TurboChef i3 Service Manual

TM

Service Manual

F O R T H E T U R B O C H E F i3TM R A P I D C O O K OV E N

© 2009-2011 TurboChef Technologies, Inc.

For further information, call 1-800-90TURBO

or

+1 214-379-6000

The information contained in this manual is important for the proper installation, use, maintenance, and repair of this oven. Follow these procedures and instructions to help ensure satisfactory baking results and years of trouble-free service.

Errors – descriptive, typographic, or pictorial – are subject to correction. Specifications are subject to change without notice.

Please carefully read this manual and retain it for future reference.

©2009-2010 TurboChef Technologies, Inc.

Table of Contents

Important Safety Instructions

General Safety Information |

i |

Reducing Fire Risk |

i |

Grounding Instructions |

ii |

Power Cord Replacement |

ii |

Precautions to be Observed Before and During Servicing to Avoid |

|

Possible Exposure to Excessive Microwave Energy |

ii |

RF Interference Considerations |

ii |

Specifications and Installation

Theory of Operation |

1 |

Certifications |

1 |

Dimensions |

1 |

Oven Construction |

1 |

Electrical Specifications |

2 |

Unpacking Instructions |

3 |

Lifting and Placing the Oven |

3 |

Installation Near Open Heat Source |

4 |

Optional Installation Items |

4 |

Voltage Selection |

4 |

Ventilation Requirements |

4 |

Daily Maintenance |

7 |

Oven Controls and Cooking |

|

Oven Controls |

9 |

Cooking |

10 |

Step 1: Turn the Oven On |

10 |

Step 2: Select Cook Temperature |

10 |

Step 3: Warming Up |

10 |

Step 4: Soaking |

11 |

Step 5: Ready to Cook or “Idle” |

11 |

Step 6: Adjusting the Time |

11 |

Step 7: Cooking |

11 |

Step 8: Remove Food from Oven |

12 |

Step 9: Additional Cooking Options |

12 |

Step 10: Cooling Down |

12 |

Info Mode |

|

Overview of the Info Mode |

13 |

Viewing Cook Counter/Time Logs |

13 |

Viewing the Fault Log |

13 |

Viewing the Service Numbers |

14 |

Options Screen |

14 |

Network Setup |

14 |

Setting the Date/Time |

14 |

Adjusting the Volume |

15 |

Setting the F2 Alarm |

15 |

Making a Copy of the Oven Menu |

15 |

Updating the Oven Menu |

15 |

Updating the Oven Firmware |

16 |

Resetting the Oven |

16 |

Test Mode - Testing Oven Parts |

16 |

Top and Bottom Blower |

16 |

Heaters |

16 |

Magnetron Test |

16 |

Stirrer |

16 |

Status Indicators |

16 |

Fault Log |

17 |

Turning Diagnostic Mode On/Off |

17 |

Manufacturing Mode |

17 |

Microwave Leakage Test |

17 |

Microwave Power Test |

17 |

Burn-In |

17 |

Serial Number Edit |

18 |

Volt On |

18 |

Changing Temperature Measurement Setting |

18 |

Self Test |

18 |

Erase/Default Oven Settings |

18 |

Edit Mode

Overview of the Edit Mode |

19 |

Changing Set Temperatures |

19 |

Changing Food Group/Item Name |

20 |

Changing Recipe Settings |

20 |

Oven Systems

Convection System |

21 |

Blower Motor (Bottom) |

21 |

Blower Motor (Top) |

21 |

Blower Motor Speed Controller (BMSC) |

21 |

Heater Elements |

21 |

Jetplate (Bottom) |

21 |

Jetplate (Top) |

21 |

Top Jetplate Insert |

21 |

Stirrer Motor and Assembly |

22 |

Convection System Troubleshooting |

22 |

Oven Door |

22 |

Removing/Reinstalling the Oven Door |

22 |

Adjusting the Oven Door |

22 |

Interlock Switches |

24 |

Adjusting the Door Switches |

24 |

Hinges and Counter-Balance Assembly |

24 |

Adjusting the Counter-Balance Assembly |

24 |

Measuring RF Leakage for Microwave Safety |

25 |

Oven Door Troubleshooting |

26 |

Microwave System |

27 |

Capacitors |

27 |

Testing a Capacitor |

27 |

Filament Transformers |

27 |

Wiring the Filament Transformers |

27 |

High-Voltage Transformers |

28 |

Wiring the High-Voltage Transformers |

28 |

Testing a Filament or High-Voltage Transformer |

28 |

High-Voltage Diodes |

28 |

Testing a High-Voltage Diode |

29 |

Magnetrons |

30 |

Testing a Magnetron for an Open/Shorted Filament |

30 |

Stirrer Motor and Assembly |

30 |

Wave Guides |

30 |

Microwave System Troubleshooting |

30 |

Control System |

31 |

Control Board |

31 |

Display |

31 |

Electrical Compartment Cooling Fans |

31 |

Electrical Compartment Cooling Fan Thermostat |

31 |

Electrical Compartment Thermocouple |

31 |

EMI Filter |

31 |

Fuses |

32 |

High-Limit Thermostat |

32 |

Keypad |

32 |

Magnetron Cooling Fan |

32 |

Magnetron Thermostats |

32 |

Power Supply |

32 |

Relay - K1 Filament |

32 |

Relay - K2 Anode |

32 |

Relay - K3 Monitor |

32 |

Relay - K6 Voltage |

33 |

Relay - K7 Magnetron Cooling Fan |

33 |

Relay - K8 Stirrer Motor |

33 |

RTD |

33 |

Smart Card Reader |

33 |

Solid State Relay - K4/K5 Heater |

33 |

Speaker |

33 |

USB Port |

34 |

Wire Harness |

34 |

Voltage Sensor |

34 |

Control System Troubleshooting |

34 |

Filtering System |

34 |

Air Filter |

34 |

Catalytic Converter |

34 |

Drain Pan |

34 |

Vent Catalyst |

34 |

Filtering System Troubleshooting |

34 |

Troubleshooting

Overview of Troubleshooting |

35 |

Fault Code Descriptions |

35 |

Fault Code Troubleshooting - F1 Blower Running Status Bad |

37 |

Fault Code Troubleshooting - F2 Cook Temperature Low |

38 |

Fault Code Troubleshooting - F3 Magnetron Current Low |

39 |

Fault Code Troubleshooting - F4 Door Monitor Defective |

40 |

Fault Code Troubleshooting - F5 Magnetron Over Temperature |

40 |

Fault Code Troubleshooting - F6 Electrical Compartment Temperature High |

41 |

Fault Code Troubleshooting - F7 Open RTD |

41 |

Fault Code Troubleshooting - F8 Heat Low |

42 |

Fault Code Troubleshooting - F9 Cook Cavity Temperature High |

42 |

Non-Fault Code Troubleshooting - No Keypad Input |

43 |

Non-Fault Code Troubleshooting - “Cook Door Open” Message when Door is Closed |

43 |

Non-Fault Code Troubleshooting - No Display (Screen is Blank) |

44 |

Non-Fault Code Troubleshooting - Food Not Cooking Properly |

45 |

Non-Fault Code Troubleshooting - “Read Fail” Message when Loading a Menu |

46 |

Non-Fault Code Troubleshooting - “Write Fail” Message when Loading a Menu |

47 |

Non-Fault Code Troubleshooting - “Defective Media” Message When Oven is |

|

Plugged in or Restarted |

48 |

Oven Schematic |

49 |

Appendix - Replacing Oven Components |

|

Replacing Oven Components |

A-1 |

No Cover Removal Required |

A-2 |

Opening Top Cover Required |

A-4 |

Removing Top Cover Required |

A-5 |

Removing Left Side Cover Required |

A-8 |

Removing Right Side Cover Required |

A-10 |

Removing Right and Left Covers Required |

A-11 |

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When operating this oven, strictly adhere to the following safety precautions to reduce the risk of burns, electric shock, fire, injury, damage to oven or property near oven, or possible exposure to excessive microwave energy.

General Safety Information

aRead all instructions before using this appliance.

aRead and follow the specific "Precautions to be Observed Before and During Servicing to Avoid Possible Exposure to Excessive Microwave Energy" found on page ii.

aThis appliance must be grounded. Connect only to properly grounded outlet. See "Grounding Instructions" found on page ii.

aInstall or locate this appliance only in accordance with the provided installation instructions.

aSome products such as whole eggs and sealed containers (e.g., closed glass jars) may explode and should not be heated in this oven.

aUse this appliance only for its intended uses as described in this manual.

aThis appliance should be serviced only by qualified service personnel. Contact the nearest authorized service facility for examination, repair, or adjustment.

aKeep cord away from heated surfaces.

aLiquids, such as water, coffee, or tea are able to be overheated beyond the boiling point without appearing to be boiling. Visible bubbling or boiling when the container is removed from the microwave oven is not always present. THIS COULD RESULT IN VERY HOT LIQUIDS SUDDENLY BOILING OVER WHEN THE CONTAINER IS DISTURBED OR A UTENSIL IS INSERTED

INTO THE LIQUID.

XDO NOT allow children to use this appliance.

XDO NOT use corrosive chemicals or vapors in this appliance - it is not designed for industrial or

laboratory use.

X DO NOT operate this appliance if it has a damaged cord or plug, is not working properly, or has been damaged or dropped. See Power Cord Replacement found on page ii.

XDO NOT cover or block any openings on this appliance.

XDO NOT store this appliance outdoors.

XDO NOT use this product near water (e.g., near a kitchen sink, in a wet basement, near a swimming pool).

XDO NOT immerse cord or plug in water.

XDO NOT let cord hang over the edge of table or counter.

XDO NOT use a water jet for cleaning. See the Maintenance section (pages 7-8) for proper cleaning

procedures.

Reducing Fire Risk

aRemove wire twist-ties from paper or plastic bags used to facilitate cooking in the oven.

aIf materials inside the oven ignite, keep the oven door closed, turn the oven off, and disconnect the power cord or shut off power at the fuse or circuit breaker panel.

aIf smoke is observed, switch off or unplug the oven. Keep the door closed to stifle any flames.

XDO NOT use the cook cavity for storage purposes.

XDO NOT overcook food. Carefully attend to the oven if paper, plastic, or other combustible materials are

placed inside the oven to facilitate cooking.

X DO NOT leave paper products, cooking utensils, or food in the cavity when not in use.

i

INSTRUCTIONS SAFETY

SAVE THESE INSTRUCTIONS

ii SAFETY INSTRUCTIONS

Grounding Instructions

This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This oven is equipped with a cord that has a grounding wire with a grounding plug, which must be plugged into an outlet that is properly installed and grounded. Consult a qualified electrician or serviceman if uncertain about the ability to follow grounding instructions or if doubt exists as to whether the appliance is properly grounded.

X DO NOT use an extension cord. If the power cord is too short, have a qualified electrician or serviceman install an outlet near the appliance.

WARNING: Improper grounding can result in risk of electric shock.

Power Cord Replacement

If the power cord is damaged, it must only be replaced by the manufacturer, its service agent, or a similarly-qualified person.

Precautions to be Observed Before and During Servicing to Avoid Possible Exposure to Excessive Microwave Energy

(a)DO NOT operate or allow the oven to be operated with the door open.

(b)Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary: (1) interlock operation, (2) proper door closing,

(3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse.

(c)Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

(d)Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner.

(e)A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven prior to release to the owner.

Refer to pages 25-26 for leakage test procedures.

RF Interference Considerations

The i3 oven generates radio frequency signals. This device has been tested and was determined to be in compliance with applicable portions of FCC part 18 requirements and to the protection requirements of Council Directive 89/336/EEC on the approximation of the laws of the Member States relating to electromagnetic compatibility at the time of manufacture. However, some equipment with sensitivity to signals below these limits may experience interference.

If your equipment experiences interference:

aIncrease the physical separation between this oven and the sensitive equipment.

aIf the sensitive device can be grounded, do so following accepted grounding practices.

aIf battery-powered microphones are being affected, ensure that the batteries are fully charged.

aKeep sensitive equipment on separate electrical circuits if possible.

aRoute intercom wires, microphone wires, speaker cables, etc. away from the oven.

Specifications and Installation

24.5” |

(622 mm) |

21.25” |

(540 mm) |

31.25” (794 mm)

28.25” (718 mm)

39.65” (1007 mm)

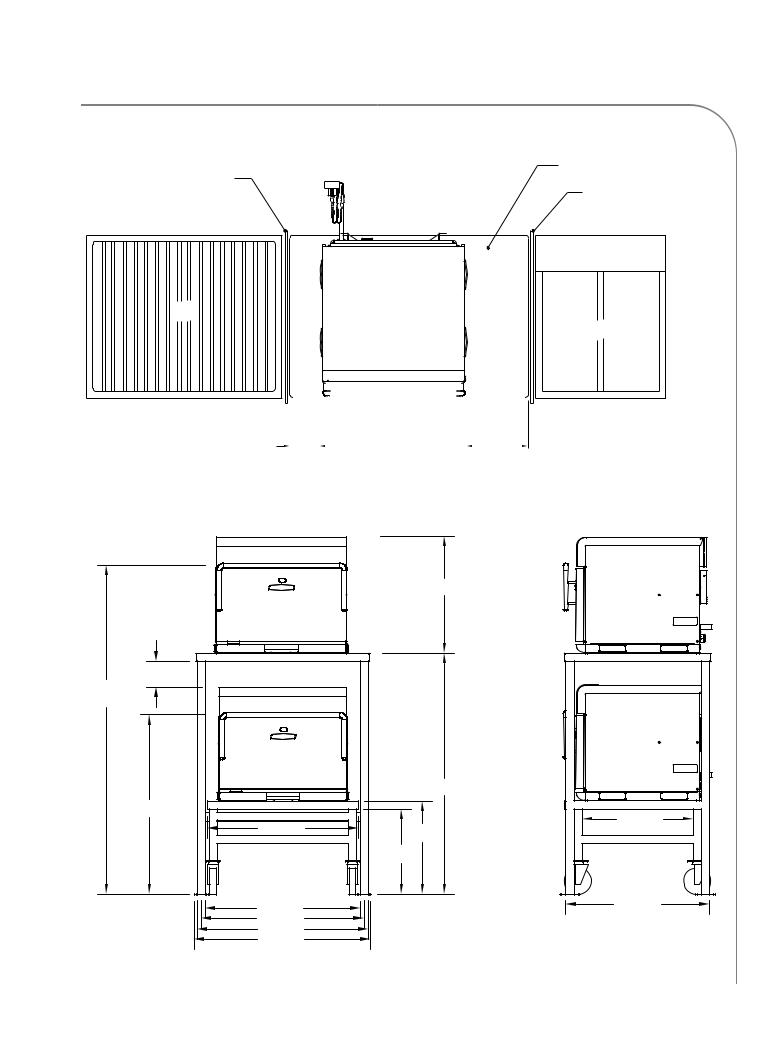

Figure 1: i3 Oven Dimensions

Theory of Operation

Utilizing TurboChef’s patented technology to rapidly cook food without compromising quality, the i3 oven provides superior cooking performance while requiring minimal space and energy consumption. The control system precisely coordinates independent top and bottom impinged airflow with microwave to deliver superior quality and throughput. The toplaunched microwave system allows for use of most standard metal pans, and integral catalytic converters allow for UL®-certified ventless operation (see page 4 for details and limitations).

This manual includes instructions for servicing, troubleshooting, installing, cleaning, and operating the i3 oven. If you have questions that are not addressed in this manual, contact Technical Service (800.90TURBO, +1 214-379-6000) or your Authorized Distributor.

Certifications

cULus, UL EPH, TÜV, CE, FDA

UL 710B (KNLZ) listed for ventless operation.

Dimensions

Oven Dimensions Height: 21.25” (540 mm) Width: 24.5” (622 mm)

Depth (footprint): 25.75” (654 mm) Depth (door closed): 31.25” (794 mm) Depth (door open): 39.65” (1007 mm) Weight: 245 lb. (111 kg)

Cook Cavity Dimensions

Height: 6.9” (175 mm)

Width: 19.4” (493 mm)

Depth: 14.75” (375 mm)

Volume: 1.14 ft3 (32.3 liters)

Clearances

Top: 19” (483 mm)

Sides: 2” (51 mm)

Oven Construction

Exterior

-Two-tone stainless steel front, top, and sides

-304 stainless steel removable grease pan

-Ergonomic door handle

-Rubber seal for surface mounting

-Side hand grips for lifting

Interior

-304 stainless steel interior

-Fully-insulated cook chamber

-Oven rack removable for cleaning

-Top and bottom jetplates

1

INSTALLATION AND SPECIFICATIONS

2SPECIFICATIONS AND INSTALLATION

Electrical Specifications

TurboChef recommends a Type D circuit breaker for all installations outside the US.

Single Phase |

|

i3 US model (i3-9500-1)* |

i3 UK model (i3-9500-2-UK) |

208/240 VAC, 60 Hz, 40 amps |

230 VAC, 50 Hz, 40 amps |

Max Input: 8300/9600 watts |

Max Input: 9200 watts |

Plug: NEMA 6-50P, 8/3 |

Plug: IEC 309, 3-pin |

i3 BK model (i3-9500-6-BK) |

i3 JK model (i3-9500-8-JK) - 50 Hz |

220 VAC, 60 Hz, 40 amps |

(i3-9500-10-JK) - 60 Hz |

Max Input: 8800 watts |

200 VAC, 50 or 60 Hz, 40 amps |

Plug: IEC 309, 3-pin |

Max Input: 8000 watts |

i3 LA model (i3-9500-7-LA) |

Plug: PSE-marked, 3-blade |

|

|

220 VAC, 60 Hz, 40 amps |

|

Max Input: 8800 watts |

|

Plug: NEMA 6-50P |

|

Multi Phase |

|

i3 DL (USA) model (i3-9500-14-DL)* |

i3 KW model (i3-9500-12-KW) |

208/240 VAC, 60 Hz, 24 amps |

400 VAC, 60 Hz, 14 amps |

Max Input: 8600/9900 watts |

Max Input: 9500 watts |

Plug: NEMA 15-30P |

Plug: IEC 309, 5-pin |

i3 BD model (i3-9500-16-BD) |

i3 ED model (i3-9500-3-ED) |

220 VAC, 60 Hz, 24 amps |

230 VAC, 50 Hz, 24 amps |

Max Input: 9100 watts |

Max Input: 9500 watts |

Plug: IEC 309, 4-pin |

Plug: IEC 309, 4-pin |

i3 LD model (i3-9500-15-LD) |

i3 SD model (i3-9500-13-SD) |

220 VAC, 60 Hz, 24 amps |

230 VAC, 60 Hz, 24 amps |

Max Input: 9100 watts |

Max Input: 9200 watts |

Plug: NEMA 15-30P |

Plug: IEC 309, 4-pin |

i3 EW model (i3-9500-4-EW) |

i3 JD model (i3-9500-9-JD) - 50 Hz |

400 VAC, 50 Hz, 14 amps |

(i3-9500-11-JD) - 60 Hz |

Max Input: 9500 watts |

200 VAC, 50 or 60 Hz, 23 amps |

Plug: IEC 309, 5-pin |

Max Input: 8000 watts |

i3 AU model (i3-9500-5-AU) |

Plug: PSE-marked, 4-blade |

|

|

400 VAC, 50 Hz, 14 amps |

|

Max Input: 9500 watts |

|

Plug: Clipsal 5-pin |

|

*North America models include a voltage sensor that detects 208 or 240 VAC. The voltage sensor does not compensate for lack-of or over-voltage installations.

Figure 2: Hand Grip Locations

Install or locate this appliance only in accordance with the instructions below.

Install or locate this appliance only in accordance with the instructions below.

Unpacking Instructions

1.Remove oven from packaging.

2.Before discarding packaging, check thoroughly for accessories, consumables, and literature.

3.Discard packaging.

4.Check cook cavity thoroughly for accessories, consumables, and literature.

5.Discard any packaging in cook cavity.

Lifting and Placing the Oven

WARNING: Oven weighs approximately 245 lb. (111 kg). Never lift with fewer than two people.

WARNING: Oven weighs approximately 245 lb. (111 kg). Never lift with fewer than two people.

WARNING: Lift the oven only by using the provided hand grips. Never lift the oven by the door handle.

WARNING: Lift the oven only by using the provided hand grips. Never lift the oven by the door handle.

WARNING: The oven must be properly placed on a table or countertop at all times. TurboChef will not recognize a fallen oven as a warrantable claim and is not liable for any injuries that may result.

WARNING: The oven must be properly placed on a table or countertop at all times. TurboChef will not recognize a fallen oven as a warrantable claim and is not liable for any injuries that may result.

WARNING: This oven is not intended for built-in installation (i.e., installing the oven in any structure that surrounds the oven by five or more sides). Be sure to provide a minimum of 2” (51 mm) clearance for all sides and 19” (483 mm) clearance for the top.

WARNING: This oven is not intended for built-in installation (i.e., installing the oven in any structure that surrounds the oven by five or more sides). Be sure to provide a minimum of 2” (51 mm) clearance for all sides and 19” (483 mm) clearance for the top.

1.Prepare a surface that is at least 30” (762 mm) deep and capable of supporting 250 lb. (113 kg). If installing onto an oven cart, make sure the wheels/casters are locked.

2.Position one or more persons at the front and rear of the oven.

3.Place hands into grips (see Figure 2) and lift.

4.Place the oven on the prepared surface or cart, ensuring no edges are hanging off the sides.

5.Install the oven rack.

6.Plug in the oven.

NOTE: The oven is primarily serviced through its top. DO NOT install shelving directly over the unit. The operator will be responsible for service charges incurred as a result of added time required to access the top of the oven.

3

INSTALLATION AND SPECIFICATIONS

4SPECIFICATIONS AND INSTALLATION

Installation Near Open Heat Source |

ChefComm Pro (CON-7006) |

|

See Figure 4, page 5. When placing a TurboChef oven near |

ChefComm Pro empowers any user of a TurboChef |

|

oven to easily and efficiently create menu settings on a |

||

an open heat source, strictly adhere to the following: |

||

computer and transfer them to an oven via smart card |

||

- If the oven is being placed near a grill or stove, |

||

or USB device. |

||

a divider must exist between the oven and the |

||

|

||

open heat source, with a minimum of 6” (152 |

ChefComm Limited (CON-7016) |

|

mm) between the oven and the divider. |

||

ChefComm Limited is a “read-and-transfer only” version of |

||

- If the oven is being placed near a fryer, a |

||

ChefComm Pro that helps ensure carefully-crafted settings |

||

divider must exist between the oven and fryer, |

||

are easy to distribute globally, while providing the peace of |

||

with a minimum of 12” (305 mm) between |

||

mind that they will not be altered. |

||

the oven and the divider. |

||

|

||

- The height of the divider must be greater than |

Voltage Selection |

|

or equal to the height of the oven (21.25” or |

||

For North America oven models, the oven will detect |

||

540 mm). |

||

208 or 240 incoming voltage. |

||

- Verify the oven location has a minimum 19” (483 |

||

|

||

mm) clearance on top and a minimum 2” (51 |

The initial voltage selection is typically completed |

|

mm) of clearance on each side. |

before the oven is used by the customer. However, if |

|

|

incoming voltage for the store is different than the pre- |

|

Optional Installation Items |

set voltage, the operator will be required to select |

|

See Figure 5, page 5. |

either 208 or 240 after pressing the On/Off key to |

|

turn on the oven. The correct voltage will be enlarged |

||

|

||

TurboChef Oven Cart |

on the screen, identifying which option to select (see |

|

Figure 3 below). |

||

- Part Number: NGC-1217-2 |

||

|

||

- H x W x D: 17.3” (439 mm) x 7.8” (706 mm) |

|

|

x 26.625” (676 mm) |

SELECT VOLTAGE: |

|

|

TurboChef Stacking Stand

-Part Number: i5-9369

-H x W x D: 44.6” (1133 mm) x 32.5” (826 mm) x 26.5” (673 mm)

208 VAC

208 VAC

240 VAC

240 VAC

Figure 3: Selecting Voltage

Oven Restraint Kit

Part Number: TC3-0242

WARNING: The Oven Restraint Kit will not prevent the oven from falling off a countertop if pulled off or allowed to slide off the edge.

WARNING: The Oven Restraint Kit will not prevent the oven from falling off a countertop if pulled off or allowed to slide off the edge.

Oven Connect

Oven ConnectTM allows you to update menu settings for multiple ovens at once, from one central location. Oven Connect can also download oven diagnostics and counters. For more information on how to network ovens, see page 14. For information on obtaining Oven Connect, contact TurboChef Customer Support at 800.90TURBO or +1 214.379.6000.

If servicing a control board, follow the instructions on page 31 to ensure proper connectivity.

Ventilation Requirements

The TurboChef model i3 oven has been approved by Underwriter’s Laboratory for ventless operation (UL 710B, KNLZ listing) for all food items except for foods classified as “fatty raw proteins.” Such foods include bone-in, skin-on chicken, raw hamburger meat, raw bacon, raw sausage, steaks, etc. If cooking these types of foods, consult local HVAC codes and authorities to ensure compliance with ventilation requirements.NOTE: In no event shall the manufacturer assume any liability for damages or injuries resulting from installations which are not in compliance with the instructions and codes previously listed.

5

Counter Top / Table

Partition |

|

|

21.25” (540 mm) |

Partition |

|

Above Counter Top |

||

21.25” (540 mm) |

||

|

||

|

Above Counter Top |

Grill |

TurboChef |

|

i3 Oven |

||

|

Deep Fryer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6” |

|

|

|

|

|

|

|

|

|

|

|

|

12” |

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

(152 mm) |

|

|

|

|

|

|

|

|

|

|

|

(305 mm) |

|

|

|

|

Minimum |

|

|

|

|

|

|

|

|

|

|

Minimum |

||||

Figure 4: Installation Near Open Heat Source

21.25” (540 mm)

4.5” |

|

(114 mm) |

|

59.7” (1516 mm) |

|

(handle) |

|

|

44.6” (1133 mm) |

32.5” (826 mm) |

|

(handle) |

20.5” (521 mm) |

|

|

35.5” (706 mm) |

17.3” |

|

(439 mm) |

|

15.8” |

|

(401 mm) |

28.6” (726 mm) |

26.5” (673 mm) |

|

|

30.0” (762 mm) |

|

31.5” (800 mm) |

|

32.5” (826 mm) |

|

Figure 5: Oven Cart and Stacking Stand Dimensions

INSTALLATION AND SPECIFICATIONS

6SPECIFICATIONS AND INSTALLATION

This page intentionally left blank.

Daily Maintenance

|

|

Daily Maintenance |

|

|

Supplies and Equipment |

|

|

|

The following steps will help maintain your i3 oven. |

- Oven Cleaner (Part Number: 103180) |

|||

|

|

Use only TurboChef Oven Cleaner and Oven Guard. |

- Oven Guard (Part Number: 103181) |

|||

|

|

The use of any other cleaning products can damage |

- Nylon scrub pad, cleaning towel, disposable gloves, |

|||

|

|

critical oven components, which will result in a |

protective eyewear, dust mask (optional), *pair of |

|||

|

|

non-warranty service call. |

|

|

tongs wrapped with towel (optional - see step 11) |

|

|

|

|

|

Step 1: Prepare the Oven |

|

|

|

|

|

|

|

||

|

|

|

|

|

WARNING: The oven operates at approximately 500°F (260°C) and may |

|

|

|

|

|

|

cause injury if not allowed to cool properly. |

|

|

|

|

|

- Turn off the oven by pressing the On/Off key. |

||

|

|

|

|

- Slightly open the oven door. Cooling takes approximately 40 minutes. |

||

|

|

|

|

- |

DO NOT attempt to clean the oven until the oven displays “Oven Off.” |

|

|

|

Step 1 |

||||

|

|

|

|

Step 2: Remove and Clean the Wire Rack |

||

|

|

|

|

|||

|

|

|

|

|

WARNING: Be sure the oven interior is cool before you remove the wire rack. |

|

|

|

|

|

- Wash, rinse, sanitize, and dry the wire rack. |

||

|

|

|

|

Step 3: Remove and Clean the Lower Jetplate |

||

|

|

|

|

|

|

|

|

|

Step 2 |

- |

Unscrew the two thumb screws on the lower jetplate. |

||

|

|

|

|

- Lift the lower jetplate by gripping the thumb screws. |

||

|

|

|

|

|||

|

|

|

|

- Remove the lower jetplate. |

||

|

|

|

|

- Wash, rinse, sanitize, and dry the lower jetplate. |

||

|

|

|

|

Step 4: Remove and Clean the Lower Air Diverter |

||

|

|

|

|

- Remove the lower air diverter. |

||

|

|

Step 3 |

- |

Wash, rinse, sanitize, and dry the lower air diverter. |

||

|

|

|

|

|||

|

|

|

|

|

WARNING: DO NOT discard the lower air diverter. The oven will not work |

|

|

|

|

|

|

without the lower air diverter installed. |

|

|

|

|

|

Step 5: Wipe the Oven Interior |

||

|

|

|

|

- Wipe any large particles from the oven interior with a damp towel. |

||

|

|

|

|

|

|

|

|

|

Step 4 |

Step 6: Clean the Oven Interior |

|||

|

|

|

|

|||

|

|

|

|

- Spray oven cleaner onto the top, bottom, and sides of the oven interior. |

||

|

|

|

|

|

CAUTION: DO NOT spray oven cleaner into the holes on the back oven |

|

|

|

|

|

|

wall. Doing so can damage critical oven components, resulting in a |

|

|

|

|

|

|

non-warranty service call. |

|

|

|

|

|

- Allow Oven Cleaner to penetrate stains for five minutes. |

||

|

|

Step 5 |

||||

|

|

- Clean the oven interior with a nylon scrub pad. |

||||

|

|

|

|

|||

|

|

|

|

NOTE: Depending on the model, the oven will utilize either a ceramic top jetplate |

||

|

|

|

|

or a metal top jetplate that incorporates a glass insert. |

||

|

|

|

|

|

CAUTION: DO NOT apply excessive pressure when wiping the top ceramic |

|

|

|

|

|

|

jetplate or glass insert; breakage will result in a non-warranty service call. |

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION: DO NOT remove the top ceramic jetplate or glass insert; breakage |

|

|

|

Step 6 |

|

|||

|

|

|

will result in a non-warranty service call. |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

MAINTENANCE DAILY

8DAILY MAINTENANCE

A

Step 7

Step 8

Step 9

Step 10

Step 11

Step 12

Step 13

Step 7: Clean and Dry the Oven Door

CAUTION: DO NOT spray cleaner directly onto the oven door gasket (A) or saturate it with water.

CAUTION: DO NOT spray cleaner directly onto the oven door gasket (A) or saturate it with water.

CAUTION: DO NOT scrub, scrape, or attempt to clean the oven door gasket (A). Doing so may cause the door to not close properly, resulting in a non-warranty service call.

CAUTION: DO NOT scrub, scrape, or attempt to clean the oven door gasket (A). Doing so may cause the door to not close properly, resulting in a non-warranty service call.

-Clean the oven door with oven cleaner and a nylon scrub pad.

-Wipe the oven door with a damp towel.

Step 8: Rinse the Oven Interior

CAUTION: DO NOT use a hose or water jet for cleaning. Doing so can damage critical oven components, resulting in a non-warranty service call.

CAUTION: DO NOT use a hose or water jet for cleaning. Doing so can damage critical oven components, resulting in a non-warranty service call.

-Rinse the oven interior with clean water.

-Thoroughly dry the oven interior with a clean towel.

Step 9: Apply TurboChef Oven Guard

-Spray Oven Guard onto a clean towel.

-Wipe the oven’s interior walls and the inside of the oven door.

CAUTION: DO NOT apply Oven Guard to the oven door gasket. Doing so may damage the gasket, resulting in a non-warranty service call.

CAUTION: DO NOT apply Oven Guard to the oven door gasket. Doing so may damage the gasket, resulting in a non-warranty service call.

Step 10: Reinstall Components

-Reinstall the lower air diverter.

-Reinstall the lower jetplate. Screw in the two thumb screws to lock the lower jetplate in place.

-Reinstall the wire rack and close the oven door.

Step 11: Clean the Drain Pan

-Remove the lower front panel.

-Remove the drain pan entirely from the bottom of the oven.

-Wipe down* the inside of the area the drain pan fits within.

-Empty, clean, and reinstall the drain pan.

-Reinstall the lower front panel.

Step 12: Clean the Oven Exterior

- Wipe the oven exterior with a clean, damp towel.

CAUTION: DO NOT spray chemicals into any openings, such as the louvers on the side panels or the rear vent catalyst housing. Doing so can damage critical oven components, resulting in a non-warranty service call.

CAUTION: DO NOT spray chemicals into any openings, such as the louvers on the side panels or the rear vent catalyst housing. Doing so can damage critical oven components, resulting in a non-warranty service call.

Step 13: Clean the Air Filter (once per week)

-Remove the air filter from the back panel.

-Gently wash by hand in the sink or rinse with hot water.

CAUTION: DO NOT use a water jet. Doing so will shorten the life of the filter.

CAUTION: DO NOT use a water jet. Doing so will shorten the life of the filter.

-Reinstall the air filter, or replace it if large holes are present or if the mesh is becoming detached from the frame.

CAUTION: DO NOT operate the oven without the air filter in place.

CAUTION: DO NOT operate the oven without the air filter in place.

Oven Controls and Cooking

9

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

A B C |

D E F |

|

|

|

|

|

4 |

5 |

6 |

|

7 |

7 |

|

|

G H I |

J K L |

M N O |

|

S T O P |

|

|

|

|

||

|

|

|

B A C K |

|

|

|

|

|

|

|

|

|

E N T E R |

|

|

|

|

|

|

|

7 |

8 |

9 |

|

|

|

|

|

P Q R S |

T U V |

W X Y Z |

|

|

|

|

|

B A C K |

0 |

|

|

|

|

|

|

|

E N T E R |

|

|

|

|

|

|

S T O P |

|

|

2 |

1 |

4 |

5 |

3 |

6 |

8 |

|

Figure 6: Oven Controls

Oven Controls

1. On/Off Key

Press to turn the oven on (begin warmup) or off (cool down), or to exit Info Mode (page 13).

2. Info Key

When the oven is off or cooling down, press to access the Info Mode (see page 13).

3. Up and Down Keys

When the oven is ready to cook (i.e., warmed up and waiting for a cook command), press the Up or Down key to view additional food groups or items.

When the oven is in the Info Mode (see page 13), press to navigate between screens 1 and 2.

When editing a food item, press to navigate between editable fields (Figure 30, page 20).

4. Display

The display shows information relevant to the current oven operation and/or user options.

5. Back/Stop Key

When the oven is cooking, press the Back/Stop key to immediately terminate a cook cycle. When the oven is ready to cook (i.e., warmed up and waiting for a cook command), or in the Info Mode (see page 11), press the Back/Stop key to return to the previous screen.

6. Enter Key

Press the Enter key when saving changes to food item settings (Figure 30, page 20), or whenever instructed by the oven screen.

7. Soft Keys

There are ten soft keys - five to the left and right of the display. Press a soft key to select an option adjacent to that key on the display.

NOTE: Soft keys are labeled L1-L5 and R1-R5 in this manual (where applicable) for identification purposes.

8. Numeric Keypad

Use the numeric keypad to enter access passwords or modify cook settings (Figure 30, page 20). The numeric keypad also contains a Back/Stop key and an Enter key, which are functionally identical to Items 5 and 6.

COOKING AND CONTROLS OVEN

10 OVEN CONTROLS AND COOKING

Cooking

The oven is preprogrammed with recipe settings at the time of manufacture and is ready to operate out of the box. If these settings are erased, new menu settings must be either loaded via smart card/USB drive (page 15) or programmed manually (pages 19-20). The oven will not cook unless settings are present.

Note that the steps below are not always sequential. Typically, multiple items will be cooked before cooling the oven (Step 10).

Step 1: Turn the Oven On

TURBOCHEF i3

OVEN OFF

READY TO CLEAN

When the oven is off (Figure 7), the oven temperature has receded below 150°F (66°C), but the display and keypad remain on.

Press the On/Off key to turn the oven on.

Figure 7: Oven Off

Step 2: Select Cook Temperature

SELECT COOK TEMPERATURE

TEMP 1: 500F

TEMP 1: 500F

TEMP 2: 350F

TEMP 2: 350F

Figure 8: Cook Temperature Select

The oven can store either one or two cook temperatures. To select a temperature, press the adjacent soft key.

Each temperature has 10 food groups assigned to it, and each group consists of 10 food items (100 items per temperature). The operator will only be able to cook items associated with the selected temperature; to cook other items on the menu, a new temperature must be selected.

NOTE: If both temperature settings are the same, this screen will be bypassed and access to all 200 food items will be allowed.

Step 3: Warming Up

During this step, the oven warms to the selected or pre-set temperature.

WARMING UP

OVEN CC = 244F

OVEN SP = 500F

Figure 9: Warming Up

Step 4: Soaking

Once the oven temperature reaches the set point, the oven will continue to warm for eight minutes to ensure the cook cavity surfaces absorb enough heat so as to not affect cooking results. This process is called “soaking.”

Step 5: Ready to Cook or “Idle”

WARNING: Inside of oven and oven door are hot!

WARNING: Inside of oven and oven door are hot!

1.Place the food into the oven.

2.Select a food group by pressing its adjacent soft key, or press the Up or Down key for additional food groups, if available.

3.Select an item to cook by pressing its adjacent soft key.

Step 6: Adjusting the Time

ADJUST TIME

01:40

START COOK

Figure 10: Adjust Time

Step 7: Cooking

|

COOKING |

GROUP 1 |

ITEM 1 |

|

01:17 |

The Adjust Time option is turned off by default. If you want the ability to modify the cook time before each cook cycle, this feature can be turned on from the “Options” screen (see page 14).

1.If the “Adjust Time” screen appears, change the cook time if needed by using the number keys.

2.Press Enter or the bottom-right soft key to confirm and begin cooking.

NOTE: To immediately terminate a cook cycle, press the Back/Stop key.

NOTE: If the oven door is opened during a cook cycle, the cycle will pause until the door is closed and “Resume” is selected.

Figure 11: Cooking

11

COOKING AND CONTROLS OVEN

Loading...

Loading...