Page 1

Topload Washers

TLW12C_SVG

Metered and Nonmetered

Installation/Operation

Original Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. 202630R2

September 2016

Page 2

Page 3

WARNING

Failure to install, maintain, and/or operate this machine according to the manufacturer's instructions

may result in conditions which can produce bodily

injury and/or property damage.

W030

WARNING

For your safety and to reduce the risk of fire or an

explosion, do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or

any other appliance.

W022

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all possible conditions and situations that may occur. It must

be understood that common sense, caution, and carefulness are factors which cannot be built into these

washers. These factors MUST BE supplied by the person(s) installing, maintaining, or operating the washer.

Always contact the distributor, service agent, or the manufacturer

about any problems or conditions you do not understand.

Read all instructions before using washer.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

3 Part No. 202630R2

Page 4

Table of Contents

Safety Information..................................................................................6

Explanation of Safety Messages....................................................................... 6

Important Safety Instructions........................................................................... 6

Dimensions.............................................................................................8

Installation........................................................................................... 10

Before You Start........................................................................................... 10

Tools........................................................................................................ 10

Order of Installation Steps..........................................................................10

Remove the Shipping Brace and Shipping Plug............................................... 10

Wipe Out Inside of Wash Tub.........................................................................11

Connect Fill Hoses........................................................................................ 11

Water Supply Requirements....................................................................... 12

Connecting Hoses......................................................................................12

Risers.......................................................................................................12

Connect Drain Hose to Drain Receptacle.........................................................13

Drain Facilities..........................................................................................13

High Standpipe Installation........................................................................ 13

Low Standpipe Installation.........................................................................14

Position and Level the Washer........................................................................14

Plug In the Washer........................................................................................ 15

Electrical Requirements............................................................................. 15

Earth/Ground Instructions.......................................................................... 16

Add Water to the Washer............................................................................... 16

Check Lid Switch......................................................................................... 16

Check Installation......................................................................................... 16

Vending....................................................................................................... 17

Meter Case............................................................................................... 17

Slide Extension Assembly..........................................................................17

Models Prepped for Card Reader and Non-Metered Models.......................... 18

Additional Security....................................................................................18

Operation............................................................................................. 20

Operation Instructions for Coin Slide Operated and Nonmetered Washers.......... 20

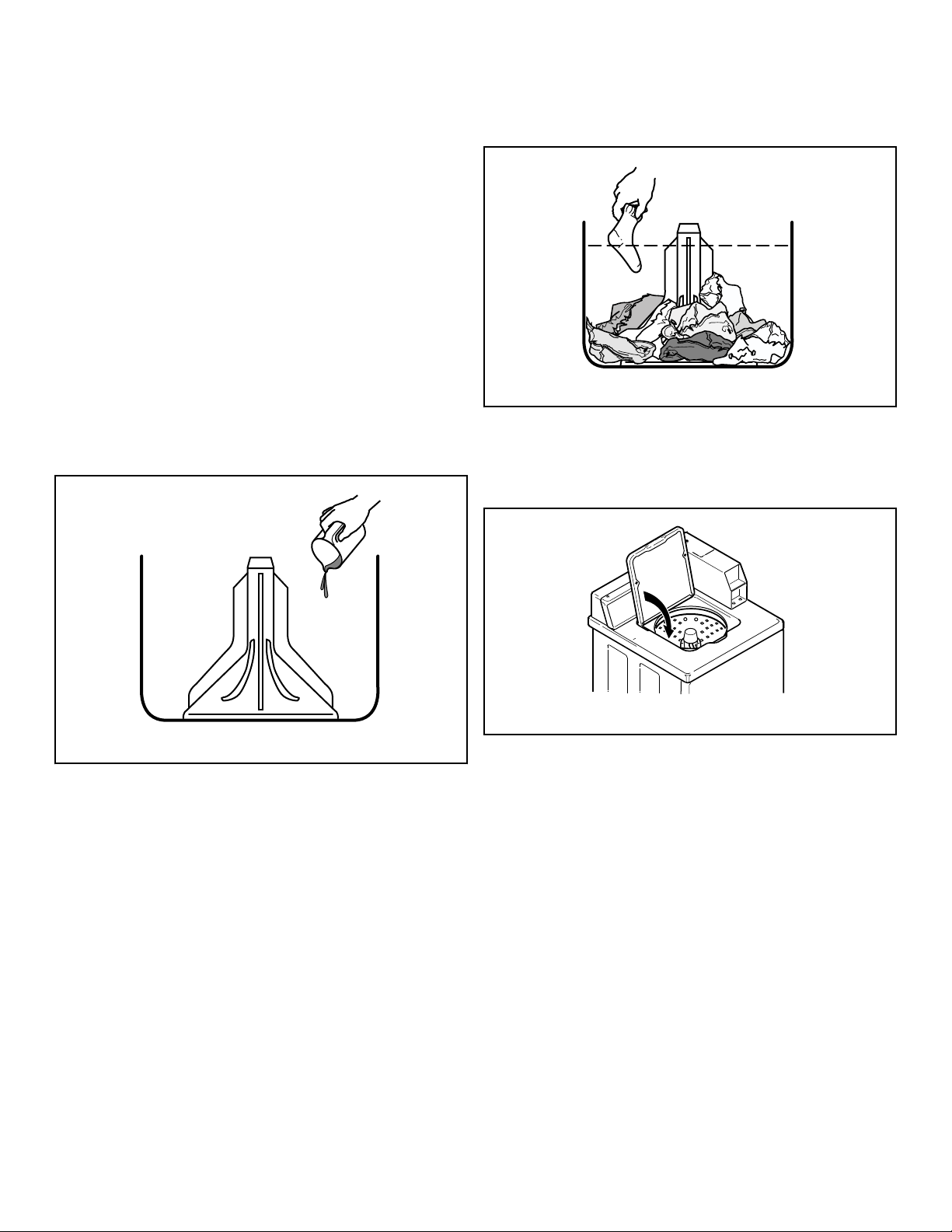

Add Detergent...........................................................................................20

Load Laundry........................................................................................... 20

Close Lid..................................................................................................20

Set Wash Temperature and Fabric/Cycle Selector......................................... 20

Start Washer..............................................................................................21

Indicator Lights.........................................................................................22

©

Copyright 2016, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

4 Part No. 202630R2

Page 5

Control Modes.......................................................................................... 22

Rapid Advance..........................................................................................23

Setting Dipswitch...................................................................................... 23

Operation Instructions for MDC Washers........................................................ 23

Add Detergent...........................................................................................23

Load Laundry........................................................................................... 23

Close Lid..................................................................................................24

Set Fabric Selector and Wash Temperature...................................................24

Insert Coins or Card...................................................................................24

Start Washer..............................................................................................24

Indicator Lights.........................................................................................25

Maintenance.........................................................................................26

User-Maintenance Instructions....................................................................... 26

Cold Weather Care.................................................................................... 26

Care of Your Washer..................................................................................26

Replacing Hoses........................................................................................26

Filter Screens............................................................................................ 26

Reinstallation of Shipping Materials............................................................... 26

Shipping Brace..........................................................................................26

Shipping Plug........................................................................................... 26

Motor Overload Protector.............................................................................. 26

Troubleshooting....................................................................................28

Contact Information............................................................................. 30

Installer Checklist.................................................................................31

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

5 Part No. 202630R2

Page 6

Safety Information

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,” and

“CAUTION”), followed by specific instructions, are found in this

manual and on machine decals. These precautions are intended

for the personal safety of the operator, user, servicer, and those

maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if

not avoided, will cause severe personal injury or

death.

WARNING

Indicates a hazardous situation that, if not avoided,

could cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided,

may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and

“NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specific procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is important but not hazard related.

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your washer,

follow these basic precautions:

W023

• Read all instructions before using the washer.

• Install the washer according to the INSTALLATION INSTRUCTIONS. Refer to the EARTH/GROUND INSTRUCTIONS in the INSTALLATION manual for the proper earth/

ground connection of the washer. All connections for water,

drain, electrical power and earth/ground must comply with local codes and be made by licensed personnel when required.

Do not do it yourself.

• Do not install or store the washer where it will be exposed to

water and/or weather.

• Do not add the following substances or textiles containing

traces of the following substances to the wash water: gasoline,

kerosene, waxes, cooking oils, vegetable oils, machine oils,

dry-cleaning solvents, flammable chemicals, thinners or other

flammable or explosive substances. These substances give off

vapors that could ignite, explode or cause the fabric to catch

on fire by itself.

• Under certain conditions, hydrogen gas may be produced in a

hot water system that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using a

washing machine or combination washer-dryer, turn on all hot

water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. THE

GAS IS FLAMMABLE, DO NOT SMOKE OR USE AN

OPEN FLAME DURING THIS TIME.

• To reduce the risk of an electric shock or fire, DO NOT use an

extension cord or an adapter to connect the washer to the electrical power source.

• Do not allow children to play on or in the washer. Close supervision of children is necessary when the washer is used

near children. This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by a person responsible for their

safety. This is a safety rule for all appliances.

• Cleaning and user maintenance shall not be made by children

without supervision.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

6 Part No. 202630R2

Page 7

Safety Information

• Children less than three years should be kept away unless

continuously supervised.

• Do not reach into the washer if the washtub or agitator, if applicable, is moving.

• Never operate the washer with any guards, panels and/or parts

removed or broken. DO NOT tamper with the controls or bypass any safety devices.

• Use your washer only for its intended purpose, washing

clothes. Always follow the fabric care instructions supplied

by the garment manufacturer.

• Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. To reduce the risk of poisoning or chemical burns, keep them out of the reach of children at all times (preferably in a locked cabinet). Heed all

warnings or precautions.

• Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener

or product.

• Lid MUST BE CLOSED any time the washer is to agitate or

spin. DO NOT bypass the lid switch to permit the washer to

agitate or spin with the lid open. A brake will stop the washtub within seconds if the lid is opened during spinning. If the

washtub does not stop when the lid is opened, remove the

washer from use and call the service person.

• Be sure water connections have a shut-off valve and that fill

hose connections are tight. CLOSE the shut-off valves at the

end of each wash day.

• Keep your washer in good condition. Bumping or dropping

the washer can damage safety features. If this occurs, have

your washer checked by a qualified service person.

• Do not repair or replace any part of the washer, or attempt any

servicing unless specifically recommended in the user-maintenance instructions or in published user-repair instructions that

you understand and have the skills to carry out. ALWAYS disconnect the washer from electrical supply before attempting

any service.

• Disconnect the power cord by grasping the plug, not the cord.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

• Before the washer is removed from service or discarded, remove the lid or door to the washing compartment.

• Failure to install, maintain, and/or operate this washer according to the manufacturer’s instructions may result in conditions

which can produce bodily injury and/or property damage.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do not understand.

NOTE: The WARNING and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Observe and be aware of other labels and precautions that are located on the machine. They are intended to provide instruction for safe use of the machine. Common sense, caution and care must be exercised when installing, maintaining, or operating the

washer.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

7 Part No. 202630R2

Page 8

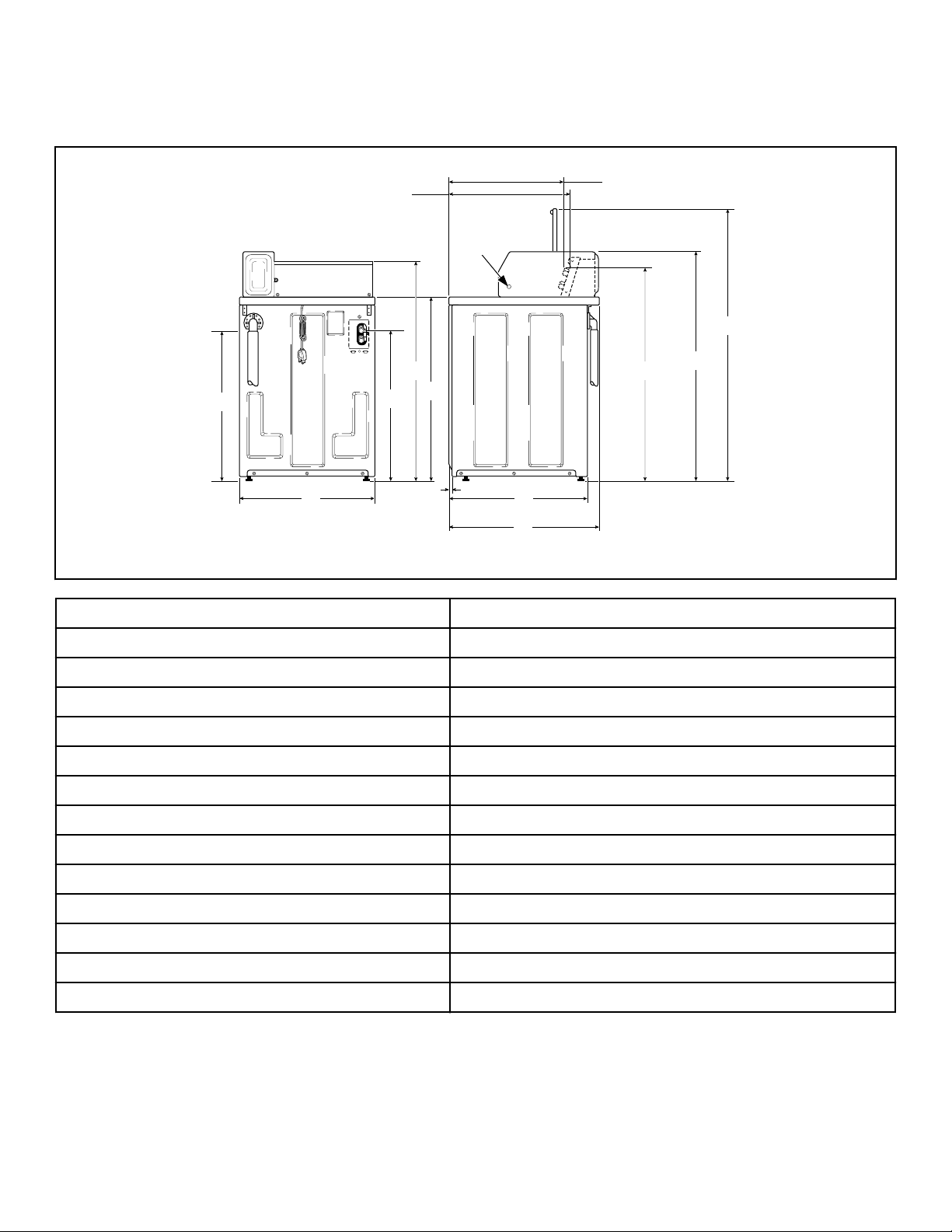

Metered Models

C

H

TLW2051N_SVG

M

L

K

J

I

H

G

F

E

D

C

B

A

1

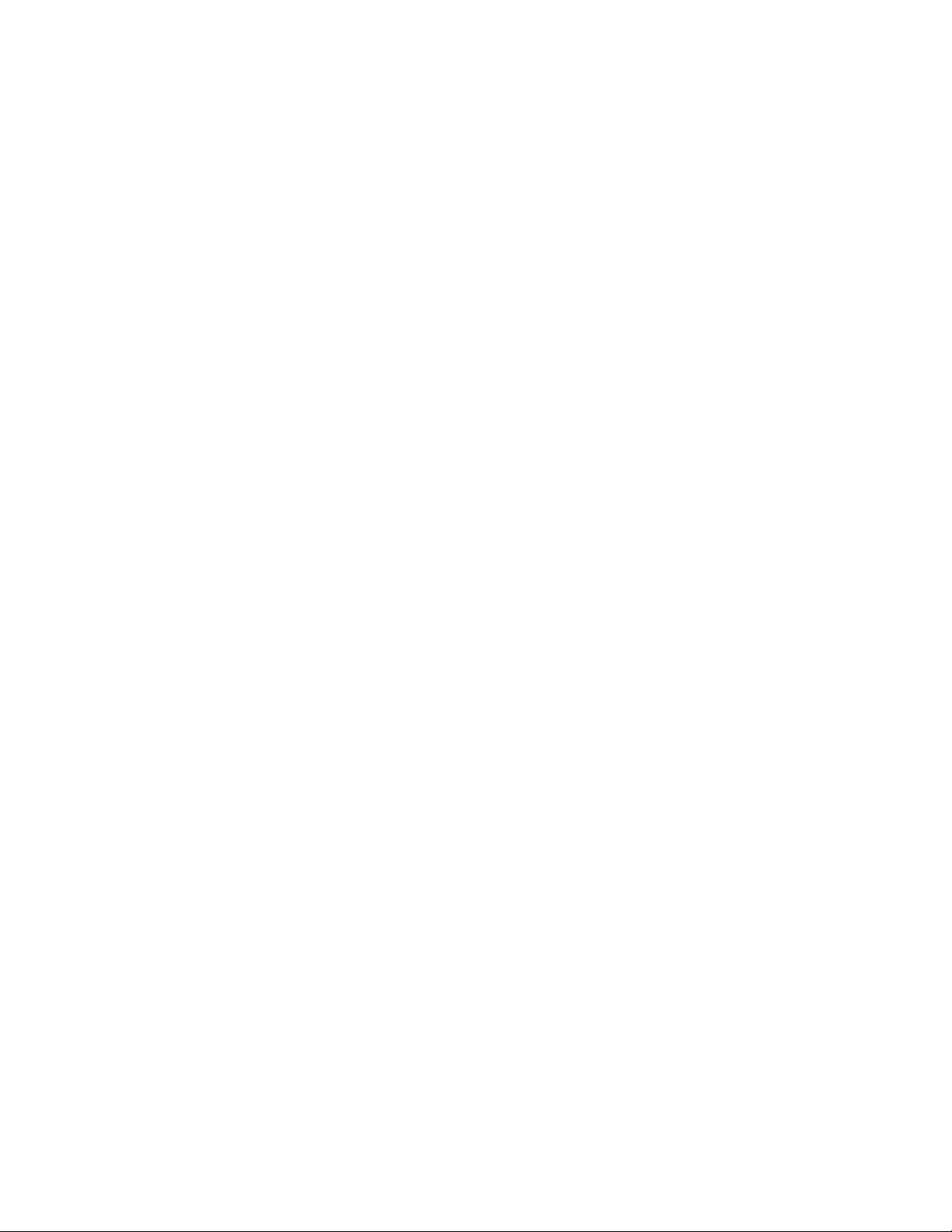

Dimensions

Dimensions

1. Pilot Hole

A - Electronic Control Models 570 mm [22.44 in.]

B - Coin Slide Models 548 mm [21.56 in.]

C 1295 mm [51 in.]

D 1092 mm [43 in.]

E - Electronic Control Models 970 mm [38.19 in.]

E - Coin Slide Models 1026 mm [40.38 in.]

F 711 mm [28 in.]

G 660 mm [26 in.]

H 11 mm [0.44 in.]

I 914 mm [36 in.]

J 1048 mm [41.25 in.]

K 730 mm [28.75 in.]

L 651 mm [25.63 in.]

M 775 mm [30.5 in.]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

8 Part No. 202630R2

Page 9

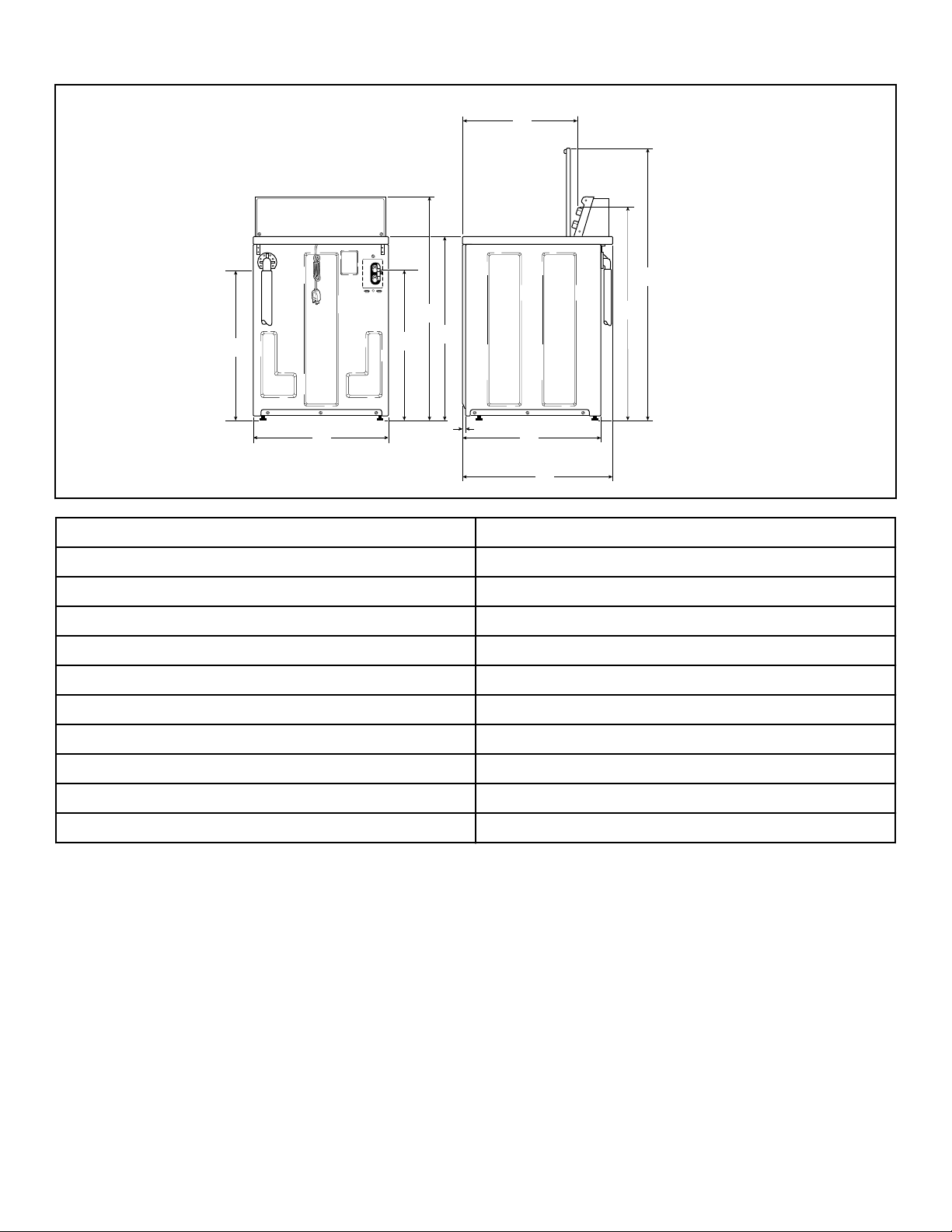

Nonmetered Models

C

H

TLW2050N_SVG

K

J

I

H

G

F

E

D

C

B

A

Dimensions

A 548 mm [21.56 in.]

B 1295 mm [51 in.]

C 1026 mm [40.38 in.]

D 711 mm [28 in.]

E 660 mm [26 in.]

F 11 mm [0.44 in.]

G 914 mm [36 in.]

H 1048 mm [41.25 in.]

I 730 mm [28.75 in.]

J 651 mm [25.63 in.]

K 775 mm [30.5 in.]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

9 Part No. 202630R2

Page 10

Installation

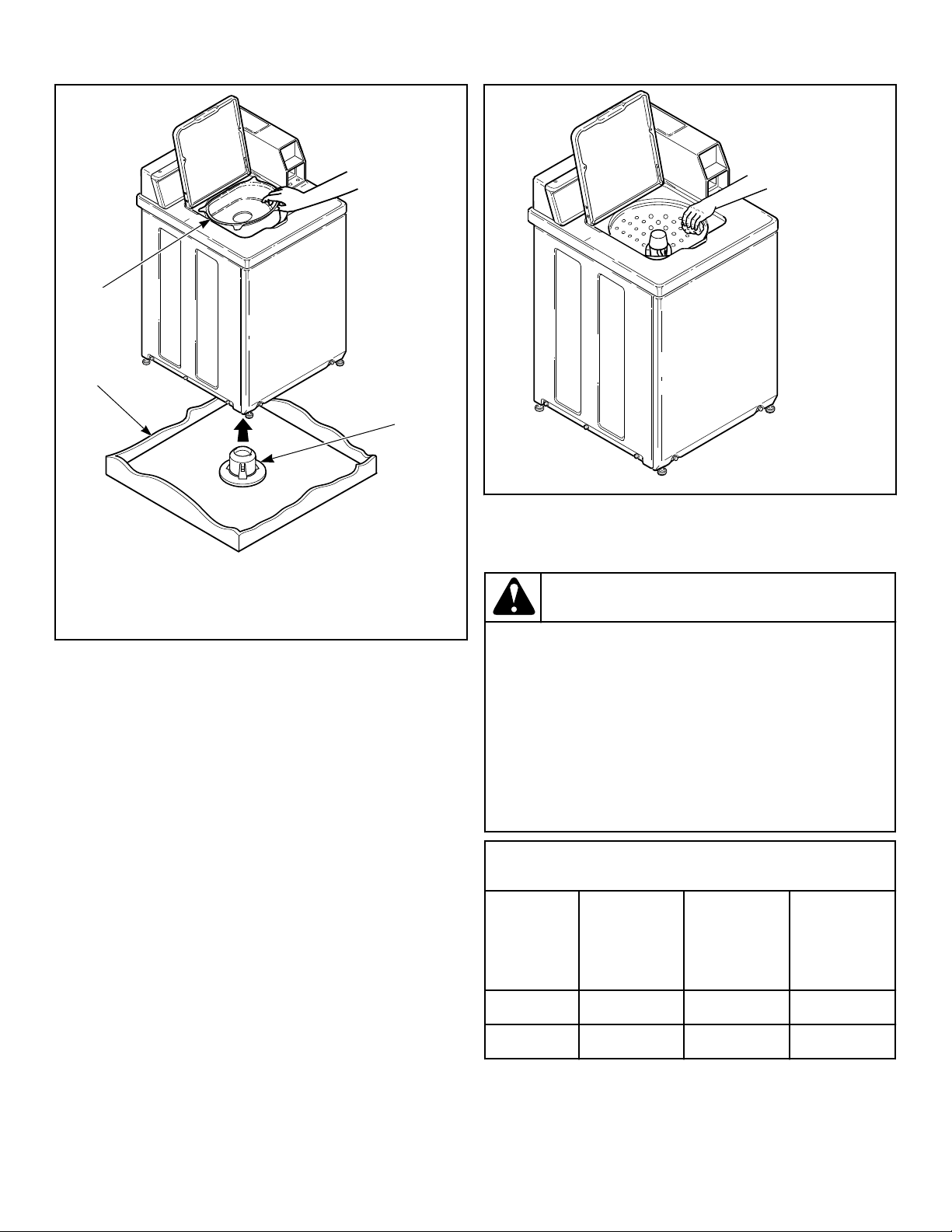

TLW2215N_SVG

1

2

3

4

5

6

Installation

Before You Start

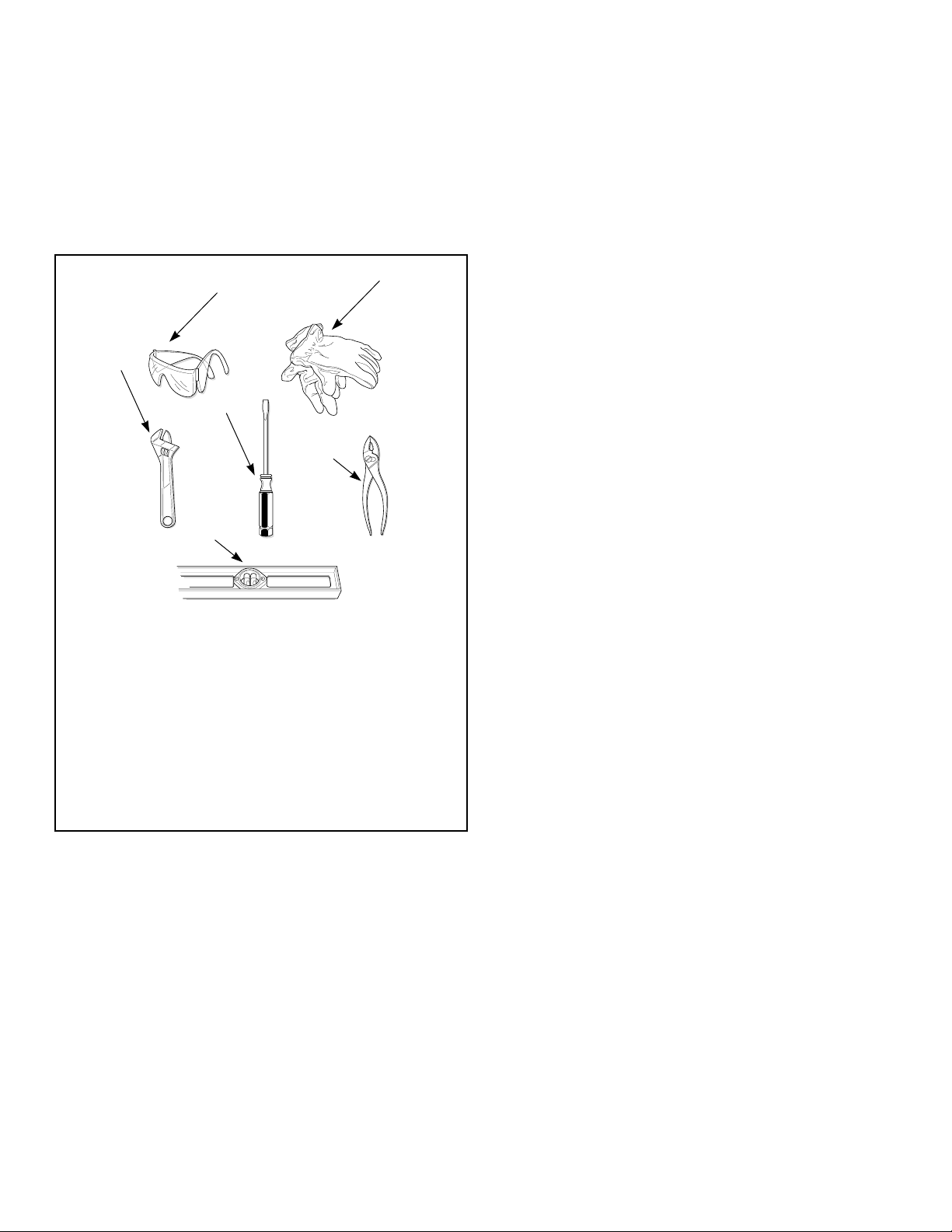

Tools

For most installations, the basic tools you will need are:

1. Remove the shipping brace and shipping plug.

2. Wipe out inside of the washer.

3. Connect the fill hoses.

4. Connect the drain hose to the drain receptacle.

5. Position and level the washer.

6. Plug in the washer.

7. Add water to the washer.

8. Check the lid switch.

9. Check installation.

Remove the Shipping Brace and

Shipping Plug

1. Remove the shipping brace from under the lid.

2. The shipping plug will be released from the base of the washer when removing the cardboard base from the washer. Refer

to Figure 2 .

The shipping brace and plug should be saved and must be reinstalled whenever washer is moved or transported to a new location. This will prevent damage to washer components.

Do not tilt washer to front or sides when moving.

NOTE: A cloth rag and all-purpose cleaner are also

needed.

1. Safety Glasses

2. Gloves

3. Wrench

4. Screwdriver

5. Pliers

6. Level

Figure 1

NOTE: If the washer is delivered on a cold day (below

freezing), or is stored in an unheated room or area during the cold months, do not attempt to operate it until

the washer has had a chance to warm up.

NOTE: Install dryer before washer. This allows room for

attaching exhaust duct.

NOTE: This appliance is suitable for use in countries

having a warm, damp climate.

Refer to User-Maintenance section for instructions on reinstalling

shipping brace and shipping plug.

Order of Installation Steps

The proper order of steps must be followed to ensure correct installation. Refer to the list below when installing your unit.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

10 Part No. 202630R2

Page 11

TLW2098N_svg

3

2

1

TLW2099N_SVG

Installation

1. Shipping Brace

2. Shipping Plug

3. Cardboard Base

Figure 2

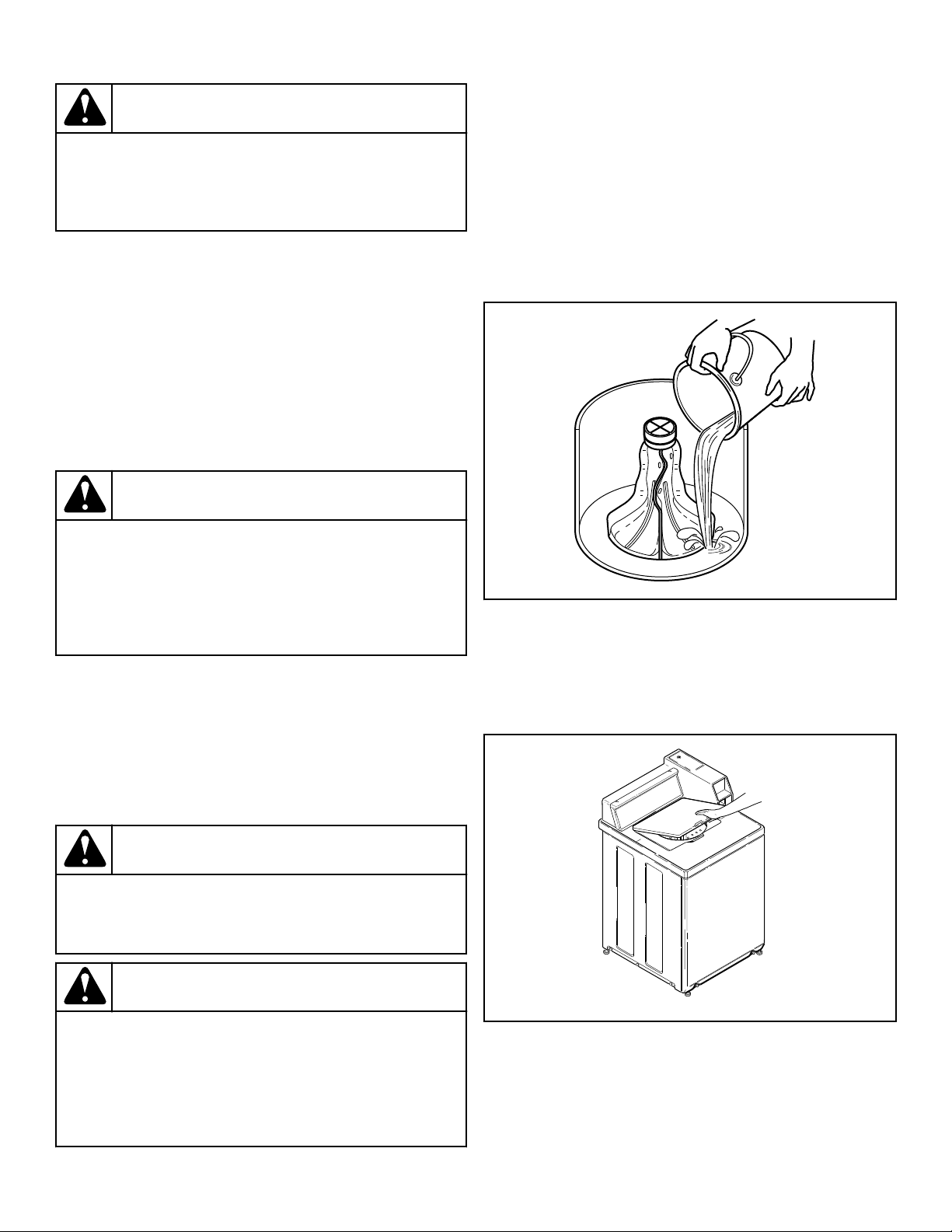

Wipe Out Inside of Wash Tub

Prior to first wash, use an all purpose cleaner or a detergent

and water solution and a damp cloth to remove shipping dust

from inside of the washer.

Figure 3

Connect Fill Hoses

WARNING

Under certain conditions, hydrogen gas may be produced in a hot water system that has not been used

for two weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for

such a period and before using the washer, turn on

all hot water faucets and let the water flow from each

for several minutes. This will release any accumulated hydrogen gas. The gas is flammable. Do not

smoke or use an open flame during this time.

Mixing Valve Flow Rates

Pressure

kPa [psi]

HOT

liters per minute [gallons

per minute]

COLD

liters per minute [gallons

per minute]

WARM

liters per minute [gallons

per minute]

W029

©

DO NOT COPY or TRANSMIT

Copyright, Alliance Laundry Systems LLC -

138 [20] 12.9 [3.4] 12.9 [3.4] 15.1 [4.0]

827 [120] 17.4 [4.6] 17.4 [4.6] 17.4 [4.6]

11 Part No. 202630R2

Page 12

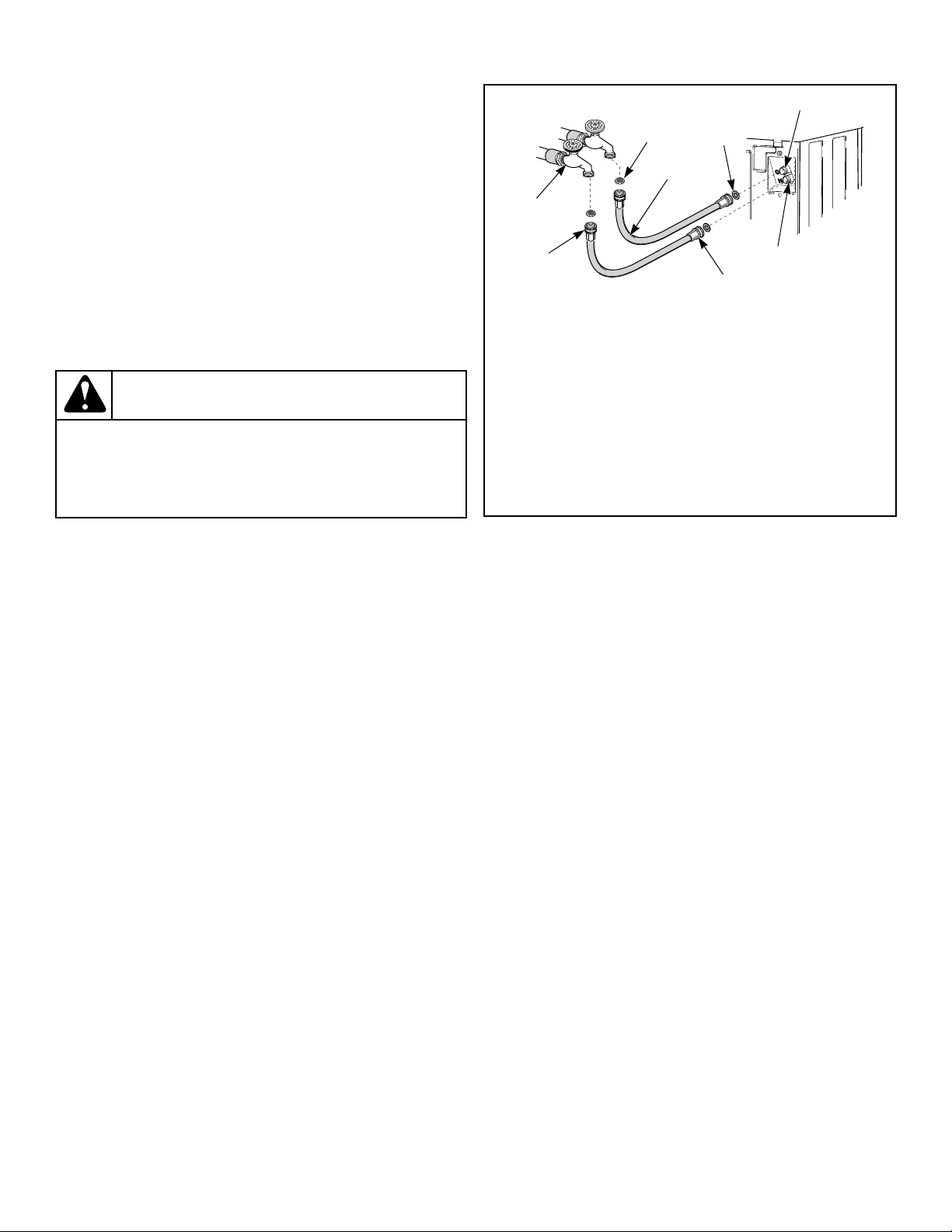

TLW1988N_SVG

HOT

COLD

8

7

6

5

4

3

2

1

Installation

Water Supply Requirements

Water supply faucets must fit standard 19 mm [3/4 inch] female

garden hose couplings. DO NOT USE SLIP-ON OR CLAMPON CONNECTIONS.

NOTE: Water supply faucets should be readily accessible to permit turning them off when washer is not being

used.

Recommended cold water temperature is 10° to 24° Celsius [50°

to 75° Fahrenheit]. Recommended maximum hot water temperature is 51° Celsius [125° Fahrenheit]. Warm water is a mixture of

hot and cold water. Warm water temperature is dependent upon

the water temperature and the pressure of both the hot and cold

water supply lines.

WARNING

To prevent personal injury, avoid contact with inlet

water temperatures higher than 51° Celsius [125°

Fahrenheit] and hot surfaces.

W748

1. Filter Screen (Screen must be facing outward)

2. Fill Hose

3. Rubber Washer (Plain)

4. Cold Water Connection

5. Hot Water Connection

6. Install this end of hose to valve connections at rear of

washer.

7. Install this end of hose to water supply faucet.

8. Faucet

Water pressure must be a minimum of 138 to a maximum of 827

kPa [minimum of 20 to a maximum of 120 pounds per square

inch] static pressure measured at the faucet.

NOTE: Water pressure under 138 kPa [20 pounds per

square inch] will cause an extended fill time in the

washer and decreased rinse performance.

Turn on the water supply faucets and flush the lines for approximately two minutes to remove any foreign materials that could

clog the screens in the water mixing valve. This is especially important when installing your washer in a newly constructed or

renovated building. Build-up may have occurred during construction.

Connecting Hoses

1. Insert rubber washers and filter screens (from accessories

bag) in water fill hose couplings (two hoses supplied with

washer). The filter screen must be facing outward.

2. Connect fill hose couplings with filter screens to water supply

faucets.

3. Connect the other hose couplings to the hot and cold valve

connections at the rear of the washer.

4. Thread hose couplings onto valve connections finger tight.

Then turn 1/4 turn with pliers.

IMPORTANT: DO NOT cross thread or overtighten

couplings. This will cause them to leak.

5. Turn water on and check for leaks.

6. If leaks are found, retighten the hose couplings.

7. Continue tightening and rechecking until no leaks are found.

Figure 4

IMPORTANT:

Hoses and other natural rubber parts deteriorate after

extended use. Hoses may develop cracks, blisters or

material wear from the temperature and constant high

pressure they are subjected to.

All hoses should be checked on a monthly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be replaced immediately. All hoses should be replaced every five years.

IMPORTANT: Turn off water supply faucets after checkout and demonstration. Owner should turn off water

supply whenever there will be an extended period of

non-use.

NOTE: Longer fill hoses are available (as optional

equipment at extra cost) if the hoses (supplied with the

washer) are not long enough for the installation. Order

hoses as follows:

• No. 20617 Fill Hose: 2.44 m [8 feet] (2 GHT hose couplings)

• No. 20618 Fill Hose: 3.05 m [10 feet] (2 GHT hose couplings)

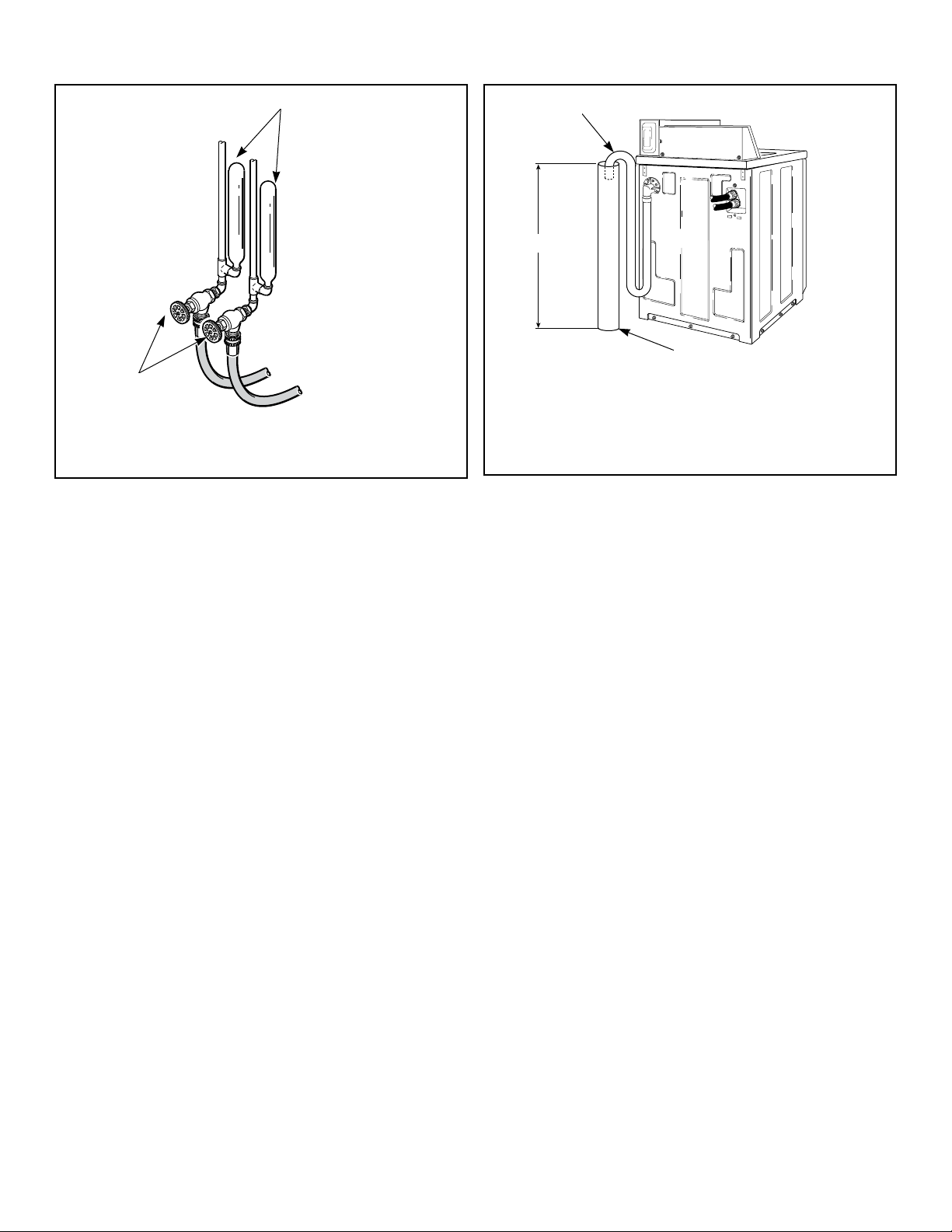

Risers

Risers (or air cushions) may have to be installed if the pipes

knock or pound when flow of water stops. The risers are more efficient when installed as close as possible to the water supply faucets. Refer to Figure 5 .

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

12 Part No. 202630R2

Page 13

W005I_SVG

2

1

1. Risers (Air cushions)

TLW2251N_SVG

3

2

1

2. Water Supply Faucets

Installation

1. Drain Hose

2. Standpipe

3. Recommended Standpipe Height 914 mm [36 in.] Mini-

mum

Figure 5

Connect Drain Hose to Drain

Receptacle

IMPORTANT: The drain hose installation is a very important factor in the washer installation. If care is not

taken when the drain hose is installed, a siphoning action can be started which will cause water to be siphoned from the washer during the cycle.

Drain Facilities

End of drain hose should never be in water as siphoning action

can be started that will cause water to be siphoned back into the

washer.

The curved end of drain hose MUST be installed even with or

above the height of the cabinet top of the washer to prevent siphoning. Refer to Figure 6 .

Figure 6

The standpipe or drain receptacle must be capable of handling a

minimum of 38 mm [1-1/2 inches] outside diameter drain hose.

The drain hose should fit loose within the standpipe (it should not

be snug fit). Never install the drain hose into a “sealed” drain system as air cannot escape and will restrict the water from being

drained from the washer. A sealed drain system may also allow

water to be pumped back into the washer during agitation. Both

of these conditions may result in flooding of the washer.

Remove the drain hose from its shipping position on the rear of

the washer by unhooking the hose from the retainer clamp.

If necessary, follow the instructions for your type of drain receptacle (high standpipe or low standpipe) to properly install the

drain hose.

High Standpipe Installation

NOTE: No. 562P3 Siphon Break Kit and No. 25863 Hose

Coupling are not required for this type of installation.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

13 Part No. 202630R2

Page 14

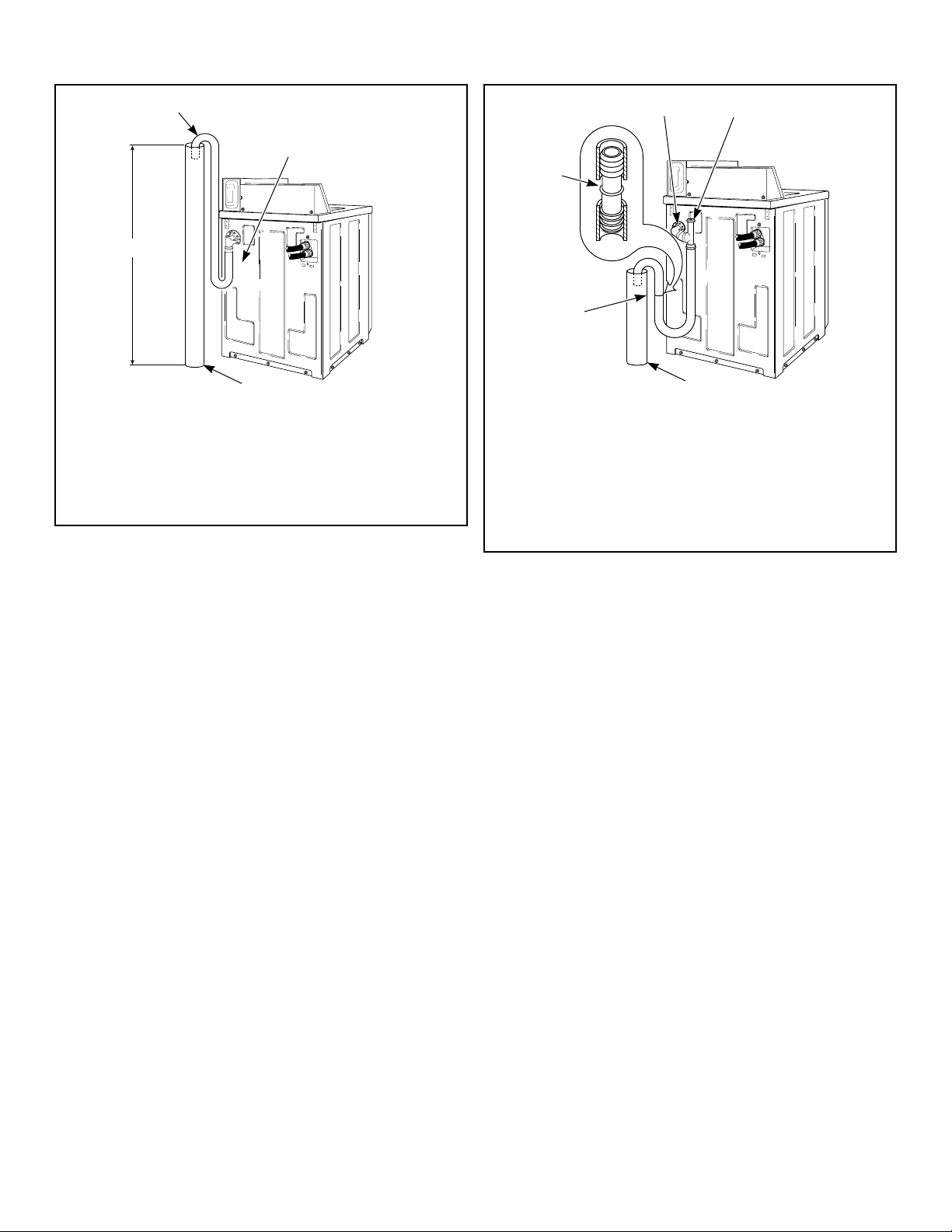

{

TLW2210N_SVG

4

3

2

1

TLW2211N_SVG

{

3

2

1

5

4

Installation

1. Drain Hose

2. Cut Drain Hose off at This End to Fit the Washer Installa-

tion

3. Standpipe

4. Maximum Standpipe Height Not To Exceed 1.5 m [5 ft.]

Figure 7

IMPORTANT: Drain receptacle must be capable of handling a minimum of 38 mm [1-1/2 inch] outside diameter drain hose.

Low Standpipe Installation

If the drain facility is lower than the cabinet top, a siphon break

kit, Part No. 562P3, must be installed in the drain hose to prevent

siphoning action and drain hose MUST be cut to fit the washer

installation. Refer to Figure 8 . Use one No. 25863 Hose Coupling to splice hose. The No. 562P3 Siphon Break Kit and No.

25863 Hose Coupling are available as optional equipment at extra cost through an authorized dealer or parts distributor. Installation instructions are supplied with the kit.

OPTIONAL: Raise the standpipe to the recommended height of

914 mm [36 inches].

IMPORTANT: Drain receptacle must be capable of handling a minimum of 38 mm [1-1/2 inch] outside diameter drain hose.

Drain Hose Elbow

1.

2. 562P3 Siphon Break Kit

3. Standpipe

4. Cut Hose in This Area and Install No. 25863 Hose Cou-

pling

5. 25863 Hose Coupling

Figure 8

Position and Level the Washer

1. Position washer so it has sufficient clearance for installation

and servicing.

2. Place washer in position on a clean, dry, and reasonably firm

floor. Installing the washer on any type of carpeting is not recommended.

3. Place rubber cups (from accessories bag) on all four leveling

legs.

4. Place a level on the cabinet top and check if the washer is level from side to side and front to back.

5. If washer is not level, tilt washer back to access the front leveling legs. Loosen the locknuts and adjust legs by screwing

into or out of washer base.

6. Once adjusted, tilt the washer forward on front legs and lower

back down into position to set the rear self-leveling legs.

7. Washer must not rock. When washer is level and does not

rock, tighten locknuts securely against bottom of washer base.

If these locknuts are not tight, washer will not remain stationary during operation.

Improper installation or flexing of weak floor will cause excessive vibration.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Do not slide washer across floor once the leveling legs have been

extended, as legs and base could become damaged.

14 Part No. 202630R2

Page 15

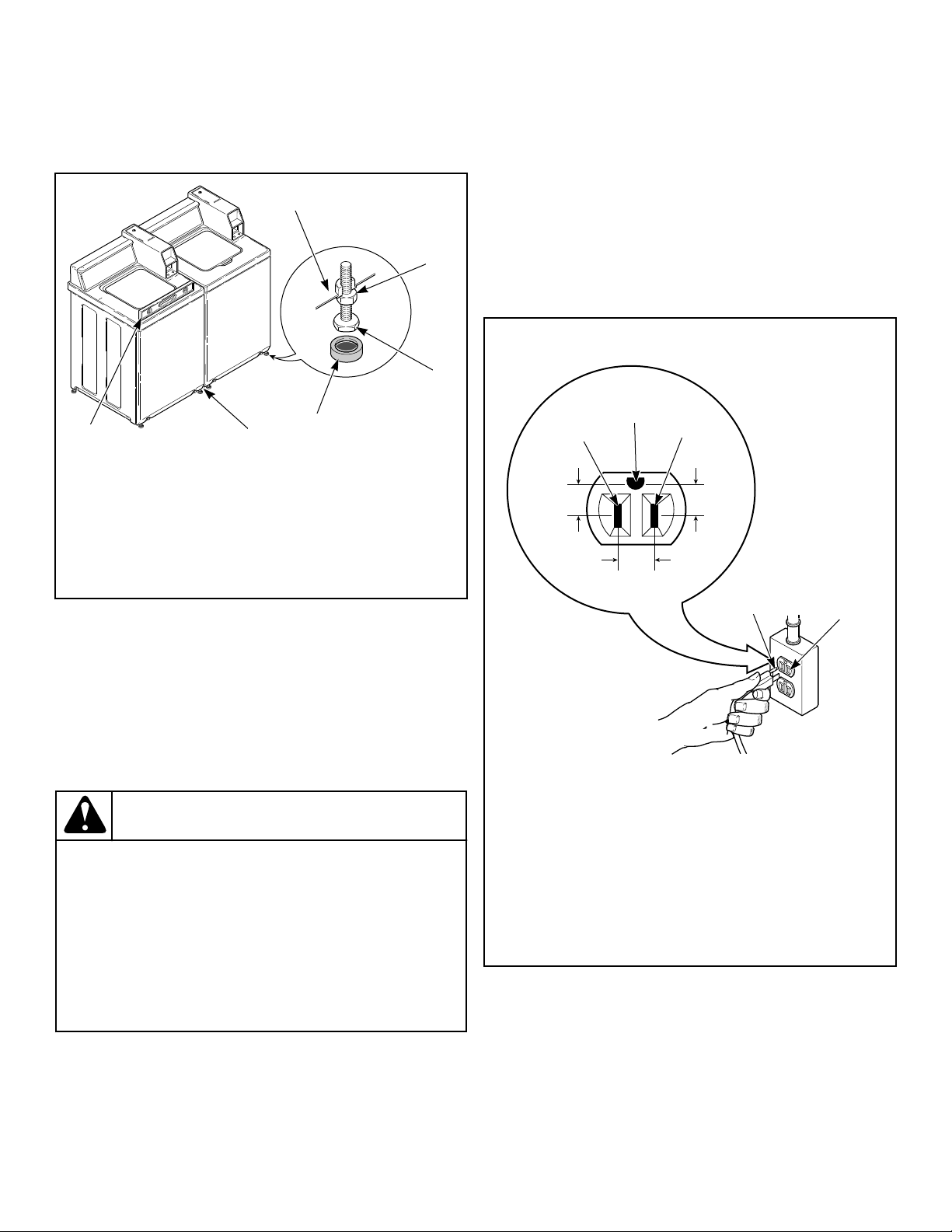

TLW2100N_SVG

6

5

4

3

2

1

DRY2022N_SVG

7

6

8

5

4

3

2

1

Installation

NOTE: For areas with uneven floors, a No. 566P3

Adjustable Rear Leg Extension Kit is available as

optional equipment at extra cost.

8. Verify that unit does not rock.

1. Washer Base

2. Locknut

3. Leveling Leg

4. Rubber Cup

5. 13 mm [1/2 inch] Clearance Between Washers

6. Level

• DO NOT operate other appliances on the same circuit. Use

separately fused 15 Amp circuits.

The washer is designed to be operated on a separate branch, polarized, three-wire, effective earth/ground, 120 Volt, 60 Hertz,

AC (alternating current), circuit protected by a 15 ampere fuse,

equivalent fusetron or circuit breaker.

The three-prong earth/ground plug on the power cord should be

plugged directly into a polarized three-slot effective earth/ground

receptacle rated 110/120 Volts AC (alternating current) 15 Amps.

Refer to Figure 10 to determine correct polarity of the wall receptacle.

Standard 120 Volt, 60 Hertz 3-Wire Effective Earth/

Ground Circuit

Figure 9

Plug In the Washer

Electrical Requirements

120 Volt, 60 Hertz with 3-Prong Earth/Ground Plug

NOTE: The wiring diagram is located in the control

hood.

WARNING

To reduce the risk of fire, electrical shock or personal injury, all wiring and grounding MUST conform

with the latest edition of the Canadian Electrical

Code, Parts I and II, and such local regulations as

might apply. It is the customer’s responsibility to

have the wiring and fuses checked by a qualified

electrician to make sure the laundry room has adequate electrical power to operate the washer.

When plugging in the washer:

• DO NOT overload circuits.

• DO NOT use an extension cord.

• DO NOT use an adapter.

1. L1

2. Earth/Ground

3. Neutral Side

4. Round Earth/Ground Prong

5. Neutral

6. 0 V.A.C.

7. 120 ± 12 V.A.C.

8. 120 ± 12 V.A.C.

Figure 10

W110

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

15 Part No. 202630R2

Page 16

TLW2056N_SVG

TLW2101N_SVG

Installation

WARNING

To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to connect

the washer to the electric power source.

W082

Earth/Ground Instructions

This appliance must be properly connected to protective earth/

ground. In the event of malfunction or breakdown, the earth/

ground will reduce the risk of electric shock by providing a path

of least resistance for electric current.

The appliance is equipped with a cord having an equipment earth/

ground conductor and a three-prong earth/ground plug. The plug

must be plugged into an appropriate outlet that is properly installed and connected to a protective earth/ground in accordance with

all local codes and ordinances.

WARNING

Improper connection of the equipment earth/ground

conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if

you are in doubt as to whether the unit is properly

connected to a protective earth/ground.

W893

• DO NOT modify the plug provided with the unit – if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

• If the laundry room’s electrical supply does not meet the

above specifications and/or if you are not sure the laundry

room has an effective earth/ground, have a qualified electrician or your local electrical utility company check it and correct any problems.

Add Water to the Washer

To prevent damage to pump, do not run washer before adding at

least 0.95 liter [one quart] water to the tub. If the washer is run

before any water is added, the pump seal may overheat, causing

the pump to leak. Once installed, the water retained in the drain

system from the previous cycle will provide sufficient cooling to

prevent pump seal damage.

NOTE: The agitator should not be removed except for

service. The washtub is designed to be self-cleaning.

Figure 11

Check Lid Switch

Washer should stop filling, agitating and spinning when lid is

opened during a wash cycle.

©

DO NOT COPY or TRANSMIT

WARNING

Any disassembly requiring the use of tools must be

performed by a suitably qualified service person.

W299

WARNING

This unit is equipped with a three-prong (earth/

ground) plug for your protection against shock hazard and should be plugged directly into a protective

earth/ ground three-prong receptacle. Do not cut or

remove the earth/ground prong from this plug.

W823

Copyright, Alliance Laundry Systems LLC -

Figure 12

Check Installation

1. Refer to Installer Checklist on the back cover of this manual

and make sure that washer is installed correctly.

16 Part No. 202630R2

Page 17

2. Run washer through one complete cycle to make sure it is op-

TLW2160N_SVG

1

TLW1610K_SVG

7

6

5

4

3

2

1

TLW2163N_SVG

3

2

1

erating properly.

Vending

Meter Case

The factory mounted coin meter case does not include the service

door lock, coin slide (if applicable), coin drawer, coin drawer

lock or keys. These parts must be ordered (at extra cost) according to the purchaser’s requirements direct from the manufacturer

of your choice.

NOTE: You have the option of using a screw type lock

or a 1/4 turn lock on the meter case service door. If you

choose to use a screw lock, then the special bracket

(located inside the meter case) must be used. DO NOT

use the special bracket if a 1/4 turn lock is used.

Coin Drawer Security - For additional security, drill out the two

pilot holes on each side of the front of the meter case to 6.4 or 7.9

mm [1/4 or 5/16 inch] holes and install a bicycle lock through

these holes.

NOTE: An 203 mm [8 in.] coin drawer is required for

coin operated electronic control models.

Installation

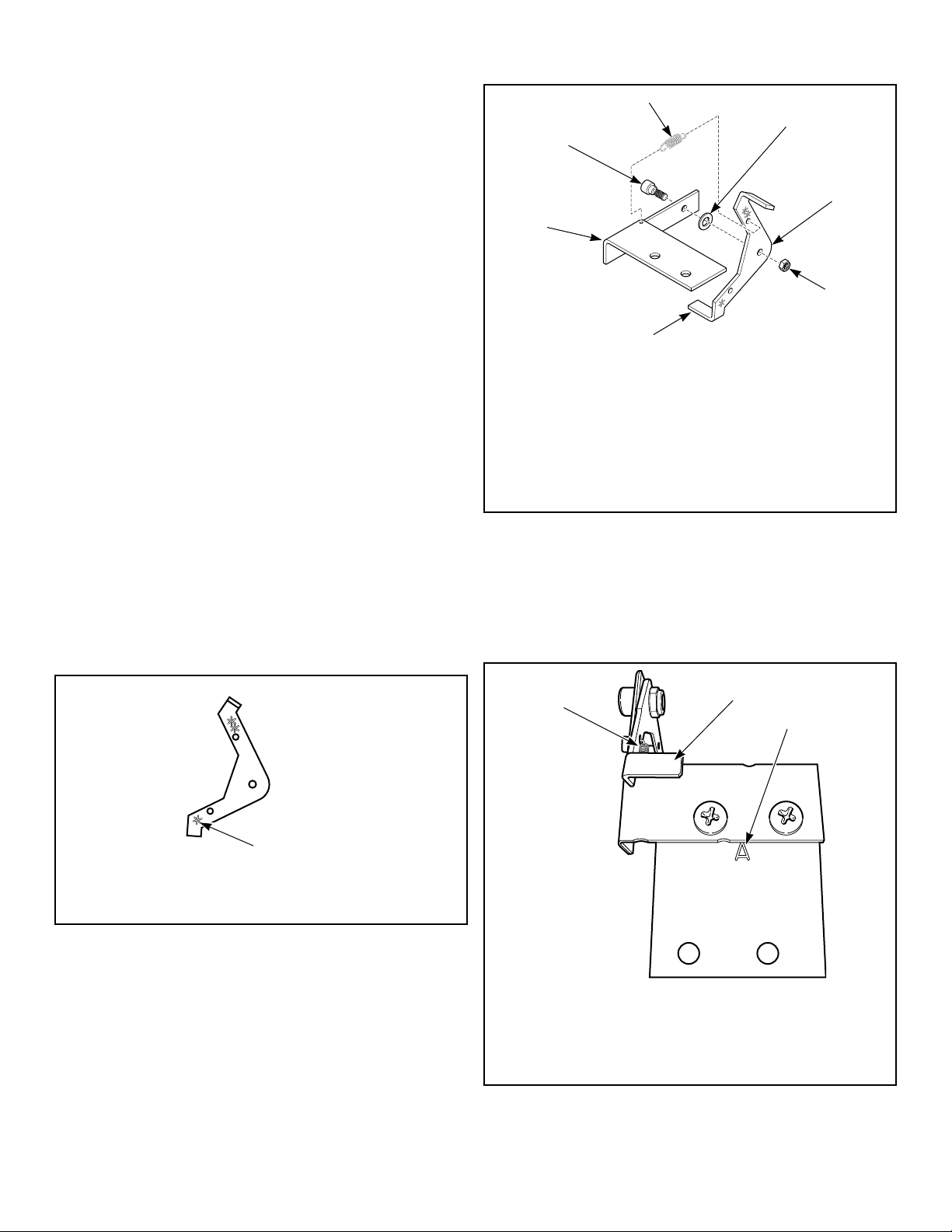

1. Shoulder Bolt

2. Spring

3. Flat Washer

4. Rounded Corner

5. Nut

6. Extension Lever

7. Extension Bracket

Figure 14

Slide Extension Assembly

5. Install extension bracket and lever assembly onto coin slide

bracket using two screws and locknuts. Refer to Figure 15 .

1. Remove slide extension parts from parts accessories bag included in unit.

2. Install extension lever with arm that has one star facing down.

IMPORTANT: Install coin slide bracket with side

marked “A” facing up and toward extension bracket

and lever assembly. Refer to Figure 15 .

Refer to Figure 13 .

1. One Star

3. Install extension lever with rounded corner facing away from

4. Install spring to extension bracket with hook facing down. In-

extension bracket using shoulder bolt, flat washer and nut.

Refer to Figure 14 .

stall other end of spring to extension lever with hook facing

left while standing in front of unit. Refer to Figure 14 .

Figure 13

1. Spring Installed

2. Extension Bracket and Lever Assembly

3. Coin Slide Bracket - Letter "A"

Figure 15

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

17 Part No. 202630R2

Page 18

TLW2164N_SVG

2

1

TLW2157N_SVG

1

FLW6R_SVG

1

Installation

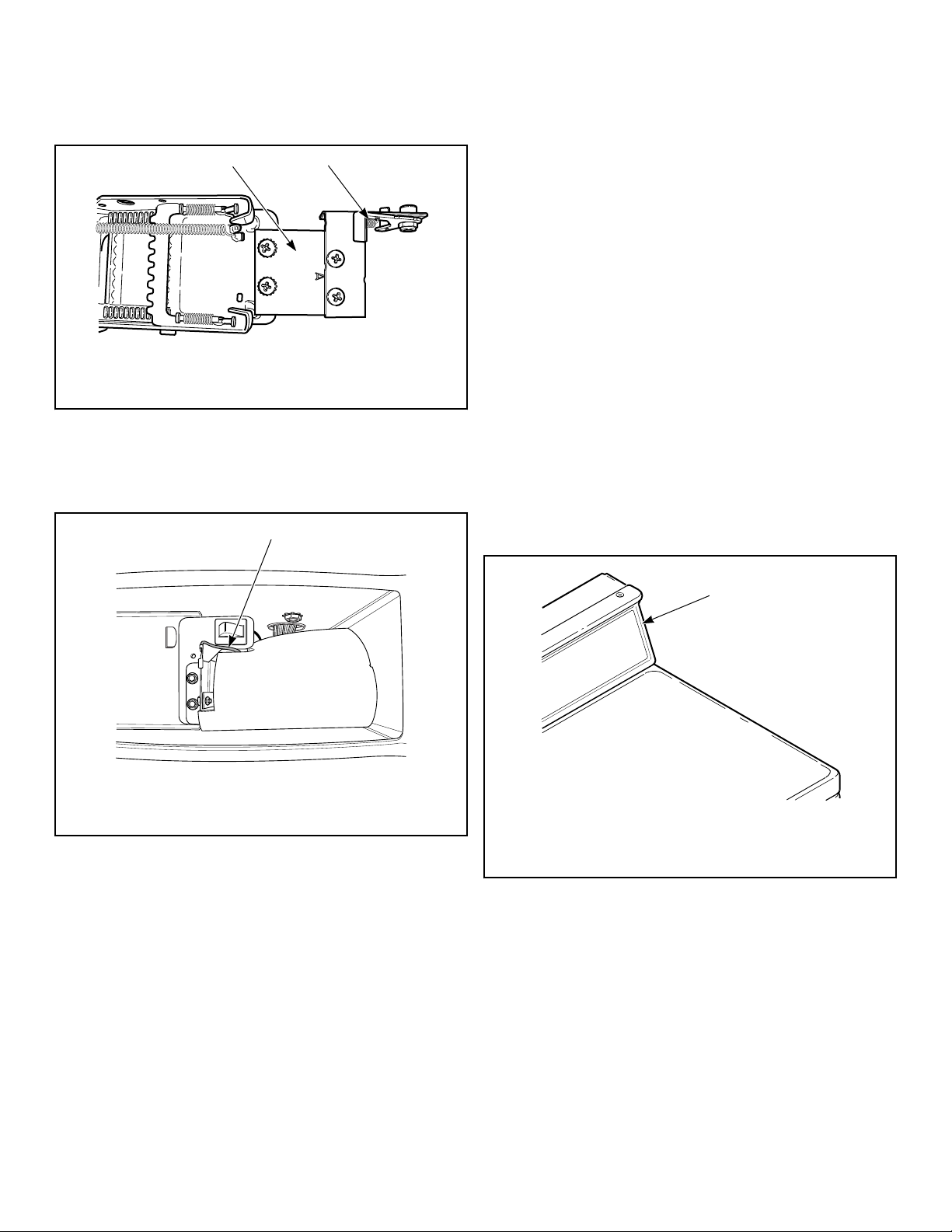

6. Install coin slide extension assembly onto top of coin slide using two remaining screws and lockwashers. Place lockwasher

under head of screws, above bracket “A”. Refer to Figure 16 .

1. Coin Slide Extension Assembly

2. Spring Installed

Figure 16

7. Before installing coin slide and extension, make sure ground

wire is tucked under control shield to provide clearance for

coin slide. Refer to Figure 17 .

Installing Coin Slide Assembly Into Meter Case: Option Two

1. Install coin slide according to manufacturer’s instructions.

2. Insert coins into coin slide and slowly push slide in. Stop before coins fall into coin box. This will allow installing extension through meter case service door opening.

3. Install slide extension onto top of coin slide using two screws.

Refer to Figure 16 .

4. Check to make sure coin slide is operating properly by inserting coins and starting a cycle. The IN USE light will turn on,

or flash if it is already on, to indicate proper operation.

Models Prepped for Card Reader and Non-Metered Models

The machine is shipped from the factory with the Electronic Control Diagnostic Harness Assembly unplugged. To avoid unauthorized manual programming or vending, perform the following

steps.

1. Open control panel.

2. Locate diagnostic harness on electronic control.

3. Plug connectors for “white/black” wire and “red/blue” wire

together.

1. Ground Wire Placement

Figure 17

Installing Coin Slide Assembly Into Meter Case:

Option One

1. Insert coins and partially extend coin slide.

2. Insert coin slide on its side through meter case opening. Then

rotate 90 degrees to its proper orientation.

3. Return coin slide and hook slide pins onto meter case.

4. Continue coin slide installation according to manufacturer’s

instructions.

5. Check to make sure coin slide is operating properly by inserting coins and starting a cycle. The IN USE light will turn on,

or flash if it is already on, to indicate proper operation.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

1. Control Panel

Figure 18

Additional Security

Located on the service door of meter case models is a flat Phillips

head screw. During shipment, this screw is used to attach the

service door to the meter case. For additional security, this screw

can be reinstalled inside the control hood of your unit. Refer to

instructions below for installation.

Tamper-resistant screws also can be installed for additional security. Tamper-resistant screws, bits and bit holder are available as

optional equipment at extra cost. Part numbers are:

• Bit (No. 8 screws) Part No. 281P4

18 Part No. 202630R2

Page 19

• Bit (No. 12 screws) Part No. 282P4

TLW2102N_SVG

3

2

1

• Control panel tamper-resistant screw Part No. 35528

• Front panel tamper-resistant screw Part No. 35527

The following list is the procedure required to install the Phillips

head screw and tamper-resistant screws:

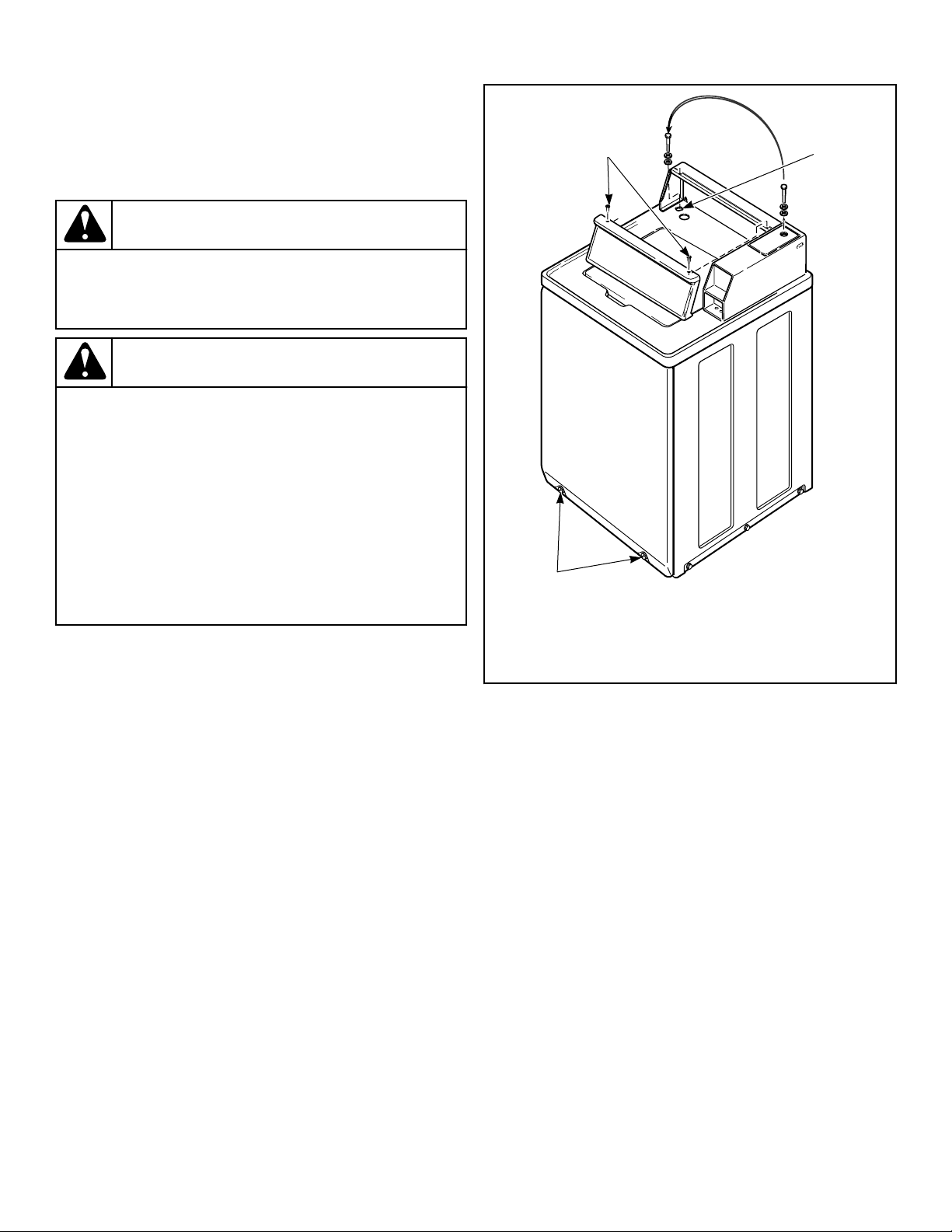

WARNING

Any disassembly requiring the use of tools must be

performed by a suitably qualified service person.

W299

WARNING

To reduce the risk of electric shock, fire, explosion,

serious injury or death:

• Disconnect electric power to the washer before

servicing.

• Never start the washer with any guards/panels removed.

• Whenever earth/ground wires are removed during

servicing, these earth/ground wires must be reconnected to ensure that the washer is properly

connected to a protective earth/ground.

Installation

W883

1. Remove the Phillips head screw from service door (refer to

Figure 19 ).

2. Remove two screws holding control panel to control hood.

3. Tilt control panel forward and lay on a protective pad to prevent scratching of cabinet top.

4. Insert Phillips head screw down through double “D” hole in

left rear corner of cabinet top (inside control hood) until it engages retainer nut located on left rear corner gusset of cabinet.

5. Finger tighten screw.

IMPORTANT: Do not use a power driver to tighten

screw. Torque of a power driver could over-tighten

screw causing damage to cabinet assembly.

6. Secure control panel to control hood using two No. 8 tamperresistant screws, Part No. 35528.

7. Remove two screws holding front panel to base of washer and

install two No. 12 tamper-resistant screws, Part No. 35527.

1. 35528 No. 8 Screws

2. Double “D” Hole

3. 35527 No. 12 Screws

Figure 19

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

19 Part No. 202630R2

Page 20

Operation

W395I_SVG

W392I_SVG

TLW2202N_SVG

Operation Instructions for Coin Slide

Operated and Nonmetered Washers

IMPORTANT: Prior to first wash, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside of washer.

IMPORTANT: Remove all sharp objects from laundry to

avoid tears and rips to items during normal machine

operation.

Add Detergent

1. Pour measured amount of detergent into washtub. Refer to

package directions.

2. NEVER POUR UNDILUTED BLEACH DIRECTLY ON

LAUNDRY. Follow package directions when using bleach.

Operation

Figure 21

Close Lid

Washer will not operate with lid open.

Figure 20

Load Laundry

1. Load dry clothes loosely into washtub – DO NOT overload!

(6.3 kg [14 lbs.] maximum dry clothes load)

2. When washing large items such as shag rugs and bedspreads,

add several small items to balance wash load.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 22

Set Wash Temperature and Fabric/Cycle Selector

One Speed Washers

NOTE: Wash temperature and cycle settings may be

changed any time before first wash fill is complete.

Set wash temperature/cycle at either *HOT/NORMAL, *WARM/

PERM PRESS, *COLD/SPECIAL, or HOT/NORMAL, WARM/

PERM PRESS, COLD/SPECIAL.

Settings with asterisk (*) are Energy Saving Cycles.

20 Part No. 202630R2

Page 21

TLW2045N_SVG

TLW2084N_SVG

TLW2085N_SVG

W297I_SVG

Operation

One Speed Washers

Two Speed Washers

Figure 23

Two Speed Washers

Figure 25

Start Washer

Metered Models

NOTE: Wash temperature and fabric selector settings

may be changed any time before first wash fill is complete.

Set wash temperature at HOT (COLD rinse), WARM (COLD

rinse) or COLD (COLD rinse).

Two Speed Washers

Figure 24

Set fabric selector at *NORMAL, *PERM PRESS/ CASUAL,

NORMAL or PERM PRESS/CASUAL for regular loads. Set at

*DELICATE or DELICATE for delicate loads.

1. Insert money by placing coin(s) in slide.

2. Carefully push slide in as far as possible and then pull slide

out as far as possible.

3. The IN USE light will come on indicating start of cycle.

Figure 26

Nonmetered Models

1. Push start switch.

2. The IN USE light will come on indicating start of cycle.

Settings with asterisk (*) are Energy Saving Cycles.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

21 Part No. 202630R2

Page 22

TLW2048N_SVG

Operation

Control Modes

Power-Up Mode

The control enters this mode after power is applied to the washer.

In Power-Up Mode, the control will detect the state it was in at

power-down to determine what mode to enter. After the control

completes operation in the Power-Up Mode, it will enter either

the Ready, Test or Run Modes.

Ready Mode

In Ready Mode, the control will wait for the vend to be satisfied

before entering Run Mode.

Run Mode

Figure 27

Indicator Lights

IN USE This light will remain on while washer is in

use.

RINSE This light will be on during the rinse portion

of the cycle.

SPIN This light will be on during the rinse/final

spin only. Washer will stop automatically at

end of cycle. (SPIN and IN USE lights will

go out indicating end of cycle.) Leave lid

open after removing laundry.

IMPORTANT: If washer fails to operate properly after

installation, make sure electrical service and water

supply faucets are turned on. Are all the controls properly set? Have a qualified service person refer to the

wiring diagram (located inside of washer control hood),

check for broken, loose or incorrect wiring.

Should washer stop, but IN USE, RINSE or SPIN light remain

on, the motor overload protector may have cycled. Refer to Maintenance section.

WARNING

To reduce the risk of bodily injury, do not remove

laundry from washer until all lights are out, and all

moving parts have stopped.

W092

The washer will stop (pause) shortly before the first spin.

In Run Mode, the control is running a cycle. The IN USE LED

will be lit. For metered models, any time the control receives a

coin slide pulse during a cycle, the IN USE LED will flash briefly to indicate the coin input. For nonmetered models, any time

the control receives a pulse from the push-to-start switch during a

cycle, the IN USE LED will flash briefly to indicate the push-tostart input.

Lid Open Mode

The control enters Lid Open Mode when the lid is opened during

Run Mode. All cycle activity is stopped. The cycle time count

down stops unless the lid is opened during the last three minutes

of the final spin step. In this case the time will continue to count

down.

End of Cycle Mode

The control enters End of Cycle Mode when a cycle is complete.

The IN USE LED will be off. The control will remain in this

mode until the lid is opened or vend has been satisfied.

Error Mode

In Error Mode, the IN USE LED flashes to display fill and drain

errors (refer to paragraphs below). Error Mode can only be exited

by powering down washer. The Error Mode can be turned off by

setting dipswitch 2 to the CLOSED position. Refer to Table 1 .

Fill Error

A Fill Error will occur if the tub does not fill within 62 minutes

of the start of the cycle. A Fill Error is indicated by the control

flashing the IN USE LED twice separated by a one and a half

second pause until the control is powered down. If Error Mode is

turned off (refer to Table 1 ), the fill error will not occur and the

control will continue to wait for the fill level to be reached.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Drain Error

A Drain Error will occur if the tub is not empty after a spin cycle.

A Drain Error is indicated by the control flashing the IN USE

22 Part No. 202630R2

Page 23

W395I_SVG

Operation

LED three times separated by a one and a half second pause until

the control is powered down. If Error Mode is turned off (refer to

Table 1 ), the drain error will not occur and the machine cycle

will advance to the next cycle step as though the water had been

pumped out.

Rapid Advance

The Rapid Advance feature allows the owner to quickly advance

into a cycle and advance an active cycle to a specific cycle step.

To enter Rapid Advance and advance through each cycle step,

open the meter case service door (on metered models) or the control hood (on nonmetered models), unplug the white bullet connector with the black/white and gray/yellow wires on the hood

wire harness for at least one second, and then reconnect it. Each

time the connector is unplugged and reconnected, the control will

advance through the following steps:

• From Ready Mode, cycle will advance to wash (start of cycle).

• From wash, cycle will advance to rinse following a short

pause. Wait for pause before advancing to next step.

• From rinse, cycle will advance to final spin following a short

pause. Wait for pause before advancing to next step.

• From final spin, cycle will advance to End of Cycle Mode.

• Open lid to clear End of Cycle Mode and return to Ready

Mode.

Operation Instructions for MDC

Washers

IMPORTANT: Prior to first wash, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside of washer.

IMPORTANT: Remove all sharp objects from laundry to

avoid tears and rips to items during normal machine

operation.

Add Detergent

1. Pour measured amount of detergent into washtub. Refer to

package directions.

2. NEVER POUR UNDILUTED BLEACH DIRECTLY ON

LAUNDRY. Follow package directions when using bleach.

Setting Dipswitch

Cycle settings can be changed using the 8-Position dipswitch

mounted on the control. The control reads the dipswitch settings

at power-up. The control must be powered down to change the

dipswitch settings. The control is shipped from the factory with

all the switches in the OPEN position. Refer to Table 1 for dips-

witch settings.

Switch 1 is used to select whether a long or short cycle will be

used. Switch 2 is used to turn Error Mode on or off. Switches 3

through 8 are not used at this time.

Open (De-

Switch No.

1 Long Cycle Short Cycle

2 Error Mode On Error Mode Off

3-8 Not Used

fault) Closed

Table 1

Figure 28

Load Laundry

1. Load dry clothes loosely into washtub – DO NOT overload!

(6.3 kg [14 lbs.] maximum dry clothes load)

2. When washing large items such as shag rugs and bedspreads,

add several small items to balance wash load.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

23 Part No. 202630R2

Page 24

W392I_SVG

TLW2202N_SVG

FLW1920N_SVG

W388I_SVG

DRY2633N_SVG

Operation

Figure 29

Close Lid

Washer will not operate with lid open.

Insert Coins or Card

To Insert Coins

1. Insert coin(s) in coin slot.

2. Check pricing as seen on digital display.

Figure 32

To Insert Card

Figure 30

Set Fabric Selector and Wash Temperature

Push touchpad for NORMAL/HOT, NORMAL/WARM, PERM

PRESS/WARM or DELICATES/COLD. Light indicates selection.

Insert card into opening.

Figure 33

Start Washer

After vend price has been satisfied, push the START pad. LID

MUST BE CLOSED TO START WASHER.

NOTE: Always follow manufacturer's care label instructions.

©

DO NOT COPY or TRANSMIT

Figure 31

Copyright, Alliance Laundry Systems LLC -

24 Part No. 202630R2

Page 25

FLW1923N_SVG

Figure 34

Indicator Lights

WASH WASH is lit at the beginning of a Wash cycle

and will remain lit until the Wash cycle is

complete.

RINSE RINSE is lit at the beginning of the Rinse cy-

cle and will remain lit until the cycle is complete.

Operation

SPIN SPIN is lit for all Spin cycles.

START START flashes one second on and one second

off when the full vend price has been satisfied.

WARNING

To reduce the risk of bodily injury, do not remove

laundry from washer until all lights are out, and all

moving parts have stopped.

The washer will stop (pause) shortly before the first spin.

W092

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

25 Part No. 202630R2

Page 26

Maintenance

TLW2103N_SVG

2

1

4

3

Maintenance

User-Maintenance Instructions

Cold Weather Care

If the unit is delivered on a cold day (below freezing), or is stored

in an unheated room or area during the cold months, do not attempt to operate the washer until it has had a chance to warm up.

Water from the previous cycle may remain.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the control panel.

Some cleaning products may harm the finish on the control panel

or damage the interior. DO NOT use products that contain alcohol on the control panel. Wipe the panel dry after cleaning.

Wipe the washer cabinet as needed. If detergent, bleach or other

washing products are spilled on the cabinet, wipe immediately.

Some products will cause permanent damage if spilled on the

cabinet.

Do not use scouring pads or abrasive cleansers.

The washtub will need no particular care though it may need rinsing or wiping after some unusual loads have been washed. This

also may be necessary if too little detergent has been used.

Reinstallation of Shipping Materials

You must install the shipping brace and shipping plug any time

the washer is moved.

Shipping Brace

The shipping brace in the lid opening should be saved and reinstalled whenever the washer is moved. To reinstall the brace,

open the washer lid and place the brace over the washer agitator,

placing the back of the brace into the lid opening first.

Shipping Plug

The plastic shipping plug should be saved and reinstalled any

time the washer is moved. The plug fits into two openings: The

base opening and the shipping plug opening on the bottom of the

movable pivot dome. The plug MUST be inserted into both openings to prevent damage to the washer. In order to accomplish this,

the shipping plug opening must be directly lined up with the base

opening.

Refer to Figure 35 .

Leave the lid open to allow the inside of the washer to dry out

after use. This helps prevent musty odors from developing.

The agitator should not be removed except for service. The washtub is designed to be self cleaning.

Replacing Hoses

Hoses and other natural rubber parts deteriorate after extended

use. Hoses may develop cracks, blisters or material wear from the

temperature and constant high pressure they are subjected to.

All hoses should be checked on a monthly basis for any visible

signs of deterioration. Any hose showing the signs of deterioration listed above should be replaced immediately. All hoses

should be replaced every five years.

Filter Screens

Check the filter screens in the fill hoses for debris or damage every six months. Clean or replace them if necessary.

If the washer is filling with water slower than normal, check the

filter screens. Clean or replace them if necessary.

Order filter screen Part No. 803615 from the nearest authorized

parts distributor.

1. Shipping Plug Opening

2. Base Opening

3. Shipping Plug

4. Shipping Brace

Figure 35

Motor Overload Protector

The internal overload protector will stop the motor automatically

in the event of an overload.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

The overload protector will reset itself in two or three minutes

and the motor will restart automatically.

26 Part No. 202630R2

Page 27

If the overload protector stops motor again, remove the washer

from use and call the service person to correct the problem.

Maintenance

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

27 Part No. 202630R2

Page 28

Troubleshooting

Try these troubleshooting tips before making a service call. They

may save you time and money.

Washer Symptom Possible Cause/Solution

Won’t Fill • Make sure lid is closed.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• Insert coin(s) or card. (metered models only)

• Check for proper operation of coin slide switch (coin slide models only).

• Push START switch to start the washer (nonmetered models only).

• Make sure that the controls are properly set.

• Make sure hot and cold water faucets are turned on.

• Make sure drain hose is not kinked or twisted.

• During the rinse portion of the cycle, the tub won’t fill with water. Instead, there is a

spray rinse.

• Make sure that the last spin has been completed.

• Clean the screens in the water mixing valve and the filter screens located at the faucet

end of the fill hoses. (Owner is responsible for service calls regarding cleaning of the

screens.)

• Water is being siphoned from the washer during the cycle. Refer to the Installation

instructions to make sure that the drain hose has been properly installed.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

Troubleshooting

Won’t Start • Make sure lid is closed.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• Insert coin(s) or card. (metered models only)

• Check for proper operation of coin slide switch (coin slide models only).

• Push START switch to start the washer (nonmetered models only).

• Make sure that the controls are properly set.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

Won’t Agitate • Make sure lid is closed.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• Insert coin(s) or card. (metered models only)

• Push START switch to start the washer (nonmetered models only).

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Broken drive belt. Call the service person.

• Have a qualified electrician check polarity and earth/ground. Refer to Electrical Requirements section.

Table continues...

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

28 Part No. 202630R2

Page 29

Troubleshooting

Washer Symptom Possible Cause/Solution

Won’t Spin • Make sure lid is closed.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• Insert coin(s) or card. (metered models only)

• Push START switch to start the washer (nonmetered models only).

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Broken drive belt. Call the service person.

• Have a qualified electrician check polarity and earth/ground. Refer to Electrical Requirements section.

Stops/Pauses During Cycle • Pauses are part of the washer’s normal operation. The washer will stop (pause) shortly

before the wash and rinse spins.

• Check the laundry room fuse or circuit breaker.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

Won’t Drain • Make sure drain hose is not kinked or twisted.

• Make sure drain hose is not clogged.

• Make sure drain receptacle is not clogged.

• Refer to the Installation instructions to make sure that the drain hose has been properly installed.

Water Leaks • Check that fill hoses are properly installed on the faucets and the washer’s water mix-

ing valve.

• Check the condition of the fill hoses. Replace fill hoses every five years.

• Make sure drain receptacle is not clogged.

• Check laundry room plumbing.

• Laundry load may be oversudsing or overloaded. Use less detergent (or low-sudsing

detergent) and proper load sizes.

Is Noisy • Wash load may be unbalanced. Open lid and redistribute the load.

• Make sure washer is level. Uneven leveling can cause vibration.

• A newly installed washer may make a knocking sound if the machine has been in storage. The belt may have settled. Run washer through 4-5 cycles to loosen belt. Washer

operation will not be affected.

Load is too Wet • Wash load may be unbalanced. Open lid and redistribute the load.

• Load is too small. Add items to make full load.

Wrong Water Temperature • Make sure that the controls are properly set.

• Check fill hoses. Make sure hot faucet hose is connected to hot mixing valve (indicated with “H” on the valve bracket) and cold faucet is connected to cold mixing valve

(indicated with “C” on the valve bracket).

• Make sure laundry room water heater is adjusted properly.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

29 Part No. 202630R2

Page 30

Contact Information

TLW12C_SVG1

1

Contact Information

If service is required, contact the nearest Factory Authorized

Service Center.

If you are unable to locate an authorized service center or are unsatisfied with the service performed on your unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

+32 56 41 20 54 Wevelgem, Belgium

When calling or writing about your unit, PLEASE GIVE THE

MODEL AND SERIAL NUMBERS. The model and serial numbers are located on the serial plate. The serial plate will be in the

location shown in Figure 36 .

Date Purchased ______________________________

Model Number ______________________________

Serial Number _______________________________

Please include a copy of your bill of sale and any service receipts

you have.

WARNING

To reduce the risk of serious injury or death, DO NOT

repair or replace any part of the unit or attempt any

servicing unless specifically recommended in the

user-maintenance instructions or in published userrepair instructions that you understand and have the

skills to carry out.

W329

If replacement parts are required, contact the source from where

you purchased your unit or call +1 (920) 748-3950 or +32 56 41

20 54 for the name and address of the nearest authorized parts

distributor.

1. Serial Plate

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 36

30 Part No. 202630R2

Page 31

Fast Track for Installing the Washer

TLW2098N_SVG1

TLW2201N_SVG

TLW2099N_SVG

D254I_SVG

TLW1988N_SVG

HOT

COLD

TLW2056N_SVG

TLW2251N_SVG1

TLW2101N_SVG

Installer Checklist

Installer Checklist

1 Remove the Shipping

Brace and Shipping

Plug.

CHECK CHECK

2 Wipe Out Inside of

Washer.

CHECK CHECK

3 Connect Fill Hoses.

CHECK CHECK

5 Position and Level the

Washer.

6 Plug In the Washer.

7 Add Water to the

Washer.

4 Connect Drain Hose to

Drain Receptacle.

CHECK CHECK

Refer to the manual for more detailed information

8 Check Lid Switch.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

31 Part No. 202630R2

Page 32

Lave-linge à chargement par le

TLW12C_SVG

haut

Modèles avec et sans monnayeur

Installation / Fonctionnement

Traduction des instructions originales

Conserver ces instructions à titre de référence.

(Si la machine est vendue, le guide doit être remis au nouveau propriétaire.)

www.alliancelaundry.com

N° réf. 202630CAR2

Septembre 2016

Page 33

Page 34

MISE EN GARDE

Le défaut d’installer, d’entretenir ou de faire fonctionner cette machine en conformité avec les instructions du fabricant risque de créer des conditions

dangereuses pouvant provoquer de graves blessures et/ou dommages.

W030

MISE EN GARDE

Pour renforcer votre sécurité et réduire le risque

d’incendie ou d’explosion, ne pas entreposer ni utiliser d’essence ou d’autres vapeurs ou liquides inflammables dans le voisinage de cette machine ou

de tout autre appareil.

W022

REMARQUE : Les mises en garde intitulées AVERTISSEMENT et IMPORTANT figurant dans ce manuel ne

sont pas destinées à couvrir toutes les situations susceptibles de se produire. Le bon sens, la prudence et

l’attention sont des paramètres qui n’ont rien à voir

avec la conception des machines à laver. Il s’agit de

comportements devant IMPÉRATIVEMENT être adoptés

par les personnes qui installent, entretiennent et utilisent la machine.

Toujours contacter le distributeur, un réparateur ou le fabricant en

cas de problèmes ou de situations difficiles à comprendre.

Lire le mode d’emploi complet avant d’utiliser le lave-lin-

ge.

©

Copyright, Alliance Laundry Systems LLC - NE PAS CO-

PIER ni TRANSMETTRE

3 N° réf. 202630CAR2

Page 35

Table des matières

Sécurité.................................................................................................. 6

Explications des consignes de sécurité.............................................................. 6

Instructions importantes sur la sécurité............................................................. 6

Dimensions.............................................................................................8

Installation........................................................................................... 10

Avant de commencer..................................................................................... 10

Outillage...................................................................................................10

Ordre des étapes d'installation :...................................................................10

Déposer l’attache d’expédition et le bouchon d’expédition................................10

Essuyer l’intérieur de la cuve de lavage...........................................................11

Connecter les tuyaux de remplissage...............................................................11

Alimentation en eau...................................................................................12

Raccordement des tuyaux...........................................................................12

Tuyaux d'élévation.....................................................................................13

Raccorder le tuyau de vidange à la bouche de vidange......................................13

Système de vidange................................................................................... 13

Installation d’une colonne montante haute................................................... 13

Installation sur colonne montante basse....................................................... 14

Mettre le lave-linge à sa place et de niveau......................................................14

Brancher le lave-linge................................................................................... 15

Installation électrique.................................................................................15

Instructions de mise à la terre..................................................................... 16

Verser de l’eau dans le lave-linge....................................................................16

Vérifiez l'interrupteur du couvercle.................................................................16

Contrôler l’installation...................................................................................17

Dépôt de monnaie......................................................................................... 17

Boîtier du compteur...................................................................................17

Extension du tiroir.....................................................................................17

Modèles prêts à recevoir un lecteur de cartes et modèles sans compteur..........18

Sécurité supplémentaire............................................................................. 19

Fonctionnement....................................................................................21

Instructions de fonctionnement pour les laveuses avec glissière à monnaie ou sans

monnayeur................................................................................................21

Ajouter du détergent.................................................................................. 21

Charger les vêtements................................................................................21

Fermer le couvercle................................................................................... 21

Régler la température de lavage et le sélecteur de tissu/de cycle.....................21

Démarrer le lave-linge............................................................................... 22

©

Copyright 2016, Alliance Laundry Systems LLC

Tous droits réservés. Toute reproduction, même partielle, de cet ouvrage est interdite. Une copie ou diffusion par quelque procédé que ce soit sans

le consentement écrit de l’éditor constitue une contrefacon.

©

Copyright, Alliance Laundry Systems LLC - NE PAS CO-

PIER ni TRANSMETTRE

4 N° réf. 202630CAR2

Page 36

Voyants lumineux......................................................................................23

Modes de commande................................................................................. 24

Rapid Advance (saut d'étapes).................................................................... 24

Configuration du commutateur DIP.............................................................24

Mode d’emploi des lave-linges MDC..............................................................25

Ajouter du détergent.................................................................................. 25

Charger les vêtements................................................................................25

Fermer le couvercle................................................................................... 25

Régler le sélecteur de tissus et la température de lavage................................ 25

Insérer les pièces de monnaie ou la carte......................................................26

Démarrer le lave-linge............................................................................... 26

Voyants lumineux......................................................................................26

Maintenance.........................................................................................27

Consignes d’entretien destinées à l’utilisateur..................................................27

Entretien par temps froid............................................................................27

Entretien de votre lave-linge.......................................................................27

Tuyaux de rechange...................................................................................27

Filtres.......................................................................................................27

Réinstallation des accessoires d'expédition...................................................... 27

Attache d’expédition..................................................................................27

Bouchon d’expédition................................................................................27

Protection anti-surcharge............................................................................... 28

Dépannage............................................................................................29

Coordonnées.........................................................................................32

Liste de vérification destinée à l’installateur..........................................33

©

Copyright, Alliance Laundry Systems LLC - NE PAS CO-

PIER ni TRANSMETTRE

5 N° réf. 202630CAR2

Page 37

Sécurité

Sécurité

Explications des consignes de sécurité

Des mises en garde (« DANGER », « AVERTISSEMENT » et

« ATTENTION »), suivies d’instructions particulières, figurent

dans le manuel et sur des autocollants de la machine. Ces mises

en garde ont pour objet d’assurer la sécurité des exploitants, utilisateurs, réparateurs et personnels d’entretien de la machine.

DANGER

Signale un danger imminent pouvant entraîner des

blessures graves, voire mortelles.

MISE EN GARDE

Signale une situation dangereuse pouvant entraîner

des blessures graves, voire mortelles.

ATTENTION

Signale une situation dangereuse pouvant causer

des blessures légères ou modérées et des dommages matériels.

D’autres messages (« IMPORTANT » et « REMARQUE ») sont

également utilisés, suivis d’instructions particulières.

IMPORTANT : Le mot « IMPORTANT » signale au lecteur que si des procédures particulières ne sont pas

suivies, il y a risque de dommages mineurs à l’appareil.

REMARQUE : « REMARQUE » sert à communiquer des

renseignements importants, mais qui n’ont pas trait à

un danger particulier, sur l’installation, le fonctionnement, l’entretien ou la réparation de l’appareil.

Instructions importantes sur la sécurité

Conserver ces instructions

MISE EN GARDE

Pour réduire les risques d’incendie, de chocs électriques, de blessures graves voire la mort lors de l’utilisation de la machine à laver, respecter les consignes

de base suivantes :

W023

• Lisez toutes les instructions avant d’utiliser la laveuse.

• Installer le lave-linge conformément aux INSTRUCTIONS

D’INSTALLATION. Se reporter aux INSTRUCTIONS DE

MISE À LA TERRE dans le GUIDE D'INSTALLATION

pour mettre correctement la machine à laver à la terre. Tous

les raccords pour l'alimentation en eau et en électricité, pour

la vidange et pour la mise à la terre doivent être conformes

aux codes locaux et, au besoin, être faits par un technicien autorisé. Ne pas le faire soi-même.

• N’installez pas et n’entreposez pas la laveuse à un endroit où

elle sera exposée à l'eau et aux conditions météorologiques.

• N’ajoutez pas les substances suivantes ou des tissus contenant

des traces des produits suivants dans la laveuse : essence, kérosène, cire, huile de cuisson, huile végétale, huile machine,

solvant de nettoyage à sec, produits chimiques inflammables,

diluant à peinture ou toute autre substance inflammable ou explosive. Ces substances libèrent des émanations qui peuvent

s'enflammer, exploser ou rendre le tissu inflammable.

• Dans certaines conditions, de l’hydrogène gazeux peut se dégager d’un circuit d’eau chaude n’ayant pas été utilisé pendant deux semaines ou plus. L’HYDROGÈNE EST UN GAZ

EXPLOSIF. Si le système d’eau chaude n’a pas été utilisé

pendant au moins deux semaines, faites couler l’eau chaude

de tous les robinets pendant plusieurs minutes avant d’utiliser

la laveuse ou un appareil laveuse-sécheuse combiné. Vous

évacuerez ainsi l’hydrogène gazeux qui pourrait s’être accumulé. CE GAZ EST INFLAMMABLE, NE PAS FUMER OU

UTILISER UNE FLAMME NUE DURANT CETTE OPÉRATION.

• Pour réduire les risques de décharge électrique et d’incendie,

N’UTILISEZ PAS de rallonge électrique ou d’adaptateur pour

brancher l’appareil à une source d’alimentation électrique.

• Ne laissez pas jouer des enfants sur ou à l’intérieur du lavelinge. Il est nécessaire de surveiller attentivement les enfants

qui jouent près de la laveuse. Cet appareil n’est pas destiné à

être utilisé par des personnes (y compris des enfants) dotés de

capacités physiques, sensorielles ou mentales réduites, ou

manquant de connaissance ou d'expérience, à moins qu'ils ne

soient surveillés par ou qu'ils aient reçu des instructions con-

©

Copyright, Alliance Laundry Systems LLC - NE PAS CO-