Page 1

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically-treated rubber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well-ventilated

area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Certaines poussières générées par le ponçage, sciage, le perçage et d’autres activités de constructions électriques contiennent des substances chimiques

reconnues dans l’État de la Californie comme étant une cause de cancer, de malformations congénitales et d’autres problèmes reproductifs. Des exemples de ces

substances chimiques sont :

• Le plomb, provenant des peintures à base de plomb

• La silice cristalline, provenant des briques, du ciment et d’autre matériaux de construction

• L’arsenic et le chrome, provenant des caoutchoucs traités chimiquement

Les risques résultant de ces expositions varient en fonction de la fréquence à laquelle vous effectuez ce type de travaux. Pour réduire l’exposition à ces substances

chimiques : travaillez dans une zone ventilée et portez un équipement adapté, comme un masque à poussière conçu spécialement pour filtrer les particules

microscopiques.

Parte del polvo creado por el lijado, aserrado, esmerilado, taladrado y otras actividades de construcción contienen sustancias químicas identificadas por el estado

de California como causantes de cáncer, o defectos de nacimientos, y/u otros daños reproductivos. Algunos ejemplos de estos productos químicos son:

• El plomo de las pinturas a base de plomo.

• La sílice cristalina de los ladrillos y cemento y otros productos de mampostería.

• El arsénico y el cromo de goma tratados químicamente.

El riesgo derivado de estas exposiciones puede variar dependiendo de la frecuencia con que se realice este tipo de trabajo. Para reducir la exposición a estas

sustancias químicas, trabaje siempre en áreas bien ventilada y lleve equipos de seguridad adecuados, tales como máscaras contra el polvo especialmente

diseñadas para filtrar partículas microscópicas.

940454_Z1MANPRO1.indd 2 25/09/2014 17:25

Page 2

GB

Operating and

Safety Instructions

Instructions d’utilisation

F

et consignes de sécurité

Instrucciones de

ESP

uso y de seguridad

Instruções de

PT

Operação e Segurança

取扱説明書およ

JP

び安全の手引き

20V Combi Hammer Drill

T20 CH

tritontools.com

940454_Z1MANPRO1.indd 2 25/09/2014 17:25

Page 3

GB

Original Instructions

Thank you for purchasing this Triton tool. This manual contains information necessary for safe and effective operation of this product. This

product has unique features and, even if you are familiar with similar products, it is necessary to read this manual carefully to ensure you

fully understand the instructions. Ensure all users of the tool read and fully understand this manual.

Contents

Specification 2

Product Familiarisation 3

Description of Symbols 4

General Safety 4

Additional Safety for Battery-Operated Drills and Screwdrivers 5

Battery Pack & Charger Safety 5

Intended Use 6

Unpacking Your Tool 6

Before Use 6

Operation 7

Accessories 7

Maintenance 7

Disposal 7

Guarantee 9

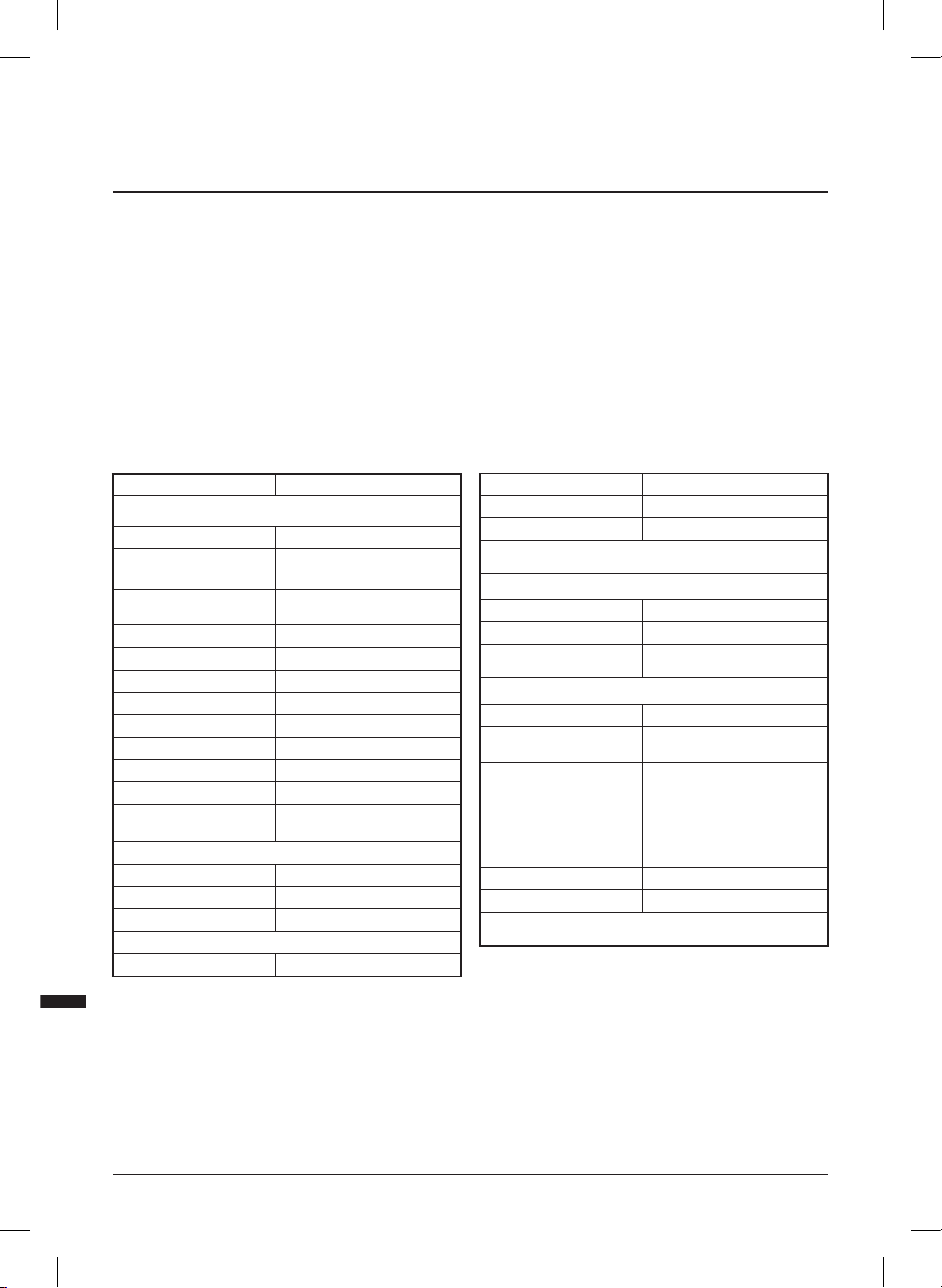

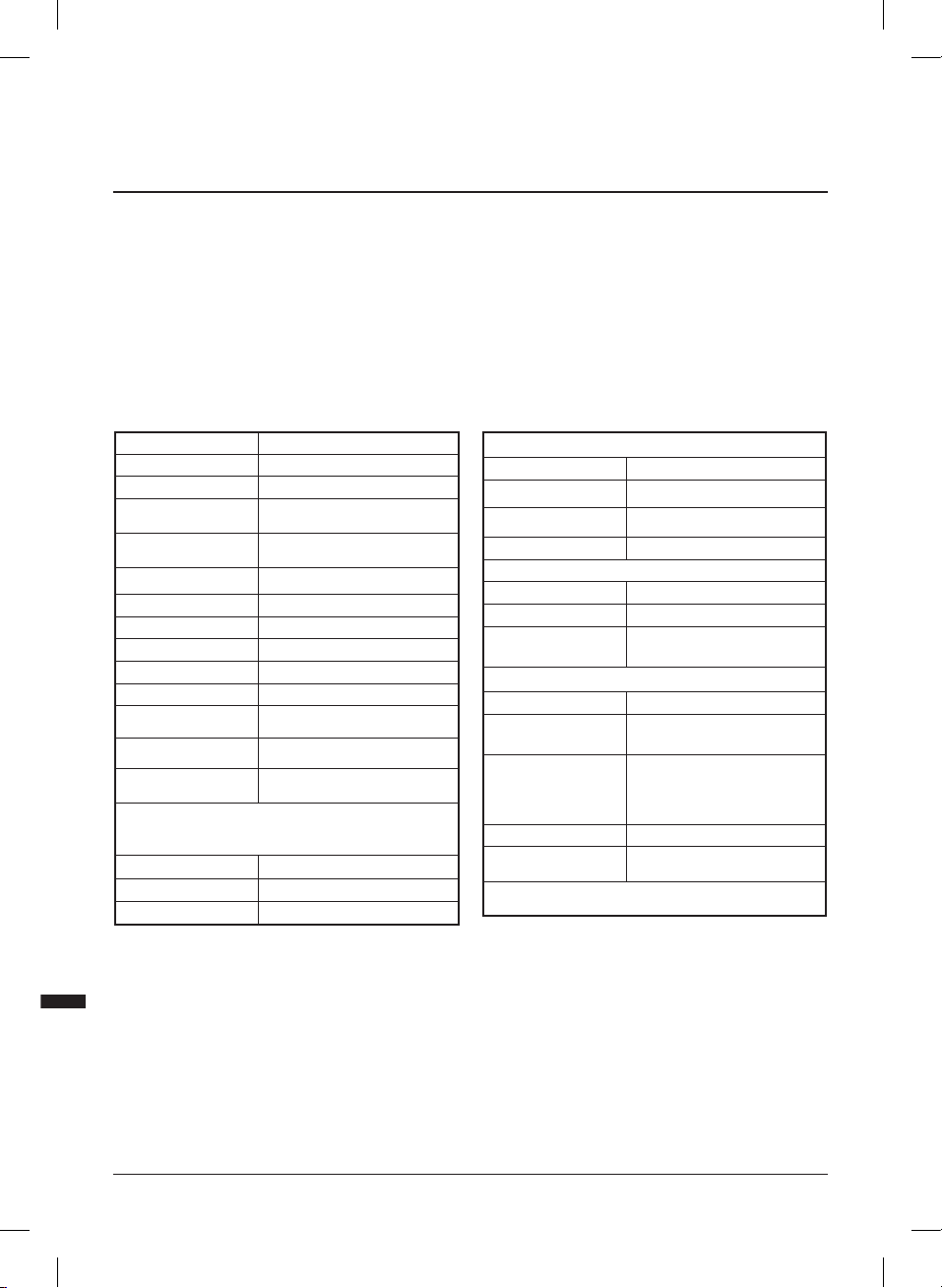

Specification

Model number: T20CH

Drill

Voltage: 20V, d.c

No load speed: 0 - 450min-1 (low gear)

Impact frequency: 7200/min (low gear)

Gears: 2

Speed control: Trigger

Torque settings: 16+2

Maximum torque: 48Nm

Chuck capacity: 1.5 - 13mm ( 1⁄16 – ½" )

Drilling capacity (wood): 26mm ( 1-1⁄32" )

Drilling capacity (masonry): 10mm ( 3⁄8" )

Drilling capacity (steel): 13mm (½" )

Weight: 3.9kg (8.6lbs)

Sound and vibration information:

Sound pressure LPA: 87.6dB(A)

Sound power LWA: 98.6dB(A)

Uncertainty K: 3dB

Weighted vibration:

(metal) a

: 2.373m/s

h,D

0 - 1600min-1 (high gear)

25,600/min (high gear)

(with 4.0 Ah battery pack fitted)

2

(concrete) a

: 7.104m/s

h,ID

(no load/max.speed) a

Uncertainty K: 1.5m/s

The sound intensity level for the operator may exceed 85dB(A) and sound protection

measures are necessary.

: 1.707m/s

h,NL

Battery Pack

Technology: Samsung Li-Ion cells

Voltage: 20V, d.c.

Model & capacity: T20HCB, 4.0Ah

Battery charger

Charger model: T20BC

Charging times: 1hr (for T20HCB: 4Ah battery pack)

Input Voltage: EU: 220-240V, a.c. 50/60Hz, 80W

Power output: 20V, d.c., 3.0A

Length of power cord: 2m (6-1⁄2')

As part of our ongoing product development, specifications of Triton products may alter

without notice.

2

2

2

T20B, 2.0Ah

30min (T20B: 2Ah battery pack)

SA: 220-240V, a.c. 50/60Hz, 80W

AU: 220-240V, a.c. 50/60Hz, 80W

JP: 100-120V, a.c. 50/60Hz, 1.3A

US/CAN: 120V, a.c. 60Hz, 1.3A

WARNING: Always wear ear protection where the sound level exceeds 85dB(A) and limit the time of exposure if necessary. If sound levels are uncomfortable, even with ear protection, stop using

the tool immediately and check the ear protection is correctly fitted and provides the correct level of sound attenuation for the level of sound produced by your tool.

WARNING: User exposure to tool vibration can result in loss of sense of touch, numbness, tingling and reduced ability to grip. Long term exposure can lead to a chronic condition. If necessary, limit

the length of time exposed to vibration and use anti-vibration gloves. Do not operate the tool with hands below a normal comfortable temperature, as vibration will have a greater effect. Use the

figures provided in the specification relating to vibration to calculate the duration and frequency of operating the tool.

Sound and vibration levels in the specification are determined according to EN60745 or similar international standards. The figures represent normal use for the tool in normal working conditions.

A poorly maintained, incorrectly assembled, or misused tool, may produce increased levels of noise and vibration. www.osha.europa.eu provides information on sound and vibration levels in the

workplace that may be useful to domestic users who use tools for long periods of time.

2

940454_Z1MANPRO1.indd 2 25/09/2014 17:25

Page 4

GB

Product Familiarisation

1. Keyless Chuck

2. Torque Adjustment Collar

3. Mode Selector

4. Gear Selector

5. Forward/Reverse Switch

6. Speed Control Trigger Switch

7. Battery Release Button

8. Belt Clip

9. Battery Pack*

10. LED Guide Light

11. T20 Battery Charger

Accessories (not shown):

• Soft carry case

Converter Plug

UK users: do not attempt to remove the installed UK converter plug and use it on other

appliances.

Do not remove the installed UK converter plug and attempt to insert it directly into UK mains

power supply sockets.

If the UK converter plug is damaged, please contact an authorised Triton service centre.

1 2 3 4

11

*NOTE: Battery provided may differ from image.

10

5

6

7

8

9

3

940454_Z1MANPRO1.indd 3 25/09/2014 17:25

Page 5

GB

Description of Symbols

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Read instruction manual

General Safety

WARNING Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

WARNING: This appliance is not intended for use by persons (including children)

with reduced, physical or mental capabilities or lack of experience or knowledge.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

Work area safety

Caution!

DO NOT incinerate batteries!

For indoors use only (battery and battery charger)!

Internal time-lag fuse with rated current 3.15A

T3.15A

Environmental Protection

Waste electrical products should not be disposed of with household waste. Please

recycle where facilities exist. Check with your local authority or retailer for recycling

advice.

Environmental Protection

Waste electrical products and batteries, including Li-Ion batteries, should not be

disposed of with household waste. Please recycle where facilities exist. Check with

your local authority or retailer for recycling advice.

Li-ion battery cells are recyclable and should not be disposed of with household

waste. Please recycle where facilities exist. Check with your local authority or

retailer for recycling advice

Li-ion

Conforms to relevant legislation and safety standards. (Only EU model)

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool

on. A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

Power Tool Use & Care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

4

940454_Z1MANPRO1.indd 4 25/09/2014 17:25

Page 6

GB

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

Battery tools use and care

a) Recharge only with charger specified by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of fire when used with another battery

pack.

b) Use power tools only with specifically designated battery packs.

Use of any other battery packs may create a risk of injury and fire

c) When battery pack is not in use, keep it away from other metal objects, like paper

clips, coins, keys, nails, screws and other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause a burns or

a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If

contact accidentally occurs, flush with water. If liquid contact eyes, additionally

seek medical help. Liquid ejected from the battery may cause irritation or burns.

WARNING: When used in Australia or New Zealand, it is recommended that this tool is ALWAYS

supplied via Residual Current Device (RCD) with a rated residual current of 30mA or less.

Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Additional Safety for BatteryOperated Drills & Screwdrivers

For safety relating to protective clothing/equipment and general health hazards relating to

power tools; refer to General and Electrical Safety sections in this manual

• Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss

• Hold power tools by insulated gripping surfaces, when performing an operation where

the cutting accessory may contact hidden wiring. Cutting accessory and/or fasteners

contacting a “live” wire may make exposed metal parts of the power tool “live” and give

the operator an electric shock.

Important: It is imperative to follow all national safety regulations concerning installation,

operation and maintenance

• Do not allow anyone under the age of 18 years to use this tool, and ensure that operators

are qualified and familiar with the operating and safety instructions

• If batteries are to be charged outdoors, ensure that the power supply and charger are

protected against weather/moisture

• When using the drill, use safety equipment including safety glasses or shield, ear

defenders, and protective clothing including safety gloves. Wear a dust mask if the drilling

operation creates dust

• Use metal and voltage detectors to locate concealed electric, water or gas lines. Avoid

touching live components or conductors

• Ensure that the lighting is adequate

• Ensure that the drill bit is securely fixed in the chuck. Insecure drill bits can be ejected

from the machine causing a hazard

• Ensure that the drill bit is in contact with the workpiece prior to starting up the tool

• Before drilling, check that there is sufficient clearance for the drill bit under the workpiece

• Do not put pressure on the tool, to do so would shorten its service life

• Drill bits get hot during operation, allow to cool prior to handling them

• Never use your hands to remove sawdust, chips or waste close by the bit

• If you are interrupted when operating the drill, complete the process and switch off before

looking up

• Where possible, use clamps or a vice to hold your work

• Examine the chuck regularly for signs of wear or damage. Have damaged parts repaired

by a qualified service centre

• Always wait until the drill has come to a complete stop before putting it down

• Periodically check all nuts, bolts and other fixings and tighten where necessary

Battery and Charger Safety

Use the battery charger correctly

• Refer to the section of this manual relating to use of the battery charger before attempting

to charge the battery pack.

• Do not attempt to use the charger with any batteries other than those supplied. Keep your

battery charger clean; foreign objects or dirt may cause a short or block air vents. Failure

to follow these instructions may cause overheating or fire

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard

• Children should be supervised to ensure that they do not play with the appliance.

Warning: Do not recharge non-rechargeable batteries

Use batteries correctly

• Only charge batteries using the charger provided. Only use batteries provided with this

power tool, or others recommended by the supplier. Keep batteries clean; foreign objects

or dirt may cause a short. Allow batteries to cool for 15 minutes after charging or heavy

use. Failure to follow these instructions may cause overheating or fire.

• When not in use batteries should be stored at room temperature (approx. 20˚C). Ensure

that batteries cannot accidentally short in storage.

NOTICE for Battery Packs

• DANGER – Risk of battery packs include burn hazard, fire hazard and explosion hazard

• CAUTION - Do Not Open, Disassemble, Crush, Heat above 60 degree C or incinerate. Do

Not dispose of in fire or similar.

• CAUTION – for Primary batteries, do not charge.

• CAUTION – only charge battery with charger model T20BC. For Safety use of battery

charger, make reference to the instruction manual of the battery charger.

• CAUTION - Follow Manufacturer’s Instructions

Battery and charger safety features

The battery pack and charger are fitted with a number of safety features which may be

triggered during charging or operation:

• Over-charge protection: Charger automatically switches off when the battery pack has

reached full charge capacity, protecting the internal components of the battery pack

• Over-discharge protection: Prevents the battery from discharging beyond the

recommended lowest safety voltage

• Over-heat protection: Sensor switches off if the battery becomes too hot during operation.

This can happen if the tool is overloaded or being used for extended periods of time. Up to

30 minutes cooling time may be required depending on the ambient temperature

• Overload protection: Battery temporarily stops if it is overloaded or the maximum current

draw is exceeded, protecting the internal components. The battery will resume normal

operation when the current draw returns to a normal safe level. This may take a few

seconds

• Short circuit protection: The battery pack will stop working immediately if a short circuit

occurs, this prevents damage to the battery pack or tool

WARNING for Australia and New Zealand

• WARNING: When used in Australia or New Zealand, it is recommended that this tool is

ALWAYS supplied via Residual Current Device (RCD) with a rated residual current of

30mA or less.

5

940454_Z1MANPRO1.indd 5 25/09/2014 17:25

Page 7

GB

Intended Use

• Battery operated drill with screwdriver, drill and hammer drill functions suitable for

medium duty drilling and driving tasks

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its features and

functions

• Ensure that all parts of the tool are present and in good condition. If any parts are missing

or damaged, have such parts replaced before attempting to use this tool

Before Use

• This cordless impact driver has been shipped in a low charge condition. Charge the

battery before use

Battery charger operation

• The charger and battery pack may become warm while charging. This is normal and does

not indicate a problem

• Use the charger at normal room temperatures whenever possible. To prevent overheating,

do not cover the charger and do not charge the battery in direct sunlight or near sources

of heat

If the battery does not charge properly:

• Check current at power outlet by plugging in a lamp or other appliance

• If charging problems persist, have the impact driver, battery pack and battery charger

checked by an electrician or a power tool technician

Charging the battery pack

1. Depress the Battery Release Button (7) and remove the battery from the tool

2. Insert the battery pack into the T20 Battery Charger (11). Do not use excessive force

when inserting the battery pack. If it does not slide into place easily, it is not being

inserted correctly

3. Initially only the green LED may flash as it evaluates the status of the battery. When

charging the red LED will illuminate and the green LED will be OFF

4. When the battery is fully charged the red LED will be OFF and the green LED will

illuminate

5. The battery charger will constantly monitor the condition of the battery when charging

6. Remove the battery pack as soon as possible when completely charged

7. Disconnect the charger from the power supply and store in a clean, dry environment out of

the reach of children

• Normal battery charging time is approximately 1hour for a recently fully discharged 4Ah

battery at normal temperature. Charging times will vary outside these conditions. 2.0Ah

battery: Please note the full charging time will be approximately 30 minutes

• You do not need to fully discharge the battery before recharging but you should not

attempt to recharge a battery that is already fully charged

• You can interrupt charging at any point to use the battery. Under normal conditions the

charger charges at a higher rate but reduces the charging rate as the battery becomes

fully charged. An 80% charge is achieved after 1/2hr of charging

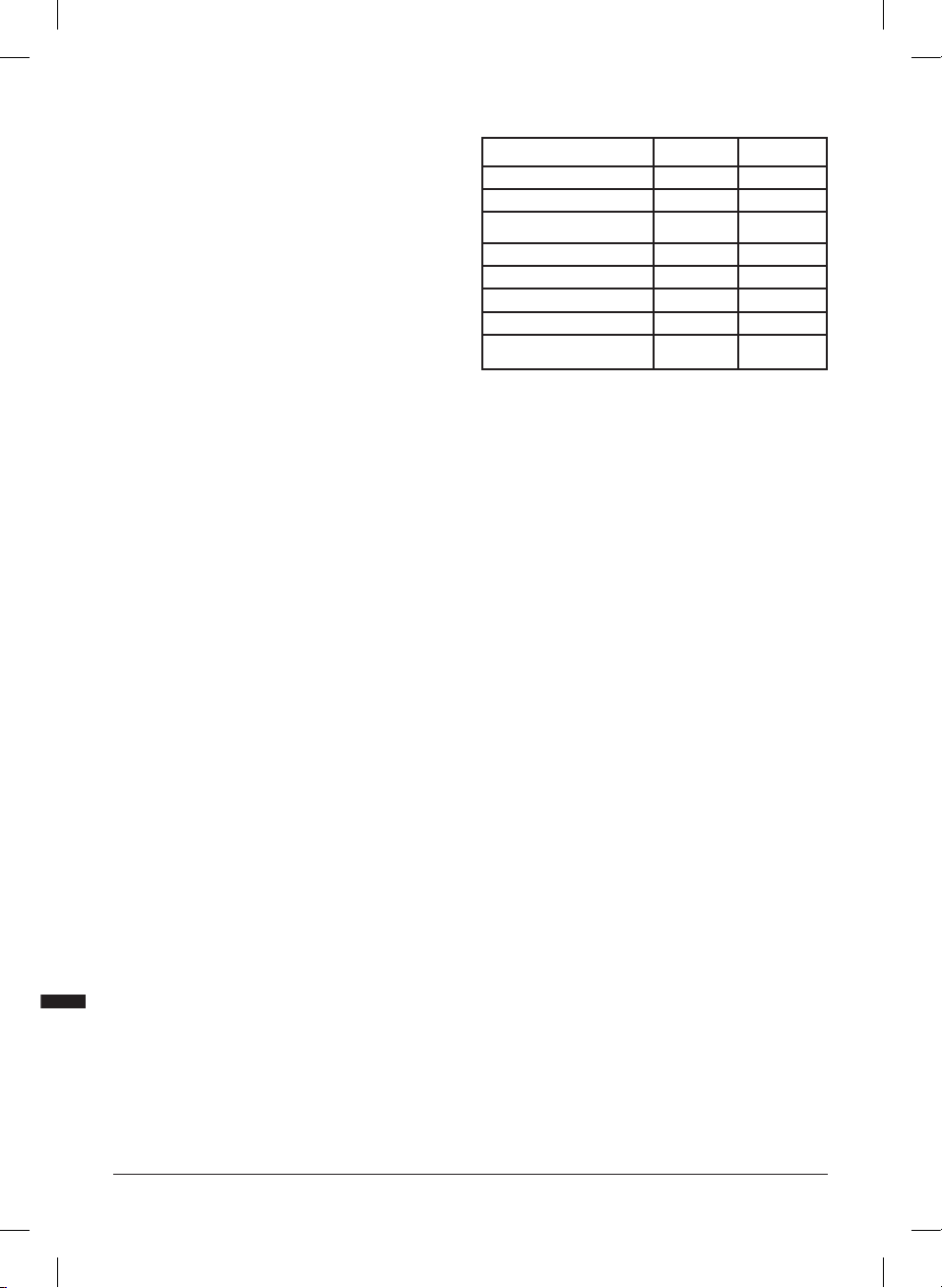

Battery charging table

Red LED Green LED

Charger plugged In OFF Flashing

Charger evaluating battery OFF Flashing

Fast charging ON Off

Highly discharged battery slow charging Flashing Off

Abnormal battery temperature charging Flashing Off

Fully Charged OFF On

Battery or charger fault Flashing Flashing

Temporary abnormal temperature

condition

Note: If the lights on the battery charger fail to illuminate according to the chart above or

indicate a fault condition:

• Check the battery is firmly seated in the battery charger

• Check all connections and that mains power is switched on

On On

Initial charge

• The initial charge will vary depending on the existing charge in the battery. Allow the

battery to reach full charge as indicated on the charger

• After discharging, recharge the battery completely, as indicated by the LED on the battery

charger, for the next 4 to 5 uses. This will ensure that the battery is performing to its

highest capacity

• Subsequent full charges will take approximately 1 hour (T20HCB: 4Ah battery), however

the battery can be recharged when the battery is only partially discharged

Re-charging the battery

• After use, a lithium-ion battery must be allowed to cool down before charging

• If a hot battery is inserted into the charger both LEDs will illuminate. The charger will

begin to charge when the battery has cooled sufficiently (this may take several minutes)

Installing the battery

• The battery should fit easily into the battery charger or drill unit. If the battery is difficult

to fit, check the condition of the battery and contacts

Battery - length of service

• The length of service from each charging cycle will depend on the type of workload. The

battery charger and battery for this impact driver have been designed to provide a long

trouble-free working life. The charger intelligently monitors the condition of the battery

and selects the ideal charging rate for the condition of the battery. It protects the battery

from over-charging or charging at too high a rate. However, like all batteries, performance

will be reduced over time

To maximise battery life:

• Store and charge the battery in a cool area. Temperatures above or below normal room

temperature will reduce battery life

• Never store lithium-ion batteries in a discharged condition. Recharge them immediately

after they are discharged. For storing long term, store fully charged

• All batteries gradually lose their charge, even lithium-ion batteries, but the discharge rate

is very low. If the impact driver is stored for long periods of time without use, recharge

the battery every three to four months and disconnect the battery from the power tool

before it is stored. This practice will prevent the lithium-ion battery being damaged when

stored

6

940454_Z1MANPRO1.indd 6 25/09/2014 17:25

Page 8

GB

Fitting a drill or driver bit

WARNING: DO NOT fit any attachment with a maximum speed lower than the no load speed

of the machine.

1. Rotate the Keyless Chuck (1) collar clockwise and insert the bit into the chuck

2. Rotate the Keyless Chuck collar anti-clockwise to secure the drill bit

Note: DO NOT run the tool whilst tightening or releasing the chuck. Ideally select the locked

middle position of the Forward/Reverse Switch (5).

3. When the bit is held tightly, test that it is positioned centrally by running the tool. The bit

should rotate smoothly without uneven rotation. If the bit is not central, release the chuck,

reposition the bit and retighten the chuck

Direction control

• The rotation direction can be set using the Forward/Reverse Switch (5)

• To let the chuck rotate clockwise, push the Forward/Reverse Switch to the left

• To let the chuck rotate anti-clockwise, push the Forward/Reverse Switch to the right

• When the Forward/Reverse Switch is in the central position, the tool is locked

WARNING: DO NOT attempt to move the forward/reverse selector when the tool is running

Speed control

• This drill driver features a 2-speed gearbox:

- 1st gear range: 0 – 450min

- 2nd gear range: 0 – 1600min

• Use the Gear Selector (4) to set the gear: forward for first gear, back for second gear

Note: The first gear would be used normally for driving screws for example and offers higher

torque and superior control at low rpm. The second gear would normally be used exclusively

for drilling.

-1

-1

Torque control

• This drill driver is fitted with torque control, which limits the torque output of the drill,

enabling screws to be driven without the risk of damage

• There are 16 torque settings and two drill settings. The lower the number, the lower the

torque

• To adjust the torque, select the first gear and rotate the Torque Adjustment Collar (2) until

the setting you require is aligned with the arrow on the combi hammer drill housing

• Check that the torque setting is correct by practising first on a piece of scrap material

Mode selection

• For drilling, select the correct gear, then rotate the Mode Selector (3) to the drill symbol.

This will lock the tool for maximum torque

• For screwdriving, select the correct gear, then rotate the Mode Selector to the screw

symbol. This will activate the torque clutch

• For masonry drilling, select the correct gear, then rotate the Mode Selector to the

hammer symbol. This will lock the tool for maximum torque and activate impact hammer

function

WARNING: The drill driver can be fitted with a drive adaptor for use with driving nuts and bolts.

Do not attempt to use this tool in the drill position when doing so. Use the 16 torque settings

and the first gear to allow the torque clutch to protect the tool from excessive load. The use

of a spanner to loosen or tighten a nut/bolt is recommended. This allows the tool to speed up

the operation, without risk of damage, when high torque is required at the beginning or end

of the operation.

Operation

WARNING: Always use adequate protective equipment, including eye protection, respiratory

and hearing protection, when working with this tool.

Switching on and off

• To start the tool, squeeze the Speed Control Trigger Switch (6). The LED Guide Light (10)

will illuminate

• Further pressure on the trigger will increase the running speed of the tool

• Release the Speed Control Trigger Switch to stop the tool

Note: It is possible the drill driver may switch off during heavy use due to thermal protection

of the battery and internal components. This may prevent the tool being used again for a short

period of time and does not represent a fault condition.

Drilling guidance

• Use sharp drill bits and ensure that drill bits are suitable for the material being drilled

• Never exceed the maximum drilling capacities listed in ‘Specification’

• Begin drilling at slow speeds by partially squeezing the trigger switch

• Reduce pressure on the trigger when the drill bit is about to break through to the other

side of material

• To avoid splintering on breakthrough, either clamp a piece of scrap wood to the back

of the workpiece or continue the hole from the back of the wood when the drill bit first

breaks through

Drilling metal

• Support thin material with a piece of scrap wood

• Mark the intended hole position using a hammer and centre punch

• Use only HSS (high speed steel) drill bits or others recommended for drilling into metal

• Prior to drilling large holes, use a smaller bit to drill a pilot hole

• Use a suitable coolant/lubricant to prolong the service life of the drill bit, and produce good

results

Drilling masonry

• Always use a masonry drill bit, preferably a TCT masonry bit, when drilling into walls,

stone or concrete

• DO NOT apply too much pressure to the back of the tool. If debris blocks the drill hole, run

the drill slowly and remove the bit from the hole. Repeat until the hole is clear of debris

and continue

Accessories

• A range of accessories, including a 2Ah battery (T20B), 4Ah high capacity battery

(T20HCB), drill and screwdriver bits is available from your Triton dealer. Spare parts can be

purchased from your Triton dealer or online at www.toolsparesonline.com

Maintenance

• This tool is manufactured using class leading components and makes use of the latest

in intelligent circuitry that protects the tool and its components. In normal use it should

provide a long working life

Cleaning

• Keep your machine clean at all times. Dirt and dust will cause internal parts to wear

quickly, and shorten the machine’s service life. Clean the body of your machine with a

soft brush or dry cloth. If available, use clean, dry, compressed air to blow through the

ventilation holes

Storage

• Store this tool and its accessories after use in its case, in a dry, secure place out of the

reach of children

Disposal

Always adhere to national regulations when disposing of power tools that are no longer

functional and are not viable for repair.

• Do not dispose of power tools, batteries or other waste electrical and electronic equipment

(WEEE), with household waste

• Contact your local waste disposal authority for information on the correct way to dispose

of power tools and batteries

940454_Z1MANPRO1.indd 7 25/09/2014 17:25

7

Page 9

GB

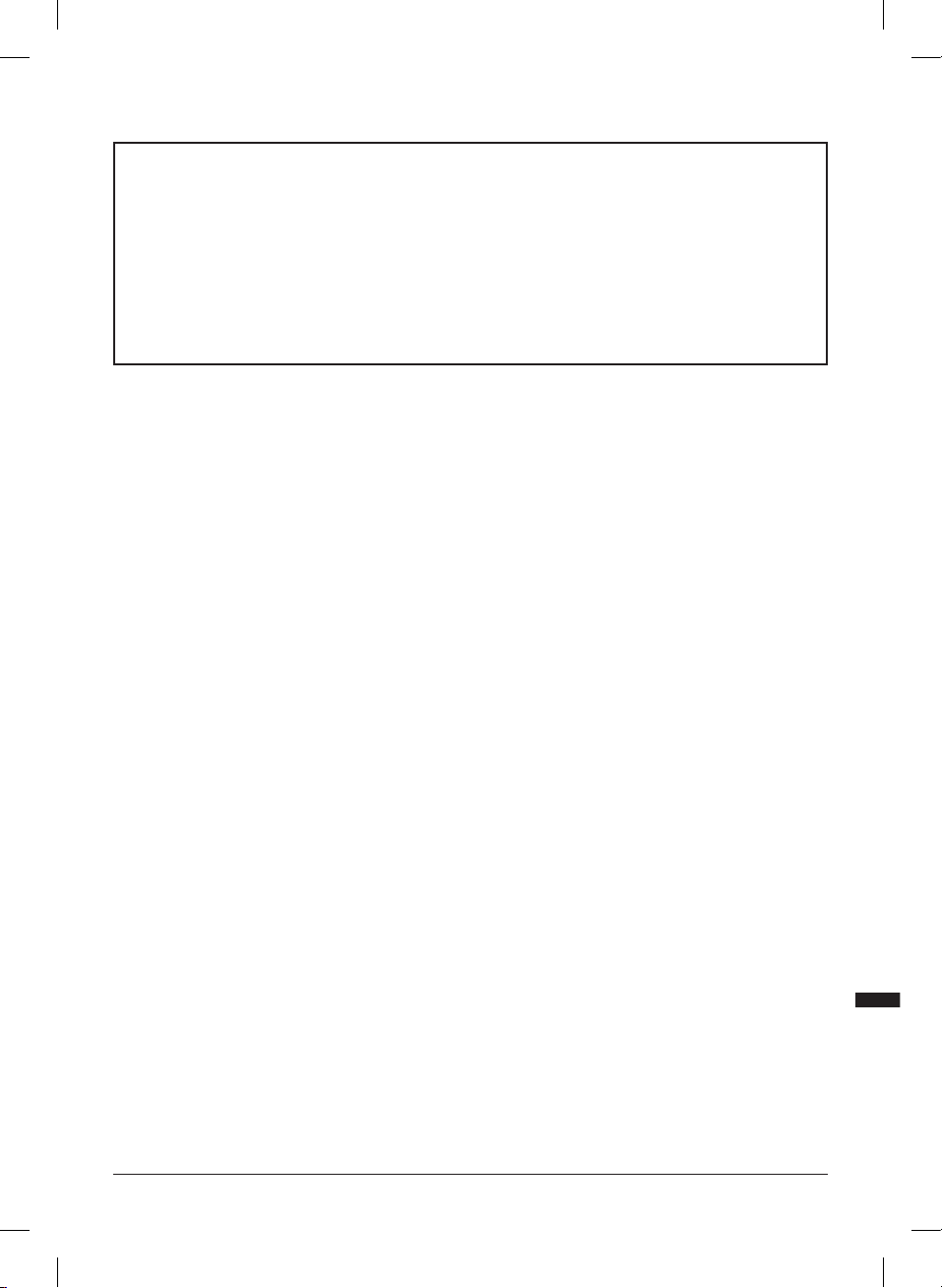

Troubleshooting

Problem Possible cause Solution

Red charging LED does not illuminate and battery not

charging

Battery pack has low capacity

Drill cannot be switched on (trigger switch does not move)

Drill does not start when on/off trigger switch is depressed

Screws do not reach deep enough into the workpiece

Screws are driven too deep into the workpiece surface Too much torque; torque clutch setting too high Choose a lower torque setting

During masonry drilling the drill bit does not penetrate

the wall

Battery not fully seated Clean battery socket of charger

Charger not powered Recheck mains connection

Battery not being fully charged Charge the battery until the charger indicates a full charge

Battery pack has been charged over 100 times and capacity

has started to reduce

The forward/reverse switch may be in the middle (‘locked’)

position

Battery completely discharged Recharge ba ttery or replace with a fully charged battery

Defective battery Replace battery

Machine defective Contact your Triton dealer or authorised service centre

Not enough torque; torque clutch setting too low Choose a higher torque setting

Low battery voltage Recharge battery or replace with a fully charged ba ttery

Unsuitable or blunt drill bit Replace drill bit with a new high quality masonry drill bit

Drill bit too large See ‘Specifications’ for maximum drilling capacities

Drill not set to hammer mode

This is normal for battery packs. Contact your Triton dealer

to purchase a replacement battery pack

Slide the forward/reverse switch either to the left or right

Rotate mode selector to switch the machine into hammer

drill mode (see ‘Mode Selection’)

8

940454_Z1MANPRO1.indd 8 25/09/2014 17:25

Page 10

GB

Guarantee

To register your guarantee visit our web site at

www.tritontools.com* and enter your details.

Your details will be included on our mailing list (unless indicated otherwise) for

information on future releases. Details provided will not be made available to any third

party.

Purchase Record

Date of Purchase: ___ / ___ / ____

Model: T20CH Retain your receipt as proof of purchase art pr

Triton Preci sion Power Tools guara ntees to the purcha ser of this product t hat if any part

proves to be d efective due to faul ty materials or wo rkmanship within 3 Y EARS fro m the

date of orig inal purchase,

Triton will rep air, or at its discretio n replace, the fault y part free of cha rge.

This guar antee does not appl y to commercial use nor d oes it extend to nor mal wear and

tear or dama ge as a result of accide nt, abuse or misuse.

* Register o nline within 30 days .

Terms & conditi ons apply.

This does not affect your statutory rights oves to be defecti

9

940454_Z1MANPRO1.indd 9 25/09/2014 17:25

Page 11

F

Traductions des instructions originales

Nous vous remercions d’avoir choisi cet équipement Triton. Ces instructions contiennent les informations nécessaires au fonctionnement

efficace et sûr de ce produit. Veuillez lire attentivement ce manuel pour vous assurer de tirer pleinement avantage des caractéristiques

uniques de votre nouvel équipement. Gardez ce manuel à portée de main et assurez-vous que tous les utilisateurs l’aient lu et bien compris

avant toute utilisation.

Table des matières

Caractéristiques techniques 16

Nomenclature 17

Consignes générales de sécurité 17

Consignes de sécurité relatives aux perceuses sans fil 18

Consignes générales de sécurité relatives aux chargeurs de batterie 18

Usage conforme 19

Avant utilisation 19

Instructions d’utilisation 20

Accessoires 20

Entretien 20

Recyclage 20

Garantie 21

Déclaration de conformité 21

Caractéristiques techniques

Numéro du modèle : T20CH

Perceuse

Tension : 20 V CC

Vitesse à vide : 0 - 450 min-1 (bas régime)

Fréquence des percussions : 7200 coups/min (bas régime)

Régime de la boite de vitesse : 2

Contrôle de la vitesse : par pression de la gâchette

Réglage du couple : 16 +2

Couple maximum : 48 Nm

Capacité du mandrin : 1,5 – 13 mm ( 1⁄16 – ½" )

Capacité de perçage (bois) : 26 mm ( 1-1⁄32" )

Capacité de perçage (matériaux

de construction) :

Capacité de perçage (acier) 13 mm (½" )

Poids : 3,9 kg (8,6 lbs)

0 - 1600 min-1 (haut régime)

25600 coups/min (haut régime)

10 mm ( 3⁄8" )

(avec batterie 4,0 Ah)

Informations sur le niveau d’intensité sonore et

vibratoire

Pression acoustique Lpa : 87,6 dB (A)

Puissance acoustique Lwa 98,6 db (A)

Incertitude K : 3 dB

Vibration pondérée

(métal) a

: 2,373 m/s2

h,D

(béton) a

: 7,104 m/s

h,ID

(vitesse à vide/vitesse max) ah: 1,707 m/s2

Incertitude K : 1,5 m/s²

2

Bloc-batterie

Technologie : Li-ion à cellules Samsung

Tension : 20 V CC

Modèle et capacité : T20HCB 4,0 Ah

T20B 2,0 Ah

Chargeur

Modèle de chargeur : T20BC

Temps de charge : 1 heure (pour T20HCB : bloc-batterie 4 Ah)

Tension d’entrée : Europe : 220-240 V CA 50/60 Hz 80 W

Tension de sortie : 20 V CC 3,0 A

Longueur du câble

d’alimentation :

Du fait de l’évolution constante de nos produits, les caractéristiques des produits

Silverline peuvent changer sans notification préalable.

30 min (T20B : bloc-batterie 2 Ah)

Afrique du Sud : 220-240 V CA 50/60 Hz 80 W

Australie : 220-240 V CA 50/60 Hz 80 W

Japon : 100-120 V CA 50/60 Hz 1,3 A

USA/Canada : 120 V CA 60 Hz, 1,3 A

2 m (6-1⁄2')

Attention : Toujours porter des protections sonores lorsque le niveau d’intensité est supérieur à 85 dB(A) et limiter le temps d’exposition si nécessaire. Si l’intensité sonore devient inconfortable,

même avec les protections, arrêter immédiatement d’utiliser l’appareil, vérifier que les protections soient bien mises et qu’elles soient adéquates avec le niveau sonore produit par l’appareil.

Attention : L’exposition de l’utilisateur aux vibrations peut engendrer une perte du toucher, des engourdissements, des picotements et ainsi réduire la capacité de préhension. De longues

expositions peuvent également provoquer ces symptômes de façon chronique. Si nécessaire, limiter le temps d’exposition aux vibrations, et porter des gants anti-vibrations. Ne pas utilisez cet

appareil avec vos mains sous des conditions en dessous de températures normales, car l’effet vibratoire en est accentué. Se référer au cas de figures des caractéristiques relatives aux vibrations

pour calculer le temps et fréquence d’utilisation de l’appareil.

Les niveaux sonores et vibratoires des caractéristiques techniques sont déterminés en fonction de la norme EN60745 ou autres normes internationales. . Ces données correspondent à un

usage normale de l’appareil, et ce dans des conditions de travail normales. Un appareil mal entretenu, mal assemblé ou mal utilisé peut augmenter les niveaux sonores et vibratoires. Pour plus

d’informations sur la directive des émissions sonores et vibratoires, visitez le site http://osha.europa.eu/fr.

10

940454_Z1MANPRO1.indd 10 25/09/2014 17:25

Page 12

F

Nomenclature

1. Mandrin sans clé

2. Bague de réglage du couple

3. Sélecteur du mode

4. Sélecteur du régime de vitesse

5. Sélecteur du sens de rotation

6. Gâchette du contrôle de la vitesse

7. Bouton de relâche de la batterie

8. Clip de ceinture

9. Batterie 4,0 Ah

10. Guide de lumière LED

11. Chargeur de batterie T20

Accessoires (non montrés)

• Sacoche de transport souple

Remarque : La batterie fournie peut différer de l’image

Prise GB/UE

Pour le Royaume-Uni seulement : N’essayez pas d’enlever l’adaptateur GB installé et de

l’utiliser avec d’autres appareils

N’enlever pas l’adaptateur GB installé et n’essayez pas de le brancher directement dans une

prise de courant

Si l’adaptateur GB est endommagé, veuillez contacter un service après-vente agréé « Triton ».

Symboles

Port de protection auditive

Port de lunettes de sécurité

Port du masque respiratoire

Port du casque

Lire le manuel d’instructions

ATTENTION!

Ne pas brûler les batteries !

Pour usage intérieur uniquement (batterie et chargeur de batterie)

Fusible à action retardée et à courant nominal de 3,15 A

T3.15A

Protection de l’environnement

Les produits électriques usagés ne doivent pas être jetés avec les ordures

ménagères. Veuillez les recycler dans les centres prévus à cet effet. Pour de plus

amples informations, veuillez contacter votre municipalité ou point de vente.

Protection de l’environnement

Les produits électriques usagés et les batteries, ainsi que les batteries au lithiumion, ne doivent pas être jetés avec les ordures ménagères. Veuillez les recycler dans

les centres prévus à cet effet. Pour de plus amples informations, veuillez contacter

votre municipalité ou point de vente.

Les batteries Li-ion ne doivent pas être jetées avec les ordures ménagères.

Veuillez les recycler dans les centres prévus à cet effet. Pour de plus amples

informations, veuillez contacter votre municipalité ou point de vente. Conforme à

la réglementation et aux normes de sécurité pertinentes. (Valable uniquement pour

Li-ion

les modèles UE)

Conforme à la réglementation et aux normes de sécurité pertinentes (pour le modèle

UE uniquement)

Consignes générales de sécurité

AVERTISSEMENT : Veuillez lire l’intégralité des consignes de sécurité et des instructions. Le

non-respect de ces consignes et instructions peut entraîner un risque de choc électrique, d’incendie et/

ou se traduire par des blessures graves.

Attention : Cet appareil n’est pas conçu pour être utilisé par des personnes (enfants compris) ayant

des capacités physiques ou mentales réduites, ou n’ayant pas la connaissance ou l’expérience

requise.

Veuillez conserver ces instructions et consignes de sécurité pour référence ultérieure.

L’expression « appareil électrique » employée dans les présentes consignes recouvre aussi

bien les appareils filaires à brancher sur le secteur que les appareils sans fils fonctionnant

sous batterie.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones encombrées et mal

éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils électriques dans des environnements explosifs, tels

qu’à proximité de liquides, de gaz ou de poussières inflammables. Les appareils

électriques produisent des étincelles susceptibles d’enflammer la poussière ou les

vapeurs présentes.

c) Eloigner les enfants et les passants pendant l’utilisation d’un appareil électrique.

Ceux-ci peuvent provoquer une perte d’attention et faire perdre la maîtrise de l’appareil.

Sécurité électrique

a) La prise d’un appareil électrique doit être adaptée à la prise du secteur. Ne jamais

modifier la prise en aucune façon. Ne jamais utiliser d’adaptateur sur la prise

électrique d’appareil mis à la terre. Des prises non modifiées, adaptées aux boîtiers

de prise de courant, réduiront le risque de décharge électrique.

b) Eviter le contact corporel avec les surfaces mises à la terre telles que tuyaux,

radiateurs, cuisinières et réfrigérateurs. Le risque de décharge électrique est plus

important si le corps est mis à la terre.

c) Ne pas exposer l’appareil électrique à la pluie ou à l’humidité. L’infiltration d’eau

dans un appareil électrique accroît le risque de décharge électrique.

d) Ne pas maltraiter le cordon électrique. Ne jamais utiliser le cordon électrique pour

porter, tirer ou débrancher l’appareil. Protéger le cordon électrique de la chaleur, du

contact avec l’essence, des bords tranchants et pièces rotatives. Un cordon électrique

endommagé ou entortillé accroît le risque de décharge électrique.

e) Lors d’une utilisation de l’appareil électrique en extérieur, se servir d’une rallonge

appropriée à une utilisation en extérieur. Cela réduit le risque de décharge électrique.

f) Si une utilisation de l’appareil électrique dans un environnement humide ne peut

être évitée, utiliser une alimentation protégée par un disjoncteur différentiel.

L’utilisation d’un disjoncteur différentiel réduit le risque de décharge électrique.

Sécurité des personnes

a) Rester vigilant et faire preuve de bon sens lors de la manipulation de l’appareil.

Ne pas utiliser un appareil électrique lorsque l’on se trouve dans un état de

fatigue, ou sous l’influence de drogues, d’alcool ou de médicaments. Un moment

d’inattention pendant l’utilisation d’un outil électrique peut se traduire par des blessures

graves.

b) Porter un équipement de protection approprié. Toujours porter une protection

oculaire. Le port de masque à poussières, chaussures de sécurité antidérapantes,

casque de sécurité et protections antibruit adaptés aux différentes conditions de travail

réduit le risque de blessures corporelles.

c) Eviter tout démarrage accidentel ou intempestif. S’assurer que l’interrupteur

marche-arrêt soit en position d’arrêt avant de brancher l’appareil sur

l’alimentation secteur ou d’installer la batterie, de prendre l’appareil ou de

le transporter. Porter un appareil électrique tout en maintenant le doigt posé sur

l’interrupteur ou brancher un appareil électrique dont l’interrupteur est sur la position de

marche est source d’accidents.

d) Enlever toute clé et tout instrument de réglage avant de mettre l’appareil

électrique en marche. Une clé ou un instrument de réglage laissé fixé à un élément en

rotation de l’appareil électrique peut entraîner des blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours en position

stable permettant de conserver l’équilibre. Cela permet de mieux contrôler l’appareil

électrique dans des situations inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements amples ou des

bijoux pendants. Eloigner cheveux, vêtements et gants des pièces en mouvement.

Les vêtements amples, les bijoux pendants et cheveux longs peuvent être happés par les

pièces en rotation.

11

940454_Z1MANPRO1.indd 11 25/09/2014 17:25

Page 13

F

g) Si l’appareil est pourvu de dispositifs destinés au raccord d’équipements d’extraction

et de récupération de la poussière/sciure, s’assurer qu’ils soient bien fixés et utilisés

correctement. L’utilisation de ces dispositifs peut réduire les risques dus à la poussière.

Utilisation et entretien des appareils électriques

a) Ne pas forcer sur l’appareil électrique. Utiliser l’appareil électrique approprié au

travail à effectuer. Un appareil électrique adapté et employé au rythme pour lequel il

a été conçu permettra de réaliser un travail de meilleure qualité et dans de meilleures

conditions de sécurité.

b) Ne pas utiliser un appareil électrique dont l’interrupteur marche-arrêt est hors

service. Tout appareil électrique dont la commande ne s’effectue plus par l’interrupteur

marche-arrêt est dangereux et doit être réparé.

c) Débrancher l’appareil électrique ou démonter sa batterie avant d’effectuer tout

réglage ou changement d’accessoire et avant de le ranger. De telles mesures

préventives réduiront les risques de démarrage accidentel.

d) Ranger les appareils électriques inutilisés hors de portée des enfants et ne

pas permettre l’utilisation de cet appareil aux personnes non habituées à son

maniement ou n’ayant pas lu les présentes instructions. Les appareils électriques

sont dangereux dans les mains d’utilisateurs inexpérimentés.

e) Veiller à l’entretien des appareils électriques. Vérifier que les éléments rotatifs

soient bien alignés et non grippés. S’assurer de l’absence de pièces cassées

ou endommagées susceptibles de nuire au bon fonctionnement de l’appareil. Si

l’appareil électrique est endommagé, le faire réparer avant toute utilisation. De

nombreux accidents sont dus à l’utilisation d’appareils électriques mal entretenus.

f) Veiller à ce que les outils de coupe soient tenus affûtés et propres. Des outils de coupe

bien entretenus, aux tranchants bien affûtés, sont moins susceptibles de se gripper et sont

plus faciles à contrôler.

g) Utiliser l’appareil électrique, les accessoires et outils à monter conformément

à ces instructions, en tenant compte des conditions de travail et de la tâche à

réaliser. Toute utilisation d’un appareil électrique autre que celle pour laquelle il a été

conçu peut entraîner des situations à risque.

Utilisation et entretien des outils à batterie

a) Ne rechargez qu’avec le chargeur indiqué par le fabricant. Un chargeur qui est

adapté à un type de batterie pourrait causer un incendie lorsqu’il est utilisé avec

une autre batterie.

b) N’utilisez les outils électriques qu’avec les batteries désignées spécifiquement.

L’utilisation de toute autre batterie peut créer un risque de blessures et d’incendie.

c) Lorsque la batterie n’est pas en utilisation, gardez-la éloignée de tout objet

métallique tel que trombone, pièce, clé, clou, vis et tout autre petit objet

métallique qui pourrait créer une connexion d’une borne à l’autre. Court-circuiter

les bornes de la batterie peut causer des brulures ou un incendie.

d) En cas d’usage abusif, du liquide peut être éjecté de la batterie ; évitez le contact.

Si vous entrez accidentellement en contact avec ce liquide, lavez à grande eau. Si

le liquide entre en contact avec vos yeux, sollicitez de l’aide médicale. Le liquide

éjecté par la batterie peut causer des irritations de la peau ou des brulures.

ATTENTION : Lorsque utilisé en Australie ou en Nouvelle Zélande, il est recommandé que cet

appareil soit toujours alimenté via un disjoncteur différentiel ayant un courant résiduel de 30

mA ou moins.

Révision

a) Ne faire réparer votre appareil électrique que par un réparateur qualifié

utilisant uniquement des pièces de rechange identiques. Cela permet de

maintenir la sécurité d’utilisation de l’appareil électrique

Consignes de sécurité relatives aux

outils de perçage sans fil

Pour les aspects de sécurité concernant les équipements et l’habillement de protection ainsi

que les dangers que présente l’utilisation d’un appareil électroportatif, consultez la section «

Consignes générales de sécurité relatives aux appareils électriques » du présent manuel.

• Portez une protection auditive lorsque vous percez en mode percussion. L’exposition aux

bruits peut causer une perte de l’audition.

• Tenez les outils électroportatifs par leurs poignées isolées lorsque l’accessoire de coupe

pourrait entrer en contact avec des fils électriques cachés. Les fixations peuvent être

en contact avec un fil sous tension ce qui mettrait les parties métalliques de l’outil

électroportatif sous tension et pourraient donner un choc électrique à l’utilisateur.

• Important : Il est impératif de suivre toutes les réglementations nationales de sécurité

concernant l’installation, le fonctionnement et l’entretien de l’appareil.

• Il est interdit à toute personne de moins de 18 ans d’employer cet appareil. Tout utilisateur

de l’appareil doit être formé à l’utilisation d’une perceuse et doit connaitre les instructions

d’utilisation et de sécurité.

• Si les batteries doivent être rechargées en extérieur, assurez-vous que la source

d’alimentation et que le chargeur soient protégés des intempéries et de l’humidité.

• L’utilisation d’une perceuse demande le port d’équipements de sécurité tels que lunettes

ou visière de sécurité, casque anti-bruit et habillement protecteur tel que gants de

sécurité. Portez un masque filtrant si le perçage crée de la poussière.

• Détectez la présence de câbles électriques et de conduites d’eau ou de gaz à l’aide

d’un détecteur de métal et de tension. Ne touchez pas les composants ou conducteurs

électriques sous tension.

• Assurez-vous de disposer d’un éclairage suffisant.

• Assurez-vous que les forets soient bien fixés dans le mandrin. Les forets mal insérés

peuvent être éjectés de la machine et représentent un danger.

• Assurez-vous que la perceuse soit en contact avec la pièce de travail avant de

commencer à percer.

• Avant de commencer le perçage, assurez-vous de disposer de suffisamment d’espace

libre sous la pièce à percer.

• N’exercez pas de pression sur l’appareil car cela réduirait sa durée de vie utile.

• Les accessoires (mèches, etc.) pourront avoir atteint des températures élevées lors du

perçage, laissez-les refroidir avant de les manipuler.

• Ne retirez jamais la sciure ou la poussière avec les mains à proximité de la mèche.

• Si l’on vous interrompt pendant le perçage, terminez l’opération et éteignez l’appareil

avant de vous concentrer sur l’évènement.

• Dans la mesure du possible, et s’il y a lieu, immobilisez bien la pièce à percer.

• Examinez le mandrin régulièrement à la recherche de tout signe d’usure ou de dommage.

Faites réparer les pièces endommagées par un centre de réparation homologué.

• Attendez toujours que la machine soit parvenue à un arrêt complet avant de la déposer.

• Vérifiez régulièrement que les écrous, boulons et autres dispositifs de fixation soient

bien serrés.

Consignes générales de sécurité

relatives aux chargeurs de batterie

Utilisation correcte du chargeur de batterie

• Reportez-vous à la section du présent manuel traitant de l’utilisation du chargeur de

batterie avant de commencer à charger le bloc-batterie.

• N’utilisez pas le chargeur pour d’autres batteries que celles fournies. Maintenez le

chargeur propre car les objets étrangers et la saleté peuvent entraîner un court-circuit

ou boucher les orifices de ventilation. Le non-respect de ces consignes peut amener

l’appareil à surchauffer ou à prendre feu.

• Si le cordon électrique est endommagé, il doit être remplacé par le fabricant, par un

centre agrée de réparation ou autre personne qualifiée pour éviter tout risque.

• Les enfants doivent être surveillés pour s’assurer qu’ils ne jouent pas avec l’appareil.

Attention : Ne rechargez pas des batteries non-rechargeables.

Utilisation correcte des batteries

• Veuillez ne charger les batteries de l’appareil qu’à l’aide du chargeur fourni. N’utilisez

avec cet appareil que les batteries fournies ou des batteries recommandées par votre

fournisseur. Maintenez les batteries propres car les objets étrangers et la saleté peuvent

entraîner un court-circuit. Laissez la batterie refroidir 15 minutes après toute recharge

ou utilisation prolongée. Le non-respect de ces consignes peut amener l’appareil à

surchauffer ou à prendre feu.

• Lorsqu’elles ne sont pas utilisées, les batteries doivent être rangées dans un endroit sec

proche de la température ambiante (20 ˚C). Assurez-vous que les batteries ne peuvent pas

se court-circuiter accidentellement pendant la période de rangement.

Notice pour blocs-batterie

DANGER – Les blocs-batterie représentent un risque d’incendie et d’explosion

ATTENTION – N’ouvrez pas, ne démontez pas, n’écrasez pas, ne chauffez pas à plus de 60° C

et ne brulez pas. Ne jetez pas dans un feu.

ATTENTION – Ne chargez pas de batteries non-rechargeables.

ATTENTION – Ne chargez les batteries qu’avec le chargeur T20BC. Pour un usage en toute

sécurité du chargeur, référez-vous au manuel d’instructions du chargeur.

ATTENTION – Suivez les instructions du fabricant

Fonctionnalités de sécurité de la batterie et du

chargeur :

Le bloc-batterie et le chargeur sont munis d’un certain nombre dispositifs de sécurité qui

peuvent être activés lors du chargement ou de l’utilisation de la visseuse :

• Protection de surcharge : le chargeur s’arrête automatiquement lorsque la batterie a

atteint sa capacité de charge maximale, ce qui protège les composants internes du

bloc-batterie.

• Protection de décharge : évite que la batterie ne se décharge au-delà de la tension

minimale de sécurité.

• Protection de surchauffe : Des capteurs éteignent l’appareil si la batterie devient trop

chaude durant l’utilisation. Cela peut arriver après une longue période d’utilisation ou un

travail trop intense. Selon la température ambiante, 30minutes peuvent être nécessaire

pour le refroidissement de la batterie.

12

940454_Z1MANPRO1.indd 12 25/09/2014 17:25

Page 14

F

• Protection de surcharge électrique : la batterie s’arrête temporairement si le débit du

courant dépasse le niveau maximum. La batterie redémarre dès que le niveau de courant

redevient normal et sûr .Cela peut prendre quelque secondes.

• Protection de court-circuit : en cas de court-circuit, le bloc-batterie s’arrête

automatiquement, ce qui évite de d’endommager le bloc-batterie ou l’outil.

Avertissement pour l’Australie et la Nouvelle-Zélande

ATTENTION : Lorsque utilisé en Australie ou en Nouvelle Zélande, il est recommandé que cet

appareil soit toujours alimenté via un disjoncteur différentiel ayant un courant résiduel de 30

mA ou moins.

Usage conforme

• Visseuse à choc sans fil alimentée par batterie compatible avec des opérations moyennes

de vissage de boulons et d’écrous

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage et familiarisezvous avec toutes les caractéristiques du produit

• Vérifiez que tous les pièces sont présentes. Si des pièces sont endommagées ou

manquantes, remplacer-les avant d’utiliser l’appareil.

Avant utilisation

• La perceuse-visseuse a été envoyée en condition de faible charge. Chargez la batterie

avant utilisation.

Utiliser le chargeur et la batterie

• Le chargeur etle bloc-batterie peuvent devenir chauds pendant la charge. Ceci est tout à

fait normal et n’indique pas un signe de problème.

• Si possible, utilisez le chargeur dans une pièce à température normale. Pour éviter de

surchauffer, ne pas couvrir le chargeur et ne couvrez pas la batterie directement au soleil

ou une source de chaleur.

• Si la batterie ne se charge pas correctement :

- Vérifiez le courant de la prise en branchant une lampe ou autre appareil.

- Si le problème persiste, faites contrôler l’outil, le bloc-batterie et le chargeur par un

électricien ou un technicien spécialisé.

Charger le bloc-batterie :

1. Appuyez sur le bouton de relâche de la batterie (6) et retirez la batterie de la visseuse.

2. Insérez le bloc-batterie dans le chargeur de batterie T20 (11). N’appliquez pas de force

excessive pour insérer la batterie. Si elle ne glisse pas facilement, la batterie n’est pas

insérée correctement.

3. Au début, seul le témoin lumineux vert clignotera pour indiquer l’évaluation de l’état de

charge de la batterie. Lors de la charge, le témoin lumineux vert s’éteint, et le rouge

s’allume.

4. Lorsque la batterie est entièrement chargée, le vert s’allume et le rouge s’éteint.

5. Le chargeur contrôle à tout moment les conditions de charge.

6. Retirez le bloc-batterie dès que la charge est complétée.

7. Débranchez le chargeur de sa source d’alimentation, et rangez-le dans un endroit propre,

sec et hors de portée des enfants.

• Le temps normal de charge est d’1 heure environ pour une batterie de 4 Ah récemment

déchargée sous des conditions normales de température. Le temps de charge varie selon

ces conditions. Batterie de 2,0 Ah : A noter que le temps de charge pour cette batterie

est de 30 minutes.

• Il n’y pas besoin d’attendre que la batterie soit totalement déchargée avant de recharger,

mais ne rechargez pas la batterie si elle est déjà entièrement chargée.

• Vous pouvez arrêter la charge à tout moment pour utiliser la batterie. Sous des conditions

normales, le taux de charge diminue au fur et mesure que la batterie est pleine. 80% de

la charge est obtenue en ½ heure.

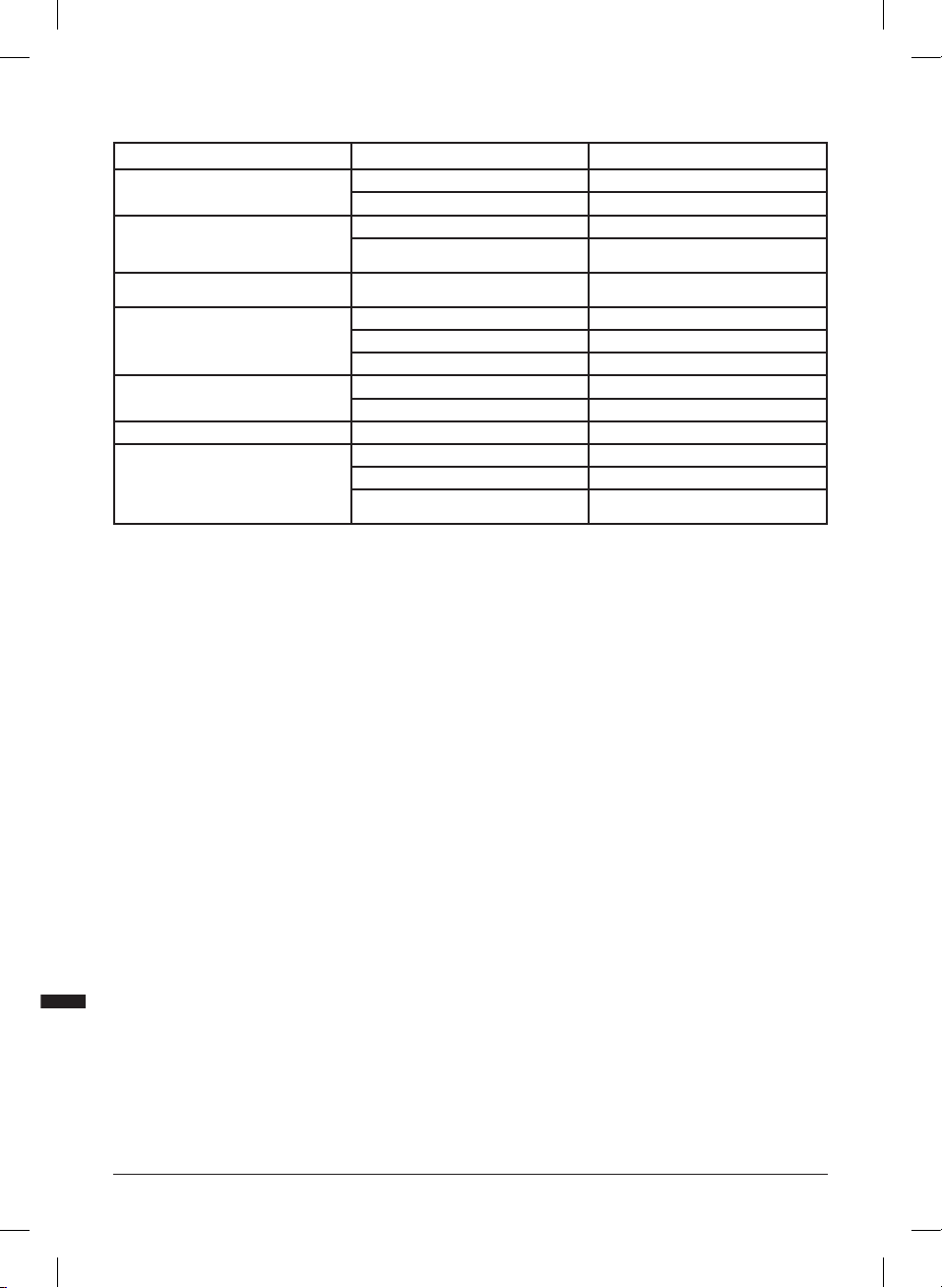

Table de chargement

Témoin

lumineux

rouge

Chargeur branché éteint clignotant

Chargeur évaluant la charge éteint clignotant

Charge rapide allumé éteint

Très peu de batterie, charge lente clignotant éteint

Température de charge anormale clignotant éteint

Entièrement chargée éteint allumé

Défaut de batterie ou du chargeur clignotant clignotant

Condition temporaire de température de

charge anormale

Note : Si les lumières du chargeur n’indiquent aucune des situations ci-dessus ou indiquent

un défaut :

• Vérifiez que la batterie soit correctement positionnée sur le chargeur.

• Vérifiez tous et l’alimentation.

allumé allumé

Témoin

lumineux

vert

Charge initiale

• La charge initiale dépend de l’état de charge de la batterie. Rechargez jusqu’à ce que le

chargeur indique qu’elle soit entièrement pleine.

• Déchargez la batterie puis rechargez-la pour 3-5 heures, et re-déchargez-la. Répétez

cette opération 4-5 fois afin d’assurer une meilleure performance de charge de la batterie.

• Les prochaines charges ne dureront que 1 heure (T20HCB : batterie 4 Ah), voire moins si

la batterie n’est pas complètement déchargée.

Re-charger la batterie

• Après utilisation, il est recommandé de laisser refroidir une batterie en lithium-ion avant

de charger.

• Si une batterie est insérée dans le chargeur alors qu’elle est toujours chaude, le témoin

vert s’allumera. Il faudra attendre quelques minutes que la batterie refroidisse pour que le

chargeur commence à charger.

Insérer la batterie

• N’exercez pas de force inutile pour insérer la batterie. Si elle ne s’insère pas facilement,

positionnez la batterie correctement afin qu’elle glisse facilement dans le compartiment

(ou il est possible que la batterie et/ou la perceuse soient endommagées).

Durée de service de la batterie

La durée de service dépendra des travaux effectués. La batterie et le chargeur de cet outil ont

été conçus pour offrir une longue durée de vie maximale. Le chargeur intelligent contrôle les

conditions de charge et régule le taux de charge en fonction de l’état de charge de la batterie,

ce qui protège la batterie d’être surchargée ou de charger avec un taux trop important.

Cependant, comme toutes les batteries, le phénomène d’usure dans le temps est possible.

Maximiser la durée de vie de la batterie

• Rangez et chargez votre batterie dans un endroit frais. Des pièces à température audessus ou en dessous de la normale peuvent diminuer la durée de vie de la batterie.

• Ne rangez jamais une batterie Li-ion déchargée. Rechargez toujours immédiatement

après qu’elle ait été déchargée. Pour un rangement à long terme, chargez la batterie

complètement.

• Toutes les batteries perdent graduellement leur charge, même les batteries li-ion, bien

que leur taux de décharge soit particulièrement bas. Plus la température est élevée, plus

elles se déchargent vite. Si vous rangez la batterie pour une longue période sans l’utiliser,

il est recommandé de recharger la batterie tous les deux ou trois mois. Ceci augmentera

la durée de vie de la batterie.

13

940454_Z1MANPRO1.indd 13 25/09/2014 17:25

Page 15

F

Fixer un foret ou un embout de tournevis

Attention : Ne fixez jamais des accessoires ayant une vitesse maximale inférieure à la vitesse

à vide de l’appareil.

1. Tourner la bague du mandrin sans clé (1) dans le sens des aiguilles d’une montre et

insérez le foret ou l’embout dans le mandrin.

2. Tourner la bague du mandrin (1) dans le sens contraire des aiguilles d’une montre pour

maintenir en toute sécurité le foret ou l’embout.

Remarque : Ne faites jamais fonctionner l’outil lors du serrage ou desserrage du mandrin. De

préférence, choisissez la position de blocage du sélecteur du sens de rotation (5).

3. Lorsque le foret ou l’embout est maintenu correctement dans le mandrin, mettez la

perceuse en marche pour vérifier qu’il soit bien centré. Si la rotation n’est pas régulière

recommencez l’opération.

Choisir le sens de rotation

• Le sens de rotation se sélectionne avec le sélecteur du sens de rotation (5)

• Pour une rotation dans le sens des aiguilles d’une montre, poussez le sélecteur vers la

gauche

• Pour une rotation dans le sens contraire des aiguilles d’une montre, poussez le sélecteur

vers la droite.

• Lorsque le sélecteur est positionné au milieu, la perceuse-visseuse est bloquée.

ATTENTION : Ne changez jamais le sens de rotation lorsque l’appareil est en marche.

Contrôle de la vitesse

• Cette perceuse -visseuse possède une boite de vitesse à deux régimes :

- Première vitesse, bas régime : 0 - 450 min

- Deuxième vitesse, haut régime : 0 - 1600 min

• Utilisez le sélecteur du régime de vitesse (4).Faites glisser le sélecteur vers l’avant pour

la première vitesse, vers l’arrière pour la seconde.

Remarque : La vitesse en bas régime est normalement utilisée pour visser, en donnant un

couple important et un meilleur contrôle à faible vitesse. La seconde vitesse est généralement

utilisée pour percer.

-1

-1

Réglage de couple

• Cette perceuse-visseuse possède un contrôle de couple, qui limite le couple appliqué à

l’embout, ce qui permet d’effectuer un vissage sans risque d’endommagement.

• Il y a 16 paramètres de couple pour le vissage et un pour le perçage. Plus le numéro du

paramètre est petit, plus le couple est faible.

• Pour ajuster le couple, faites tourner la bague de réglage du couple (2), jusqu’à ce que le

numéro du paramètre voulu s’aligne avec la flèche indiquée sur la perceuse à percussion.

• Vérifiez que le paramètre de couple a bien été choisi en effectuant un test sur un support

quelconque.

Sélection du mode

• Pour le perçage, choisissez le régime de vitesse adéquat, puis tournez le sélecteur du

mode (3) sur le symbole du foret. Cela permettra de procurer et maintenir le couple

maximal.

• Pour le vissage, choisissez le régime de vitesse adéquat, puis tournez le sélecteur du

mode (3) sur le symbole de la vis. Cela activera l’embrayage du couple

• Pour le perçage dans les matériaux de construction, choisissez le régime de vitesse

adéquat, puis tournez le sélecteur du mode (3) sur le symbole du marteau. Cela permettra

d’activer le mode percussion et de procurer et maintenir le couple maximal.

ATTENTION : Un adaptateur peut être installé sur la perceuse pour visser des écrous et

des boulons. Ne jamais utiliser cet adaptateur en mode perceuse. Utilisez les 16 réglages

du sélecteur de couple et la première vitesse pour empêcher toute surcharge de travail.

L’utilisation d’une clé pour serrer ou desserrer les écrous et les boulons est recommandée.

Ceci permet de travailler également plus rapidement et en toute sécurité, surtout lorsqu’un

couple important est requis au début et à la fin d’un travail.

Instructions d’utilisation

ATTENTION : Utilisez toujours des équipements de protection tels que des protections

oculaires, auditives et respiratoires lorsque vous utilisez cet appareil.

Mise en marche

• Pour démarrer la perceuse-visseuse, appuyez sur la gâchette de contrôle de la vitesse (6).

Le guide de lumière LED (10) s’allumera automatiquement.

• Une pression plus importante sur la gâchette augmente la vitesse de rotation.

• Relâchez la gâchette pour arrêter l’appareil.

Remarque : Il est possible que la perceuse s’éteigne lors de travaux importants à cause du

déclenchement de la protection thermique de la batterie et des composants internes. La

perceuse pourra être utilisée après un certain moment, cela n’est donc pas un défaut de

l’appareil.

Conseil pour le perçage

• Utilisez un foret tranchant et assurez-vous qu’il soit compatible avec le matériau à percer.

• Ne dépassez jamais la capacité maximale de perçage indiquée dans les ‘caractéristiques

techniques’.

• Commencez par percer à faible vitesse en appuyant partiellement sur la gâchette(8).

• Réduisez la pression exercée sur la perceuse lorsque le foret est sur le point de

transpercer le matériau.

• Pour éviter que le matériau se fende lors du perçage, vous pouvez soit serrer un morceau

de bois sur la partie arrière de la pièce de travail, soit continuer à percer depuis l’autre

côté (si le foret a commencé à transpercer la pièce).

Percer le métal

• Pour les métaux peu épais, aidez-vous d’une pièce de bois

• Marquez l’endroit où vous souhaitez percer avec un marteau et un pointeau

• Utilisez des forets HSS (acier rapide) ou d’autres recommandés pour le perçage du métal.

• Pour des perçages larges, effectuez d’abord un pré-perçage avec un foret de plus petit

diamètre pour s’en servir de guide.

• Appliquez un lubrifiant ou un liquide de refroidissement sur vos forets pour garantir un

meilleur résultat, mais également pour les conserver plus longtemps.

Percer les matériaux de construction

• Utilisez toujours des forets de maçonnerie, de préférence en TCT, lorsque vous percez

dans les murs, la pierre ou le béton.

• N’exercez pas trop de pression sur l’arrière de l’appareil. Si des débris bloquent le trou de

perçage, faites tourner la perceuse lentement et retirez le foret du trou. Recommencez

jusqu’à ce que le trou soit dégagé.

Accessoires

• Une variété d’accessoires, tels que la batterie 2,0 Ah (T20B), la batterie haute capacité 4

Ah (T20HCB) ainsi que des forets et embouts de vissage, sont disponibles depuis votre

revendeur Triton. Des pièces de rechanges peuvent être obtenues depuis votre revendeur

Triton ou depuis www.toolsparesonline.com

Entretien

• Cet appareil est conçu avec des composants de qualité et utilise les derniers circuits

intelligents pour protéger au maximum l’appareil et ses composants. Un usage normal

garantit une longue durabilité de l’appareil.

Nettoyage

• Gardez l’appareil toujours propre. La poussière et la saleté provoquent l’usure rapide

des éléments internes de l’appareil et réduit sa durabilité. Utilisez une brosse souple ou

un chiffon sec pour le nettoyage. Si possible, nettoyez les orifices de ventilation à l’air

comprimé propre et sec

Rangement

• Rangez l’outil et ses accessoires dans un endroit sec et sûre, hors portée des enfants.

Recyclage

Lorsque l’appareil n’est plus en état de fonctionner et qu’il n’est pas réparable, recyclez

l’appareil conformément aux régulations nationales.

• Ne jetez pas les outils électriques, les batteries et autres équipements électriques ou

électroniques(DEEE) avec les ordures ménagères

• Contactez les autorités locales compétentes en matière de gestion des déchets pour vous

informer de la procédure à suivre pour recycler les outils électriques et les batteries.

14

940454_Z1MANPRO1.indd 14 25/09/2014 17:25

Page 16

F

En cas de problème

Problème Cause possible Solution

Le LED rouge ne s’allume pas et la batterie ne se charge pas

Les batteries sont faibles

La perceuse ne se met pas en marche

(gâchette bloquée)

La perceuse ne démarre pas, même en appuyant sur la

gâchette

Les vis ne vont pas assez en profondeur

Les vis sont trop en profondeur Le couple est trop important Choisissez un couple moins grand

Pendant le perçage des matériaux de maçonneries, le foret

ne pénètre pas dans le mur

La batterie n’est pas insérée correctement Nettoyez la prise du chargeur

Le chargeur n’est pas alimenté Vérifiez le branchement

La batterie n’est pas complètement chargée

La batterie a été rechargée plus de 100 fois et sa capacité a

commencé à diminuer

Le sélecteur du sens de rotation est au milieu Poussez le bouton à droite ou à gauche

La batterie est complètement vide Rechargez la batterie et utilisez une autre

La batterie est défectueuse Remplacez-la

La perceuse est défectueuse

Le couple n’est pas assez important Choisissez un couple plus grand

Batterie faible Rechargez la batterie ou utilisez une autre

Foret incompatible ou émoussé

Foret trop large

Mode marteau non sélectionné sur la perceuse

Chargez la batterie jusqu’à ce que le chargeur indique la

charge complète

Ceci est normal : contactez votre revendeur Triton pour

remplacer la batterie

Contactez votre revendeur Silverline ou un centre de

réparation agrée.

Remplacez le foret avec un nouveau de haute qualité adapté

pour les matériaux de construction

Faites tourner le sélecteur de mode pour mettre l’appareil en

mode marteau (voir ‘Sélection du mode’)

Rotate mode selector to switch the machine into hammer

drill mode (see ‘Mode Selection’)

Garantie

Pour valider votre garantie, rendez-vous sur notre site internet www.tritontools.com* et

saisissez vos coordonnées.

Vos coordonnées seront introduites dans notre liste de diffusion (sauf indication

contraire) afin de vous informer de nos prochaines nouveautés. Les informations que

vous nous fournirez ne seront pas communiquées à des tiers.

Pense-bête

Date d’achat : ___ / ___ / ____

Modèle: T20CH

Veuillez conserver votre ticket de caisse comme preuve d’achat. art pr

Si toute pièce de ce produit s’avérait défectueuse du fait d’un vice

de fabrication ou de matériau dans les 3 A NS suivant la date d’achat,

Triton Precision Power Tools s’engage auprès de l’acheteur de ce

produit à réparer ou, à sa discrétion, à remplacer gr atuitement la pièce

défectueuse.

Cette garant ie ne s’applique pas à l’utilisatio n commerciale et ne

s’étend pas non plus à l’usure normale ou aux dommages causés par

des accidents, des mauvais traitements ou une utilisation impropre.

* Enregis trez votre produit en ligne dans les 30 jours suivant la date

d’achat.

Offre soumise à conditions.

Ceci n’affecte pas vos droits statutaires.

15

940454_Z1MANPRO1.indd 15 25/09/2014 17:25

Page 17

E

Traducción del manual original

Gracias por haber elegido esta herramienta Triton. Estas instrucciones contienen la información necesaria para un funcionamiento seguro

y eficaz de este producto. Lea este manual atentamente para asegurarse de obtener todas las ventajas de las características únicas de su