Unimac UW80AV-Extractor Parts Diagram

Washer-Extractor

Pocket Hardmount

UWAV and UWB2

Refer to Page 5 for Model Numbers

W

A

R

N

IN

G

M

A

C

H

I

N

E

M

A

Y

B

E

H

O

T

A

N

D

C

A

U

S

E

B

U

R

N

S

A

T

T

E

M

P

T

N

O

E

N

T

R

Y

U

N

T

I

L

B

A

S

K

E

T

H

A

S

S

T

O

P

P

E

D

S

E

R

I

O

U

S

I

N

J

U

R

Y

M

A

Y

R

E

S

U

LT

Troubleshooting

www.comlaundry.com

PHM1393C

Part No. F232218R1

July 2008

Table of

Contents

Section 1 – Safety Information ...............................................................2

General Safety Precautions....................................................................2

Important Safety Instructions ................................................................3

Locating an Authorized Servicer...........................................................5

Section 2 – Introduction..........................................................................6

Customer Service...................................................................................6

Nameplate Location...............................................................................6

Model Identification ..............................................................................7

Section 3 – Theory of Operation.............................................................8

Starting the Machine..............................................................................8

Fill..........................................................................................................8

Supply....................................................................................................8

Wash......................................................................................................8

Spray-Rinse ...........................................................................................8

Drain......................................................................................................8

Extract....................................................................................................8

Section 4 – Troubleshooting....................................................................9

1. Control Has No Visible Display (F-Voltage) .............................10

2. Control Has No Visible Display (Q-Voltage).............................14

3. No Fill Analysis ..........................................................................18

4. Water Runs Continuously into the Washer-Extractor.................22

5. Door Lock Switch Analysis........................................................26

6. No Fuseboard Functions .............................................................30

7. No Motor Operation (With No AC Drive Fault) ........................34

8. No Motor Operation (With AC Drive Fault) ..............................40

9. The Motor is Running, But at an Abnormal Speed.....................41

10. No Spin .......................................................................................44

11. Fill Alarm Analysis.....................................................................45

12. Empty Alarm Analysis................................................................48

13. Automatic Supply Dispenser Analysis .......................................52

14. No Keypad Functions..................................................................53

15. Door Unlocking Function ...........................................................54

16. Excessive Cycle Time.................................................................58

17. Excessive Vibration and/or Noise During Spin..........................59

18. Stop/Done Situation in Mid Cycle..............................................59

19. Pumps Turning on in Mid Cycle Without Being

Programmed to Do So.................................................................59

© Copyright 2008, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

F232218 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 1

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING,” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer and those maintaining the machine.

a DANGER

Danger indicates the presence of a hazard that will cause severe personal injury, death or substantial property

damage if the danger is ignored.

a WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death or substantial property

damage if the warning is ignored.

a CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

General Safety Precautions

In the interest of safety, some general precautions relating to the operation of this machine follow.

WARNING

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

(continued)

2 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer-extractor before servicing.

• Never start the washer-extractor with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer-extractor is properly grounded.

W460

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

W007

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your

washer, follow these basic precautions:

1. Read all instructions before using the washer-extractor.

2. Refer to the GROUNDING INSTRUCTIONS in the INSTALLATION manual (supplied with your washerextractor) for the proper grounding of the washer-extractor.

3. Do not wash textiles that have been previously cleaned in, washed in, soaked in or spotted with gasoline, drycleaning solvents or other flammable or explosive substances. They give off vapors that could ignite or

explode.

4. Do not add gasoline, dry-cleaning solvents or other flammable or explosive substances to the wash water.

These substances give off vapors that could ignite or explode.

5. Under certain conditions, hydrogen gas may be produced in a hot water system that has not been used for two

weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for such a

period, before using a washer-extractor, turn on all hot water faucets and let the water flow from each for

several minutes. This will release any accumulated hydrogen gas. The gas is flammable. Do not smoke or use

an open flame during this time.

W023E

F232218 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

6. Do not allow children to play on or in a washer-extractor. Close supervision of children is necessary when the

washer-extractor is used near children.

7. Before the washer-extractor is removed from service or discarded, remove the door to the washing

compartment.

8. Do not reach into the washer-extractor if the wash basket is moving.

9. Do not install or store the washer-extractor where it will be exposed to water and/or weather.

10. Do not tamper with the washer-extractor’s controls.

11. Do not repair or replace any part of the washer-extractor or attempt any servicing unless specifically

recommended in the user-maintenance instructions or in published user-repair instructions that the user

understands and has the skills to carry out.

12. To reduce the risk of an electrical shock or fire, DO NOT use an extension cord or an adapter to connect the

washer-extractor to an electrical power source.

13. Use the washer-extractor only for its intended purpose, washing clothes.

14. ALWAYS disconnect the washer-extractor from its electrical supply before attempting any service.

15. Install the washer-extractor according to the INSTALLATION INSTRUCTIONS. All connections for water,

drain, electrical power and grounding must comply with local codes and, when required, be made by licensed

personnel.

16. To reduce the risk of fire, textiles which have traces of any flammable substances such as vegetable oil,

cooking oil, machine oil, flammable chemicals, thinner, etc. or anything containing wax or chemicals such as

in mops or cleaning cloths, must not be put into the washer-extractor. These flammable substances may cause

the fabric to ignite.

17. Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the

fabric softener or product.

18. Keep the washer-extractor in good condition. Bumping or dropping the washer-extractor can damage its safety

features. If this occurs, have the washer-extractor checked by a qualified service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure that water connections have a shut-off valve and that fill hose connections are tight. CLOSE the shutoff valves at the end of each wash day.

21. The loading door MUST BE CLOSED any time the washer-extractor is to fill, tumble or spin. DO NOT bypass the loading door switch and permit the washer-extractor to operate with the loading door open.

22. Always read and follow the manufacturer’s instructions on packages of laundry and cleaning aids. Heed all

warnings and precautions. To reduce the risk of poisoning or chemical burns, keep them out of the reach of

children at all times (preferably in a locked cabinet).

23. Always follow the fabric care instructions supplied by the textile manufacturer.

24. Never operate the washer-extractor with any guards and/or panels removed.

25. DO NOT operate the washer-extractor with missing or broken parts.

26. DO NOT by-pass any safety devices.

27. Failure to install, maintain and/or operate this washer-extractor according to the manufacturer's instructions

may result in conditions that can produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not

meant to cover all possible conditions and situations that may occur. Common sense, caution and care must

be exercised when installing, maintaining and operating the washer-extractor.

Any problems or conditions not understood should be reported to the dealer, distributor, service agent or the

manufacturer.

4 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

F232218 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Customer Service

Section 2

Introduction

Alliance Laundry Systems is not responsible for

personal injury or property damage resulting from

improper service. Review all service information

before beginning repairs.

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name of the nearest authorized parts distributor.

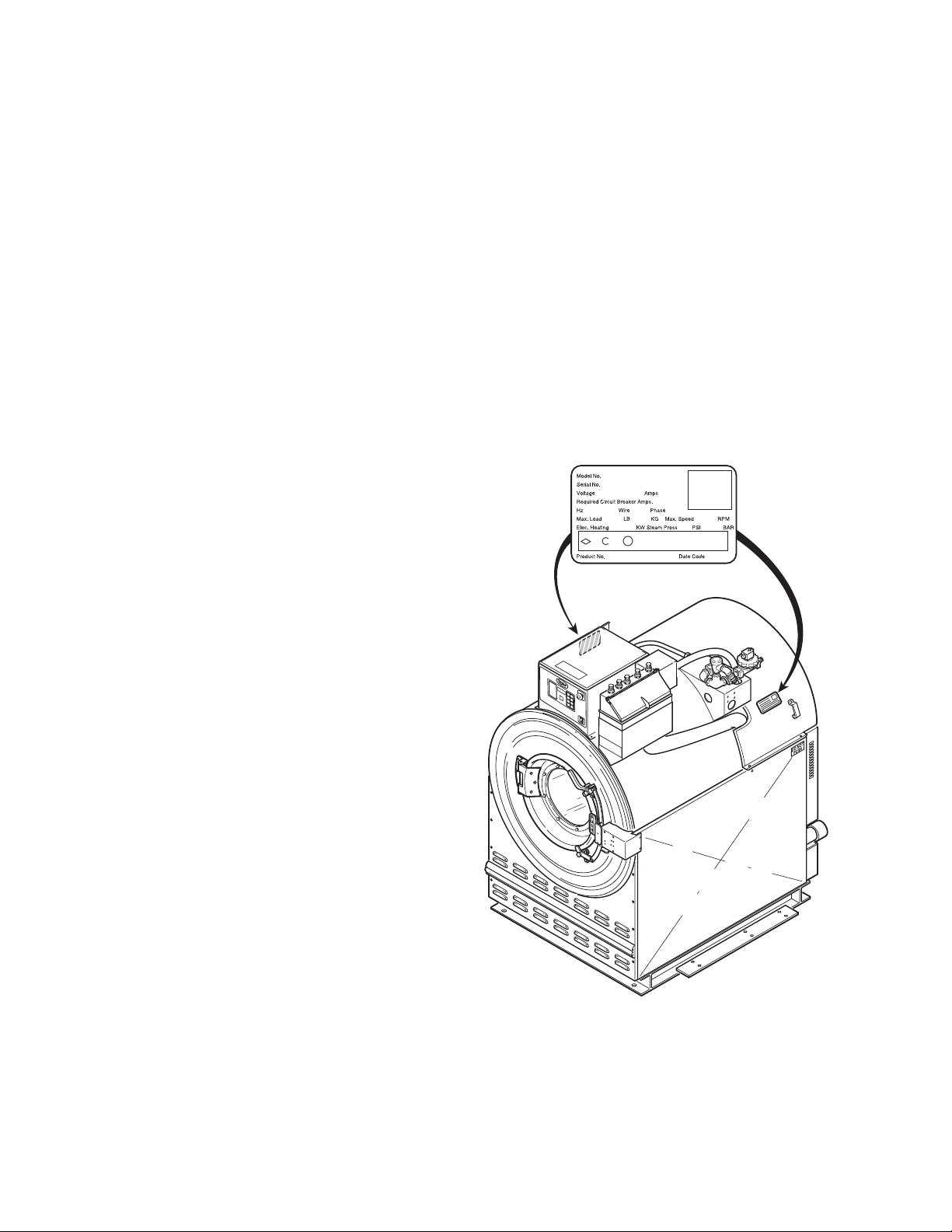

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

For technical assistance, call (920) 748-3121.

PHM2517P

6 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Model Identification

Information in this manual is applicable to these washer-extractors.

Introduction

UW35AV

UW60AV

UW80AV

UW100AV

UW125AV

UW35B2

UW60B2

F232218 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3

Theory of Operation

Starting the Machine

The door lock will not allow a cycle to be started until

the door has been closed.

Fill

The operator selects a cycle and starts the machine.

Water enters the machine through water valves that are

controlled by the microcomputer. As water fills the

basket, a column of air is trapped in a pressure bulb and

hose. The air pressure continues to increase as the

basket flls with water. When the desired water level is

reached, the water level switch triggers the

microcomputer and the water valves turn off.

A vacuum breaker installed in the inlet plumbing or a

shell overflow and air gap prevents the backflow of

water.

Supply

The operator can either connect external liquid supplies

to the machine or fill the supply dispenser with liquid

or dry supplies. The supply dispenser’s nozzles flush

the compartments with water at the appropriate times

throughout a cycle.

Wash

The basket includes ribs that lift the laundry from the

wash water. The laundry then tumbles back into the

bath.

Spray-Rinse

The spray-rinse consists of a hose connected from the

hot and cold water inlet valves to the center of the door

glass. A nozzle on the inside of the door glass produces

a fan-shaped spray that disperses water throughout the

load.

Drain

UW washer-extractors use a normally-open gravitytype drain system. No pump is used. When the drain

valve opens, the perforated basket allows water to drain

from it.

In the event of a power failure, the drain valve will

open automatically and the machine will drain.

Standard UW washer-extractors include a single drain

valve. Dual drain models are available as an option. On

dual drain models, the 2 drain valves open and close

together.

Extract

A final high-speed extract step removes water from the

load, which maximizes drying efficiency.

The door lock system will not allow the door to be

opened until the cycle has finished.

In 2-speed and variable-speed models, 1 dual-speed

motor drives the basket’s shaft with a V-belt. In 3speed models, 2 motors drive the basket’s cylinder with

a V-belt.

UW35, UW60, UW80, UW100 and UW125 models

use 2 flange-type bearing that are bolted to the frame.

UW150 models use 2 bearings that are held in place by

a single cast-iron trunnion that is bolted to the frame.

8 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 4

Troubleshooting

WARNING

To reduce the risk of electrical shock, fire, explosion, serious injury or death:

• Disconnect electrical power to the washer-extractor before servicing it.

• Close the gas shut-off valve to the washer-extractor (when applicable) before servicing it.

• Never start the washer-extractor with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer-extractor is properly grounded.

W461R1

F232218 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

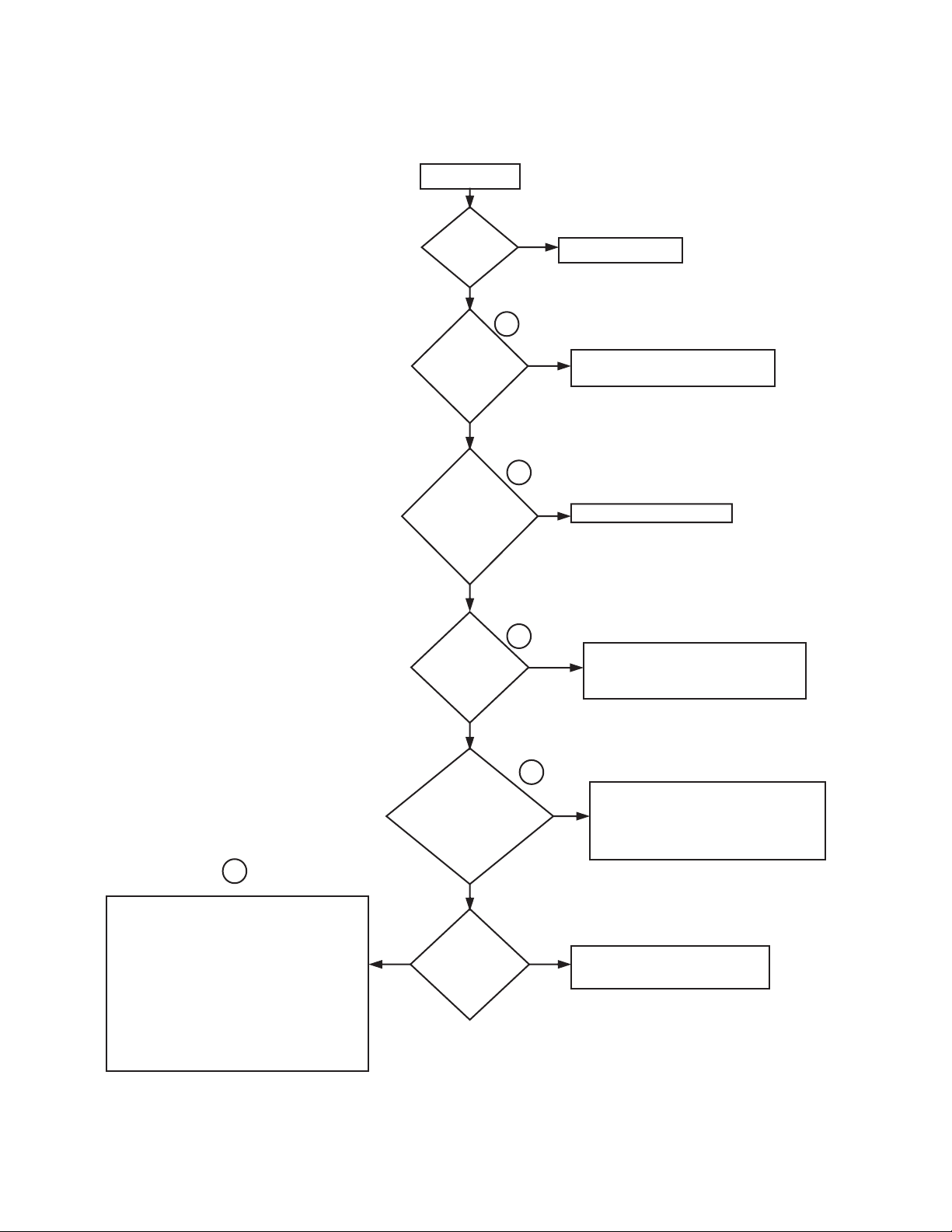

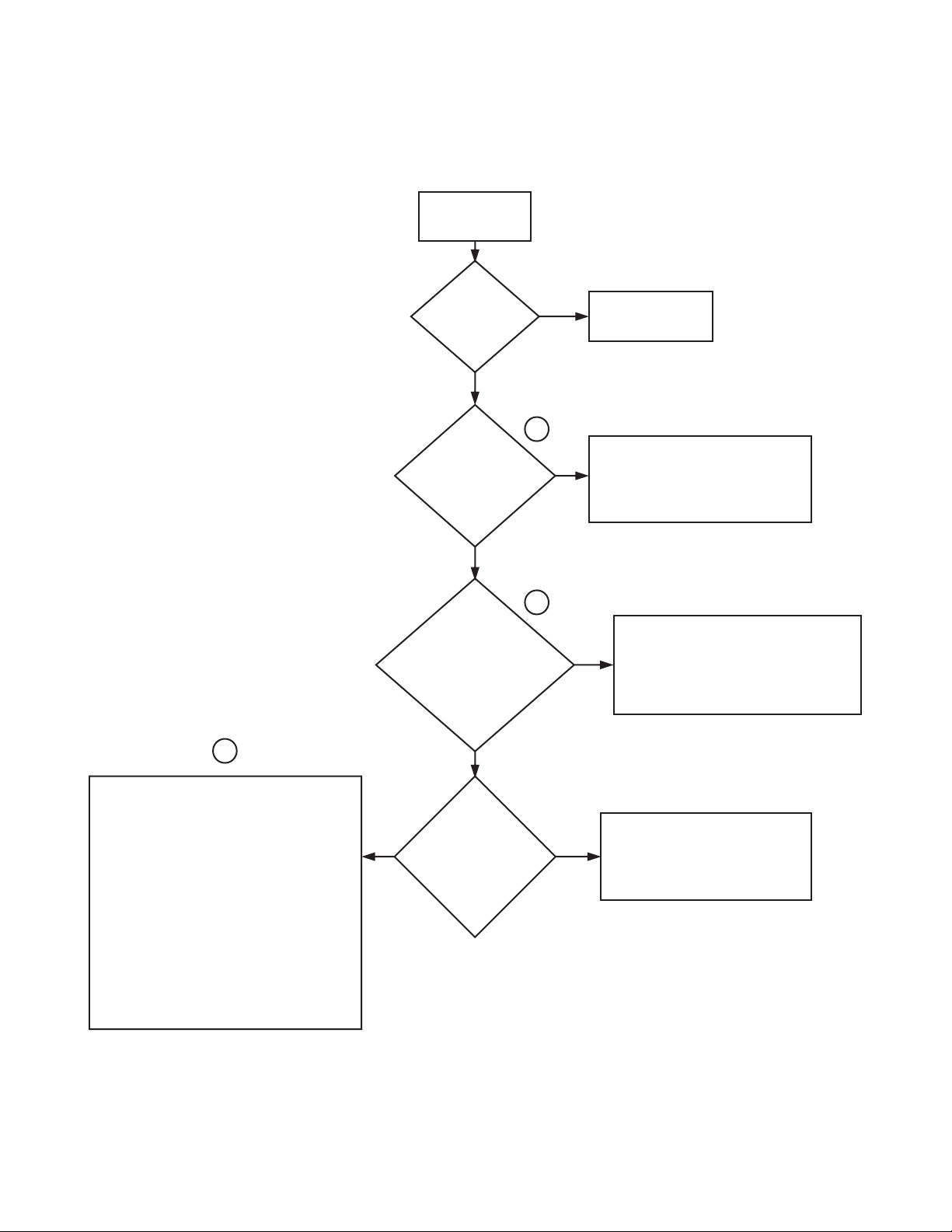

1. Control Has No Visible Display (F-Voltage)

THE CONTROL HAS

NO VISIBLE DISPLAY.

IS

THE MAIN

POWER CIRCUIT

BREAKER

ON?

NO

YES

TURN ON THE MAIN POWER

CIRCUIT BREAKER.

NOTE: THE TCI TRANSFORMER IS

LOCATED ON THE LEFT SIDE OF THE

FRAME UNDERNEATH THE OUTER

PANELS.

5

IS THERE 10VDC ON THE RIBBON CABLE LOCATED

BETWEEN THE FUSEBOARD AND THE COMPUTER?

IF NOT, REPLACE IT.

IF THERE IS 10VDC ON THE RIBBON CABLE, DISCONNECT

ALL OF THE CABLES FROM THE COMPUTER EXCEPT

THE GROUND WIRE AND THE RIBBON CABLE FROM THE

FUSEBOARD. IF THE COMPUTER STILL DOESN’T SHOW A

DISPLAY, THE FUSEBOARD MAY NOT BE WORKING

PROPERLY. CONTACT THE FACTORY BEFORE REPLACING IT.

IF THE FUSEBOARD DOES SHOW A DISPLAY, RECONNECT

THE RIBBON CABLE.

NOTE: IF THE J40 RIBBON CABLE IS INSTALLED

INCORRECTLY, THERE WILL BE NO DISPLAY.

IS THERE

VOLTAGE

(380-480 VOLTS)

INTO AND OUT OF

THE QF2 CIRCUIT

BREAKER?

IS THERE

VOLTAGE IN TO

(380-480 VOLTS)

AND OUT OF (200-240

VOLTS) THE TC1

TRANSFORMER?

IS THERE

VOLTAGE (220

VOLTS) INTO

AND OUT OF

THE E-STOP

SWITCH SB1?

IS THERE

VOLTAGE (220

VOLTS) ON THE J6

WHITE TRANSFORMER

PLUG ON THE FUSEBOARD

BETWEEN PINS 5

AND 6?

YES

IS THERE

10VDC BETWEEN

THE +10VDC MALE

SPADE AND THE

GROUND?

YES

YES

YES

YES

1

NO

RESET THE QF2 CIRCUIT BREAKER. IF, AFTER

RESETTING, THERE IS STILL NO VOLTAGE,

REPLACE THE QF2 CIRCUIT BREAKER.

2

NO

REPLACE THE TC1 TRANSFORMER.

3

NO

RESET AND RETURN (EITHER BY PULLING OR BY

TWISTING AND PULLING) THE E-STOP SWITCH SB1.

IF, AFTER RESETTING AND RETURNING, THERE IS

STILL NO VOLTAGE, REPLACE THE E-STOP

SWITCH SB1.

4

RETURN TO THE TOP. CHECK EACH OF THE ABOVE

STEPS CAREFULLY.

NO

ALSO, ON THE J6 WHITE TRANSFORMER PLUG ON

THE FUSEBOARD, MAKE SURE THAT THERE IS

VOLTAGE BETWEEN PIN 5 TO GROUND AND PIN 6 TO

GROUND.

NO

CHECK THE F17 (125MA) FUSE LOCATED

BESIDE THE TRANSFORMER. IF THE FUSE IS

BLOWN, REPLACE IT. IF THE FUSE ISN’T

BLOWN, REPLACE THE FUSEBOARD.

PHM2100S

10 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

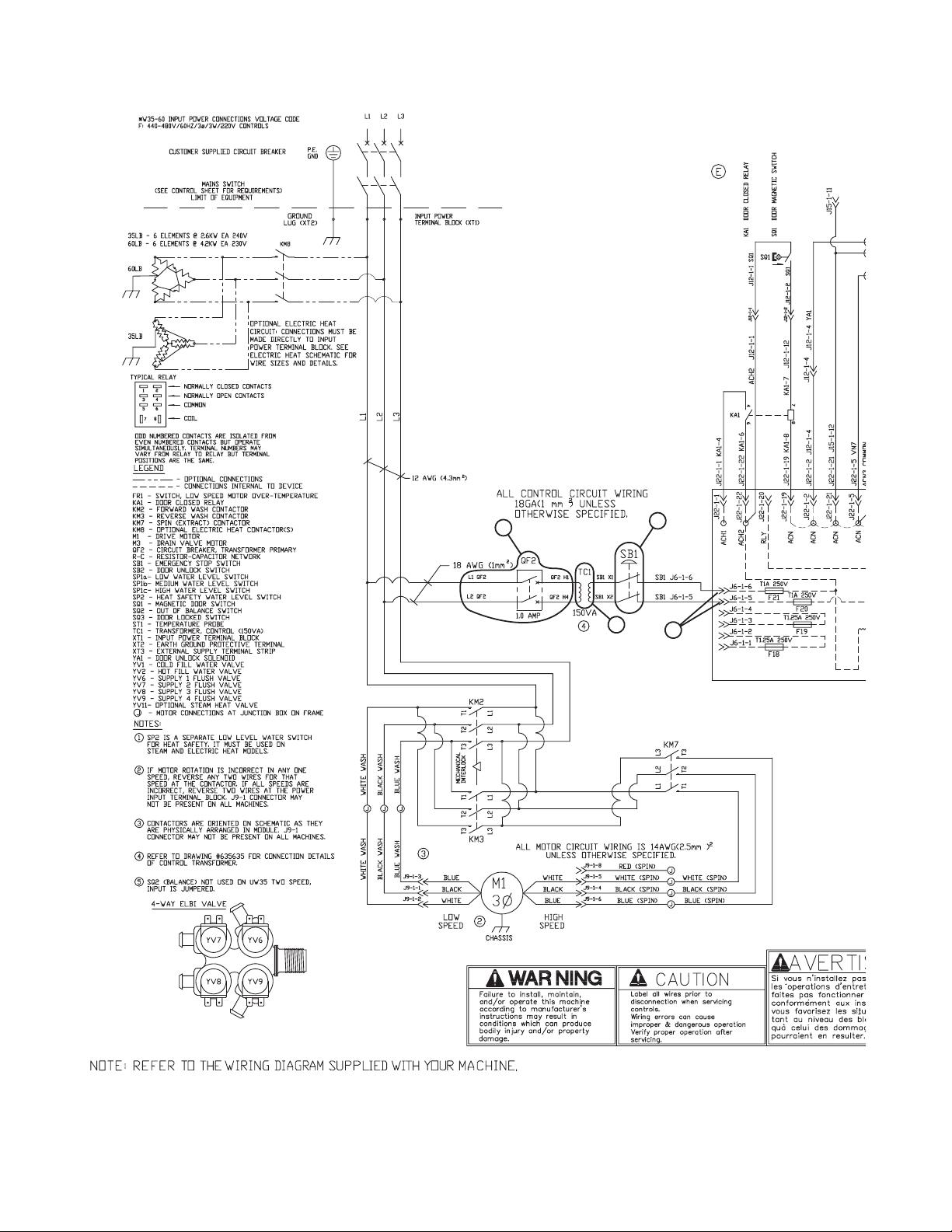

Please refer to the following 2 pages for wiring diagram information.

F232218 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

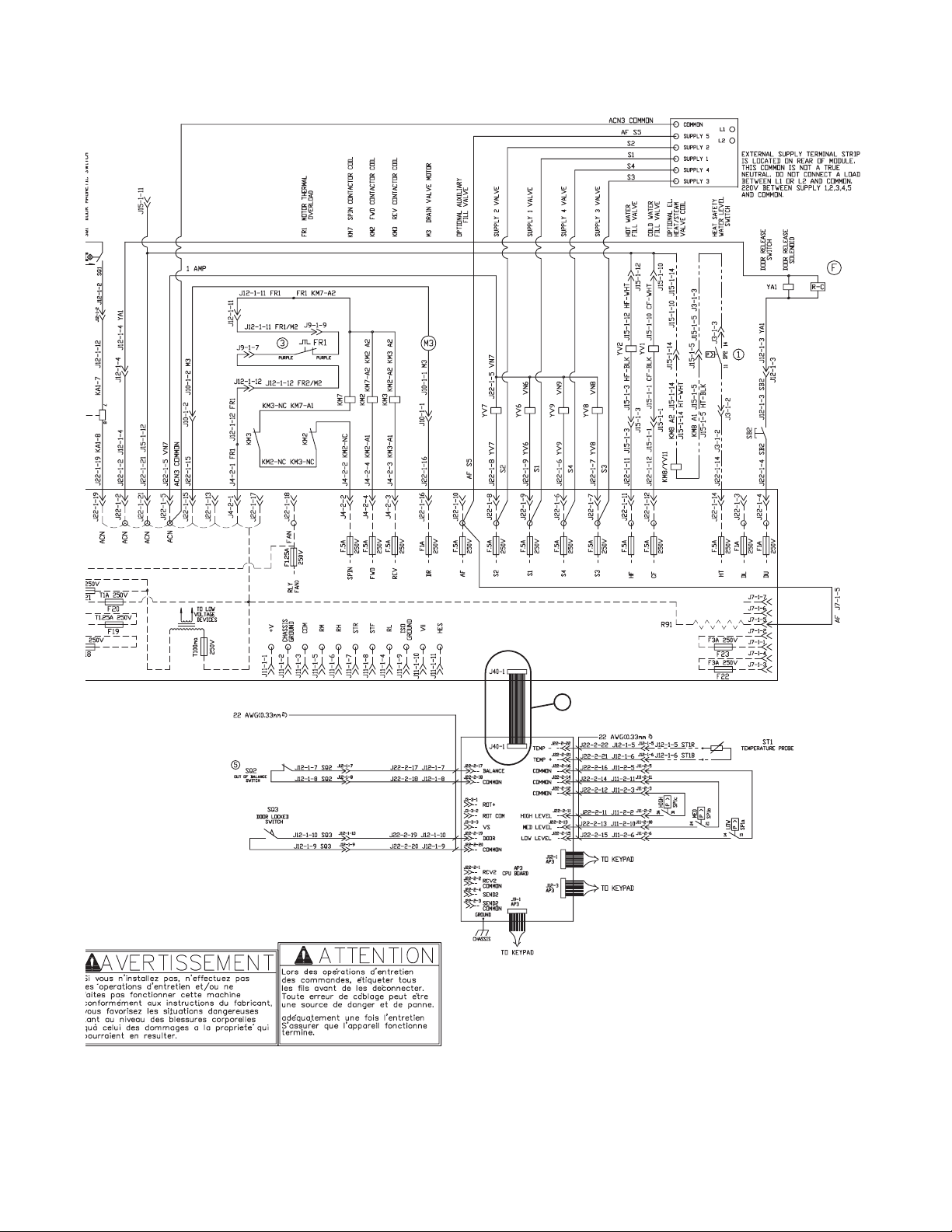

Control Has No Visible Display (F-Voltage) (Sheet 1 of 2)

1

3

2

4

12 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

Control Has No Visible Display (F-Voltage) (Sheet 2 of 2)

5

PHM2033S

F063731200R7

F232218 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

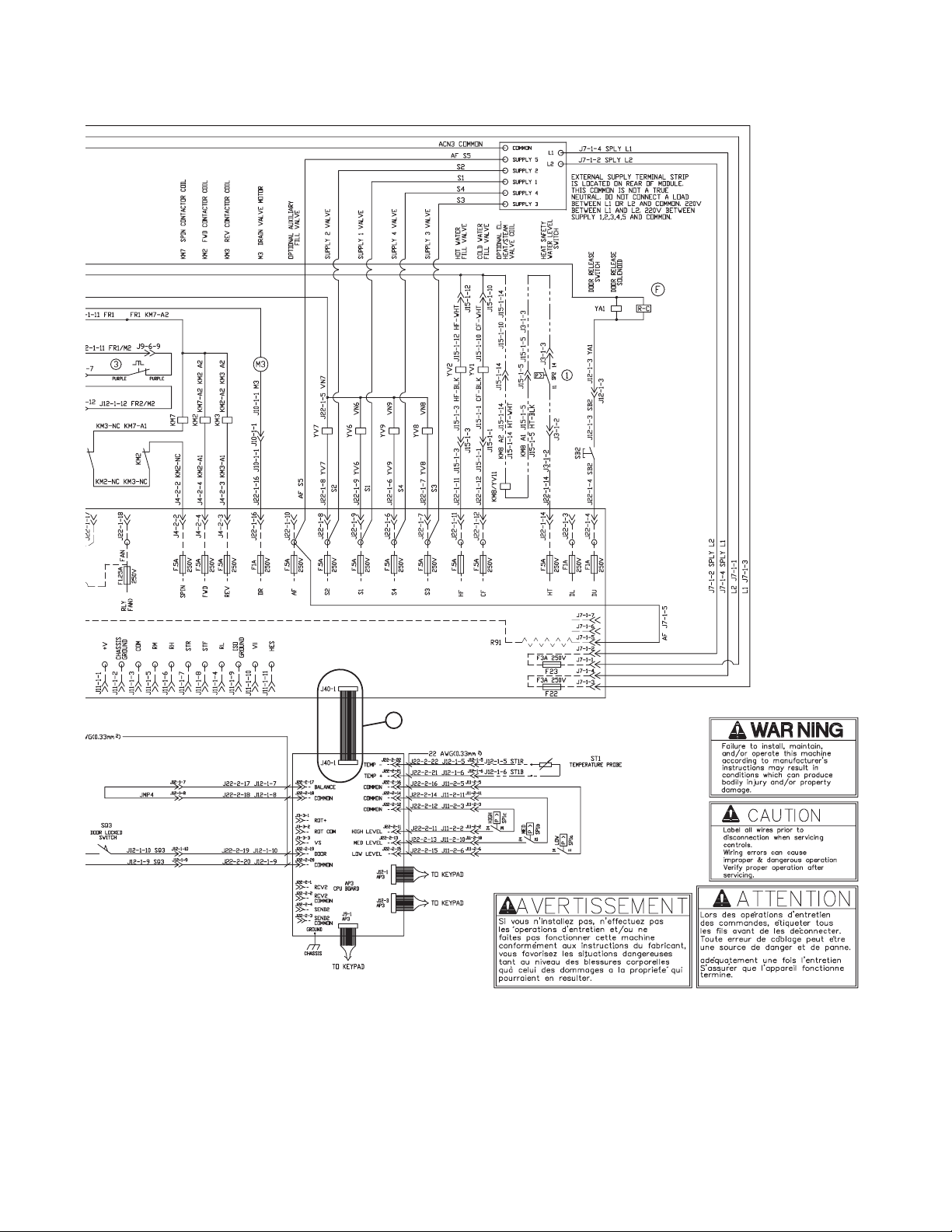

2. Control Has No Visible Display (Q-Voltage)

THE CONTROL

HAS NO

VISIBLE DISPLAY.

IS THE

MAIN POWER

CIRCUIT

BREAKER

ON?

YES

IS THERE

VO LTAGE

(200 - 240 VOLTS)

INTO AND OUT OF THE

E-STOP SWITCH

SB1?

YES

IS THERE

VO LTAGE

(200 - 240 VOLTS)

ON THE J6 WHITE

TRANSFORMER PLUG

ON THE FUSEBOARD

BETWEEN PINS 5

AND 6?

NO

1

NO

2

TURN ON THE MAIN

POWER CIRCUIT

BREAKER.

RESET AND RETURN (EITHER BY

PULLING OR BY TWISTING AND

PULLING) THE E-STOP SWITCH SB1. IF,

AFTER RESETTING AND RETURNING,

THERE IS STILL NO VOLTAGE,

REPLACE THE E-STOP SWITCH SB1.

RETURN TO THE TOP. CHECK EACH OF THE

ABOVE STEPS CAREFULLY.

NO

ALSO, ON THE J6 WHITE TRANSFORMER

PLUG ON THE FUSEBOARD, MAKE SURE

THAT THERE IS VOLTAGE BETWEEN PIN 5

TO GROUND AND PIN 6 TO GROUND.

3

IS THERE 10VDC ON THE RIBBON CABLE

LOCATED BETWEEN THE FUSEBOARD AND

THE COMPUTER? IF NOT, REPLACE IT.

IF THERE IS 10VDC ON THE RIBBON CABLE,

DISCONNECT ALL OF THE CABLES FROM THE

COMPUTER EXCEPT THE GROUND WIRE

AND THE RIBBON CABLE FROM THE

FUSEBOARD. IF THE COMPUTER STILL DOESN’T

SHOW A DISPLAY, THE FUSEBOARD MAY NOT

BE WORKING PROPERLY. CONTACT THE

FACTORY BEFORE REPLACING IT.

IF THE FUSEBOARD DOES SHOW A DISPLAY,

RECONNECT THE RIBBON CABLE.

NOTE: IF THE J40 RIBBON CABLE IS INSTALLED

INCORRECTLY, THERE WILL BE NO DISPLAY.

14 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

YES

10VDC BETWEEN

YES

IS THERE

THE +10VDC

MALE SPADE

AND THE

GROUND?

NO

CHECK THE F17 (125MA) FUSE

LOCATED BESIDE THE

TRANSFORMER. IF THE FUSE IS

BLOWN, REPLACE IT. IF THE FUSE

ISN’T BLOWN, REPLACE THE

FUSEBOARD.

PHM2101S

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232218 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

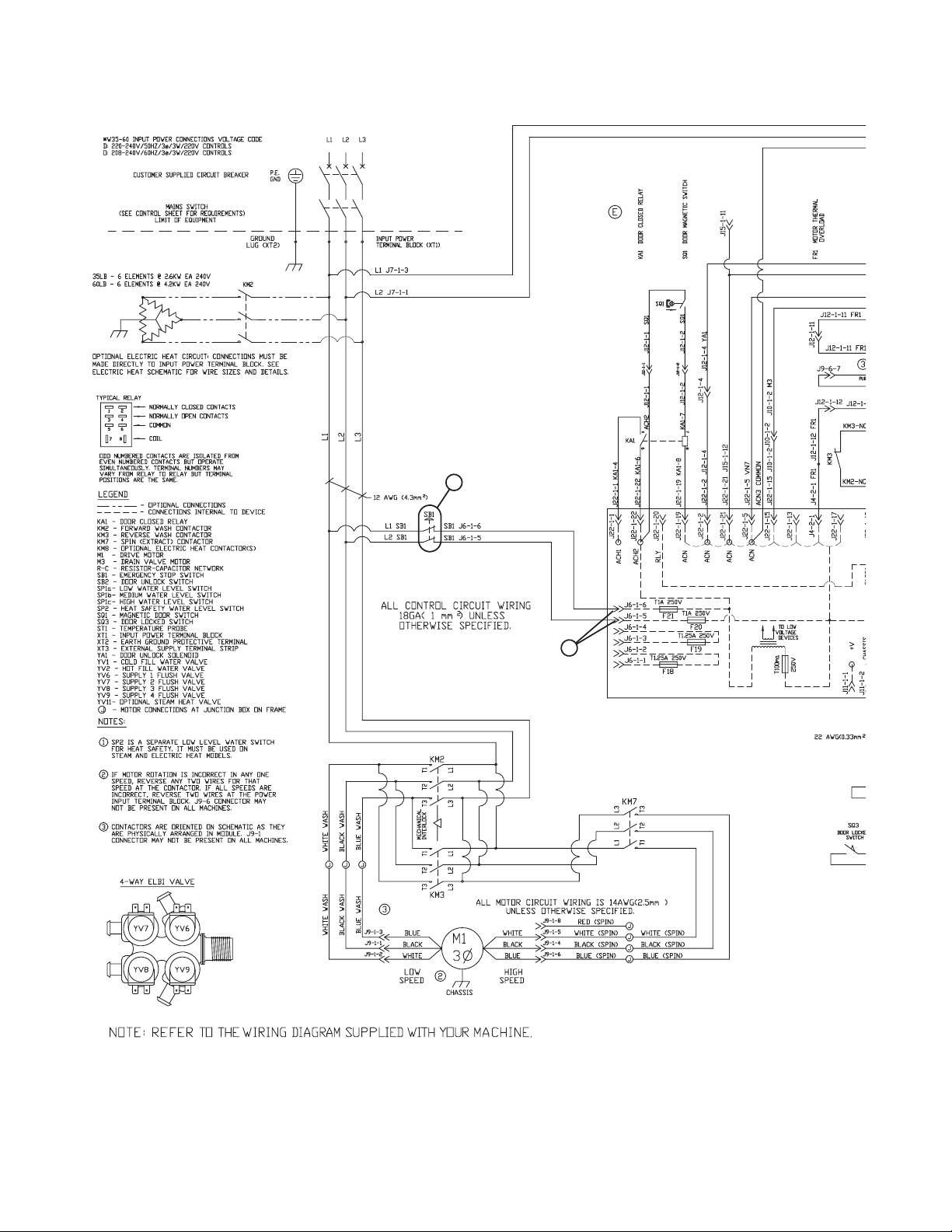

Troubleshooting

Control Has No Visible Display (Q-Voltage) (Sheet 1 of 2)

1

2

16 F232218

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

Control Has No Visible Display (Q-Voltage) (Sheet 2 of 2)

3

PHM2035S

F063687900R7

F232218 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...