................................................................9

3.2 Installation of the Optional Base..............................................................................................10

3.2.1 Preliminary Consideration..........................................................................................................10

3.2.2 Installation of the Wash Select II Unit.........................................................................................12

4 Electrical Installation....................................................................................................................15

4.1 Wiring the Modem (Option)......................................................................................................15

4.1.1 At the Unit..................................................................................................................................15

4.1.2 At the Phone Jack......................................................................................................................15

4.2 Wiring for Internet Credit Clearance (Option)..........................................................................16

4.3 Wiring for WashPay Integration or Kwik Trip (Option).............................................................16

4.4 Wiring the Car Wash................................................................................................................17

4.4.1 Wash Outputs............................................................................................................................17

4.4.2 Wash-In-Use..............................................................................................................................18

4.4.3 Wash-Fault.................................................................................................................................19

4.5 Wire the POS4000...................................................................................................................19

4.6 Wiring 115 VAC Main Power ...................................................................................................19

4.6.1 Measure Wire Lengths...............................................................................................................20

4.6.2 Attach the Three-prong Connector.............................................................................................20

4.7 Wiring the Intercom..................................................................................................................22

Document Number: WS21001 i

Document Title: Wash Select II POS Installation Manual

4.7.1 Connecting a 2-wire Intercom System .......................................................................................23

4.7.2 Connecting a 3-wire Intercom System .......................................................................................23

4.7.3 Connecting a 4-wire Intercom System .......................................................................................24

WASH SELECT II

4.8 Wiring External Fleet Device Interface.....................................................................................24

4.8.1 Hook up to Washcard Control Box.............................................................................................24

4.8.2 Hook Up to Express Key Control Box ........................................................................................25

4.8.3 Hook Up to eWash Control Box.................................................................................................26

5 Startup / Programming.................................................................................................................28

5.1 Wash Setup..............................................................................................................................28

5.1.1 Wash Prices...............................................................................................................................28

5.1.2 Wash Names..............................................................................................................................29

5.2 Wash Interface.........................................................................................................................29

5.2.1 Relay Stacking...........................................................................................................................29

5.2.2 Relay Latching...........................................................................................................................29

5.2.3 Relay Pattern.............................................................................................................................30

5.2.4 Auto Out of Service Detect.........................................................................................................30

5.2.5 Wash Handshaking....................................................................................................................31

5.2.6 Wash Fault.................................................................................................................................31

5.2.7 Out-of-Service Timer (OOS).......................................................................................................31

5.3 Customer Interface Menu.........................................................................................................31

5.3.1 Customer Stacking.....................................................................................................................31

5.3.2 Forced Selection........................................................................................................................31

5.3.3 Allow Upgrades..........................................................................................................................32

5.3.4 Auto Selection Time...................................................................................................................32

5.4 Connecting to a POS4000.......................................................................................................32

5.5 Multi-unit Fleet System (Optional Feature)..............................................................................33

5.6 Tokens (Optional).....................................................................................................................34

5.7 Testing the Entry System.........................................................................................................35

5.8 Testing the Washes.................................................................................................................35

Appendix A. Guide for Alternate Keypad Functions....................................................................38

Appendix B. Recorded S peech Messages....................................................................................40

Appendix C. Paging Error Codes...................................................................................................44

Appendix D. Additional Steps for Canadian WSII Install.............................................................46

Appendix E. Single Gate Installation (Without Gate Controller).................................................54

Document Number: WS21001 ii

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Index of Figures

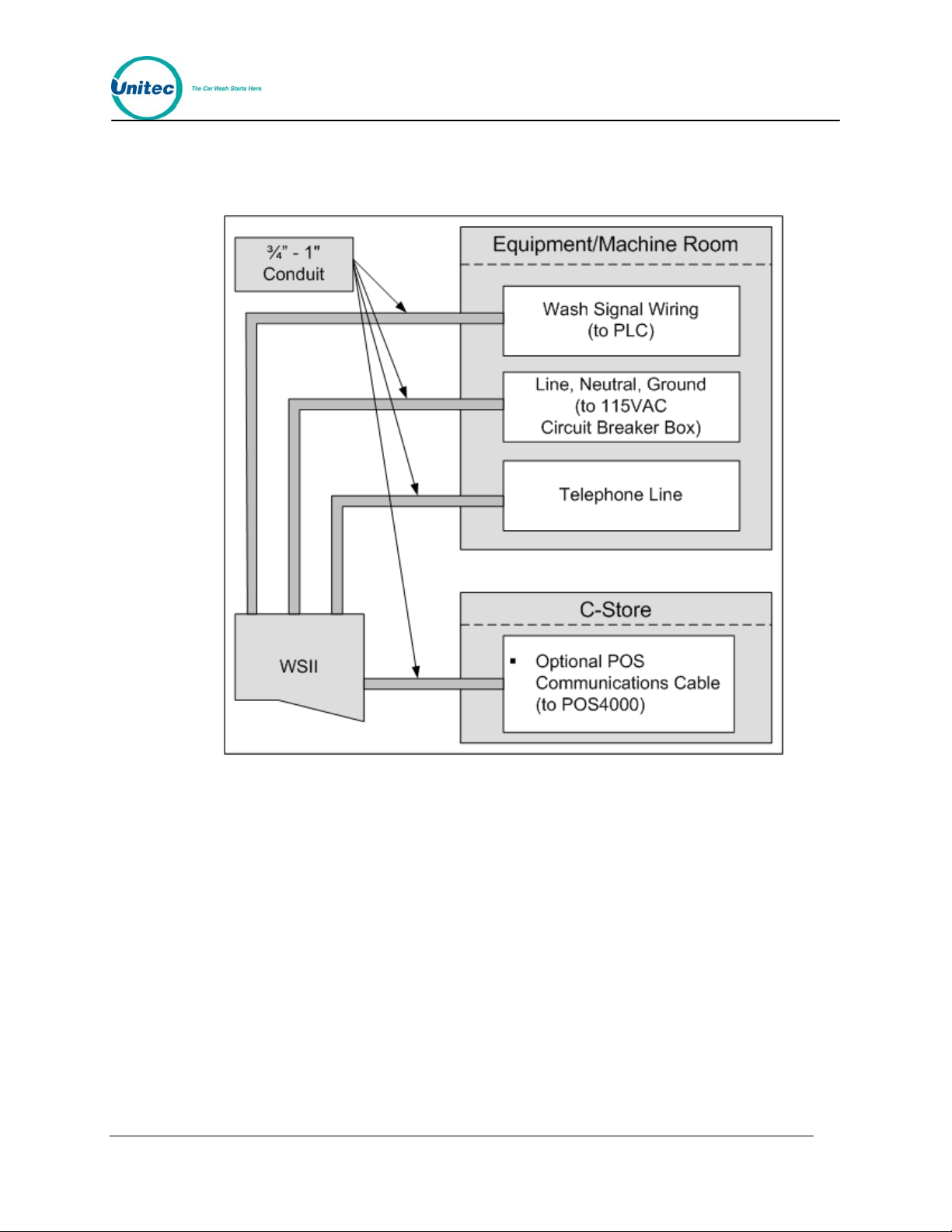

Figure 1. Conduits with Modem Line Layout....................................................................................2

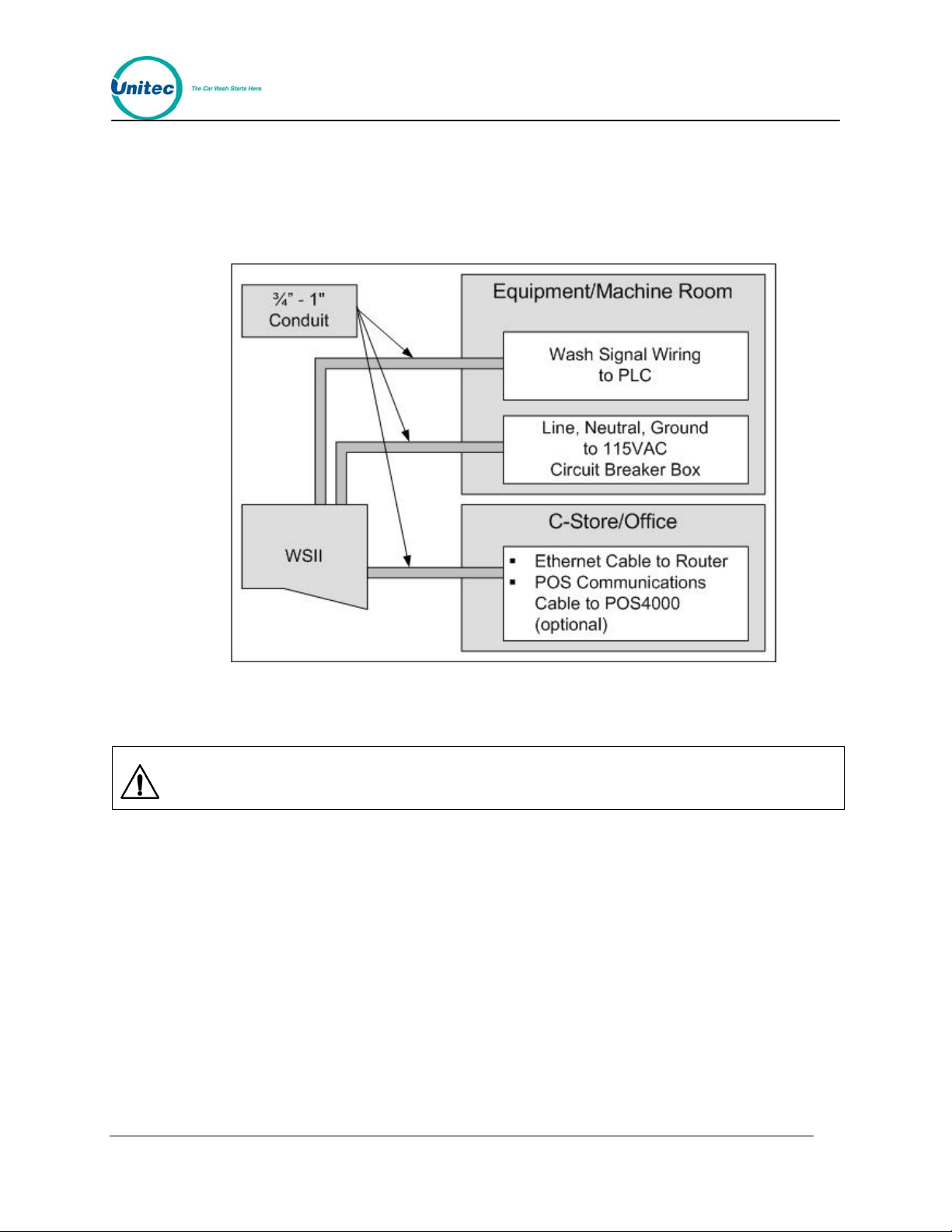

Figure 2. Conduits with Ethernet Cable Layout...............................................................................3

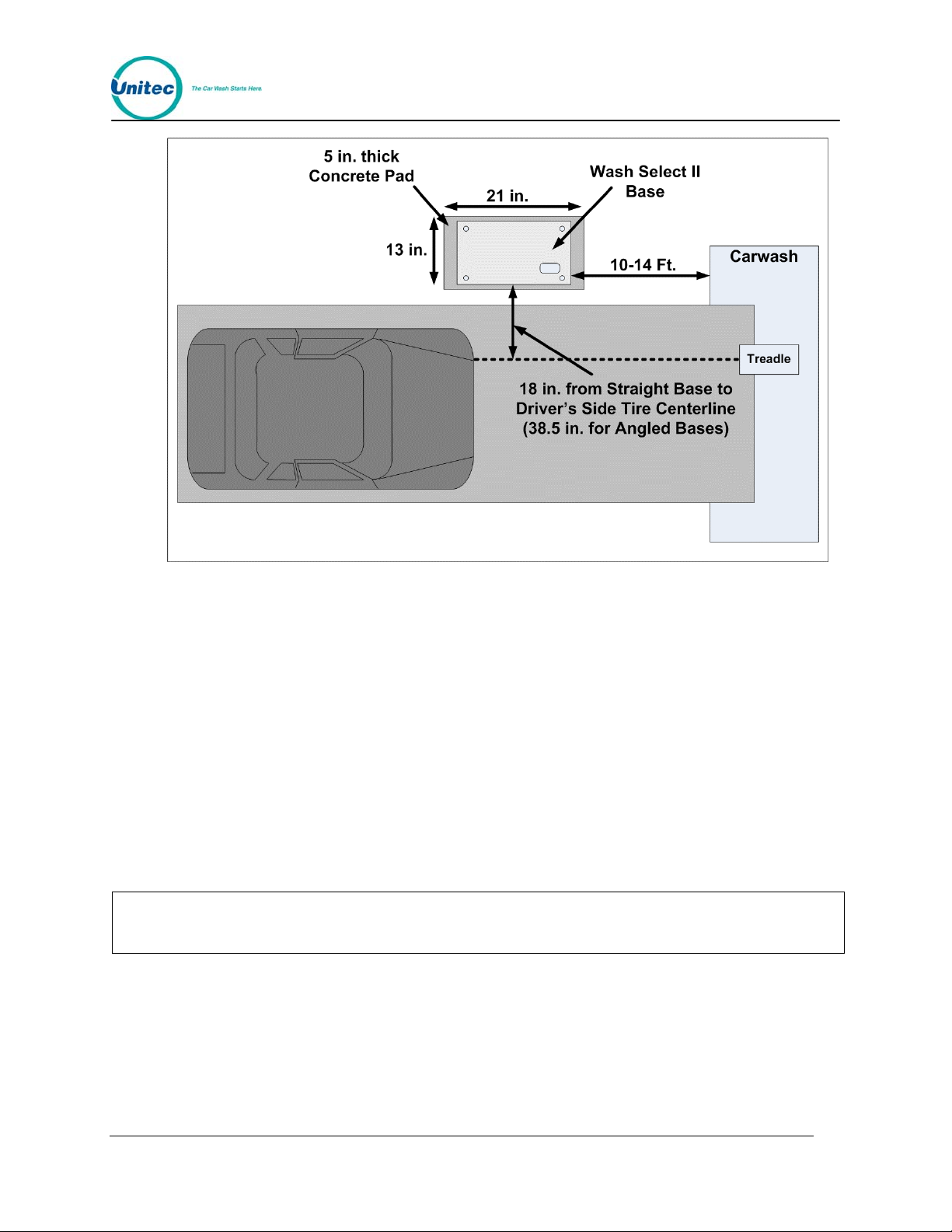

Figure 3. Wash Select II Base Placement .......................................................................................5

Figure 4. Wash Select II Installation ..............................................................................................10

Figure 5. Straight Base ..................................................................................................................11

Figure 6. Angled Base....................................................................................................................11

Figure 7. Setting Anchor Bolts.......................................................................................................12

Figure 8. Modem Wiring................................................................................................................. 15

Figure 9. IPTran and DataTran Connections.................................................................................16

Figure 10. Ethernet Cable Wiring Inside the Wash Select II..........................................................17

Figure 11. AC Connector ...............................................................................................................20

Figure 12. Inside the AC Connector...............................................................................................21

Figure 13. Thread Power Cord Through Line Insulator.................................................................21

Figure 14. Line - Neutral - Ground Connections............................................................................22

Figure 15. Intercom Adaptor Board................................................................................................23

Figure 16. Standard Wash Select II Keypad.................................................................................. 28

Figure 17. Wash out of Service Sequence ....................................................................................30

Figure 18. Alternate Keypad Functions..........................................................................................38

Figure 19. Outside/Inside of IDX Coin Acceptor............................................................................49

Figure 20. Sample Site Layout.......................................................................................................54

Figure 21. Gate Position ................................................................................................................56

Figure 22. Gate Reset Loop Dimensions....................................................................................... 56

Figure 23. Gate Base Bolt Positioning...........................................................................................57

Figure 24. Gate Wiring...................................................................................................................58

Index of Tables

Table 1. Wash Relays....................................................................................................................18

Table 2. Wash-In-Use Signal.........................................................................................................18

Table 3. Wash-fault SIGNAL.......................................................................................................... 19

Table 4. POS4000 Connection......................................................................................................19

Table 5. J1 of Unitec Wash Card interface board..........................................................................24

Table 6. J 2 of Unitec Wash Card interface board.........................................................................25

Table 7. Washcard input assignments........................................................................................... 25

Table 8. J1 of Unitec Wash Card interface board..........................................................................25

Table 9. J 2 of Unitec Wash Card interface board.........................................................................25

Table 10. 24 VAC Source Connection...........................................................................................26

Table 11. J1 of Unitec Wash Card Interface Board.......................................................................26

Table 12. J2 of Unitec Wash Card Interface Board.......................................................................27

Table 13. 24 VAC Connection ....................................................................................................... 27

Table 14. POS 4000 Cable Connections.......................................................................................32

Table 15. Multi-Unit Fleet Cable Connections...............................................................................33

Table 16. Remote Wash Select II Bay Addresses.........................................................................34

Table 17. Pager Error Codes.........................................................................................................44

Table 18. Wash Select II Token Values......................................................................................... 49

Table 19. Canadian IDX Program Configuration...........................................................................50

Document Number: WS21001 iii

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

[THIS PAGE INTENTIONALLY LEFT BLANK]

Document Number: WS21001 iv

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

1 Site Planning

The Wash Select II is a self-serve unattended automatic car wash entry system designed

specifically for the self-serve car wash market. The Wash Select II accepts various forms of

payment, interacts with customers at the car wash entrance, an d arms the car wash.

It is important to consider a few points prior to the actua l installa tion of the Wash Select II unit.

Among these considerations are the correct running of electrical conduit, and the proper

positioning of all of the carwash machines. In this section, these issues will be discussed in

detail. When proper planning is implemented, the Wash Select II installation will go smoothly,

and the unit will operate reliably.

1.1 Electrical Planning

1.1.1 Site Grounding Considerations:

Make sure that the protective earth ground wire does not carry any motor return current. Only

the neutral wire should carry return current.

1.1.2 Electrical Requirements of the Wash Select II

The Wash Select II will need to have 115-120 VAC on a 5-Amp dedicated breaker, which

should be provided during wash construction. Most installers will have power supplied directly

from one of the three phases used to power the wash motors and controllers. If this met hod is

used, special attention should be given to proper earth grounding at the unit, as well as in the

breaker panel.

Generally, most car wash manufacturers use a five-wire system to provide the arming signals

for the selected wash packages. This means that one common line and four arming input

wires are fed from the car wash’s Programmable Logic Controller (PLC) to the Wash Se lect II

unit. In addition to these five, a Wash-In-Use Hot and Wash-In-Use Neutral are required to

reset the wash electroni cs. Typically, these are also provided by the PLC. It is important to

consider this fact when planning the conduit runs, because there will need to be 2 separate

runs from the wash to the Wash Select II—one for AC power, and one for PLC Control Wires

& Optional Phone connection. If you are connecting to a POS4000 then you should have an

additional conduit run to the POS4000 (C-store), unless you hav e the RF option.

Another important point to remember is that the Wash Select II is equipped to accept credit

cards, so a separate run may be required from the nearest phone jack to the main conduit

run. There is no guarantee that a credit upgrade will not be performed, so the installer should

think ahead and make provisions. If there is an undedicated phone line nearby, then every

attempt should be made to try to route the conduit so that access is easily gained to it. For

example, a junction box can be placed in the run at that particular point.

If an undedicated telephone line is not nearby, try to route the conduit so that one is

accessible at a later date. An important rule to remember is that the telephone cable should

Document Number: WS21001 1

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

not be run in the same conduit as the main power lines. Telephone, as well as intercom

connections, can be run in the POS4000 connection conduit (Wash Select II POS system) if

you are connecting to a POS4000 in a C-store.

Figure 1. Conduits with Modem Line Layout

Document Number: WS21001 2

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

For Internet credit clearing, Kwik Trip, or WashPay integration, Ethernet cable will be needed.

This cable should be standard CAT 5 or CAT 6. This cable can be p ulled thr ough the existing

POS4000 communications conduit run from the C-Store to the Wash Select II. The cable

CANNOT be longer than 295 feet. The cable should extend at least 2 feet into the WSII and

be run into the back office of the store/office to the fr ame switch or router.

Figure 2. Conduits with Ethernet Cable Layout

DO NOT RUN CABLE OUTSIDE OF A CONDUIT!

Important:

Follow all local and National Electric Codes.

Finally, it should be understood that the Wash Select II unit is to be powered by wires of at

least 16 AWG, or larger. Failure to adhere to this recommendation could result in a fire or

injury. When installing the conduit, it is suggested that it be a minimum of ¾” in size, and be

made of metal versus PVC.

Document Number: WS21001 3

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

1.2 Mechanical Planning

1.2.1 Position of the Unit

The proper positioning of the Wash Select II unit is very important. Figure 2 of this section

should be used as a reference for good layout practices. There are several layout

considerations that follow, which may be a good idea to think about. They are meant for

suggestion only, and are not permission to circumvent wash manufa cturer guidelin es.

The Wash Select II unit should be placed 10-14 feet from the car wash entrance to ensure

the proper timing and flow of customers. The wash’s treadle switch should be centered along

the horizontal plane, approximately 18” inches out from the front of the Wash Select II unit.

Note that the Wash Select II unit extends 6” out from the leading edge of the optional straight

base and even more for an angled base (refer to angled base dimensions). This will ensure

that the car/truck’s wheel is aligned with the treadle switch, as shown in Figure 2. Finally, a

concrete post can be positioned just to the front and left corner of the unit, to act as a

protective buffer. A typical size for this post is between 30 and 35 inches.

1.2.2 Mechanical Requirements

It is strongly recommended that the unit be surrounded with a brick or concrete housing for

maximum security. However, since this may not be realistic in some installations, mounting it

on a concrete slab will suffice.

This manual assumes that the optional base will be installed simultaneously with the unit. In

this case, the concrete should be a minimum of 5” inches thick, 21” inches wide, and 13”

inches long (Refer to Figure 2). The dimensions and positioning of the mounting holes for the

base will be covered in the “Mechanical Installation” se ction of this manu al.

The front edge of the standard base should be 18 inche s from the driver’s side tire centerline.

(For angled bases, this distance should be 38.5 inches.) This provides the appropriate

distance for customers to comfortably reach the unit o make their select ions.

Document Number: WS21001 4

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Figure 3. Wash Select II Base Placement

1.3 Miscellaneous Planning

1.3.1 Precautionary Considerations

A large percentage of sites contain “Floor Heat”. Floor heat is an under-concrete heat

exchanger system, consisting of an elaborate network of plumbing, through which anti-freeze

circulates. In many cases this plumbing can run beside, under, or over conduit. Before

marking and drilling into any area, the site floor heat diagrams should be reviewed, and the

appropriate action taken to prevent any damage.

1.3.2 Unpacking & Checking Parts

Note:

Open each of the shipping boxes and ensure the following items are present:

If any parts are missing, please call Unitec Technical Services at 1-443-561-1200.

1.3.2.1 Wash Select II – Standard Installation

Wash Select II Main Case Assembly

Allen Wrench For Door

Document Number: WS21001 5

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Installation & Operation Manuals

Keys & Lock core set

(4) Bolts to secure top assembly to optional base

(4) Washers to be used on bolts for optional base

1.3.3 Wash Select II – Option Packages

The following items should be added to the standard installation checklist, if that specific

option was purchased with it.

WASH SELECT II – CREDIT OPTION

Extra Roll of Thermal Printer Paper

IPTran credit modem

WASH SELECT II - SPEECH OPTION

Microphone (for message recording)

WASH SELECT II PROXIMITY SWITCH OPTION

Infrared Relay Block (installed on Wash Select II power supply cover)

WASH SELECT II – OPTIONAL BASE

Base

(4) Concrete Anchor Bolts

(4) Washers

(4) Nuts

WASH SELECT II – WASHPAY INTEGRATION

CAT5E Ethernet Cable

Expansion board

Document Number: WS21001 6

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

2 T ools R equired for Installa tion

2.1 Mechanical Installation Tools

It is highly recommended that the Wash Select II be bricked in! All attempts should be made

to achieve that end. It is ultimately the responsibility of individual distributors to make this

decision, and if the decision is made that it will not be po ssible, Unitec offers an optional base

at an affordable price. The following tools are recommended for the typical mechanical

installation of this Wash Select II unit and optional base:

6” inch or longer ratchet extension (for optional straight base)

¾” inch deep well socket and socket wrench

Open end 9/16” inch wrench

Small, thin blade, flat-tip screwdriver

Hammer drill

½” Concrete hammer drill bit

Hammer

Dual-plane Level

50’ foot tape measure

2.2 Electrical Installation Tools

In addition to the mechanical assembling of the Wash Select II unit to the base (and th e entire

package to the concrete), there will be a number of electrical connections, which must be

made. These connections will require the use of the following common elect rical tools:

Small, thin tipped, straight screwdriver (1/8” tip, for green Phoenix connectors)

Wire strippers (capable of handling 10-22 AWG wire)

Cable or wire tie wraps

Diagonal cutters

Needle nose pliers

Telephone wire crimping tool and 4-pin, RJ11 / 14 modular plugs (for modem, if

present) Radio Shack Part # 279-384

Document Number: WS21001 7

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Document Number: WS21001 8

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

3 Mechanical Installation

Unitec recommends the bricking in of the WSII when installed on property that is not

manned or is not in plain sight of station or busin ess personnel.

Unitec also recommends the connection of the WSII to a monitored security system in

these situations or any situation where vandalism or t heft may occu r.

The use of the included door sensor and a custo mer supplied shock se nsor mounted

on the door is recommended as wel l.

Note:

3.1 Bricking in the Wash Select II

For optimum security the Wash Select II unit should be mounted on a concrete slab and

bricked in.

Tips on Bricking in:

Conduit openings are at the right side of the bottom of the case.

Bolt holes are at the bottom of the case to secure to the concrete slab.

The concrete slab should be built so that the bottom of the Wash Select II case is

32.5” from the floor.

Outer dimensions of the Wash Select II are:

Including reinforcing

band along front

edge

Not including reinforcing

band around front edge

Tall 23.62” 23.24”

Wide 18.11” 17.74”

Deep 19.26” 19.25”

The following drawing shows such an installation:

Document Number: WS21001 9

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Figure 4. Wash Select II Installation

Most installers may need to increase the protection and o rganization of the wires that

Hint:

run from the conduit to the bottom of the Wash Select II main cabinet. Flexible conduit

can be used to perform this function. The connectors ca n be attached to the metal

conduit by way of PVC cement.

3.2 Installation of the Optional Base

This document outlines the installation of the optional base.

3.2.1 Preliminary Consideration

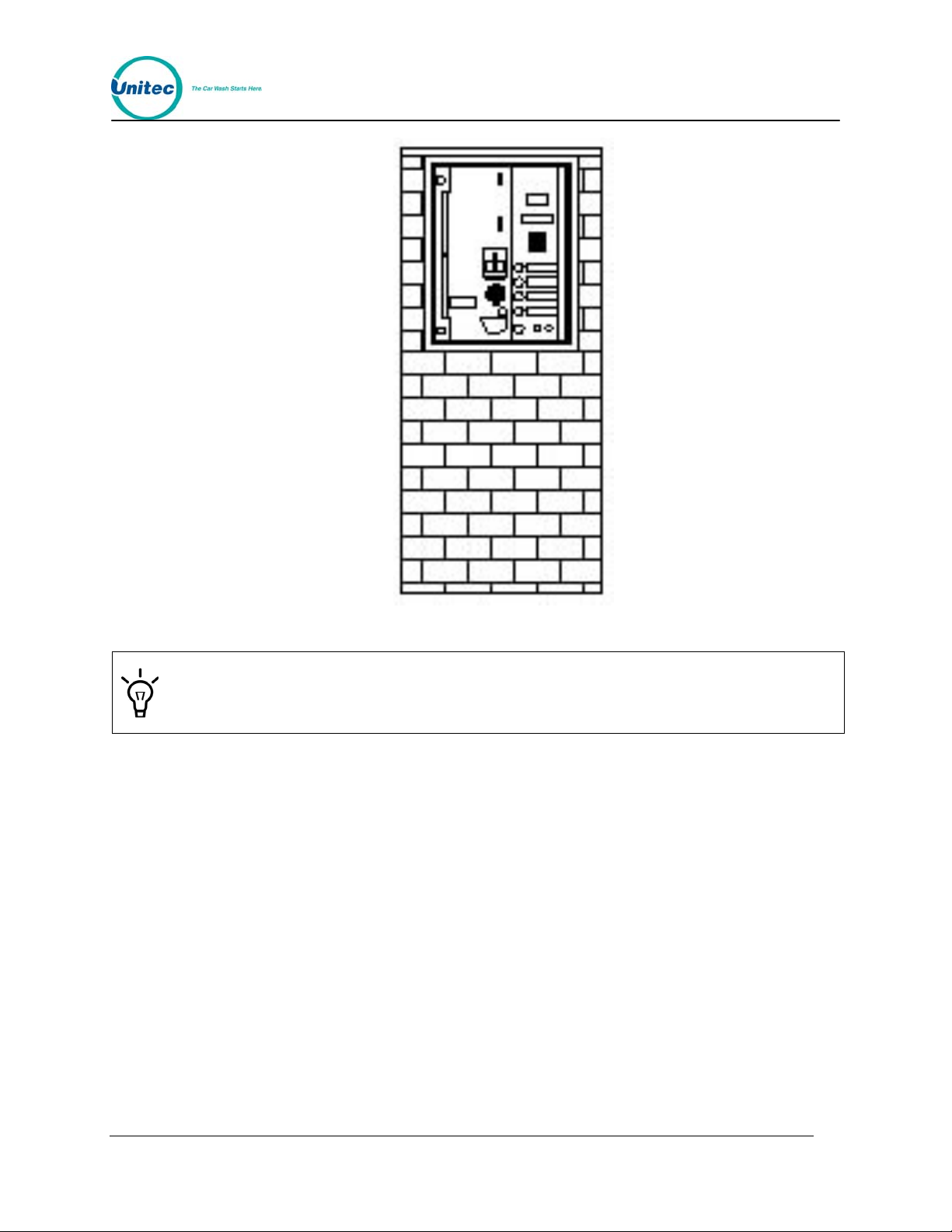

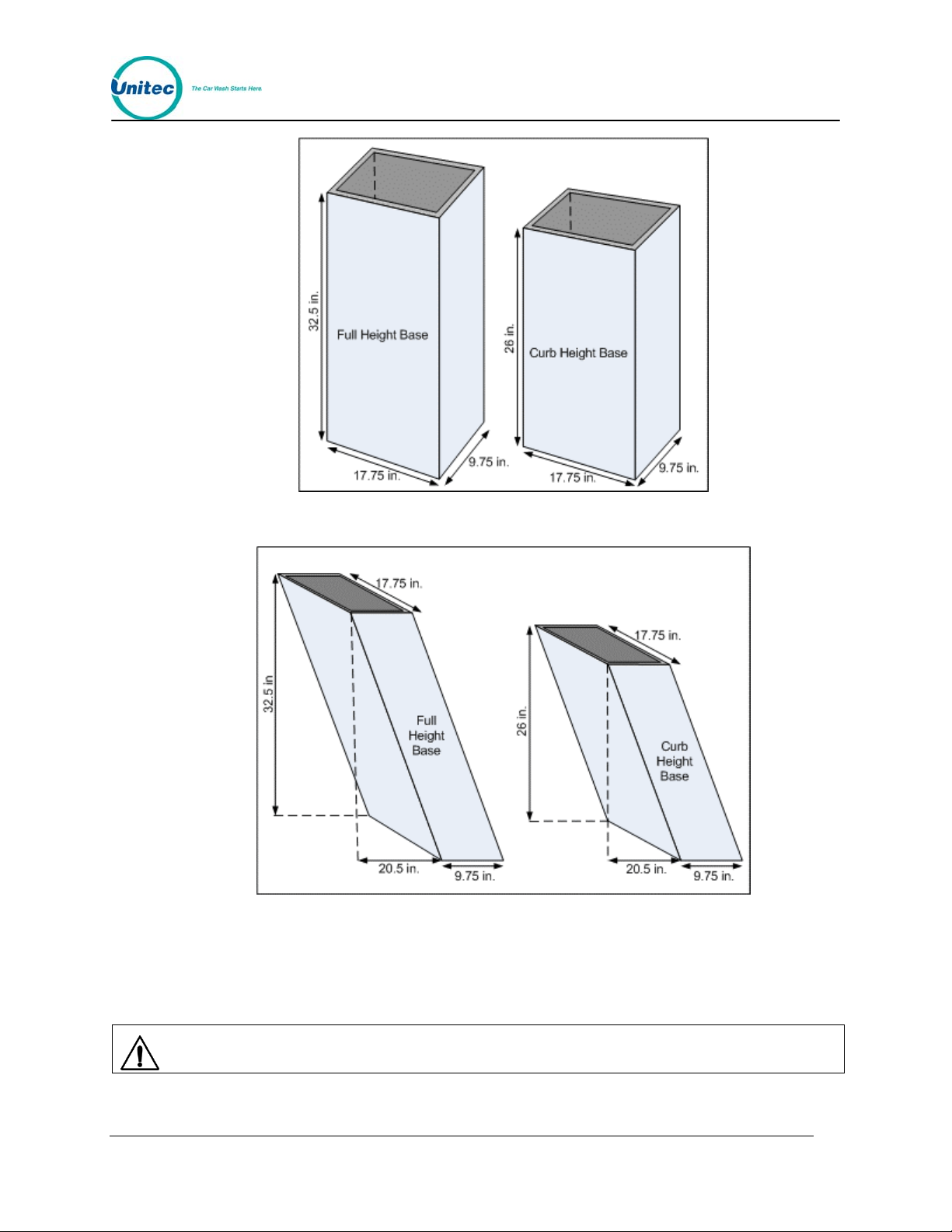

The Wash Select II base comes in two distinct styles, straight and angled. The following

procedures are applicable to the straight base only. Refer to the documentation you received

with the angled base (MN1001 Angled Base Addendum) for installation procedures for the

angled base.

Document Number: WS21001 10

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

Figure 5. Straight Base

Figure 6. Angled Base

1.

Mark the 4 holes that you intend to drill in order to mount the Wash Select II

optional base. Mark the holes with a marker as the base is sitting on top of the

concrete. It is important to keep in mind that the conduit run will need to protrude

through the large opening in the lower right corner, at least 3 inches.

Warning:

Document Number: WS21001 11

Document Title: Wash Select II POS Installation Manual

DO NOT BEGIN MOUNTING OF THE BASE UNTIL ALL WIRES & CABLES HAVE

BEEN PULLED THROUGH THE CONDUIT!

2. Remove the base from the marked location and proceed to drill the holes, using

WASH SELECT II

the hammer drill, and the ½” inch concrete drill bit. Ensure that the holes are

drilled deep enough to insert the anchor bolts. A good depth is approximately 2”2½” inches from the surface of the concrete.

3. It should be noted that while the anchor bolts are rugged and durable, they could

become damaged if struck recklessly. Care should be given to strike only the top

of the anchors, where the force will be distributed by the provided area on top of

the anchor bolt. Use the hammer to drive each of the provided anchors into the

drilled concrete holes.

Figure 7. Setting Anchor Bolts

4.

When all anchor bolts have been set, place one nut onto each of them, and use

the ratchet and socket to tighten it, until as many of the threads from the bolts as

possible are showing. This first set of nuts will be used later for the correct

leveling of the base. You may remove the nuts if you have the appropriate shims

and wish to use those instead.

5. Slide the base down over top of the conduit, while feeding the wire runs up

through the conduit holes and out the top of the base. It is very important to allow

at least 66” inches of wire to remain draped over the top of the base, so that there

is enough left to make all of the electrical connections. It is also recommended

that 3” or more of conduit protrude into the base. This is to ens ure that standing

water will not accumulate in the conduit. There should also be sufficient threads

on the anchor bolts left to secure the base in place with the remaining 4 nuts. If

this is not the case, the holes in the concrete were drilled too deep, and the

installer should use smaller, or no leveling nuts.

6. Place the level on top of the base, and adjust the leveling bolts with the open-

ended wrench (or add the appropriate number of shims). When it is level across

the short and long sides, hand tighten the remaining 4 nuts onto t he bolts.

7. Once the base has been verified in its final position at least once, and all of the

above requirements have been met, it is safe to securely fasten the 4 nuts with

the socket wrench. When this has been successfully completed, there should be

no movement in the base whatsoever.

3.2.2 Installation of the Wash Select II Unit

1. Once the base is properly leveled and secured, ensure that there is sufficient

length of wire draped out the top to make the final electrical connections. If not,

new cable should be pulled prior to this step. If there is sufficient length, proceed

to feed them under and through the bottom of the Wash Select II main cabinet.

They should fit easily into the conduit holes, which are pre-cut into the bottom,

right-hand corner of the unit.

Document Number: WS21001 12

Document Title: Wash Select II POS Installation Manual

2. Set the unit onto the base, and align the four base holes to the pre-cut holes in

3. If the unit is to be wired into an existing or new security alarm system, the installer

WASH SELECT II

the Wash Select II. Use the remaining 4 bolts (with washers on) to secure the top

unit to the base. This is done by feeding the bolts through the holes in each of the

four corners in the bottom of the main cabinet, and then tightening with the 9/16 “

wrench.

will need to acquire the 2 spade terminal connectors, termination block, sticky

wire fasteners, and appropriate lengths of 22 AWG insulat ed wire.

Note:

When wiring the switch, it is important to ensure that the terminal block is mounted to an

easily accessed, un-used, portion of the Wash Select II case. It should also be in close

proximity to the naturally occurring cable runs inside of the unit. This is don e in o rder to easily

run security system wires to one common termination point, while still keeping a relatively

neat appearance. A good recommended routing method would be to secure the wires from

the terminals of the switch along the inside, top, left side of the Wash Select II case, and have

it continue down to the bottom, just underneath the bill stacker .

The terminal block can be mounted there, and then any wires that will be brought in from the

outside system can be pulled through the same wire shielding that connects the bill validator

to the main circuit board. This same shielding can be purchased and used to wrap the switch

wires.

The alarm device connected to the switch must be a Class-2 device.

Document Number: WS21001 13

Document Title: Wash Select II POS Installation Manual

WASH SELECT II

[THIS PAGE INTENTIONALLY LEFT BLANK]

Document Number: WS21001 14

Document Title: Wash Select II POS Installation Manual

Loading...

Loading...