Page 1

Washer-Extractors

CAR4C_SVG

Twin Tub

UM202

Design 3 Models

Installation/Operation/Maintenance

Original Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

F8221501ENR3

September 2014

Page 2

Page 3

Table of Contents

Introduction........................................................................................... 5

Model Identification........................................................................................5

Serial Plate Location....................................................................................... 5

Replacement Parts ......................................................................................... 5

Customer Service............................................................................................5

Model Number Familiarization Guide...............................................................5

Safety Information..................................................................................7

Explanation of Safety Messages....................................................................... 7

Important Safety Instructions........................................................................... 7

Safety Decals................................................................................................. 8

Operator Safety.............................................................................................. 8

Specifications and Dimensions.............................................................. 10

Specifications and Dimensions.......................................................................10

Installation........................................................................................... 14

Dimensional Clearances................................................................................ 14

Machine Foundation......................................................................................14

Machine Anchoring.......................................................................................14

Shipping Block and String Removal............................................................... 14

Electrical Installation.....................................................................................14

Input Voltage Requirements....................................................................... 15

Connection Specifications.......................................................................... 15

Grounding................................................................................................ 15

Phase Adder..............................................................................................15

Thermal Overload Protector....................................................................... 15

Circuit Breakers........................................................................................ 15

Drain Connection..........................................................................................16

Water Connection......................................................................................... 17

Control Function Test ...................................................................................18

Operation............................................................................................. 19

Control Panel................................................................................................19

Operating Instructions................................................................................... 19

Maintenance......................................................................................... 22

Maintenance.................................................................................................22

Daily........................................................................................................... 22

©

Copyright 2014, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 3

Page 4

Weekly........................................................................................................ 22

Monthly....................................................................................................... 22

Care of Stainless Steel...................................................................................22

Disposal of Unit.................................................................................... 24

4

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 5

Introduction

CAR19N_SVG

1

Introduction

Model Identification

Information in this manual is applicable to this model:

UM202*

* This manual applies to models with U3 in the 9th and 10th positions in the model number [e.g. UM202M1O U30001].

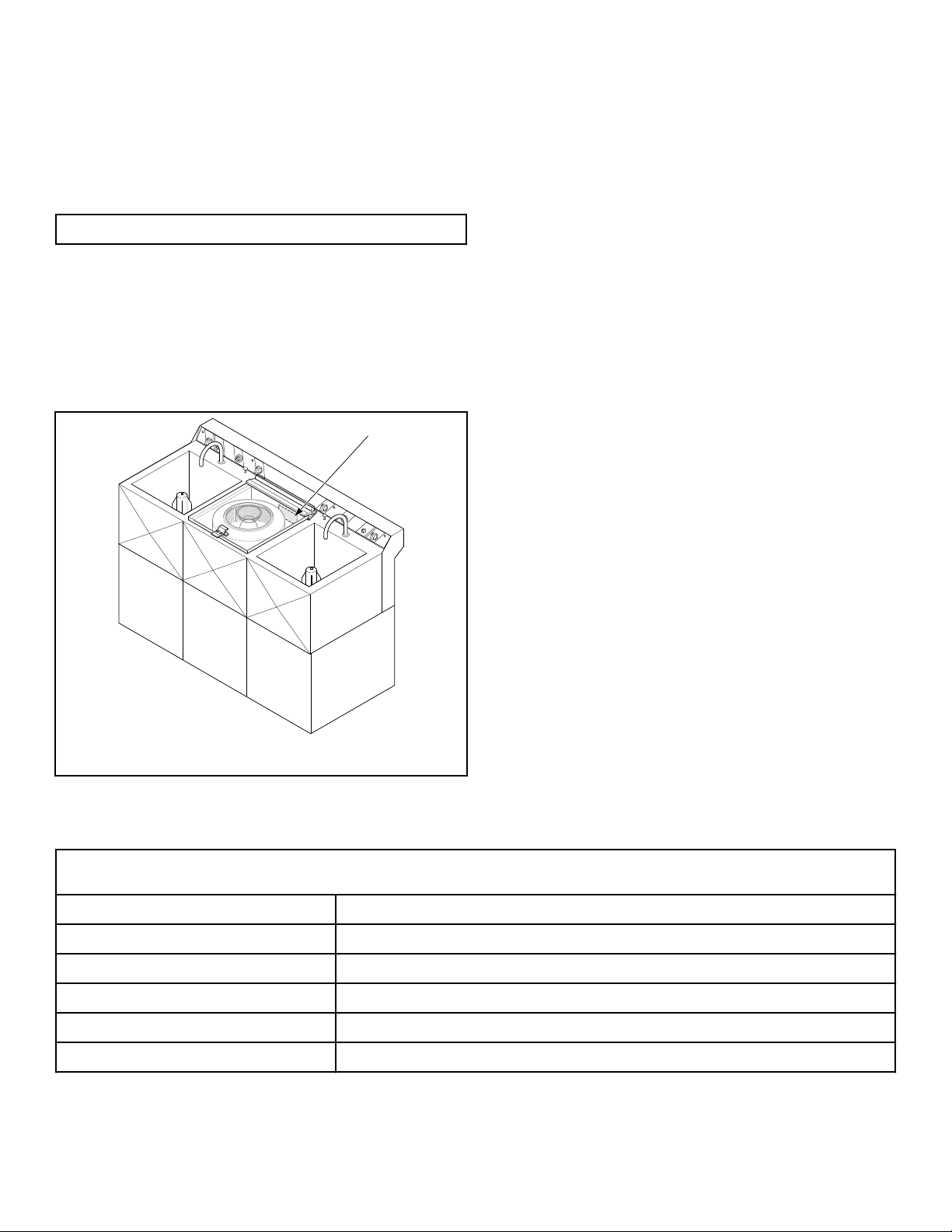

Serial Plate Location

The serial plate decal is located at the rear of the machine. Always provide the machine’s serial number and model number

when ordering parts or when seeking technical assistance.

Replacement Parts

If literature or replacement parts are required, contact the source

from which the machine was purchased or contact Alliance Laundry Systems at +1 (920) 748-3950 for the name and address of

the nearest authorized parts distributor.

Customer Service

For technical assistance, contact your local distributor or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

Alliance International: +32 56 41 20 54 Wevelgem, Belgium

1. Serial Plate

Figure 1

Model Number Familiarization Guide

Sample Model Number: UM202M1OU30001

UM Model Number Prefix

202 Washer-Extractor

M Type of Electrical Control

1 Washer-Extractor Speed Capability [1 = 1 speed]

O Electrical Characteristics

U3 Design Series

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 5

Page 6

MAX LOAD:

MODE L NO:

CAR18N_SVG

UM202M1OU30001

XXXXXXXXX

208 – 240

FLA:

24 lbs 11 kg

SERI AL NO:

VO LTAGE:

NUMBER OF WIRES:

amps

CIRCUIT BREAKER SIZE: amps

SCHEM ATIC:

SUP P LY WATER:

60

3

HZ:

30 – 85

psi, 2 – 5.7 bar

PHASE:

R ip on , W I 54 971 U .S .A .

Introduction

Sample Model Number: UM202M1OU30001

0001 Option Identification [varies from machine to machine]

Table 1

Example of Serial Plate

Figure 2

6

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 7

Safety Information

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,” and

“CAUTION”), followed by specific instructions, are found in this

manual and on machine decals. These precautions are intended

for the personal safety of the operator, user, servicer, and those

maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if

not avoided, will cause severe personal injury or

death.

WARNING

Indicates a hazardous situation that, if not avoided,

could cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided,

may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and

“NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specific procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is important but not hazard related.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your washer,

follow these basic precautions:

W023

• Read all instructions before using the washer.

• Install the washer according the INSTALLATION instructions. Refer to the GROUNDING instructions in the INSTALLATION manual for the proper grounding of the washer. All connections for water, drain, electrical power and

grounding must comply with local codes and be made by licensed personnel when required. It is recommended that the

machine be installed by qualified technicians.

• Do not install or store the washer where it will be exposed to

water and/or weather.

• To prevent fire and explosion, keep the area around machine

free from flammable and combustible products. Do not add

the following substances or textiles containing traces of the

following substances to the wash water: gasoline, kerosene,

waxes, cooking oils, vegetable oils, machine oils, dry-cleaning solvents, flammable chemicals, thinners, or other flammable or explosive substances. These substances give off vapors

that could ignite, explode or cause the fabric to catch fire by

itself.

• Under certain conditions, hydrogen gas may be produced in a

hot water system that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using a

washing machine or combination washer-dryer, turn on all hot

water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. The

gas is flammable, do not smoke or use an open flame during

this time.

• To reduce the risk of an electric shock or fire, DO NOT use

an extension cord or an adapter to connect the washer to the

electrical power source.

• Do not allow children to play on or in the washer. Close supervision of children is necessary when the washer is used

near children. This appliance is not intended for use by young

children or infirm persons without supervision. Young children should be supervised to ensure that they do not play with

the appliance. This is a safety rule for all appliances.

• DO NOT reach and/or climb into the tub or onto the washer,

ESPECIALLY if the wash drum is moving. This is an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

• Never operate the washer with any guards, panels and/or parts

removed or broken. DO NOT bypass any safety devices or

tamper with the controls.

• Use washer only for its intended purpose, washing textiles.

Never wash machine parts or automotive parts in the machine. This could result in serious damage to the basket or

tub.

• Use only low-sudsing, no-foaming types of commercial detergent. Be aware that hazardous chemicals may be present.

Wear hand and eye protection when adding detergents and

chemicals. Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Heed all

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 7

Page 8

Safety Information

warnings or precautions. To reduce the risk of poisoning or

chemical burns, keep them out of the reach of children at all

times [preferably in a locked cabinet].

• Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener

or product.

• Always follow the fabric care instructions supplied by the textile manufacturer.

• The lid MUST BE CLOSED any time the washer is to spin.

DO NOT bypass the lid release button by permitting the

washer to operate with the lid open. Do not attempt to open

the lid until the extract compartment has drained and all moving parts have stopped.

• Be aware that hot water is used to flush the supply dispenser,

if applicable. Avoid opening the dispenser lid while the machine is running.

• Do not attach anything to the supply dispenser’s nozzles, if

applicable. The air gap must be maintained.

• Do not operate the machine without the water reuse plug or

water reuse system in place, if applicable.

• Be sure water connections have a shut-off valve and that fill

hose connections are tight. CLOSE the shut-off valves at the

end of each wash day.

• Keep washer in good condition. Bumping or dropping the

washer can damage safety features. If this occurs, have washer checked by a qualified service person.

• DANGER: Before inspecting or servicing machine, power

supply must be turned OFF. The servicer needs to wait for at

least 5 minutes after turning the power OFF and needs to

check for residual voltage with a voltage meter. The inverter

capacitor or EMC filter remains charged with high voltage for

some time after powering OFF. This is an imminently hazardous situation that, if not avoided, will cause severe personal

injury or death.

• Do not repair or replace any part of the washer, or attempt any

servicing unless specifically recommended in the user-maintenance instructions or in published user-repair instructions

that the user understands and has the skills to carry out. ALWAYS disconnect the washer from electrical, power and water supplies before attempting any service.

• Disconnect the power by turning off the circuit breaker or by

unplugging the machine. Replace worn power cords.

• Before the washer is removed from service or discarded, remove the lid to the washing compartment.

• Failure to install, maintain, and/or operate this washer according to the manufacturer’s instructions may result in conditions

which can produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Common sense, caution and care must be exercised when installing, maintaining, or operating the

washer.

Any problems or conditions not understood should be reported to

the dealer, distributor, service agent or the manufacturer.

WARNING

Machine installations must comply with minimum

specifications and requirements stated in the applicable Installation Manual, any applicable municipal

building codes, water supply requirements, electrical

wiring regulations and any other relevant statutory

regulations. Due to varied requirements and applicable local codes, this machine must be installed, adjusted, and serviced by qualified maintenance personnel familiar with applicable local codes and the

construction and operation of this type of machinery. They must also be familiar with the potential

hazards involved. Failure to observe this warning

may result in personal injury, property damage,

and/or equipment damage, and will void the warranty.

W820

WARNING

Install the machine on a level floor of sufficient

strength. Failure to do so may result in conditions

which can produce serious injury, death and/or property damage.

W703

Safety Decals

Safety decals appear at crucial locations on the machine. Failure

to maintain legible safety decals could result in injury to the operator or service technician.

Use manufacturer-authorized spare parts to avoid safety hazards.

Operator Safety

WARNING

NEVER insert hands or objects into the wash or extract compartments until it has completely stopped.

Doing so could result in serious injury.

SW725

1. Verify that all warning signs are present and legible. Replace

as necessary.

2. Check lid lock and interlock before starting operation of the

machine:

8

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 9

a. Attempt to start the machine with the lid open. The ma-

chine should not start.

b. Close the lid without locking it and attempt to start the

machine. The machine should not start.

c. Close and lock the lid and start a cycle. Attempt to open

the lid. The lid should not open.

If the lid lock and interlock are not functioning properly, call a

service technician.

3. Do not attempt to operate the machine if any of the following

conditions are present:

a. The lid does not remain securely locked during the entire

cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly grounded circuit.

Do not bypass any safety devices in the machine.

Safety Information

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 9

Page 10

Specifications and Dimensions

Specifications and Dimensions

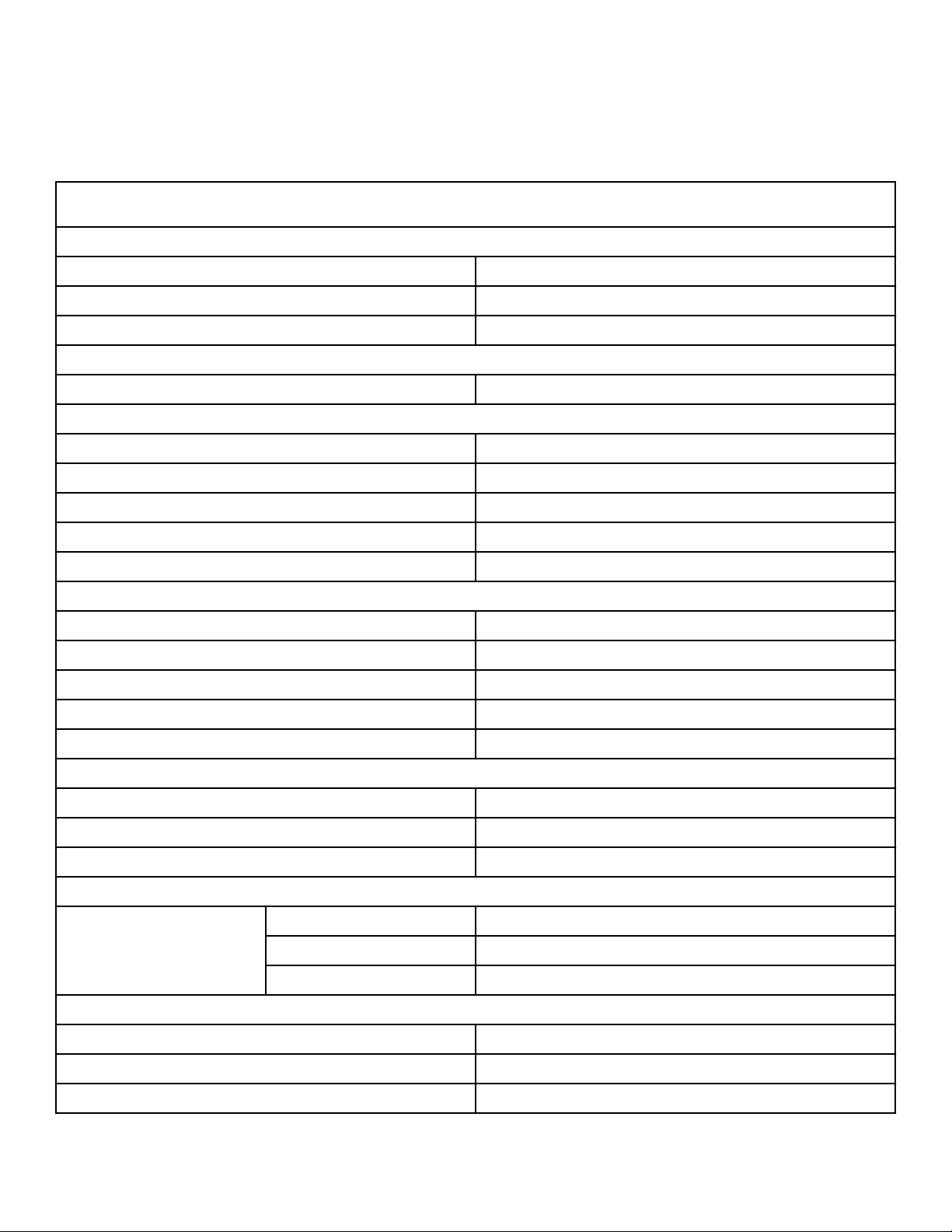

Specification

Overall Dimensions

Overall width, in. [mm] 60 [1524]

Overall depth, in. [mm] 29.5 [749]

Overall height, in. [mm] 40 [1016]

Weight & Shipping Information

Net weight, lb. [kg] 475 [215]

Wash Compartment Information

Width, in. [mm] 20.25 [514]

Length, in. [mm] 22.25 [565]

Depth, in. [mm] 11.75 [298]

Specifications and Dimensions

Volume, cu. ft. [liter] 2.74 [77.6]

Dry weight capacity, lb. [kg] 12 [5.45]

Extractor Basket Information

Basket volume, cu. ft. [liter] 1.09 [30.9]

Basket diameter, in. [mm] 16.06 [409]

Basket depth, in. [mm] 9.25 [235]

Basket dry weight capacity, lb. [kg] 12 [5.45]

Perforation open area, % 1.5

Drive Train Information

Number of motors in drive train 3

Wash motor power, hp [kW] 2 x 0.50 [0.38]

Extract motor power, hp [kW] 1 x 1.0 [0.75]

Water Consumption

Average water consumption

per agitation cycle, gallons [liters]

Low 14 [53]

Medium 17 [64]

High 21 [80]

Drain Information

Drain connection size, in. [mm] 2 [50]

Number of drain outlets 1

Drain flow capacity, gallons [liters] per min. 27 [101]

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 10

Page 11

Specification

Recommended drain pit size, cu. ft. [liters] 7.7 [219]

Water Supply Information

Water inlet connection size, in. [mm] .75NH [G.75]

Number of water inlets [1 hot, 1 cold] 2

Inlet flow capacity, gallons [liters] per min. 21 [79]

Operating Speeds

Specifications and Dimensions

Wash agitator speed, reversals per minute [Input frequency: 60

60/50

Hz/50 Hz]

Power Consumption

Average power consumption per cycle, kW-hr 0.25

Average HVAC load, Btu/hr [kcal/hr] 200 [51]

Centrifugal Force Data

Extract centrifugal force, G’s 208-240 V, 60 Hz 690

220-240 V, 50 Hz 496

Table 2

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 11

Page 12

CAR20N_SVG

G

H

F

E

3

2

1

4

D

C

B

A

A

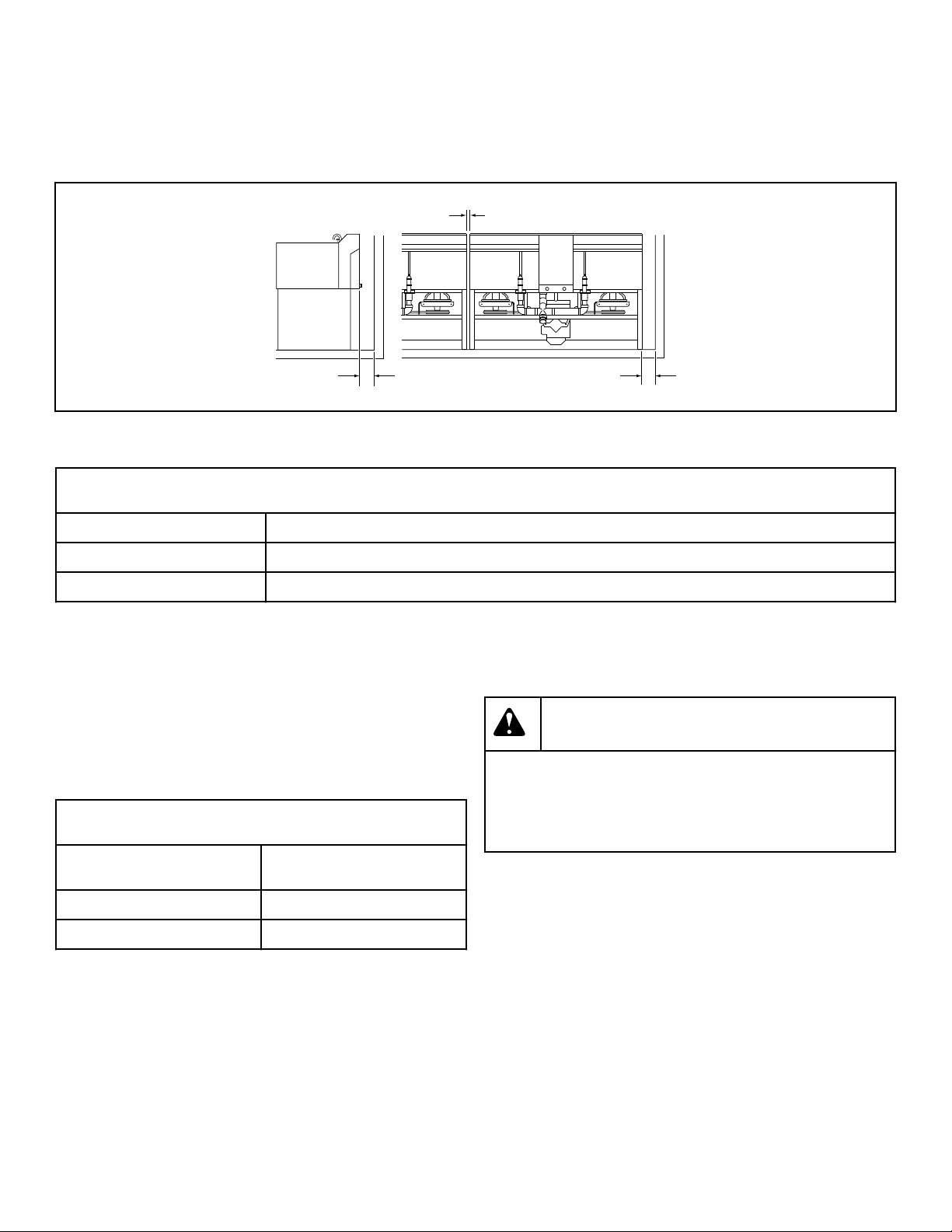

Specifications and Dimensions

Machine Capacity Dimensions

1. Faucet

2. Agitator

3. Extractor Basket

4. Control Panel

Machine Capacity Dimensions [Refer to Figure 3 ]

A 60 in. [1524 mm]

B 11.75 in. [298 mm]

C 18.38 in. [467 mm]

D 17 in. [432 mm]

E 16.5 in. [419 mm]

F 29.5 in. [749 mm]

G 21.5 in. [546 mm]

H 40.5 in. [1029 mm]

Figure 3

Table 3

12

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 13

Plumbing Dimensions

CAR21N_SVG

P

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

5

4

4

4

3

2

1

1

1

1. Drain Outlet

2. Hot Water Inlet

3. Cold Water Inlet

4. Electrical Connection

5. Overflow Level

Specifications and Dimensions

Figure 4

Plumbing Dimensions [Refer to Figure 4 ]

A 40 in. [1016 mm]

B 33.47 in. [852 mm]

C 26.47 in. [675 mm]

D 34.5 in. [876 mm]

E 60 in. [1524 mm]

F 9.75 in. [248 mm]

G 21 in. [533 mm]

H 33.5 in. [851 mm]

I 6.75 in. [171 mm]

J 1.13 in. [29 mm]

K 3.88 in. [98 mm]

L 29.5 in. [749 mm]

M 6.75 in. [171 mm]

N 6.75 in. [171 mm]

O 3.88 in. [98 mm]

P 1.75 in. [44 mm]

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 13

Table 4

Page 14

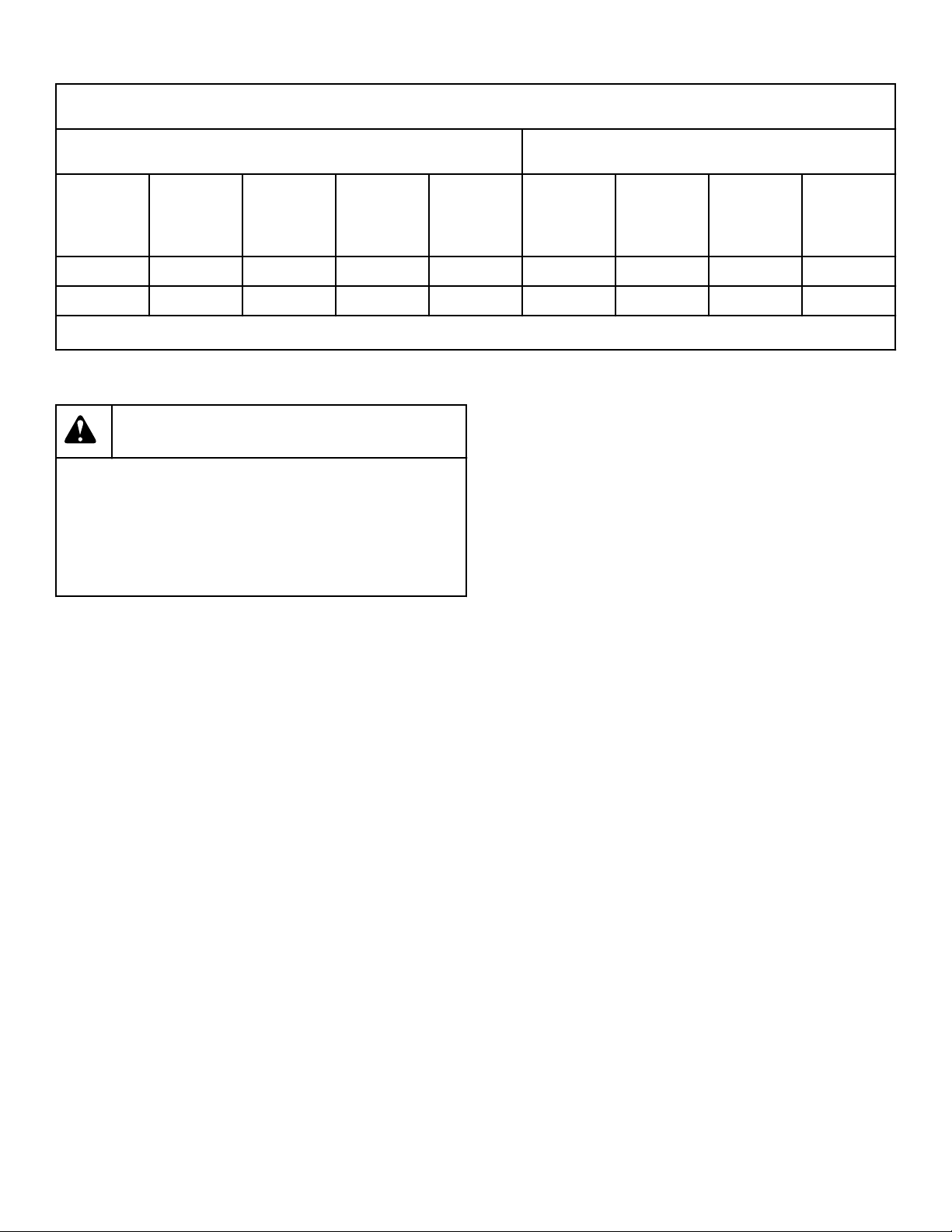

Dimensional Clearances

CAR22N_SVG

C

B

A

Dimensional Clearances

Installation

Installation

Figure 5

Dimensional Clearances [Refer to Figure 5 ]

A 6 in. [152 mm]

B .5 in. [13 mm]

C 6 in. [152 mm]

Machine Foundation

The machine may be placed on any level floor as long as floor

will hold the weight of the machine.

Position the machine and level with shims or grout under the corners.

Floor Load Data

Specification

Static floor load 840 lbs. [3.7 kN]

Static pressure 68 lbs-ft2 [3.3 kN-m2]

Table 6

Table 5

Shipping Block and String Removal

WARNING

To avoid severe personal injury and machine damage, remove the shipping block and shipping string

before connecting power to the machine.

W754

The shipping string is provided to open lid before power is connected to machine. Operating machine with shipping string installed will prevent the wash basket from stopping when lid is

open.

To open lid before power is connected, pull the shipping string to

the left and hold, then lift lid open.

Machine Anchoring

Bolting to floor is optional. To bolt down the machine, use 3/8

inch bolt holes located on the frame at the bottom of each corner.

One quarter inch machine anchors should be used.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 14

IMPORTANT: If machine is operated with shipping

block in place, damage to machine, tub and drive motor may result. To avoid damage to machine, remove

shipping block before operation.

Electrical Installation

Page 15

Installation

Input Voltage Requirements

WARNING

Turn off power and water before attempting any

maintenance, repairs, or service, or before opening

any service panel or door.

W532

Electrical Specifications

Voltage Cycle Phase Wire

208-240 60 Hz 3 3

220-240 50 Hz 3 3

NOTE: The control voltage is 24 V for all systems.

Table 7

If a delta supply system is used, the high leg must be connected

to the L3 lead at the J-box.

Electrical connections are made at the rear of the machine. The

machine must be connected to the proper electrical supply shown

on the identification plate attached to the rear of the machine, using copper conductors only.

IMPORTANT: Alliance Laundry Systems warranty does

not cover components that fail as a result of improper

input voltage.

Make sure the correct transformer jumper [208 Volt or 240 Volt]

is in place. Refer to the “optional” Electrical Service Connection

label located on the back of the machine near the electrical service input for machine electrical requirements.

Grounding

For personal safety and proper operation, the machine must be

grounded in accordance with local codes. The ground connection

must be to a proven earth ground at the location service panel

and/or to a grounded metal cold water pipe.

Use wire size indicated in Electrical Specifications table for runs

up to 50 feet. Use next larger size for runs of 50 – 100 feet. Use

TWO sizes larger for runs greater than 100 feet. This protects

against voltage drop which would result in a reduction of starting

torque.

Connection Specifications

IMPORTANT: Connection must be made by a qualified

electrician using wiring diagram provided with machine. Use liquid-tight conduit and copper connectors.

IMPORTANT: Electrical ratings are subject to change.

Refer to serial decal for electrical ratings information

specific to your machine.

WARNING

Dangerous voltages are present inside the machine.

Only qualified personnel should attempt adjustments

and troubleshooting. Disconnect power from the machine before removing any cover and guards, and

before attempting any service procedures.

W736

WARNING

Hazardous Voltage. Can cause shock, burn or death.

Verify that a ground wire from a proven earth ground

is connected to the lug near the input power block

on this machine.

Phase Adder

If three-phase service is not available and a Roto-Phase or other

phase adder is used, the artificial leg must be connected to the

L3A lead.

Thermal Overload Protector

Machine has thermal overload protectors in each drive motor

windings and a separate fuse for control circuit.

Circuit Breakers

Three-phase machines require a separate, three-phase inversetime circuit breaker to prevent damage to the motors by disconnecting all legs if one should be lost accidentally.

IMPORTANT: The machine should be connected to an

individual branch circuit not shared with lighting or

other equipment.

F8221501ENR3

W360

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 15

Page 16

Installation

Electrical Specifications

Voltage Designation Standard

Full

Load

Code Voltage Cycle Phase Wire

Amps Breaker AWG mm2

D 220-240 50 3 3 7 15 14 2.5

O 208-240 60 3 3 7 15 14 2.5

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per National Electric Code, article 310.

Table 8

WARNING

Ensure that a ground wire from a proven earth

ground is connected to the ground lug near the input

power block on this machine. Without proper

grounding, personal injury from electric shock could

occur and machine malfunctions may be evident.

SW008

IMPORTANT: Installation shall conform with local codes or, in absence of local codes, with the National

Electric Code ANSI/NFPA No. 70. Overloaded or undersized lines, or any low voltage condition will burn out

motors and solenoid windings.

Drain Connection

A flexible connection must be made to a vented drain system to

prevent damage to rigid drain pipes. Drain should be vented to

ensure proper flow and prevent siphoning. If proper drain size is

not available or practical, a surge tank is required. A surge tank

along with a sump pump should be used when gravity drainage is

not possible.

16

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 17

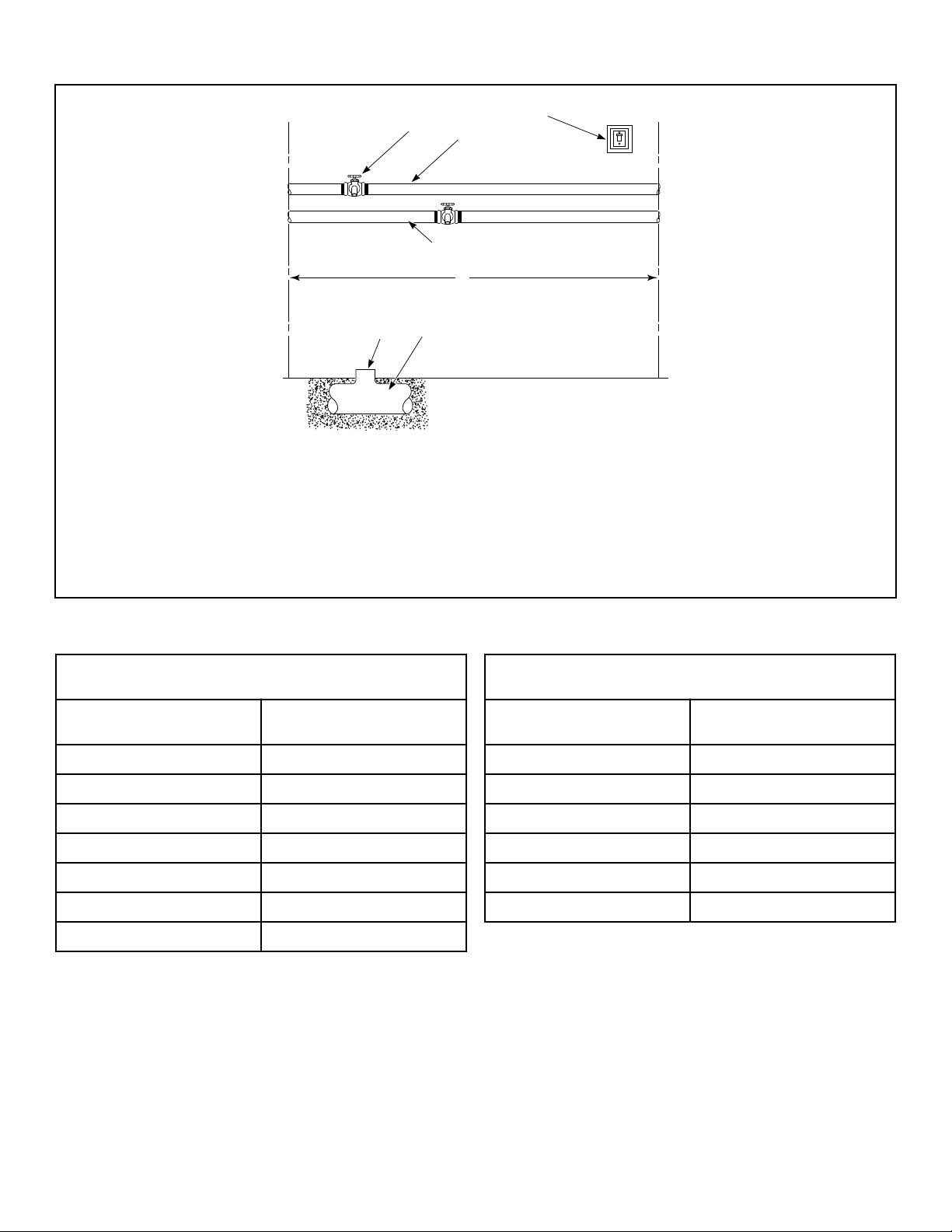

Rear View of Wall

CAR26N_SVG

7

6

5

4

3

2

1

1. 15 Amp – Three-Phase Circuit Breaker

2. 0.75 in. [19 mm] Water Outlet

3. 0.75 in. [19 mm] min. Cold Water Supply Line

4. 0.75 in. [19 mm] min. Hot Water Supply Line

5. 60 in. [152 mm] Required

6. 2 in. [51 mm] min. Waste Line Tee

7. 4 in. [102 mm] min. Waste Line

Installation

Drain Line Sizing / Minimum Drain ID

Number of Machines Drain Line Size

1 2 in. [51 mm]

2 3 in. [76 mm]

3 4 in. [102 mm]

4 4 in. [102 mm]

5 4 in. [102 mm]

6 4 in. [102 mm]

7 – 10 6 in. [152 mm]

Table 9

Water Connection

Connections should be supplied by a hot and a cold water line of

at least the sizes shown in the Water Supply Line Sizing table.

Refer to Table 10 .

Figure 6

Water Supply Line Sizing

Number of Machines Drain Line Size

1 0.75 in. [19 mm]

2 1 in. [25 mm]

3 1.25 in. [32 mm]

4 1.5 in. [38 mm]

5 1.5 in. [38 mm]

6 – 10 2 in. [51 mm]

Table 10

To connect water service to machine with rubber hoses, use the

following procedure:

1. Before installing hoses, flush the water system for at least two

minutes.

2. Check filters in the machine’s inlet hoses for proper fit and

cleanliness before connecting.

3. Hang hoses in a large loop; do not allow them to kink.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 17

Page 18

Y041_SVG

2

1

Y042I_SVG

2

1

Installation

If additional hose lengths are needed, use flexible hoses with

screen filters.

WARNING

To prevent personal injury, avoid contact with inlet

water temperatures higher than 125° Fahrenheit [51°

Celsius] and hot surfaces.

W748

Install vacuum breakers and check valves when required by local

codes.

1. 0.75 in. [19 mm] Cold and Hot Water Supply Line

2. 0.5 in. [13 mm] Faucet Lines

1. Check the power supply for correct voltage, phase, and cycles

to be sure they are correct for the machine.

2. Open manual shut-off valves to the machine.

3. Turn on electric power.

4. Check the lid interlock before starting operation:

a. Turn extract timer dial clockwise to the two minute mark,

remain for five seconds, and return dial to “off” position.

b. Once rotation has stopped press the lid release button and

open the lid to the extract-rinse compartment.

c. Attempt to start the machine with the lid open. The ma-

chine should not start.

d. Close the lid without locking it and attempt to start the

machine. The machine should not start.

e. Close and lock the lid and start a cycle. Attempt to open

the lid.

If the lid lock and interlock are not functioning properly, call a

service technician.

5. Run a complete cycle, checking operation of water inlet

valves, drain, and extract functions.

6. Check that basket rotation is clockwise in the extract step. If

rotation is not clockwise, disconnect power and have a qualified electrician reverse lines L1 and L2 at power input block.

Figure 7

Install a screen filter in each hose to keep rust and other foreign

particles out of the solenoid valves.

Suitable air cushions should be installed in supply lines to prevent “hammering” Refer to Figure 8 .

1. Water Supply Faucets

2. Risers [Air Cushions]

Figure 8

Control Function Test

The machine should be cleaned after the installation is complete.

A function test should then be executed on the unloaded machine:

18

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

Page 19

Operation

CAR23N_SVG

CAR12N_SVG

Control Panel

Figure 9 shows the control panel for both standard and car wash

top-loading machines.

Operation

The RUN indicator light indicates a wash cycle is in progress.

The WASH timer can be set to up to 15 minutes for wash cycle

times. Machine will start automatically after timer is set. Agitation will begin when selected water level is reached.

The LID LOCK indicator light indicates when the lid is properly closed when the extract-rinse compartment is rotating.

After extract-rinse basket stops spinning, pressing the LID RE-

LEASE button unlocks the extract-rinse compartment’s lid.

The EXTRACT and RINSE timers allow operator to set the

amount of time for extract and rinse cycles. Machine will start

automatically after timers are set. The rinse will begin 30 seconds

after basket begins to spin.

Operating Instructions

1. Turn on the main power source [circuit breaker].

2. Close drain of wash compartment to be used. Refer to Figure

10 .

Figure 9

Figure 10

3. Select desired temperature and water level.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 19

Page 20

CAR13N_SVG

CAR14N_SVG

CAR24N_SVG

1

Operation

1.

Drain

Figure 13

Figure 11

4. Add detergent and bleach, if desired, to water. Use ONLY liquid bleach.

5. Set wash timer for 30 seconds to begin filling tub and allow

detergent/bleach to mix.

6. Place washables in compartment. Distribute evenly around

agitator. Refer to Figure 12 .

Recommended Cycle Times

Ex-

Items Wash

tract Rinse

Fluff-Dry Washables

Bath mats, towels,

6 min. 5 min. 3 min.

face cloths, spreads,

mop heads, rugs, athletic and camp washables

No-Iron Washables

Sheets 4 min. 4 min. 2 min.

Pillow slips 8 min. 4 min. 2 min.

Tablecloths/napkins 8 min. 4 min. 2 min.

Specialties

Blankets 5 min. 4 min. 3 min.

Drapes 5 min. 5 min. 3 min.

Uniforms 8 min. 4 min. 2 min.

Figure 12

NOTE: Place stringy items such as mop heads in a

laundry net to prevent blockage of drains.

7. Set wash timer to desired time.

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT F8221501ENR3

20

NOTE: Each compartment has a 12 pound dry

weight capacity.

Table 11

8. When cycle is finished, place washables in extract-rinse compartment. Distribute evenly around agitator. Refer to Figure

14 .

Page 21

WARNING

U145I_SVG

CAR25N_SVG

1

Operating the machine with severe out-of-balance

loads could result in personal injury and serious

equipment damage.

NOTE: Place loosely woven washables first, then

sheets, pillow slips and other closely woven articles.

Operation

W728

1. Drain

Figure 15

Figure 14

IMPORTANT: All articles must be be fully inserted

into extract-rinse compartment. During an extract,

articles partially outside extract basket may cause

machine damage.

9. Close lid, making sure lid is locked.

10. Set extract timer and rinse timer to desired cycle times. Refer

to Figure 15 .

11. When cycle is complete, wait until basket stops, then press

LID RELEASE button to open lid. Refer to Figure 15 .

12. Remove washables.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 21

Page 22

Maintenance

Maintenance

Maintenance

WARNING

Sharp edges can cause personal injury. Wear safety

glasses and gloves, use proper tools and provide

lighting when handling sheet metal parts.

W366R1

IMPORTANT: Replace all panels that are removed to

perform service and maintenance procedures. Do not

operate the machine with missing guards or with broken or missing parts. Do not bypass any safety devices.

Daily

IMPORTANT: Lid lock should be checked daily to ensure proper operation. Also check that all safety and

instruction stickers are on the machine. Replace missing or illegible safety labels.

1. Clean the machine’s main body, front and side panels with

mild detergent. Rinse with clean water.

2. Clean lid of all foreign matter.

3. Inspect and clean extract basket.

4. Leave lid open after each completed cycle to allow moisture

to evaporate.

Weekly

1. Verify that the drain system is free from obstruction.

2. Inspect water inlet valve hose connections on the back of the

machine for leaks.

Monthly

NOTE: Disconnect power to the machine at its source

before performing the monthly maintenance procedures.

1. Vacuum lint from motor vents.

2. Clean lint and debris from extract compartment’s drain.

3. Remove and clean water inlet valve and hose screen filters.

Replace if worn or damaged.

4. Wipe clean inside of wash compartment.

5. Clean all electronic boards of moisture and dust with canned

air.

6. Check basket ball to see if it needs grease. If basket does not

rock easily and does not return to level position when pushed

down on one side, add grease to top of nylon basket ball cap.

7. Check extract motor vibration pads. Pads must be replaced if

pads are worn and metal is showing.

8. Tighten transmission and extract motor mounting nuts, if necessary.

9. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace if worn or

damaged.

10. Check hoses for any visible signs of deterioration. Any hose

showing signs of cracking, blisters or material wear should be

replaced immediately. All hoses should be replaced every five

years.

11. Check if belt(s) require replacement or adjustment. Call a

qualified service technician in either case.

a. Check each belt for uneven wear and frayed edges.

b. Verify that each belt is properly aligned.

CAUTION

To help avoid personal injury, take care when doing

any maintenance or making any check or repair. Follow manufacturer’s instructions for all materials

used during service and maintenance of this machine. If used or handled improperly, they can be

hazardous. Improper or incomplete service can also

affect the machine and result in personal injury, or

damage to the machine and may void the warranty.

W357

Care of Stainless Steel

• Remove dirt and grease with detergent and water. Thoroughly

rinse and dry after washing.

• Avoid contact with dissimilar metals to prevent galvanic corrosion when salty or acidic solutions are present.

• Do not allow salty or acidic solutions to evaporate and dry on

stainless steel. Wipe clean of any residues.

• Rub in the direction of the polish lines or “grain” of the stainless steel to avoid scratch marks when using abrasive cleaners. Use stainless steel wool or soft, non-metal bristle brushes.

Do not use ordinary steel wool or steel brushes.

• If the stainless steel appears to be rusting, the source of the

rust may be an iron or steel part not made of stainless steel,

such as a nail or screw.

• Remove discoloration or heat tint from overheating by scouring with a powder or by employing special chemical solutions.

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 22

Page 23

• Do not leave sterilizing solutions on stainless steel equipment

for prolonged periods of time.

• When an external chemical supply is used, ensure no siphoning of chemicals occurs when the machine is not in use. Highly concentrated chemicals can cause severe damage to stainless steel and other components within the machine. Damage

of this kind is not covered by the manufacturer’s warranty.

Locate the pump and tubing below the machines’s injection

point to prevent siphoning of chemicals into the machine.

Maintenance

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 23

Page 24

Disposal of Unit

MIX1N_SVG

This appliance is marked according to the European directive

2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

This symbol on the product or on its packaging indicates that this

product shall not be treated as household waste. Refer to Figure

16 . Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic equipment. Ensuring this product is disposed of correctly will help prevent potential negative consequences for the environment and human

health which could otherwise be caused by inappropriate waste

handling of this product. The recycling of materials will help to

conserve natural resources. For more detailed information about

recycling of this product, please contact the local city office,

household waste disposal service, or the source from which the

product was purchased.

Disposal of Unit

Figure 16

F8221501ENR3

©

Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 24

Loading...

Loading...