Tumble Dryer

TMB1276C

UniLinc Control

Refer to Page 4 for Model Identification

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

TMB1276C

www.comlaundry.com

Part No. 70444801R4

August 2012

Table of

Contents

Introduction......................................................................................... 4

Model Identification ............................................................................. 4

Nameplate Location.............................................................................. 4

Preliminary Information.................................................................... 5

About the Control ................................................................................. 5

DIP Switch Configuration................................................................ 5

Power Failure Recovery................................................................... 5

Communications .............................................................................. 5

Audit Information ........................................................................... 5

IR Communications Menu............................................................... 6

IR Communications Error Menu ..................................................... 6

Restore to Factory Defaults ............................................................ 6

Entering Program Mode................................................................... 6

UniLinc Identification ........................................................................ 7

Operational Keypad.............................................................................. 7

Operation Modes .................................................................................. 8

General Modes of Operation............................................................ 8

Power-up Mode................................................................................ 8

Idle Mode......................................................................................... 8

Run Mode......................................................................................... 8

Rapid Advance Mode ...................................................................... 8

Pause Mode...................................................................................... 8

Error Mode....................................................................................... 8

Communication Mode ..................................................................... 8

Cool Down Mode............................................................................. 8

End of Cycle Mode .......................................................................... 9

Extended Tumble Mode................................................................... 9

Reversing Mode (reversing models only)........................................ 9

Entering Diagnostic Mode From Idle Mode.................................... 9

Machine Cycle Definition and Operation......................................... 10

Machine Cycle Operation..................................................................... 10

Time Dry Cycle................................................................................ 10

Auto-Dry Cycle................................................................................ 10

Moisture Dry Cycle (if equipped).................................................... 10

Rotation Sensor Equipped Machines.................................................... 10

Cycle Menu........................................................................................... 10

To Start a Cycle ............................................................................... 11

Run Menu ............................................................................................. 12

Contrast/Backlight Menu...................................................................... 13

Close Door Menu.................................................................................. 13

Run Diagnostic Menu........................................................................... 14

Temp and Moisture Menu .................................................................... 15

Cycle Stopped Menu............................................................................. 16

Error Menu............................................................................................ 16

Open Door Menu .................................................................................. 17

Clean Lint Screen Menu ....................................................................... 17

Load Sensed Menu ............................................................................... 17

© Copyright 2012, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Service Moisture Sensor Menu............................................................. 17

Menu Navigation................................................................................. 18

The UniLinc.......................................................................................... 18

Menu to Menu Navigation............................................................... 18

Screen to Screen Menu Navigation.................................................. 18

Menu Navigation with Parameters................................................... 18

Cycle Name and Banner Editing...................................................... 18

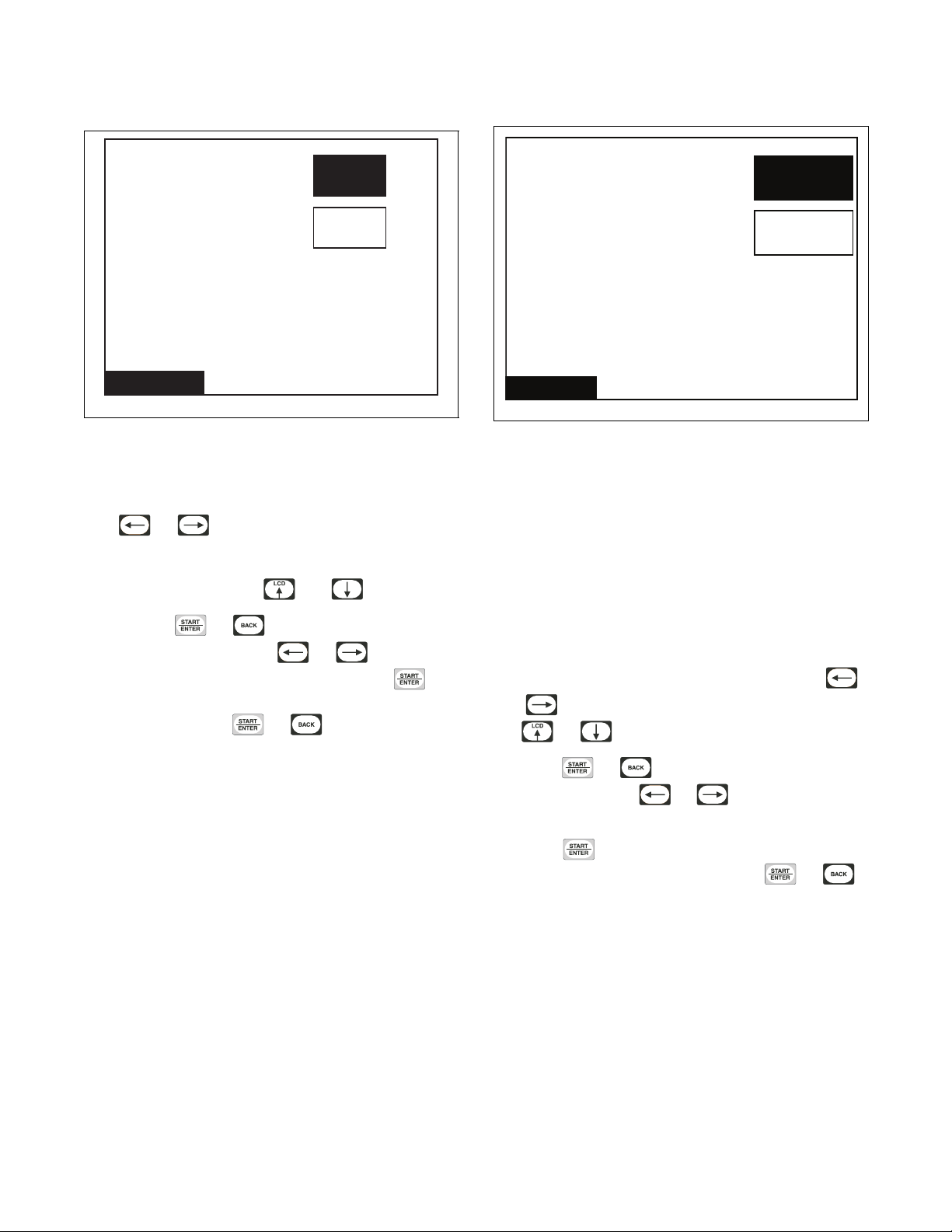

Display Screen Maps ............................................................................ 19

System Menu Map Tree................................................................... 19

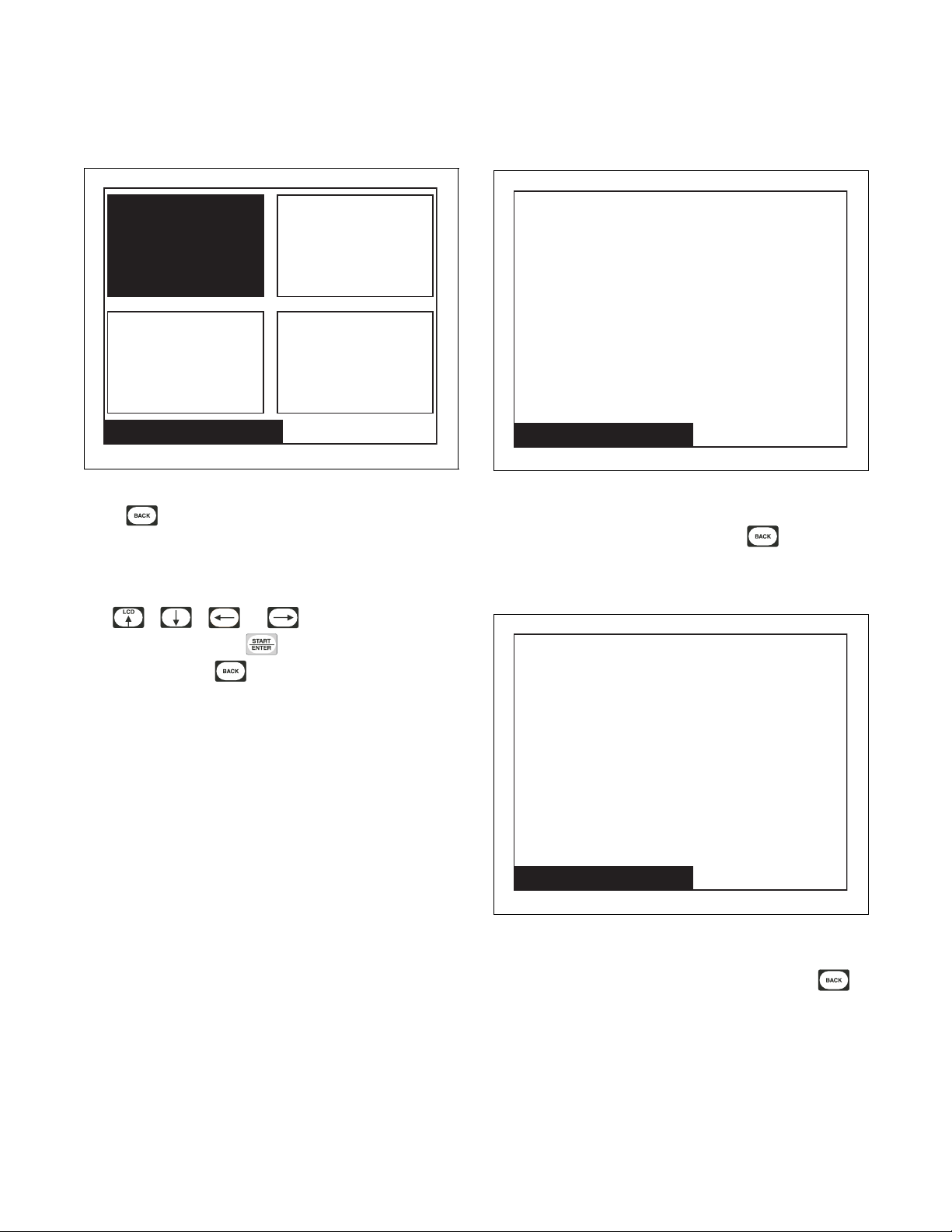

Run Menu Map Tree........................................................................ 20

Service Menu Map Tree................................................................... 20

Programming UniLinc ....................................................................... 21

System Menu ........................................................................................ 21

Save Changes Menu ............................................................................. 21

Program Menu .................................................................................... 22

Program Menu ...................................................................................... 22

Modify Cycle........................................................................................ 22

Available Characters........................................................................ 23

Cycle, Segment and Step Programming Flow Diagram....................... 24

Modify Cycle Segment Menu Navigation ....................................... 24

Global Setup ........................................................................................ 25

Global Setup Menu............................................................................... 25

Language Menu .................................................................................... 25

Date/Time Menu................................................................................... 26

Banners Menu....................................................................................... 26

Rapid Advance Menu ........................................................................... 27

Audio Menu.......................................................................................... 27

Miscellaneous Menu............................................................................. 28

Ignition Retry Menu ............................................................................. 28

Temperature Menu................................................................................ 29

Reverse Cylinder Menu (if equipped) .................................................. 29

Cool Down Menu ................................................................................. 30

Moisture Menu (if equipped)................................................................ 30

Factory Defaults Menu ......................................................................... 31

Diagnostics........................................................................................... 32

Diagnostic Menu................................................................................... 32

Test Menu ............................................................................................. 32

Test Cycle Menu.............................................................................. 32

Test Cycle Chart .............................................................................. 33

Inputs Outputs Menu........................................................................ 34

Alarms Menus....................................................................................... 35

Machine ID Menu................................................................................. 35

Machine Errors................................................................................... 36

PDA Communications Error................................................................. 36

Network Communications Error........................................................... 36

Open Thermistor Error ......................................................................... 36

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Shorted Thermistor Error...................................................................... 36

Stove and Cabinet Limit Errors............................................................ 36

Auto Ignition Retry and Heat Error (Gas Models Only)...................... 37

Air Flow Switch Errors......................................................................... 37

Airflow Switch Sensed Closed While Not In Run Mode ................ 37

Airflow Switch Does Not Close After Cycle Started ...................... 37

Airflow Switch Bounces During A Running Cycle......................... 37

Rotation Sensor Error ........................................................................... 37

Moisture Sensor Error........................................................................... 38

Fan Motor Contactor Error ................................................................... 38

Fan Motor Centrifugal Switch Error..................................................... 38

DIP Switch/Harness Index Mismatch Error ......................................... 38

Laundry Management........................................................................ 39

Laundry Management Menus............................................................... 39

Maintenance ........................................................................................ 40

Service Schedule Menu ........................................................................ 40

Daily Menu (Service)....................................................................... 40

Monthly Menu (Service).................................................................. 40

Quarterly Menu (Service) ................................................................ 41

Bi-Annual Menu (Service)............................................................... 41

Cycle Charts ........................................................................................ 42

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Introduction

Machine ID

Model: UT030NUOG2K0W01

Serial #: 1107002759

Install Date: 07/01/2011

Machine Type: 30

Control SN: 11410113

Front End SW: 1

Display SW: 1

Node Number: 250

Model Identification

Information in this manual is applicable to these

models:

Gas Steam/Thermal Oil Electric

25 Pound

30 Pound

35 Pound

50 Pound

55 Pound

75 Pound

120 Pound

170 Pound

200 Pound

UA025L

UA025N

UA030L

UA030N

UA035L

UA035N

UA050L

UA050N

UA055L

UA055N

UA075L

UA075N

UT075L

UA120L

UA120N

UA170L

UA170N

UA200L

UA200N

UT025L

UT025N

UT030L

UT030N

UT035L

UT035N

UT050L

UT050N

UT055L

UT055N

UT075N

UTF75L

UTF75N

UT120L

UT120N

UT170L

UT170N

UT200L

UT200N

UU025L

UU025N

UU030L

UU030N

UU035L

UU035N

UU050L

UU050N

UU055L

UU055N

UU075L

UU075N

UU120L

UU120N

UU170L

UU170N

UU200L

UU200N

UT025S UU025S UT025E UU025E

UT030S UU030S UT030E UU030E

UT035S UU035S UT035E UU035E

UT050S

UT050T

Not Applicable

UT075S

UT075T

UT120S

UT120T

UT170S

UT170T

UT200S

UT200T

UU050S

UU050T

UU075S

UU075T

UU120S

UU120T

UU170S

UU170T

UU200S

UU200T

UT050E UU050E

UT055E UU055E

UB075E

UT075E

UT120E

UU120E

Not Applicable

Not Applicable

UU075E

Includes models with the following control suffixes:

UO – UniLinc OPL RU – reversing UniLinc OPL

Nameplate Location

The nameplate is located on the back of the machine

and is programmed in the UniLinc Control. To access

Machine ID Menu through the control:

1. Press and hold , then , then

keypads at the same time.

2. Press the keypad until Diagnostic is

highlighted.

3. Press the keypad.

4. Press the keypad until Machine ID is

highlighted.

5. Press the keypad.

Always provide the machine’s serial number and

model number when ordering parts or when seeking

technical assistance. Refer to Figure 1.

TMB1332R

Figure 1

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Preliminary Information

About the Control

The UniLinc control on the tumble dryer is an

advanced, graphical, programmable computer that lets

the owner control most machine features by

interacting with the control.

UniLinc allows the owner to program custom cycles,

run diagnostic cycles, and retrieve audit and error

information.

Tumble dryers shipped from the factory have default

cycles and other settings built in. The owner can

change the default cycle or any cycle.

IMPORTANT: It is extremely important that the

tumble dryer has a positive ground and that all

mechanical and electrical connections are made

before applying power to or operating the tumble

dryer.

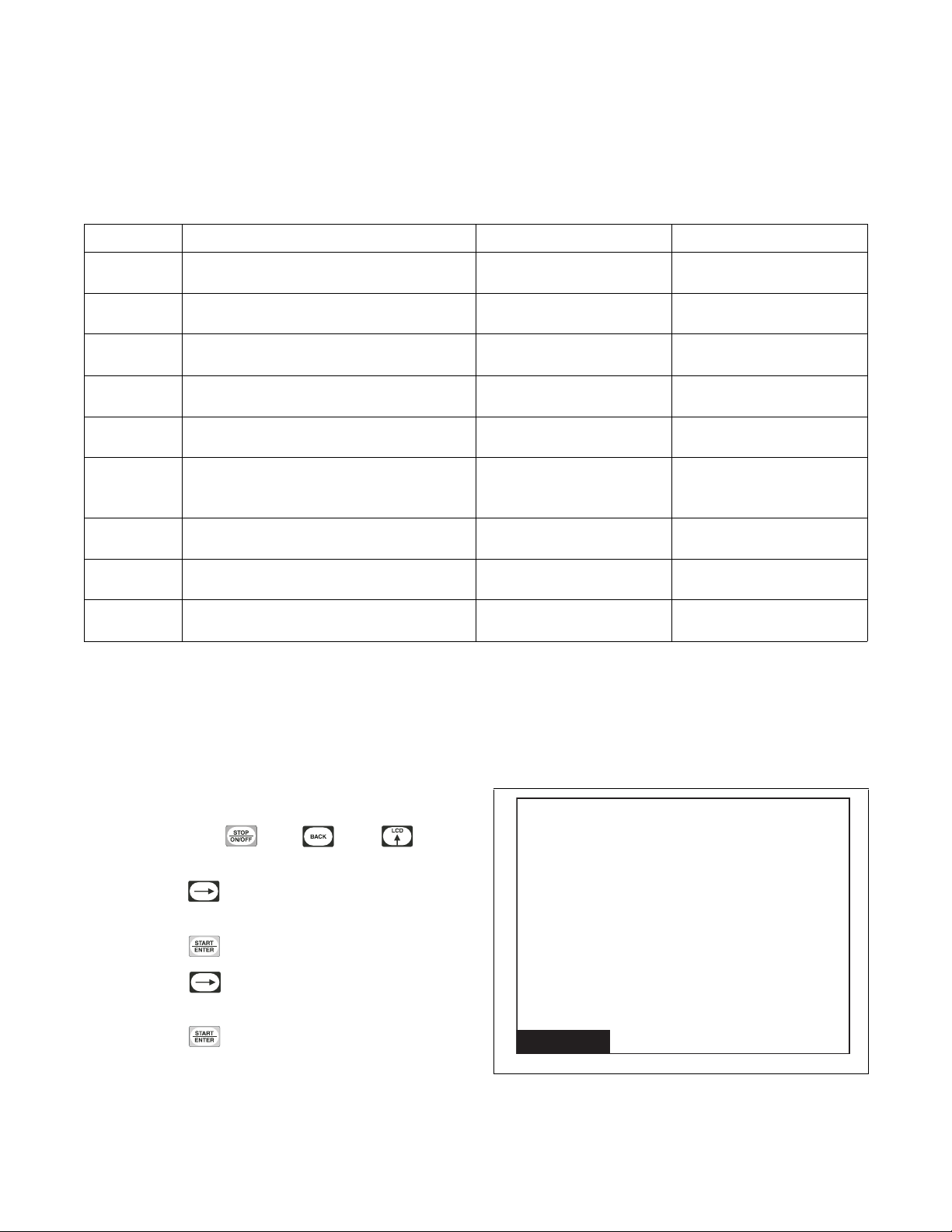

DIP Switch Configuration

Make sure DIP switches are configured properly for

the machine. Refer to Figure 2 below.

Power Failure Recovery

If a cycle is in progress when the power fails, and if

the power outage lasts three or more seconds, the cycle

is lost and cannot be resumed when power recovers. If

the power outage lasts less than three seconds, the

control will resume the cycle when the power

recovers.

Communications

The control has the ability to communicate with a

PDA and a laptop with an IrDA device running the

UniLinc software. Devices such as PDAs and laptops

that are IrDA capable (able to transmit information to

machine) that have been tested and approved for use

with the UniLinc software can be used as a tool for

managing the machine.

The control will also accept communication with a

network which allows the control to be linked to a

personal computer. This network link allows an owner

to program, collect data and run diagnostics on any

machine. For detailed information on network

communications, refer to the network instructions.

Figure 2

TMB1445R

Audit Information

The control collects and stores audit information,

which can be accessed with a PDA, PC or network.

Refer to the following list for some of the available

audit information. Refer to UniLinc PC and PDA

Application User Instructions.

• Total Number of Individual Cycle Counters

• Last 25 Machine Cycles

• Service History

• End of Cycle to Loading Door Open Time

• End of Cycle to Start of Next Cycle Time

• Total Number of Machine Cycles

• Total Number of Operating Minutes

• Power Failure Audit Data

The PDA, PC or network can receive audit and

program data from the control, and send programming

data and diagnostic commands to the control. Refer to

UniLinc PC and PDA Application User Instructions

for additional information.

70444801

Some of the above listed audit data is available

manually. Refer to Laundry Management section.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Preliminary Information

Invalid Data

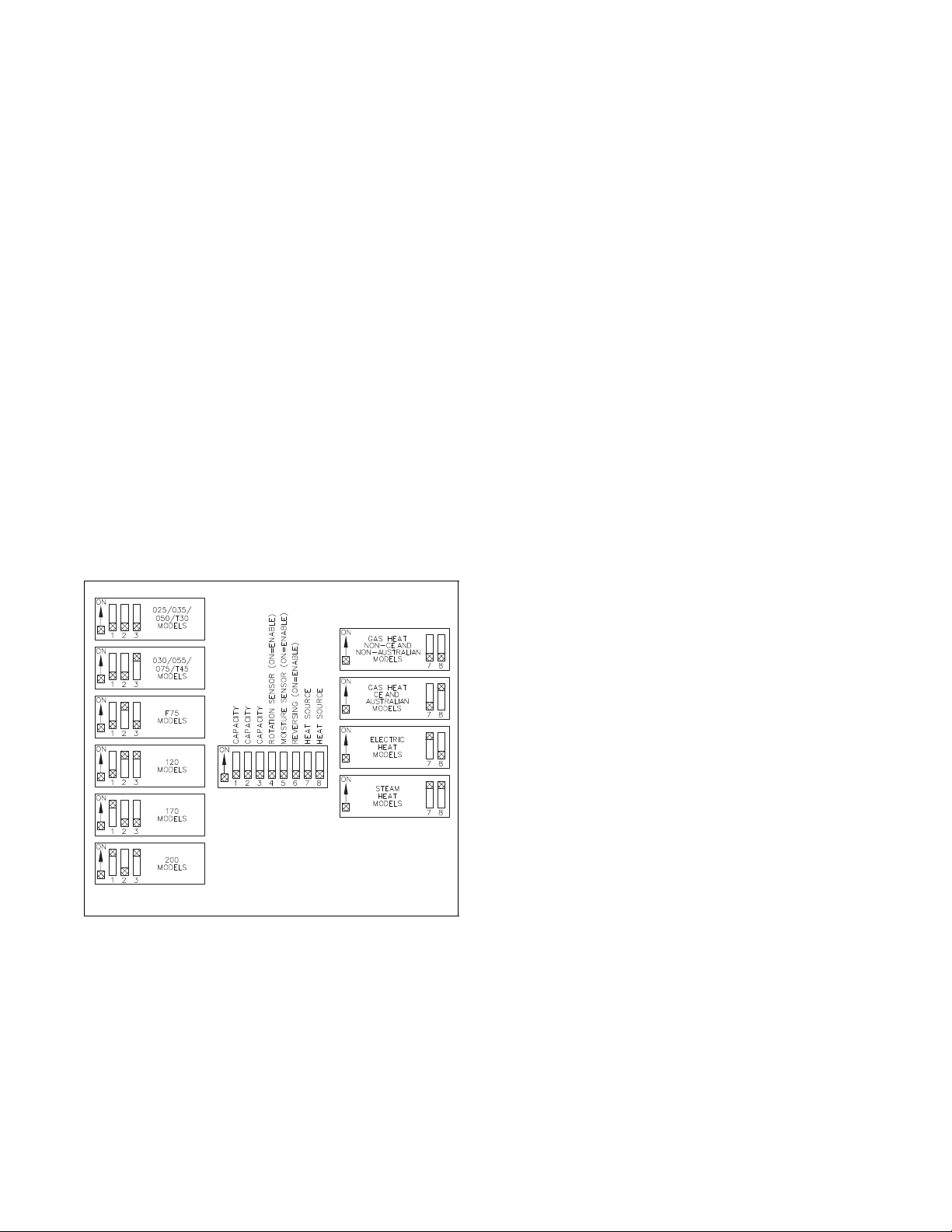

IR Communications Menu

PHM1003R

Figure 3

The IR Communications Menu displays while the

control is communicating with a PDA. The control

will jump back to the previous page when the

communication is complete.

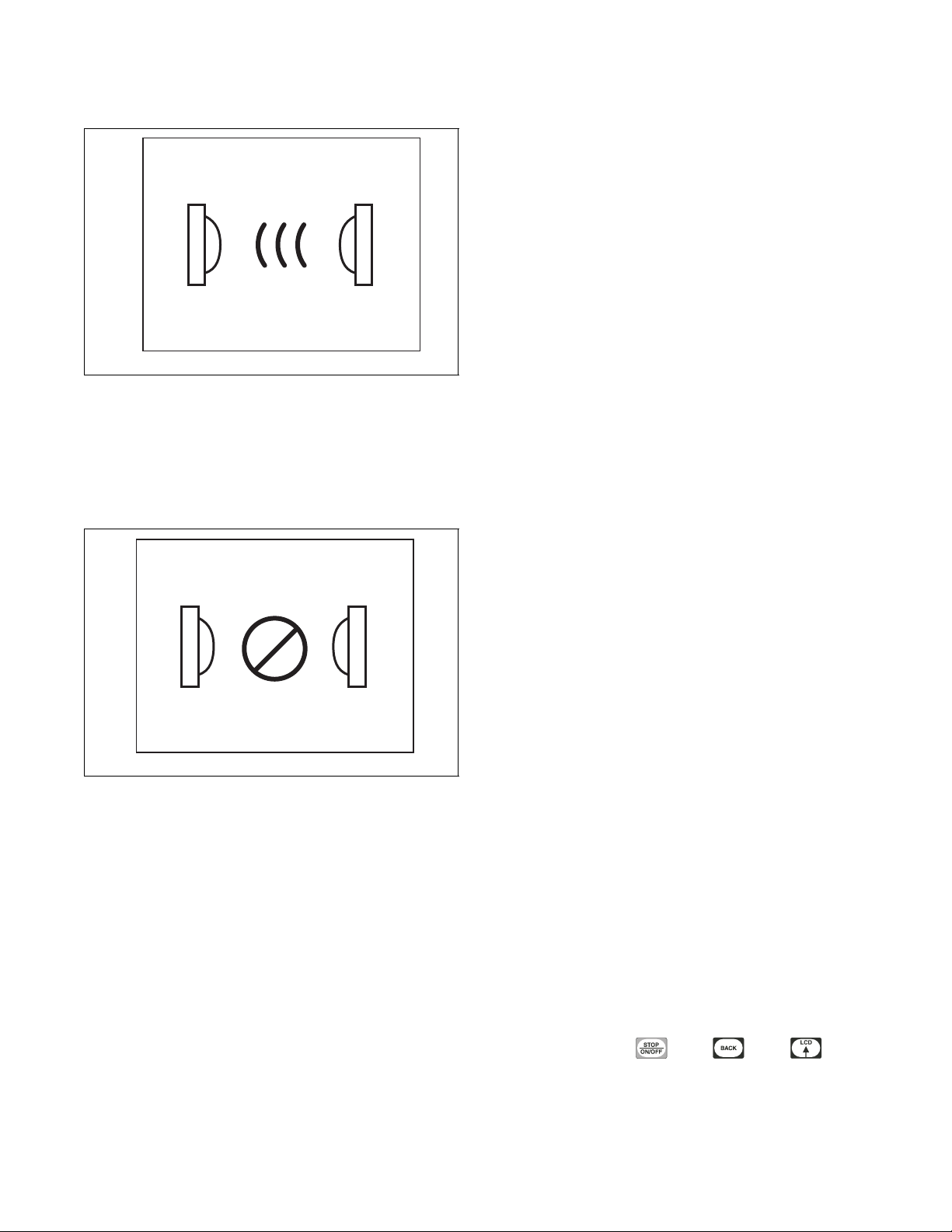

IR Communications Error Menu

Medium (M) Temperature = 160 (°F)

Low (L) Temperature = 140 (°F)

Very Low (VL) Temperature = 120 (°F)

Cool Down Temperature = 100 (°F)

Cool Down Time = 2 (minutes)

Rapid Advance = Disabled

Multi-Segment Cycles = Disabled

LCD Backlight ON/OFF = On

Banner # 1 = Blank

Banner # 2 = Blank

Daylight Saving = Enabled

Key Pad Audio = Enabled

End of Cycle Audio = Low (5 seconds)

End of Cycle External Signal = Enabled (5 seconds)

Clean Lint Screen Reminder = Off

Display Limit Errors = Disabled

Manual Diagnostics = Enabled (accessable via PC and

PDA only)

PHM1004N

Figure 4

The IR Communications Error Menu displays after the

control had an error communicating with a PDA. The

control will return to previous page after 3 seconds.

Restore to Factory Defaults

When the user selects Restore All Cycles And Global

Settings To Factory-Defaults, the control resets all of

the default values. The control also resets Machine

Cycles #1 through #41. The control will also reset the

following to factory-defaults:

Default Global Settings

Language = English

Ignition Retries = 3

Temperature Units = Fahrenheit (°F)

*Manual Programming = Enabled (accessable via PC

and PDA only)

**Reverse Cylinder Rotate Time = 120 (seconds)

**Reverse Cylinder Stop Time = 6 (seconds)

**Advanced Reversing = OFF

***Advanced Options for Moisture Dry = Disabled

***Display Moisture Sensor Error = Disabled

*If manual programming is disabled, programming

changes to UniLinc can only be made with an external

communication device. Refer to UniLinc PC and

PDA Application User Instructions.

**Only available on units equipped with reversing

feature.

***Only available on units equipped with moisture

sensing feature.

Refer to Factory Defaults, Menu section for

information on Restoring Factory Defaults.

Entering Program Mode

1. Press and hold , then , then to

enter the System Menu. Select Program to enter

programming options.

High (H) Temperature = 190 (°F)

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

UniLinc Identification

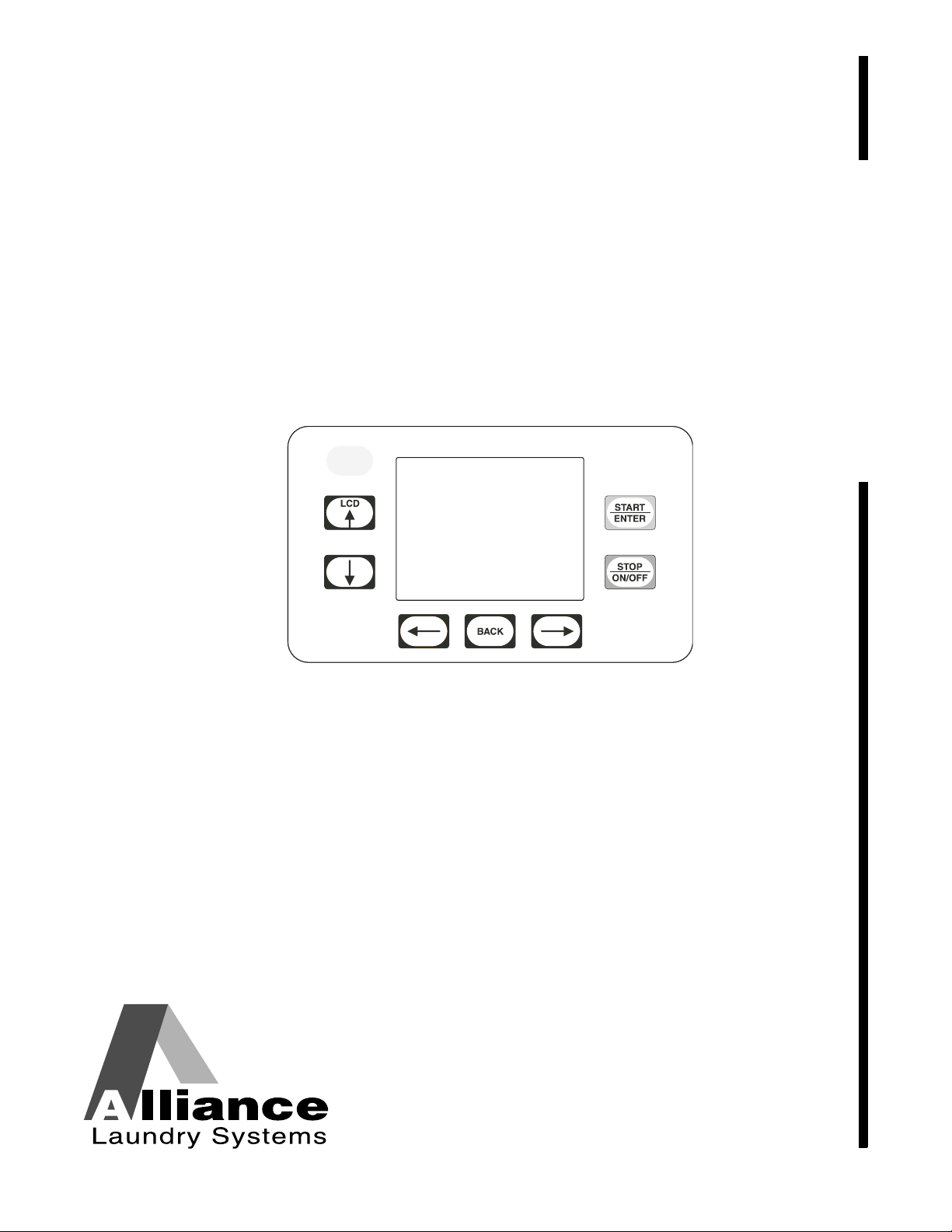

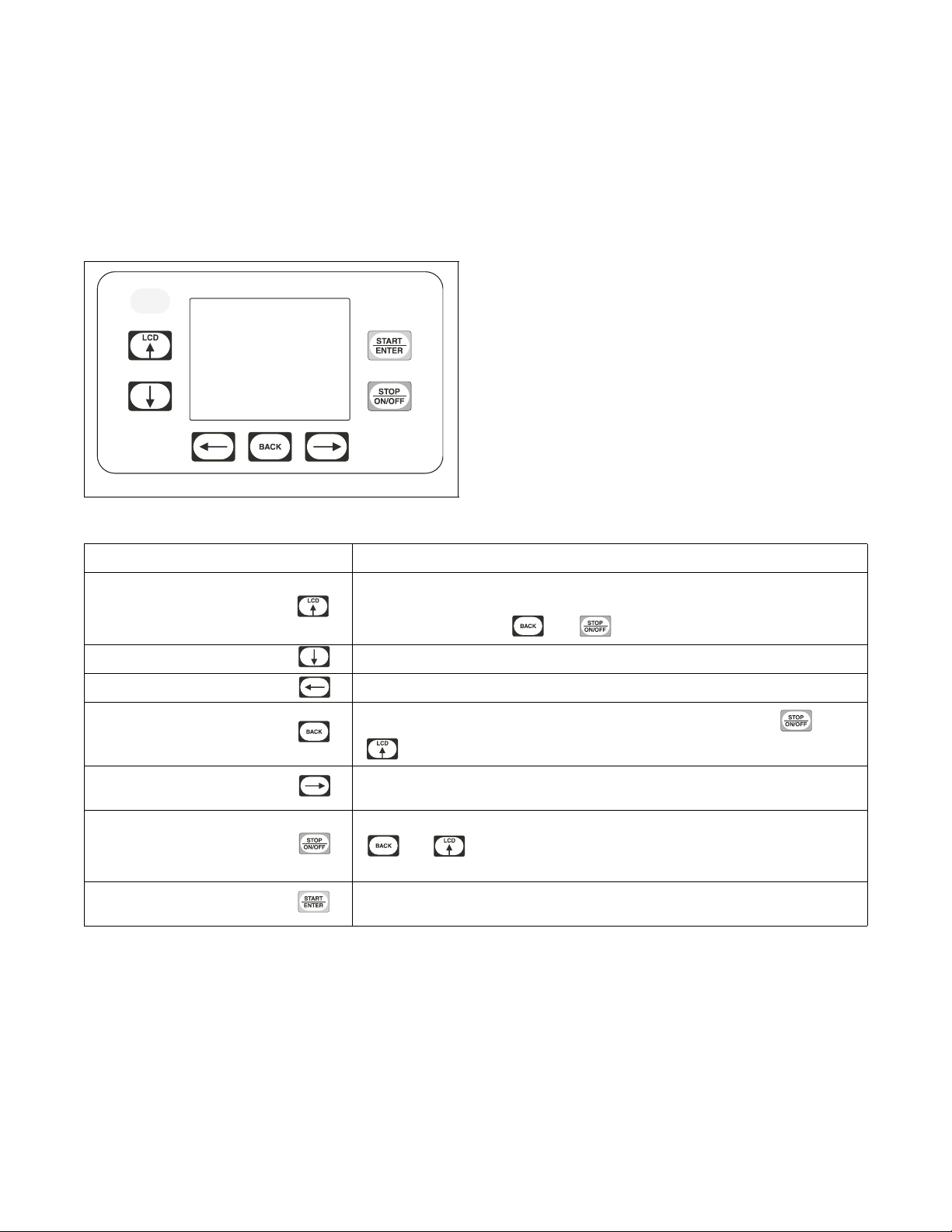

Operational Keypad

The control includes seven keypads. These functions

are available to the operator and are intended to

control and manage operation of the tumble dryer.

Refer to Figure 5 and Table 1.

TMB1276C

Figure 5

Keypad Description

LCD/UP ARROW

DOWN ARROW

LEFT ARROW

BACK

RIGHT ARROW

STOP/ON/OFF

START/ENTER

Press to move the cursor on display and to edit programming values. Also, press

while in Cycle Menu or Run Menu to change to the

Menu. Also, press with and to enter System Menu.

Press to move the cursor on display and edit programming values.

Press to move the cursor on display.

Press to move back to the previous display menu. Also, press with and

to enter System Menu.

Press to move the cursor on display. Press while running a cycle to get to Run

Diagnostic Menu.

Press to stop and abort a machine cycle during Run Mode. Also press with

and to enter System Menu. When in Cycle Programming Menu,

press to turn segments and cycles on and off.

Press to start or rapid advance a machine cycle during Run Mode. Also, press to

save edited programming values when used in programming menus.

Tab le 1

Contrast Adjust/Backlight

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

UniLinc Identification

Operation Modes

General Modes of Operation

In each mode of operation, the user may press keypads

or communicate with the control to change the

displayed menu.

Power-up Mode

The control enters this mode at power-up. After the

control completes operation in the Power-up Mode it

will enter Idle Mode. The display is blank during

Power-up Mode.

Idle Mode

The control is ready for operation in Idle Mode.

Control can display different menus depending on user

input (keypad press, opening or closing the loading

door, or PDA communication). If there is no user input

for one minute, control will turn off the LCD

backlight. The control will light when there is user

input. If there is no user input for 10 minutes, the

display will go blank.

If the control is in Idle Mode, Cycle Menu is

displayed, loading and lint door closed, and the

keypad is pressed, control will enter Run Mode.

Run Mode

The Control enters Run Mode during a cycle. The

Display shows machine cycle time remaining, the

current cycle type, segment, temperature, and

graphical indicators. Loading and lint doors are closed

during Run Mode. Press keypad to stop cycle

and enter Pause Mode. Press keypad to enter

Run Diagnostic Menu. Control enters Pause Mode if

loading or lint door opens. Press to Rapid

Advance.

Rapid Advance Mode

If the Rapid Advance Option is enabled, the user can

advance a running machine cycle by pressing the

keypad. In a Time Dry cycle, pressing the

keypad will decrease the remaining time by one

minute. Pressing and holding the keypad will

decrease the remaining time by four minutes per

second until the end of the cycle.

In the Cool Down segment, pressing the keypad

will decrease the remaining time by one minute.

When the cycle is completed, the audit counter, Total

Rapid Advance Cycles is incremented rather than the

Total Machine Cycles audit counter. In addition this

cycle is recorded in the audit list “Last 25 Machine

Cycles Completed”. If the Rapid Advance Option is

disabled preventing a manual Rapid Advance, the user

may still execute a Rapid Advance using the PDA or

PC. Refer to UniLinc PC and PDA Application User

Instructions for additional information on using a

PDA or PC to Rapid Advance a cycle.

Pause Mode

If keypad is pressed or the loading or lint door is

opened while in Run Mode, control enters Pause

Mode.

If the door is opened then closed, the control will

prompt the user to press to resume the cycle.

If is pressed while already in Pause Mode, the

control will enter End of Cycle Mode.

Error Mode

This mode will be entered to display all fatal machine

errors.

Communication Mode

This mode is entered whenever the control is

communicating with a PDA or a network. Refer to

UniLinc PC and PDA Application User Instructions.

Cool Down Mode

The control enters the Cool Down Mode after the heat

segment of the cycle is completed or fatal error occurs.

The control turns the heater off and for steam heated

units turns the damper motor on. The cool down

segment will end once the cool down temperature has

been reached or the programmed cool down time

expires, which ever happens first.

In the Auto-Dry and Moisture Dry cycles, pressing the

keypad will advance the cycle to the next

enabled segment. Note that Auto-Dry cycles only have

one programmable segment.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

UniLinc Identification

End of Cycle Mode

The control enters End of Cycle Mode after the cool

down segment is finished. The display will show a

graphic prompting the user to open the loading door. If

the door has not been opened or a keypad has not been

pressed after two minutes, the machine will enter

Extended Tumble Mode. This mode is exited when the

door is opened or a

or keypad is pressed.

The control will then return to Idle Mode.

Extended Tumble Mode

The Extended Tumble Mode has two portions. The

Anti-Wrinkle Tumble is entered two minutes after the

cycle has ended if the door is not opened. The cylinder

will tumble for 30 seconds every two minutes for up to

one hour.

If the door hasn’t been opened and no keys have been

pressed one hour after the Anti-Wrinkle Tumble has

ended, the control increments the Anti-Wrinkle Time

Exceeded audit counter and enters Delayed Tumble.

The cylinder will tumble for two minutes every 60

minutes for up to 18 hours.

Reversing Mode (reversing models only)

Models equipped with the reversing feature will rotate

in the forward direction, pause, rotate in the reverse

direction and then pause for programmable times and

segments of the cycle. Factory default reversing rotate

time is 120 seconds and reversing stop time is 6

seconds for all cycles with reversing enabled.

Entering Diagnostic Mode From Idle Mode

When entered from the Idle Mode, the control will be

running a test selected by the user via keypad presses

or communication with a device. The diagnostic tests

available from the Idle Mode are the Test Cycle and

Inputs Outputs Menus.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Machine Cycle Definition and Operation

For Technical Service

Distributor ABC

1-800-555-5555

Cycle41:Five

Minute Low

Cycle02:

Sheets Blend

Cycle01:

Towels

Cycle Menu

There are 41 machine cycles that can be selected and

run. Machine cycles can be modified or made

“unavailable” by manually editing them in Modify

Cycle Menu or by using the PDA or network to

download a modified machine cycle into the control.

Machine cycles cannot be deleted, but can be made

“unavailable” so that they are not visible from the

Cycle Menu. New machine cycles cannot be created,

but existing machine cycles that have been edited to be

“unavailable” may be re-edited to be available again.

Machine Cycle Operation

When a cycle is run, the control runs the cycle

segment by segment in a sequence. First the control

examines the Cycle Type chosen to determine if it is a

Time Dry, Auto-Dry or Moisture Dry (if equipped)

cycle type. Then the first segment is examined to see if

it is programmed to “On” or “Off”. If the segment is

programmed to “Off”, control skips to the next

segment.

At the start of some machine cycles, the control

displays a Total Remaining Cycle time. This time is

taken from the machine cycles as they are

programmed. The Total Remaining Cycle Time begins

to count down as soon as the cycle is started.

Rotation Sensor Equipped

Machines

On machines equipped with a rotation sensor, the

control monitors the rotation sensor to verify the

cylinder is rotating. The control calculates the

cylinder’s RPM. If the RPM drops to zero while the

cylinder is supposed to be rotating, the control will

advance to the Cool Down segment of the cycle and an

error message will be displayed.

Cycle Menu

Time Dry Cycle

In this type of cycle, the control will regulate the

temperature and time duration as programmed for the

cycle chosen.

Auto-Dry Cycle

If this type of cycle is selected, the control determines

the cycle time based on the temperature and dryness

level programmed for the cycle chosen.

Moisture Dry Cycle (if equipped)

In this type of cycle, the control checks the

programmed material type, programmed target

moisture content, programmed temperature and the

data received from the moisture sensing system to

achieve the desire results.

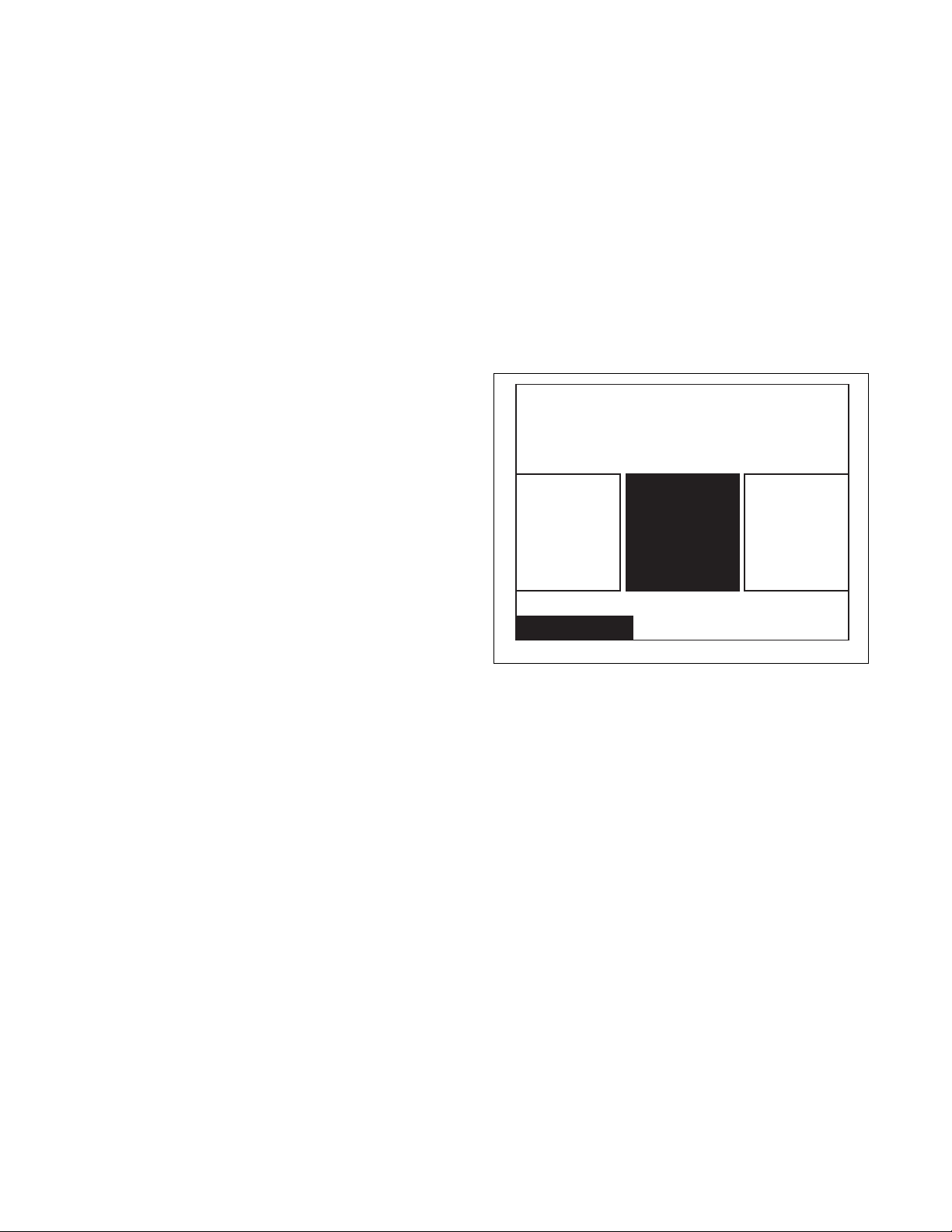

TMB1301R

Figure 6

The Cycle Menu is the first menu displayed by the

control after power-up. The Cycle Menu allows the

user to select one of the 41 machine cycles. Machine

cycles that are turned off will not be displayed on the

Cycle Menu. As a default, the last run cycle will be

displayed in the center, highlighted position. The

factory default cycle will be Cycle01.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Machine Cycle Definition and Operation

To Start a Cycle

1. Press the or keypad to change cycles.

2. Press the keypad to move the cycle in the

right most menu box to the center, highlighted

position.

3. Press the keypad to move the cycle in the

left most menu box to the center, highlighted

position.

4. Moving the and keypads allows the

selected cycle to scroll through the center,

highlighted position.

5. Press to start selected cycle.

NOTE: Press and hold or keypad to

make highlighted area move rapidly.

NOTE: If door is not closed when the keypad

is pressed, display will jump to the Close Door

Menu.

Press any keypad to clear the menu and return to the

Cycle Menu.

Optional settings are performed by either pressing a

keypad or by a combination of keypad presses:

• Press the keypad to jump control to the

Contrast Adjust/Backlight Menu.

• Press the keypad to enter the Service Menu.

• Press and hold , then , then to

enter the System Menu.

A Banner is displayed above the Cycle Selections in

the Cycle Menu. If Banner 1 and Banner 2 are

programmed, Banner 1 displays for ten (10) seconds

and Banner 2 displays for ten (10) seconds. If only one

Banner is programmed it will be the only one shown.

Refer to Banner Menu Section.

During communication with the PDA or network, all

menus enter IR Communications Menu.

Every night at midnight the control will enter Service

Menu if the machine is in idle mode on the Cycle

Menu.

When a keypad is pressed or the door is opened or an

IR communication takes place, the control will turn

the LCD contrast on and the backlight back on (if

programmed).

Control will also enter specific service sub-menu for

that day.

Bi-Annual Menu displays on the last day of June and

December.

Quarterly Menu displays on the first day of the month

for January, April, July and October.

Monthly Menu displays on all other first days of the

month.

Daily Menu displays on all other days.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Machine Cycle Definition and Operation

180 F

Cycle01: Towels

Time Dry

Segment01

Run Menu

TMB1302R

30:00

1

2

3

4

5

10

6

7

8

9

Run Menu

Run Menu provides cycle and segment information

while the machine is operating. Refer to Figure 7.

1 Cycle Number and Name 7 Heat / No Heat Indicator

2 Cycle Type (and Material Type for Moisture 8 Menu Indicator

3 Segment (Number or Cool Down) Indicator for Auto-Dry Cycle Type and Moisture

4 Programmed Temperature Sensing Models)

5 Graphical Temperature Indicator (Actual) 10 Reversing Enabled / Disabled

6 Basket Animation

The Run Menu cannot be navigated by manipulating

the arrow keypads. Press keypad to rapid

advance the cycle.

The Run menus include the Run Menu, the Run

Diagnostic Menu, and the various sub-screens of the

Run Diagnostic Menu. Press the keypad to jump

to the Run Diagnostic Menu.

TMB1302R

Sensing Models) 9 Cycle Time Remaining (or Cycle Progress

Figure 7

Press the keypad to stop the cycle in any of the

Run menus.

When the keypad is pressed, the display will

jump to the Cycle Stopped Menu. Refer to Operation

Modes section for more detail.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Machine Cycle Definition and Operation

Contrast / Backlight Menu

Contrast Backlight

Contrast/Backlight Menu

PHM1008R

Figure 8

Press the keypad from Cycle Menu or Run Menu

to enter the Contrast Adjust/Backlight Menu. The

Contrast Adjust/Backlight Menu allows the user to

adjust contrast and turn the backlight on or off.

Close Door Menu

TMB1303R

Figure 9

The Close Door Menu displays when loading door or

lint door on the machine is open and needs to be

closed.

Close door or press the keypad to return to Cycle

Menu.

Press the or keypad to highlight “Contrast”

or “Backlight” menu items.

Once the menu item has been selected, press the

or keypad to change contrast. The backlight is

either on or off and will have a factory default of on.

Press the keypad to enter the previous page.

If the Contrast Adjust/Backlight Menu is selected from

the Run Menu and the keypad is pressed, the

cycle is stopped.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Machine Cycle Definition and Operation

Alarms

Run Diagnostic Menu

Machine ID

Inputs and

Outputs

Temp and

Moisture

Run Diagnostic Menu

TMB1304R

Figure 10

The Run Mode Diagnostic Menu allows user to access

diagnostic information of the cycle currently running.

The menu contains temperature and moisture, inputs

and outputs, alarms, and machine ID.

While machine is running, press the keypad to

enter Run Diagnostic Menu.

Press the , , or keypad to

navigate the menu. Refer to Diagnostics section for

more description of these menus.

Press the keypad to choose selection.

The keypad will stop the cycle.

If the keypad is pressed, display enters Run

Menu. If nothing is selected for 15 seconds, the

display will return to Run Menu.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Temp and Moisture Menu

8

6

9

3

1

5

2

4

7

11

10

Cycle01: Towels

Moisture Dry: Cotton

Segment01

Machine Cycle Definition and Operation

05:00

Moisture Custom

35%

Save

7%

Actual

Temp

155 F

160 FProgram

Run Menu

TMB1305R

TMB1305R

1 Cycle Number and Name 8 Programmed Moisture Content (Moisture

2 Cycle Type and Material Type (Moisture Sensing Models only)

Sensing Models only) 9 Menu Indicator

3 Segment (Number or Cool Down) 10 Cycle Progress Indicator / Cycle Time

4 Segment Time Elapsed Remaining

5 Actual Temperature 11 Save Current Moisture as Target (Moisture

Sensing Models only) or Save Elapsed Time6 Programmed Temperature

7 Actual Moisture Content (Moisture Sensing as Total Cycle Time (Time Dry Cycles)

Models only)

Figure 11

A sub-menu of the Run Diagnostic Menu, the Temp

and Moisture Menu is used to display detailed

operating data and, if enabled, allow the user to change

the programmed temperature, time or moisture of a

currently running cycle. The top portion of the display

contains the same information listed in the Run Menu

detailing Cycle, Number and Name, Cycle Type,

Material Type and Segment.

Press keypad to enter Run Mode Diagnostic

Menu. Press keypad to pause/stop the cycle, the

control will enter Cycle Stopped Menu. Press the

keypad to advance the cycle one segment.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Press or keypads to highlight programmed

temperature, moisture/dryness, time or custom save.

Press the or keypads to edit the selected

value of temperature, moisture, dryness or time. All

changes take effect immediately, but don’t change the

saved cycle.

On Moisture Sensing models, pressing while

Custom Save is highlighted will set the current actual

moisture as the new programmed moisture for the

running cycle. The current cycle will then advance to

the Cool Down segment and the control will return to

Run Menu.

While running a Time Dry cycle, pressing while

Custom Save is highlighted will set the total elapsed

cycle time as the new programmed total cycle time.

The current cycle will then advance to the Cool Down

segment and the control will return to Run Menu.

15

Machine Cycle Definition and Operation

Cycle Stopped

Press START Key to Resume

Press STOP Key to Abort Cycle

Cycle Stopped

Press BACK Key to Exit

Extended Tumble in 0:50

Cabinet High Limit

Error

Fan Motor Contactor

Error

Press STOP Key to Abort Cycle

Cycle Stopped Menu

TMB1357R

Figure 12

The Cycle Stopped Menu will be displayed in Pause

Mode. Press to resume the cycle or to

abort the cycle and go to the Open Door Menu.

Error Menu

TMB1307R

Figure 14

The Error Menu will be displayed as a result of an

error during a cycle, the Test Cycle or while on the

Cycle Menu.

If a fatal error occurs during a cycle, the Error Menu

display will alternate with the Run Menu every three

seconds until is pressed or the Cool Down is

complete.

Figure 13

The Cycle Stopped Menu will display an error, if one

occurs, at the end of a cycle or when is pressed.

The time remaining until Extended Tumble will be

displayed. Press to exit to go to Open Door

Menu or open the door to go to the Cycle Menu.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TMB1341R

70444801

Machine Cycle Definition and Operation

Extended Tumble in 0:50

Clean Lint Screen

Press BACK Key to Exit

Is the machine basket empty?

NoYes

Press BACK Key to Exit

Service Moisture Sensor Soon

Open Door Menu

TMB1340R

Figure 15

The Open Door Menu is displayed from the Run Menu

prior to a completed cycle. The time until Extended

Tumble is shown at the top of the display.

Open the door or press the or keypad to

return to the Cycle Menu.

Clean Lint Screen Menu

Load Sensed Menu

TMB1364R

Figure 17

The Load Sensed Menu will show from the Cycle

Menu only after eleven minutes of Idle Mode, without

user interaction, having consistently sensed a load for

that entire period. The menu prompts to the operator to

indicate whether the machine basket is empty. No is

highlighted by default. If the user presses the

keypad while No is selected, the control will

return to the Cycle Menu. If the user selects Yes, the

control will display the Service Moisture Sensor

Menu.

The Clean Lint Screen Menu is displayed from the

Open Door Menu only after globally programmed

number of cycles have been completed. Press to

return to the Cycle Menu

Figure 16

TMB1308R

Service Moisture Sensor Menu

TMB1365R

Figure 18

The Service Moisture Sensor Menu will show from the

Load Sensed Menu indicating to the operator that the

Moisture Sensor System may need service soon. The

menu also instructs the user that the keypad may

be pressed to return to the Cycle Menu.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Menu Navigation

The UniLinc

The front-end control allows the user to control

machine operation and programming by pressing

keypads to select options on the display menus and by

navigating between display menus.

The user can navigate the control in the following

Menu to Menu Navigation

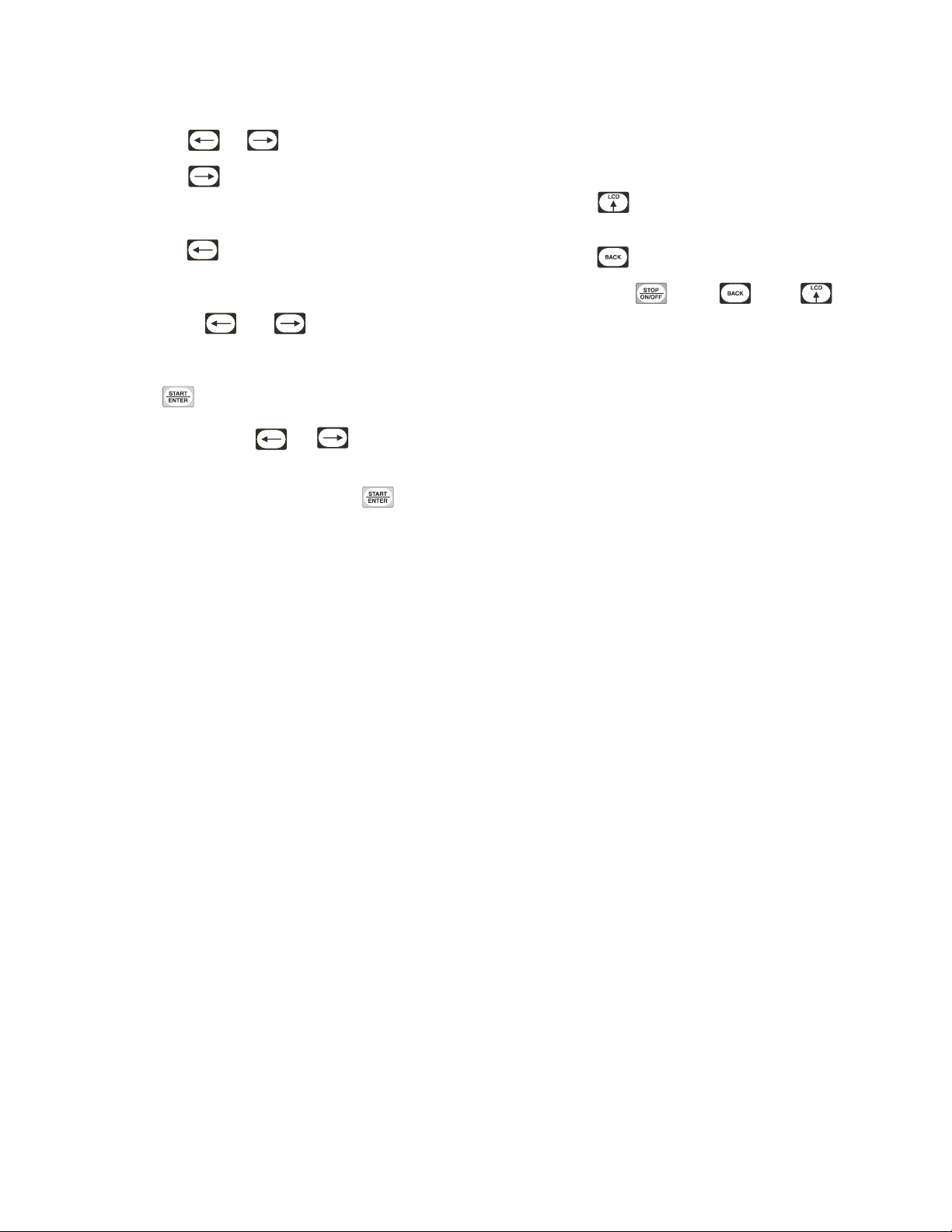

The , , and keypads are used to

select the desired menu. Once the menu is selected, the

keypad is used to enter that menu. The

keypad allows the user to return to the previous menu.

ways.

Screen to Screen Menu Navigation

In Screen to Screen Navigation, the or

keypad are used to go from one menu page to the next

(i.e., moving from Alarms [1 of 3] Menu to Alarms

[2 of 3] or Alarms [3 of 3] menus), if a menu cannot fit

entirely on the same page. The Laundry Management

Menu uses this navigation method. Cycle

programming also uses this method.

Cycle Name and Banner Editing

This Edit Mode is used when a cycle name must be

modified or a banner created. The highlighted box is

moved over the editable item and the keypad is

pressed. The mode can be verified by seeing the first

character in the item with a blinking underscore

underneath. The character can then be changed by

using the and keypads. To enter a space or

delete a character, press the keypad.

The Cycle Name can contain the capital letters “A”

through “Z”, small letters “a” through “z”, the

numbers “0” through “9”, and special characters. The

user can go forward to the next character in the item

by using the keypad. Press the keypad to

go backward a character. If the first character in the

item is selected and the keypad is pressed, the

cursor will go to the last character of the item. Thus,

the cursor will move only within the item when the

horizontal keypads are pressed.

Press the or keypad to exit the Edit Mode.

Menu Navigation with Parameters

Another type of menu is a menu with modifiable

parameters. The and keypads are used to

navigate through the screens. The and

keypads are used to change the valve of the

highlighted item.

An example is the Temperature Menu under Global

Setup. The menu items are positioned vertically, but

the and keypads are used to navigate

through the different items while the and

keypads are used to adjust the values.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Cycle Menu

System Menu

Diagnostic Menu

Run Menu Service Menu

Close Door Menu

Contrast/ Backlight Menu

. . . . . .

Program Menu

Laundry Management

Menus (1-3)

I/O Menu

Alarms Menu (1-3)

Machine ID Menu

Test Cycle

Save Changes Menu

(After all Step Menus

and Global Menus

except Factory

Defaults)

Global Setup Menu

Language Menu

Date/ Time Menu

Banners Menu

Audio/ Ext Signal Menu

Miscellaneous Menu

Ignition Retry Menu

Temperatures Menu

Reverse Cylinder Menu

Cool Down Menu

Rapid Advance Menu

Moisture Menu

Test Menu

Modify Cycle Menu

Cycle Segment Menu

Factory Defaults Menu

Cycle Cool Down Menu

Cycle Setup Menu

TMB1358R

TMB1358R

Menu Navigation

Display Screen Maps

Refer to the following charts for maps of all of the

display menus.

System Menu Map Tree

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 19

19

Menu Navigation

TMB1310R

Cycle Menu

Service MenuSystem Menu

Contrast/Backlight Menu Close Door Menu

. . . . . .

Clean Lint Screen Menu

Contrast/Backlight Menu

Cycle Stopped Menu

Open Door Menu

Error Menu

Run Diagnostic Menu

Temp and Moisture Menu

Run Alarms Menus (1-3)

Machine ID Menu

Run I/O Menu

Run Menu

TMB1310R

Cycle Menu

Service MenuSystem Menu Run Menu

Close Door MenuContrast/Backlight Menu

. . . . . .

Daily Menu

Bi-Annual Menu

Monthly Menu

Quarterly Menu

TMB1311R

Run Menu Map Tree

Service Menu Map Tree

Figure 20

Figure 21

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Programming UniLinc

Laundry

Management

System Menu

DiagnosticProgram

Save Changes?

NoYe s

System Menu

TMB1312R

Figure 22

The System Menu allows the user to access: cycle

programming, diagnostics and laundry management.

While on the Cycle Menu press and hold ,

then , then to enter the System Menu.

Save Changes Menu

PHM1021R

Figure 23

The Save Changes Menu is used to confirm

programming changes when modifying a cycle or the

values of the Global Settings. The Save Changes

Menu will default to Yes. Using

the or keypad will move the cursor

The System Menu is a submenu of the Cycle Menu.

The navigation of the System Menu is different from

the Cycle Menu. In the Cycle Menu, the highlighted

text box was stationary. In the System Menu, the

ARROW keypads control the location of the

highlighted text box. Text will remain at the same

location but the highlighted box will move when the

, , , and keypads are pressed.

Press the keypad to enter selected menu.

Press the keypad to return to the Cycle Menu

screen.

between Yes or No. Press the keypad to make a

selection. Once the keypad is pressed, the

display will either return to the Modify Cycle Menu or

the Global Setup Menu depending in which submenu

the display was in.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Program Menu

Program Menu

Modify Cycle Global Setup

Modify Cycle

Yes

Cycle01: Towels

Time Dry

Reversing: Global

Cycle Reversing

Rotate Time

Stop Time

s

s

120

6

Program Menu

PHM1022R

Figure 24

In System Menu, select Program and press .

To program cycles, select Modify Cycle and

press .

To change properties that will affect the machine

globally, select Global Setup (i.e., language displayed,

Cool Down Temperature) and press .

Press the keypad to return to System Menu.

Modify Cycle

The Modify Cycle Menu is used to program the

cycles.

The Cycle Number will be highlighted when the

Modify Cycle is first displayed.

Press the or keypad to change cycle

selections.

The cycle can be turned on and off by pressing

the keypad. If the cycle is turned off, the Cycle

Name will display “Off” and the user will not be able

to make any changes to the cycle.

Press the keypad to make the highlighted box

move to the cycle name to the right of the cycle

number.

Press the keypad from Cycle Number to make

the display jump to the Modify Cycle Cool Down

Menu.

NOTE: All cycle numbers have to be scrolled

through even though they may be shut off.

Figure 26 illustrates the flow of the cursor during

the programming of a cycle.

To edit a cycle name, select the cycle name and press

the keypad.

The first character of the Cycle Name will have a

blinking underscore underneath to display it is ready

for editing. Use the and keypads to select

the different characters. After the desired character has

been selected, press the keypad to save the

character and move to the next character. The user

may press the keypad to go back a character.

Figure 25

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Pressing the keypad when located on the first

character will take the user to the last character, which

may be a blank space. Continue pressing the

keypad to move to desired character. The blinking

underscore is under the last character and the

keypad is pressed, the blinking underscore will move

to the first character.

Press the keypad to exit edit mode.

TMB1313R

70444801

Program Menu

NOTE: Refer to Tab le 2 for a chart of available

letters, numbers and symbols.

Cycle Type can be modified by pressing the or

keypad while Cycle Type is highlighted.

Press the keypad to move to Material Type (if

available). Press the or keypad to change

the value.

Press the keypad to modify the reversing values

if available. Press or keypad to change the

value.

Press the keypad to move highlighted box to the

first Segment Number. While the Segment Number is

highlighted, the Segment Number can be turned on or

off by using the keypad. If turned off, all sub

programming steps will become inaccessible. Segment

01 can’t be turned off.

Available Characters

In general, press the or keypad to navigate

the various Segments and or to change

their parameters.

After the Segment Menu, press the keypad to

move to the Cool Down Segment Menu.

If the current Cycle Type is Moisture Dry and the

global programming Advanced Options for Moisture

Dry is enabled, pressing from the last segment

menu will send control to the Advanced Options

Menu. Another keypad press will then go to the

Cool Down Segment Menu.

At any time, press the keypad to jump to the

Save Changes Menu.

ABCDE FGH I J KLMNOP

QRSTUVWXYZabcdef

ghi j klmnopqr s tuv

wxyz0123456789 !"

#$%&'()*+,-./:;<

=>?@[\]^_`{|}~€‚

ƒ„…†‡ˆ‰Š‹ŒŽ‘ ’“”•

–—˜™š ›œžŸ ¡¢£¤¥ ¦

§¨©ª«¬-®¯°±²³ ´µ¶

· ¸ ¹ º »¼½¾¿ АБВГДЕЖ

ЗИЙКЛМНОПРСТУФХЦ

ЧШЩЪЫЬЭЮ Я абвгдеж

зийклмнопрстуфхц

чшщъыьэюя

Tab le 2

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Program Menu

TMB1370R

Modify Cycle

Yes

Cycle01: Towels

Time Dry

Reversing: Global

Cycle Reversing

Rotate Time

Stop Time

s

s

120

6

Modify Cycle Main Menu

Modify Cycle

Cycle01: Towels

Time Dry

Cool Down: Global

Temperature

Time

Segment Reversing

2

No

100

m

F

°

Cycle Number Cycle Name

Time Dry

Material Type

Auto-Dry

Cycle

Reversing Options

(If available)

Segment #2 - 5

Options (If enabled)

Segment #1 Options

Cool Down Options

(If Heat Cycle)

Segment #1

Options

Moisture Dry

Modify Cycle

Cycle01: Towels

Auto Dry

Segment01:

Temperature

Dryness Level

Segment Reversing

0

No

H

Auto-Dry Segment Options

Modify Cycle

Cycle01: Towels

Time Dry

Segment01:

Temperature

Time

Segment Reversing

30

No

160

m

F

°

Time Dry Segment Options

Cool Down Options

Modify Cycle

Cycle01: Towels

Moisture Dry: Cotton

Segment01:

Temperature

Target Moisture

Segment Reversing

0%

No

H

Moisture Dry Segment Options

Modify Cycle

Cycle01: Towels

Moisture Dry: Cotton

Advanced Options:

Time Past Target

0

m

Moisture Dry Advanced Options

TMB1370R

Cycle, Segment and Step

Programming Flow Diagram

Modify Cycle Segment Menu Navigation

Modify Cycle Segment Menus are a subgroup of the

Modify Cycle Menu and the navigation is very similar

to the navigation of the Modify Cycle Menu. When a

segment menu is first displayed, the segment name

will be highlighted. While the segment name is

highlighted, it can be toggled on or off by pressing

the keypad. If the segment is toggled from OFF

to ON, then the last programmed parameters will be

displayed.

24

Figure 26

NOTE: The reversing features will not be available

if the unit is not equipped with that option.

Press the keypad to move to the next segment.

Press the or keypad to change the value.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Global Setup

Global Setup

Date / Time BannersLanguage

Audio / Ext

Signal

Te mp s

Moisture

Ignition

Retry

Factory

Defaults

Rapid

Advance

Misc

Reverse

Cylinder

Cool Down

Language Menu

DeutschFrançais Portuguese

Español ItalianoEnglish

Global Setup Menu

TMB1359R

Figure 27

The Global Setup Menu allows the user to make

changes to global properties of the machine. Use

the , , , and keypads to navigate

the menu. Select a menu item by pressing the

keypad. Press the keypad to enter the Program

Menu.

Language Menu

PHM1037R

Figure 28

The Language Menu is used to select the language

displayed. The user can choose English, Spanish,

Italian, French, German or Portuguese.

Press the , , or keypad to move

the highlighted box through the different selections.

English is the default language.

NOTE: Menus related to cycle operation are the

only menus that will display in the chosen language

if English is not selected. All System Menu submenus will remain in English.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Press to select a language. The Save Changes

Menu will display.

Press or to move highlighted box to “Yes ”

or “No”.

Press the keypad to return to Global Setup

Menu. If no changes were made, press the

keypad to return to Global Setup Menu.

25

Global Setup

Date / Time

Wednesday

19/

09 24

No

:

/

2011

Current Date

Day of Week

Local Time

Daylight Saving

01

Banners

Banner #1

Banner #2

Date/Time Menu

TMB1342R

Figure 29

The Date/Time Menu is used to set the date, day of the

week, time, and daylight saving option.

Press and keypads to move the

highlighted box through the different items in the

menu. Once the item is highlighted, the value can be

changed by using the and keypads. The

Save Changes Menu will display. Use or

to move highlighted box to “Yes ” or “No”.

Press the keypad to return to Global Setup

Menu. If no changes were made, press the

or keypad to return to Global Setup Menu.

The control’s Clock will automatically adjust for leapyear. The control may be programmed for automatic

daylight saving adjustment. If the Daylight Saving

option is disabled, no adjustment takes place. If it is

enabled, on the second Sunday in March, the time will

spring forward from 2:00 AM to 3:00:00 AM. On the

first Sunday in November, the time falls back from

2:00:00 AM to 1:00:00 AM.

Banners Menu

PHM1047R

Figure 30

The Banners Menu is used to create or modify the

banners that are displayed while the machine is on the

Cycle Menu. The banners are displayed at the top of

the screen.

The banners are created or modified using the Edit

Mode. Refer to Program Menu, Modify Cycle section.

Use the or keypad to highlight the

different lines and press the keypad to save the

edit. Pressing the keypad will jump to the Save

Changes Menu. Use or to move

highlighted box to “Yes ” or “No”. Press the

keypad to return to Global Setup Menu. If no changes

were made, press the or keypad to return

to Global Setup Menu.

Daylight Saving can be enabled or disabled by moving

highlighted box to Daylight Saving and

pressing or to Yes or No. The Save

Changes Menu will display. Use or to

move highlighted box to “Yes” or “No”. Press

keypad to return to Global Setup Menu. If no changes

were made, press or keypad to return to

Global Setup Menu. The factory-default value for

daylights saving is enabled.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Global Setup

Rapid Advance

Enable the Rapid Advance

Feature During Cycle Operation?

NoYes

Audio / Ext Signal

On

Low

Key Pad

End of Cycle

Volume:

5

s

Time:

No

External Signal

Enable:

5

s

Time:

Rapid Advance Menu

TMB1343R

Figure 31

The Rapid Advance Menu has the option of whether

the user will be able to rapid advance through

segments while the machine is operating. Press

the ,

selection. All the keypads have the same effect and

will toggle the selection between on or off. Press

the or keypad to jump to the Save Changes

, or keypad to change the

Audio Menu

TMB1316R

Figure 32

The Audio/External Signal Menu sets the audio

options of the keypad audio feedback, the beeper

volume and the External Signal.

Press the and keypads to move the

highlighted box through the different items in the

Audio Menu.

Menu. Use or to move highlighted box to

“Yes ” or “No”. Press keypad to return to Global

Setup Menu. If no changes were made, press

the or keypad to return to Global Setup

Menu.

Once the item is highlighted, press the and

keypads to change the value. Press the or

keypad to return to the Save Changes Menu if

changes were made.

Press the or keypad to move highlighted

box to “Yes ” or “No”. Press keypad to return to

Global Setup Menu. If no changes were made,

press or keypad to return to Global Setup

Menu.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Global Setup

Miscellaneous

No

Off

No

Multi-Segment Cycles

Number of Cycles Between

Lint Screen Reminders

Display Limit Errors

Ignition Retry

3

Number of Retries

Miscellaneous Menu

TMB1360R

Figure 33

The Miscellaneous Menu allows the user to set

whether or not multi-segment cycles may be

programmed, the number of cycles between lint screen

reminders and display limit errors. Disabling Display

Limit Errors will prevent any limit error from being

displayed on the Cycle Stopped Menu. Press the

and keypads to move the highlighted box

through the different items in the Miscellaneous

Menu. Press the or keypad to change

selections.

Press the or keypad to jump to the Save

Changes Menu. Use or to move

highlighted box to “Yes ” or “No”.

Press the keypad to return to Global Setup

Menu. If no changes were made, press or

keypad to return to Global Setup menu.

Ignition Retry Menu

TMB1318R

Figure 34

The Ignition Retry Menu sets the option of how many

retries the machine will attempt before a heater error

occurs. The user will be able to select a value from one

(1) to five (5).

Press the or keypad to change number of

balance retries.

Press the or keypad to jump to the Save

Changes Menu. Press the or keypad to

move highlighted box to “Yes ” or “No”.

Press the keypad to return to Global Setup menu.

If no changes were made, press or keypad

to return to Global Setup Menu.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70444801

Global Setup

Temperatures

190

High (H)

160

Medium (M)

140

Low (L)

Units

120

Very Low (VL)

F

°

F

°

F

°

F

°

F

°

Rotate Time

Stop Time

Advanced Reversing

Reverse Cylinder

6

No

S

S

120

Temperature Menu

TMB1361R

Figure 35

The Temperatures Menu allows the user to set global

temperatures for High, Medium, Low, Very Low and

what unit of measure to display them in. These

temperature ranges are restricted to those allowed by

Auto-Dry configurations for a given machine capacity.

Press and keypads to move the highlighted

box through the different items in the menu. Once the

item is highlighted, press the and keypads

to change the values.

Reverse Cylinder Menu (if

equipped)

TMB1320R

Figure 36

The Reverse Cylinder Menu allows the user to set the

rotate and stop time for Reverse Cylinder action and

cycle specific rotate time, stop time and Advanced

Reversing. Rotate and Stop Times valid for a heat

cycle are those available through global Reverse

Cylinder parameters. If Advance Reversing is enabled,

the user will be able to view and edit cycle specific

reversing parameters within Cycle Programming.

Refer to Figure 25.

Press the or keypad to jump to the Save

Changes Menu.

Use or to move highlighted box to “Yes”

or “No”.

Press the keypad to return to Global Setup

Menu. If no changes were made, press the

or keypad to return to Global Setup Menu.

The and keypads are used to move the

highlighted box through the different items in the

Reverse Cylinder Menu. Once the item is highlighted,

the value can be changed by using the and

keypads. Pressing the or keypad

will jump to the Save Changes Menu. Use

or to move highlighted box to “Yes” or “No”.

Press the keypad to return to Global Setup menu.

If no changes were made, press the or

keypad to return to Global Setup Menu.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Global Setup

Cool Down

100

Temperature

Time

2m

F

°

Moisture

No

Yes

Advanced Options for

Moisture Dry

Display Moisture Sensor

Error

Cool Down Menu

TMB1321R

Figure 37

The Cool Down Menu gives the user the option to

setting the Cool Down Target Temperature and Time.

The or keypads are used to move the

highlighted box between the two items in the Cool

Down Menu. Once the item is highlighted, the value

can be changed using the and keypads.

Pressing the or keypad will jump to the

Save Changes Menu. Press or to move

highlighted box to “Yes ” or “No”. Press the

keypad to return to Global Setup Menu. If no changes

were made, press the or keypad to return to

Global Setup Menu.

Moisture Menu (if equipped)

TMB1362R

Figure 38

The Moisture Menu allows the user to enable or

disable Advanced Options for Moisture Dry (only

available on units equipped with moisture sensing

feature) and Display Moisture Sensor Error. Enabling

Advanced Options for Moisture Dry allows users to

program Time Past Target which is the added number

of minutes of heat time past the cycle target moisture

level while in Cycle Programming.

With Display Moisture Sensor Error option enabled,

the control will allow the Moisture Sensor Error to be

displayed in the event that one occurs. Press the

and keypads to move the highlighted box. Press

the or keypad to change selections.

Press the or keypad to jump to the Save

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Changes Menu. Use or to move

highlighted box to “Yes ” or “No”.

Press the keypad to return to Global Setup

Menu. If no changes were made, press or

keypad to return to Global Setup Menu.

70444801

Factory Defaults Menu

Factory Defaults

Temperatures

Only

Restore All Cycles and Global

Settings to Factory Defaults

Audio Only

Banners Only

All Additional

Global Settings

! WARNING !

Restore all cycles and global

settings to factory defaults?

Ye sNo

Factory Defaults

TMB1323R

Figure 39

The Factory Defaults Menu is used to set parameters

in the software back to the factory default. Several

parameters can be set individually back to the factory

settings and all Cycles and Global settings can be

restored. The individual parameters that can be set

back to the factory settings are the Audio settings,

Temperature settings, Banners, and additional Global

settings.

Press the directional keys to navigate through the

screen. Press the keypad to make a selection. A

confirmation screen appears asking if you are sure you

want to restore the settings. Use or to

move highlighted box to “Yes” or “No”. “No” is

selected by default. Press the keypad to return to

Global Setup Menu. If no changes were made, press

the or keypad to return to Global Setup

Menu.

Global Setup

PHM1054R

Figure 40

The Factory Defaults Second Confirmation Menu is to

ensure that the factory defaults do not get accidentally

reset. Press the keypad to abort and the display

will then show the Factory Defaults Menu.

Once the keypad is pressed in any Confirmation

Screen, the Save Changes Menu displays to confirm

the programming changes. Use or to

move highlighted box to “Yes ” or “No”. Press

the keypad to return to Global Setup Menu.

The All Additional Global Settings Menu is used to

restore the global settings to the factory defaults.

The Reset All Factory Defaults Confirmation Menu is

used to confirm that the global programming

parameters and Cycle #1-41 are to be set back to

factory defaults. If “Yes” is selected the display will

jump to the Factory Defaults Second Confirmation

Menu.

70444801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Diagnostics

Machine ID

Test

Diagnostic Menu

Alarms

Test Cycle

Test Menu

Inputs and

Outputs

Diagnostics Are Disabled

Test Cycle

Outputs:

Intputs:

RPM:0Temp:90 F

Step04: Temp Index - 50, 75 -170 (12)

Moisture:1%

PRESS

DM FM FW RV HT EA IR

DR LD AFS FCRS FCLS CL SL1 SL2 IL

RS DIP1 DIP2 DIP3 DIP4 DIP5 DIP6 DIP7 DIP8

Diagnostic Menu

TMB1325R

Figure 41

The Diagnostic Menu contains Test, Alarm and

Machine ID Menus. The menus contain specific

diagnostic information and manufacturing data for the

machine. The , , and keypads

position the highlighted box. Press the keypad to

select the menu choice.

The Test Menu provides features for manufacturing

and customer service testing. The highlighted box is

moved horizontally and vertically using the

and keypads. Press the

keypad to select the menu choice.

Press the keypad to return to Diagnostic Menu.

The screen will display “Diagnostics Are Disabled” if

the manual diagnostics have been programmed off.

Diagnostic test commands via PDA and network will

still function.

Test Cycle Menu

The Test Cycle Menu is used to run several test steps

as well as a ten-minute cycle. Step 01 keypad test

requires the user to press each keypad. Step 02 Door

Status shows whether the loading and lint doors are

open or closed. Press any key to advance. Step 03

Screen Test shows four screens that test the LCD

screen. Press any key to advance through each of the

four test steps.

The Test Cycle Menu for Test Steps 4-13 is shown in

Figure 43.

Press the keypad while in the Diagnostic Menu

to return to System Menu.

Test Menu

32

Figure 42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TMB1326R

TMB1424R

Figure 43

It is similar to the Inputs/Outputs Menu except that the

test step is shown at the bottom of the display and a

key press prompt message is shown in the lower right

corner. Press to advance through the steps. Refer

to Tab le 3 for more details of each step. Press to

terminate the test.

70444801

Test Cycle Chart

Diagnostics

STEP Test Cycle Step

Keypad Test Step “Press Each Key To Advance” Advance after all keypads

1

Loading and Lint Door

2

Test Step

Display Test Step “Press Any Key To Advance

3

Display Test Step #1 Screen is blank Press any keypad.

Display Test Step #2 Horizontal Bars Press any keypad.

Display Test Step #3 Horizontal Bars (inverted) Press any keypad.

Display Test Step #4 Screen is black Press any keypad.

Machine Temperature

4

Index Display Test

Machine Capacity Capacity size of machine Press

5

Heat Source Type of heat machine is

6

Reversing Motor Present Will show if machine is

7

Rotation Sensor Present Will show if machine is

8

Moisture Sensor Present Will show if machine is

9

Moisture Sensor Test #1 Runs test for short in moisture

10

Moisture Sensor Test #2 Runs test for resistance to

11

Ten Minute Cycle Runs a ten-minute normal

12

Audio Signal Test Audio signal sounds for five

13

Display

Description

“Door Status” Press any keypad.

Through Screen Test”

Temperature index harness

value

STEP ADVANCE COMMENTS

are pressed.

Press any keypad.

Press

keypad.

keypad. DIP switch status will be

Press

configured for

Press

equipped for reversing

Press

equipped for rotation sensor

Press

equipped for moisture sensor

Press any keypad. Press

sensor circuit

Press any keypad. Press

expected moisture level

Press

cycle

Automatically

seconds

keypad. DIP switch status will be

keypad. DIP switch status will be

keypad. DIP switch status will be

keypad. DIP switch status will be

keypad. Any errors encountered are

shown.

shown.

shown.

shown.

shown.

to restart test.

This step will be skipped

if machine is not

equipped for moisture

sensor.

to restart test.

This step will be skipped

if machine is not

equipped for moisture

sensor.

displayed.

70444801

Tab le 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Diagnostics

Inputs Outputs

Outputs:

Intputs:

RPM:25 Moisture:30%

DM FM FW RV HT EA IR

DR LD AFS FCRS FCLS CL SL1 SL2 IL

RS DIP1 DIP2 DIP3 DIP4 DIP5 DIP6 DIP7 DIP8

30:29

Temp:180 F

Inputs Outputs Menu

TMB1425R

Figure 44

When the Inputs Outputs Menu is accessed through

the Diagnostic Menu, the user can manually turn on

outputs. The user can scroll through the outputs using

any of the arrow keys, the cursor is indicated by

flashing the active output on the screen. The user must

“setup” the outputs to be turned on. The keypad

is used to select individual outputs to be turned on or

off. After the keypad is pressed the control will

turn the selected outputs on and display the text

“RUNNING”. The outputs cannot be selected until

the keypad is pressed. The text “RUNNING” is

no longer displayed. The screen will still show the

selected outputs on the screen and the user can again

select outputs to be turned on or off. If the or

keypad is pressed at any time during this test,

the control will turn off all outputs if the test is running

or return to the previous screen if the test is not

running.

If the Inputs Outputs Menu is accessed through the

Run Diagnostic Menu (pressing the keypad

during a running cycle) the menu shows only what is

turned on and off as the cycle runs. Refer to Figure 44.

Abbreviations for the Inputs and Outputs are defined

in the following table:

Inputs

DR Loading Door

LD Lint Door

AFS Airflow Switch

FCRS Fan Motor Contactor Switch

FCLS Fan Motor Centrifugal Switch

CL Cabinet High Limit

SL1 Store 1 High Limit

SL2 Store 2 High Limit

IL Ignition Lockout

RS Rotation Sensor

DIP1 Dip Switch 1

DIP2 Dip Switch 2

DIP3 Dip Switch 3

DIP4 Dip Switch 4

DIP5 Dip Switch 5

DIP6 Dip Switch 6

DIP7 Dip Switch 7

DIP8 Dip Switch 8

Temp Te mperatur e

RPM Rotations per Minute

Moisture Moisture Level

Outputs

DM Damper Motor

FM Fan Motor

FW Forward Contactor

RV Reverse Contactor

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

HT Heater

EA External Alarm

IR Ignition Reset

Ta bl e 4

70444801

Diagnostics

Alarms (1 of 3)

ALARM COUNTS

C01: S02 Cabinet High Limit 12/05 03:34

C02: S05 Heat 11/29 15:55

C38: S01 Fan Motor Contactor 08/14 07:27

C07: S04 Open Thermistor 06/28 18:24

C01: Scd Open Thermistor 04/08 08:05

Alarms (2 of 3)

ALARM COUNTS

Air Flow Switch 1 Count: 0

Air Flow Switch 2 Count: 0

Air Flow Switch Bounce Count: 0

Cabinet High Limit Count: 1

Stove 1 High Limit Count: 0

Stove 2 High Limit Count: 0

Open Thermistor Count: 2

Short Thermistor Count: 0

Alarms (3 of 3)

ALARM COUNTS

Fan Motor Contactor Count: 1

Fan Motor Centrifugal Sw Count: 0

ICM Lockout Alarm Count: 1

Heat Count: 1

Rotation Count: 0

Moisture Sensor Count:

IR Count: 5

0

Network Count: 18

Machine ID

Model: UT030NUOG2K0W01

Serial #: 1107002759

Install Date: 07/01/2011

Machine Type: 30

Control SN: 11410113

Front End SW: 1

Display SW: 1

Node Number: 250

Alarms Menus

Figure 45

TMB1400R

The Alarms Menu contains three screens of

information. On the first screen, Alarms (1 of 3), the

eight most recent alarms will contain Cycle Number,

Segment Number, Alarm Type, and the Date/Time of

the Alarm.

The second screen, Alarms (2 of 3), alarm counts list 1

through 8. Alarm counts consist of how many times a

specific alarm has occurred.

The third screen, Alarms (3 of 3), is a continuation of

the alarm counts 9 through 16.

Press the or keypad to navigate to the

different screens in the Alarms Menu. Press the

keypad to go from screen 1 to screen 3. The actual

menus are informational only and cannot be navigated.

Press the keypad to return to display to

Diagnostic Menu or the Run Diagnostic Menu.

Machine ID Menu

Figure 46

70444801

Figure 47

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT