Trane VUVE Vertical Classroom Catalogue

Product Catalog

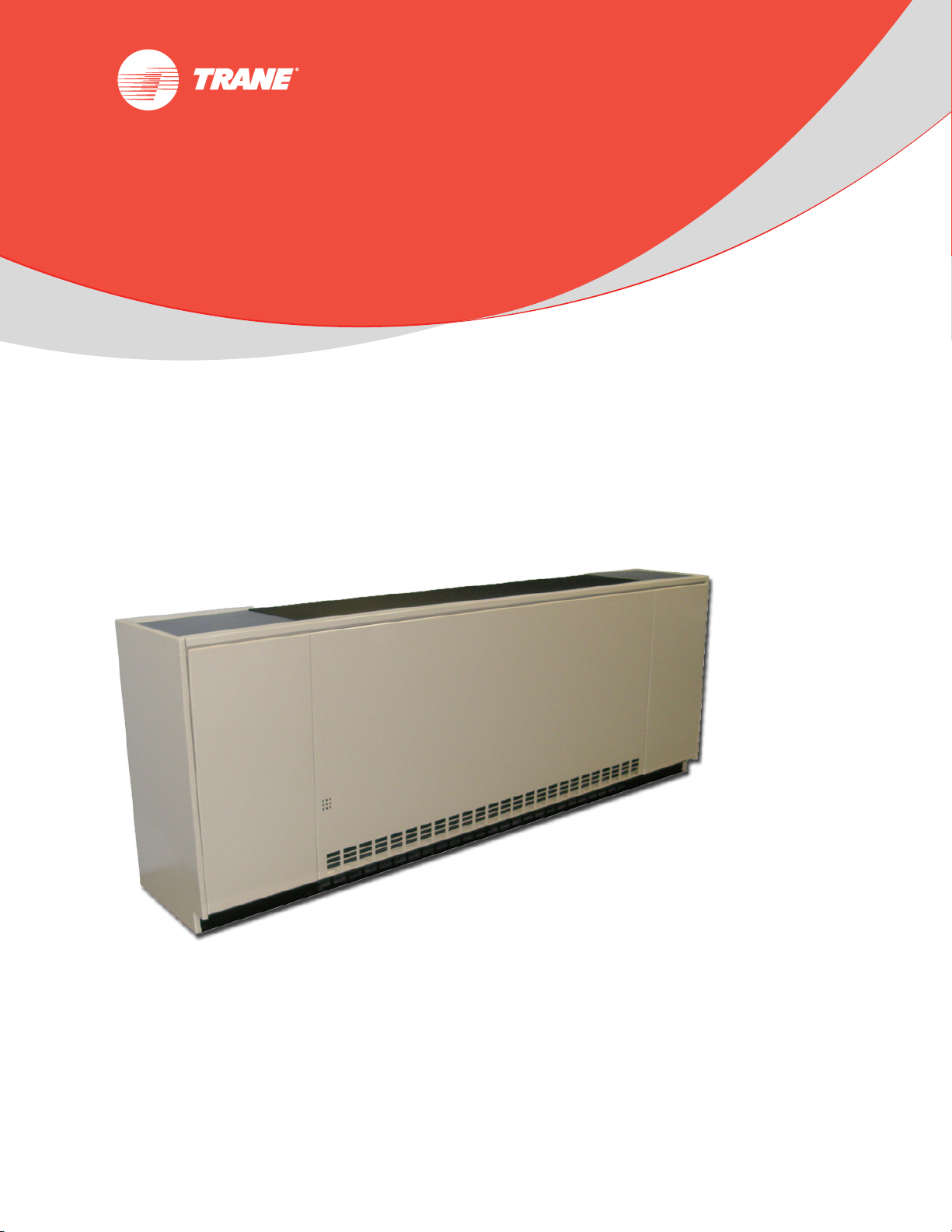

Vertical Classroom Unit Ventilator

750 cfm to 1500 cfm

June 2013 UV-PRC003-EN

Introduction

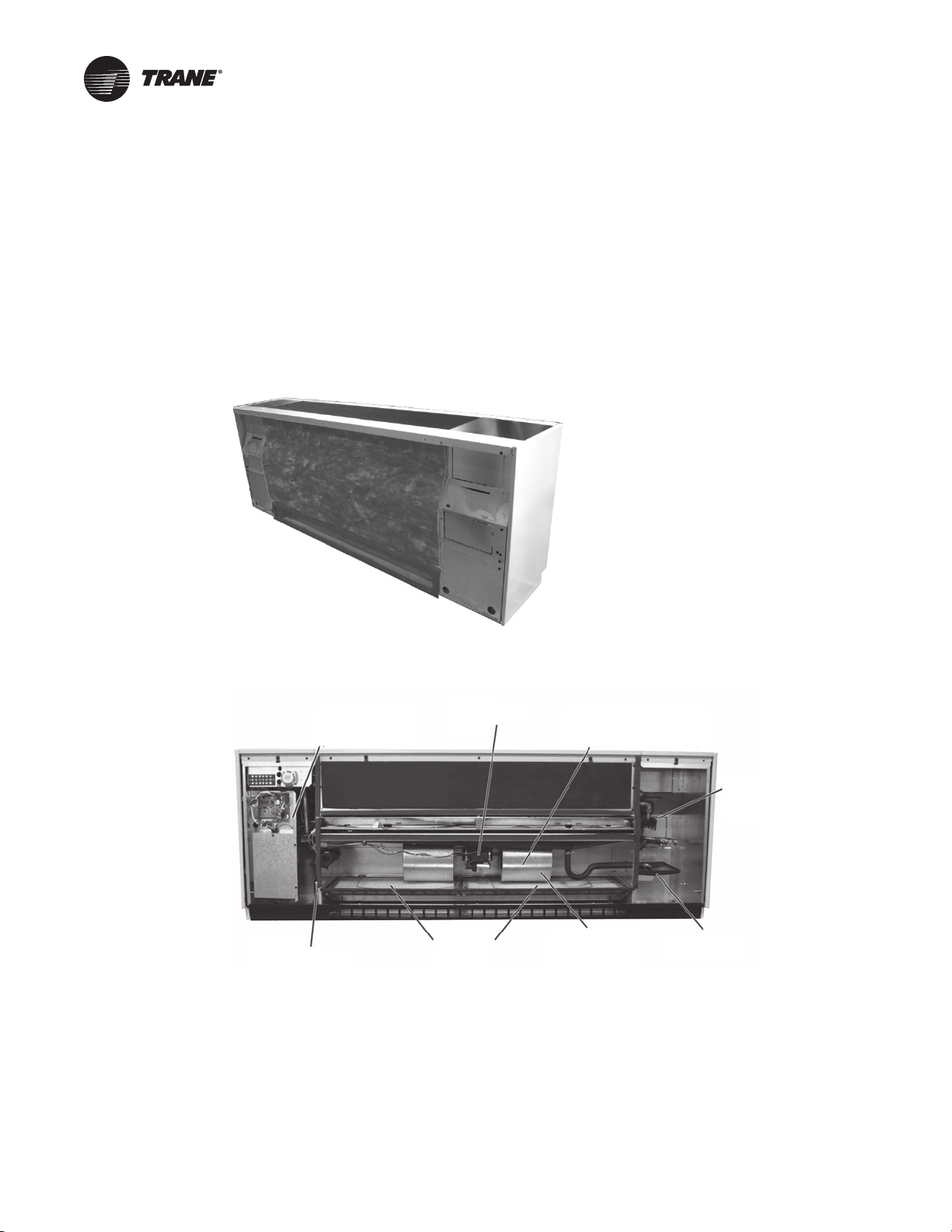

Roomy end-pockets for

install-ability and

system customization

Maintenance-free

EC motor with

direct-drive fans

Blow-through design provides

freeze protection, sound

attenuation, and safety

Hassle-free

piping

Auxiliary drain

pan option

Sealed coil, but quickly

accessed for cleaning

and visual inspection

Larger fans for

lower sound levels

Off-the-shelf

filter sizing

Linkage-free

outside air damper

The Trane Classroom Unit Ventilator

Academic performance of U.S. students depends, in part, on the ability to create a comfortable

learn-friendly surrounding. Being too hot or too cold could hinder a students ability to achieve

academic excellence.

Seasonal changes, mechanical/building disrepair, and even class attendance provide real

challenges to HVAC mechanical systems. The only thing consistent about today’s classroom is its

ability to constantly change. With this in mind, Trane introduces a NEW classroom unit ventilator

design to support today’s changing environment.

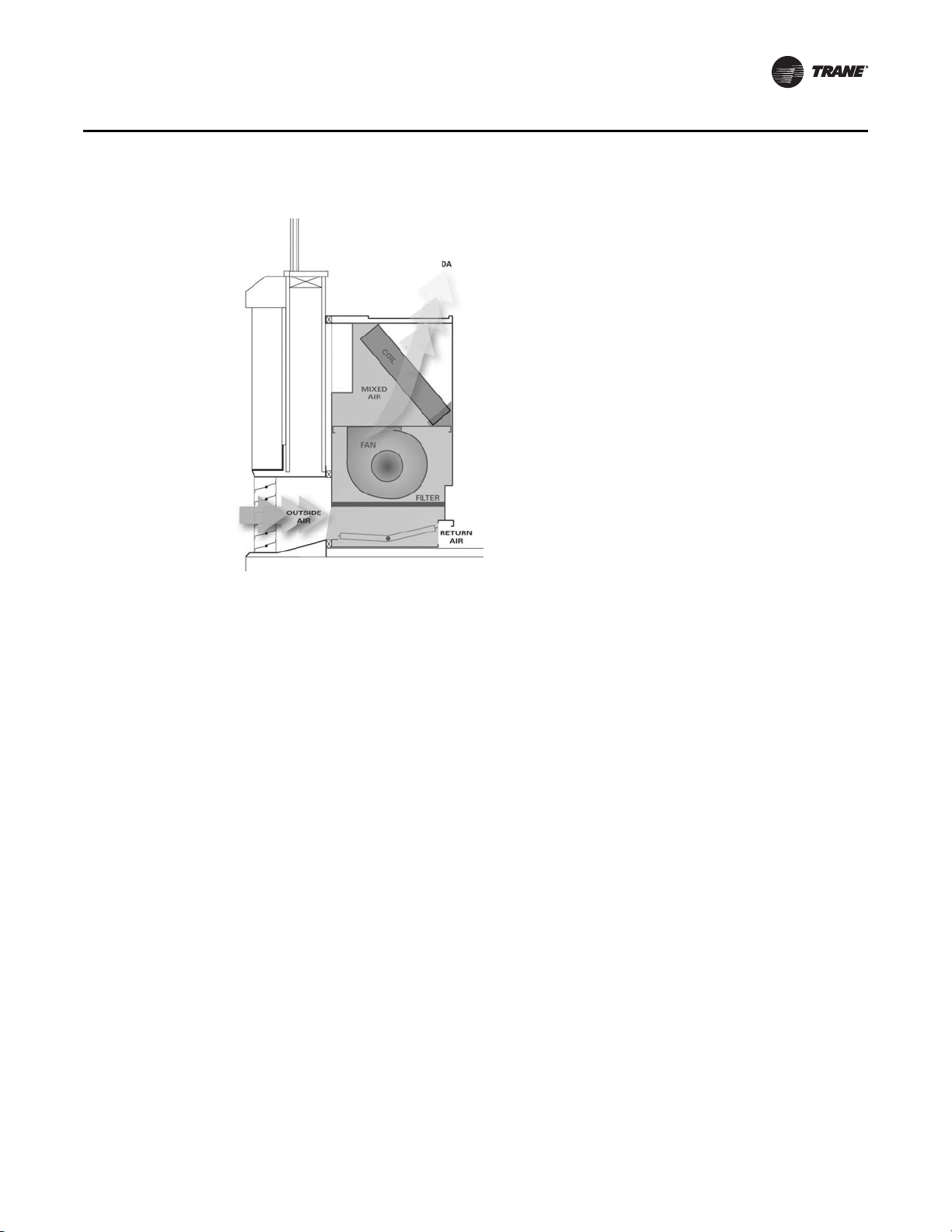

Figure 1. Back view of unit ventilator

Figure 2. Vertical classroom unit ventilator

© 2013 Trane All rights reserved UV-PRC003-EN

Introduction

Trademarks

EarthWise, Integrated Comfort, Rover, Trane, the Trane logo, TOPSS, Tracer, and Tracer Summit are

trademarks or registered trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

BACnet is a registered trademark of American Society of Heating, Refrigerating and AirConditioning Engineers (ASHRAE); Echelon, L

trademarks of Echelon Corporation.

ONMARK, LonTalk, and LONWORKS are registered

UV-PRC003-EN 3

Table of Contents

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fit and Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install-ability, Service-ability and Maintain-ability . . . . . . . . . . . . . . . . . . . . . . 5

IAQ Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A Choice in System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fan Speed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Customer Supplied Terminal Interface (CSTI) . . . . . . . . . . . . . . . . . . . . . . . . . 68

Tracer ZN520 Zone Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tracer UC400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Zone Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Valves/Piping Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Jobsite Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 UV-PRC003-EN

Features and Benefits

Fit and Finish

Equipment Size

The vertical unit ventilator delivers from 750 cfm to 1500 cfm. It is physically sized to fit the

replacement or new construction application.

Cabinet Finish

The unit cabinetry is made of a durable industrial grade metal to withstand even the most rigorous

classrooms. A smooth/glossy, appliance grade paint treatment increases the aesthetics of the

equipment while making it durable and easy to maintain.

Access

A three panel front access of the unit ventilator is ergonomically safe for lifting/removal, and allows

speedy set up during field commissioning. This design allows for the end pocket of the unit

ventilator to be open while the fan (airside) section stays closed. The panel design supports a clean

fit and finish while providing effortless access for filter change-out.

Top access to the unit mounted fan speed/sensor option was developed with the teacher or

administrative staff in mind. Access to the sensor may be made through a lock/key, or through an

easy open door.

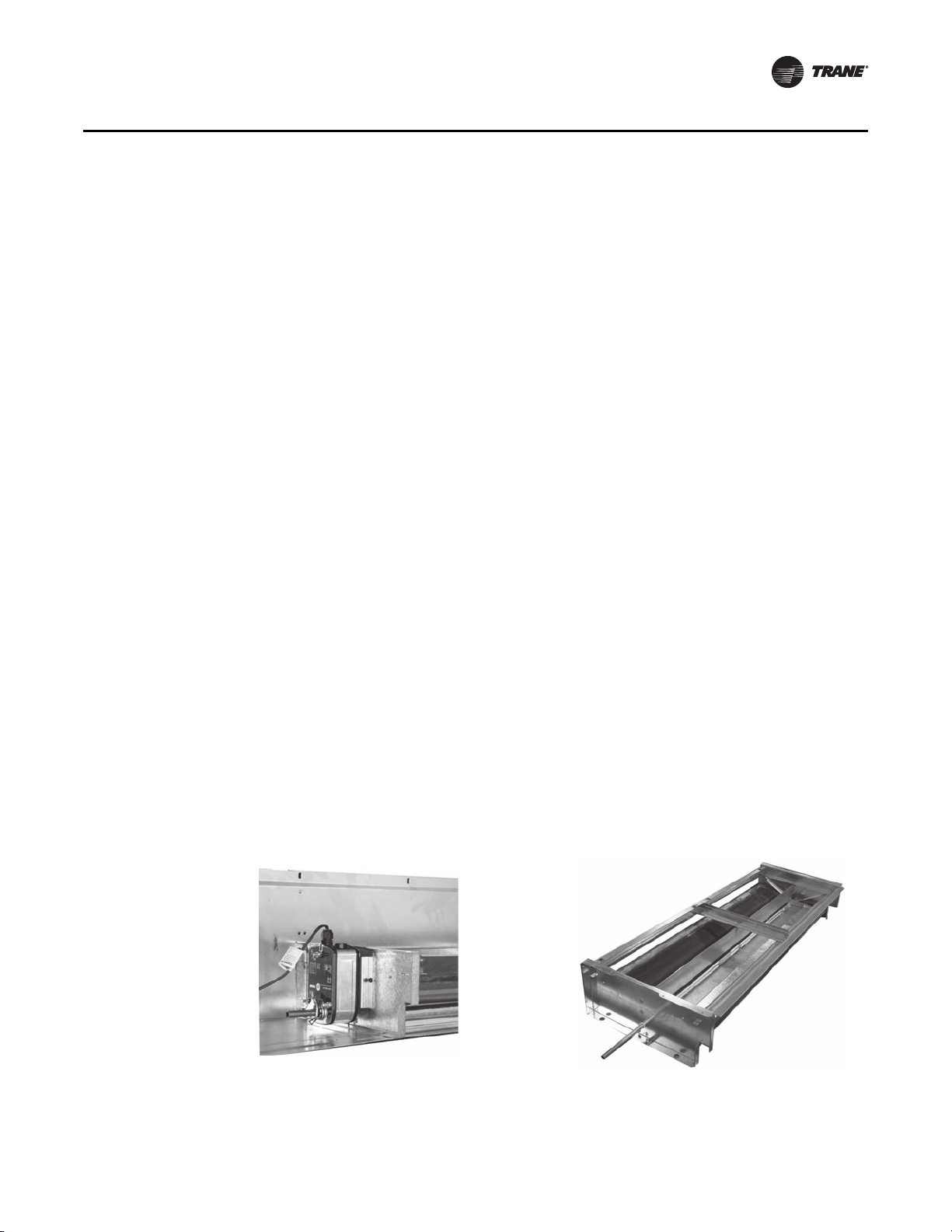

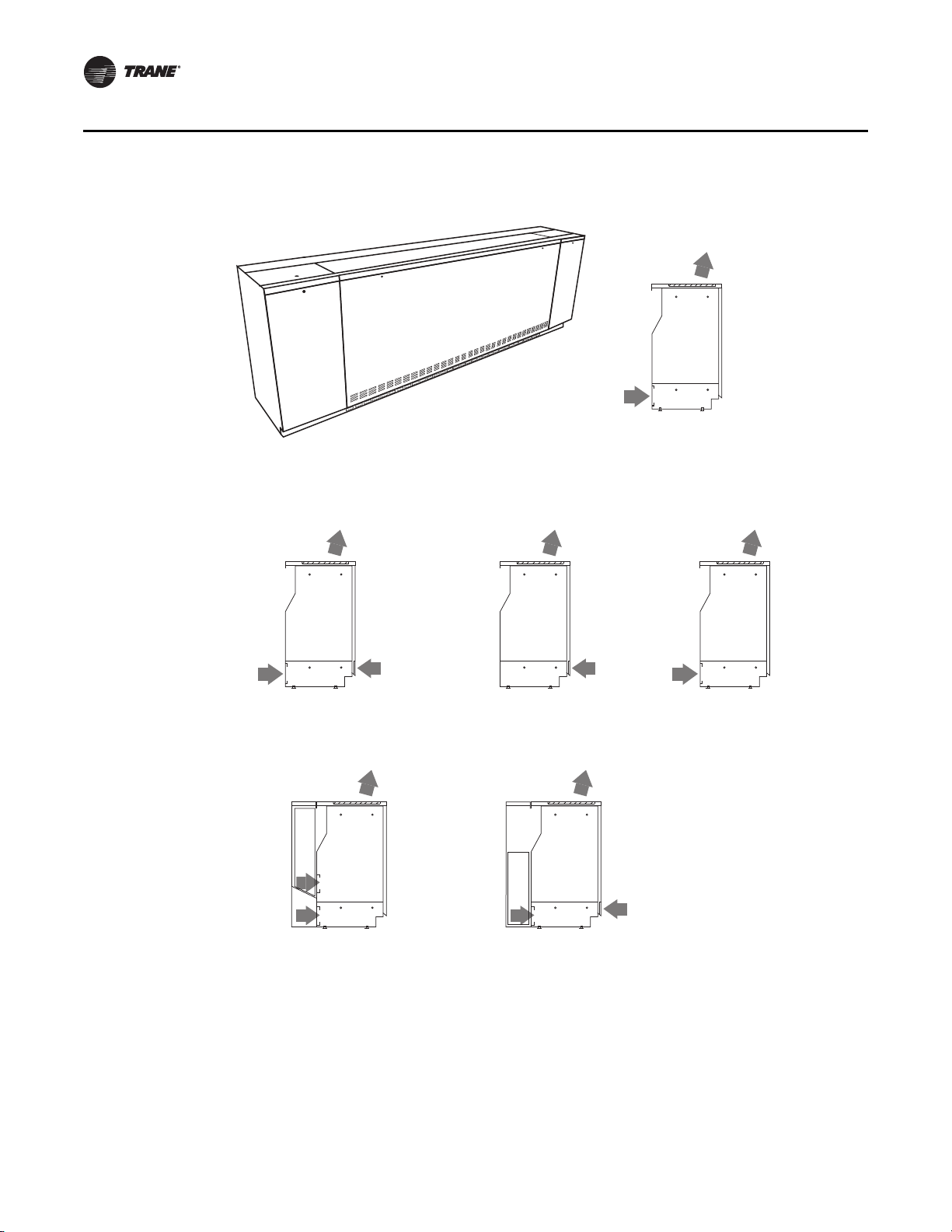

Figure 3. Fit and finish

Install-ability, Service-ability and Maintain-ability

Spacious End Pockets

Easy access to piping and controls is made through the roomy equipment end pocket design. The

coil headers and drain connections are made within the unit chassis, freeing-up valuable space in

the end pockets for piping or field add-ins. This also grants a tighter seal to prevent air leakage.

The roomy end pocket design Figure 4, p. 6 allows for application requirements such as an optional

auxiliary drain pan. The auxiliary pan may be placed under the factory or field piping package.

UV-PRC003-EN 5

Features and Benefits

Sliding Fan Deck

Convenient access to the fan motor and fan wheels for maintenance and serviceability is made in

part of the easy-slide design of the unit ventilator fan board, Figure 5. The fan board assembly

offers hassle free access to the contractor or maintenance technician. As an added benefit, Trane’s

unit ventilator includes Electronically Commutated Motors (ECM) as standard.

Figure 4. Spacious end pockets Figure 5. Sliding fan board

Energy Efficiency

Trane has a commitment to providing premium quality products that has led to the exclusive use

of Electronically Commutated Motors (ECM) in all unit ventilator models. These brushless DC

motors incorporate the latest technology for optimized energy efficiency, acoustical abatement,

maintenance free and extended motor life. Each motor has a built-in microprocessor that allows

for programmability, soft ramp-up, better airflow control, and serial communication.

• Trane units equipped with ECMs are significantly more efficient than a Permanent Split

Capacitor (PSC) motor.

• Lower operating costs on average of 50 percent (versus a PSC motor).

• The Reduced FLA option allows units to ship with a nameplate FLA rating much lower than a

typical ECM unit.

Filters

Trane unit ventilators utilize an off-the-shelf filter design to reduce or eliminate local stocking of

filters in the school. See “General Data,” p. 25 for standard filter sizes.

Note: High efficiency options, MERV 8 and MERV 13, are available. These filters provide greater

resistance and dust holding capabilities.

Hinged Control Box

The hinged control box design maintains easy access to the electrical for connection while

supporting less potential for damage on the job site from the different construction trades.

6 UV-PRC003-EN

IAQ Features

Features and Benefits

Piping

Hydronic piping for the unit ventilator may be factory installed or field provided. It fits freely inside

the unit end pockets, supplying quick hook-up during the installing phase. The motorized valves

include a trouble-free, pop-top allowing the maintenance or service technician access to the motor

without removing the valve body from the piping package.

Indoor air quality (IAQ) has become a top priority in classroom design. Giving students a healthy

place to learn and develop is crucial in every school district. It is also crucial to maintaining the

building’s overall construction and furnishings. Several features of Trane’s unit ventilator attribute

to improved IAQ.

Removable Drain Pan

The unit ventilator drain pan is dual sloped for effective condensate removal. This non-corrosive

pan eliminates the problems associated with leaking or standing water and is removable for

cleaning.

Ease of Maintenance

Internal components such as the fan and coils are accessible for visual inspection and cleaning.

Maintaining a clean system increases the efficiency of the unit and is important to good,

sustainable indoor air quality.

This design also places the coils farther away from the outside air opening, virtually eliminating the

potential for coil freezing and the added hassles of nuisance freeze-trips.

OA/RA Damper Design

The outside/return air damper is a one-piece design which is linkage free resulting in a superior air

seal (see Figure 4, p. 6). This results in lower infiltration of outside air during off cycles thus

lowering the risk of freezing equipment in the winter or the intrusion of humid air into the building

during the summer.

OA/RA Actuator

The OA/RA actuator provides true spring return operation for positive close-off of the OA/RA

damper. The spring return system of the actuator closes the outside damper if power is lost to the

building. When ordered with factory controls, the actuator is a 3-point floating design. A 2 to 10-Vdc

actuator is available when other than Trane controls are specified.

Figure 6. OA/RA Actuator and OA insulated damper

OA insulated damper

OA/RA actuator

UV-PRC003-EN 7

Features and Benefits

Unit Filter

Each classroom unit ventilator comes equipped with a standard-size throwaway filter to support

job site installation and start-up. However, the Trane unit ventilator is designed to accommodate

the use of a MERV 8 or MERV 13 high capacity filter to provide greater filtration of airborne

contaminants.

Dehumidification

Trane unit ventilators provide a broad range of dehumidification solutions. Active humidity control

involves monitoring and managing both the dry bulb temperature and the humidity in the

classroom. With this strategy, a reheat coil is placed downstream of the cooling coil to temper

(reheat) the cold, dehumidified air leaving the cooling coil to avoid over-cooling the space. Reheat

configurations are available in a variety of coil combinations.

Alternately, the Tracer™ UC400 or Tracer ZN520 controller can be configured to automatically

reduce the fan speed at part-load conditions. This helps improve the coincidental dehumidification

performance of the unit at part-load, and also lowers sound levels. To help ensure proper

ventilation in the classroom at lower fan speeds, the controller adjusts the outside air being

supplied to the classroom.

Economizer

One big advantage of a Unit Ventilator system is the ability to provide energy savings through an

economizer cycle. During mild seasons outside air is used to provide “free” cooling, thereby,

minimize or eliminate the need to run mechanical cooling equipment. To truly have an effective

economizer a Unit Ventilator must be able to bring in up to 100 percent of the design airflow

through the outside air damper opening. Trane Unit Ventilators are tested and certified to exceed

the industry standard, as defined by AHRI 840, for economizer effectiveness. This ensures the

school will realize the energy savings available through the economizer strategy.

Acoustics

Face and Bypass Actuator

The face and bypass damper actuator incorporates a direct couple design. It provides electronic

protection against overload. A limit switch is not included, nor required as part of the design. When

reaching the damper end position, the actuator automatically stops. The gears can be manually

disengaged with a button on the housing.

Quiet systems are extremely important in today’s classrooms. Trane offers many different system

solutions to balance the requirements of sound, cost, IAQ and efficiency. The Trane vertical unit

ventilator takes a comprehensive approach to delivering one of the quietest units available.

Fan and Blower Motor Assembly

Several innovative ideas have gone into the quiet design of the Trane vertical unit ventilator. The

fans diameters have been maximized to reduce the motor rpm and thus lower the noise, while still

maintaining the cfm requirements to support ventilation and capacity requirements. The unique

direct-drive fan and blower design diminishes vibration from occurring further ensuring quiet

operation.

Fan Speed Control

Trane provides the capability to vary airflow for suitable applications either with three speeds or

with a 0–10 Vdc input. This lowers the sound in the space and improves the dehumidification in the

cooling season at part-load. With field installed controls, this is accomplished with a unit-mounted

manual fan speed switch (allowing either 2- or 3-speed control) or variable speed control with a

0–10 Vdc input. ECM controls provide a soft ramp between speed changes—a significant

contributor to overall quiet operation.

8 UV-PRC003-EN

Features and Benefits

With the inclusion of the Tracer UC400 unit controller, the speed of the fan is infinitely varied

automatically in response to the load condition in the space. The controller also will adjust the

outside air being provided to properly ventilate the classroom at the lower airflow conditions.

Quiet Blow-Through Design

The Trane blow-through unit design enables additional sound attenuation by eliminating the fan

noise from entering the space directly. The position of the internal components is optimized to

enhance The performance and casing construction of Trane vertical unit ventilators further adds

to this acoustically superior design.

Certification/Standards

Comfort, energy and IAQ are all major issues that need to be woven into today’s school designs.

Therefore, it is important that designers of these systems have accurate information to make

system decisions. That is why the industry has developed performance standards and certification

programs which ensure that the equipment information provided to the design community is

correct and comparable across different manufacturers. The following list of certifications

identifies the commitment by Trane to providing the highest quality equipment and information to

our customers:

• AHRI-840

• ETL

• Tested in accordance to AHRI 350 (acoustics)

ONMARK

•L

®

UV-PRC003-EN 9

Application Considerations

A Choice in System Design

The beauty of the classroom unit ventilator goes beyond its ability to heat and cool. The unit

ventilator design provides an opportunity to create a comfortable atmosphere for living, learning

and playing, while supporting energy efficiency savings. Some of the featured benefits of a unit

ventilator are:

• Individual room control.

• Fresh air ventilation and filtration.

• Individual dehumidification sequences per zone.

• Energy savings solutions through economizing functions and Electronically Commutated

Motors.

• A choice in heating/cooling applied systems.

• And, because the equipment is mounted directly in the living space, expense associated to

installed mechanical ductwork may be avoided.

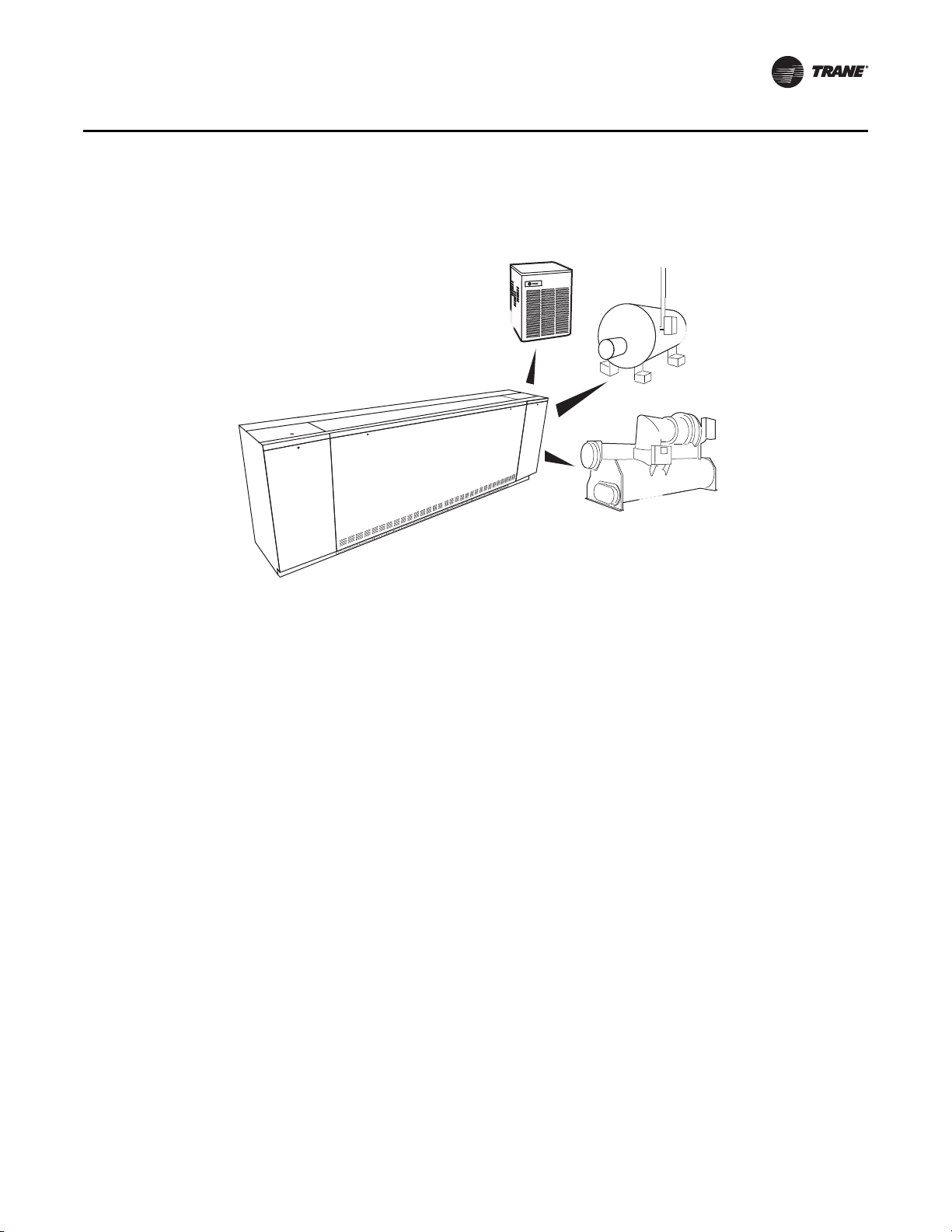

Wide Variety of Heating/Cooling Coils

Trane’s unit ventilator offers a wide variety of coil configurations to be used in many design

considerations.

In environments where cooling needs are of main interest, a two-pipe coil coupled with a chiller,

or a direct expansion coil joined with a condensing unit may be used.

For heat specific applications, Trane offers a two-pipe hot water only unit to be combined with a

boiler. Electric heat and steam options are also available for heating selections.

When there is seasonal heating and cooling, a two-pipe chilled water/hot water changeover system

may be applicable to the mechanical design. This system requires a chiller and a boiler to support

the changeover necessity. However, where space constraints may present a concern, the Trane unit

ventilator may be equipped with a direct expansion coil for cooling, with an auxiliary electric heat

coil, hot water coil, or steam coil for heating.

Four-pipe chilled water/hot water systems are also available. This system is typically applied when

both heating and cooling may be simultaneously called for in the school.

Building Automation

As part of the building automation system, the mechanical HVAC system equipment may be

optimized to lower energy consumption. By running only the mechanical devices that are required

to support the building load at a given time of day or night, true energy consumption savings may

be achieved.

Maintenance and service information through the unit sensing devices are easily defined and

cured with an automated system.

With factory shipped direct digital controls, installation and start-up of the system are more simple.

Condensate

Proper condensate trapping is required for the classroom unit ventilator’s with hydronic and direct

expansion coils (steam coils do not require a trapped condensate setup). In a properly trapped

system, when condensate forms during normal operation, the water level in the trap rises until

there is a constant flow of water through the pipe. It is imperative to maintain water in the trap, and

not allow the trap to dry out during heating season.

Equipment should be installed level to avoid condensate build-up around the coil.

Performance

Application of this product should be within the catalogs airflow and unit performance. The Trane

Official Product Selection System (TOPSS™) will aid in the selection process for a set of given

10 UV-PRC003-EN

Application Considerations

AND/OR

AND/OR

CHILLER FOR

COOLING

BOILER

FOR HEAT ADD

CONDENSER

FOR COOLING

CLASSROOM UNIT VENTILATOR

Indoor Air Quality

conditions. If this program has not been made available, ask a local Trane account manager to

supply the desired selections or provide a copy of the program.

Figure 7. System choice for the classroom unit ventilator

The Importance of Air Quality

Indoor air quality (IAQ) should be considered a top priority in the school environment. School

institutes contain a diverse day of activities that have a potential for air impurity sources including

cafeterias, art and science classrooms, vocational education areas, pools and locker rooms. Proper

ventilation and filtration of these spaces can pose some challenges.

Occupant density in classrooms is much higher than that found in office or retail spaces. The

amount of outdoor air required to ventilate a classroom is based predominantly on the number of

students expected to occupy the space. Students also move in large groups, frequently throughout

the building, resulting in widely varied thermal loads within the zones. To compound the situation,

a classroom mechanical system is typically run for 9 months of the year, and vacated for 3 months

(either by turning up or off the HVAC system). To increase the IAQ challenge even more, building

construction techniques that help reduce energy costs, also tightly seal the school. This can lead

to uncirculated/unfiltered air.

Ventilation

Ventilation is an important factor in the maintenance of healthy air. In a poor ventilated school

building, fumes and vapors are not properly exhausted allowing particles to develop. A healthier

building is a building where the air is exchanged more frequently and properly filtered. Through

ventilation, stale indoor air is exhausted and fresh treated outdoor air is drawn into the building.

The amount of ventilation air required is established by building codes and industry standards.

Most building codes reference ASHRAE Standard 62

Quality–as the minimum requirement for ventilation system design. Architects, engineers and

contractors utilize this standard when determining and calculating the type of load the building

environment will place on the mechanical system.

Trane Unit Ventilators Support Indoor Air Quality

–Ventilation for Acceptable Indoor Air

The Trane unit ventilator is tested and designed to exceed ASHRAE Standard 62. This includes the

use of a higher efficiency filtration to help introduce proper levels of “fresh” diluted air for

contaminant removal.

UV-PRC003-EN 11

Application Considerations

Energy Efficiency

Beyond the ventilation and filtration performance of the classroom unit ventilator, maintenance of

the HVAC system is a must. Several enhancements placed on the Trane unit ventilator to support

superior IAQ performance include:

• Coil presentation allows for ease of maintenance and cleaning.

• A dual sloped non-corrosive drain pan (removable) helps keep moisture in the system to a

minimum.

• Ultra low leak damper that results in a fixed air seal of the damper assembly.

• Air exchange performance that goes beyond code while maintaining the AHRI-840 certification

for economizing requirements.

• An upgrade-able MERV rated filters help reduce contaminants and increase filtration.

• Side-wall power exhaust support system to help remove the stale air from the classroom and

better support the air exchange.

• Energy recovery unit ventilator to further pretreat and dehumidify the fresh air before it enters

the classroom unit ventilator.

• Options for improved dehumidification at part-load, including automatic fan-speed control,

face and bypass dampers, and active humidity control through reheat.

A Choice in Energy Optimization

The energy consumption of a unit ventilator system can be significantly reduced through the use

of an economizer cycle. To better understand the basic function of how an outside air economizer

works, it is important to fully understand how it operates.

The economizer functions by opening an outside air damper, and bringing cooler outside air into

the space. The economizer cycle is controlled with a modulating damper motor, which opens at

specified increments dependent upon readings from outside air sensors.

Economizers also utilize a return-air damper that closes as the outside air damper opens.

Depending on the room requirements, the modulating damper motor may mix the return air with

the outside air to provide the maximum energy cost efficiencies without sacrificing comfort.

When the room thermostat calls for cooling, the economizer control provides the right mix of

outside and return air to cool the classroom. The equipment’s airflow is generated from both fan

energy and the economizing dampers. This design supports optimum ventilation and provides the

greatest energy savings. As the outside air temperature rises (typically above 55°F), the outside

damper closes to the minimum position, activating the second cooling stage on the room

thermostat—the cooling-generating device (compressor, water pump, chiller, cooling tower). The

return-air and outside air dampers modulate to support the discharged air temperature.

Dampers working together with the cooling coil is called integrated economizing, which allows a

unit ventilator to mix outside air with return air, delivering an energy-efficient, cost-savings

solution to a school.

Industry Standards

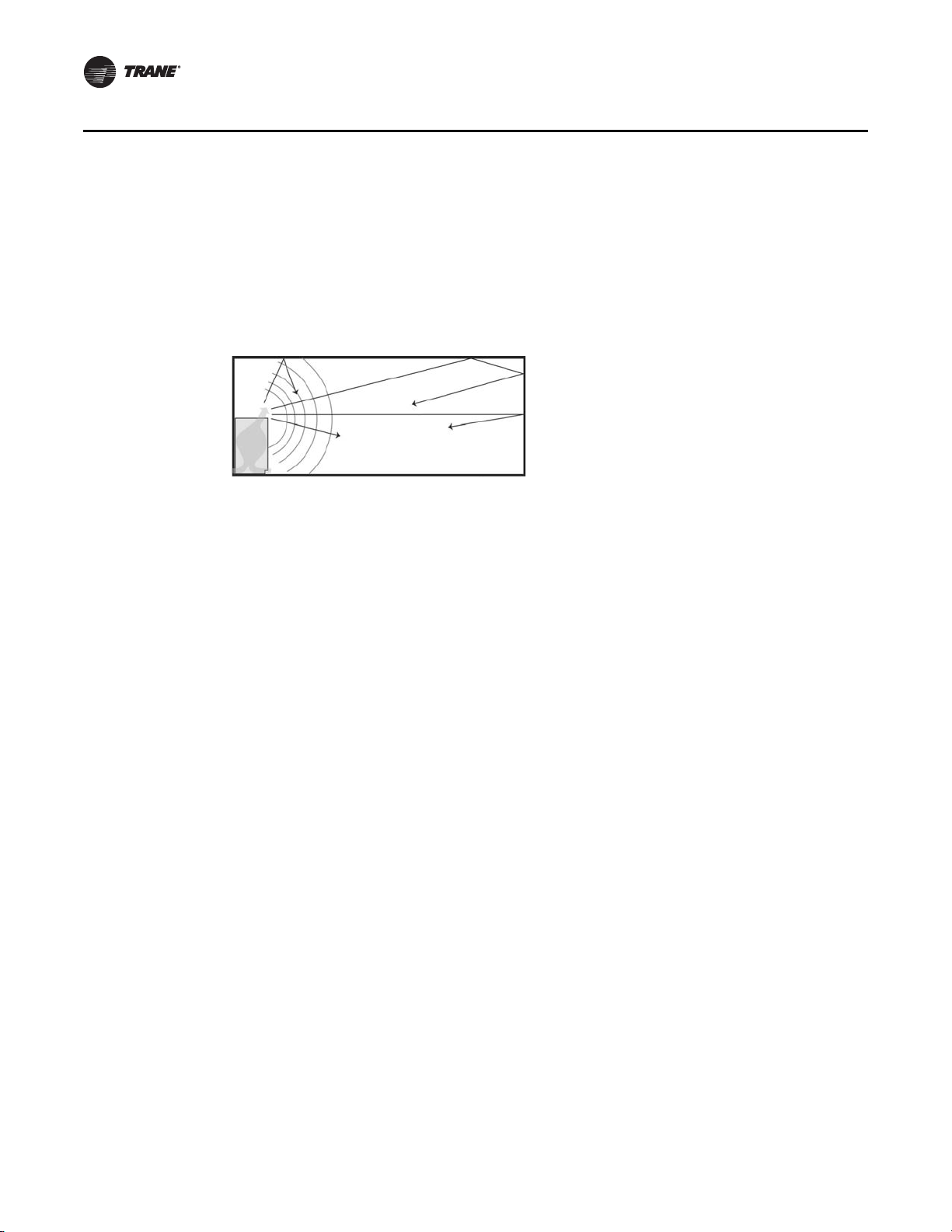

The Air-Conditioning, Heating, and Refrigeration Institute (AHRI) created the AHRI-840 standard for

classroom unit ventilators to provide a consistent method of rating the unit ventilators design

performance. To achieve AHRI-840 certification, the unit ventilator must be capable of providing a

minimum of 80 percent of its ventilation (airflow) through the outside air economizer function (see

Figure 8). This measurement ensures that the expected energy savings by the economizer is

realized in actual operation.

Only AHRI-840 certified equipment has been independently tested for compliance to the minimum

requirement. Trane was the first, and continues to be one of the few manufacturers that meet this

certification. By meeting this certification, the designer can be assured that the Trane unit ventilator

will perform with energy conservation in mind.

12 UV-PRC003-EN

Figure 8. Unit ventilator economizer

Application Considerations

Acoustics

Acoustics

A growing population, and an increase in economic pressure to maximize building footprints have

resulted in higher building occupancies and less space to place the HVAC equipment. Often times

the close proximity of the equipment—such as a floor mounted unit ventilator—may cause noise

related complaints. Reducing the likelihood of these complaints requires careful planning:

• In the equipment sizing (under sizing and over sizing could increase noise level).

• And equipment placement (absorption and number of sound sources in the room greatly affect

noise).

Room NC is the sum of all sounds entering the room. Its value is based on assumptions about the

room’s characteristics. Given the complexity of various building systems, it is extremely important

to assure that the design goals (commissioning) for classroom acoustics, IAQ, and moisture control

are met through all aspects of the space.

For example, it is not uncommon for a school to install unit ventilators that are manufacturer-rated

for a specified airflow (cfm), but which are not AHRI-840 certified. These units may ship with a fanspeed setting that delivers a lower than specified airflow, perhaps to reduce sound levels. Without

an overall building design goal, these units will be installed without delivering the specified airflow

needed to support the fresh air circulation, and possibly compromise IAQ.

Note: Unless the equipment is tested at the specified airflow, it is extremely difficult to determine

whether the unit meets the specified sound level.

Trane’s unit ventilator will not compromise air quality to support a minor reduction in airflow noise.

We encourage our engineers to specify their airflow needs at full building load requirements. Finetuning of the speed setting may be interchanged through the unit’s 3-speed fan sensor quickly and

easily. This mechanical feature ensures that the equipment supplies proper cfm to support IAQ in

the classroom, while giving complete control of equipment noise to the administrative staff.

Technology that Supports Acoustic Enhancements

Another solution to airflow noise is through Trane direct digital controls (Tracer UC400). With the

Tracer UC400 controller, an infinitely variable speed fan control for the unit ventilator delivers the

airflow output customized to support the cfm space needs. When less cfm is necessary to meet the

UV-PRC003-EN 13

Application Considerations

Ventilation

load of the classroom, the equipment operates at an optimum speed, keeping sound levels to a

minimum. Another solution for acoustically sensitive application is the option for “Low Acoustics,”

which uses the ECM technology to manage the fan speeds. However, if the room temperature rises

above the setpoint, the controller will switch to high speed for sustaining the space needs. As part

of this strategy, ventilation must also be considered. The Tracer UC400 controller will reposition

the outside air damper to confirm the minimum outside air cfm is met at both operating conditions.

This setup allows the unit ventilator to meet the space comfort condition, while providing a lower

sound level and proper ventilation.

Figure 9. Equipment placement

Ventilation for Acceptable IAQ

Supplying proper ventilation to a classroom is challenging. The various rooms that make up a

school are forever changing in their proper ventilation needs. Building occupants and their

activities generate pollutants that heighten the ventilation requirements. And because of this

intermittent occupancy, the ventilation frequency of a classroom is constantly on the move.

Ventilation systems dilute and remove indoor contaminants, while mechanical heating and cooling

systems control the indoor temperature and humidity. Supplying an adequate amount of fresh air

to an occupied classroom is necessary for good indoor air quality. IAQ should be considered a top

priority in the school environment because children are still developing physically and are more

likely to suffer the consequences of indoor pollutants. For this reason, air quality in schools is of

particular concern. Proper conditioning of the indoor air is more than a quality issue; it

encompasses the safety and stewardship of our investment in the students, staff and facility.The

beauty of a classroom unit ventilator is its ability to provide heating, cooling, ventilation and

dehumidification as a single-zone system.

ASHRAE Control Cycles

There is a variety of control systems available today in unit ventilators. The exact method of

controlling the amount of outside air and heating capacity can vary. However, all systems provide

a sequence of operation designed to provide rapid classroom warm-up and increasing amount of

ventilation air to offset classroom load.

To help supply proper ventilation to these fluctuating heat gains, the Trane unit ventilator is

designed to provide rapid classroom warm-up and increasing amounts of ventilation air to offset

classroom overheating.

14 UV-PRC003-EN

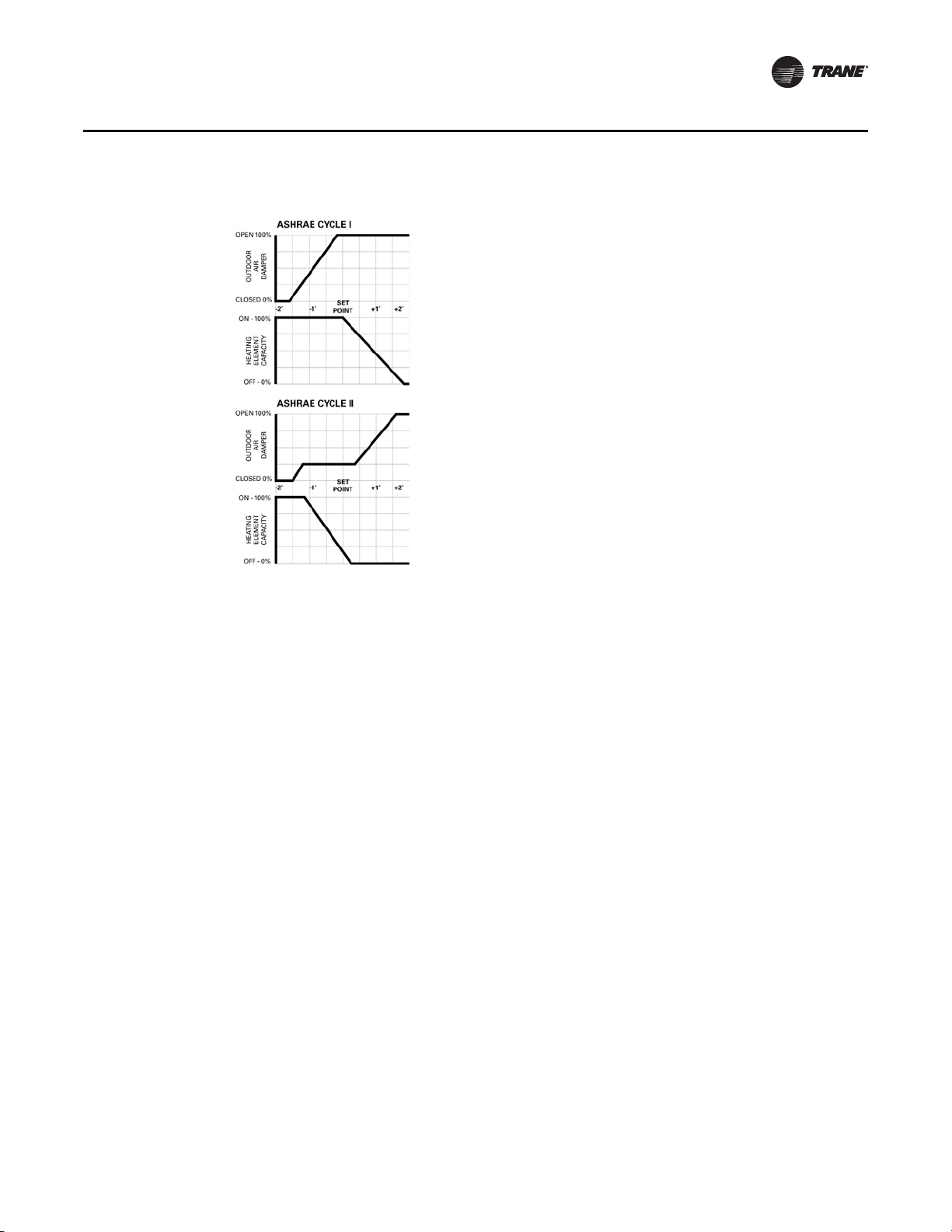

Figure 10. ASHRAE Cycle graph

Application Considerations

Ventilation

ASHRAE Cycle I

All standard unit ventilator cycles automatically close the outside air damper whenever maximum

heating capacity is required. As room temperature approaches the comfort setpoint, the outside

air damper opens fully, and the unit handles 100 percent outside air. Unit capacity is then controlled

by modulating the heating element capacity.

ASHRAE Cycle I is typically used in areas where a large quantity of outdoor air is required to offset

the air being exhausted to relieve the room of unpleasant odors and particles.

ASHRAE Cycle II

ASHRAE Cycle II is the most widely used ventilation control. Similar to Cycle I, the outside air

damper is closed during warm-up. But with Cycle II, the unit handles recirculated air through the

return air system. As temperature approaches the comfort setting, the outside air damper opens

to admit a predetermined minimum amount of outside air. This minimum has been established by

local code requirements and good engineering practices. Unit capacity is controlled by varying the

heating output. If room temperature rises above the comfort setting, the heating is turned off and

an increasing amount of outside air is admitted until only outside air is being delivered.

ASHRAE Cycle II is a very economical control sequence often referred to as integrated

economizing. This design supports optimum ventilation and provides the greatest energy savings.

This is further proof of why AHRI-840 certification is important in minimizing energy consumption

through economizer performance.

Freeze Protection

The most important advantage the Trane blow-through design provides is additional protection

against coil freeze-up. In contrast, draw-through configurations allow little mixing of the return and

outside air stream while locating the coil very close to the outside air inlet. This process creates

“cold spots” on the coil which could lead to coil freeze-up.

With a blow-through design, face and bypass with isolation valve control is not necessary to

provide proper freeze protection to the unit vent. The placement of the coil above the fan allows

enough space for the coil to avoid “cold spots” that could cause freezing.

UV-PRC003-EN 15

Application Considerations

Dehumidification

Constant Volume System

A typical unit ventilator is a constant-volume, variable-temperature device. It uses a constant fan

speed and modulates water flow through a chilled water coil to maintain the dry bulb temperature

in the space based off of a setpoint. Outdoor air is introduced at the back of the unit ventilator, and

distributed with the supply air. At design cooling load conditions, a system controlled in this

manner typically has a leaving air temperature that is cold enough (and, therefore dry enough) to

sufficiently dehumidify the space, but its ability to dehumidify can decrease significantly at partload conditions.

When the sensible load in the space decreases (part-load), the constant-volume system responds

by raising the dry-bulb temperature of the supply air. In a chilled water unit ventilator, this is

accomplished by modulating a valve to reduce the rate at which water flows through the coil.

Figure 11 shows how this affects the supply air leaving the coil—the warmer coil surface that results

from less water flow provides less sensible cooling (raising the supply air temperature) and

removes less moisture from the passing air stream.

Figure 11. Part-load dehumidification with modulated chilled water

The sensible cooling capacity of a constant volume system decreases to match the smaller sensible

cooling load. Any latent cooling (dehumidification) capacity is purely coincidental, whether the

cooling-coil medium is chilled water or refrigerant. As the load diminishes, the system delivers

even warmer supply air. Some dehumidification can occur in this situation, but only if the sensible

load is high enough.

Some designers attack this problem by oversizing the unit ventilators. This does not solve the

problem; in fact, it can make the situation worse. Increasing the capacity of the unit ventilator may

also require increasing the supply airflow. A higher-than-necessary supply airflow results in

warmer supply air and, in non arid climates, less dehumidification. It’s important to understand,

this is not just a unit, coil, or fan-sizing challenge. Rather, it’s an issue of properly controlling the

system in a manner provides sufficient dehumidification at all operating conditions. Proper

dehumidification with terminal units is a matter of proper control.

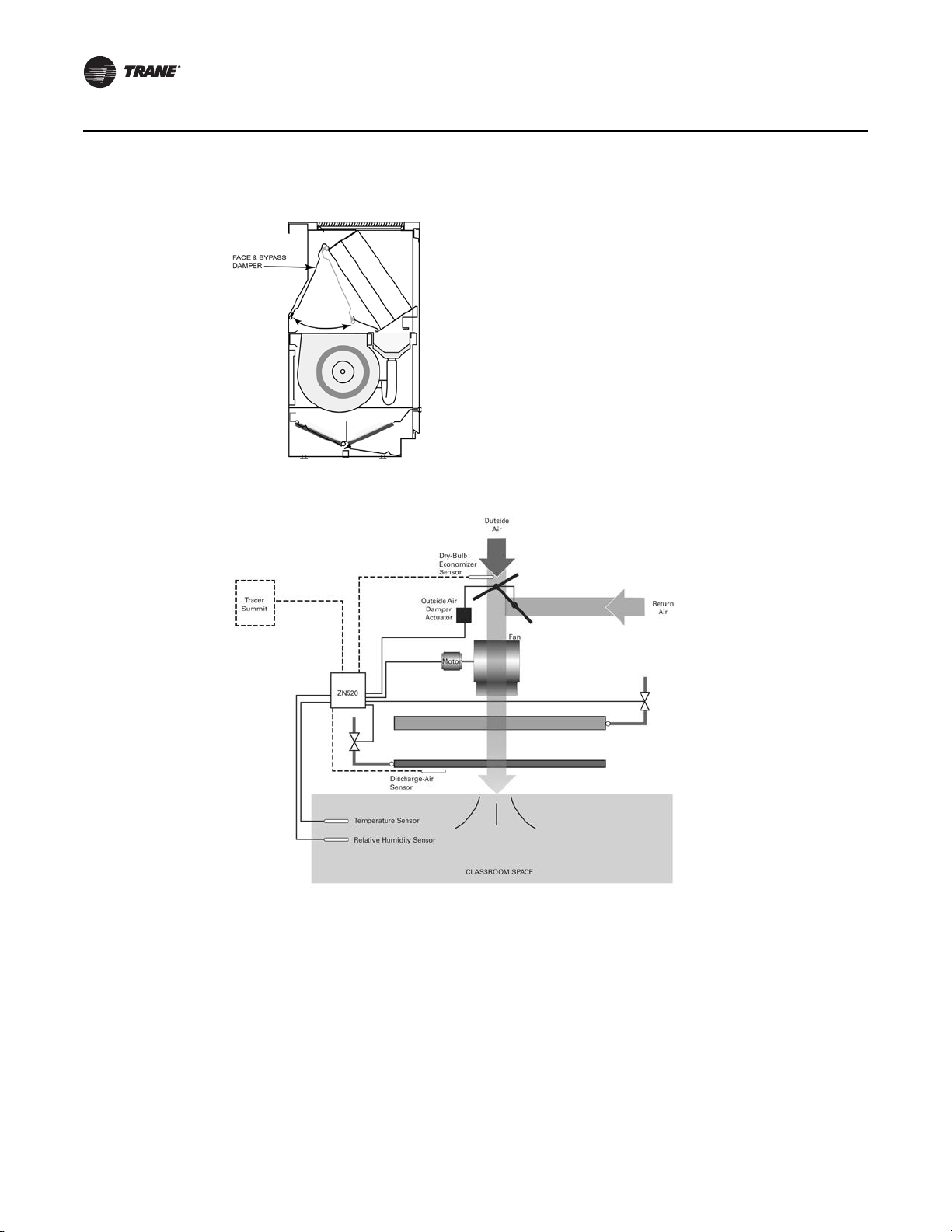

Active Humidity Control

A common method used to address this part-load humidity control challenge in a constant-volume

system is active humidity control through supply air tempering (reheat). Active humidity control

involves monitoring and controlling both the dry bulb temperature and humidity in the occupied

space. Whenever the space humidity is below the preset upper limit (typically 60 percent relative

humidity), the system operates just like a normal constant-volume system. However, if the space

humidity reaches or exceeds the upper limit, the cooling coil control valve is dri ven open regardless

of the need for sensible cooling in the space. The coil over-cools the air, increasing the

dehumidification capacity of the system.

With this control sequence, a reheat coil is placed downstream of the cooling coil to temper (reheat)

the cold, dry air leaving the cooling coil in order to avoid over-cooling the space. The key to cost-

16 UV-PRC003-EN

Application Considerations

Dehumidification

effectively applying an active humidity control system is to use reheat only when it is needed. This

requires the sensing of both the humidity and temperature in the occupied space.

When the space humidity falls below the upper limit, the system returns to the standard cooling

mode and again operates as a traditional constant-volume system.

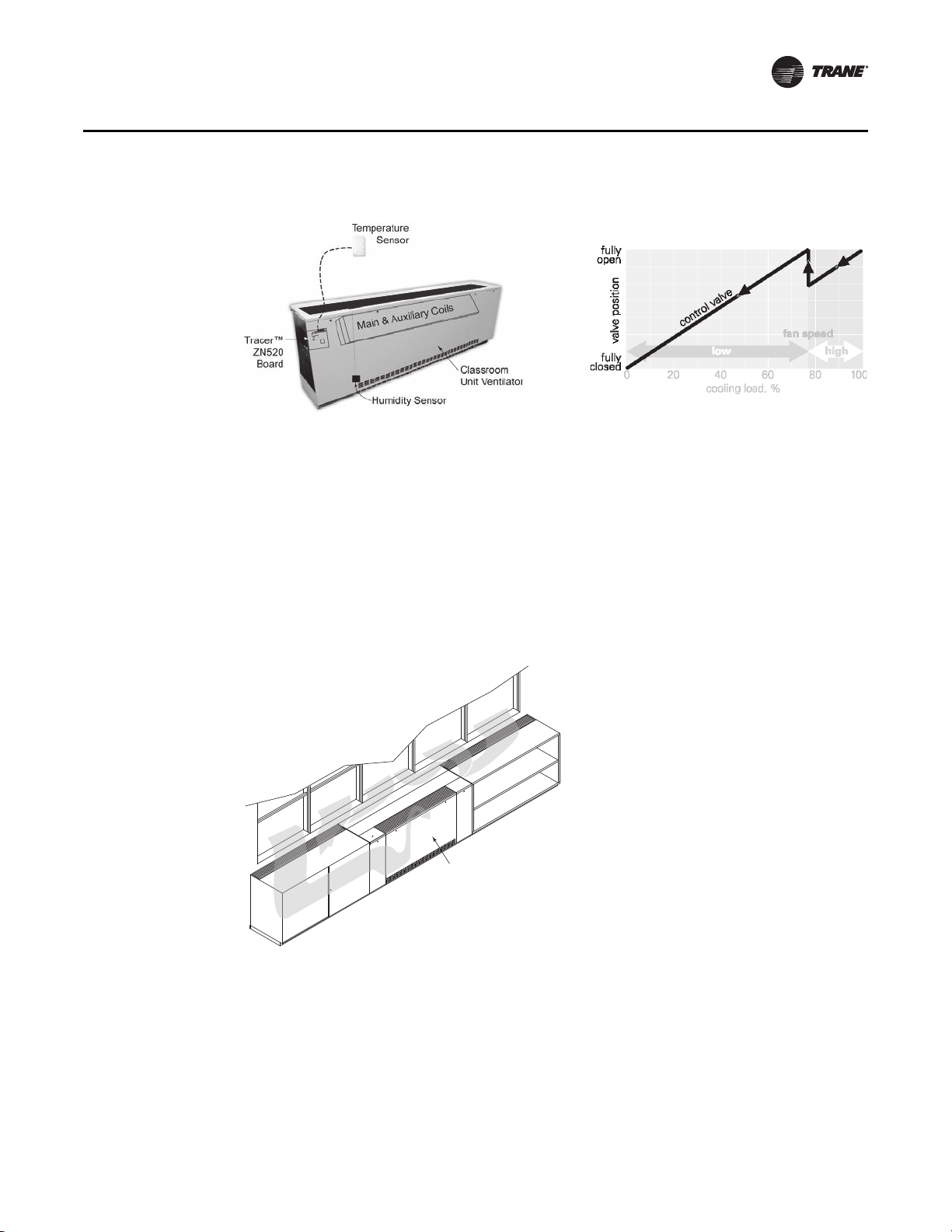

Basic components of Trane’s reheat system, include a (1) classroom unit ventilator with a main

coil and an auxiliary coil downstream, (2) the Tracer ZN520 digital controller, and (3) two

sensors, one for the temperature and one for relative humidity. Sensors may be located in the

zone, or in the return air stream.

If after hours operation is required, the addition of a building automation system (BAS) such as

Tracer Summit™ is recommended to coordinate the chillers, pumps, boiler and unit ventilators. It

also assures proper operation of the exhaust fans.

Reheat may come from new energy (electric resistance heat or boilers fueled by gas or oil) or

recovered energy.

Recovered energy reheat refers to the process of salvaging or transferring energy from another

process within the facility. In this case, the recovered energy is the by-product of a cooling process

which would normally be rejected or wasted. A common example may include a plate and frame

heat exchanger in the condenser water loop of a water-cooled chiller system.

Automatic Fan-Speed Adjustment

Reducing the fan speed (supply airflow) at part-load conditions is a way to improve the coincidental

dehumidification performance of a unit ventilator. The Tracer ZN520 digital controller can be

configured to automatically reduce fan speed when the sensible load is decreased, Figure 12, p. 18.

At full load, the fan operates at high speed and the control valve’s flow is wide open. As the cooling

load decreases, the controller modulates the valve to throttle the rate of chilled water flow through

the coil. At some point, based on valve position, the unit controller switches the fan to low speed.

Less airflow means that colder supply air is needed to maintain the target space temperature. The

control valve opens allowing the coil to remove more moisture from the passing air stream.

The controller will also adjust the outside air damper to help properly ventilate the classroom at

the lower fan speed condition.

Face and Bypass Dampers

Face and bypass control is a common and accepted method of capacity control.

The face and bypass damper, consists of a single blade installed immediately upstream of the

cooling coil. The bypass is sized to have the same pressure drop as the cooling coil so that a

constant air quantity can be maintained at all times during system operation.

Bypass control maintains the dry bulb temperature in the space by modulating the amount of air

flowing through the cooling coil, thus varying the supply air temperature to the space. As the face

and bypass damper begins to close some of the outside/return air mix is diverted around the coil

and mixed with air coming off the coil to obtain a supply air temperature that is proportional to the

reduction in space load. Because the chilled water valve remains wide open, the portion of the air

passing through the coil is dehumidified further, improving part-load dehumidification.

However, face and pass control does not actively control space humidity. It still allows the space

humidity level to rise at part-load, often higher than desired.

For more information on various methods for improving dehumidification performance of unit

ventilator systems, refer to Trane “Dehumidification in HVAC Systems” application manual

SYS-APM004-EN.

UV-PRC003-EN 17

Application Considerations

Dehumidification

Figure 12. Face and bypass damper

Figure 13. Basic components of active dehumidification control

18 UV-PRC003-EN

Figure 14. Reheat system and auto fan speed adjustment

Auto Fan Speed Adjustment with Tracer ZN520

Reheat System

Unit Ventilator

Captured

Cold Air

Dynamic Air Barrier

In areas that contend with colder climates for a significant period of time, a school may wish to

employ a dynamic air barrier package. With this dynamic (draft) barrier system, the cold air is

captured off of the window, and drawn into the classroom unit ventilator’s normal airflow cycle.

The unit ventilator treats/warms the air as if it were part of a return-air makeup system. This

captured air is then discharged into the space providing comfort to the classroom’s occupants.

This draft barrier shield should be utilized when:

• Almost 50 percent of the wall includes windows.

• Outside air temperatures fall below 35°F for a significant period of time

• Or, in retrofit applications where the windows are of a single pane thickness.

Application Considerations

Draft Barrier and OA Preconditioning

Figure 15. Dynamic air barrier

Outdoor Air Preconditioning

Conditioning the large amounts of outdoor air required for proper classroom ventilation can

significantly increase building cooling and heating loads. It also raises the system’s first cost and

operating cost. One way to reduce the impact of the outdoor air load on the unit ventilator is to use

energy recovered from the exhaust air stream to precondition the outdoor air as it’s brought into

the building.

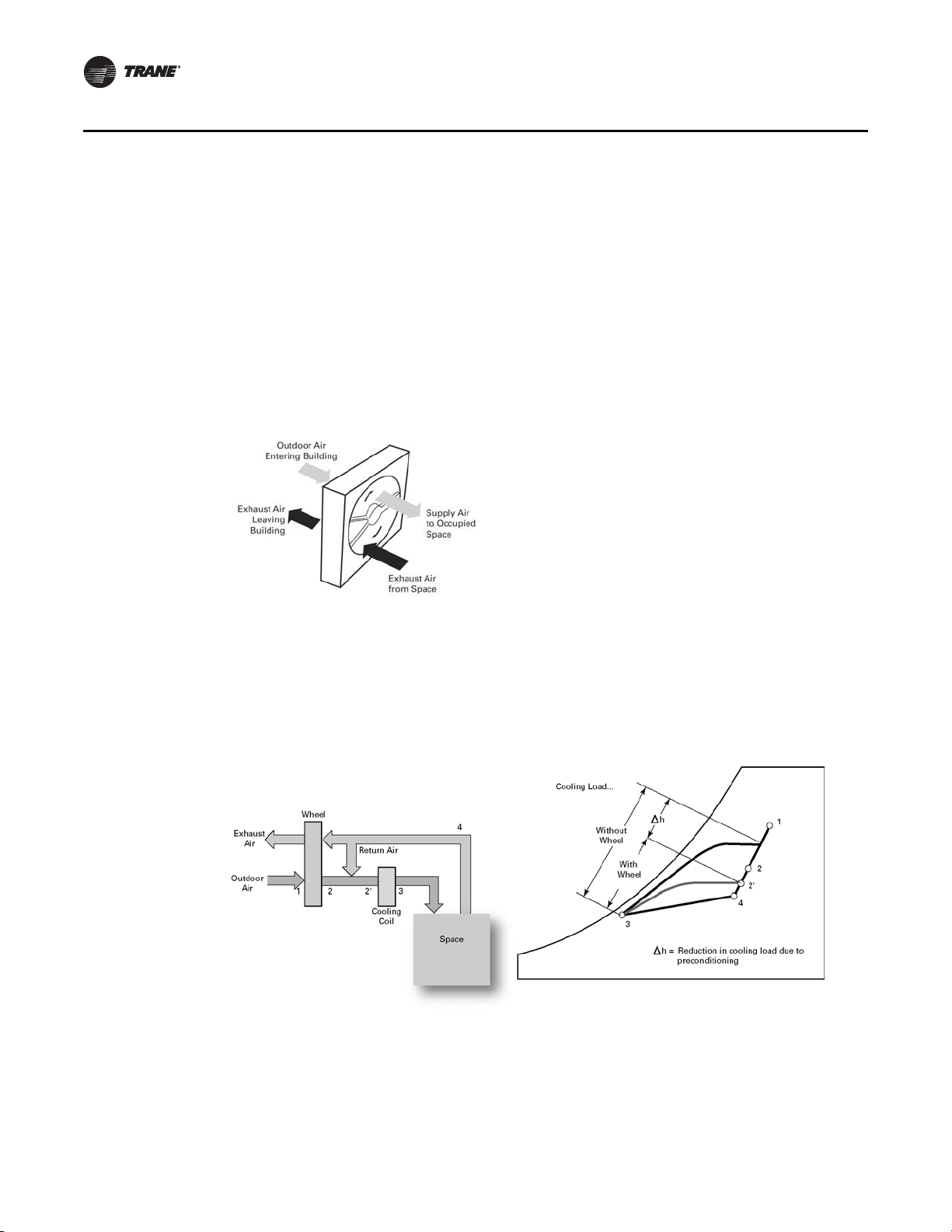

A total-energy recovery (enthalpy) wheel consists of a revolving cylinder filled with a desiccantcoated medium suitable for sensible and latent (moisture) heat transfer, Figure 16, p. 20. The

UV-PRC003-EN 19

Application Considerations

Draft Barrier and OA Preconditioning

adjacent outdoor and exhaust air streams pass through the wheel in a counterflow arrangement

that transfers energy from one air stream to the other.

During the cooling season, the drier, sensible heat and moisture transfer from the outdoor air to

the cooler, drier exhaust air. Conversely, during the heating season, sensible heat and moisture

transfers from the exhaust air to preheat and humidify the entering outdoor air stream. Figure 16

psychrometric ally depicts the impact of a preconditioning total-energy wheel on a unit ventilator.

This approach can’t directly control humidity in the space, but it can significantly reduce the

capacity (and operating cost) of the cooling and heating equipment required to condition the

outdoor air. Capable of recovering 65 to 75 percent of the energy in the exhaust air stream, totalenergy wheels used in conjunction with unit ventilators can be an attractive alternative when

upgrading existing classroom to meet ASHRAE’s ventilation requirements; they reduce, perhaps

even eliminate, the extra capacity needed at the chiller plant or boiler.

Figure 16. Energy recover wheel

The Trane ERS energy recovery unit ventilator is one example of a “cold coil” unit with outdoor

air preconditioning.

Note: Both preconditioning (energy recovery) and post conditioning (reheat) may be applied in

the same system.

For more information on outdoor-air preconditioning and energy recovery, refer to the Trane

application engineering manual, Air-to-Air Energy Recovery in HVAC Systems (SYS-APM003-EN).

Figure 17. Cold coil with outdoor air preconditioning

20 UV-PRC003-EN

Selection Procedure

Trane vertical classroom unit ventilators provide air delivery and capacities necessary to meet the

requirements of modern school classrooms. They are available with the industry’s widest selection

of coils to precisely satisfy heating, ventilating and air conditioning loads with the best individual

type of system. Unit ventilator selection involves three basic steps.

• Determine the classroom/space unit cooling and/or heating loads

• Determine the unit size

• Select the coil

Capacity Required

The first step in unit ventilator selection is to determine room heating and air conditioning loads.

The calculation of this load is essential if the equipment is to be economical in first cost and

operating cost.

Adequate ventilation is mandatory in classroom air conditioning design. The amount is often

specified by local or state codes and, in air conditioned schools, may be either the same or less than

that specified for heating systems. The usual requirement is between 15 and 25 cfm of outside air

per occupant, based on the intended use of the room. For instance, a chemistry laboratory normally

requires more ventilation for odor control than a low occupancy speech clinic.

Ventilation is an important concern and should be accurately determined to assure good indoor air

quality. Purposely oversizing units should be avoided, since it can cause comfort and control

issues.

Unit Size

Unit ventilator size is determined by three factors:

• Total air circulation

• Ventilation cooling economizer capacity required

• Total cooling or heating capacity required

Total air circulation, if not specified by code, should be sufficient to ensure comfort conditions

throughout the room. This is usually from six to nine air changes per hour, but can vary with room

design and exposure. Often rooms with large sun exposure require additional circulation to avoid

hot spots.

Ventilation cooling capacity is determined by the amount of outside air delivered with the outside

air damper fully open, and the temperature difference between the outside air and the classroom.

In air conditioning applications, ventilation cooling capacities should maintain the comfort setting

in the classroom whenever the outside air temperature is below the unit or system changeover

temperature.

UV-PRC003-EN 21

Selection Procedure

Example:

Ventilation cooling capacity = 1.085 x cfmt x (T1 - T2)

cfm

T

T

In classrooms with exceptionally heavy air conditioning loads, unit size may be determined by the

total cooling requirement. Good practice dictates 375 to 425 cfm per ton of hydronic cooling

capacity. Normally, however, Trane classroom air conditioner coils have sufficient capacities.

Example:

Given: Air circulation specified = 8 air changes per hour.

Classroom size = 35 ft long x 25 ft wide x 10 ft high

Inside design air temperature = 75 degrees F

Ventilation cooling required at 58 degrees F = 29,000 BTU

CFM required = 8 changes/hr x (35 x 25 x 10)ft

Checking ventilation cooling capacity:

29,800 BTU = 1.085 x CFM x (80-58)

CFM = 1250

This indicates that a 1250 cfm unit would have satisfactory ventilation cooling capacity at the

design changeover point of 58°F. Coil capacity will become confirmed when the coil is selected.

= Total air capacity of unit with outside air damper open 100 percent.

t

= Room temperature.

1

= Outside air temperature.

2

3

= 1170 cfm

60 Minutes/hr

Coil Selection

Selecting the correct coil is done through Trane’s Official Product Selection System (TOPSS) For

your convenience, TOPSS has a mixed air calculator built into the program.

22 UV-PRC003-EN

Model Number Descriptions

Vertical Unit Ventilator Model Number

Digits 1, 2, 3 — Unit

Configuration

VUV= Vertical Unit Ventilator

Digit 4 — Development

Sequence

E

Digits 5, 6, 7 — Nominal Airflow

075 = 750 cfm

100 = 10 0 0 cf m

125 = 1250 cfm

150 = 150 0 cfm

Digit 8 — Voltage (Volts/Hz/

Phase)

0 = 115/60/1

1 = 208/60/1

2 = 230/60/1

3 = 208/60/3

4 = 460/60/3

7 = 277/60/1

8 = 230/60/3

Digit 9 — Open Digit

Digits 10, 11 — Current Design

Sequence

Digit 12 — Face & Bypass

Y = Yes, Include Damper

N= No Damper

Digit 13 — Unit Arrangement

1 = Return Air Front / Fresh Air Back

2 = 100% Return Air Front

3 = 100% Fresh Air Back

4 = Dynamic Air Barrier

5 = ERS-Compatible w/RH

Connection

6 = ERS-Compatible w/LH Connection

Digit 14 — Preheat / Reheat /

Changeover

A = 4-Pipe Preheat (RH Clg/LH Htg)

B = 4-Pipe Preheat (LH Clg/RH Htg)

C = 4-Pipe Reheat (RH Clg/LH Htg)

D = 4-Pipe Reheat (LH Clg/RH Htg)

E = 2-Pipe (RH Connections)

F = 2-Pipe (LH Connections)

Digit 15 — Cooling / 2-Pipe Coil

0=None

B = 2-Row, 12 F.P.I.

C = 2-Row, 16 F.P.I.

D = 3-Row, 12 F.P.I.

E = 3-Row, 16 F.P.I.

F = 4-Row, 12 F.P.I.

G = 4-Row, 14 F.P.I.

H = 3-Row, 16 F.P.I, EarthWise™ Coil

J = 3-Row, DX (R-410A) Cooling Coil

Digit 16 — Heating Coil

0=None

A = 1-Row, 12 F.P.I.

B = 2-Row, 12 F.P.I.

C = 2-Row, 16 F.P.I.

D = 3-Row, 12 F.P.I.

E = 3-Row, 16 F.P.I.

F = 4-Row, 12 F.P.I.

G = 4-Row, 14 F.P.I.

H = 3-Row, 16 F.P.I, EarthWise Coil

K=Steam Low

L=Steam High

M = Electric Heat - Low

N = Electric Heat - Med

P = Electric Heat - High

Digit 17 — Motor

0 = Electronically Commutated Motor

(ECM)

1 = ECM & Low Acoustic Option

2 = ECM & Low FLA Option

3 = ECM & Low Acoustic & Low FLA

Option

Digit 18 — Other Motor Items

A= None

B = Toggle

C = Circuit Breaker

Digit 19 — 2- or 3-Way Valve Cooling Changeover Coil

0=None

2 = 2-Way; 3-Point Floating

3 = 3-Way; 3-Point Floating

4 = 2-Way; 2–10 Volt

5 = 3-Way; 2–10 Volt

6 = Isolation Valve; 2-Way

7 = Isolation Valve; 3-Way

Digit 20 — CV - Cooling or

Changeover Coil

0=None

L=Low Cv

M= Medium Cv

H= High Cv

Digit 21 — 2- or 3-Way Valve Preheat or Reheat Heating Coil

0=None

2 = 2-Way; 3-Point Floating

3 = 3-Way; 3-Point Floating

4 = 2-Way; 2–10 Volt

5 = 3-Way; 2–10 Volt

6 = Isolation Valve; 2-Way

7 = Isolation Valve; 3-Way

Digit 22 — CV - Preheat or

Reheat Heating Coil

0=None

L=Low Cv

M= Medium Cv

H= High Cv

Digit 23 — Discharge

Arrangement

0 = Opening Only, No Grille

A = Discharge Grille

B = Double Deflection Discharge

Grille

C = Grille Discharge with Wire Mesh

Digit 24 — Outside Air Damper

Control

0=None

A = 3-Wire Actuator

B = 2–10 Volt Actuator

Digit 25 — Face and Bypass

Damper Control

0=None

A = 3-Wire Actuator

B = 2–10 Volt Actuator

Digit 26 — Controls

0 = None, Unit-Mounted Speed

Switch

2 = Customer Supplied Terminal

Interface (CSTI)

3 = CSTI w/Low Temp Detection

4 = Tracer ZN520

5 = Tracer ZN520 w/Time Clock

6 = Tracer ZN520 with w/Fan Status

7 = Tracer UC400

8 = Tracer UC400 w/Time Clock

Digit 27 — Unit- or Wall-Mounted

Controls

0=None

1 = Unit-Mounted

2 = Wall-Mounted

3 = Unit-Mounted Fan Speed

Switch & Wall-Mounted

Temperature Sensor

4 = Wireless Zone Sensor

Note: The wall-mounted room sensor is

ordered as separate line item.

Digit 28 — Internal or External

Set Point

0=None

2=External

3 = Digital Display

Digit 29 — Timed Override

0=No

1=Yes

Digit 30 — Exhaust Control

A = No Exhaust Control with 3-Speed

Supply Fan

B = Exhaust Control with 2-Speed

Supply Fan

Digit 31 — Control Programming

(Sensor Included)

0=None

1 = Humidity Sensor Programming

2=CO

Sensor Programming

2

UV-PRC003-EN 23

Model Number Descriptions

Digit 32 — Unit Depth

A = Standard (16-5/8 in.)

B = 21-1/4 in. Depth with Baffle

C = 21-1/4 in. Depth with Full Sheet

Metal Back and Baffle

D = 21-1/4 in. Depth with 25 in. High

Falseback

E = 21-1/4 in. Depth with 26 in. High

Falseback

F = 21-1/4 in. Depth with 27 in. High

Falseback

G = 21-1/4 in. Depth with 28 in. High

Falseback

H = 21-1/4 in. Depth with 29 in. High

Falseback

J = 21-1/4 in. Depth without Baffle

Note: Selection “J” should be applied if

OA opening is raised above

standard baffle location.

Digit 33 — End Covers

0=None

1 = 16-5/8 in. Depth without Cutouts

2 = 16-5/8 in. Depth with 3 x 7-1/4 in.

Cutout

4 = 21-1/4 in. Depth without Cutouts

5 = 21-1/4 in. Depth with 3 x 7-1/4 in.

Cutout

6 = 21-1/4 in. Depth with 3-1/4 in. x

16-7/8 in. Cutout

Digit 34 — Front Panel

1 = Standard Front Panel

2 = Heavy Gauge Front Panel

Digit 35 — Subbase

0=No Subbase

2 = 2 in. Subbase

4 = 4 in. Subbase

6 = 6 in. Subbase

Digit 36 — Piping Package

0=None

1 = Ball Valves & P/T Ports

2 = Ball Valve & Circuit-Setter with

P/T Ports

3 = Ball Valve, Circuit-Setter with

P/T Ports & Strainer

Digit 37 — Flow Control Cooling/Changeover Coil

0=None

Digit 38 — Flow Controls Heating Coil

0=None

Digit 39 — Auxiliary Drain Pan Piping

Y = Yes, Auxiliary Drain Pan

N = No Auxiliary Drain Pan

Digit 40 — Crossover Piping

0=None

1=Internal

2 = External 1-3/8 in. Crossover

Piping

3 = External 2-1/8 in. Crossover

Piping

Digit 41 — Filter

1 = Standard Throwaway Filter

2 = MERV 8 Filter

3 = MERV 13 Filter

Digit 42 — Color

1 = Deluxe Beige

2 = Cameo White

3=Soft Dove

4 = Stone Gray

5 = Driftwood Gray

24 UV-PRC003-EN

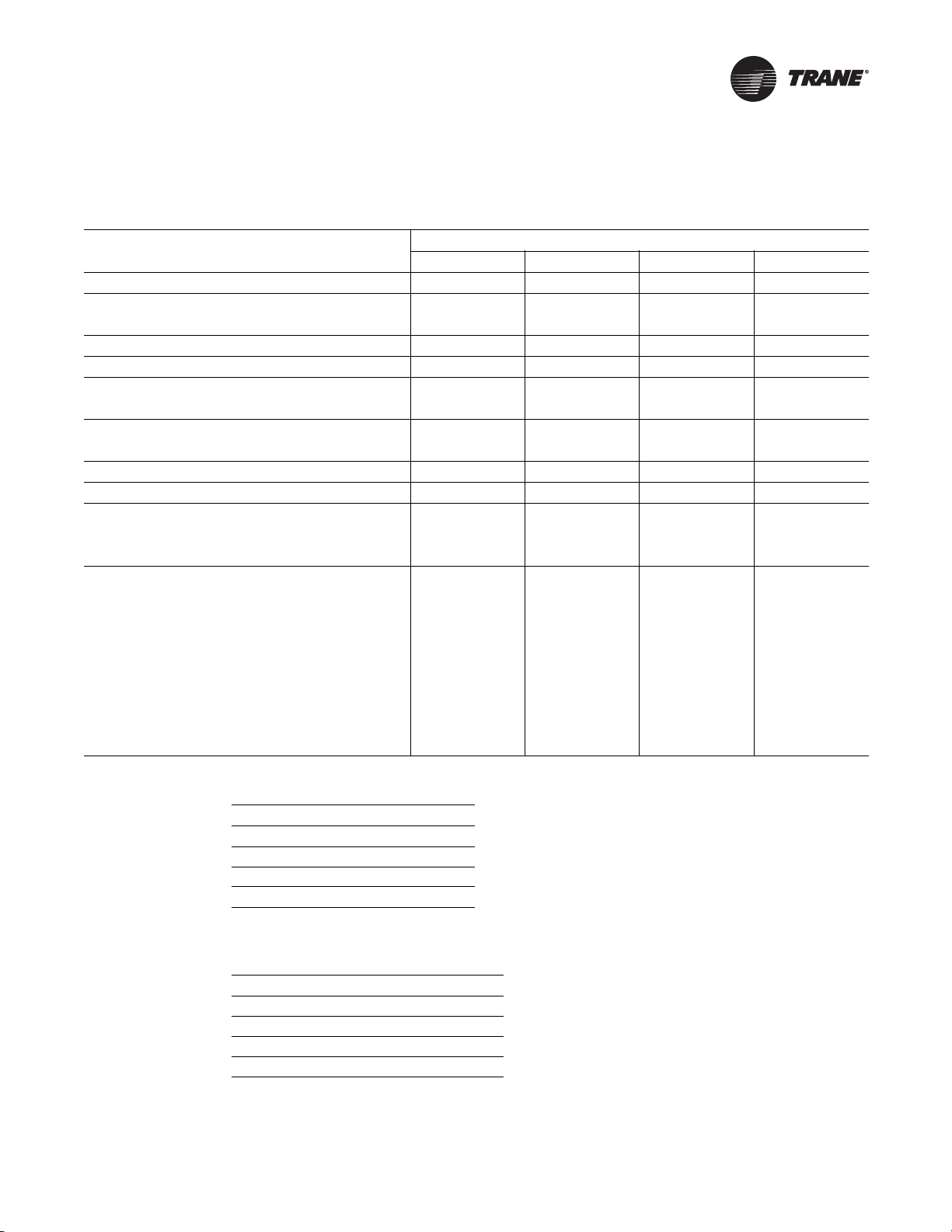

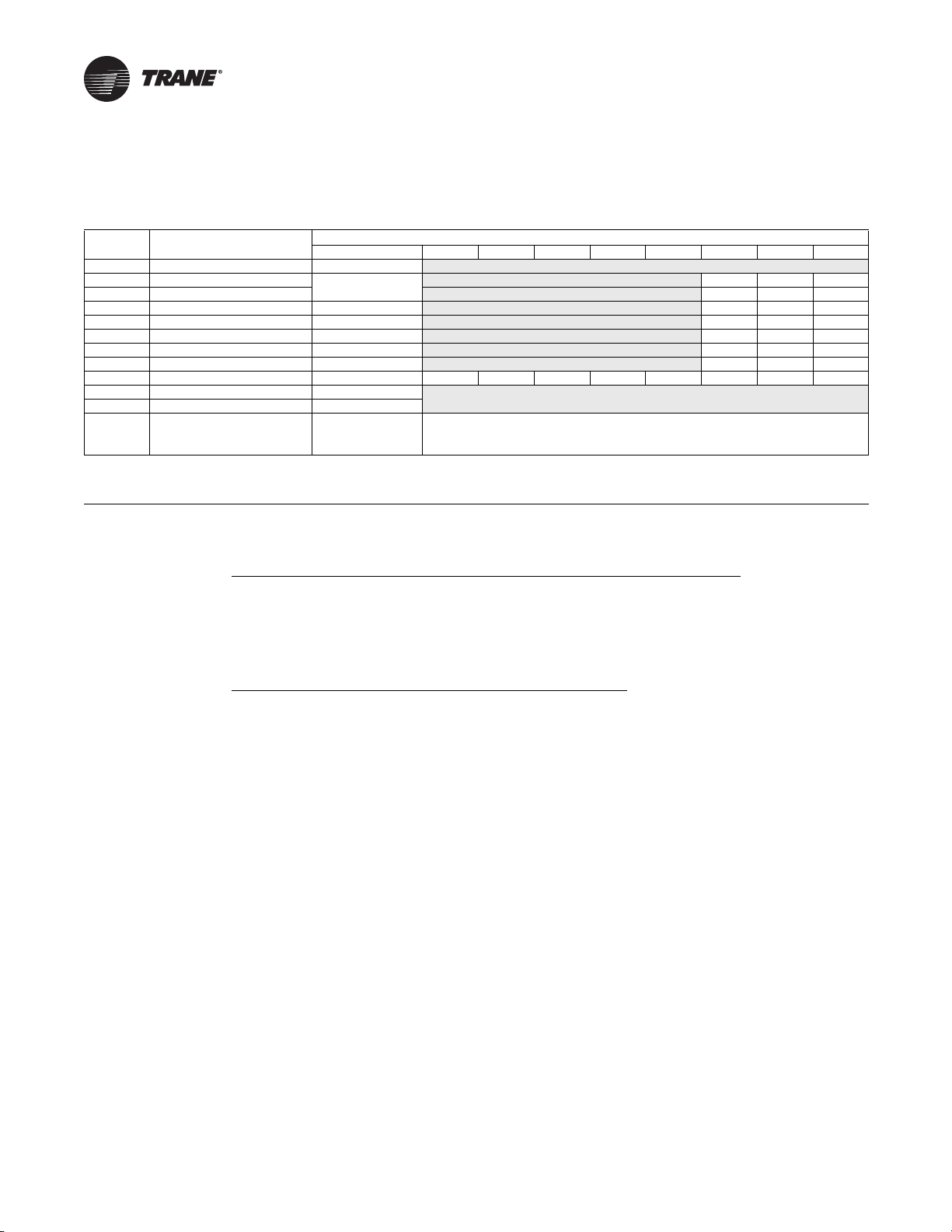

General Data

Table 1. General data

Description

Unit length without end covers (in.)

Unit depth—standard (in.)

Unit depth—with false back (in.)

Unit height—standard (in.)

Shipping weight (lb)

Nominal filter size (in.) and

quantity

Dynamic air filter nominal

size (in.) and quantity

Drain connection size (in.)

Fan type / quantity

Motor data

Quantity

Horsepower (ea.)

Coil volume (gal) by coil type

A

B

C

D

E

F

G

H

Unit size

0750 1000 1250 1500

69 81 93 105

16-5/8 16-5/8 16-5/8 16-5/8

21-1/4 21-1/4 21-1/4 21-1/4

30 30 30 30

320 405 450 470

14 x 20 x 1 (2) 14 x 24 x 1 (1) 14 x 20 x 1 (2) 14 x 24 x 1 (2)

14 x 30 x 1 (1) 14 x 24 x 1 (1) 14 x 30 x 1 (1)

7 x 42 x 1 (1) 7 x 54 x 1 (1) 7 x 66 x 1 (1) 7 x 78 x 1 (1)

7/8 ID Hose 7/8 ID Hose 7/8 ID Hose 7/8 ID Hose

FC / 2 FC / 2 FC / 4 FC / 4

1122

1/4 1/4 1/4 1/4

0.178 0.228 0.277 0.327

0.311 0.410 0.510 0.610

0.311 0.410 0.510 0.610

0.444 0.571 0.704 0.931

0.444 0.571 0.704 0.931

0.610 0.809 1.014 1.213

0.610 0.809 1.014 1.213

0.395 0.593 0.742 0.837

Table 2. Control methodology

Fan Speed

FSS 3 or infinite

CSTI 3 or infinite

Tracer ZN520 3

Tracer UC400 Infinite

(a)With a field-supplied 2–10 Vdc controller.

(a)

(a)

Table 3. Control sequences

Fan Speeds

(b)

(a)

(b)

(a)

1

1

2

2

DX operation

Electric heat operation

Sidewall Exhaust

ERSA

(a)Fan speed during sequence operation.

(b)Unit Ventilator when operating with option.

UV-PRC003-EN 25

General Data

Available in:

16 5/8" Depth

21 1/4" Depth

Digit 13 = 1

RA Front with FA Back

Available in:

21 1/4" Depth

ONLY

Digit 13 = 5, 6

(5) RH Energy Recovery System

ERS Compatible

(6) LH Energy Recovery System

ERS Compatible

Available in:

16 5/8" Depth

21 1/4" Depth

Digit 13 = 2

100% Return Air Front

Available in:

16 5/8" Depth

21 1/4" Depth

Digit 13 = 3

100% Fresh Air Back

Available in:

16 5/8" Depth

21 1/4" Depth

Digit 23 = 0, A, B, C

0 = Opening Only

A = Grille Discharge

B = Double Deflection Discharge Grille

C = Discharge Grille with Wire Mesh

Available in:

21 1/4" Depth

ONLY

Digit 13 = 4

Dynamic Air Barrier

Inlet Ar

rangement

Discharge Arrangement

Discharge and Inlet Arrangements

Figure 18. Discharge and inlet arrangements

26 UV-PRC003-EN

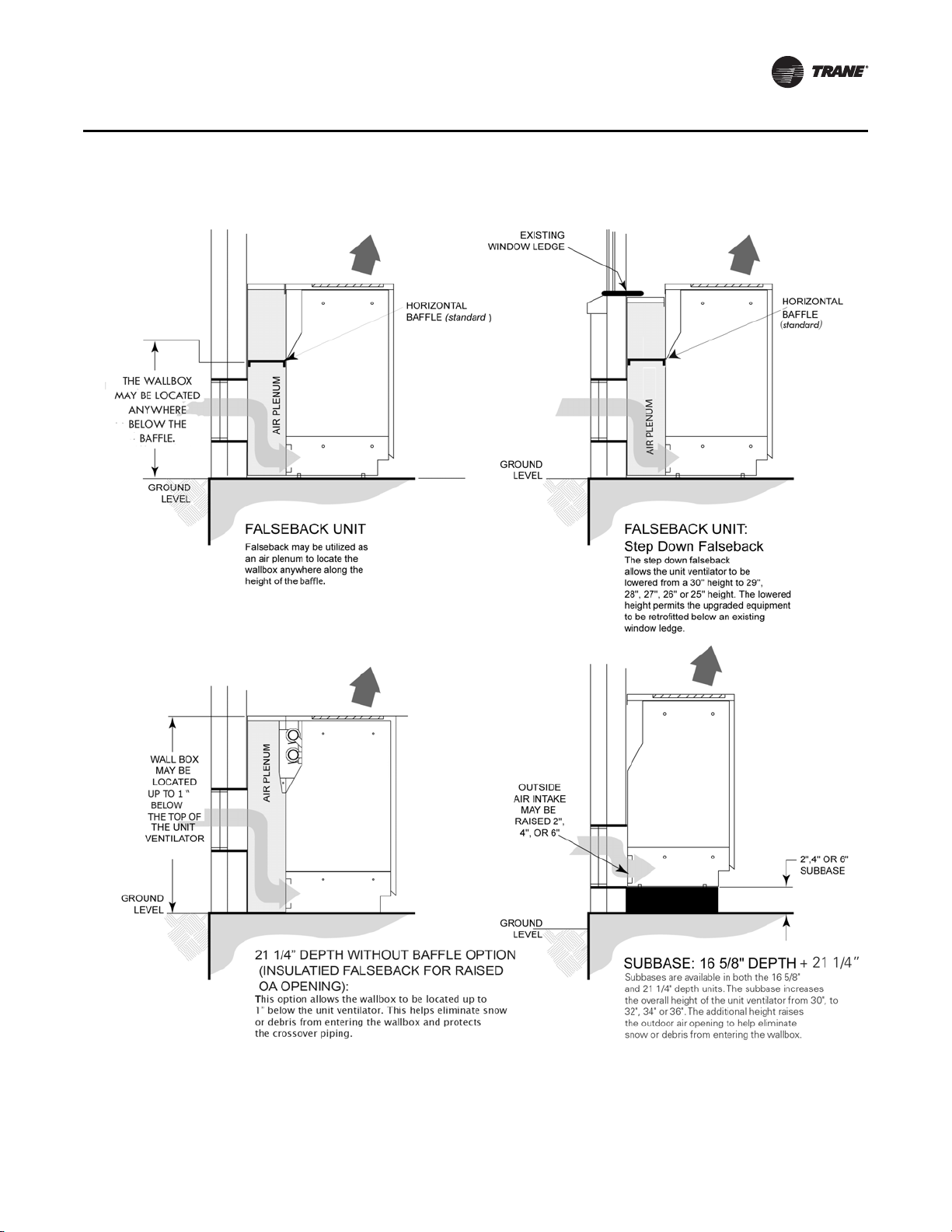

Figure 19. Falseback and subbase

General Data

Coil Combinations

UV-PRC003-EN 27

Performance Data

Table 4. Coil combination selection chart (cooling, 2-pipe changeover or heating-only coils)

Coil type Coil description

A 1-row, 12 fpi Heating only

B 2-row, 12 fpi

C 2-row, 16 fpi

D 3-row, 12 fpi

E 3-row, 16 fpi

F 4-row, 12 fpi

G 4-row, 16 fpi x

H 3-row, 16 fpi (EarthWise) x x x

J 3-row, DX (R-410A) xxxxxxxx

K Steam, low capacity

L Steam, high capacity

M Electric heat – 3-element

P Electric heat – 6-element

Notes:

1. All coil types on the left side of the grid are available in single-coil, heating only, or 2-pipe changeover with exception of coil type A.

2. For 2-coil or 4-pipe systems, select the cooling coil on the left side of the grid. An X corresponds to a valid heating coil combination.

3. Shaded areas signify valid selections with face and bypass dampers.

B and C cooling data

available in TOPSS

ABCKLMNP

x x x x xxxx

x x x x xxxx

x x x xxx

x x x xxx

x

Example 1:

4-pipe, chilled water / hot water

Type E , 3-row (16 fpi) cooling coil, may be selected with

Type B , 2-Row (12 fpi) preheat or reheat coil

Preheat or reheat coils

Heating only

Heating onlyN Electric heat – 4-element

Example 2:

4-pipe, DX cooling / steam heating

Type J , 3-row DX cooling coil, may be selected with

Type L , high-capacity steam heating coil

Notes:

• Supply and return coil connections are on the same side.

• In 4-pipe systems, the cooling coil connections are on the opposite end from the heating coil

connections.

• DX coils are always left-hand connections.

• Electric heat coils are always right-hand connections.

• Heating coils (hot water or steam) are right-hand when in the reheat position with DX cooling

coils.

28 UV-PRC003-EN

Loading...

Loading...