Trane RAUJ, R-410A Installation and Maintenance Manual

Application Guide

Tube Size and Component Selection

RAUJ Split Systems (20-120 Tons)

R-410A Refrigerant

Fin and Tube Condensers

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

March 2012 SS-APG007-EN

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provided to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout this

literature. Read these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants—including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

WARNI NG

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

SS-APG007-EN © 2012 Trane All rights reserved

Warnings, Cautions and Notices

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put on all Personal Protective Equipment

(PPE) in accordance with NFPA 70E or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

R-410A Refrigerant under Higher Pressure than R-22!

The units described in this manual use R-410A refrigerant which operates at higher pressures

than R-22 refrigerant. Use ONLY R-410A rated service equipment or components with these

units. For specific handling concerns with R-410A, please contact your local Trane

representative.

Failure to use R-410A rated service equipment or components could result in equipment

exploding under R-410A high pressures which could result in death, serious injury, or

equipment damage.

WARNI NG

WARNI NG

Trademarks

Trane, Frostat and the Trane logo are trademarks of Trane in the United States and other countries.

All trademarks referenced in this document are the trademarks of their respective owners.

ii SS-APG007-EN

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Updated Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Line Sizing, Routing, and Component Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Suction Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Expansion Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Suction Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Equipment Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Line Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hot Gas Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remodel, Retrofit, or Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Examples of Field-Installed Evaporator Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Single-Circuit RAUJs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dual-Circuit RAUJs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SS-APG007-EN iii

iv SS-APG007-EN

Overview

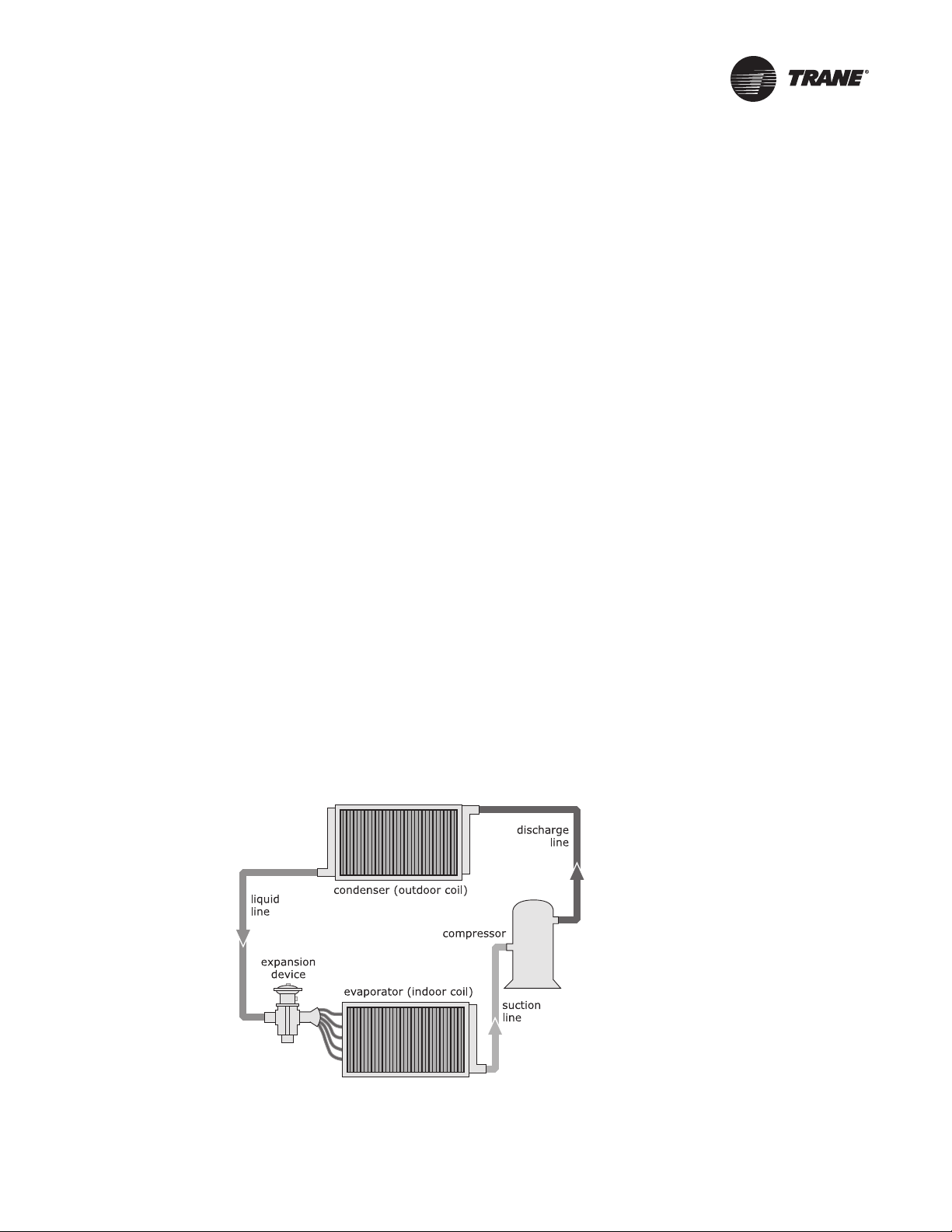

Figure 1. Interconnecting refrigerant lines in a typical split air-conditioning system

Trane’s RAUJ 20- through 120-ton condensing unit product line incorporating fin and tube

condenser coils has been designed for use only with R-410A and POE oil. R-410A is a high-pressure

refrigerant that requires the other components of the system, including the evaporator, to be rated

for R-410A pressures. For compressor lubrication, the refrigerant requires POE oil.

Traditionally, refrigerant piping practices were guided by four principles:

• Return the oil to the compressor.

• Maintain a column of liquid at the expansion valve.

• Minimize the loss of capacity.

• Minimize the refrigerant charge in the system.

These piping practices are similar for R-410A and POE oil. However, because of the different mass

flows and pressures, the line diameter required to carry the oil and refrigerant may not be the same

as a similar tonnage R-22 unit. Also, the allowable pressure drop may be greater for R-410A than

R-22.

Evidence accumulated over years of observation demonstrates that the lower the refrigerant

charge, the more reliably a split air-conditioning system performs. Any amount of refrigerant in

excess of the minimum design charge becomes difficult to manage. The excess refrigerant tends

to collect in areas that can interfere with proper operation and eventually shortens the service life

of the system.

To successfully minimize the system refrigerant charge, the correct line size should be used and

the line length must be kept to a minimum.

Background

In a split air-conditioning system, the four major components of the refrigeration system are

connected by field-assembled refrigerant piping (Figure 1). A suction line connects the

evaporator to the compressor, the discharge line connects the compressor to the condenser, and

the liquid line connects the condenser to the expansion device, which is located near the

evaporator inlet. Operational problems can occur if these refrigerant lines are designed or

installed improperly.

.

SS-APG007-EN 1

Overview

The origin of the requirements for equivalent line lengths of components, line pressure drop, and

minimum and maximum refrigerant velocities is uncertain. It appears likely that at least some of

the supporting data was derived from measurements and/or equations involving water. Some

resource materials even show water components when illustrating refrigerant piping

requirements.

Subsequent reviews of analytical and empirical data for refrigerant piping resulted in the

publication of two research papers: Pressure Losses in Tubing, Pipe, and Fittings by R.J.S. Pigott

and Refrigerant Piping Systems — Refrigerants 12, 22, 500 by the American Society of

Refrigeration Engineers (ASRE). In his paper, Pigott described his use of refrigerant as the fluid

and his direct measurement of pressure drops. His findings indicated that the pressure drop of

many line components is small and difficult to measure. For these components, he used

experimental data to derive a formula relating the geometry of the component to its pressure

drop. Overall, his calculated pressure loss of the components was less than originally

determined.

The conclusion of the ASRE research paper stated that the minimum required velocity to

maintain oil entrainment in vertical risers and horizontal lines will vary with the diameter of the

tube and with the saturation temperature of the suction gas. In other words, the minimum

required velocity for oil entrainment is not constant.

Updated Guidelines

Liquid Lines

Historically, liquid lines were sized to minimize the pressure losses within the piping circuit. Oil

movement through the piping wasn’t a concern (nor is it today) because oil is miscible in liquid

refrigerant at normal liquid-line temperatures. The historic and traditional 6 psid liquid line

pressure drop had the unintended consequence of requiring line sizes with large internal

refrigerant volumes. Since our objective is also to minimize the refrigerant charge to make the

most reliable systems, we increased the allowable liquid pressure drop to 35 psid (R-22), which

allows for the selection of a smaller liquid line while still maintaining refrigeration operation.

With R-410A refrigerant and POE oil, this pressure drop can be as high as 50 psid. Within these

guidelines, refrigeration operation is maintained while minimizing the refrigerant charge. It is

still required to limit the liquid line velocity to 600 ft/min to help avoid issues with water hammer.

Suction Lines

R-410A is a high-pressure refrigerant and allows higher-pressure drops in the suction lines. With

R-22, a 2°F loss in the suction line means a pressure drop of 3 psi. With R-410A refrigerant, that

same 2°F loss is a 5 psi drop. Additional pressure drop may be tolerated in certain applications.

R-410A refrigerant suction lines must be sized to maintain oil-entrainment velocities in both the

horizontal and vertical risers. Oil entrainment for R-410A is based on suction temperature as well

as tube diameter. At the time of this writing, no known direct oil-entrainment tests have been

conducted. Trane has used ASHRAE data to create equation-based formulas to predict the

entrainment velocities of R-410A refrigerant and POE oil. These minimum velocities are reflected

in the line sizes listed in the component selection summary (Table 2, p. 18).

2 SS-APG007-EN

Equipment Placement

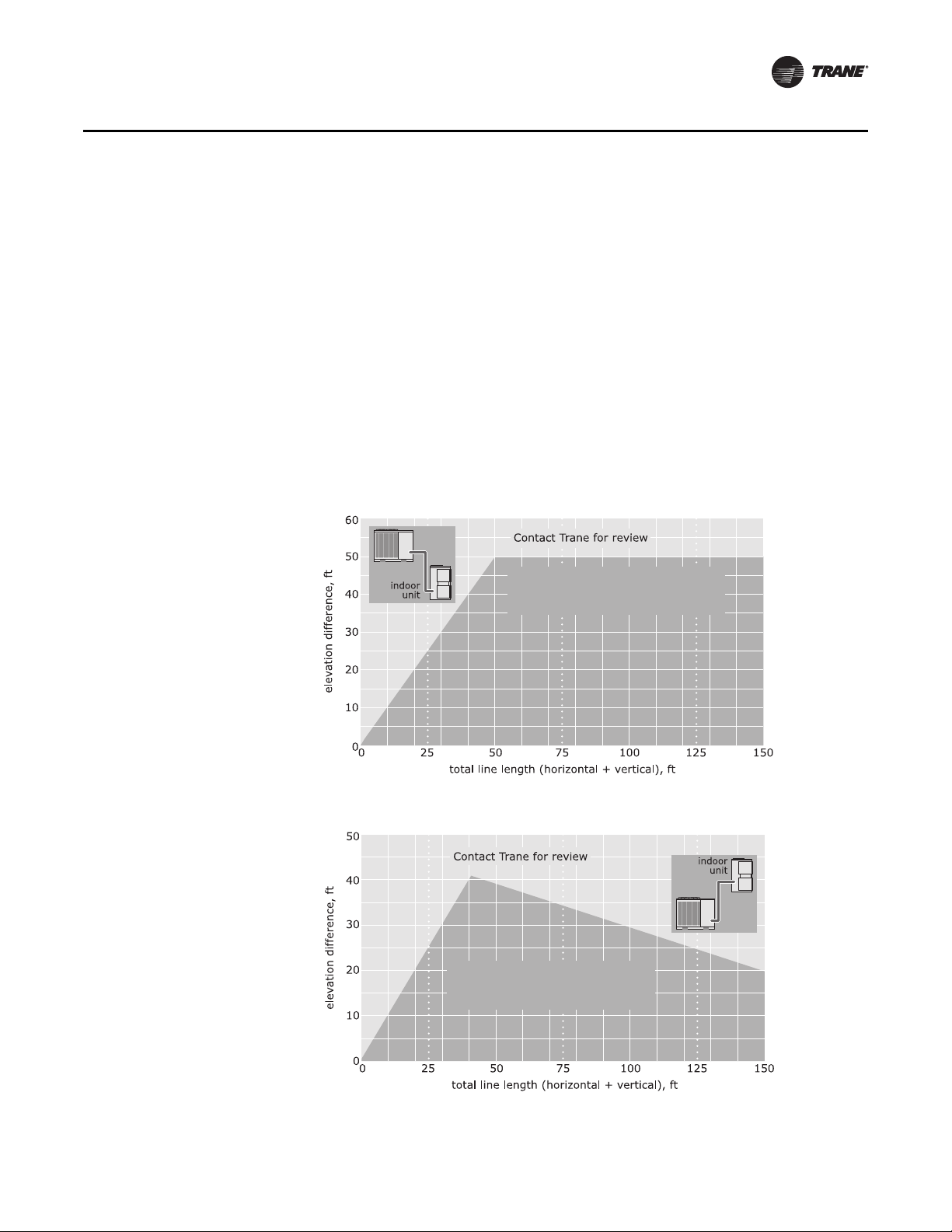

Figure 2. Allowable elevation difference: Cooling-only RAUJ above indoor unit

RAUJ

Acceptable liquid-riser height

based on total liquid-line length

(RAUJ below indoor unit)

Figure 3. Allowable elevation difference: Cooling-only RAUJ below indoor unit

Minimize Distance Between Components

For a split air-conditioning system to perform as reliably and inexpensively as possible, the

refrigerant charge must be kept to a minimum. To help accomplish this design goal:

• Site the outdoor unit as close to the indoor unit as possible.

• Route each interconnecting refrigerant line by the shortest and most direct path so that line

lengths and riser heights are no longer than absolutely necessary.

• Use only horizontal and vertical piping configurations.

• Determine whether the total length of each refrigerant line requires Trane review. Be sure to

account for the difference in elevations of the indoor and outdoor units when calculating the

total line length.

Interconnecting lines of 150 lineal ft (45.7 m) or less do not require Trane review, but only a

limited amount may be in a riser (see Figure 2 and Figure 3).

.

Overview

RAUJ

Acceptable suction-riser height

based on total suction-line length

(RAUJ above indoor unit)

SS-APG007-EN 3

Loading...

Loading...