Page 1

INSTALLERS PLEASE NOTE THESE INSTRUCTIONS ARE TO BE LEFT WITH THE USER

2180209H November 2004

Installation and

operating

instructions

T40i

booster pump

Page 2

T40i

CONTENTS Page

Important safety information 1

Introduction 2

Specifications 2

Key to main components 3

Site requirements – water 4

Site requirements – electrical 5

Fitting to the wall 6

Hose connections 7

Electrical connections 8

Replacing the cover and testing 9

Operating 10

Maintenance 10

Spare parts 11

Fault finding 12

Guarantee, service policy etc. rear cover

To ensure the product suitability for commercial and multiple

installations, please contact Triton’s specification advisory

service prior to installation.

Telephone: (024) 7632 5491

Facsimile: (024) 7632 4564

E mail: technical@triton.plc.uk

Page 3

1

T40i

1 GENERAL

1.1 Products manufactured by Triton are safe

and without risk provided they are

installed, used and maintained in good

working order in accordance with our

instructions and recommendations.

1.2 DO NOT operate the unit if it is frozen, or

suspected of being frozen. It must thaw out

before using.

1.3 Switch off the electrical supply at the mains

before removing the cover.

1.4 Read all of these instructions and retain

them for later use.

1.5 DO NOT connect to the mains water

supply.

1.6 Isolate electrical and water supplies BEFORE

proceeding with the installation.

1.7 DO NOT connect to modulating type

combination boilers, multi-point hot water

heaters, and unvented or thermal storage

systems.

1.8 Contact Customer Service (see back page),

if any of the following occur;

a) If water ceases to flow during use.

b) If the unit shows a distinct change in

performance.

c) If the pump is frozen.

d) If water has entered inside the unit

because of incorrectly fitted cover.

1.9 DO NOT restrict flow out of the pump by

placing the sprayhead in direct contact

with your body.

1.10This product is not suitable for mounting

into steam rooms or steam cubicles.

1.11DO NOT use excessive force when making

connections to the flexible hose or

sprayhead, finger tightness is sufficient.

1.12All hose connections MUST be completed

BEFORE making the electrical connections

2 ELECTRICAL

2.1 The installation must comply with BS 7671

‘Requirements for electrical installations’

(IEE wiring regulations) or any particular

regulations as specified by the local

Electrical Supply Company.

2.2 This appliance MUST be earthed.

2.3 In accordance with ‘The Plugs and Sockets

etc. (Safety) Regulations 1994’, this

appliance is intended to be permanently

connected to the fixed wiring of the

electrical mains system.

2.4 Make sure all electrical connections are

tight to prevent overheating.

2.5 Fuses do not give personal protection

against electric shock.

2.6 To enhance electrical safety a 30mA

residual current device (RCD) should be

installed in all UK electric and pumped

shower circuits. This may be part of the

consumer unit or a separate unit.

2.7 Switch off immediately at isolating switch if

water ceases to flow during use.

2.8 Other electrical equipment i.e. extractor

fans, pumps MUST NOT be connected to

the circuits within the unit.

PLEASE READ THIS IMPORTANT SAFETY INFORMATION

Page 4

2

T40i

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your T40i booster

pump. Please read them carefully.

The installation must be carried out by a suitably

qualified person and in the sequence of this

instruction book.

Care taken during the installation will ensure a

long, trouble-free life from your booster pump.

The T40i booster pump is designed to improve

the flow rate through an existing bath/tap mixer

valve. It is NOT designed to pressurise the water

supply but only to assist the flow.

IT MUST ONLY be fitted to new or existing

gravity fed shower mixer systems.

The unit is easy to install requiring no plumbing,

only simple screw-on hose connections and a

suitable power supply.

Note: It must NOT be used with instantaneous

water heaters.

This product is suitable for installation in a

bathroom.

DO NOT install the unit so close to the bath

that the supplied hose becomes twisted or

kinked and restricts the water flow.

SPECIFICATIONS

Electrical

Voltage: 240V

Pump motor rating: 73 Watt (nominal)

Water

Inlet connection – ½” BSP male thread.

Outlet connection – ½” BSP male thread.

Entry Points

Water – bottom.

Cable – top or rear.

Materials

Backplate, cover, controls – ABS.

Dimensions (in millimetres)

Height − 230

Width − 217

Depth − 80

Standards and Approvals

Complies with requirements of current British

and European safety standards for household

and similar electrical appliances.

Complies with requirements of the British

Electrotechnical Approvals Board (BEAB).

Meets with Compliance with European

Community Directives (CE).

This product is rated at 15 minutes on / 45

minutes off.

Page 5

3

T40i

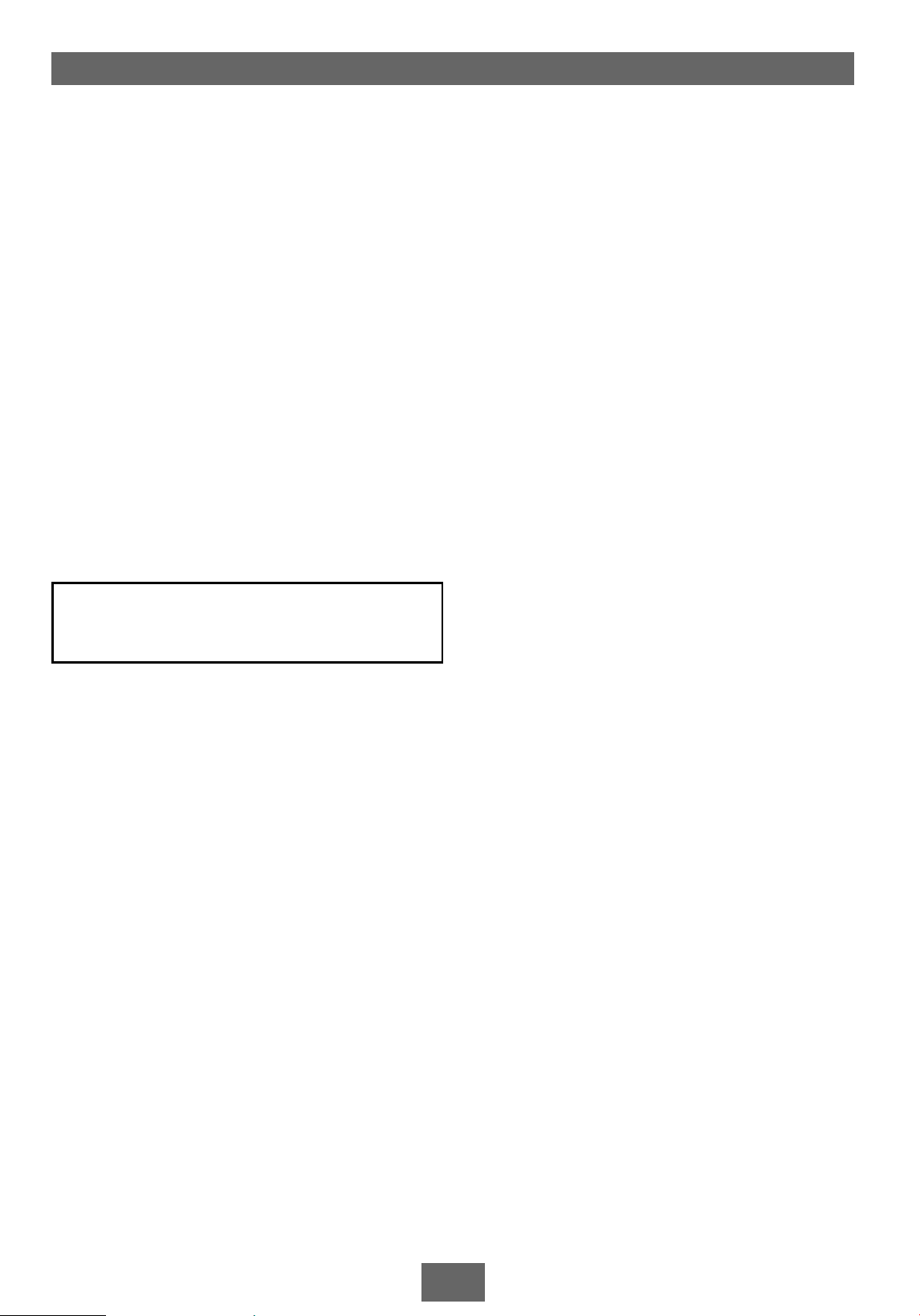

1 Top cable entry

2 Cover screw fixings

3 Terminal block

4 Cable clamp

5 Wall screw fixings

6 Rear cable entry

7 Switch assembly

8 Earth connection

9 Motor

10 Pump assembly

12

2

3

4

5

5 6

7

8

9

1 0

1 1

1 2

1 3

1 4

Fig.1

11 Inlet pipe

12 Outlet pipe

13 Inlet connection

14 Outlet connection

KEY TO MAIN COMPONENTS inside unit (fig.1)

Page 6

4

T40i

SITE REQUIREMENTS

Water

The installation must be in accordance with

Water Regulations/Byelaws.

To ensure correct operation, the T40i unit

must be connected to a gravity fed system of

hot and cold water of equal pressure (fig.2).

The T40i pump MUST NOT be connected

to the mains water supply.

The unit must be positioned BELOW the cold

water cistern and NOT placed in areas where it

will be subject to freezing conditions.

Position the unit where it will NOT be in direct

contact with water from the sprayhead.

Both hot and cold water supplies to the

existing bath/tap mixer valve MUST be direct

and separate from any other outlets or

connections.

DO NOT use jointing compound on any pipe

fittings for installation.

Note: The outlet of the T40i pump acts as a

vent and must not be connected to any form

of tap or fitting that is NOT recommended by

the manufacturer.

Generally there are four main types of hot and

cold water mixer systems to which the T40i

can be installed. These are shown in (fig.2)

through to (fig.5).

In each case, to ensure correct operation of

the booster pump, the top of the T40i unit

MUST be at least 230mm below the bottom of

the cold water cistern and the sprayhead must

be a minimum of 100mm below the water

level of the cold water cistern.

Note: Bath mixer valves incorporating a

diverter valve can have a high restriction to

water flow, so the expected improvement may

not be possible.

Water circuits supplying the T40i unit should

be installed so that the flow is not significantly

affected by other taps and appliances that are

being operated elsewhere on the premises.

Gate

valves

Gate

valve

Cold supply

Hot supply

Stop

valve

Cold

water

mains

supply

Hot water

cylinder

Isolating switch or

pull cord switch

(both fused at 3A)

Ring main

230mm min.

100mm

minimum

Water level

Outline of bath

or shower cubicle

Cold water

cistern

2' 6"

minimum

Fig.2 Typical gravity fed system with bath

tap/mixer valve arrangement

Whether the

mixer valve has

top or bottom

outlet, position

the T40i so the

hose is not

kinked or twisted

Fig.3 Mixer valve arrangement

Page 7

5

T40i

Fig.4 Push-on with blender/mixer valve

arrangement

Fig.5 Push-on type arrangement

SITE REQUIREMENTS

Electrical

THIS INSTALLATION MUST BE EARTHED.

This product must be permanently connected to

the electricity supply, via a double pole switch

with at least 3mm contact separation. This can

be a ceiling mounted pull cord switch, or a wall

mounted switch, both of which must be fused

at 3A. The switch must be readily accessible and

clearly identifiable, but out of reach of a person

using a fixed bath or shower, except for the

cord of a cord operated switch.

The installation and wiring must comply with

the current IEE regulations.

The supply cable and circuit protection must

conform with IEE wiring regulations and be

sufficient for the amperage required. In most

cases 1mm² twin and earth cable will be

adequate.

If in any doubt consult a qualified electrician or

contact Triton Customer Service for advice.

Page 8

6

T40i

FITTING TO THE WALL

Unscrew the top and bottom retaining screws

(fig.6) and lift the cover from the backplate.

Note: The control knob is an integral part of the

cover − DO NOT attempt to remove it.

Decide on the cable entry position, either top or

rear.

If top entry position is chosen, the cut-out in the

backplate must be removed (fig.7).

Loosely connect the flexible hose supplied to the

T40i inlet connection and the mixer valve outlet.

Using the backplate as a template, hold it

against the wall, making sure there is some slack

in the hose and mark the position of the fixing

holes (fig.8). Remove the flexible hose from the

T40i and mixer valve.

Drill and plug to suit the fixing screws supplied.

(The wallplugs provided are suitable for most brick

walls – use an appropriate masonry drill, but if the

wall is plasterboard or a soft building block, you

must use special wallplugs and an suitable drill

bit).

Screw the top fixing screw into position leaving

the base of the screw head protruding 6mm out

from the wall.

Hook the backplate over the top screw and fit

the bottom fixing screw into position.

The bottom fixing hole is elongated to allow for

out of square adjustment. Tighten both screws

when correctly positioned.

Fig. 6

Fig. 7

Fig. 8

Page 9

7

T40i

Existing

hose

Hose

supplied

Fig.9

HOSE CONNECTIONS

Fitting to:

Bath tap/mixer valve (fig.2)

Mixer valve (fig.3)

Push on with blender valve (fig.4)

Remove the existing sprayhead flexible hose

from bath tap/mixer valve/blender mixer

arrangement.

Screw one end of the flexible hose supplied, to

the T40i inlet connection using one of the

sealing washers to seal the joint. DO NOT

OVERTIGHTEN.

Screw the other end of the flexible hose to the

mixer outlet using the washer provided to seal

the joint. DO NOT OVERTIGHTEN.

Screw the sprayhead flexible hose to the outlet

of the T40i pump using the washer provided to

seal the joint. DO NOT OVERTIGHTEN.

DO NOT kink or twist the hoses.

Remove the sprayhead. Hold the end of the

hose to waste and turn the water on to flush the

system and to check for leaks. Turn off the

water. Replace the sprayhead and turn the

water on again. Leave running to waste until a

smooth (even if poor) flow of water is obtained.

Turn off the water.

Fitting to:

Push-on type connection (fig.5) and

(fig.9)

Unscrew the sprayhead from the existing hose

then connect the hose to the T40i inlet.

Note: This is only possible if the hose

terminates with a ½” BSP connection. Connect

the hose supplied to the T40i outlet using the

washer provided to seal the joint. DO NOT

OVERTIGHTEN.

Hold the end of the hose to waste and turn the

water on to flush the system and to check for

leaks. Turn off the water.

Connect the sprayhead to the supplied hose

using the washer provided.

Turn the water on again and leave running to

waste until a smooth (even if poor) flow of

water is obtained. Turn off the water.

Page 10

8

T40i

L

N

E

Terminal

block

Switch

Pump

Neon

indicator

Fig.10

Terminal

block

Cable

clamp

Fig.11

ELECTRICAL CONNECTIONS

Note: A double pole linked switch with a

minimum contact gap of 3mm in both poles

must be fitted in the circuit.

IMPORTANT: The T40i unit must be supplied

by fixed wiring. The supply cable must

conform to relevant tables in current IEE

regulations. The electrical rating of the T40i

is shown on the rating label within the unit.

Fig.10 shows a schematic wiring diagram.

SWITCH OFF THE ELECTRICITY SUPPLY AT THE

MAINS.

The cable entry points are shown in fig.1. The

cable can be surface clipped, hidden or via

20mm conduit.

Note: Conduit entry can only be from the rear.

Route the cable into the unit and connect to the

terminal block (fig.11) as follows:

Earth cable to terminal marked E

Neutral cable to terminal marked N

Live cable to terminal marked L

IMPORTANT: Fully tighten the terminal block

screws and make sure that no cable

insulation is trapped under the screws.

Note: The supply cable earth conductor must

be sleeved. The cable clamp (fig.10) is suitable

for up to 4mm² cable, but in most cases 1mm²

cable will be enough.

The earth continuity conductor of the electrical

installation must be effectively connected

electrically to all exposed metal parts of other

appliances and services in the room in which the

T40i is to be installed, to conform to current IEE

regulations.

The use of connections within the unit to supply

power to other equipment i.e. extractor fans,

pumps etc. will invalidate the guarantee.

DO NOT switch on the electricity supply

until the cover has been fitted.

WARNING!

This appliance must be earthed.

Page 11

9

T40i

'Dogs'

REPLACING THE COVER AND TESTING

Procedure

a) Make sure the switch spindle adaptor ‘dogs’

are positioned as shown (fig.12).

b) Position the control knob on the cover to

‘stop’ (fig.15).

c) Offer the cover to the unit and plug the

loose neon into the bracket that is located

inside the cover (fig.13).

Place the cover squarely over the backplate and

guide into position so that the extended ‘dogs’

of the spindle adaptor slot into the recess of the

control knob. Should any difficulty arise, recheck

the points above.

Secure the cover in position with the two

retaining screws. DO NOT OVERTIGHTEN.

Turn on the water supply at the mixer valve/tap

and adjust to a normal showering temperature.

Make sure the control knob is at the ‘stop’

position. Switch on the electricity supply at the

isolating switch.

Turn the control knob to the ‘start’ position

(fig.14). The pump will start and the neon will

illuminate. Check for an increase in water flow.

Turn the control knob to the ‘stop’ position

(fig.15). The water flow should decrease. Turn

off the water at the mixer valve/tap.

The installation should be checked for any leaks

from the hose connections.

Fig.13

Fig.12

Page 12

10

T40i

Fig.14

Fig.15

OPERATING

Ensure the electric isolating switch is on to the

T40i. Turn on the water supply at the mixer

valve/tap and adjust to a showering

temperature.

Switch the T40i control knob to ‘start’ (fig.14).

The pump will start and the neon will illuminate.

Adjust shower temperature as normal.

Note: With the push-on hose systems the T40i

pump should not be switched on until water

flows from the sprayhead.

When showering is completed, switch the T40i

control knob to ‘stop’ (fig.15).

Turn off the mixer valve or taps.

MAINTENANCE

It is recommended that the booster pump unit

and hoses be cleaned using a soft cloth and that

the use of abrasive or solvent cleaning fluids be

avoided.

Before cleaning, turn off the unit at the isolation

switch to avoid accidental switching on of the

booster pump.

IT IS MOST IMPORTANT TO KEEP THE EXISTING

SPRAYHEAD CLEAN IN ORDER TO MAINTAIN

THE PERFORMANCE OF THE SHOWER.

The hardness of water will determine the

frequency of cleaning. For example, if the

shower is used every day in a very hard water

area, it may be necessary to clean the sprayhead

on a weekly basis.

If the T40i pump is not used for lengthy periods,

it is recommended to turn on the water at the

mixer valve/tap then switch the pump on for

two or three minutes periodically to prevent the

motor shaft seals from seizing.

Do not run the T40i pump dry.

WARNING!

Do not use ‘powerful’ abrasive or solvent

cleaning fluids when cleaning the booster

pump as they may damage the plastic

fittings.

Page 13

11

T40i

3

5

4

2

1

1

6

7

Ref. Description Part No.

1 Pump & motor assembly 83100050

2 Microswitch 22003230

3 Terminal block & wires 82200380

4 Switch assembly 82500130

5 Cable clamp 70500820

6 Inlet pipe assembly 83304900

7 Outlet pipe assembly 83304910

− Cover assembly 80400010

− Flexible hose (chrome) 28100080

SPARE PARTS

Page 14

12

T40i

1 During use, the

water flow drops

to a reduced rate.

Pump stops

running.

2 During use, the

water flow ceases

but the pump

continues to run.

3 Water too hot or

too cold.

1.1 Interrupted power

supply.

1.2 Pump motor faulty.

2.1 Water starvation in

the system.

2.2 Air lock in pump.

3.1 Not product related

but problem with

existing water

heating system.

1.1.1 If the power neon is extinguished, check

consumer unit fuse or circuit breaker. If

blown, renew or reset as applicable. If it

fails again, consult a qualified electrician.

1.1.2 If the power neon is extinguished, check if

a general power cut. Check other

appliances and if necessary, contact local

Electricity Supply Company.

1.2.1 If the power neon is lit, have pump motor

checked by a qualified electrician or

contact Triton Customer Service.

2.1.1 Stop pump motor by switching to ‘stop’.

Check the cold water cistern is full. Ensure

water pipes are not blocked. Check there

is no simultaneous demand from the

cistern while showering.

2.2.1 Prime pump by running water through

unit without electricity switched on.

3.1.1 Consult qualified electrician or plumber.

FAULT FINDING

IMPORTANT: Switch OFF the electricity at the mains supply and remove the circuit fuse

before removing the cover from the T40i while attempting any fault finding inside the unit.

Problem/Symptom Cause Action/cure

It is advised all electrical maintenance/repairs to the T40i

should be carried out by a suitably qualified person.

Page 15

13

T40i

UKAS

QUALITY

M ANAGEMENT

003

Page 16

Service Policy

In the event of a complaint occurring, the

following procedure should be followed:

1 Telephone Customer Service on (024) 7637

2222 (08457 626591 in Scotland and in Northern

Ireland), having available the model number and

power rating of the product, together with the

date of purchase.

2 Triton Customer Service will be able to confirm

whether the fault can be rectified by either the

provision of a replacement part or a site visit from

a qualified Triton service engineer.

3 If a service call is required it will be booked and

the date of call confirmed. In order to expedite

your request, please have your postcode available

when booking a service call.

4 It is essential that you or an appointed

representative (who must be a person of 18 years

of age or more) is present during the service

engineer's visit and receipt of purchase is shown.

5 A charge will be made in the event of an

aborted service call by you but not by us, or

where a call under the terms of guarantee has

been booked and the failure is not product related

(i.e. scaling and furring, incorrect water pressure,

pressure relief device operation, electrical

installation faults).

6 If the product is no longer covered by the

guarantee, a charge will be made for the site visit

and for any parts supplied.

7 Service charges are based on the account being

settled when work is complete, the engineer will

then request payment for the invoice. If this is not

made to the service engineer or settled within ten

working days, an administration charge will be

added.

Replacement Parts Policy

Availability: It is the policy of Triton to maintain

availability of parts for the current range of

products for supply after the guarantee has

expired. Stocks of spare parts will be maintained

for the duration of the product’s manufacture and

for a period of five years thereafter.

In the event of a spare part not being available a

substitute part will be supplied.

Payment: The following payment methods can be

used to obtain spare parts:

1 By post, pre-payment of pro forma invoice by

cheque or money order.

2 By telephone, quoting credit card (MasterCard

or Visa) details.

3 By website order, www.tritonshowers.co.uk

TRITON STANDARD GUARANTEE

Triton Plc guarantee this product against all

mechanical and electrical defects arising from

faulty workmanship or materials for a period of

one year for domestic use only, from the date of

purchase, provided that it has been installed by a

competent person in full accordance with the

fitting instructions.

Any part found to be defective during this

guarantee period we undertake to repair or

replace at our option without charge so long as

it has been properly maintained and operated in

accordance with the operating instructions, and

has not been subject to misuse or damage.

This product must not be taken apart, modified

or repaired except by a person authorised by

Triton Plc. This guarantee applies only to

products installed within the United Kingdom

and does not apply to products used

commercially. This guarantee does not affect

your statutory rights.

What is not covered:

1 Breakdown due to: a) use other than

domestic use by you or your resident family;

b) wilful act or neglect; c) any malfunction

resulting from the incorrect use or quality of

electricity, gas or water or incorrect setting of

controls; d) faulty installation.

2 Repair costs for damage caused by foreign

objects or substances.

3 Total loss of the product due to nonavailability of parts.

4 Compensation for loss of use of the product

or consequential loss of any kind.

5 Call out charges where no fault has been

found with the appliance.

6 The cost of repair or replacement of pressure

relief devices, sprayheads, hoses, riser rails

and/or wall brackets, isolating switches, electrical

cable, fuses and/or circuit breakers or any other

accessories installed at the same time.

7 The cost of routine maintenance,

adjustments, overhaul modifications or loss or

damage arising therefrom, including the cost of

repairing damage, breakdown, malfunction

caused by corrosion, furring, pipe scaling,

limescale, system debris or frost.

Triton Plc

Shepperton Park

Caldwell Road

Nuneaton

Warwickshire CV11 4NR

Customer Service:

(024) 7637 2222

Scottish and Northern Ireland

Customer Service:

08457 626591

Trade Installer Hotline:

(024) 7632 5491

Fax: (024) 7632 4564

www.tritonshowers.co.uk

E mail: technical@triton.plc.uk

Loading...

Loading...