Unimac UW80PV-Extractor Parts Diagram

Washer-Extractor

Pocket Hardmount

Va ri ab le -S pe ed

WE-6 Control

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

MC010J

Part No. F232210

August 2004

Table of

Contents

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Nameplate Location.............................................................................. 3

Customer Service.................................................................................. 3

Introduction........................................................................................... 5

LED Display .................................................................................... 5

Simulator.......................................................................................... 5

Safety Information.............................................................................. 7

Explanation of Safety Messages........................................................... 7

Important Safety Instructions ............................................................... 7

Programming ...................................................................................... 9

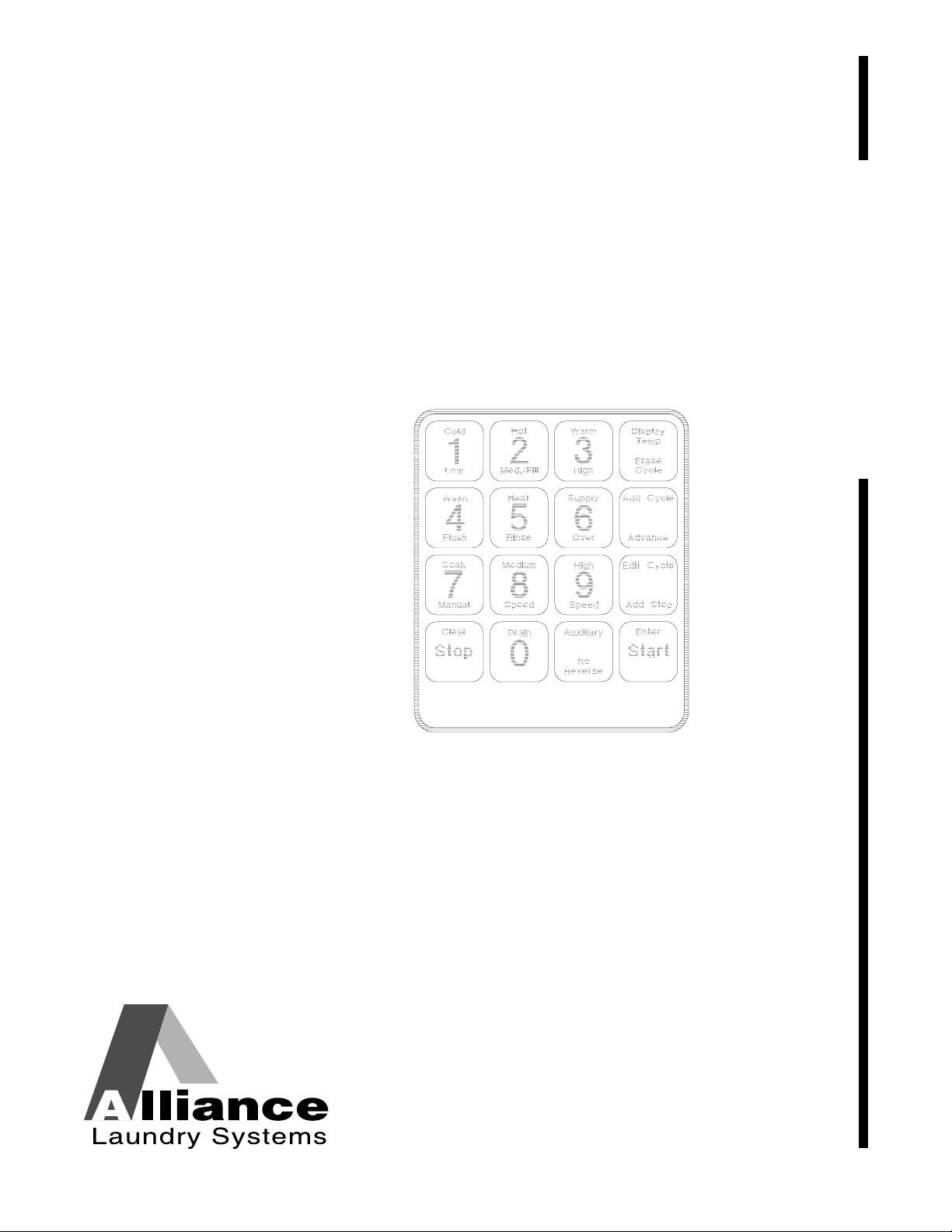

Keypad Identification ........................................................................... 9

Entering Program Mode ....................................................................... 9

Setup Mode........................................................................................... 10

To Enter Setup Mode....................................................................... 11

Programming Tutorial .......................................................................... 14

Programming Hints............................................................................... 17

Test Cycle ............................................................................................. 17

Wet Clean Testing............................................................................ 18

Manual Mode Control Feature.............................................................. 18

Auxiliary Connections ..................................................................... 19

Balance Timing Sequence for Information on

Preprogrammed Cycles ...................................................................... 19

Cycle Programming.............................................................................. 20

Displaying a Cycle in Memory........................................................ 20

Editing a Cycle................................................................................. 21

Erasing a Cycle in Memory ............................................................. 22

Programming a Wet Clean Cycle .................................................... 22

Step Programming ................................................................................ 22

Programming a Fill without Spray................................................... 22

Programming a Fill Temperature..................................................... 22

Programming a Supply Step – Models with 8 Supplies .................. 24

Programming Heat........................................................................... 27

Programming a Wash Step............................................................... 27

Programming a Wash 5 Thermal Cool-down .................................. 28

Programming No Reversing ............................................................ 29

Programming a Soak Step................................................................ 29

Programming a Drain Step............................................................... 30

Programming a Flush Step............................................................... 30

Programming a Reuse Drain Step with Third Party Water

Reuse System ................................................................................. 30

Programming a Fill through Auxiliary Fill Valve with

Third Party Water Reuse System ................................................... 31

Programming a Spin Step ................................................................ 31

Spins................................................................................................. 32

Stop Routine..................................................................................... 32

Programming a Spray Rinse Step .................................................... 32

Auxiliary .......................................................................................... 33

© Copyright 2004, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Balance Detection................................................................................. 34

Balance Switch Detection................................................................ 34

Simulator Operation and Program Transfer ......................................... 35

Simulator Operation......................................................................... 35

Transferring All Cycles from Computer to Simulator..................... 37

Transferring One Cycle from Computer to Simulator..................... 37

Transferring All Cycles from Simulator to Computer..................... 37

Transferring One Cycle from Simulator to Computer..................... 38

Preprogrammed Cycles......................................................................... 38

Cycle Categories .............................................................................. 39

Standard Supply Legend.................................................................. 39

Standard Cycle Charts...................................................................... 40

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Introduction

Model Identification

Information in this manual is applicable to these

models:

UW35PV* UW100PV*

UW60PV* UW125PV*

UW80PV*

* This manual applies to models with U5, U6, U7 or U8 in the

8th and 9th, or 9th and 10th positions in the model number

(e.g., UW60PVXU8

0001).

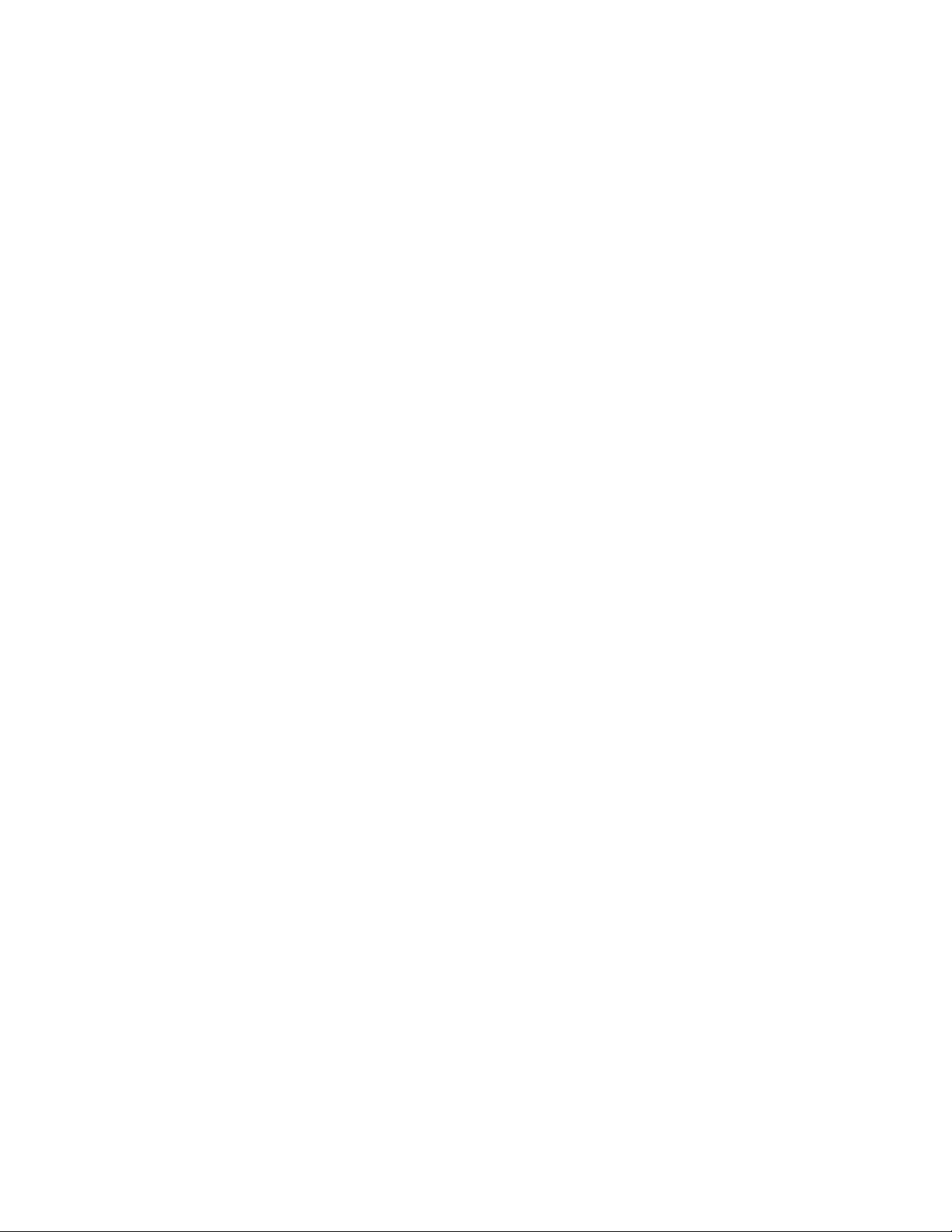

Nameplate Location

The nameplate is located above supply valve box,

below inverter exhaust fan and at top of module.

Always provide the machine’s serial number and

model number when ordering parts or when seeking

technical assistance. Refer to Figure 1.

3

¨

P

U

S

H

1 Near Supply Valves

2 Below Inverter Exhaust Fan

3 Top of Module

1

2

PHM586N

Figure 1

Customer Service

For technical assistance, contact your local distributor

or call:

(920) 748-3121

Ripon, Wisconsin

A record of each washer-extractor is on file with the

manufacturer. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assitance. Refer to Figure 1.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Introduction

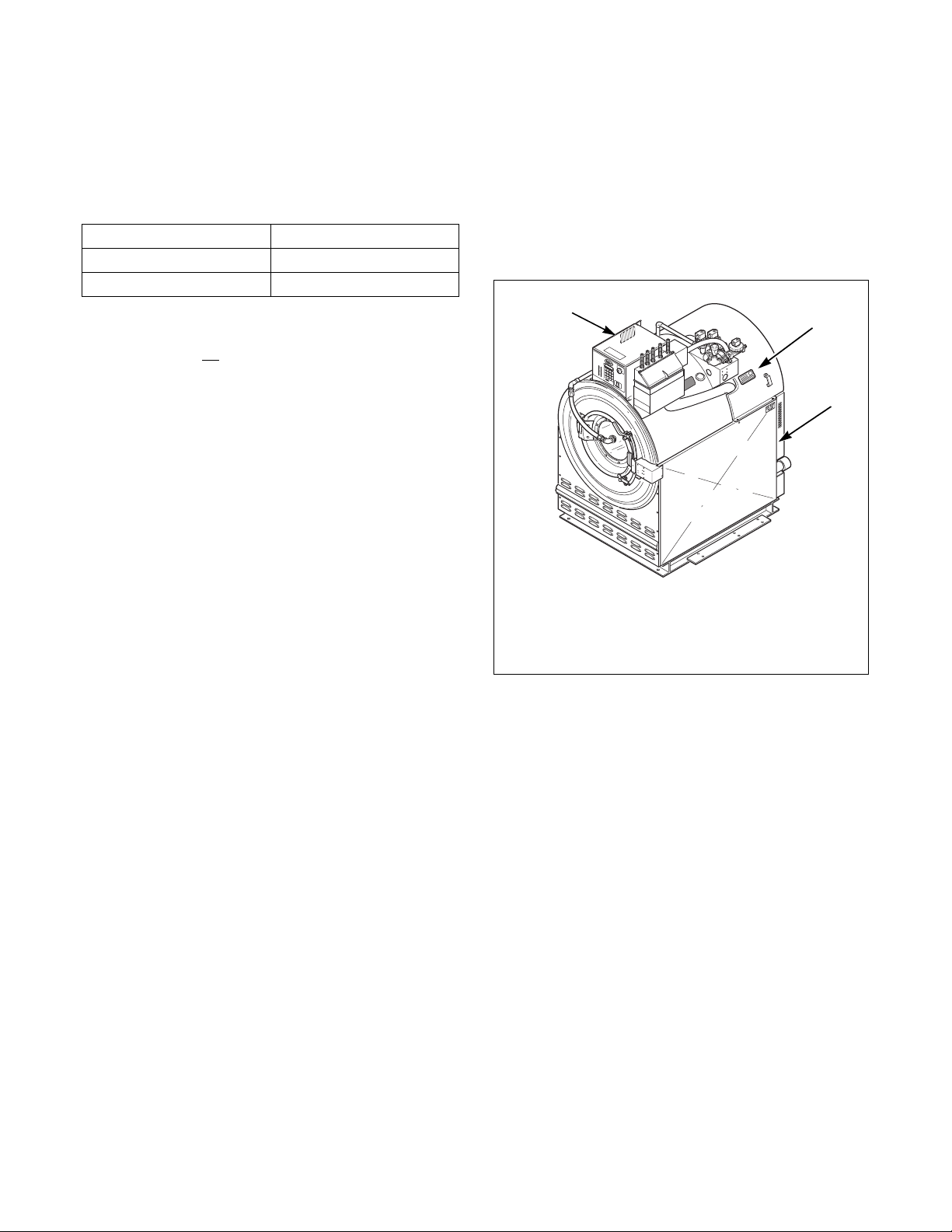

Model Number Familiarization Guide

Sample Model Number: UW60PVXU80001

UW

60

P

V

X

U8

0001

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control P = WE-6 Control

Washer-Extractor Speed Capabilities V = 7 Speeds

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

UW60PVXU80001

00000000000

200 – 240

14

20

50 – 60 2/3

1/3

Drawings:

60 27

N/A

ETL Listed

Conforms To ANSI/UL Std. 1206, 3rd Ed

Certified To CAN/CSA Std. C22.2 No.53-1968

EXAMPLE OF NAMEPLATE

Figure 2

N/A

813

0.0

PHM533R

PHM533R

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Introduction

Introduction

The WE-6 control is a field-programmable solid-state

control capable of storing and running up to 39

preprogrammed ready-to-use cycles. A detailed

description of these cycles can be found in the

Standard Cycle Charts section.

Never turn the power off while the control mode

switch is in the PROGRAM position. Such action will

disorder portions of the programmed data,

necessitating reprogramming of some or all of the

existing cycles. Always return the mode switch to

RUN position before turning the power off.

Never leave the mode switch key inserted in the switch

lock where it may be accessible to unauthorized

personnel not familiar with programming procedures.

The control in this washer-extractor is continuously on

the alert for problems within the machine. When the

control detects a problem, it immediately flashes a

letter or number or both on the display. It may activate

the signal buzzer as well.

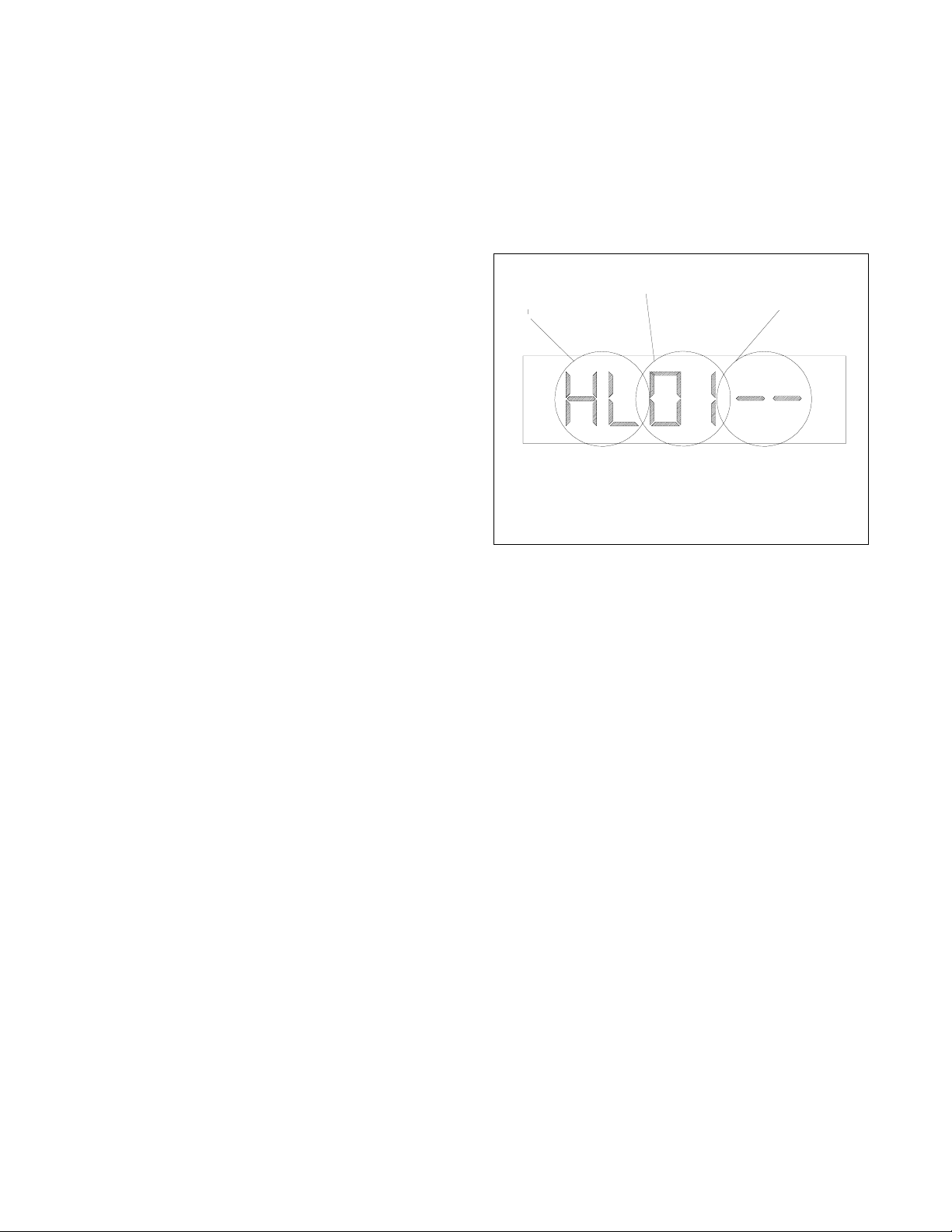

LED Display

The WE-6 control has a six-digit LED display.

References to display indications pertain to the first

four digits of the display reading left to right. The last

two digits on the right side of the display will indicate

either the last cycle used or the current cycle in

progress. Refer to Figure 3.

2

1

1 Function Being Executed

2 Step Number

3 Cycle Number

3

MC007A

Figure 3

Table 2 lists the various displays and what they mean.

Simulator

A simulator, available at extra cost, is an optional

accessory that allows the user to preprogram cycles for

all WE-6 control washer-extractors in a facility. The

information is preprogrammed into the simulator, the

simulator is connected to the washer-extractor needing

updates a, and the preprogrammed information is

downloaded into the WE-6 control on the washerextractor.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Notes

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232210

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

20. Replace worn power cords and/or loose plugs.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards and/or

panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Programming

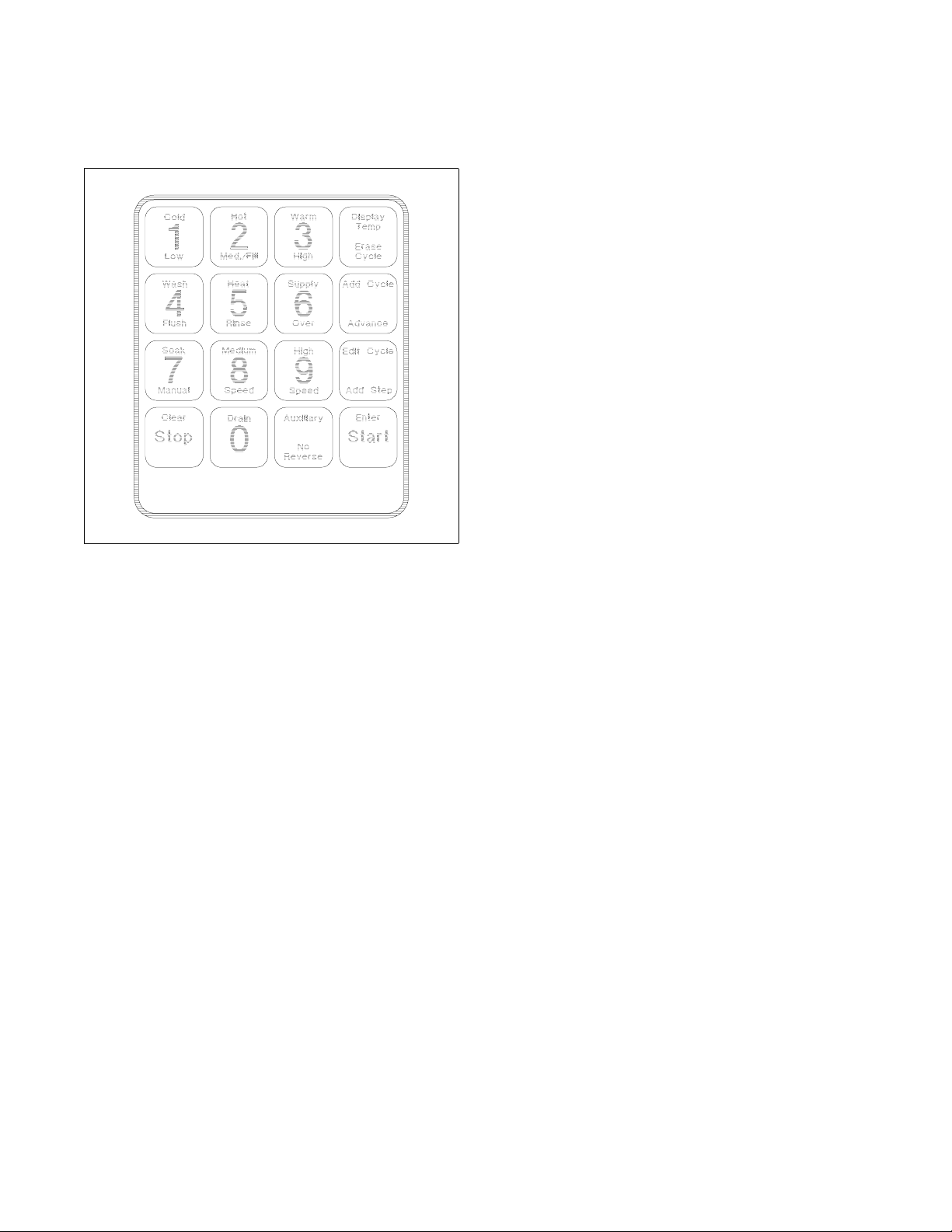

Keypad Identification

MC010J

Figure 4

All sixteen keypads are used in Program Mode.

Specific functions are printed in red on keypads.

Keypad 1–6 and Auxiliary/No Reverse keypad are

dual function keypads in Program Mode. In each

instance (with exception of Warm/High keypad), when

a keypad is first pressed in a programming step, the

word printed at top of keypad applies. In most

instances, the next time same keypad is pressed or if

another keypad has already been pressed in

programming a step, the word printed on bottom of

keypad applies.

Entering Program Mode

NOTE: Machines are factory programmed with

basic cycles to make the units operational without

programming at installation.

1. Locate key-operated programming switch on left

side of control module, viewed from front.

2. Insert key and turn switch to PROGRAM

position.

3. Display will read “CY00.”

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Programming

Setup Mode

NOTE: Enter Setup Mode while in Program Mode.

Refer to Entering Program Mode section.

In Setup Mode, prompting the WE-6 allows the

following options:

• Displaying sump temperature in Centigrade or

Fahrenheit (FAr or CEN).

• Recognizing and controlling one or two

independent drains. (Two independent drains will

apply only for special applications.)

• Enabling or disabling Advance keypad in Run

Mode.

• Enabling or disabling Manual Mode.

• Enabling or disabling wet clean functions (affects

Auxiliary 1 and 2 outputs).

• Selecting balancing routine (active if inverter

balance detection is utilized).

• Selecting machine model.

• Reading or resetting cycle count.

NOTE: Machine comes from manufacturer with

WE-6 control set up for use with machine in which

it is installed. If control needs to be reset, refer to To

Enter Setup Mode.

IMPORTANT: WE-6 control must be configured

for washer-extractor in which it is installed. Failure

to set up control for proper machine may cause

control to malfunction and void warranty.

IMPORTANT: Once WE-6 control has been

through model Setup Mode one time, it will store

machine model configuration information in

control memory and never display “SETUP” again.

It is very important that WE-6 control PC board,

or the socketed chips in this PC board are NEVER

removed from one washer and installed in another

washer without first updating and verifying model

configuration as described in instruction. Warranty

will be void if not set up properly.

IMPORTANT: DO NOT install an earlier version

WE-6 control board. THIS WILL CREATE

HAZARDOUS CONDITIONS FOR OPERATOR

AND VOID WARRANTY. Contact Alliance

Laundry Systems for additional details and

information regarding free replacement of old

control boards.

IMPORTANT: WE-6 door lock circuit MUST NOT

allow entry into door until basket has come to a

complete stop.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Programming

To Enter Setup Mode

1. Enter Program Mode. Refer to Entering

Program Mode section.

2. Press Auxiliary keypad, 2 keypad, and 9 keypad

in that order. Display shows either “CEN” (for

degrees shown in Centigrade) or “FAr” (for

degrees shown in Fahrenheit).

3. Press Enter keypad.

4. Display shows either “1DRAIN” or “2DRAIN.”

The normal prompt for most applications is

“1DRAIN.” “2DRAIN” is used only for special

applications. Consult manufacturer for full

details. To choose alternate feature, press 0

keypad.

NOTE: Enabling second drain via Auxiliary 2

output precludes control of recirculation pump and

is not necessary for Premium Wet Clean Module.

5. Press Enter keypad.

6. When desired drain is displayed display shows

“ADV” or “NO ADV.” The prompt “NO ADV”

will disable Advance keypad in Run Mode,

thereby preventing operator from advancing

control through steps of cycle before completion.

In addition, it will not be possible to advance to

any step before starting a cycle if “NO ADV” is

selected. Press 0 keypad to select enable or

disabling the Advance feature.

7. Press Enter keypad. Display will read either

“MANUAL” or “NO MAN.” If “MANUAL” is

displayed, Manual Mode will be enabled during

normal operation. If “NO MAN” is displayed,

Manual Mode will be disabled when a cycle is

run, even if Manual operation keypad sequence is

entered. To select enabling or disabling the

alternate feature, press 0 keypad.

8. Press Enter keypad. When desired Manual Mode

option is displayed, display will read “WET CL”

or “NO WCL.” If “WET CL” is displayed, wet

clean functions are enabled. If “NO WCL” is

displayed, press 0 keypad, wet clean functions

are disabled.

9. Press Enter keypad. When desired Wet Clean

option is displayed, display will read “S BAL”

(short balance timing sequence) or “L BAL”

(long balance timing sequence). Refer to Table 1

for appropriate sequence.

Model Display

UW50PVT,

UW55PVT,

UW60PVT

Design 5 models 60 lbs. or less S BAL

Design 5 models greater than 60 lbs. L BAL

Design 6 or greater model L BAL

Ta bl e 1

L BAL

NOTE: This setting will have no effect if machine is

not equipped with an AC Inverter drive balance

detection system.

NOTE: Design series can be found on serial decal of

machine. Example: UW60PVQU8

0001. Refer to

Nameplate Location section.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Programming

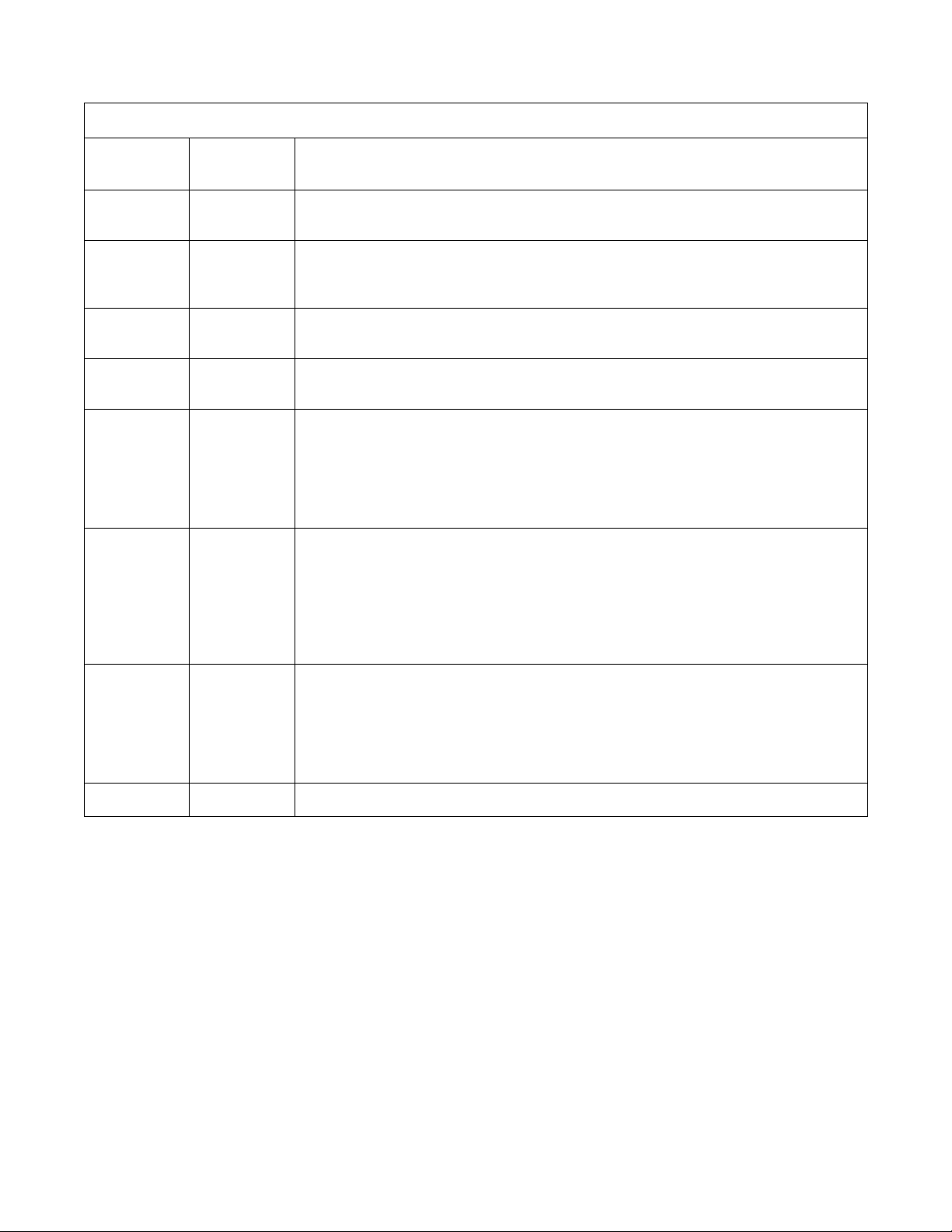

Programming Keypad

Keypad

1

2

3

Erase Cycle

4

5

Red

Keypads

Cold

Low

Hot

Med./Fill

Cold is pressed when step requires cold water.

Low is pressed for low-level fill.

Hot is pressed when step requires hot water.

Med./Fill is pressed to select medium water level.

Description

Fill is pressed in Manual Mode to operate fill valves.

War m

High

War m is pressed when step requires warm water.

High is pressed for high-level fill.

Erase Cycle Erase Cycle and a two-digit cycle code number are pressed to erase a cycle from

memory.

Was h

Was h is pressed when step is a wash or dilution rinse. Then keypad 1, 2, 3, 4, 5, 6, or 7 is

pressed to choose type of agitation.

Flush

Flush is pressed to keep drain open when water is added to machine. A temperature

selection keypad (Hot, Cold, War m) must be pressed before Flush keypad. When Flush

is programmed, water is added through door spray nozzle only; basket rotates in low

speed forward only.

Heat

Heat is pressed when auxiliary heat is needed. This must be followed by a specific

temperature selection, such as 165°F. Temperature must be entered; then a time assigned

to reach that temperature must be entered.

Rinse

Rinse is pressed when a spin-spray rinse (not available on UW125 models) is desired.

Before Rinse keypad is pressed, a temperature keypad must be pressed: Hot, Cold, or

War m. Drain will remain open, and basket will rotate at medium-spin speed (high speed

on two-speed only machines). Water is added through door spray nozzle only.

Supply

Supply is pressed when soap, bleach, or other chemicals are desired. Keypad 1, 2, 3, 4, or

5 must be pressed to indicate specific supply dispenser being used. Combinations of these

6

Over

supplies can be programmed. Refer to Programming a Supply Step.

Over is pressed when an overflow of water is desired. Drain is closed and water is added,

using fill valves only, without regard to level. Water flows out overflow connection for

time assigned to step.

Add Cycle Add Cycle Add Cycle is pressed to begin process of programming a new cycle into memory.

Ta bl e 2

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

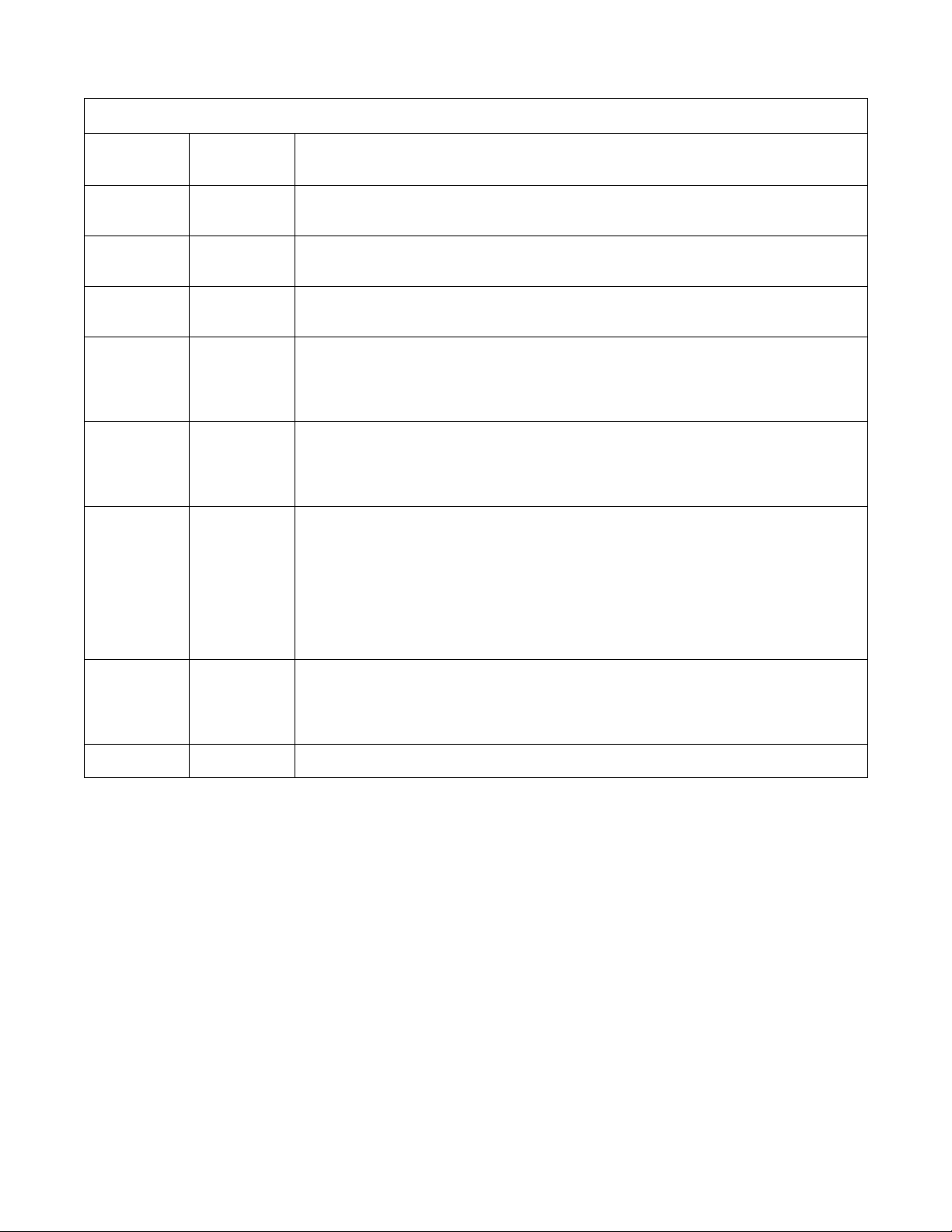

Programming Keypad (Continued)

Programming

Keypad

7

8

9

Edit Cycle

Add Step

Clear (black

on red

background)

0

Red

Keypads

Description

Soak Soak is used when no agitation is desired. This follows a fill and/or supply step. Time

must be assigned in hours and minutes. (Wash 3 also provides no agitation.)

Medium

Speed

Medium Speed is pressed when a medium spin only is desired for washing delicate items

not suited for high speed spin or when an intermediate spin is desired.

High Speed High Speed is pressed when a fast spin is desired. Pressing High Speed keypad once will

activate the H1 spin; twice, the H2 spin; and three times, H3 spin.

Edit Cycle

Edit Cycle is pressed followed by a two-digit cycle code number to display steps of a

preprogrammed cycle. Cycle may be altered during edit cycle procedure by deleting,

changing, or adding steps.

Add Step

Clear (black

on red

background)

Add Step is pressed to add a step to an existing cycle during edit cycle procedure.

Clear is pressed when an error has been made in programming a step. Instead of pressing

Enter as step is completed, press Clear to eliminate incorrect information. (Clear should

never be pressed when displaying a cycle unless a particular step is to be eliminated or

changed. Refer to Displaying a Cycle in Memory.)

Drain Drain is pressed after a wash, dilution rinse, or soak step is programmed in order to

remove water from machine. A time must be assigned that will allow machine to reach

empty. If control has been prompted for two drains, press 1 keypad or 2 keypad for

desired drain valve. Refer to Prompting WE-6 section in Operation Manual. There are

always three possible selections for drain step. These are selected after Drain keypad is

pressed. Press 1 keypad for drain 1 (main drain), 2 keypad for a drain to reuse tank A, and

3 keypad for a drain to reuse tank B. For special applications utilizing “2DRAIN,” contact

manufacturer.

Auxiliary

Auxiliary

Auxiliary is pressed to activate buzzer or other auxiliary output. NOTE: Auxiliary 4 is

used to activate recovery fill valve for machines equipped with water reuse system.

No Reverse

No Reverse

No Reverse is used to rotate basket in one direction only during a step and should be

pressed just before pressing Enter keypad.

Enter Enter Enter is pressed to enter programming information into control’s memory.

Table 2 (Continued)

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Programming

Programming Tutorial

The following procedure guides the programmer

through a complete cycle and allows hands-on

experience for programming cycles. The complete

cycle is listed at the end of this section.

1. Enter Program Mode. Refer to Entering

Program Mode section.

2. Press Add Cycle keypad. Display will read

“ACYC00.”

3. A two-digit number from 01 to 39 must be

entered. Refer to Standard Cycle Charts section.

NOTE: Cycle number 01 is recommended because

standard program versions use this short cycle for

performing a chemical supply setup.

4. If using cycle number 01, press 0 keypad, then

1 keypad, then Enter keypad. Display will read

“CYC01.”

a. If display alternately flashes “EXISTS” and

“EDIT?,” press Clear/Stop keypad. Display

will read “CYC01.”

b. Erase existing cycle by pressing Erase Cycle

keypad. Display will read “ECYC01.” Press

0 keypad, then 1 keypad, then Enter keypad.

Display will read “WA I T ” briefly and then

“CYC01.”

c. Press Add Cycle keypad. Display will read

“ACYC01.” Press 0 keypad, then 1 keypad,

then Enter keypad. Display will show “0101.”

(“01” means step 1 and “01” means cycle

number.)

5. Enter desired water temperature and fill level. For

this tutorial, step 1 will be Hot Fill and Low

Level.

a. Press Hot keypad (2) and then Low keypad

(1). Display will read “HL0101.”

7. For this tutorial, step 2 in cycle will be an

addition of a supply step.

a. To add supply No. 1, press Supply keypad (6)

and then 1 keypad. Display will read

“S10201.”

b. Press Enter keypad and display will read

“M---S.”

c. Enter desired time in minutes and seconds for

supply valve to be turned on (thirty seconds is

the recommended time).

Press 0 keypad for minutes, and display will

read “0M-00S.”

Press 3 keypad and then 0 keypad. Display

will read “0M-30S,” indicating a supply time

of thirty seconds.

8. Press Enter keypad. Display will change to read

“0301,” indicating control is ready for step 3 of

cycle 01.

9. If no other supply is required, the next step is to

choose type of wash desired and assign it a time.

Refer to Programming a Wash Step section for

available wash types. For this tutorial choose a

wash with standard reversing action (Wash 1) and

a time of six minutes.

a. Press Wash keypad (4) and then 1 keypad.

Display will read “W10301.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter desired wash time (6 minutes is

recommended). Press 6 keypad. Display will

read “6M-00S,” indicating a wash step of six

minutes.

10. Press Enter keypad. Display will read “0401,”

indicating that control is ready for step 4 of

cycle 01.

b. Press Enter keypad. Display will read

“M---S.”

c. Enter desired fill time. (4 minutes is

recommended.) Press 4 keypad. Display will

read “4M-00S”. (“4M” means 4 minutes and

“00S” means 0 seconds.)

6. Press Enter keypad. Display will read “0201,”

indicating that control is ready for step 2 of

cycle 01.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Programming

11. For this tutorial, step 4 will be a drain step.

a. Press Drain keypad (0). (A drain step usually

follows a wash step). Display will read

“D-0401.”

This program allows a choice among drains 1,

a, or b. (NOTE: 1 is sewer, “a” is Tank a and

“b” is Tank b.) For this application, press 1

keypad. Display will read “D10401.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter maximum time desired for control to

allow machine to drain to empty. (One minute

is recommended.) Press 1 keypad. Display

will change to “1M-00S,” indicating a drain

step of one minute.

NOTE: The manufacturer does not recommend

more than one minute for a drain step. If machine

does not drain in amount of time programmed,

“EMTY” alarm will be displayed. Refer to Error

Recovery Routine in Operation Manual.

12. Press Enter keypad. Display will now read

“0501,” indicating that control is ready for step 5

of cycle 01.

13. For this tutorial, step 5 in cycles will be a warm

rinse.

a. Press Warm keypad (3) and then Rinse keypad

(5). Display will read “WR0501.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter rinse time in minutes and seconds. A

spray rinse lasting 2-1/2 minutes is

recommended.

Press 2 keypad. Display will read “2M-00S.”

Press 3 keypad and 0 keypad. Display will

read “2M-30S,” indicating a spray rinse of

2 minutes and 30 seconds.

15. For this tutorial, step 6 in cycle will be a warm

fill and high level for a dilution rinse.

NOTE: Rinse key controls a spin-spray rinse. A

dilution rinse is the same as a wash step without the

addition of detergents. Refer to Programming a

Wash Step section.

a. Press Warm keypad (3) twice to turn on two

hot and two cold water valves to reduce fill

time. Display will read “W-0601.” Press High

keypad (3 keypad). Display will read

“WH0601.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter desired time for control to allow

machine to fill to high level (five minutes is

recommended). Press 5 keypad. Display will

read “5M-00S” indicating a dilution rinse of

5 minutes.

NOTE: If machine does not fill high level in amount

of time programmed, “FILL” alarm will be

displayed. Refer to Error Recovery Routine in

Operation Manual.

16. Press Enter keypad. Display will read “0701.”

17. For this tutorial, step 7 in cycle will be an add

sour.

a. Press Supply keypad (6) and 3 keypad (3 is

for supply 3 location). Display will read

“S30701.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter length of time for supply to be activated

(thirty seconds is recommended).

Press 0 keypad for minutes; press 3 keypad

and then 0 keypad for seconds. Display will

read “0M-30S” indicating an add sour step of

0 minutes and 30 seconds.

14. Press Enter keypad. Display will read “0601,”

indicating that control is ready for step 6 of

cycle 01.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

18. Press Enter keypad. Display will read “0801,”

indicating that control is ready for step 8.

15

Programming

19. For this tutorial, step 8 will be an agitation action

for dilution rinse.

a. Press Wash keypad (4) and 1 keypad to

program an action with normal reversing.

Refer to Programming a Wash Step section.

Display will read “W10801.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter time for dilution rinse (three minutes is

recommended).

Press 3 keypad. Display will read “3M-00S,”

indicating an agitation action dilution rinse of

3 minutes.

20. Press Enter keypad. Display will read “0901,”

indicating that control is ready for step 9.

21. For this tutorial, step 9 in cycle 9 will be a

dilution rinse water drain.

a. Press Drain keypad. Display will read

“D-0901.” Press 1 keypad for draining to

sewer. Display will read “D10901.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter length of time control will allow

machine to drain (one minute is

recommended).

Press 1 keypad. Display reads “1M-00S,”

indicating a drain step of one minute.

22. Press Enter keypad. Display will read “1001,”

indicating that control is ready for step 10 of

cycle 01.

23. For this tutorial, step 10 in cycle will be an

extract step.

a. Press Medium Speed keypad (8). Display will

read “MS1001,” indicating a medium-speed

spin.

24. Press Enter keypad. Display flashes “SDLY”

(slow-down delay) for one second.

Display will read “0M-00S,” allowing

programmer to enter time for a slow-down delay.

NOTE: Do not program a slow-down delay time if

the slow-down delay is followed by a spin (all

consecutive spins are skipped when a slow-down

delay is programmed).

For no slow-down delay, press Enter keypad.

25. For this tutorial, step 11 in cycle will be a spin

step.

a. Press High Speed keypad (9) once. Display

will read “H11101.”

NOTE: Pressing High Speed keypad repeatedly

when programming a high speed step will cause

control display to proceed from “H1” to “H2,” and

then to “H3,” maximum-speed spin. After “H3”

appears and High Speed keypad is pressed again,

“H1” will reappear.

b. Press Enter keypad. Display will read

“M---S.”

c. Enter a length of time for high speed spin (six

minutes is recommended). Press 6 keypad.

Display will read “6M-00S.”

NOTE: High Speed spin is not preceded

automatically by medium-speed spin as with

nonvariable-speed UW rigid-mount models.

Medium-speed spin only or high speed spin 1, 2, or

3 may be programmed.

26. Press Enter keypad. Display will flash “SDLY”

(slow-down delay) for one second. (“SDLY” also

displays during the entire actual delay time.)

Display will read “0M-00S,” prompting

programmer to enter a time for slow-down delay.

Display will read “1201.”

b. Press Enter keypad. Display will read

“M---S.”

c. Enter length of time for medium-speed spin

(one minute is recommended).

Press 1 keypad. Display will read “1M-00S,”

indicating 1 minute and 0 seconds.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232210

Programming

NOTE: For machines with a software ID Code of

HRWC10 or earlier, a slow-down delay of 60

seconds minimum must be programmed after each

medium-speed, spray-rinse or high speed 1 or a

delay of 99 seconds must be programmed after

each high speed spin 2 or high speed 3.

For machines with software code HRWC12 or

later, no slow-down is required.

NOTE: For machines with a software ID Code of

HRWC12 or later, if application requires that

water fill valves remain off while basket is coasting

to a stop, enter desired delay time (Example:

60 seconds). Press Enter keypad.

27. The previous step ends tutorial. Cycle 01,

consisting of 11 steps, has been programmed.

To end cycle, turn Program Mode switch located

on left side of control module to RUN position

and remove key. Display will read “NEXT.”

Programmer can select Cycle 01 and press Enter

keypad to run cycle as it is set up; or a cycle of

the programmer’s own design can be

programmed.

NOTE: Cycle 01 can be reprogrammed as machine

came from factory. Refer to Standard Cycle Charts

section or it can remain as set up in tutorial.

Programming Hints

Refer to Standard Cycle Charts section.

NOTE: The control can only be programmed step

by step.

When entering timed portion of a step (such as a fill),

use a time that is reasonable for local installation. If

water pressure is low or if water lines are small,

increase time allowed. Drain needs to empty the

machine in less than one minute.

NOTE: Drain times of more than one minute are

not recommended.

Except for soak, heat, and cool-down (Wash 5) steps,

which are timed in hours and minutes, the maximum

time per step is 9 minutes and 99 seconds. If more time

is needed, add more steps to total complete time

desired. For example, if a 15-minute wash is desired,

program a wash step for 9 minutes and 00 seconds,

immediately followed by another wash step for 6

minutes and 00 seconds.

When a fill or addition of supplies without agitation is

desired, first program a Wash 3 step for 0 minutes and

01 seconds. Program fill or supply step as desired.

When control advances to next step, it will remain in

Wash Mode as programmed in previous step unless

instructed to do otherwise.

Tuto rial Cycle

Step Description Min:sec

1 Hot Fill to Low Level 4:00

2 Supply 1 0:30

3Wash 1 6:00

4 Drain 1 1:00

5 Warm Spray Rinse 2:30

6 Warm/Warm Fill to High Level 5:00

7 Supply 3 0:30

8Wash 1 3:00

9 Drain 1 1:00

10 Medium Speed Spin 1:00

11 High Speed Spin No. 1

SDLY

Stop Routine

Ta bl e 3

6:00

0:60

Test Cycle

Cycle number 39 is a test cycle used to analyze

washer-extractor functions.

Step 01 in cycle number 39 is a cold fill to low level.

This step is designed to give not quite enough time to

complete a fill, causing the display to read “FILL.”

Press the Start keypad to continue the fill, and the test

cycle will proceed.

Step 02 in the test cycle is a drain step. Again, the time

allotted is shorter than it would be in a normal cycle.

The display will read “EMTY.” To proceed, press the

Start keypad.

The steps in the test cycle are relatively short with the

exception of steps 3, 21, 25, 27, 28, and 29. These can

be shortened by pressing the Advance keypad to go on

to the next step.

The operator may skip to any next step in the cycle

with the exception of a drain step: Drain steps must be

allowed to complete. To skip forward in the test cycle,

press the Advance keypad.

NOTE: The Advance feature may be disabled.

F232210

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Loading...

Loading...